Page 1

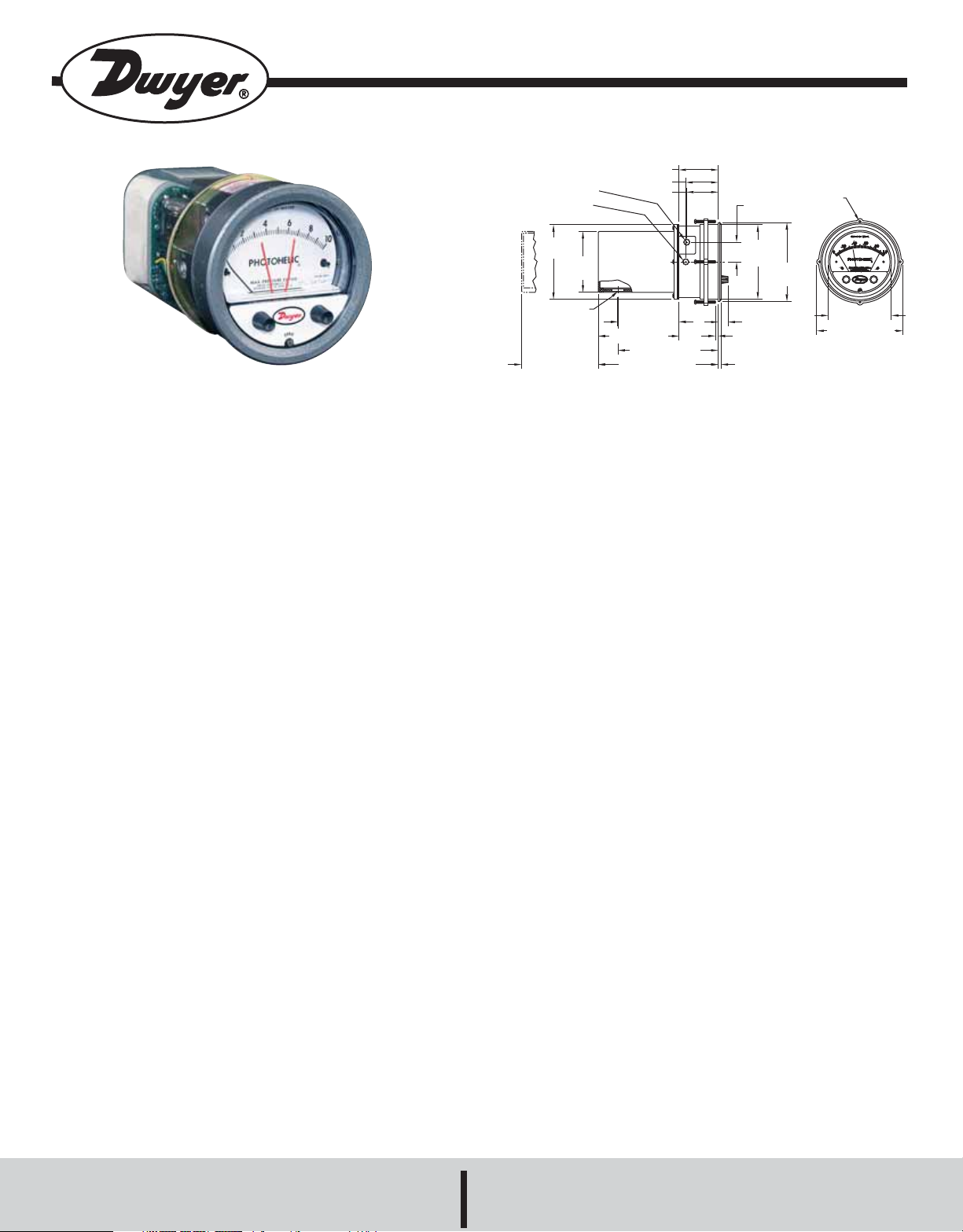

Series 3000 Photohelic®Pressure Switch/Gage

2-1/2 [63.50]

2-1/16 [52.39]

2 [50.80]

1-1/4

[31.75]

(4) 6-32 HOLES

EQUALLY SPACED ON

A 5-1/8 [130.18] B.C.

Ø4-47/64

[120.25]

Ø5

[127.00]

Ø4 [101.60]

FACE

5-1/2 [139.70]

O.D.

MOUNTING

RING

5/8 [15.88]

5/8 [15.88] PANEL

MAX

3/16 [4.76]

3-7/8 [98.43]

5-1/8 [130.18]

6-3/8 [161.93]

(7-5/8 [193.68])

4-3/8 [111.13]

HOUSING REMOVAL

3/4 CONDUIT

CONNECTION

Ø4-3/4

[120.65]

3-7/8 SQ

[98.43]

1/8 FEMALE NPT HIGH

PRESSURE CONNECTION

1/8 FEMALE NPT LOW

PRESSURE CONNECTION

Specifications - Installation and Operating Instructions

Fig. 1

Bulletin B-33

The Photohelic®Switch/Gage is a very versatile, precise pressure

switch combined with the time-proven Magnehelic®pressure gage.

Models are available with one or two phototransistor actuated relays.

Gage reading is unaffected by switch operation. Easy to adjust set points

have knob controls. Applied pressure and switch set points are fully

visible at all times. Deadband is one pointer width - less than 1% of full

scale. Double-pole double-throw relays can be easily interlocked to

provide variable deadband control. For positive, negative or differential

pressure only on 3600S models. Full scale ranges available from 0-.25

in w.c. to 0-6000 psig.

PHOTOHELIC®GAGE SENSING - HOW IT WORKS

In a typical control application, the Photohelic®switch/gage controls

between high and low pressure set points. When pressure changes,

reaching either set point pressure, the beam from an LED to the limiting

phototransistor will be cut off by the helix-driven light shield. The

resulting signal change is electronically amplified to actuate its DPDT

slave relay and switching occurs. Dead band between make and break

is 1% of full scale or less - just enough to assure positive, chatter-free

operation.

SPECIFICATIONS

GAGE SPECIFICATIONS

Service: Air and non-combustible, compatible gases.

Wetted Materials: Consult factory.

Accuracy: ±2% of full scale at 70°F (21.1°C). ±3% on -0 and ±4% on

-00 models.

Pressure Limits: -20˝ Hg. to 25 psig (-0.677 to 1.72 bar). MP option;

35 psig (2.41 bar), HP option; 80 psig (5.52 bar). 36003S – 36010S;

150 psig (10.34 bar). 36020S and higher; 1.2 x full scale pressure.

Temperature Limits: 20 to 120°F (-6.67 to 48.9°C); Low temperature

option available.

Process Connections: 1/8˝ female NPT.

Size: 4˝ (101.6 mm) dial face, 5˝ (127 mm) O.D. x 8-1/4˝ (209.55 mm).

Weight: 4 lb (1.81 kg).

SWITCH SPECIFICATIONS

Switch Type: Each setpoint has 2 Form C relays (DPDT).

Repeatability: ±1% of full scale.

Electrical Rating: 10A @ 28 VDC, 10A @ 120, 240 VAC.

Electrical Connections: Screw terminals.

Power Requirements: 120 VAC, 50/60 Hz; 240 VAC & 24 VAC;

Power optional.

Mounting Orientation: Diaphragm in vertical position. Consult factory

for other position orientations.

Set Point Adjustment: Adjustable knobs on face.

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Phone: 219/879-8000 www.dwyer-inst.com

Page 2

Bulletin B-33

SNAP RING GROOVE

4-13/16˝ (122 mm)

DIA. HOLE REQUIRED

FOR PANEL MOUNTING

1/8˝ MALE NPT PRESSURE CONNECTIONS.

SINGLE HIGH PRESSURE CONNECTION

FOR SERIES 36000A MODELS.

page 2

INSTALLATION

1. Location

All parts of the Dwyer®Photohelic®pressure switch/gage are ruggedly

constructed and will stand a moderate amount of vibration, physical

shock, and handling. Normal care in handling and installation is all that

is required. In cases where instrument panel vibration is severe, the

panel should be a spring mounted or the amplifier-relay unit mounted

remotely on a more stable surface.

Select a location where the ambient temperature will not exceed 120°F.

Pneumatic pressure sensing lines may be run any necessary distance.

For example, 250 foot sensing lines will not affect accuracy but will damp

the reading slightly. Do not restrict lines. If pulsating pressure or vibration

causes excessive pointer oscillation or relay chatter, consult factory for

additional damping means.

2. Position

The Photohelic

®

Pressure Switch/Gage may be mounted as an integral

package or the amplifier-load relay assembly and housing may be

mounted remotely from the indicating gage-phototransistor unit.

Extension cords with 7 pin plugs and receptacles are available from

Dwyer for interconnection of the two units.

The unit may be mounted in any desired position, scale vertical or

horizontal, without affecting its accuracy, but must be rezeroed if position

is changed from horizontal to vertical or vice versa. The -0 and -00

models must be mounted with the scale vertical.

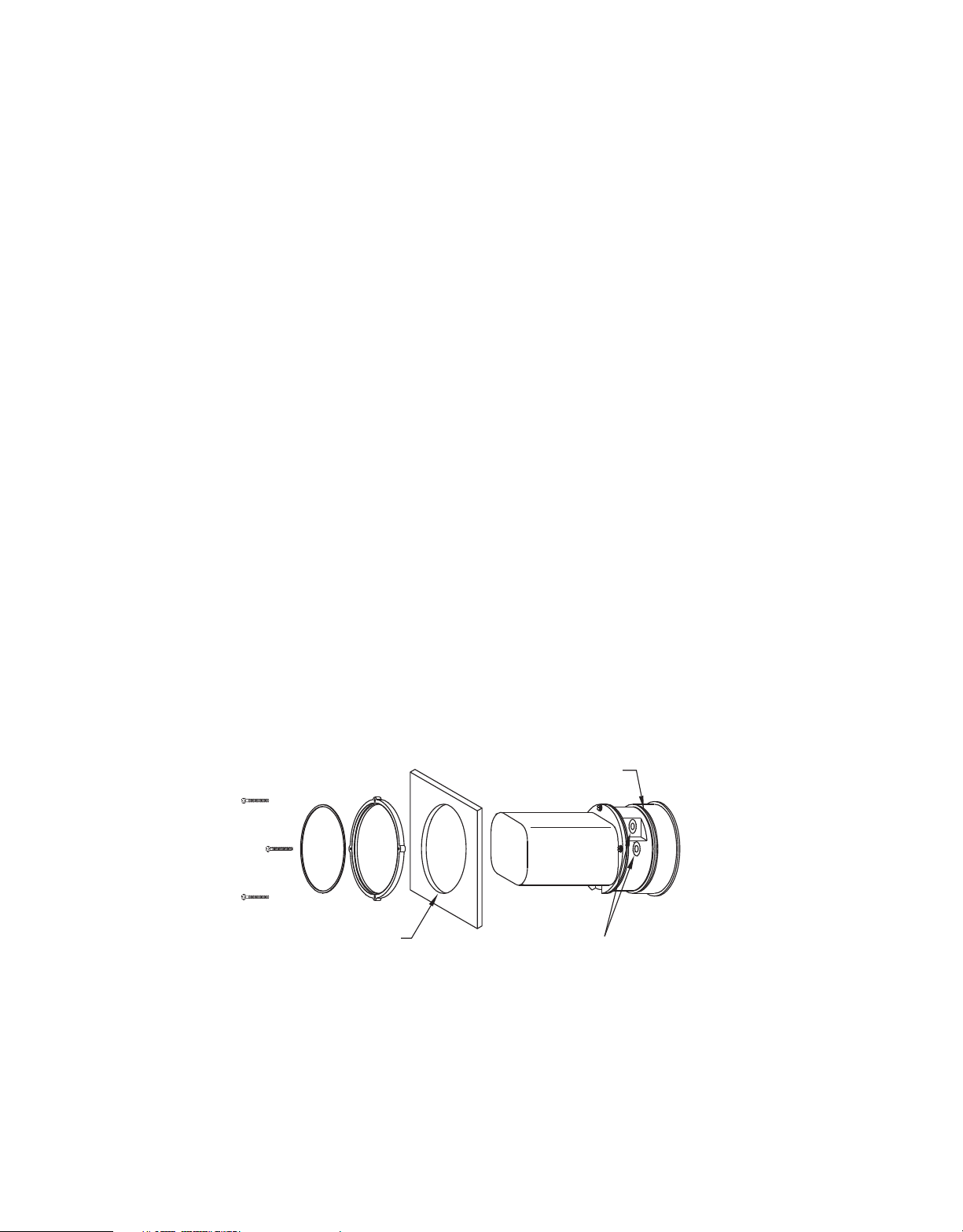

3. Mounting

The Photohelic

®

Switch/Gage is normally mounted before making

electrical connections, as the electrical enclosure is independent of the

mounting means and may be removed at any time.

Panel Mounting

Normal mounting is flush or through panel is shown in Fig. 2. Be sure to

allow 4-3/8˝ extra space behind the unit for electrical enclosure removal.

Make a single 4-13/16˝ diameter hole in the panel. Insert the entire

Photohelic®Switch/Gage unit from the front, then slip on the mounting

ring and snap ring from the rear. Seat the snap ring in its groove, back

up the mounting ring against snap ring and tighten the four (4) 2˝ No. 632 clamp screws provided. If behind panel space is critical, the amplifierrelay unit can be mounted remotely. See the Remote-Relay Mounting

Instructions for details.

Through Panel Mounting

Fig. 2

Page 3

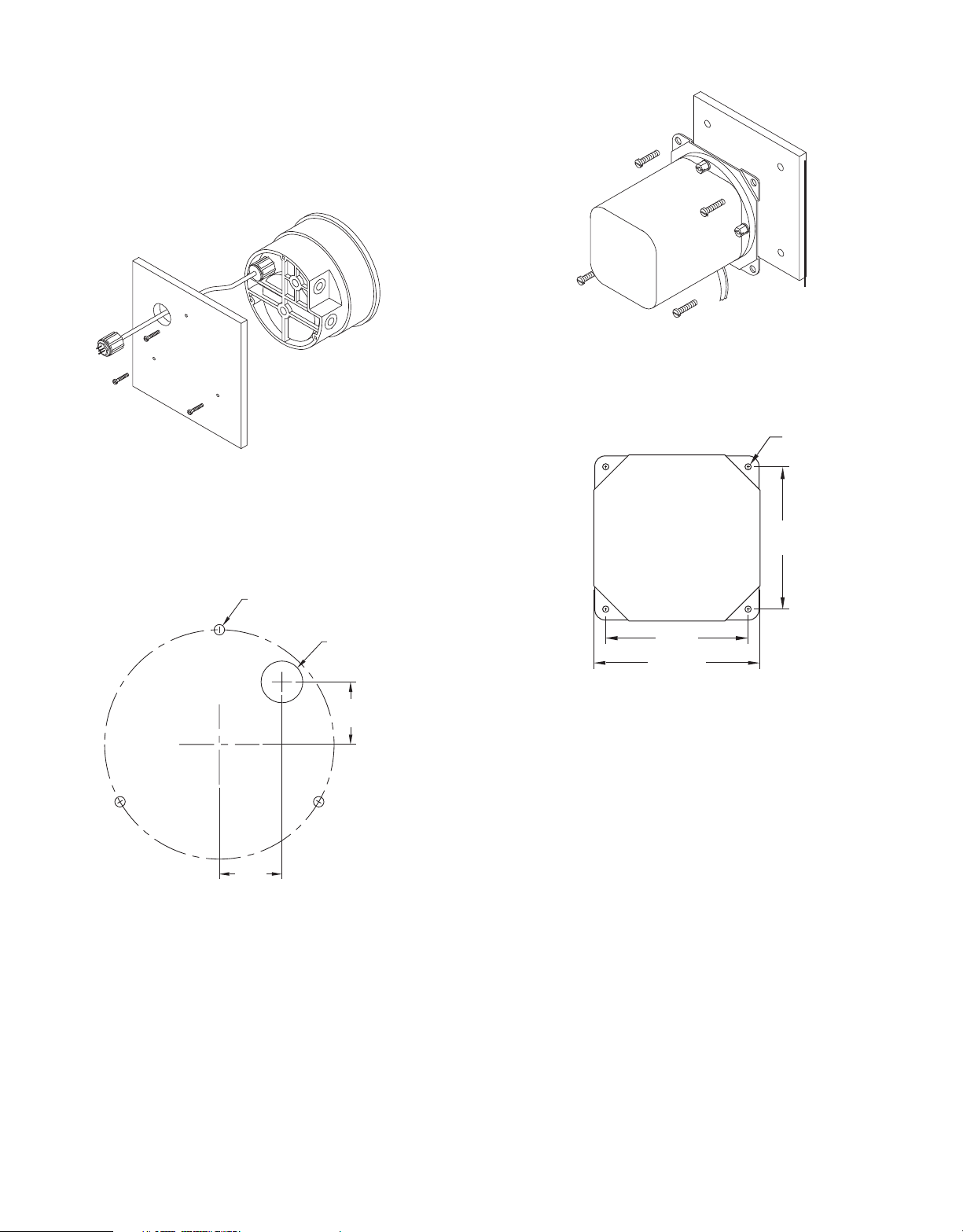

Gage Mounting with Relays Remote

4-9/32

[108.74]

5

[127.00] SQ

4-9/32

[108.74]

Ø3/16

TYP 4 PLACES

1-1/8

[28.58]

1-1/8

[28.58]

THREE 3/16 DIA.

HOLES AT 120°

SURFACE MTG.

3/4 DIA. HOLE

FOR WIRE CONN.

Where it is desirable to mount the amplifier-relay unit separate from the

gage-phototransistor unit, the gage may be mounted either as shown in

Fig. 2 (except less amplifier-relay portion) or surface mounted as shown

in Fig. 3A. Use the layout shown in Fig. 3B to locate holes. The complete

package cannot be surface mounted.

Surface Mounting

Fig. 3A

Bulletin B-33

page 3

Remote Amplifier-Relay Unit

Fig. 4A

Hole Layout

Hole Layout (Front)

Fig. 3B

Remote Relays Mounting

The amplifier - relay unit may be mounted remotely as shown in Fig. 4A.

Use the hole layout as shown in Fig. 4B for this option.

Additional mounting information for special requirements is available

from the factory.

Fig. 4B

4. Pneumatic Connections & Zeroing

After installation but before making pressure connections, set the

indicating pointer exactly on the zero mark, using the zero adjust screw

located at the bottom of the front cover. Note that this adjustment can

only be made with the high and low pressure taps both open to

atmosphere.

Connect the high and low pressure taps to positive, negative, or

differential pressure sensing points. Use 1/4˝ diameter metal or other

instrument tubing and 1/8˝ NPT adaptors at the Dwyer

®

. Photohelic

pressure/switch gage. Adaptors for rubber or soft plastic tubing are

furnished with the instrument for use where this type of connection is

preferred.

®

If the Photohelic

one of the pressure taps must be left open to atmosphere. This will allow

the reference pressure to enter. In this case, installation of a Dwyer

Switch/Gage is not used to sense differential pressure,

®

. No.

A-331 Filter Plug or similar fitting in the reference pressure tap is

recommended to reduce the possibility of dust entering the instrument.

®

®

Note: If the Photohelic

switch/gage is over pressured, pointer may

‘jump” from full scale back to zero and remain there until the excess

pressure condition is relieved. Users should be aware of possible false

zero pressure indications under this conditions.

Page 4

Bulletin B-33

4-3/8 [111.13]

COVER MOUNTING SCREWS

SUPPORT CONDUIT

FROM PANEL

COVER PULL

OUT

FLEXIBLE CONDUIT

SECTION B SECTION C

SECTION A

SECTION D

SECTION E

CIRCUIT:

POWER SUPPLY:

CONTACT RATING:

page 4

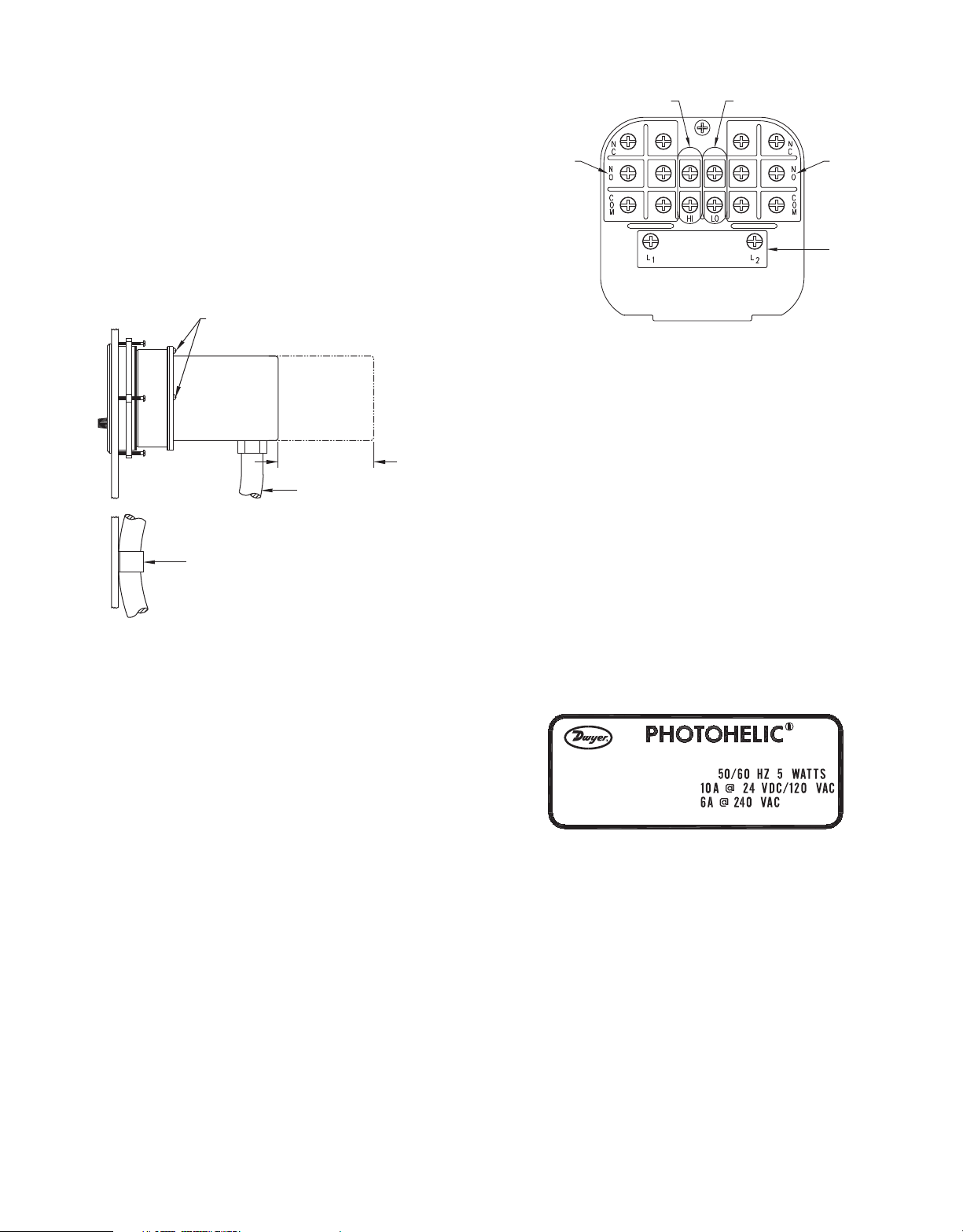

ELECTRICAL CONNECTIONS

1. Cover

The amplifier-relay unit has an easy to remove housing. Remove the

three (3) screws as shown in Fig. 5 and slide the housing off. Make all

the electrical connections before reinstalling and refastening the

housing.

2. Conduit

Electrical access to the connection box portion of the relay housing is by

bottom opening for 3/4˝ conduit. Use of flexible conduit is recommended.

It should be supported from the panel or other suitable surface to prevent

the wiring system from exerting undue strain on the instrument. See Fig.

5.

Mounting Details

Terminal Board

CAUTION: Do not apply electrical

current to terminals in sections B and C.

Fig. 6

Separate Ground Wire attachment is provided for by a No. 6-32 screw

on the mounting bracket near the conduit opening. An additional ground

wire connection is located on the side of the gage body for use when the

amplifier-relay unit is mounted remotely.

Single Set-Point instruments are furnished with the right or high setpoint components and circuitry in place. These are connected to

Sections A and B of the terminal board. The left or low set-point

components are omitted.

Fig. 5

3. Terminal or Connection Board Layout

In Fig. 6,”Terminal Board”, Section A contains the connections for the

load or slave relay actuated by the high or right set-point. This relay is a

double pole, double throw type. The two top connections are normally

closed, the two middle connections are normally open, and the bottom

connections are the common pair. The relay is in its normal or DeEnergized position when pressure is below the right hand set-point.

Section D is exactly the same as Section A except that its load or slave

relay is controlled by the low or left set-point. The De-Energized position

is below the left hand pointer set-point.

Section B contains the external connections to the holding coil circuit for

the high or right set-point relay and Section C contains similar

connections for the low or left set-point relay. The function and use of

these connections varies somewhat depending on the circuit style of the

instrument. See paragraphs 5 and 6 for details.

Section E contains the power connections for the control unit

transformer primary. The transformer in turn supplies reduced voltage

power for the LED, phototransistor, amplifier unit, and load relay pull in

and holding coils. Connections must always be made to this section in

order to put the unit in operation. Standard units are designed for 117

VAC input to the transformer. Special units are also available for other

voltages.

4. Circuit Style

The Photohelic

®

Switch/Gage is available with several factory installed

optional internal circuits. They are identified as to style by a label shown

in Fig. 7. This label is mounted prominently on the terminal board of each

instrument. The letter H denotes a circuit in which the relay can be made

to latch or remain energized after pressure increase to its set-point.

Circuit Label

Fig. 7

The letter “L” denotes a circuit in which the relay can be made to latch or

remain de-energized after pressure decrease to its set-point. Two letters

are required to fully identify a dual set-point unit. Thus, circuit style HH,

which is standard, is a dual set-point circuit which has provisions for

latching on pressure increase to either set-point. Single relay units are

identified by the letters “SR” followed by “H” for the standard unit or “L”

for the special low latch unit. Units for use with other than standard 117

VAC will be so indicated on the label.

Page 5

RESET

RESET

Bulletin B-33

117 VOLT LINE

RESET JUMPERS

1/6 HP*

117 VOLT

LOAD

page 5

5. Dual Set Point Automatic Reset

Circuit Style HH is used for simple on-off switching applications. To place

in service, connect load circuits to the appropriate terminals in Section A

(Fig. 6) for the right set-point and Section D for the left set-point. Note the

the N.O. contacts are open when the gage pressure pointer is to the left

of the set-point pointers. No connections are necessary in Section B and

C. Make external ground connections as required and connect power to

Section E for the control unit. To use circuit style LL for automatic reset,

a jumper wire must be installed between the upper and lower terminals

in sections B and/or C.

6. Dual Set Point Manual Reset

Circuit Style HH may also be used for manual reset applications where it

is desired to have maintained contact on either relay following pressure

increase above its set-point. Load or signal connections are made to the

appropriate terminals in Sections A and D (as in paragraph above).

Connect terminals in Sections B and C through normally closed switches

or push buttons as shown in Fig. 8. Use of “dry-circuit” type switches

such as Dwyer Part No. A-601 with palladium, gold, etc. or rotary wiping

action type contacts is recommended. Make external ground

connections as required and connect power to Section E for the control

unit.

Circuit style LL is used for manual reset applications which require that

contact be maintained following pressure decrease below the set-point.

Load connections are made to the appropriate terminals in Sections A

and D. A normally open type manual reset switch such as Dwyer Part No.

A-601 is connected to the terminals in sections B and C. The circuit must

be “armed” by momentarily closing the switch while the black pointer is

to the right of the set-point. From that point on, the circuit will latch on

pressure decrease below the set-point and remain latched on pressure

increase until manually reset with the optional switch.

9. Dual Set-Point Special Purpose Circuits

Circuit Style LL may be used where manual reset following maintained

contact on pressure decrease to either set-point is desired. Circuit Styles

HL and LH are combination units. For special combinations of features,

special units, and detailed instructions regarding their use, consult

factory.

®

10. Single Set-Point Photohelic

Switch/Gage

The single set-point Photohelic®Switch/Gage is furnished with the right

set-point only. Terminals in Section A and B (Fig. 6) are connected to this

relay. Circuit Style SRH is wired or automatic reset as in paragraph 5.

Manual reset is accomplished by adding a normally closed reset switch

or push button to the circuit as described in paragraph 6.

11. Single Set-Point Special

Manual reset after actuation on falling pressure can be obtained by using

Circuit Style SRL. Consult the factory for special units and detailed

instructions regarding their use.

12. Placing in Service

In normal operation each relay is de-energized when the pressure

applied to the instrument is below its set-point. Special low-latching units

will ordinarily have to be reset before placing on the line in normal

operation.

High-Low Limit Control (Circuit HH)

Manual Reset with Circuit HH

CAUTION: Do not apply electrical

current to terminals in sections B and C.

Fig. 8

7. Dual Set Point Automatic and Manual Reset Combinations

Circuit style HH may be used with either set-point wired and operating as

in paragraph 5 and other set-point wired and operating as in paragraph

6.

8. High Low Limit Control - Dual Set-Point

Circuit style HH may be used to control fans, dampers, pumps, etc.

between the set-points of a Photohelic

®

Switch/Gage. To accomplish this,

use one set-point relay to reset the other as shown in the wiring diagram

Fig. 9. In this typical application, the load (for instance a fan) would be

connected to the N.C. contacts of the right set-point relay, Section A (Fig.

6)/ On pressure rise to the right set-point, its relay would pull in and hold

even though pressure might then fall below that set-point, its relay would

automatically be De-Energized, return to its normal position and in so

doing, open the holding coil circuit from Section B (Fig. 6). The right setpoint relay would thus be reset and the cycle could repeat.

*Note: For larger motors, use the Photohelic® in a maintained contact,

117 Volt Control or Push Button Circuit of the motor starter.

Fig. 9

13. Failure Mode

The Photohelic®Switch/Gage circuit design provides certain protection in

the event of a loss of pressure or electrical power. In either case, both

relays will de-energize, returning to their normal “zero pressure” state.

The exceptions to this are models with center zero ranges. Because the

relays on all standard models are always energized when the indicating

(black) pointer is to the right of their respective set points, the relay action

on loss of pressure will depend on set-point position, since either of them

could be located to the left of zero. As an example; if the left pointer were

set at -2 in. w.c. and negative pressure was -3 in. w.c., a loss of that

pressure would allow the black pointer to return to the center and thus

cause the low set-point relay to energize.

MAINTENANCE

Photohelic

®

Switch/Gages are precision instruments, expertly assembled

and calibrated at the factory. They require no lubrication or periodic

servicing. If the interior is protected from dust, dirt corrosive gases and

fluids, years of trouble-free service may be expected. Zero adjustment

should be checked and reset occasionally to maintain accuracy. Any

repairs necessary to either the Magnehelic® pressure gage or the

electronic components should be performed by a trained instrument

mechanic. In most cases, this is best accomplished by returning the

complete Photohelic

®

Switch/Gage to the Dwyer Instruments, Inc.

factory.

Page 6

Bulletin B-33

page 6

PHOTOHELIC®PRESSURE SWITCH/GAGE

MODEL AND RANGES

Range,

Inches

of

Model

3000-00

3000-0

3001

3002

3003

3004

3005

3006

3008

3010

3015

3020

3025

3030

3040

3050

3060

3080

3100

3150

*Note: The Photohelic

specifications for the acceptance of unlisted components.

Water

0-.25

0-.50

0-1.0

0-2.0

0-3.0

0-4.0

0-5.0

0-6.0

0-8.0

0-10

0-15

0-20

0-25

0-30

0-40

0-50

0-60

0-80

0-100

0-150

Minor

Div.

.005

.01

.02

.05

.10

.10

.10

.20

.20

.20

.50

.50

.50

1.0

1.0

1.0

2.0

2.0

2.0

5.0

Model

3300-0

3301

3302

3304

3310

3320

3330

Model

3201

3202

3203

3204

3205

3210

3215

3220

3230

36003S

36006S

36010S

36020S

36030S

36060S

36100S

36300S

36600S

®

pressure switch/gage may be used in an Under Writers Laboratories approved industrial control panel if the usage conforms to UL

Range,

Zero

Center

Inches

of Water

.25-0-.25

.5-0-.5

1-0-1

2-0-2

5-0-5

10-0-10

15-0-15

Range

PSIG

0-1

0-2

0-3

0-4

0-5

0-10

0-15

0-20

0-30

0-30

0-60

0-100

0-200

0-300

0-600

0-1000

0-3000

0-6000

Minor

Div.

.01

.02

.05

.10

.20

.50

1.0

Minor

Div.

PSIG

.02

.05

.10

.10

.10

.20

.50

.50

1.0

1.0

2.0

2.0

5.0

10

20

20

100

200

Dual Scale Air Velocity Units

(for use with pitot tube)

Range, Air

Velocity

FPM

300-2000

500-2800

500-4000

1000-5600

2000-12500

Minor Div.

MM

.20

.50

.50

1.0

2.0

2.0

Minor

Div.

MM

.50

Model

3000-00AV

3000-0AV

3001-AV

3002-AV

3010-AV

Model

3000-6MM

3000-10MM

3000-25MM

3000-50MM

3000-80MM

3000-100MM

Model

3300-20MM

Ranges,

Inches of

Water

0-.25

0-50

0-1.0

0-2.0

0-10

Range,

MM of

Water

0-6

0-10

0-25

0-50

0-80

0-100

Range,

Zero

Center

MM of

Water

10-0-10

Model

3000-15CM

3000-20CM

3000-25CM

3000-50CM

3000-80CM

3000-100CM

3000-150CM

3000-200CM

3000-250CM

3000-300CM

Model

3300-4CM

3300-10CM

3300-30CM

Model

3000-60Pa

3000-125Pa

3000-250Pa

3000-500Pa

3000-750Pa

Range

CM of

Water

0-15

0-20

0-25

0-50

0-80

0-100

0-150

0-200

0-250

0-300

Range,

Zero

Center

Cm of

Water

2-0-2

5-0-5

15-0-15

Range,

Pascals

0-60

0-125

0-250

0-500

0-750

Minor

Div.

CM

.50

.50

.50

1.0

2.0

2.0

5.0

5.0

5.0

10.0

Minor

Div.

CM

.10

.20

1.0

Minor

Div.

Pascals

2.0

5.0

5.0

10.0

25.0

Model

3300-250Pa

3300-500Pa

Model

3000-1kPa

3000-1.5kPa

3000-2kPa

3000-3kPa

3000-4kPa

3000-5kPa

3000-8kPa

3000-10kPa

3000-15kPa

3000-20kPa

3000-25kPa

3000-30kPa

Model

3300-1kPa

3300-3kPa

Range,

Zero

Center

Pascals

125-0-125

250-0-250

Range

KiloPascals

0-1.0

0-1.5

0-2.0

0-3.0

0-4.0

0-5.0

0-8.0

0-10

0-15

0-20

0-25

0-30

Range,

Zero

Center

Kilopascals

.5-0-.5

1.5-0-1.5

Minor Div.

Pascals

125-0-125

250-0-250

Minor Div.

KiloPascals

.02

.05

.05

.10

.10

.10

.20

.20

.50

.50

.50

1.0

Minor

Div.

Kilopascals

.02

.10

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Page 7

Boletín B-33

2-1/2 [63.50]

2-1/16 [52.39]

2 [50.80]

1-1/4

[31.75]

(4) 6-32 HOLES

EQUALLY SPACED ON

A 5-1/8 [130.18] B.C.

Ø4-47/64

[120.25]

Ø5

[127.00]

Ø4 [101.60]

FAC E

5-1/2 [139.70]

O.D.

MOUNTING

RING

5/8 [15.88]

5/8 [15.88] PANEL

MAX

3/16 [4.76]

3-7/8 [98.43]

5-1/8 [130.18]

6-3/8 [161.93]

(7-5/8 [193.68])

4-3/8 [111.13]

HOUSING REMOVAL

3/4 CONDUIT

CONNECTION

Ø4-3/4

[120.65]

3-7/8 SQ

[98.43]

1/8 FEMALE NPT HIGH

PRESSURE CONNECTION

1/8 FEMALE NPT LOW

PRESSURE CONNECTION

El Interruptor/Indicador de Presión Photohelic®Serie 3000

INSTRUCCIONES Y OPERACION

El Interruptor/Indicador de Presión Photohelic®es un an interruptor

de presión muy versátile y preciso, combinado con el indicador de

presión de respuesta rápida Magnehelic®. Los modelos están

disponibles con uno o dos fototransistores que actúan sobre relés. A la

lectura del indicador no le afecta la operación del interruptor. Facilidad

de ajuste del punto de trabajo mediante botones de control. Las presión

aplicada y los puntos do interrupción (disparos) son claramente visibles

en todo momento. La banda muerta tiene una anchura de menos del

1% del fondo de escala. Los relés de doble circuito, doble disparo

pueden ser facilmente entrelazados para proporcionar un control

variable de la banda muerta. Para presión positiva, negativa y

diferencial; para models de un sólo relé, presión positiva sólo en modelo

36000S. Rangos de fondo escala disponibles de 0 - 0.25” c.a. a 0 - 6000

psig.

SENTIDO DEL PHOTOHELIC®SU FUNCIONAMIENTO

En una applicación de control tipica, el interruptor/indicador Photohelic

controla entre los puntos de trabajo de alta y baja presión. Cuando la

presión cambia, alcanzando cualquier presión del punto de trabajo, el

haz de lud de un LED dirigido hacia el fototransistor limitador será

interrumpido por el escudo de luz del eje helicoidal. El cambio de la

señal resultante es electronicamente amplificada para actuar sobre su

relé esclavo DPDT y ocasiona el disparo del interruptor. La banda

muerta entre lo marcado y el corte es del 1% del fondo de escala o

menor. Suficiente para asegurar una operación positiva y libre de

errores.

*

Figura 1

ESPECIFICACIONES

GAGE SPECIFICATIONS

Service: Air and non-combustible, compatible gases.

Wetted Materials: Consult factory.

Accuracy: ±2% of full scale at 70°F (21.1°C). ±3% on -0 and ±4% on -

00 models.

Pressure Limits: -20" Hg. to 25 psig (-0.677 to 1.72 bar). MP option;

35 psig (2.41 bar), HP option; 80 psig (5.52 bar). 36003S – 36010S;

150 psig (10.34 bar). 36020S and higher; 1.2 x full scale pressure.

Temperature Limits: 20 to 120°F.

(-6.67 to 48.9°C) Low temperature option available.

Process Connections: 1/8˝ female NPT.

Size: 4˝ (101.6 mm) dial face, 5˝ (127 mm) O.D. x 8-1/4˝ (209.55 mm).

Weight: 4 lb (1.81 kg).

SWITCH SPECIFICATIONS

®

Switch Type: Each setpoint has 2 Form C relays (DPDT).

Repeatability: ±1% of full scale.

Electrical Rating: 10A @ 28 VDC, 10A @ 120, 240 VAC.

Electrical Connections: Screw terminals.

Power Requirements: 120 VAC, 50/60 Hz; 240 VAC & 24 VAC Power

optional.

Mounting Orientation: Diaphragm in vertical position. Consult factory

for other position orientations.

Set Point Adjustment: Adjustable knobs on face.

Page 8

Ranura Del Anillo De Suceccion

Tapones De Presion

Neumatica

Ø4-13/16 [122.24]

Dianetroaguiero

Boletín B-33

P. 2

INSTALACION

Localización: Todas las partes del interruptor/indicador Photohelic®de

Dwyer®están robustamente construidas para soportar una moderada

cantidad de vibración, impacto físico y manejo del mismo. Un cuidado

normal en su manejo e instalación es todo lo que se precisa. En los

casos en los que la vibración del panel de instrumentos sea intensa, éste

deberá estar montado sobre algún resorte, o bien, la unidad del reléamplificador estar montada en una superficie más estable.

Elegir un lugar donde la temperatura ambiente no exceda de 120°F

(49°C).

Las lineas sensoras de presión neumática deben alargarse a la distancia

que sea necesaria. Por ejemplo, 250 pies (75 m) de lineas sensoras no

afectarán a la precisión, pero amortiguarán la lectura ligeramente. Si la

presión pulsante o la vibración dan lugar a un punto de excesiva

oscilación o el relé castañea, consultar con la fábrica para medios

adicionales de amortiguamiento. Ver accesorios adecuados con el

Boletín S-101.

Pocisión: El Photohelic®debe ser montado como un conjunto

compacto, o bien el modulo rele carga-amplificador ensamblado y su

carcasa se monta en un lugar remoto de la unidad indicadorfototransistor. Los cables de extgension con conexion de 7 pies y los

conectores están disponibles en Dwyer para interconectar las dos

unidades.

Montaje: El Photohelic®se monta normalmente antes de hacer las

conexiones eléctricas, por lo tanto la carcasa eléctrica es independiente

de la forma me montaje y puede ser quitada en cualquier momento.

Montaje en Panel: El montaje normal es embutir o atravesar el panel

como muestra la Fig. 2. Asegúrase de que deja un espacio extra de 43/8” (111 mm) detrás de la unidad; quitar la carcasa eléctrica. Hacer un

simple agujero de 4 13/16˝ (122 mm) de diametro en el panel. Inserter

todo el Photohelic®por el frontal del panel, luego deslizar el anillo de

sujección y encajar el anillo por la parte de atrás. Coloque el anillo de

sujección en su ranura, mueva hacia atrás el anillo de sujección y una

vez más encaje el anillo y apriete los cuatro (4) tornillos de abrazadera

de 2˝ (50 mm) No. 6-32 que se suministran. Si el espacio detrás del

panel es crítico, la unidad relé-amplificador se puede montar de forma

remota. Ver Instrucciones de Mantaje de Relé Remoto para más

detalles.

La unidad puede estar montada en la posición que se

desee, la escala vertical u horizontal, sin que ello afecta a la precisión,

pero debe ser recalibrado el cero si la posición cambia de horizontal a

vertical o viceversa. Los models - 0 y - 00 deben estar montados con la

escala vertical.

Atraves del Panel de Montaje

Figura 2

Page 9

Montaje del Indicador con los Relés Remotos: Donde se desee

1-1/8

[28.58]

1-1/8

[28.58]

Tiesogujeros De Ø3/16 [4.76] Diam.

Separados 120° en la

superjiciede montaje

Agujerode 3/4" [19.05] de diam.

para conexion del cableado

4-9/32

[108.74]

5

[127.00] SQ

4-9/32

[108.74]

Ø3/16

TYP 4 PLACES

montar la unidad relé-amplificador separada de la unidad

indicador/fototransistor, el indicador puede montarse de cualquiera de

las maneras mostra-das en la Fig. 2 (excepto la parte del reléamplificador) o montarse sobre superficie como se muestra en la Fig 3A.

Utilice el trazado monstrado en la Fig. 3B para localizer los agujeros. El

conjunto completo no se puede montar sobre superficie.

Boletín B-33

P. 3

Figura 3A

Montaje Sobresuperficie

Figura 3B

Esquema del Agujero (de frente)

Unidad Relé-Amplificador Remota

Figura 4A

Figura 4B

Esquema de los Agujeros

Conecte las espitas de alta y baja presión a los puntos de presión

positiva, negativa o diferencial. Utilice tubo metálico de 4” NPT (3.175

mm) del interruptor/indicador de presión Photohelic®de Dwyer®. Los

adaptores para tubos de caucho o de plástico blando son

proporcionados con el instrumento para utilizarlos cuando se prefiera

este tipo de conexión.

Montaje Remoto de los Relés: La unidad relé-amplificador puede

montarse remotamente como se muestra en la Fig. 4A. Ulice el trazado

de agujeros que se muestra en la Fig. 4B para esta opcion. Para mas

información sobre el montaje para requerimientos especiales, consulte

con la fabrica.

Conexiones Neumaticas y Ajuste del Cero: Después de la

instalación, pero antes de hacer las conexiones de presión, coloque el

puntero de indicación (la aguja) exactamente sobre la marca del cero,

usando el tornillo de ajuste del cero situado en la parte de abajo de la

cubierta frontal. Tenga en cuenta que este ajuste sólo se pueda hacer

con las espitas de alta y baja presión abiertas a la atmósfera.

Si el Photohelic®no se usa para detectar presión diferencial, una de las

espitas de presión debe abierta a la atmósfera. Esto permitirá la entrada

de la presión de referencia. En este caso, se recomienda la instalación

de un filtro de Dwyer®No. A-331 u otro similar apropiado en la espita de

la presión de referencia para reducir la posibilidad de entrada de polvo

en el instrumento.

Nota: Si el interruptor/indicador Photohelic®está sobre-presionado, el

puntero (aguja) “salta” desde el final de la escala hasta el cero y se

mantiene ahí hasta que la condición de exceso de presión se alivia. Los

usuarios deberían ser consecuentes de las posible indicaciones de falso

cero bajo esta condición.

Page 10

Boletín B-33

4-3/8 [111.13]

Tornillos De Montaje De La Cubierta

Soporte Del Conducto

Del Panel

Espacio Para

Sacar La Cubierta

Conducto Flexible

Seccion B Seccion C

Seccion A

Seccion D

Seccion E

TIPO DE CIRCUITO:

TENSION DE ALLMENTACION:

RANGO DE CONTACTO:

P. 4

CONEXIONES ELECTRICAS

1. Cubierta: La unidad relé-amplificador tiene una carcasa fácil de

quitar. Quite los tres (3) tornillos como se muestra en la Fig. 5 y deslice

hacia afuera la carcasa. Haga todas las conexiones eléctircas antes de

reinstaler y reasegurar la carcasa.

2. Conducto: El acceso eléctrico a la parte de la carcasa del relé de la

caja de conexión se hace abriendo un tapón para conductos de (19 mm).

Se recomienda el uso de conductos flexibles. Este se sujetaría al panel

u otra superficie apta para prevenir el sistema de cableado de un

esfuerso de tensión indebido en el instrumento. Ver Fig. 5.

3. Esquema del Terminal o Placa de Conexión: En la Fig. 6, “Placa

de Terminales,” la Seccion A contiene las conexiones para al relé de

carga o esclavo actuado por el punto de trabajo derecho o de alta. Este

relé es de tipo doble polo, de doble circuito. Las dos conexiones

superiores son normalmente carradas, las dos del medio son

normalmente abiertas y las dos de abajo son el común. El relé está en

su posición normal o des-energizado cuando la presión está por debajo

del punto de trabejo del lado derecho (del alta).

La Seccion D es exactamente igual que la Seccion A, excepto que su

relé de carga o esclavo está controlado por el punto de trabajo izquierdo

o de baja. La posición

des-energizada está pro debajo del punto de trabajo del lado izquierdo

(de baja).

La Seccion B contiene las conexiones externas para el mantenimiento

del circuito bobinado para relé del punto de trabajo derecho o de alta y

la Seccion C, contiene conexiones similares para el relé del punto de

trabajo izquierdo o de baja. La función y uso de estas conexiones varía

algo dependiendo del tipo de circuito del instrumento. Ver párrafos 5 y

6 para más detalles.

La Seccion E contiene las conexiones de alimentación para el

transformador primario de la unidad de control. El transformador a

cambio suministra un reducido voltaje de alimentación para el LED, el

fototransistor, la unidad amplificadora y tirar del relé descarga y

mantener el bobinado. Las unidades estánder están diseñadas para 117

VCA de entrada al transformador. También están disponibles unidades

especiales para otros voltajes.

Está provisto de una atadura para Cable Separado a Tierra mediante

un tornillo No. 6-32 en la repisa montada carca de la abertura del

conducto. Está localizado un cable adicional a tierra en el lateral del

cuerpo de indicación para usa lo cuando la unidad relé-amplificador está

montada remotamente.

Los instrumentos de un Punto de Trabajo se suministran con los

componentes del punto de trabajo de alta o derecho y la circuitería

correspondiente. Esta está conectada a las Secciones A y B de la placa

de terminales. Los componentes del punto de trabajo izquierdo o de

baja están omitidos.

4. Tipo de Circuito: El Photohelic®está disponible con varios circuitos

internos opcionales instalados en fábrica. Están identificados como tipo

por una etiqueta mostrada en la Fig. 7. Esta ertiqueta se monta de forma

prominente en la placa de terminal de cada instrumento. La letra H

indica un circuito cuyo relé puede pasar a almacenar un estado eléctrico

o retenerse energizado (activado) después de que la presión sobrepase

or un incremento su punto de trabajo.

La letra L indica un circuito en el cual el relé pueda pasar a almancer un

estado eléctrico o retenerse des-energizado después de que la presión

sobrepase por decremento su punto de trabajo. Se necesitan dos letras

para indentificar completamente una unidad de doble punto de trabajo.

Así, el ecicuito de tipo HH, el cual es el estándar, es un circuito de doble

punto de trabajo, el cual está provisto para el almacenamiento do

estados de corriente (latching) cuando ambos puntos de trabajo son

sobrepasados por un incremento de la presión. Las unidadas de un sólo

relé están identificadas por las retras SR seguidas de una H para la

unidad estánder o por una L para unidades especiales de

almacenamiento de estado de corriente (lach) en decremento. Las

unidades para usar con otros estándares distinos de 117 VCA serán así

indicados en la etiqueta.

5. Reset Automatico de Doble Punto de Trabajo: El circuito tipo HH

se usa para aplicaciones simples de interruptor on-off. Para ponerlo en

sevicio conecte los circuitos de carga a los terminales apropiados en la

Sección A (Fig. 8) para el punto de trabajo derecho y en la Sección D

para el punto de trabajo izquierdo. No son necesarias las conexiones en

las Secciones B y C. Tenga en cuente que los contactos N.A. están

abiertos cuando la aguja del indicador de presión está a la izquierdo de

los punteros de los puntos de trabajo. No es necesaria ninguna

conexión en las Secciones B y C. Haga las conexiones externas a tierra

como se requieren y conecte la alimentación a la Sección E para el

control de la unidad.

Para usar el circuito tipo LL para reset automatico, se debe instalar un

puente de hilo entre los terminales superior e inferior de las secciones b

y/o C.

Figura 5

Detalles del Montaje

Figura 6

Placa de Terminales

Figura 7 Etiqueta del Circuito

Page 11

6. Reset Manual de Doble Punto de Trabajo: El circuito tipo HH

RESET

RESET

Carga

1/6 HP

117 V

Linea De 117 V

Puentes De Reset

también se puede utilizar para aplicaciones con reset manual donda se

desee hacer un contacto mantenido sobra cualquier relé después de

que la presión haya aumentado por encima de su punto de trabajo. Las

conexiones de carga o señal se hacen a los terminales apropiados en

las Secciones A y D (como en el párrafo 5 anterior). Connectar los

terminales en las secciones B y C mediante interruptores Nomalmente

Cerrado (N.C.) o pulsadores como se muestra en la Fig. 8. Se

recomienda el uso de interruptores tip “dry-circuit” (circuito seco), tales

como el Dwyer P/N A-601 con contactos de paladio, oro, etc, o de tipo

rotativo protegidos del exterior. Haga las conexiones externas a tierra

como se requiere y conecte la alimentación a la Sección E para el

control de la unidad.

PRECAUCION: No applicar corriente eléctricas

a los terminales de las secciones B y C.

Figura 8 Reset Manual con Circuito HH

Boletín B-33

P. 5

8. Controlo del Límite Alta Baja-Doble Punto de Trabajo: El circuito

tipo HH puede usarse para controlar ventiladores, tiros, bombas, etc.,

entre los puntos de tr bajo de un Photohelic®. Para efectuar esto, use el

relé de un punto de trabajo para hacer reset del otro como se muestra

en el diagrama eléctrico de la Fig. 9. En esta típica aplicación la carga

(por ejemplo, un ventilador) se conectaría a los contactos N.C. del relé

del punto de trabajo, Sección A (Fig. 6). Al aumentar la presión en el

punto de trabajo derecho, su relé se cargaría y se manendría aunqué la

presión pudiera caer por debajo de ese punto de trabajo. Si la presión

continúa cayendo hasta el punto de trabajo izquierdo, su relé se desenergizaria automáticamente, volviendo a su posición normal y, en tal

situación, se abre el circuito del bobinado mantenido de la Sección B

(Fig. 6). El relé del punto de trabajo derecho se haría así un reset y el

icilo se repetiría.

9. Circuitos de Doble Punto de Trabajo de Propósito Especial: El

circuito tipo LL se puede usar donde se desee de forma que al hacer un

reset manual se mantenga el contacto al decrecer la presión en

cualquiera de los puntos de trabajo. Los circuitos tip LH y HL son

unidades hechas con combinaciones. Para características especiales

de combinaciones, unidades especiales e instrucciones detalladas en

cuanto a su uso, consulte con la fábrica.

10. Photohelic®de un Punto de Trabajo: El Photohelic®de un punto

de trabajo derecho solamente. Los terminales de las Secciones A y B

(Fig. 6) están conectados a este relé. El circuito tipo SRH está cableado

para rese automático, come se explica en el párrafo 5 anterior. El reset

manual está efectuado para añadir un interruptor de reset tipo N.C. o un

pulsador al circuito descrito en el párrafo 6 anterior.

El circuito LL se usa para aplicaciones de reset manual el las cuales se

requiere que el contacto se mantenga despues de que la presión haya

disminuido por debajo del punto de trabajo.

Las conexiones de carga se hacen a los terminales apropiados en las

Secciones A y D. Se conecta un interruptor de tipo N.A, para el reset

manual, tal como el Dwyer P/N A-601, a los terminales de las Secciones

B y C. El circuito puede quedar “arruinado” por un cierre momentáneo

del interruptor mientras la aguja negra está a la derecha del punto de

trabajo. Desde ese punto, el circuito almacena el estado de corriente

cuando la presión decrece por debajo del punto de trabajo y retiene este

estado de corriente cuando la presión veulve a crecer, hasta que se

hace un reset manualmente con el interruptor opcional.

7. Combanaciones de Reset Manual y Automático de Doble Punto

de Trabajo: El circuito tipo HH puede usarse con cualquiera de los

puntos de trabajo, cableado y operando como en el párrafo 5 anterior y

el otro punto de trabajo cableado y operando como en el párrafo 8.

11. Punto de Trabajo Unico Especial: Se puede obtener un reset

manual después de la actuación en caida de presión al usar un circuito

tipo SRL. Consulte con la fábrica para unidades especiales e

instrucciones detalladas en cuanto a su uso.

12. Situación en Servicio: En operación normal cada rel se desenergiza cuando la presión aplicada al instrumento está por debajo de

su punto de trabajo. Las uni-dades especiales de almacenamiento de

estado eléctrico en bajada, generalmente se les tendrá que hacer un

reset antes de situarías en la línea en operación normal.

13. Modo de Fallo: El diseño del circuito del Photohelic®está provisto

de cierta protección en caso de una pérdida de presión o de

alimentación eléctrica. En cualquier caso, ambos relés se desenergizaran, volviendo a su estado normal de “Presión Cero.” Las

excepciones a esto son modelos con rangos de cero centrado.

Debido a que los relés en todos los models estánder están siempre

energizados cuando la aguja inidcadora está a la derecha de sus

respectivos puntos de trabajo, la acción del relé en la pérdida de presión

dependerá de la posición del punto de trabajo, desde cualquiera de ellos

se podria localizar a la izquierda del cero. Como ejemplo: Si el puntero

izquierda estuviera ajustado a -2” c.a. y la presión negativa fuera de -3”

c.a., una pérdida de esa presión permitiría que la aguja indicadora

(negra) volviera al centro y así causa que el relé del punto de trabajo en

baja se energiza.

Nota: Para motores mayores, utilice el Photohelic en un contacto

mantenido, controle los 117 V ó pulse el boton del circuito del

estarter del motor.

Figura 9 Control de Limite Alta-Baja (Circuito HH)

Page 12

Boletín B-33

P. 6

MANTENIMIENTO Y SERVICIO

Los Interruptores/Indicadores Photohelic®de Dwyer®son instrumentos de precisión, expertamente ensamblados y calibrados en la fábrica.

No necesitan lubricación o revisiones periódicas. Si el interior está protegido del polvo, suciedad, gases corrosivos y fluídos, se pueden

esperar años de servicio sin ningún problema.

El ajuste del cero debería ser revisado y reajustado de vez en cuando para mantener la precision.

Cualquier reparación necessaria para cualquiera de los indicadores de presión Magnehelic®de Dwyer®o para los componentes electrónicos

debería ser realizada por un mecánico entranado de instrumentos. En muchos casos, la major elección es mandar al interruptor/indicador

completo Photohelic a la fábrica de Dwyer.

Model

3000-00

3000-0

3001

3002

3003

3004

3005

3006

3008

3010

3015

3020

3025

3030

3040

3050

3060

3080

3100

3150

Range,

Inches

of

Water

0-.25

0-.50

0-1.0

0-2.0

0-3.0

0-4.0

0-5.0

0-6.0

0-8.0

0-10

0-15

0-20

0-25

0-30

0-40

0-50

0-60

0-80

0-100

0-150

Minor

Div.

.005

.01

.02

.05

.10

.10

.10

.20

.20

.20

.50

.50

.50

1.0

1.0

1.0

2.0

2.0

2.0

5.0

Model

3300-0

3301

3302

3304

3310

3320

3330

Model

3201

3202

3203

3204

3205

3210

3215

3220

3230

36003S

36006S

36010S

36020S

36030S

36060S

36100S

36300S

36600S

Range,

Zero

Center

Inches

of Water

.25-0-.25

.5-0-.5

1-0-1

2-0-2

5-0-5

10-0-10

15-0-15

Range

PSIG

0-1

0-2

0-3

0-4

0-5

0-10

0-15

0-20

0-30

0-30

0-60

0-100

0-200

0-300

0-600

0-1000

0-3000

0-6000

El Interrutor/Indicador de Presión Photohelic

Los Modelos y Rangos

Dual Scale Air Velocity Units

(for use with pitot tube)

Minor

Model

Div.

3000-00AV

.01

3000-0AV

.02

3001-AV

.05

3002-AV

.10

3010-AV

.20

.50

1.0

Model

Minor

3000-6MM

Div.

3000-10MM

PSIG

3000-25MM

.02

3000-50MM

.05

3000-80MM

.10

3000-100MM

.10

.10

.20

.50

.50

Model

1.0

3300-20MM

1.0

2.0

2.0

5.0

10

20

20

100

200

Ranges,

Inches of

Water

0-.25

0-50

0-1.0

0-2.0

0-10

Range,

MM of

Water

0-6

0-10

0-25

0-50

0-80

0-100

Range,

Zero

Center

MM of

Water

10-0-10

Range, Air

Velocity

FPM

300-2000

500-2800

500-4000

1000-5600

2000-12500

Minor Div.

MM

.20

.50

.50

1.0

2.0

2.0

Minor

Div.

MM

.50

Model

3000-15CM

3000-20CM

3000-25CM

3000-50CM

3000-80CM

3000-100CM

3000-150CM

3000-200CM

3000-250CM

3000-300CM

Model

3300-4CM

3300-10CM

3300-30CM

Model

3000-60Pa

3000-125Pa

3000-250Pa

3000-500Pa

3000-750Pa

®

Range

CM of

Water

0-15

0-20

0-25

0-50

0-80

0-100

0-150

0-200

0-250

0-300

Range,

Zero

Center

Cm of

Water

2-0-2

5-0-5

15-0-15

Range,

Pascals

0-60

0-125

0-250

0-500

0-750

Minor

Div.

CM

.50

.50

.50

1.0

2.0

2.0

5.0

5.0

5.0

10.0

Minor

Div.

CM

.10

.20

1.0

Minor

Div.

Pascals

2.0

5.0

5.0

10.0

25.0

Model

3300-250Pa

3300-500Pa

Model

3000-1kPa

3000-1.5kPa

3000-2kPa

3000-3kPa

3000-4kPa

3000-5kPa

3000-8kPa

3000-10kPa

3000-15kPa

3000-20kPa

3000-25kPa

3000-30kPa

Model

3300-1kPa

3300-3kPa

Range,

Zero

Center

Pascals

125-0-125

250-0-250

Range

KiloPascals

0-1.0

0-1.5

0-2.0

0-3.0

0-4.0

0-5.0

0-8.0

0-10

0-15

0-20

0-25

0-30

Range,

Zero

Center

Kilopascals

.5-0-.5

1.5-0-1.5

Minor Div.

Pascals

125-0-125

250-0-250

Minor Div.

KiloPascals

.02

.05

.05

.10

.10

.10

.20

.20

.50

.50

.50

1.0

Minor

Div.

Kilopascals

.02

.10

©Copyright 2010 Dwyer Instruments, Inc. Printed in U.S.A. 7/10 FR# 13-440202-02 Rev.5

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Loading...

Loading...