Page 1

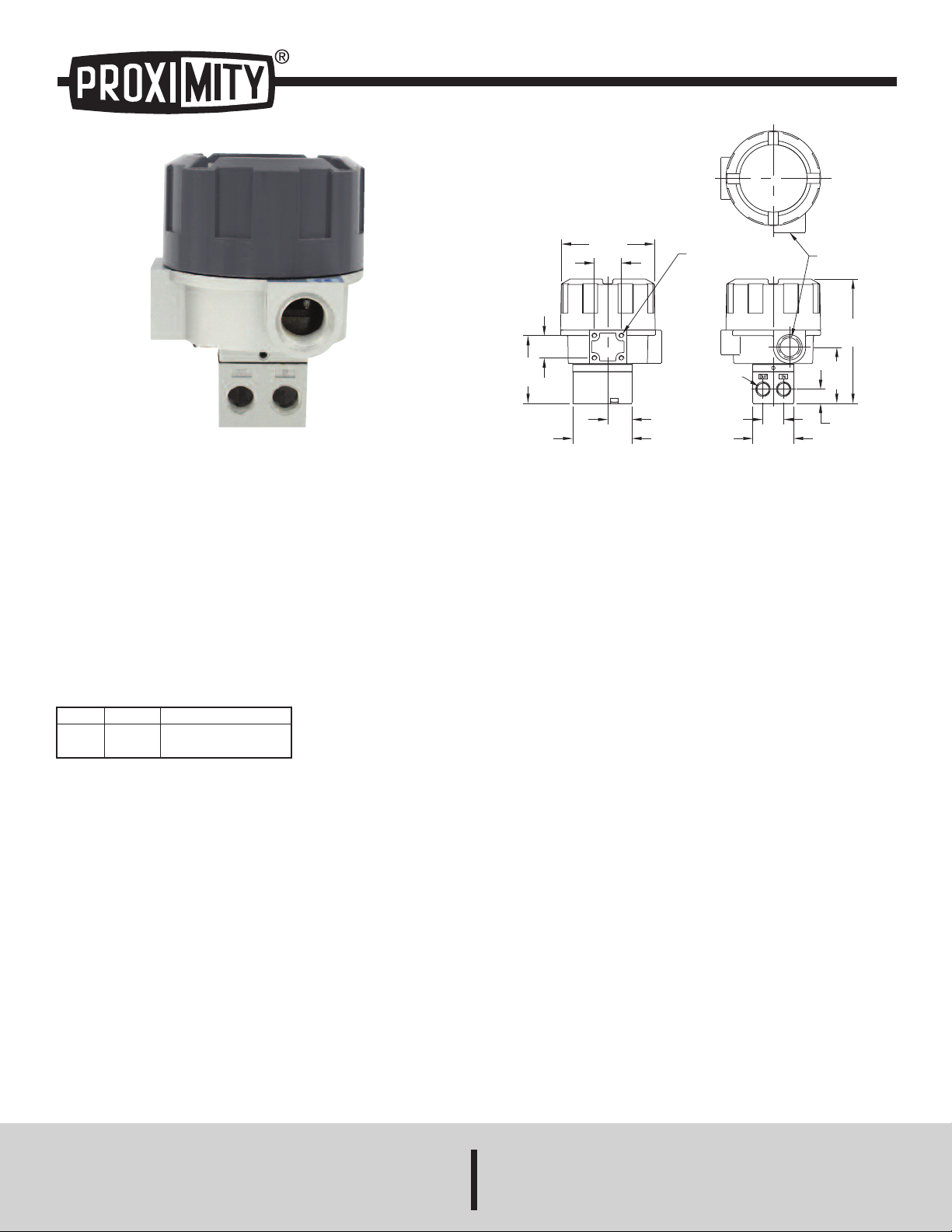

Series 2900 Current to Pressure Transducer

1/2 NPT PORT FOR

CONDUIT PIPING

4-19/32

(116.6)

2-5/64

(52.6)

33/64

(13.1)

1

-1/2

(

38.1)

4

9/64

(

19.4)

4 #10-32-UNF

TAPPED HOLES FOR

MOUNTING

Ø3-1/2

(Ø88.9)

1

(25.4)

2

7/32

(

21.3)

2

-1/2

(

63.5)

2-3/16

(55.6)

5

7/64

(

22.4)

IN & OUT

PORTS 1/4-18 NPT

4 PLACES

Specifications - Installation and Operating Instructions

Bulletin V-5

The Series 2900 Current to Pressure Transducer delivers reliable

high performance for the toughest applications in the most hazardous

environments. Its NEMA 4X housing is designed and FM and CSA

approved for both intrinsically safe and explosion-proof operation. This

unit has advanced circuitry which includes electronic feedback control

for superior vibration protection and highly accurate output. The Series

2900 is not position sensitive and the easily accessible zero and span

adjustments make field calibration quick and easy. For ease of

installation, this model has input and output ports on both the front and

back. It is also not vibration sensitive, which makes the Series 2900 ideal

for field mounting on a valve. These features coupled with the unit’s

compact size help make set-up and installation simple.

Model

2913-E

2916-E

Input

4-20 mA

4-20 mA

Output

3-15 psig (0.2-1.0 bar)

6-30 psig (0.4-2.1 bar)

SPECIFICATIONS

Service: Oil free, clean dry air filtered to 40 microns.

Input Signal: 4-20 mA.

Air Supply: Minimum: 5 psig (0.3 bar) above maximum output;

Maximum: 100 psig (6.9 bar).

Output: 3 to 15 psig (0.2 to 1.0 bar), 6 to 30 psig (0.4 to 2.1 bar).

Accuracy: ±0.1% of span.

Hysteresis: ±0.1% of span.

Repeatability: ±0.1% of span.

Deadband: 0.02% of span.

Power Requirement: Loop powered.

Temperature Limits: Operating: -40 to 160°F (-40 to 71°C); Storage: -

40 to 200°F (-40 to 93°C).

Pressure Connections: 1/4˝ female NPT.

Electrical Connection: 1/2˝ female NPT.

Air Consumption: 0.05 scfm (0.02 l/s) at midrange typical.

Output Capacity: 4.5 scfm (2.1 l/s) at 25 psig (1.7 bar) supply; 12.0

scfm (5.7 l/s) at 100 psig (6.9 bar) supply.

Enclosure: Chromate-treated aluminum with epoxy paint.

Enclosure Rating: Weatherproof NEMA 4X (IP65), Explosion-proof

and intrinsically safe.

Weight: 1.8 lb (0.82 kg).

Agency Approvals: CE, CSA, FM.

PROXIMITY CONTROLS

A DIVISION OF DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A.

Phone: 219/879-8000 www.dwyer-inst.com

Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Page 2

INSTALLATION

Requirements

The Series 2900 transducer is suitable for installation in the following

locations: Intrinsically safe operation in hazardous locations outdoors

(NEMA 4X, CSA.ENC.4 & IP65) and Explosion-proof installation in

hazardous locations outdoors (NEMA 4X, CSA.ENC.4 & IP65).

ARNING

W

ll wiring must be made to all local and national codes

A

ppropriate to the area of installation.

a

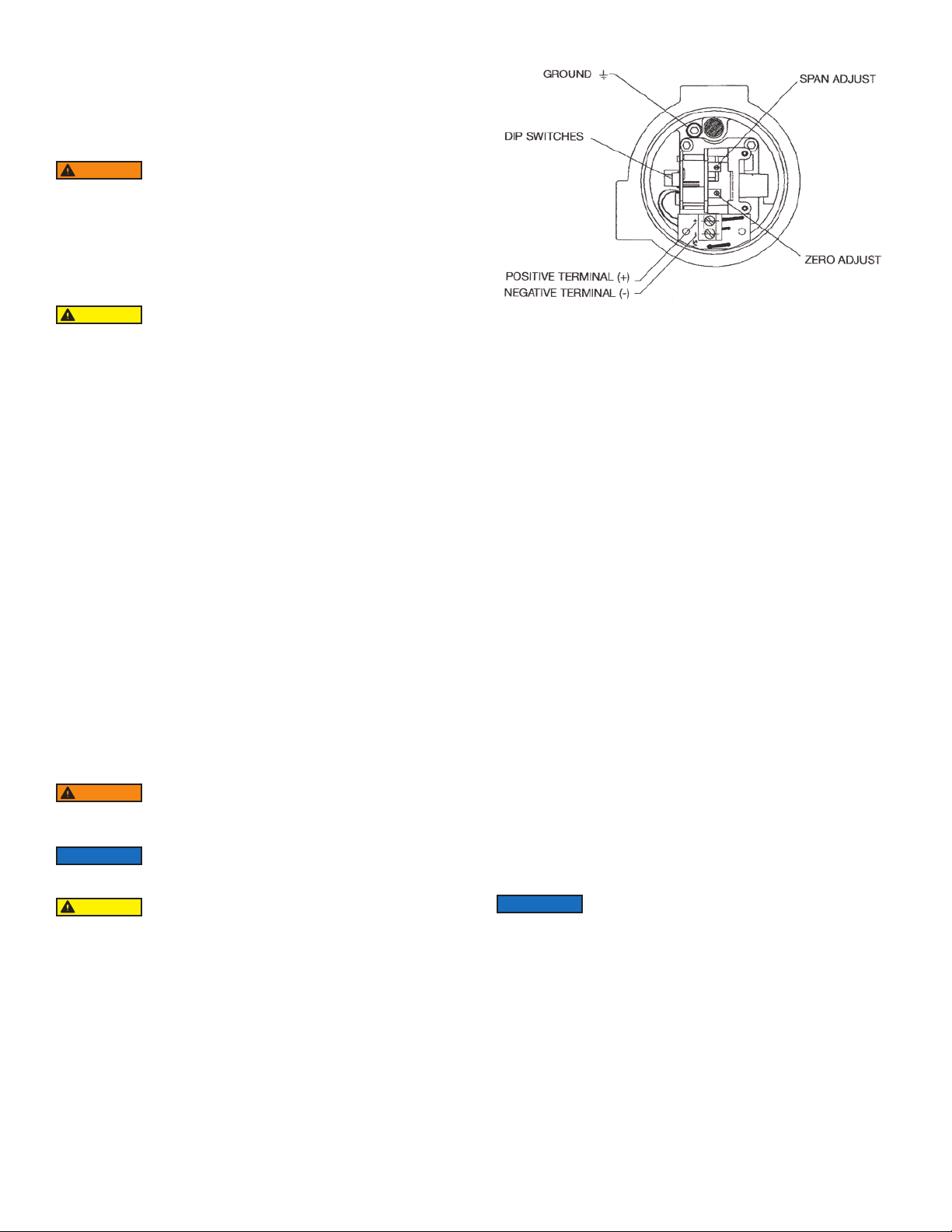

Electrical Input: 4-20 mA DC current source. It is recommended that

shielded cable be used and that the shield be grounded to unit and earth

ground. See Figure 1 for location of ground screw.

Air Supply: Clean, dry, oil free instrument air filtered to 40 microns.

CAUTION

o a safe area.

t

Use caution not to scar threads of fitting during installation as

his can void integrity of the seal. Exhaust gas must be vented

t

Mounting

The Series 2900 has been designed to mount inline, to a standard valve

yoke with the A-180 valve mounting kit.

Pneumatic Connections

Clean all pipe lines to remove dirt and scale prior to installation. Supply

air must be filtered to 40 microns and free of moisture and lubricants.

Two 1/4˝ NPT ports are provided for supply air connections. Either port

may be used. The unused port must be plugged with the pipe plug

included with the unit.

Two 1/4˝ NPT ports are provided for pneumatic output connections.

Either port may be used and one may be used for the mounting of an

output gage. If no gage is installed, the unused port must be plugged

with the pipe plug included with the unit.

Electrical Connections

The Series 2900 is supplied with a 1/2˝ NPT electrical conduit

connection. A two position terminal block that is wire ready is supplied

for 22-12 AWG wire. Wire should be stripped approximately 1/4˝ before

insertion. The terminals are labeled “+” and “–” on the terminal board

(see Figure 1).

It is recommended that shielded cable be used and that the shield be

grounded at the unit (ground screw provided) and to earth ground.

WARNING

friction and must be taken into account during installation.

NOTICE

The I/P transducer enclosure contains aluminum and is

considered to constitute a potential risk of ignition by impact or

Observe polarity. Reverse polarity will not damage the unit, but

unit will not operate.

Zero Adjustment and Span Adjustment

Figure 1

Factory Mutual Research (FM) Intrinsically Safe Ratings:

XP/I/1/BCD/T6 Ta = 70°C; DIP/II, III/1/EFG/T6 Ta = 70°C; IS/I, II,

III/1/CDEFG/T4 Ta = 70°C - 431-990-025 Entity; I/0/AEx ia IIB T4 Ta =

70°C - 431-990-025 Entity; NI/I/2/ABCD/T4 Ta = 70°C; Type 4X Entity

Parameters: Ui (Vmax) = 30 V, li (lmax) = 125 mA, Pi = 0.70 W, Ci = 0

mH

Equipment Ratings:

Explosion-proof for Class I Division 1, Groups B, C, and D. T6, Dust

Ignitionproof for Class I, Division 1, Groups E, F, and G, T6; Intrinsically

safe for Class I, II, and III, Division 1, Groups C, D, E, F, and G, T4

hazardous (classified) locations and intrinsically safe for Class I, Zone

0, Group IIB, T4 hazardous (classified) locations and suitable for Class

I, Groups A, B, C, D, T4, and Class II and III, Division 2, Groups F and

G, T6 hazardous (classified) locations.

CSA Intrinsically Safe Ratings:

Class I Division 1, Groups B, C, and D; Class I, Division 2, Groups

A, B, C and D; Class II, Division 1, Groups E, F, and G; Class II and III,

Division 2, Groups F and G. Rated 7 to 30 VDC, 4 to 20 mA; Enclosure

Type 4X; Type 4X; Temperature Code T6 (CL I Div 1). T4 (CL I, Div 2),

T6 (CL II, III, Div 2); Maximum Ambient 70°C.

Ex ia IIB (Class I, Zone 0, Group IIB)

Temperature Code T4; Maximum Ambient 70°C; Enclosure Type 4X;

Intrinsically Safe with the following entity Parameters when installed as

per drawing 531-990-0246 Ui = 30 V, li = 125 mA, Pi = 0.70 W, Ci = 0

µF, Li 0 mH.

CAUTION

Conduit should be connected to prevent condensation from

collecting in the unit.

NOTICE

Cable capacitance and inductance must be considered when

connecting to pressure transducer.

Page 3

igure 2

actory Mutual and Canadian Standards Association I.S.

F

NOTICE

. The IS Barriers or Equipment (Associated Apparatus) must be Factory Mutual

2

Research Approved and the configuration of Associated Apparatus may be

installed within the Hazardous (Classified) location for which it is approved. The

Associated Apparatus and hazardous location loop apparatus manufacturer's

control drawings must be followed when installing this equipment. An AEx (ib)

ssociated Apparatus is suitable only for connection to Class I, Zone I,

A

azardous (Classified) Locations and is not suitable for Class I, Zone 0, or Class

H

, Division I Hazardous (Classified) Locations.

I

3. Installation should be in accordance with ANSI/ISA RP12.6 “Installation of

Intrinsically Safe Systems for Hazardous (Classified) Locations” and Article 500

of the National Electrical Code (ANSI/NFPA 70).

4. All units suitable for Type 4X installations.

5. The Intrinsic Safety Entity concept allows the interconnection of two FM

Approved intrinsically safe devices with entity parameters not specifically

examined in combination as a system when:

Ui or Vmax > Uo or Voc or Vt > 7.2 Volts

Ii or Imax > Io or Isc or It

Ca or Co > Ci + Ccable

La or Lo > Li + Lcable

Pi > Po

6. No revision to this drawing is permitted without prior Factory Mutual Research

Approval.

Hazardous Location Units:

FM & CSA

Explosion Proof:

Class I, Division 1, Groups B, C & D

Models 2913-E & 2916-E

Dust Ignition Proof:

Class II & III, Division 1, Groups E, F & G

Models 2913-E & 2916-E

. Control equipment connected to the Associated Apparatus

1

ust not use or generate more than 250 Vrms or VDC.

m

F

Installation Drawing

Entity Parameters:

Ui (Vmax) = 30 V

Ii (Imax) = 125 mA

Pi = 0.70 watts

Ci = 0 uF

Li = mH

Intrinsically Safe:

Class I, II & III, Division 1

Groups C, D, E, F & G

Models 2913-E & 2916-E

Suitable For:

Class I, II & III, Division 2,

Groups A, B, C, D, F & G

Models 2913-E & 2916-E

ATEX (KEMA)

Explosion-proof/Intrinsically Safe Pending

EC Declaration of Conformity

RFI/EMI Effect: Less than .5% of span change in output pressure per En

61000-4-3:1998, Amendment 1, Performance Criterion A.

OPERATION

Calibration

All units are shipped from the factory calibrated, direct acting. If the user

requires a different mode of operation (i.e. reverse acting, split range) it

is necessary to reposition internal electrical dip switches located on the

circuit board (see Figure 1) as indicated in Figure 3.

Though the units are factory calibrated for direct acting operation, it is

suggested that the user check the calibration to ensure that settings and

operation match the application requirements.

witch

S

1 2 3 4 5678910 11 12

ON

FF

O

Figure 3

irect Acting Switch Settings

D

NOTICE

It is not necessary to remove the plastic cover of the unit for

calibration if the Direct Acting mode is desired.

Direct Acting Calibration

In direct acting operation the unit is calibrated so that minimum input

signal corresponds to minimum output pressure and increasing input

signal results in increasing output pressure.

Apply the minimum input signal of the range being used (e.g. 4 mA).

Observe the output pressure. If necessary, adjust the zero screw until

reaching minimum output pressure setting. Turn zero screw clockwise to

decrease and counter-clockwise to increase.

Apply the maximum input signal of the range being used (e.g. 20 mA).

Observe the output pressure. If necessary, adjust the span screw until

reaching maximum output pressure setting. After setting the span it will

be necessary to recheck the zero. Repeat steps until both end points are

at required values.

Reverse Acting Calibration

When calibrating to operate in the reverse acting mode the minimum

input signal produces the maximum output pressure and increasing the

input signal results in decreasing the output pressure. Setting the unit to

operate in the reverse acting mode is accomplished by positioning

internal electrical dip switches located on the circuit board (see Figure

1).

WARNING

Transducer fails in direct mode regardless of operating mode selected.

Do not touch any components on circuit board except dip

switches. Do not reverse the input leads. Damage may occur.

Page 4

Access circuit board by first removing the die cast cover of the unit. Then

remove plastic cover by taking out two screws. Position the dip switches

as illustrated in Figure 4. Set the input signal to the minimum value being

used. Turn the zero screw to set the maximum output pressure. Turn

screw clockwise to decrease and counter-clockwise to increase. Set the

span by applying the maximum input signal. Turn the span screw to set

the minimum output pressure. Turn screw counter-clockwise to decrease

and clockwise to increase. It may be necessary to repeat steps until both

end points are at desired values. Replace both covers.

OTICE

N

Switches not shown match Direct Acting Settings (see Figure

3).

witch

S

3 4 5 6 7 10

N

O

FF

O

igure 4

Reverse Acting Switch Settings

F

Split Range Calibration

ARNING

W

o not touch any components on circuit board except dip

D

witches.

s

When calibrated to operate in the split range mode a full input signal (i.e.

4-20 mA) will operate the unit at one half the normal output span (i.e. 39 psig, 9-15 psig). Setting the unit to operate in the split range mode is

accomplished by positioning internal electrical dip switches. Access

circuit board by first removing the die cast cover of the unit. Then remove

plastic cover by taking out two screws. Position switches as illustrated in

Figure 5. Replace both covers. After replacing covers, refer to the

appropriate calibration procedure (Direct Acting or Reverse Acting) to get

to desired output range (i.e. 3-9 psig, 9-15 psig).

NOTICE

Switches not shown match Direct Acting Settings (see Figure

3).

Switch

1 2

ON

OFF

Split Range Switch Settings

Figure 5

TROUBLESHOOTING

Problem

Sluggish

performance

Output won’t go

above 0

Output stays below

3 psi with increase

of input

Unit will not go full

scale with full-scale

input

NOTICE

If problems are not solved by troubleshooting procedures,

contact an applications engineer for further assistance.

Look For

Blocked orifice

No air input

Input leads reversed

Bad electrical connection

Circuit board failure

Insufficient supply pressure

Leak in connections

Circuit board failure

Solution

Clean external orifice

Check Instrument

air supply

Reverse input leads

Check input wiring

Factory Repair

Increase supply

pressure

Check connections

Factory Repair

MAINTENANCE

NOTICE

Under normal circumstances, no maintenance should be

required.

Failures due to instrument supply air contamination are not covered by

warranty. Use of oil and/or water saturated instrument air can cause

erratic operation. Poor quality instrument air can result in unit failure. It

is recommended that a filter regulator (such as Dwyer Series AFR) be

placed upstream of each unit where oil and/or water laden instrument air

is suspected. If clean, dry air is not used the orifice can become blocked.

To clean, first turn off supply air, then remove the screw located on the

side of the unit above the “out” port. Unplug the orifice using a wire that

has a smaller diameter than 0.012˝ (0.30 mm). Replace screw tightly into

unit.

WARNING

and temperatures can exceed those listed under specifications.

These products are intended for use in industrial compressedair systems only. Do not use these products where pressures

The Series 2900 Current to Pressure Transducers are not field

repairable and should be returned if repair is needed (field repair should

not be attempted and may void warranty). Be sure to include a brief

description of the problem plus any relevant application notes. Contact

customer service to receive a return goods authorization number before

shipping.

©Copyright 2013 Dwyer Instruments, Inc. Printed in U.S.A. 8/13 FR# R2-443363-00 Rev. 3

PROXIMITY CONTROLS

A DIVISION OF DWYER INSTRUMENTS, INC.

Phone: 219/879-8000 www.dwyer-inst.com

Fax: 219/872-9057 e-mail: info@dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A.

Loading...

Loading...