Page 1

Model 471B Digital Thermo Anemometer

Specifications and Operating Instructions

PECIFICATIONS

S

ervice: Air velocity and temperature of clean, dry air.

S

emperature Limits:

T

rocess Air Velocity: -20 to 212°F (-29 to 100°C);

P

Process Temperature: -40 to 212°F (-40 to 100°C);

Ambient: 5 to 125°F (-15 to 51°C).

Display: 4.5 digit LCD.

esolution: 0.1%, 0.1°F/°C.

R

ange Air Velocity: 0 to 6000 FPM (0 to 30 m/s).

R

ccuracy Air Velocity: ±3% FS within temperature range of 40 to 90°F (4 to

A

2°C).

3

Range Volumetric Air Flow: 19,999 in selected flow units.

Range Temperature: -40 to 212°F (-40 to 100°C).

Accuracy Temperature: ±0.5°F (±0.28°C) from 32 to 122°F (0 to 50 °C); ±1.5°F

±0.83°C) from -40°F to 32°F (-40 to 0°C) & 122 to 212°F (50 to 100°C).

(

robe Length: 8˝ (203 mm) insertion.

P

able Length: 28˝ (71 cm) retracted, 6 ft (183 cm) extended.

C

Power Requirements: 9V alkaline battery included.

Weight: 16 oz (454 g).

Agency Approvals: CE, RoHS.

ulletin TE-471B

B

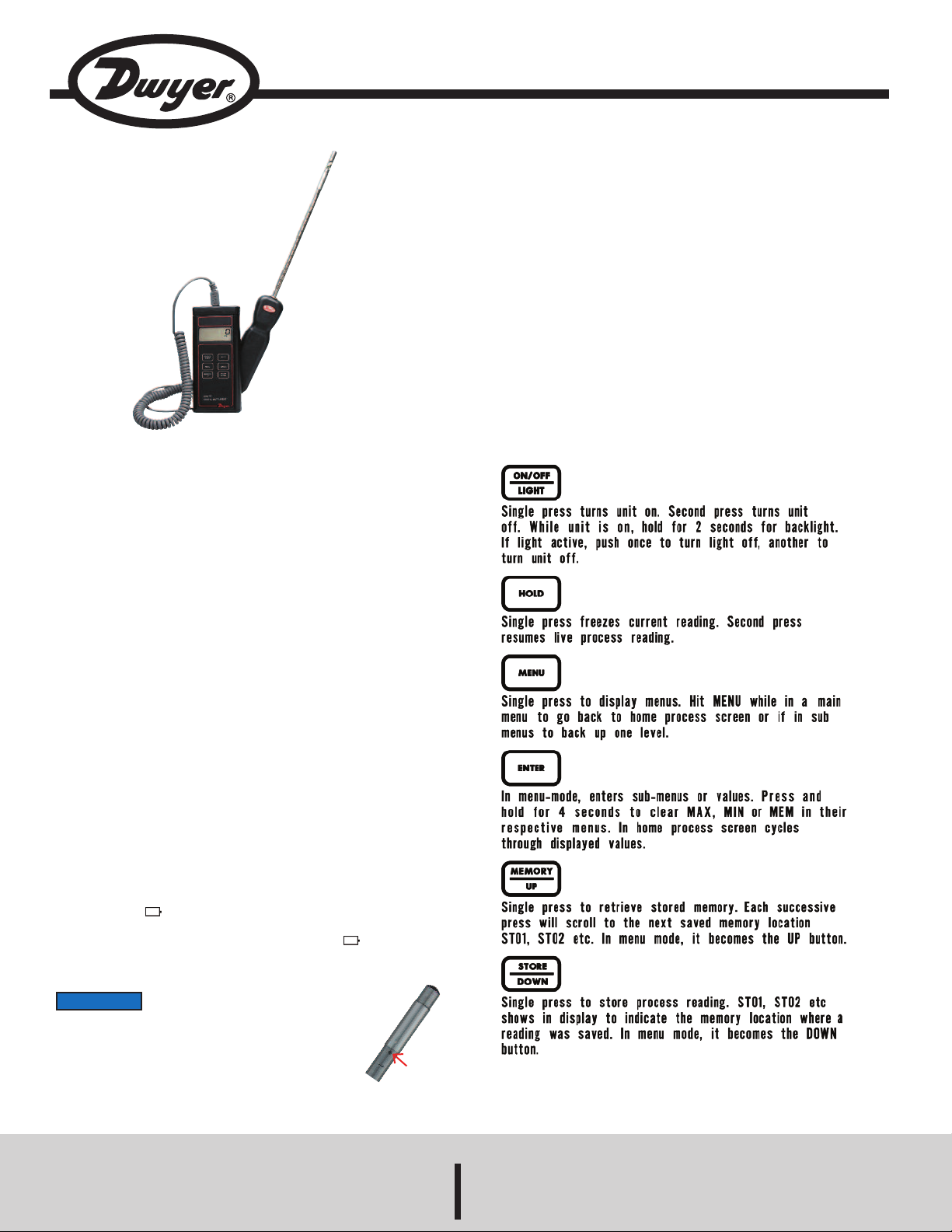

The Model 471B Digital Thermo Anemometers are versatile dual function

instruments that quickly and easily measure air velocity or volumetric flow plus air

temperature in imperial or metric units. High contrast LCD display shows both

selected readings simultaneously. Convenient backlight provides perfect visibility in

ow light conditions. Light automatically shuts off after 2-1/2 minutes to prolong

l

attery life. Low battery warning is included. Stainless steel probe with comfortable

b

hand grip is etched with insertion depth marks from 0 to 8 inches and 0 to 20 cm.

Extruded aluminum housing fully protects electronics, yet is lightweight and

comfortable to hold even when taking multiple readings as part of duct traverses.

Up to 99 readings may be stored for later retrieval. An integral sliding cover protects

sensors when not in use. Items included with the 471B are 9 volt alkaline battery,

sensing probe, wrist strap and custom carrying case.

Battery Installation

The unit is shipped with a separate 9 volt alkaline battery which must be installed

before operation. Remove the two screws holding the bottom endcap in place and

remove it. Connect the battery to the enclosed battery clip, observing correct

polarity. Be careful not to trap the wires between the case or foam pad which

retains the battery. This could make it difficult to install the battery or remove it later

for replacement. Be sure the rubber gasket is properly seated in the gasket

channel and replace the endcap. Note that the endcap will only fit one way

because the holes are slightly off-center. Place the “Z” shaped wrist strap clip in

one of the screw recesses and replace the screws. Do not overtighten. Attach the

wrist strap to the clip.

When battery replacement becomes necessary, use only 9 volt alkaline type

batteries such as a Duracell

carbon types, often labeled Heavy-Duty, are not recommended because of their

shorter life and an increased potential for leakage. Alkaline batteries are a better

value because they last typically up to three times longer in this device.

Low Battery Indicator

A weak battery may cause improper operation or inaccurate measurements. A low

battery indicator ( ) is provided on the display to show when the battery needs

to be replaced. Although the unit may appear to function and read properly, the

accuracy of the readings cannot be guaranteed when the ( ) indicator is empty

of power segments. Replace the battery with a fresh one. Do not leave an

exhausted battery in the unit due to potential battery leakage.

®

MN1604, or Eveready®522 or equivalent. Zinc-

OPERATING INSTRUCTIONS

NOTICE

DWYER INSTRUMENTS, INC.

The side of the probe with dot should face the flow.

Duracell® is a registered trademark of The Gillette Company

®

Eveready

is a registered trademark of Eveready Battery Company, Inc.

Phone: 219/879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A. Fax: 219/872-9057 e-mail: info@dwyemail.com

Page 2

HOLD

Memory

HOLD will appear on the home screen when the HOLD button is pressed, indicating

he process reading has been frozen.

t

Memory Storage and Retrieval

rom the home screen, push MEMORY/UP to view all previously stored values. Cycle

F

up or down through the stored data with the MEMORY/UP or STORE/DOWN buttons.

From the home screen, press STORE/DOWN to store data points to memory. For both

data storage and data memory retrieval, press MENU to return to the home screen.

MENUS

Maximum

Push ENTER to see the maximum recorded reading. When viewing the maximum

recorded reading, hold ENTE R for 4 seconds to clear. Push MEMORY/UP or

STORE/DOWN to cycle through parameters.

Minimum

ress ENTER to see

P

ocations.

l

Hold ENTER for 4 seconds to clear all stored memory

DEL.

Engineering Units

ress ENTER to see current engineering units. Press MEMORY/UP or STORE/DOWN to

P

select another unit.

Area

Press ENTER to view the current duct shape setting. for rectangular or

for circular will appear. To alter between the two, push the MEMORY/UP button or

STORE/DOWN buttons. If a circle duct shape is selected, press ENTER to see the

diameter value. If rectangle is chosen, ENTER will allow adjustment of the and

of the duct. A numeral position will blink indicating it can be adjusted with the

MEMORY/UP or STORE/DOWN buttons. Hit ENTER to store a value.

Note: In metric mode dimensions will be displayed in mm. Inches will be the value

when using imperial units.

Power Management

Push ENTER to see the minimum recorded reading. When viewing the minimum

recorded reading, hold ENTER for 4 seconds to clear. Push MEMORY/UP or

STORE/DOWN to cycle through parameters.

Average

Press ENTER to view the AVG function. This function will adjust the process reading

on the home screen to report the average reading over the period of selected time.

Press MEMORY/UP or STORE/DOWN to select between 0, 10, 30, or 60 second values.

Push ENTER to store the desired value.

©Copyright 2014 Dwyer Instruments, Inc. Printed in U.S.A. 5/14 FR# 02-443916-00 Rev. 3

DWYER INSTRUMENTS, INC.

Pu sh ENTER to see current time off setting. Select 30 or 10 values indicating minutes

for power to automatically shut-off. By selecting 0, the auto shut-off is disengaged

and the unit will only turn off manually by the ON/OFF/LIGHT button.

MAINTENANCE/REPAIR

Upon final installation of the Model 471B, no routine maintenance is required. The

Model 471B is not field serviceable and should be returned if repair is needed.

Field repair should not be attempted and may void warranty.

WARRANTY/RETURN

Refer to “Terms and Conditions of Sales” in our catalog and on our website.

Contact customer service to receive a Return Goods Authorization number before

shipping the product back for repair. Be sure to include a brief description of the

problem plus any additional application notes.

Phone: 219/879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A. Fax: 219/872-9057 e-mail: info@dwyemail.com

Loading...

Loading...