Page 1

Series 2800 Current to Pressure Transducer

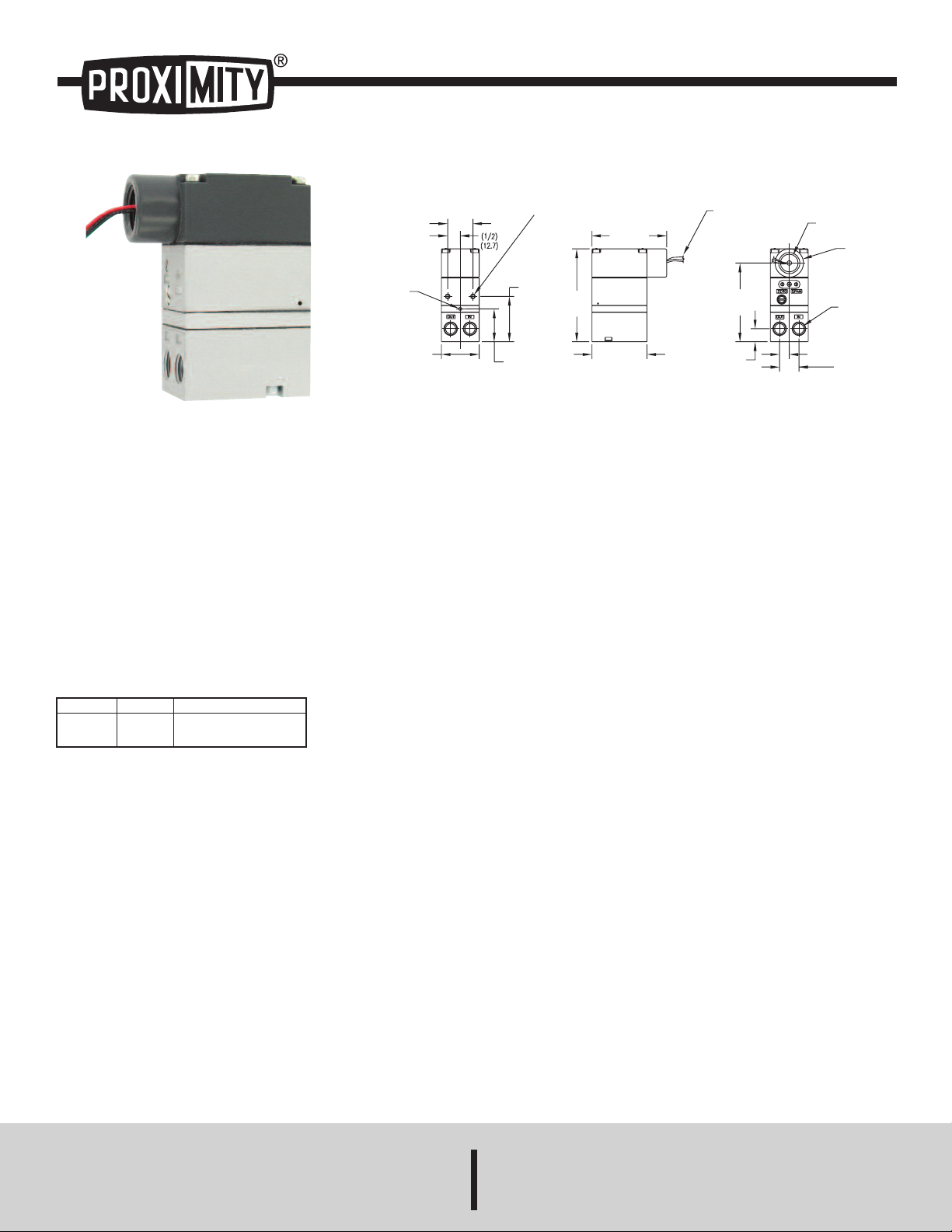

1

[25.4]

Ø1/8

[

Ø3.17]

1-1/2

[38.1]

1-19/64

[33.0]

1-51/64

[45.7]

3-11/16

[

93.7]

MOUNTING HOLES

#10-32 UNF-2B X 3/8 DP

2 PLCS

2-3/16

[

55.4]

2

-15/16

[74.7]

22 GA. WIRE LEADS

APPROX. 18˝ LONG

POS, NEG, GRD

3-1/8

[

79.2]

3

3/64

[13.1]

25/64

[9.72]

4

9/64

[19.4]

1

/2 NPT

Ø1-1/8

[Ø28.7]

IN & OUT PORTS

1/4-18 NPT

4 PLCS

Specifications - Installation and Operating Instructions

Bulletin V-4

The Series 2800 Current to Pressure Transducer converts a current

input to a linearly proportional pneumatic output pressure. This unit

utilizes a closed loop pressure feedback system that closely controls

output and compensates for vibration, mounting angle, temperature, and

supply pressure variations. These characteristics make this unit ideal for

field mounting on a valve. The control mechanism is a piezoceramic

actuator encapsulated in a protective skin, which provides a constant

defense against humidity and contaminants. These features make this

unit ideal for use in demanding applications. The 2800 also comes in a

NEMA 4X enclosure and is field reversible. It is FM and CSA approved

intrinsically safe, as well. For ease of installation, this model has input

and output ports on both the front and back and can be easily panel

mounted.

Model

2813-WP

2816-WP

Input

4-20 mA

4-20 mA

Output

3-15 psig (0.2-1.0 bar)

6-30 psig (0.4-2.1 bar)

SPECIFICATIONS

Service: Oil free, clean dry air filtered to 40 microns.

Input Signal: 4-20 mA.

Air Supply: Minimum: 5 psig (0.3 bar) above maximum output;

Maximum: 100 psig (6.9 bar).

Output: 3 to 15 psig (0.2 to 1.0 bar), 6 to 30 psig (0.4 to 2.1 bar).

Accuracy: ±0.1% of span.

Hysteresis: ±0.1% of span.

Repeatability: ±0.1% of span.

Deadband: 0.02% of span.

Power Requirement: Loop powered.

Temperature Limits: Operating: -40 to 160°F (-40 to 71°C); Storage: -

40 to 200°F (-40 to 93°C).

Pressure Connections: 1/4˝ female NPT.

Electrical Connection: 1/2˝ female NPT.

Air Consumption: 0.025 scfm (0.01 l/s) at midrange typical.

Output Capacity: 4.5 scfm (2.1 l/s) at 25 psig (1.7 bar) supply; 12.0

scfm (5.7 l/s) at 100 psig (6.9 bar) supply.

Enclosure: Chromate-treated aluminum with epoxy paint.

Enclosure Rating: NEMA 4X (IP65) and Intrinsically safe.

Weight: 0.8 lb (0.37 kg).

Agency Approvals: CSA, CE, FM.

PROXIMITY CONTROLS

A DIVISION OF DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A.

Phone: 219/879-8000 www.dwyer-inst.com

Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Page 2

INSTALLATION

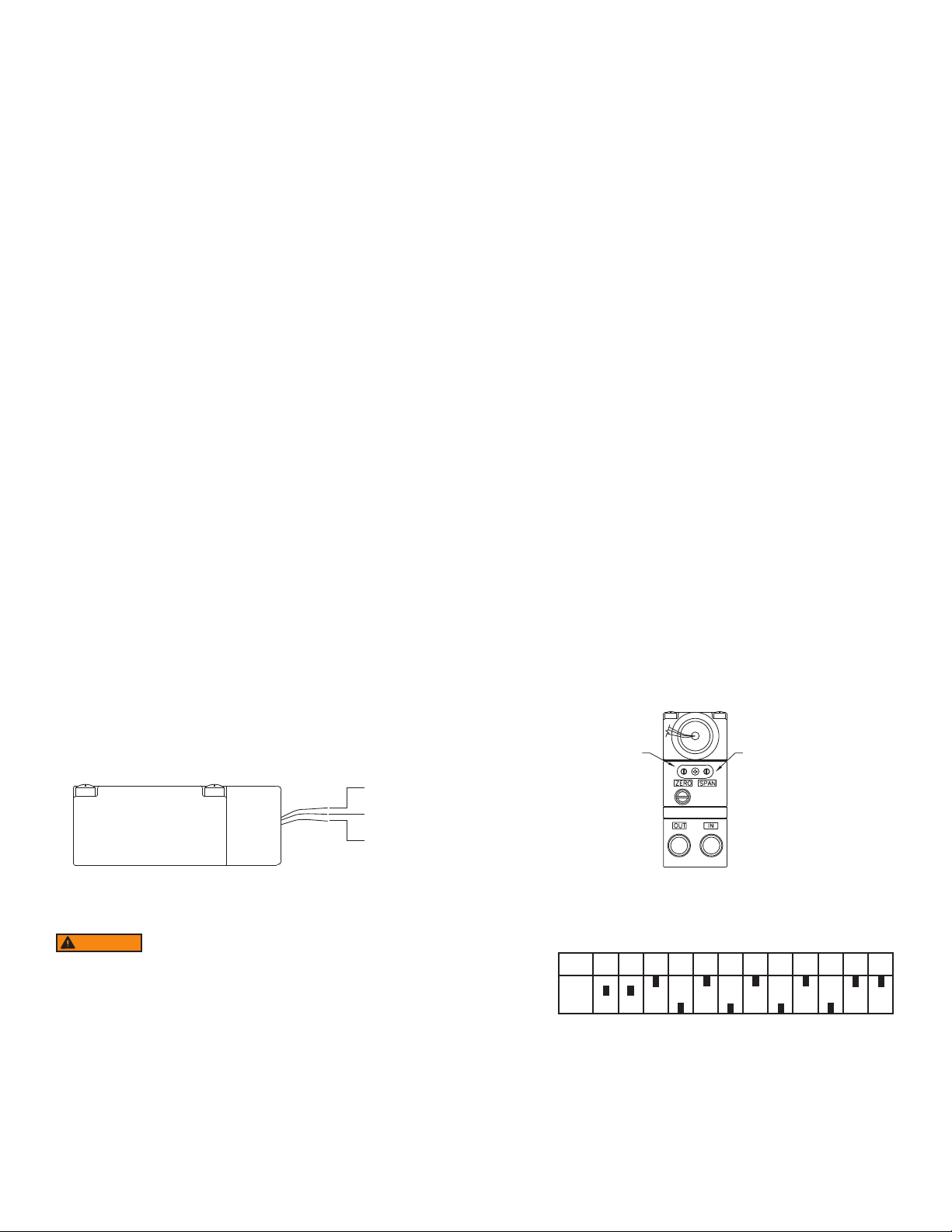

GREEN LEAD (GND)

RED LEAD (+)

BLACK LEAD (-)

ZERO

ADJUSTMENT

SPAN

ADJUSTMENT

The Series 2800 transducer is a force balance device in which the piezo

actuator is positioned in relation to a nozzle as the input signal is varied.

The application of an electrical signal causes axial movement of the

actuator. The actuator moves toward the nozzle and creates back

pressure which acts as a pilot pressure to an integral booster relay.

Mounting

Each Series 2800 comes with a mounting kit which enables, panel or

wall mounting of the unit. Optional mounting kits are available for DINrail, pipe, or valve mounting. The 2800 may be mounted at any angle.

Panel: With access to rear of panel, attach transducer to panel using two

10-32 screws and the two threaded mounting holes on the back of the

unit. With no access to the rear of a panel, attach bracket to transducer

using two 10-32 holes on the back of the unit and mount bracket to panel

using four 10-32 screws.

Inline: The Series 2800 has been designed to mount inline to a standard

valve yoke with the A-180 valve mounting kit.

The A-182 pipe mounting kit includes the bracket, U-bolt, and nuts

needed to mount the transducer to a 1-1/2˝ pipe. Just attach the bracket

to the transducer using the two 10-32 holes on the back of the unit. Then,

place the U-bolt around the pipe and through the bracket. Finally, place

the nuts on the U-bolt and tighten.

Pneumatic Connections

Clean all pipe lines to remove dirt and scale before installation. Supply

air must be filtered to 40 microns and free of moisture and lubricants.

Two 1/4˝ NPT ports are provided for supply air connections. Either port

may be used. The unused port must be plugged with the pipe plug

included with the unit.

Two 1/4˝ NPT ports are provided for pneumatic output connections.

Either port may be used and one may be used for the mounting of an

output gage. If no gage is installed, the unused port must be plugged

with the pipe plug included with the unit. Avoid getting pipe sealant inside

the piping or transducer.

Equipment Ratings:

Intrinsically safe for Class I, II, and III, Division 1, Groups C, D, E, F, and

G hazardous (classified) locations and intrinsically safe for Class I, Zone

0, Group IIB hazardous (classified) locations and suitable for Class I, II,

and III, Division 2, Groups A, B, C, D, F, and G.

CSA Intrinsically Safe Ratings:

Class I, Division 2, Groups A, B, C and D; Class II, Division 2, Groups F,

and G; Class III. Rated 7 to 30 VDC, 4 to 20 mA; Temperature Code T4;

Maximum Ambient 70°C.

Ex ia IIB (Class I, Zone 0, Group IIB); Temperature Code T4; Intrinsically

safe with the following entity Parameters when installed as per drawing

531-990-044; Ui = 30 V, li = 125 mA, Pi = 0.70 W, Ci = 0 µF, Li = 0 mH.

OPERATION

Calibration

All units are shipped from the factory calibrated, direct acting. If the user

requires a different mode of operation (i.e. reverse acting, split range) it

is necessary to reposition internal electrical switches as indicated in the

following sections. Though the units are factory calibrated for direct

acting it is suggested that the user check the calibration. It is not

necessary to remove the cover of the unit for calibration if the direct

acting mode is desired.

Direct Acting Calibration

In direct acting operation the unit is calibrated so that minimum input

signal corresponds to minimum output pressure and increasing input

signal results in increasing output pressure. Apply the minimum input

signal of the range being used (e.g. 4mA) (see figure 2). Observe the

output pressure. If necessary, adjust the zero screw until reaching

minimum output pressure setting. Turn zero screw clockwise to

decrease and counter-clockwise to increase.

Apply the maximum input signal of the range being used (e.g. 20 mA).

Observe the output pressure. If necessary, adjust the span screw until

reaching maximum output pressure setting. Turn span screw clockwise

to decrease and counter-clockwise to increase. After setting the span it

will be necessary to recheck the zero. Repeat steps 1-4 until both end

points are at required values.

Electrical Connections

Electrical connections are made to the red (+) and black (-) leads. The

green lead is furnished for case ground (see figure 1).

Figure 1

I/P Conduit Connection

WARNING

friction and must be taken into account during installation.

The I/P transducer enclosure contains aluminum and is

considered to constitute a potential risk of ignition by impact or

Factory Mutual Research Corporation (FM) Intrinsically Safe

Ratings: IS / I, II, III / 1 / CDEFG / T4 Ta = 70°C - 431-990-023; Entity;

Type 4X NI/1/2/ABCD; S/II, III/2/FG/T4 Ta = 70°C; Type 4X. Entity

Parameters: Ui (Vmax)=30V, Li (lmax) = 125 mA, Pi = 0.70 W, Ci = 0

µF, Li= 0 mH

Zero Adjustment and Span Adjustment

Signal

4-20 mA

Direct Acting - Position of switches for forward acting operation. Standard

Switch 1 2 3 4 5 6 7 8 9 10 11 12

ON

OFF

setting as supplied by factory.

Figure 2

Figure 3

Page 3

Reverse Acting Calibration

When calibrated to operate in the reverse acting mode the minimum

input signal produces the maximum output pressure and increasing the

input signal results in decreasing the output pressure. Setting the unit to

operate in the reverse acting mode is accomplished by positioning

internal electrical switches.

Disconnect input signal and supply pressure. Take off the top cover by

removing the four screws.

CAUTION

o not reverse the input leads. Avoid touching circuit board.

D

horting possible.

S

Position switches as illustrated in figure 4. Replace cover. Set the input

signal to the minimum value being used. Turn the zero screw to set the

maximum output pressure. Set the span by applying the maximum input

signal. Turn the span screw to set the minimum output pressure. It may

be necessary to repeat steps above until both end points are at desired

values.

Switch 3 4 5 6 7 10

ON

FF

O

Position of Switches for Reverse Acting Operation

Note: Switches not shown match Direct Acting Setting

Figure 4

(see Figure 3)

Split Range

When calibrated to operate in the split range mode, a full input signal (i.e.

4-20 mA) will operate the unit at one half the normal output span (i.e. 39 psig, 9-15 psig). Setting the unit to operate in the split range mode is

accomplished by positioning internal electrical switches. Disconnect

input signal and supply pressure. Take off the top cover of the unit by

removing the four screws.

MAINTENANCE

OTICE

N

nder normal circumstances, no maintenance should be

U

equired.

r

Cleaning

If clean, dry air is not used the orifice can become blocked. To clean, first

turn off supply air, then remove the screw located under the zero

adjustment. Unplug the orifice by using a wire that has a smaller

diameter than 0.012˝ (0.30mm). Use compressed air to blow out any

loose particles inside the orifice screw assembly.

Precautions

The bonnet should be removed only if a different operation mode is

desired which requires a change in circuit board switch settings. In this

case, precautions are necessary.

Never handle circuit board unless properly grounded to prevent ESD

(Electro-static Discharge).

If ESD grounding equipment is not available, hold the 2800 by its

castings and adjust switches using a non-conductive device such as a

pencil or a small rubber handled screwdriver.

Never remove circuit board for any reason. This will shift other

components and possibly damage the pressure sensor, both cases

resulting in malfunction.

Use caution when replacing bonnet. If any resistance is felt, remove

bonnet and determine the interference. Typically it will be the strain relief

grommet on the wires. The grommet should be oriented so it sits beside

the switches.

Clean and dry air should be used with the 2800. Foreign matter in the

supply line can clog the orifice openings. (.013˝ for a 3-15 psig unit,

smaller for higher range unit.) Foreign matter can also collect on the

actuator causing erratic operation. Moisture in the supply line can

damage circuit board components.

CAUTION

Avoid touching circuit board. Shorting possible.

Position switches as illustrated in figure 5. Replace cover. After setting

switches, refer to the appropriate calibration procedure (Direct Acting or

Reverse Acting) to get to desired output range (i.e. 3-9 psig, 9-15 psig).

Switch 1 2

Signal

4-20 mA

Position of Switches for Split Range Operation

Note: Switches not shown match Direct Acting Settings

ON

OFF

Figure 5

(see Figure 3)

The electrical specifications as outlined in these instructions must be

complied to. If more than one 2800 unit is driven by the same PLC, there

must be a minimum of 9.5 VDC available to each unit.

If difficulty is experienced during calibration or if turning the zero or span

screw has no effect on the unit, a resetting technique can be taken. Turn

both the zero and span screw a minimum of 30 revolutions in one

direction. Then turn both screws exactly 15 revolutions in the opposite

direction. This procedure will put the potentiometers at their midpoint of

effective adjustability. Next, calibrate to desired settings starting with the

zero screw.

Reverse Acting Mode: For reverse acting units, the zero adjustment

refers to the minimum electrical signal and maximum output pressure.

The span refers to the maximum signal and the minimum output

pressure. For calibration in reverse mode the resetting technique can be

taken if necessary and calibration should always begin with the zero

screw.

Page 4

TROUBLESHOOTING

Problem

Sluggish performance

or reduced range

Leakage

Low or improper span

Erratic Operation

Check

Blocked orifice

Supply pressure

Connections

Supply pressure connections

Moisture in air supply

Loose wires or connections

NOTICE

ARNING

W

effect of pressure present at the supply port. If devices connected to the output port

have a pressure rating less than the pressure present at the supply port, then

ressure relieving or pressure limiting devices must be employed to protect the

p

evices from over pressurization, possibly causing physical damage, personal

d

njury and/or property damage.

i

The Series 2800 Current to Pressure Transducers are not field repairable and

should be returned if repair is needed (field repair should not be attempted and may

void warranty). Be sure to include a brief description of the problem plus any

elevant application notes. Contact customer service to receive a return goods

r

uthorization number before shipping.

a

f problems are not solved by troubleshooting procedures,

I

contact an applications engineer for further assistance.

ailure Modes: This device must not be used for protecting

F

final control elements connected to the output port from the

©Copyright 2013 Dwyer Instruments, Inc. Printed in U.S.A. 8/13 FR# R2-443362-00 Rev. 3

PROXIMITY CONTROLS

A DIVISION OF DWYER INSTRUMENTS, INC.

Phone: 219/879-8000 www.dwyer-inst.com

Fax: 219/872-9057 e-mail: info@dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A.

Loading...

Loading...