Page 1

Bulletin E-70-A

A

B

C

D

E

F

DWYER

TO SET POINT

LEADS

(SEE NOTE)

LOAD

Series

3000 MRS

Photohelic®Differential Pressure Switch/Gage

Specifications — Installation and Operating Instructions

Using solid state technology, the Series 3000MRS Photohelic

switch/gage

able differential pressure switch with a large easy-to-read analog

pressure gage employing the durable, time-proven Magnehelic

design. Switch setting is easy to adjust with large external knobs

on the gage face. Gage reading is unaffected by switch operation

— will indicate accurately even if power is interrupted. Solid state

design now results in greatly reduced size and weight. Units can

be flush mounted in 4

hardware supplied. For applications requiring high cycle rates,

choose 3000MRS models with SPST (N.O.) solid state relays. All

models provide both low and high limit control and include 18inch (45 cm) cable assemblies for electrical connections.

Gage accuracy is ±2% of full scale and switch repeatability is

±1%. Switch deadband is one pointer width — less than 1% of full

scale. Compatible with air and other non-combustible, non-corrosive gases, they can be used in systems with pressures to 25 psig

(1.725 bar). Optional construction is available for use to either

35 psig (2.42 bar) or 80 psig (5.51 bar).

Accessories

Mounting ring, snap ring (4) 6-32 x 11⁄4˝ RH machine screws

18˝ (45 cm) cable assembly (panel mounting)

3

⁄16˝ tubing to 1⁄8˝ NPT adapters (3) 6-32 x 5⁄16˝ RH machine screws

(2)

1

⁄8˝ NPT pipe plugs (surface mounting)

(2)

CAUTION- Do not exceed specified electrical ratings for supply voltage, switching voltage and

switching current. Permanent damage, not covered

by warranty, will result. This unit is designed to be

powered only by 24 VDC. Switched current must be

AC. See specifications.

combines the functions of a precise, highly repeat-

13

⁄16˝ (122 mm) hole or surface mounted with

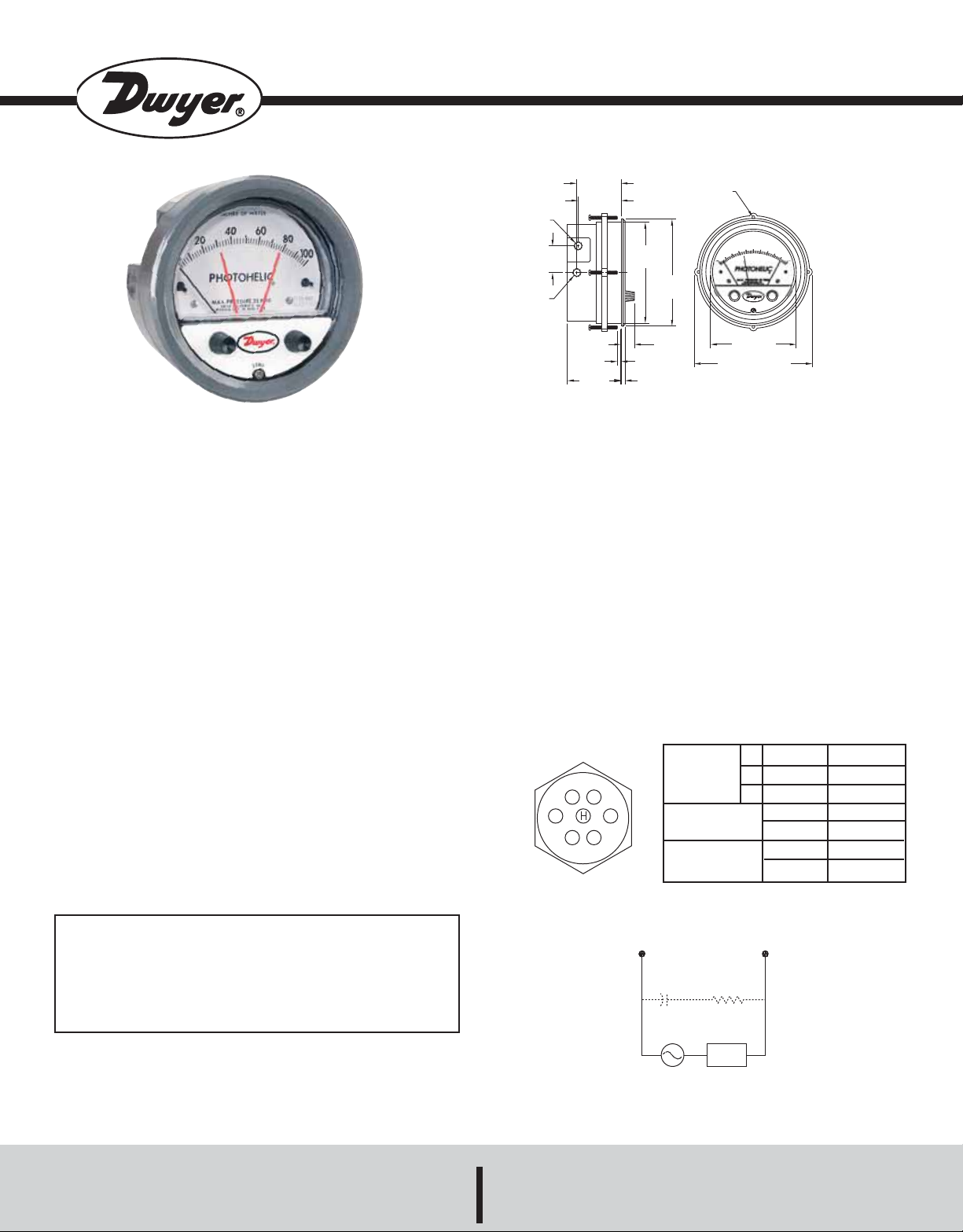

ELECTRICAL CONNECTIONS

1/8 FEMALE NPT HIGH

PRESSURE CONNECTION

1/8 FEMALE NPT HIGH

PRESSURE CONNECTION

1/8 FEMALE NPT LOW

PRESSURE CONNECTION

®

®

SPECIFICATIONS

GAGE SPECIFICATIONS

Service: Air and non-combustible, compatible gases.

Wetted Materials: Consult Factory.

Accuracy: ±2% of full scale (3000-0 ±3% of full scale).

Pressure Limit: -20˝ Hg. to 25 psig (-0.677 bar to 1.72 bar). MP option;

35 psig (2.41 bar), HP option; 80 psig (5.52 bar).

Temperature Limits: 20 to 120°F. (-6.67 to 48.9°C).

Process Connections: 1/8-27 female NPT (duplicated side and back).

Size: 4˝ (101.6 mm) dial face, 5˝ (127mm) O.D. x 3-1/8˝ (79.38 mm).

Weight: 1.8 Ib., (816 g).

SWITCH SPECIFICATIONS 3000MRS

Switch Type: Each setpoint has a solid state relay.

Switching Voltage: 20-280 VAC (47 - 63 Hz).

Switching Current: 1.0 amp (AC) max., 0.01 mA (AC) min, (2) SPST

N.O.

Electrical Connections: 18˝ (46 cm) cable assembly with 6 conductors,

Optional lengths to 100´ (30.5 m).

Power Requirements: 24 VDC, regulated ± 10%.

Mounting Orientation: Diaphragm in vertical position. Consult factory

for other position orientations.

Set Point Adjustment: Adjustable knobs on face.

No Connection to H

1-1/4

[31.75]

2-1/61

[52.39]

[50.80]

2-1/2

[63.50]

(4) 6-32 HOLES

EQUALLY SPACED ON A

Ø4-47/64

[120.25]

5/8 [15.88]

PANEL MAX

3/16

[4.76]

5-1/8 [130.18] B.C.

Ø5

[127.00]

5/8

[15.88]

Power

Supply

Low

Set Point

High

Set Point

INCHES OF WATER

.4O

.60

.80

.2O

Ø4 [101.60]

FACE

5-1/2 [139.70] O.D.

MOUNTING RING

LETTER

+

-

COLOR

A

B

C

D

E

F

Red

Black

Green

Blue

White

Orange

2

Electrical connections are made by means of the cable assembly

supplied which has a multi-pin female plug installed on one end

which mates with the male connector on the rear of the gage. Wire

leads on the opposite end of the assembly are connected in

accordance with the drawing and chart to the right.

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Note: An R/C snubber (P/N A-600) is recommended

for solenoid or contactor (inductive) loads.

Phone: 219/879-8000 www.dwyer-inst.com

Page 2

INSTALLATION

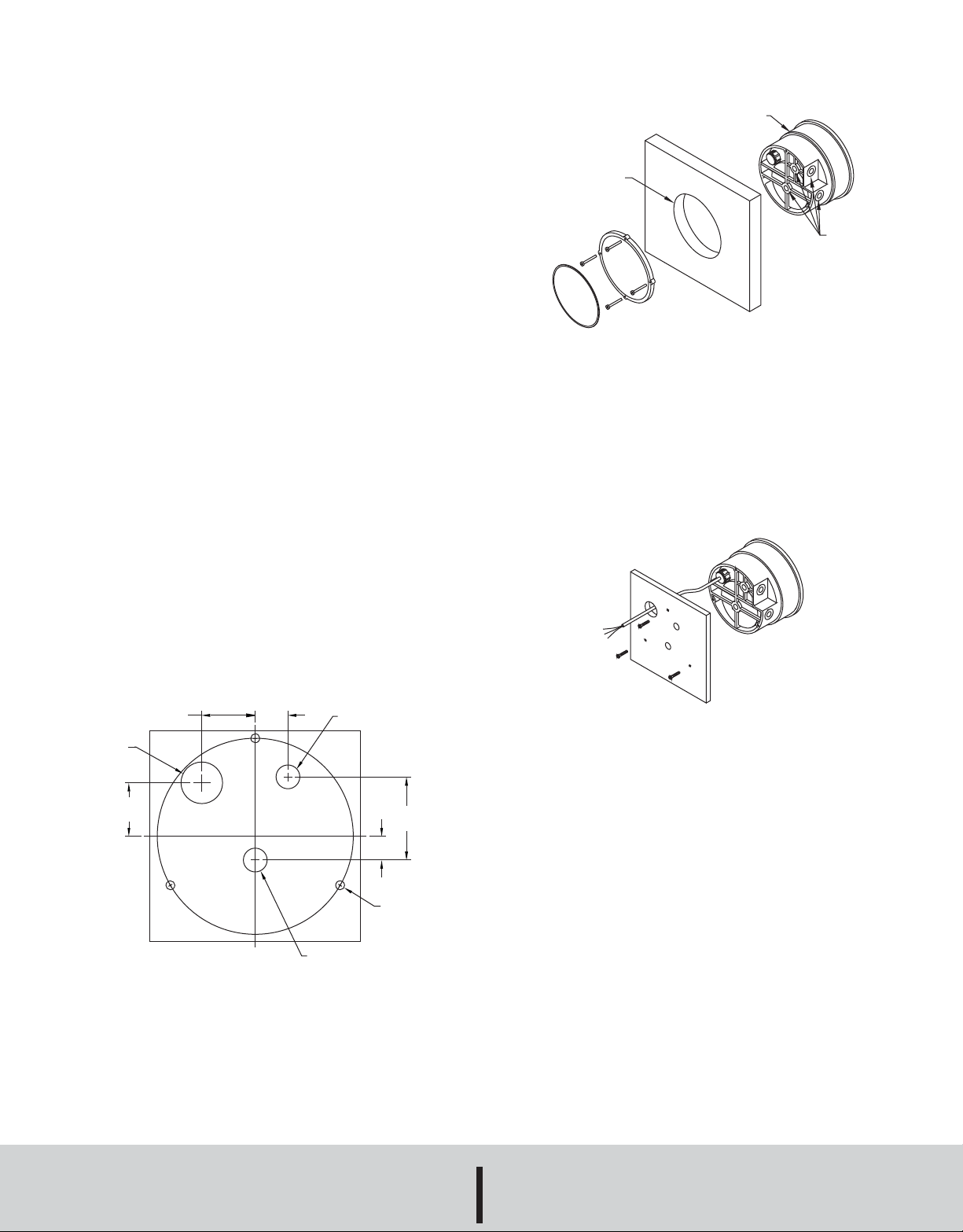

Ø4-3/4 [120.65] HOLE

SNAP RING

GROOVE

PNEUMATIC

PRESSURE TAPS

Ø7/8 [22.23]

HOLE IN PANEL

FOR WIRE

CONNECTION

1-1/8

[28.58]

11/16

[17.46]

1-1/8

[28.58]

Ø1/2 [12.70]

HOLE FOR

HIGH PRESSURE

CONNECTION

1-3/4

[44.45]

1/2

[12.70]

Ø1/2 [12.70] HOLE FOR

LOW PRESSURE CONNECTION

(3) Ø3/16 [4.77]

HOLES EQUALLY

SPACED ON

A 4-1/8 [104.78] B.C.

1. LOCATION: Select a location where the temperature of the unit will be between 20°F and 120°F. The

tubing feeding pressure to the instrument can be

run practically any length required but long lengths

will increase response time slightly. Avoid surfaces

with excessive vibration.

2. POSITION: All standard models are calibrated with

the diaphragm vertical and should be used in that

position for maximum accuracy. If your application

requires mounting in other than a vertical position,

be sure to specify this when ordering.

4. MOUNTING: The Photohelic®Switch/Gage may

be either panel mounted or surface mounted.

3. PRESSURE CONNECTIONS: For convenience,

two sets of 1/8˝ female NPT ports are available. Plug

the unused set with pipe plugs provided. Attach

tubing from positive pressure sour ce to port marked

"HI" or from negative (Vacuum) source to port

marked "LOW". In either case, opposite port must

be vented to atmosphere. In dusty environments,

we recommend use of an A-331 Filter Vent Plug to

keep interior of instrument clean. For differential

pressures the higher source is connected to the "HI"

port and lower to the "LOW" port.

©Copyright 2009 Dwyer Instruments, Inc. Printed in U.S.A. 7/09 FR# 13-440658-00 Rev. 3

A. PANEL MOUNTING: Cut a 4-3/4˝ or 120mm dia.

hole in panel and insert the complete unit from the

front. Slip on the mounting ring and install the split

snap ring in the groove on the bezel. Seat the mounting ring against the snap ring and thread the four

screws through the tapped holes. Tighten screws

against rear of panel.

B. SURFACE MOUNTING:Drill (3) 3/16˝ dia. holes for

mounting screws and (1) 7/8˝ dia. hole for wire assembly as shown in hole location drawing. Insert screws

from rear of panel and thread into tapped holes on

back of Photohelic

®

Switch/Gage case. If rear pressure

connections are to be used, make 1/2˝ dia. holes located as shown in hole location drawing in left column.

Once Photohelic

®

Switch/Gage unit is securely mounted, plug wire assembly into 7 pin connector on rear of

unit, being careful to match pin locations.

5. ZEROING: Once the Photohelic

®

Switch/Gage is

mounted in its final position, check to be sure pointer aligns with zero on scale, when no pressure is

applied and both low and high pressure ports are

vented to atmosphere. To adjust, turn small slotted

screw at center-bottom of gage face.

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Loading...

Loading...