Page 1

Bulletin F-92

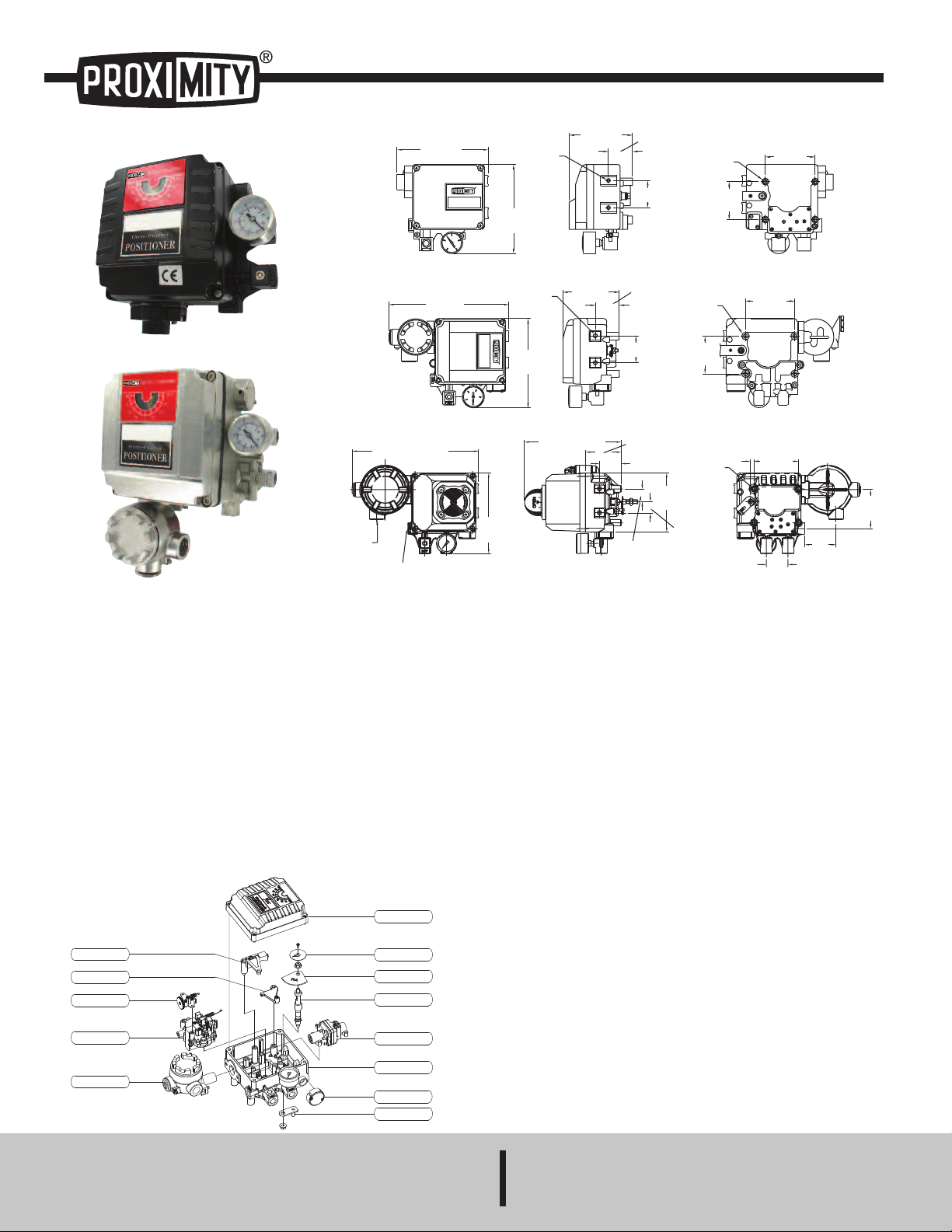

SPAN UNIT

CONNECTOR

ZERO UNIT

TORQUE MOTOR

JUNCTION BOX

FEEDBACK LEVER

VENT UNIT

BASE BODY

PILOT VALVE

FEEDBACK SHAFT

CAM

INDICATOR

COVER

INTERNAL LIMIT SWITCH VERSION

STAINLESS STEEL VERSION

STANDARD VERSION

1-49/64

[45.01]

2-35/64

[64.51]

3-5/32

[80.32]

3

-39/64

[

91.82]

5

/16

[

8.00]

4-M8x1.25P

4-51/64

[122.02]

2

-57/64 [73.51]

1

-49/64

[

45.01]

6

1/64

[24.30]

1-3/64

[26.51]

CONDUIT

ENTRY

2-PF (G) 1/2

2-NPT 1/2

OUT 2

PT (NPT) 1/4

1

0-5/16 [261.85]

6-37/64

[167.04]

7-7/8 [200.03]

6

-9/16

[

166.69]

8

-3/4

[225.30]

2

X M8X1.25

1

-31/32

[

50.01]

4-9/16

[115.89]

1-25/32

[45.24]

3-19/32

[91.29]

4

X M8X1.25

2-3/4

[69.85]

6-43/64

[169.47]

6

-9/16

[

166.69]

2X M8X1.25

1-25/32

[

45.24]

4

-41/64

[

117.87]

1

-31/32

[

50.01]

4

X M8X1.25

3-5/8

[92.08]

2

-49/64

[

70.25]

Electro-Pneumatic

POSITIONER

Electro-Pneumatic

POSITIONER

Series 265ER PRECISOR®II Electro-Pneumatic Rotary Positioner

Specifications - Installation and Operating Instructions

The Series 265ER PRECISOR®II Electro-Pneumatic Positioner is used for

rotary operation of pneumatic rotary valve actuators by means of electrical

controller or control systems with an analog output signal of 4 to 20 mA or split

ranges.

FEATURES

• There is no resonance in the range of 5 to 200 Hz.

• Perform 1/2 Split Control without any other substitutes.

• Easy to adjust zero and span.

• Easy to convert from Reverse Action to Direct Action or vice versa.

• Easy Feedback Connection.

• Fast and accurate response.

• Low air consumption.

• Easy to protect from hunting effect by using output orifice in small size of

actuator.

• Designed as block build structure for maintenance and repair.

STRUCTURE

PROXIMITY DIV., DWYER INSTRUMENTS, INC.

P.O. BOX 358 • MICHIGAN CITY, INDIANA 46360 U.S. A.

SPECIFICATIONS

Input Signal: 4 to 20 mA DC.

Input Impedance: 250 ±15 Ω.

Material: Aluminum diecasting.

Air Supply: 20 to 101 psig (1.4 to 7.0 bar).

Air Supply Connection: 1/4˝ NPT.

Gage Connection: 1/8˝ NPT.

Electrical Connection: Screw terminal.

Conduit Connection: 1/2˝ NPT female.

Linearity: ±2% of FS.

Hysteresis: 1% of FS.

Sensitivity: ±0.5% of FS.

Repeatability: ±0.5% of FS.

Air Consumption: 0.10 scfm (3 LPM) at 20 psig (1.4 bar) supply.

Flow Capacity: 28 scfm (80 LPM) at 20 psig (1.4 bar) supply.

Stroke: 0 to 90°.

Enclosure Rating: IP66.

Operating/Ambient Temperature Limits:

265ER-XX and 265-XXLS: -4 to 158°F (-20 to 70°C);

265ER-XXSS: -40 to 158°F (-40 to 70°C);

265ER-XXFM: 4 to 140°F (-20 to 60°C).

Weight: 6.2 lb (2.8 kg).

Phone: 219/879-8000 www.dwyer-inst.com

Fax: 219/872-9057 e-mail: info@dwyermail.com

Page 2

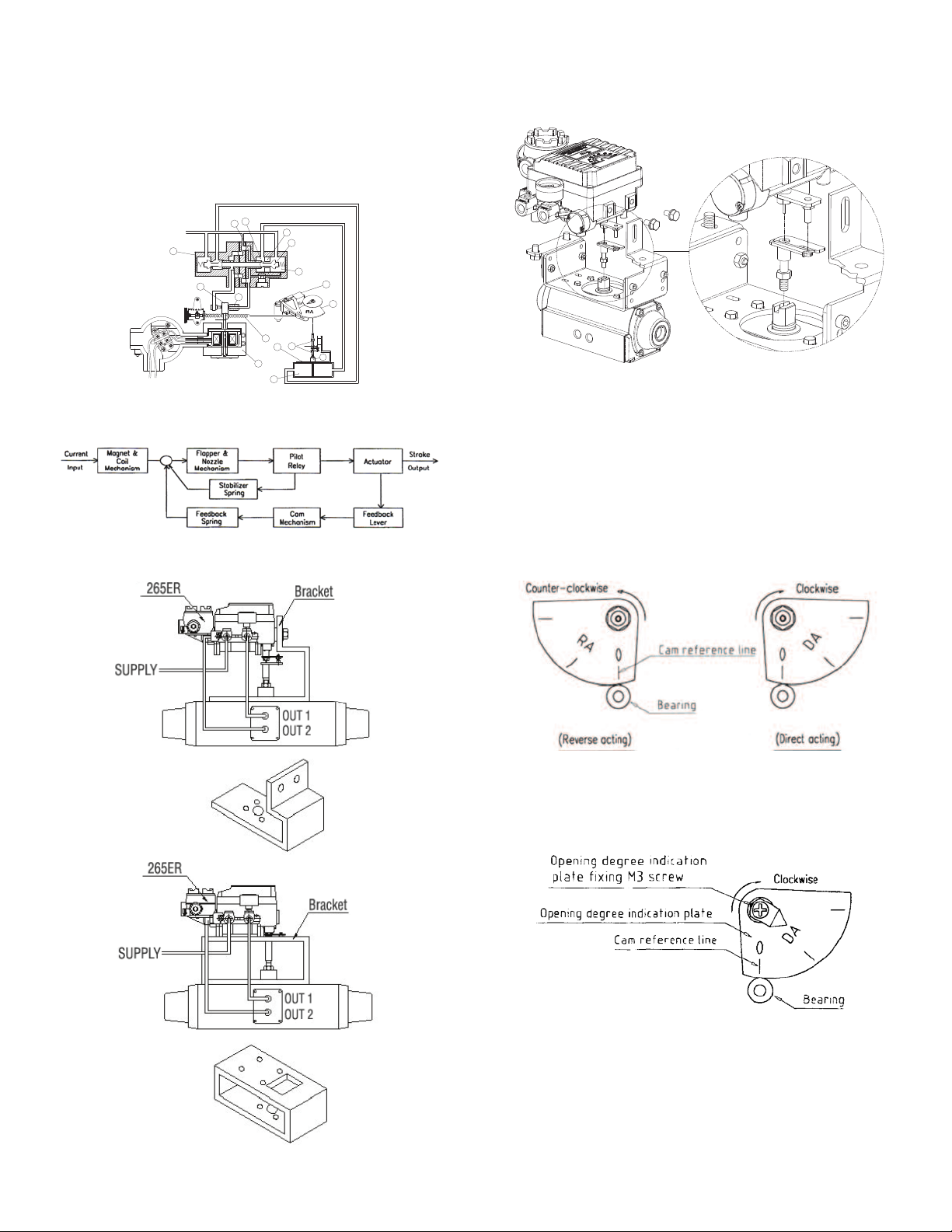

RINCIPLE OF OPERATION

S

P

A

R

E

INPUT SIGNAL

4~20 mA

OUT2

O

UT1

SUPPLY

OUT2 OUT1

OUT2

OUT1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

15

E

P

ncrease the input current signal to change in lift position of valve. Force exerted

I

y (1) Torque Motor reduces Nozzle Back Pressure with increase in gap between

b

2) Flapper and (3) Nozzle. Then (5) Spool moves upward and the (7) Seat opens

(

simultaneously. Air pressure of OUT1 pipe is discharged to (10) Actuator. As

pressure in the actuator chamber goes up, (12) Actuator Stem starts to rotate.

The movement of (12) Actuator Stem exerted force to the (a) Feedback Spring

hrough Feedback Shaft connections. Then (10) Actuator will stop at the point of

t

orce balance exerted by the input current signal and the feedback spring.

f

BLOCK DIAGRAM OF 265ER

INSTALLATION

Example of attaching to actuator

onnection with Feedback Shaft

C

ttach to the position at which the positioner feedback shaft and the rotary

A

ctuator main shaft are almost concentric (range in which the spring pin of

a

eedback shaft edge enters the hole of fork lever assembly shaft edge).

f

NSTALLATION cont.

I

Cam Attaching Procedure

Use the DA face of cam to turn the actuator main shaft clockwise (viewed from

the positioner front cover side) at the time of input feedback shaft. Use the RA

face to turn it counter-clockwise (reverse action). Correctly attach the cam to the

lange part of feedback shaft. Attach the cam in the procedure of loosening the

f

exagonal nut with flange first, setting the using actuator to the starting position

h

nd then setting the cam reference line and the bearing contact point of span

a

adjusting arm unit to the matching position. Do not apply the supply pressure

when attaching the cam as other wise it is very dangerous. When the positioner

is shipped out of our plant, the cam is tentatively tightened to the shaft. Be sure

to firmly lock the cam to the lock nut [tightening torque 17.7 to 22.1 in-lbs (2.0 to

2.5 Nm)].

Attaching Procedure of Opening Degree Indication Plate

Lock the cam and then adjust the zero point and span. Then fix the opening

degree indication plate to the shaft using the M3 screw provided. At the time, set

the opening degree indication plate to the state of attaching reference line.

Page 3

AIR PIPING CONNECTION

SPARE

Grounding

External Grounding Terminal

M4*0.7P Round Head Screw

Internal Grounding Terminal

M4*0.7P Round Head Screw

00

DADA

RARA

00

00

DADA

RARA

00

RARA

00

00

DADA

00

DADA

RARA

00

S

UP.

OUT 1

OUT 2

OUT2

SUP.

OUT2

SUP.

OUT2

SUP.

OUT2

SUP.

Direct Action

Reverse Action

I

NPUT SIGNAL

4

~20 mA

SUP.

OUT1

I

NPUT SIGNAL

4

~20 mA

S

UP.

O

UT 1

O

UT 2

INPUT SIGNAL

4~20 mA

SUP.

O

UT 2

INPUT SIGNAL

4~20 mA

Fully purge the pipe to remove foreign matter. Use a clean supply air fully

removed of humidity and dust. Use a Series AFR filter regulator to keep supply air

ressure constant. When using the double acting type as the single acting type,

p

lind either OUT1 or OUT2 and also remove the pressure gauge to close its

b

onnection.

c

ELECTRICAL WIRING

Connect the (+) and (-) output terminals from the regulator with the (+) and (-)

input terminals, respectively, of the positioner.

- Use Cable Gland in pressure tight packing type. (Cable O.D.= 0.375˝).

- Use 1/2˝ NPT standard for conduit thread connection type. There is a

spare bolt in the terminal board.

Zero Adjustment

Set input signal to the Stroke starting signal (4

mA) then turn the Zero Adjuster clockwise or

ounterclockwise. In case of Spring Actuator,

c

heck if it is set to standard pressure in Zero

c

oint. If not, repeat Zero adjustment.

P

pan Adjustment

S

djust Range Adjustment so that an Actuator

A

tops at 0% position of the Stroke by the 0%

s

applied input signal and 100% position for

100% input signal respectively. Check Zero

Point and repeat Zero Span Adjustment. 1/2

plit Range can be used by Zero and Span

S

djustment. After setting, tighten up Lock

A

crew of Span adjustment.

S

uto/Manual Switch

A

his is a Switch for changing Auto and Manual. Shipped products are set for Auto.

T

o use Manual operation, turn A/M Switch counterclockwise. In manual operation,

T

the pressure of an AFR regulator connects to Actuator. After using, return switch

to "A". Not available for Single Acting - OUT2 and Double Acting.

Seat Adjuster

o need to adjust in the field because Seat

N

djuster is to be adjusted before shipment for

A

alanced pressure point of output pressure.

b

Seat Adjuster is always used for Doubleacting. If the balanced pressure point of

output pressure needs to be changed, use

Seat Adjuster. If the sensitivity is poor

because of the actuator type of load

condition, turn the seat adjuster screw

clockwise. If hunting occurs, turn the seat

adjuster screw counterclockwise. (The

amount of turning varies by actuators. Do not

loosen the stopper screw at this time since it

is set to avoid the screw coming.)

ADJUSTMENT

Check the following prior to starting the adjustment:

• The pipeline is correctly connected with the pressure supply port and OUT1 and

OUT2 port.

• The wires are correctly connected with the (+), (-) and grounding terminals.

• The actuator and positioner are sturdily connected.

• For locking of the auto/manual changeover screw of pilot valve (fully tightened

in the clockwise direction).

• The span adjusting lever of internal feedback lever is attached to the correct

(Direct or Reverse) position.

• For correct use of the cam face (Direct or Reverse) and that flange nut is firmly

locked.

High Pressure Balance

(13.1 - 14.5 psi Ps)

Med. Pressure Balance

(7.3 psi Ps)

Low Pressure Balance

(5.8 - 7.3 psi Ps)

Ps = Sup. Pressure

.

Page 4

AINTENANCE

M

f the supply air is fouled, the positioner may not operate normally. Periodically

I

heck the compressed air cleaning system and make sure that clean air is always

c

upplied. When disassembling the pilot valve, coat grease to the O-ring of the

s

sliding section. When the fixed orifice is clogged with carbon particles or others,

remove the pilot valve Auto/Manual changeover screw (built-in fixed aperture)

and clean it by inserting a 32 AWG wire into the aperture. If it must be replaced

ith new one, stop the supply pressure and remove the stopper screw of the pilot

w

alve. Check the positioner once a year. Treatment at an early stage is especially

v

mportant if the positioner is used in severe environments, like coastal area. In

i

he unlikely event the 265ER Series Positioner should fail, the unit can be

t

returned to the factory for warranty repair if the warranty period has not expired.

Contact our customer service department for a RGA number and to setup the

return.

AUTION AND HANDLING

C

o not apply large vibration or impact to the positioner. The positioner must be

D

handled very carefully during transportation and operation. If the positioner is

used at temperatures outside of the specification, the sealing materials

deteriorate quickly and also the positioner may not operate normally. Do not

remove the terminal cover at a dangerous position during power conduction. Be

ure that the terminal cover and body cover are installed during the operation. If

s

ou leave the positioner at the operation site for a long time without using it, put

y

he cover on it so that rain water does not enter the positioner. If the atmosphere

t

is of high temperature or high humidity, take measures to avoid condensation

inside. The condensation control measures must be taken thoroughly for export

shipment

TROUBLESHOOTING

Condition

Not operating with Input

Signal applied

OUT1 pressure raised,

does not come down

Output pressure is

operated by A/M switch

only

Hunting occurs

Actuator is operated by

On/Off only

Linearity is not good

Hysteresis is not good

Cause

Too low or no supply air

Loose connection

Wrong wiring for (+) and (-)

Short or open circuit of terminal

motor

Clogged nozzle

Loose or wrong setting

of feedback lever

Leakage of A/M switch

Wrong contact or search of

Flapper

Clogged fixed orifice

Clogged nozzle

Off-positioned stabilizer spring

Too low of actuator volume

Clogged fixed orifice

Wrong connection of

OUT1 and OUT2 tube

Wrong setting of feed-back

lever

Wrong Zero, Span Adjustment

Supply pressure is unstable

Wrong setting of Seat Adjuster

Loose connection of actuator

and positioner

Cam Shaft is worn out

What To Do

Input or increase supply air

Tighten set screw of terminal

Connect wiring (+) and (-)

Replace Motor Unit

Replace Motor Unit

Correct setting and tighten

Tighten or replace A/M switch

Replace Motor Unit

Clean or replace fixed orifice

Clean nozzle or replace Motor

Unit

Insert stabilizer spring

Insert orifice

Clean or replace fixed orifice

Correct position of tube

Readjust setting of feedback lever

Readjustment of Zero, Span

Adjustment

Replace regulator

Readjust Seat Adjuster

Tighten connection

Replace Cam Shaft

©Copyright 2014 Dwyer Instruments, Inc. Printed in U.S.A. 4/14 FR# RP-443333-20 Rev. 7

PROXIMITY DIV., DWYER INSTRUMENTS, INC.

P.O. BOX 358 • MICHIGAN CITY, INDIANA 46360 U.S. A.

Phone: 219/879-8000 www.dwyer-inst.com

Fax: 219/872-9057 e-mail: info@dwyermail.com

Loading...

Loading...