Page 1

Bulletin H-10

No. 460 Air Meter

perating Instructions and Parts List

O

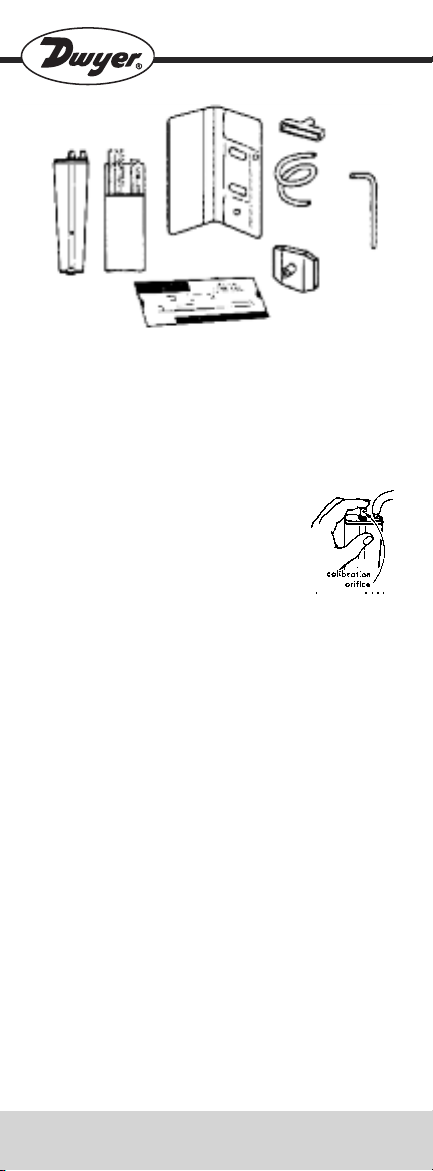

• Air Meter

White plastic ball

•

• Bottom plug

• Chemically treated

pipe stem cleaners

• Nylon bristles to clean

calibration orifice

• Case

The No. 460 Air Meter is a precision air velocity and

static pressure indicator based on the principle of the

variable area flowmeter. With the meter in a vertical

position, air comes in through the outer of the two top

connectors, passes into the scale chamber and enters

the tapered indicating tube at the bottom, causing the

white plastic ball to lift. Height of ball indicates static

pressure or air velocity.

Air velocity is registered from 260 to 1200 fpm on low range, 1000 to 4000

fpm on high range. Static pressure is .005˝ to .09˝ water, low range and .05˝

to 1.0˝, high range. To read on high range scale, cap exposed connector

with finger as shown in sketch. To read on low range scale, do not cap connector.

STATIC PRESSURE—To read static pressure, secure angle connector to

meter with tubing supplied. For minus pressure readings, use center connector on the meter. For plus pressure readings, use outer connector. Hold

meter vertically, inserting angle connector in unit under test, and read pressure in inches of water on appropriate high or low range scale. For accurate

static pressure measurements in ducts and equipment having appreciable

air velocity, select a location where duct face parallels air stream and drill a

1/4˝ opening, leaving minimum burr. Secure supply grille probe to angle

connector, place over opening permitting as little leakage as possible and

read static pressure as above.

FURNACE DRAFT—Secure angle connector to center connection of Air

Meter with rubber tubing. Holding meter vertically, insert angle connector

into furnace combustion chamber for over-fire draft reading. For last pass

or smoke pipe draft, connect into the breeching on the furnace side of any

damper or draft control. To determine draft loss through furnace, subtract

over-fire draft reading from smoke pipe draft. For adjustment of barometric

draft controls, follow furnace or boiler manufacturer's recommendations for

over-fire draft setting.

AIR FILTER TEST—To obtain pressure drop across an air filter, follow procedure outlined above to determine static pressure on each side of the filter.

Subtract the smaller from the larger to get correct static pressure drop in

inches of water. Follow manufacturer's recommendations for filter cleaning

or replacement.

• Supply grille probe

14˝ length 3/16˝ x

•

5/16˝ rubber tubing

• Angle connector

• Return grille probe

• Air velocity calculator

• Instructions (not shown)

Copyright 2012 Dwyer Instruments, Inc. Printed in U.S.A. 7/12

DWYER INSTRUMENTS, INC.

P.O. Box 373 • MICHIGAN CITY, IN 46360 U.S.A.

Phone: 219/879-8000 Fax: 219/872-9057

www.dwyer-inst.com

Page 2

UCT AIR VELOCITY—To determine air velocity, within a confined space,

D

as in a duct, first find static pressure in duct as outlined above under Static

Pressure. Total pressure, or sum of velocity and static pressure, is then

ound by removing supply grille probe and inserting angle connector into

f

duct with angled portion directed into air stream. Subtract static pressure

from total pressure to get velocity pressure, then refer to Air Velocity calcu-

ator to find air velocity. (Note: Air velocity determined will be true only for

l

the point of measurement—average velocity across duct may vary from this

figure.)

SUPPLY GRILLE VELOCITY—To measure

ir velocity and determine cfm discharged from

a

supply grilles in air distribution systems, connect supply grille probe to Air Meter and use

s indicated in sketch. Balancing a system on

a

a comparative basis, i.e. adjusting the controls

ame, presents no problem. Using Air Meter as shown, traverse the face of

s

the grille. Take readings at a number of points to determine average velocity,

then make adjustment to increase or decrease flow as required. With orna-

ental diffusers it may not be practical to use supply grille probe. If so, angle

m

connector alone may be used, taking care to obtain measurement at same

point within diffuser face.

Calculate actual air delivered through a grille in cubic feet per minute as

follows:

Cfm = Average velocity in fpm x Effective grille area in sq. ft.

Determining effective area of most grilles, however, is difficult. Where

possible, refer to available technical data supplied by grille manufacturer.

Some manufacturers specify effective area; others give coefficient of discharge; still others, a pressure loss through grille with equivalent flow in cfm.

In all cases, great care is necessary to obtain an accurate value for the cfm.

When manufacturer specifies effective area for a grille, cfm discharged

may be calculated as directed above. If manufacturer specifies coefficient

of discharge the formula becomes:

Cfm = Average velocity in fpm x Grille area in sq. ft. x Discharge coeff.

If manufacturer supplies data showing cfm corresponding to total pressure behind grille face or pressure loss through grille, cfm may be determined by inserting angle connector through grille face and directing tip into

air stream. Reading obtained will be total pressure in inches of water and

cfm can be found by referring to manufacturer’s data. (Note: This technique

may be used only with grille fully open, if of the adjustable type.)

dated by partial closing with dampers, approximate cfm may be found by

multiplying average velocity versus face area by a factor of .7.

RETURN GRILLE VELOCITY—To measure velocity of air entering a return

grille, connect return grille probe to Air meter and use as indicated in sketch.

Rubber tube is secured to center connector of meter. To determine volume

of air entering grille, make a careful traverse of grille face to find average

velocity. For conventional return grilles, measure actual face area, excluding

For grilles where no data is supplied or when data is invali-

so the discharge velocities of all grilles are the

center strips, border, etc. Approximate volume

can be calculated as follows:

Cfm = Average air velocity in fpm x Face area

in sq. ft. x 95. For plain lattice grilles with a relatively greater reduction in open area, the measured open area should be substituted in the

formula.

MAINTENANCE—Keep your Air Meter—

1. DRY—If moisture enters, remove bottom fitting, let moisture slowly evap-

orate. Use chemically treated pipe stem cleaner to clean indicating tube

thoroughly, removing any moisture remaining.

2. CLEAN—Use pipe stem cleaner to remove dust, lint, dirt, etc.

3. STATIC-FREE—If a static electricity charge causes ball to stick, use

chemically treated stem cleaner as in (1.) above.

4. CALIBRATED—Keep the high range calibration orifice clean and open

with nylon bristles supplied. Do not use wire, pins or drills which might enlarge opening. do not replace the 14˝ length of 3/16˝ x 5/16˝ rubber tubing

with tube of different size or length.

DWYER INSTRUMENTS, INC.

P.O. Box 373 • MICHIGAN CITY, IN 46360 U.S.A.

FR# 64-440081-00 Rev. 5

Phone: 219/879-8000 Fax: 219/872-9057

www.dwyer-inst.com

Loading...

Loading...