Page 1

Series BV2 Two-Piece Ball Valve

Bulletin F-61

1100

1000

Working Pressure (P.S.I.G.)

®

Pressure Temperature Ratings

0°C 50°C 100°C 150°C 200°C

900

800

700

600

500

400

300

200

100

0

100°F 200°F 300°F 400°F 450°F

Working Temperature (°F)

Installation, Operating and Maintenance Instructions

H

F

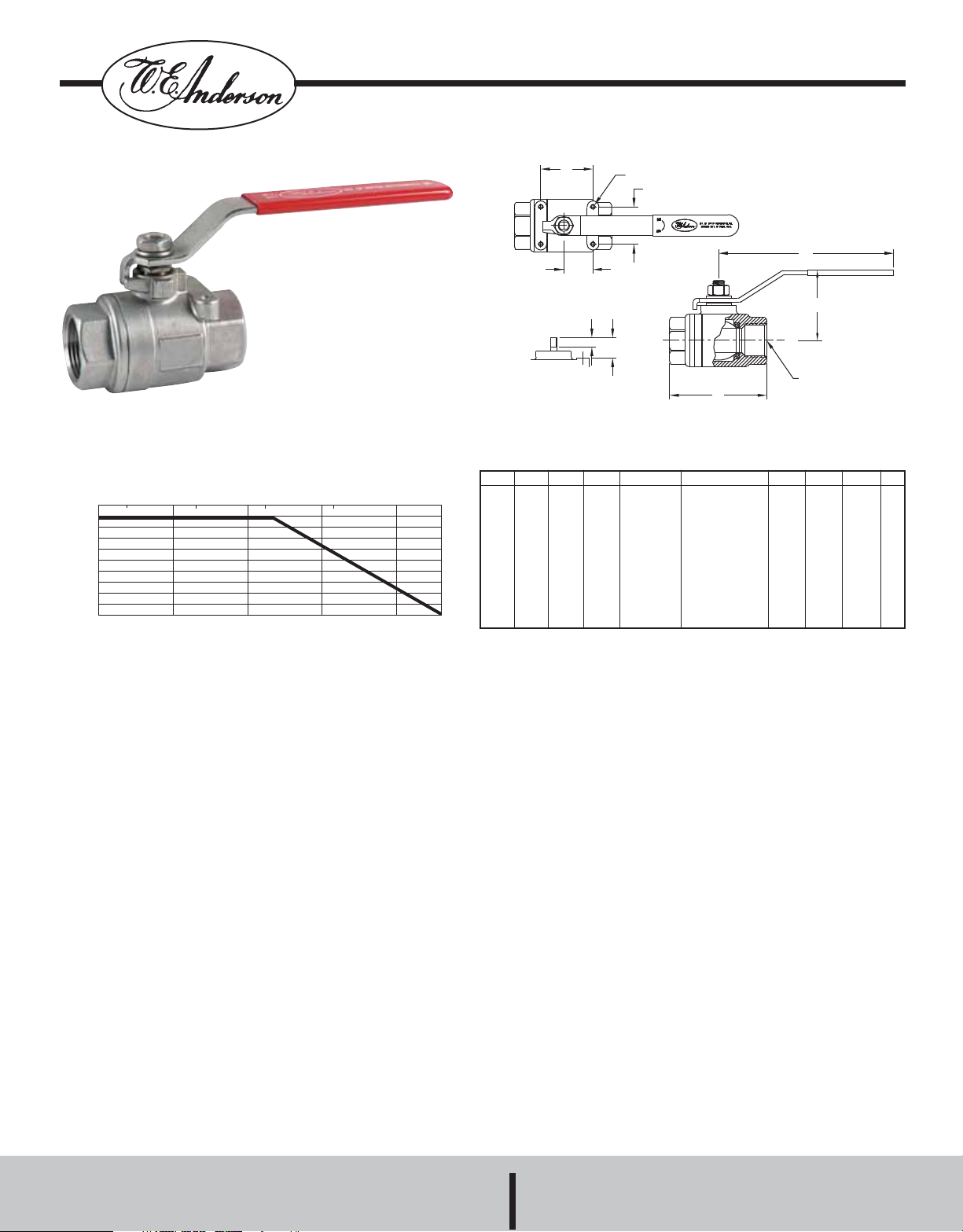

Dimensions are given in inches.

Size

1/4˝

3/8˝

1/2˝

3/4˝

1˝

1-1/4˝

1-1/2˝

2˝

2-1/2˝

3˝

A

2.165

2.165

2.559

2.992

3.465

3.976

4.331

4.882

6.299

6.929

B

1.969

1.969

2.205

2.323

2.717

2.953

3.268

3.622

5.039

5.394

(K)

C

4.055

4.055

5.236

5.236

6.024

6.024

7.520

7.520

9.724

9.724

E

(L)

D

1/4˝ NPT

3/8˝ NPT

1/2˝ NPT

3/4˝ NPT

1˝ NPT

1-1/4˝ NPT

1-1/2˝ NPT

2˝ NPT

2-1/2˝ NPT

3˝ NPT

G

A

E

(2) 3/16-24 UNC

(2) 3/16-24 UNC

(2) 3/16-24 UNC

(2) 3/16-24 UNC

(2) 3/16-24 UNC

(2) 1/4-20 UNC

(2) 1/4-20 UNC

(2) 1/4-20 UNC

(2) 1/4-20 UNC

(2) 1/4-20 UNC

F

.500

.500

.500

.882

.882

1.000

1.000

1.000

1.382

1.382

C

D

G

.500

.500

.500

.882

.882

1.000

1.000

1.000

1.382

1.382

B

Cv

H

8

N/A

15

N/A

17

N/A

27

N/A

35

N/A

46

N/A

80

N/A

110

2.000

310

2.764

360

2.764

The Series BV2 is the economical choice for quality, stainless steel ball

valves for use in chemical, petrochemical, pulp and paper, and general

applications. Providing excellent corrosion resistance, the Series BV2

body and tailpiece are constructed of CF8M grade investment cast stainless steel, while the ball and stem are manufactured from 316 SS.

Reinforced TFE seats and body seals provide broad chemical compatibility and bubble tight shutoff to 1000 psi.

The internally loaded blow-out proof stem provides for safety in the event

SPECIFICATIONS

Size: 1/4˝ - 3˝ NPT.

Material: ASTM A182 GR. CF8M Body and Tlpc;

Reinforced TFE Seats and Seals;

316 SS Ball and Stem;

304 SS Handle and Locknut.

Max. Pressure: 1000 psi (69 bar) WOG; 150 psi (10.3 bar) SWP.

Max. Temp: -40°F(-40°C) to 450°F (232°C).

of overpressure. Full port design allows maximum Cv with minimal pressure drop. Integral actuator mounting pad allows for ease of automation.

Optional locking handle prevents accidental operation. The Series BV2

is available in sizes ranging from 1/4” to 3” NPT.

INSTALLATION

Prior to installation, inspect valve and pipe ends to make sure they are

free from debris. Material trapped inside the valve can cause damage to

the seats and result in leakage. Clean pipe ends and check for proper

threading to prevent damage to valve internals.

Use a PTFE based thread sealant applied to the pipe threads. With valve

in the OPEN position, install pipe. Use a smooth wrench on the hex portion of the valve, not the valve body, to tighten. Use pipe wrenches on

pipe and pipe fittings only.

©Copyright 2010 Dwyer Instruments, Inc. Printed in U.S.A. 2/10 FR# R2-443081-00 Rev. 2

OPERATION

These valves are bi-directional and can be installed with flow in either

direction. Rotate the handle 90 degrees counterclockwise to open and

90 degrees clockwise to close. Check to make sure the process media

is compatible with the valve materials. See “Physical Data”. Do not

exceed pressure or temperature maximum ratings.

MAINTENANCE

The Series BV2 is a non-repairable valve. The only maintenance

required is the occasional tightening of the packing gland nut. Over time

some leakage may occur through the stem orifice. If this occurs tighten

the packing gland nut approximately 1/4 turn.

W.E. ANDERSON DIV., DWYER INSTRUMENTS, INC.

P.O. BOX 358 • MICHIGAN CITY, INDIANA 46361 U.S.A.

Phone: 219/879-8000 www.dwyer-inst.com

Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Loading...

Loading...