Page 1

Bulletin 949-1194

a Division of Dwyer Instruments, Incorporated

PO Box 338 Michigan City, IN 46361-0338

(800) 828-4588 (219) 879-8000 FAX (219) 872-9057

www.love-controls.com

❍

❍

❍

LOVE CONTROLS

®

LOVE

INSTRUCTIONS FOR THE 2600 SERIES

MICROPROCESSOR BASED

TEMPERATURE /PROCESS CONTROL

May, 2013 Page 1 of 52 949-1194 Rev. 7

Page 2

CONTENTS

GETTING STARTED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

MODEL IDENTIFICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

WIRING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Input Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Output Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Wiring for 4 to 20mA Transmitter inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Wiring for Optional Inputs and Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Wiring for Option 924 Remote Set Point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Wiring for Option 926 Remote Set Point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Wiring for Option 928 Remote Set Point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Wiring for Option 934 Analog Retransmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Wiring for Option 936 Analog Retransmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Wiring for Option 948 4-Stage Set Point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Wiring for Option 992, 993, 995, 996 Serial Communications . . . . . . . . . . . . . . . . .11

FRONT PANEL KEY FUNCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

PASSWORD TABLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

SECURITY LEVEL SELECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

NOTATION CONVENTIONS FOR THE MENUS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

DISPLAY CONVENTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

THE HOME DISPLAY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Programming and Operation for Ramp / Soak Feature . . . . . . . . . . . . . . . . . . . . . . . . . .15

AUTO / MANUAL OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Self Tune Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Operation AND PROGRAMMING OF OPTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Options 924, 926, 928, Analog Remote Set Point . . . . . . . . . . . . . . . . . . . . . . . . . .19

Option 934, 936, Isolated Analog Retransmission. . . . . . . . . . . . . . . . . . . . . . . . . .20

Option 948, 4-Stage Set Point. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Option 992, 993, 995, 996 Serial Communication. . . . . . . . . . . . . . . . . . . . . . . . . .21

Serial Communications Options and Nonvolatile Memory . . . . . . . . . . . . . . . . . . . .22

MENU SELECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

PRIMARY MENU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

SECONDARY MENU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

SECURE MENU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

ERROR MESSAGES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41-43

CONFIGURATION MENU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

INPUT RANGES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

DIMENSIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

© 2001, Love Controls. All rights reserved. No portion may be copied without the express

written consent of Love Controls.

May, 2013 Page 2 of 52 949-1194 Rev. 7

Page 3

GETTING STARTED

1. Install the control as described on page 5.

2. Wire your control following the instructions on pages 5-11. If you are using a two-

wire transmitter as an input, see the drawing and instructions on page 7. Option

wiring instructions are on pages 8-11. Option descriptions and specific instructions

start on page 19.

3. Most controls do not need many (if any) program changes to work on your process.

For best results when changing the programming, make all the necessary changes

in the Secure Menu (page 31) before making changes to the Secondary Menu (page

24). If error messages occur, check the Error Messages on page 41-43 for help.

Take the example of a Model 26010 that comes from the factory programmed for type J

thermocouples. Suppose for this example you wish to change the input to a 100 ohm

Platinum RTD and limit the set point range between 0° and 300°C.

First, enter the Secure menu by pressing and holding the UP ARROW & ENTER

keys for 5 Seconds. Press the INDEX key until the display shows I n P and press the

DOWN ARROW until the display shows P385. Don’t forget to press the ENTER

key to retain your setting.

Next, press the INDEX key to display U n i t . Press the DOWN ARROW until the

display shows C. Press ENTER.

Next, press the INDEX key until S P L is displayed (pass the dPt, I n P t , and S E n C

selections). Press the UP ARROW until the display shows 0. Press ENTER.

Finally, press INDEX key to display S P H . Press the DOWN ARROW until the

display shows 3 0 0 . Press ENTER.

The necessary program changes are now complete. After 30 seconds the display will

switch back to the temperature reading. If you want to return faster, press the

UP ARROW & ENTER keys (at the same time) and then press the DOWN

ARROW & INDEX keys (again at the same time). This will ‘back out’ of the menu and

immediately display the temperature reading.

If you want to use Self Tune

®

, Auto/Manual, or the Ramp/Soak Programmer features, see

the special sections on these items. Page numbers for these are in the Contents section

on the previous page.

May, 2013 Page 3 of 52 949-1194 Rev. 7

Page 4

MODEL IDENTIFICATION

26

Options (blank if none)

Alarm

0 = No

1 = Yes

Output A

1 = SSR*

3 = Relay*

5 = Current

Output B

0 = None

1 = SSR*

3 = Relay*

5 = Current

* Note: Switched15 VDC output standard on Output 1 or Output 3.

Option Description

924 Analog Remote Set Point, 0 to 10 VDC, scalable.

926 Analog Remote Set Point, 0 to 20 mADC, scalable (may be programmed for 1 to

5mA, 4 to 20 mA, etc.).

928 Analog Remote Set Point, 0 to 10,000 ohms, scalable.

934 Analog Retransmission of Process Variable or Set Variable, 0 to 20 mAdc, scalable

(may be programmed for 1 to 5mA, 4 to 20 mA, etc.).

936 Analog Retransmission of Process Variable or Set Variable, 0 to 10 VDC, scalable.

948 4-Stage Set Point. One of four pre-set set point values can be implemented via

contact closure.

992 RS-485 Serial Communications, Lovelink™ protocol.

993 RS-232 Serial Communications, Lovelink™ protocol.

995 RS-232 Serial Communications, Modbus

996 RS-485 Serial Communications, Modbus

®

protocol.

®

protocol.

Lovelink™, Lovelink™II, and Mother Node™ are Trademarks of Love Controls.

MODBUS

®

is a trademark of Schneider Automation.

May, 2013 Page 4 of 52 949-1194 Rev. 7

Page 5

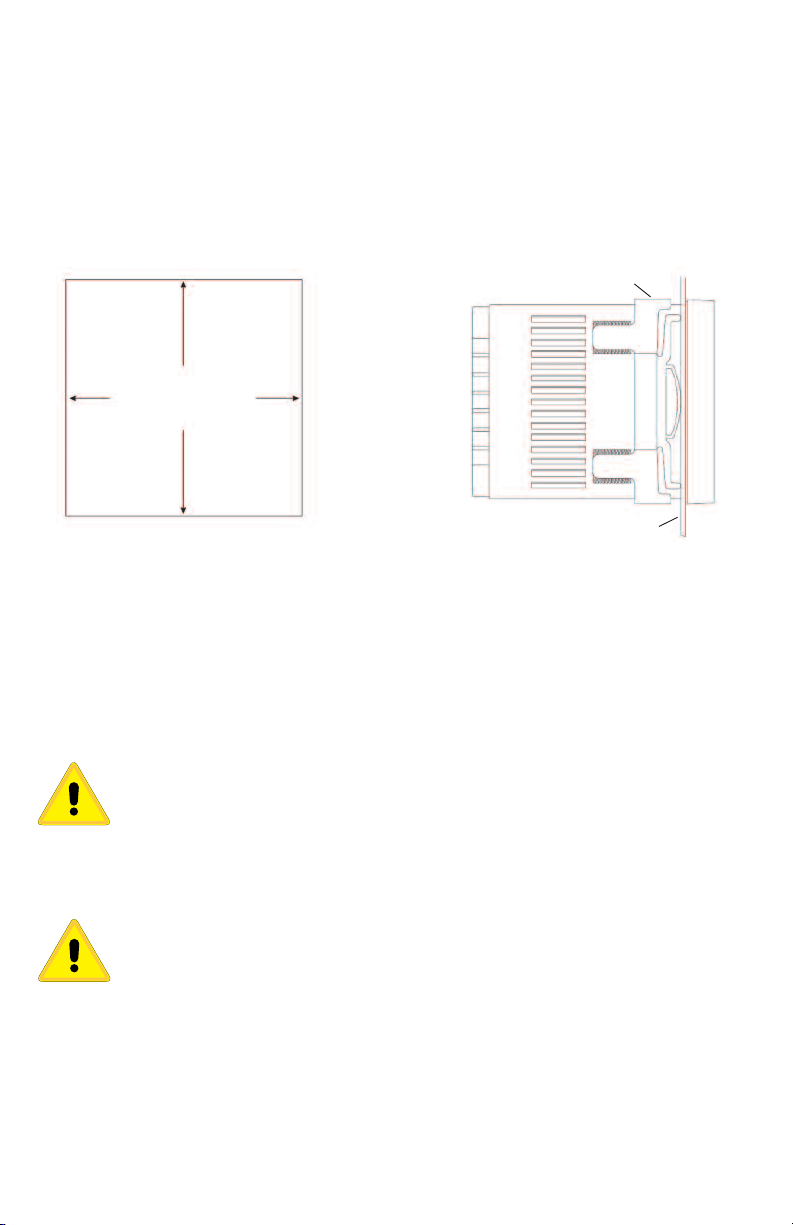

INSTALLATION

92.0 mm

(3.620 in)

MOUNTING COLLAR

+0.8

-0.0

+0.032

-0.000

PANEL

Mount the instrument in a location that will not be subject to excessive temperature, shock,

or vibration. All models are designed for mounting in an enclosed panel.

Select the position desired for the instrument on the panel. If more than one instrument is

required, maintain the minimum of spacing requirements as shown on the drawing below.

Closer spacing will structurally weaken the panel, and invalidate the IP66, UL type 4X rating

of the panel.

Prepare the panel by cutting and deburring the required opening.

PANEL CUTOUT

From the front of the panel, slide the housing through the cut out. The housing gasket should

be against the housing flange before installing.

From the rear of the panel slide the mounting collar over the housing. Hold the housing with

one hand and using the other hand, push the collar evenly against the panel until the spring

loops are slightly compressed. The ratchets will hold the mounting collar and housing in

place.

CAUTION: It is not necessary to remove the instrument chassis from the

housing for installation. If the instrument chassis is removed from the

housing, you must follow industry standard practice for control and

protection against Electro-Static Discharge (ESD). Failure to exercise good

ESD practices may cause damage to the instrument.

WIRING

Do not run RTD, thermocouple, or other class 2 wiring in the same conduit as

power leads. Use only the type of thermocouple or RTD probe for which the

control has been programmed. Maintain separation between wiring of sensor,

optional inputs and outputs and other wiring. See the “Secure Menu” for input

selection.

For thermocouple input always use extension leads of the same type designated

for your thermocouple.

May, 2013 Page 5 of 52 949-1194 Rev. 7

Page 6

For supply connections use No. 16 AWG or larger wires rated for at least 75°C. Use copper

conductors only. All line voltage output circuits must have a common disconnect and be

connected to the same pole of the disconnect.

Input wiring for thermocouple, current, and RTD; and output wiring for current and 15 VDC is

rated CLASS 2.

Control wiring is as shown (view is from rear of instrument showing wiring terminals).

Note: Illustrations shown inside the wiring terminals represent internal circuitry.

See next page for output wiring chart.

INPUT WIRING

Wire inputs as shown in the chart below.

Terminals 1 3 4 5

Thermocouple + RTD - 3 wire A B B

RTD - 2 wire A B & J J (Jumper 3 to 4)

Voltage + Current - +

Key: ‘+’ = positive; ‘-’ = negative; ‘A’ = ‘odd’ colored lead; ‘B’ = ‘common’ leads; ‘J’ = Jumper.

May, 2013 Page 6 of 52 949-1194 Rev. 7

Page 7

OUTPUT WIRING

Wire outputs as shown in the chart below.

Terminals

SP1 SSR

SP1 15 VDC

SP1 Relay

SP1 Current

SP2 SSR

SP2 15 VDC

SP2 Relay

SP2 Current

10

+

+

13

NC

14

C

C

+

15

NO

NO

-

16NC17

C

C

+

NO

-

NO

-

27-28

18

Key: ‘+’ = positive; ‘-’ = negative; ‘NC’ = Normally Closed; ‘NO’ = Normally Open; ‘C’

= Common.

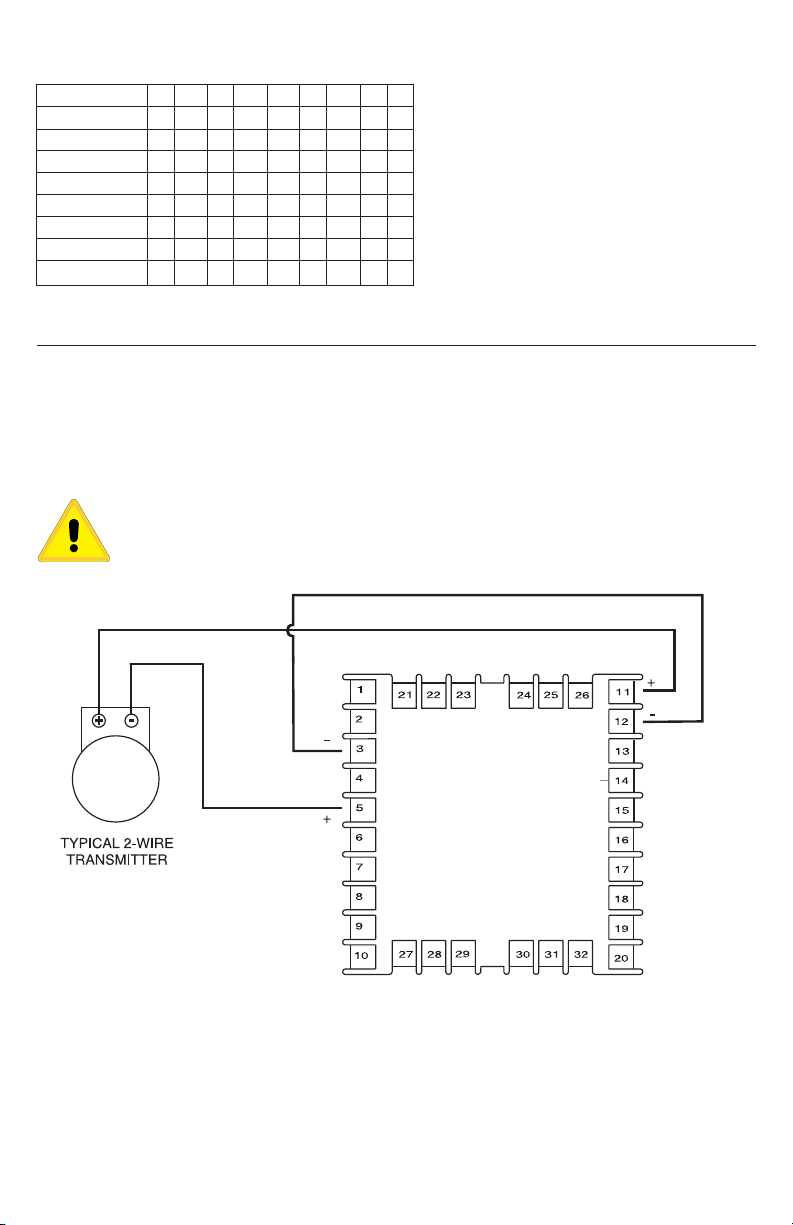

WIRING FOR 4 TO 20MA TRANSMITTER INPUTS

Wire power and outputs as shown above. Two-wire transmitters wire as shown below.

View is of instrument as seen from the rear to show wiring terminals.

For three- or four-wire transmitters follow the wiring instructions provided with your

transmitter.

CAUTION: DO NOT WIRE THE 24 VOLT POWER SUPPLY ACROSS THE

INPUT OF THE CONTROL. DAMAGE TO THE CONTROL INPUT CIRCUITRY

WILL RESULT.

May, 2013 Page 7 of 52 949-1194 Rev. 7

Page 8

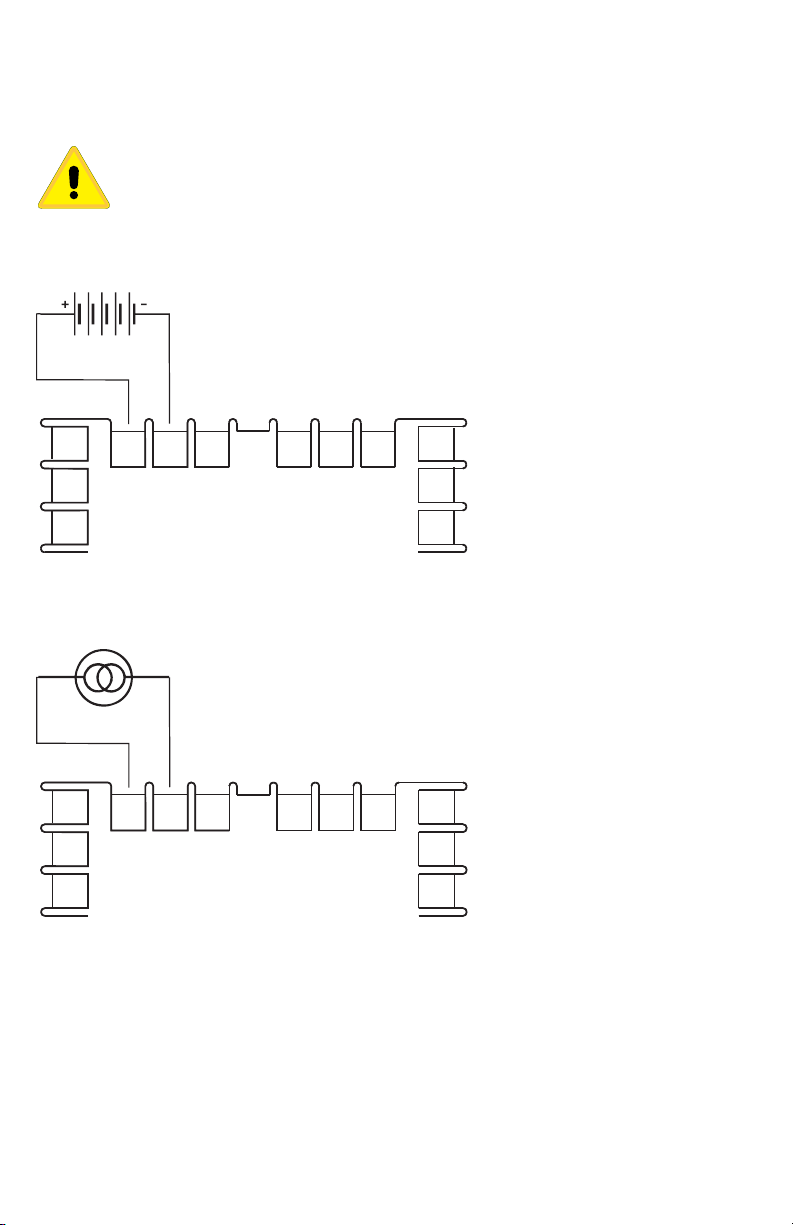

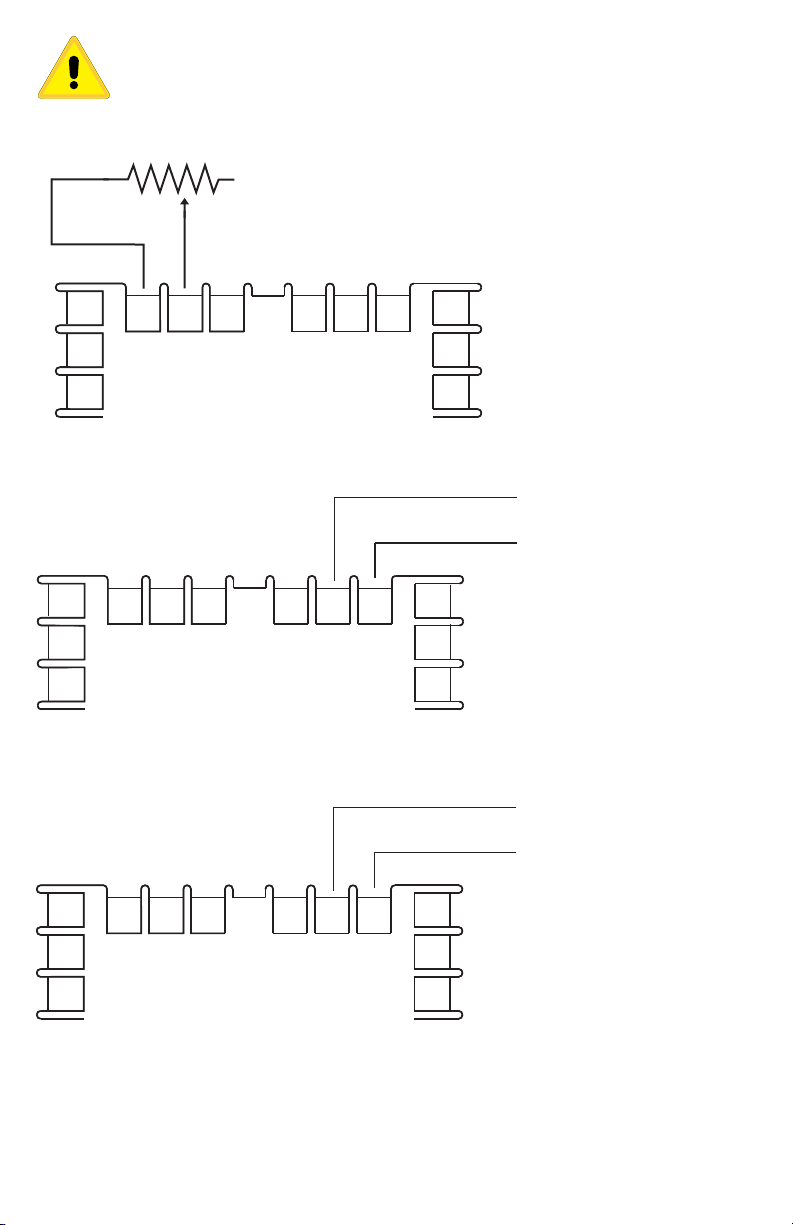

WIRING FOR OPTIONAL INPUTS AND OUTPUTS

3

2

1

21

22

23

24

25

26

13

12

11

+

-

Option 924

Option 924: Input 0 to 10 VDC,

1 Megohm Impedance

3

2

1

21

22

23

24

25

26

13

12

11

+

-

Option 926

Option 926: Input 0 to 20 mADC,

10 Ohms Impedance

All wiring shown below is Class 2. Shielded twisted pair is required for Options 992 and

996. Shielded cable is required for Options 993 and 995. Options 924, 926, and 928

share a common ground with input.

CAUTION: DO NOT RUN SIGNAL WIRING IN THE SAME CONDUIT OR

CHASE AS THE POWER WIRING. ERRATIC OPERATION OR DAMAGE TO

THE CONTROL CIRCUITRY WILL RESULT.

WIRING FOR OPTION 924 REMOTE SET POINT

WIRING FOR OPTION 926 REMOTE SET POINT

May, 2013 Page 8 of 52 949-1194 Rev. 7

Page 9

CAUTION: DO NOT RUN SIGNAL WIRING IN THE SAME CONDUIT OR

3

2

1

21

22

23

2

4

25

2

6

13

12

11

Option 928

Option 928: Input 0 to 10 kohms,

4µA Search Current

3

2

1

21

22

23

24

25

26

13

12

11

+

-

Option 934: Output 0 to 20 mADC,

into 600 Ohms maximum

3

2

1

21

22

23

24

25

26

13

12

11

+

-

Option 936: Output 0 to 10 VDC,

20 mADC maximum

CHASE AS THE POWER WIRING. ERRATIC OPERATION OR DAMAGE TO

THE CONTROL CIRCUITRY WILL RESULT.

WIRING FOR OPTION 928 REMOTE SET POINT

WIRING FOR OPTION 934 ANALOG RETRANSMISSION

WIRING FOR OPTION 936 ANALOG RETRANSMISSION

May, 2013 Page 9 of 52 949-1194 Rev. 7

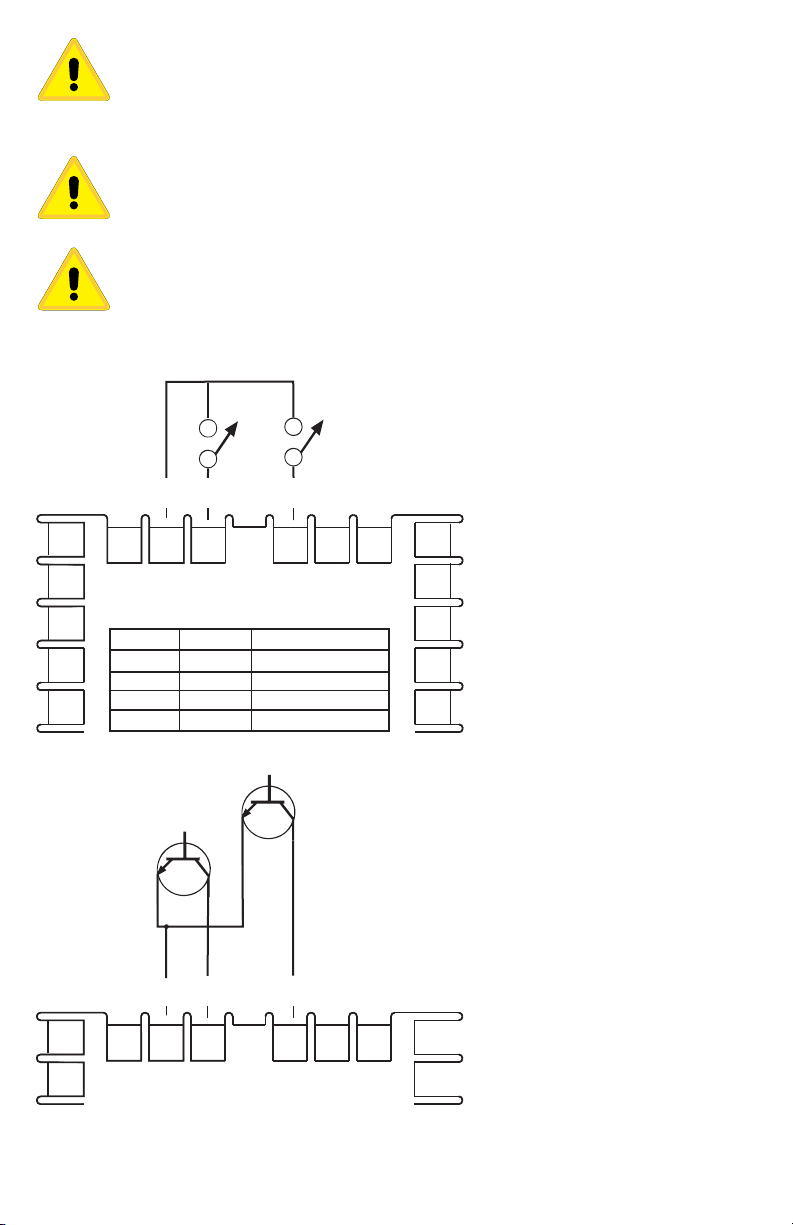

Page 10

CAUTION: DO NOT RUN SIGNAL WIRING IN THE SAME CONDUIT OR

5

4

3

2

1

21

22

23

24

25

26

15

14

13

12

11

Option 948

C A B

Switch Truth Table for Option 948

A to C B to C Active Set Point

open open 1SP1

closed open 2SP1

open closed 3SP1

closed closed 4SP1

2

1

21

22

23

24

25

26

12

11

C A B

Wiring for

Relay control

(Coil wiring

not shown)

Alternate

wiring for

Transistor

control.

Use NPN

open collector

transistors.

(Drive circuit

not shown)

CHASE AS THE POWER WIRING. ERRATIC OPERATION OR DAMAGE TO

THE CONTROL CIRCUITRY WILL RESULT.

WIRING FOR OPTION 948 4-STAGE SET POINT

SWITCH CONTACTS FOR OPTION 948 MUST BE ISOLATED AND CAN NOT

SHARE WIRING WITH OTHER CONTROLS.

TRANSISTOR DRIVE MUST BE ISOLATED AND MAY NOT SHARE A

COMMON GROUND WITH OTHER EQUIPMENT OR OTHER CONTROLS.

May, 2013 Page 10 of 52 949-1194 Rev. 7

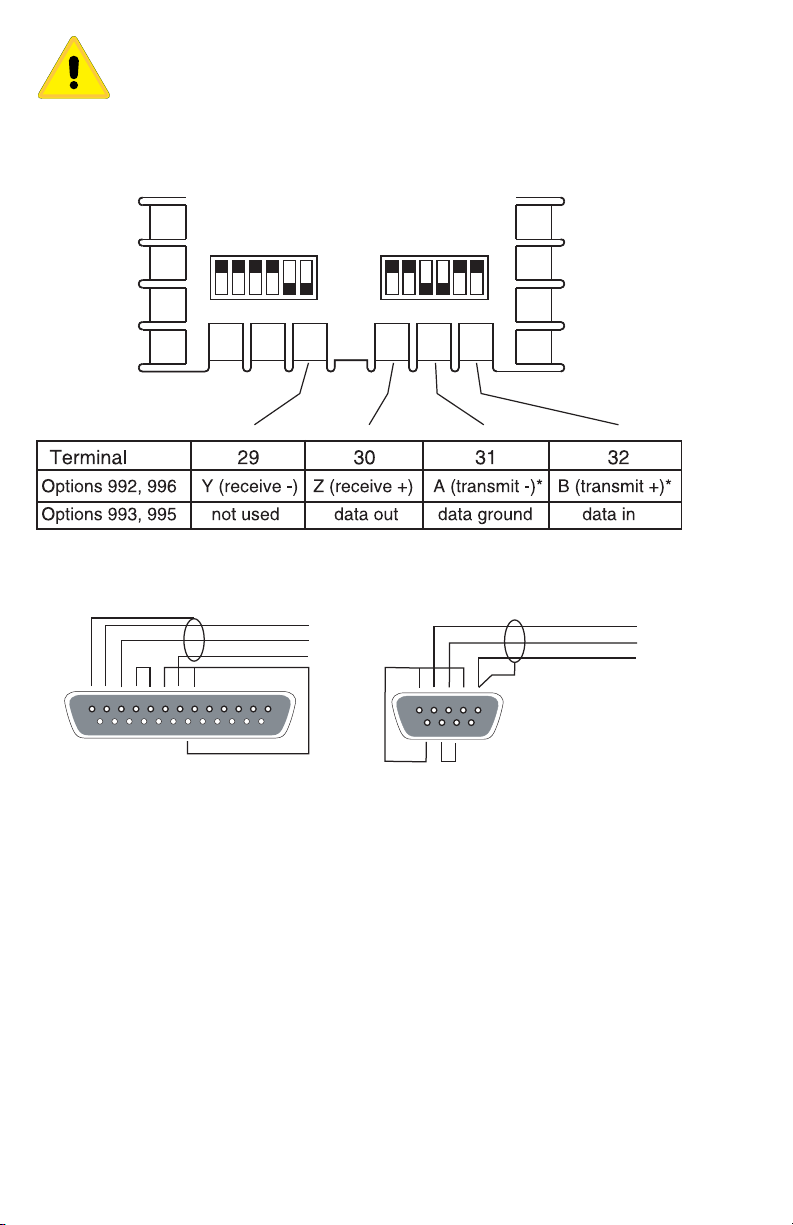

Page 11

CAUTION: DO NOT RUN SIGNAL WIRING IN THE SAME CONDUIT OR

10

9

8

7

27 28

29

30

31

32

20

1

9

1

8

1

7

*For half-duplex operation wire only A and B. Do not connect to Y and Z.

Options 992, 996

DIP Switch Positions*

Half Duplex* Full Duplex

1 2 3 4 5 6

1 2 3 4 5 6

1 2 3 4 5 6 7 8 9 10 11 12 13

14 15 16 17 18 19 20 21 22 23 24 25

DATA IN 30

DATA OUT 32

DATA GROUND 31

PIN DESCRIPTION

1 SHIELD

2 TRANSMIT

3 RECEIVE

4 RTS

5 CTS

PIN DESCRIPTION

6 DSR

7 GROUND

8 DCD

20 DTR

DB-25 WIRING

(VIEWED FROM WIRE SIDE)

1 2 3 4 5

6 7 8 9

RS-232 DB-9 WIRING

(VIEWED FROM WIRE SIDE)

PIN DESCRIPTION

1 DCD

2 RECEIVE

3 TRANSMIT

4 DTR

5 GROUND

6 DSR

7 RTS

8 CTS

DATA OUT 32

DATA IN 30

DATA GROUND 31

CHASE AS THE POWER WIRING. ERRATIC OPERATION OR DAMAGE TO

THE CONTROL CIRCUITRY WILL RESULT.

WIRING FOR OPTION 992, 993, 995, 996 SERIAL COMMUNICATIONS

May, 2013 Page 11 of 52 949-1194 Rev. 7

Page 12

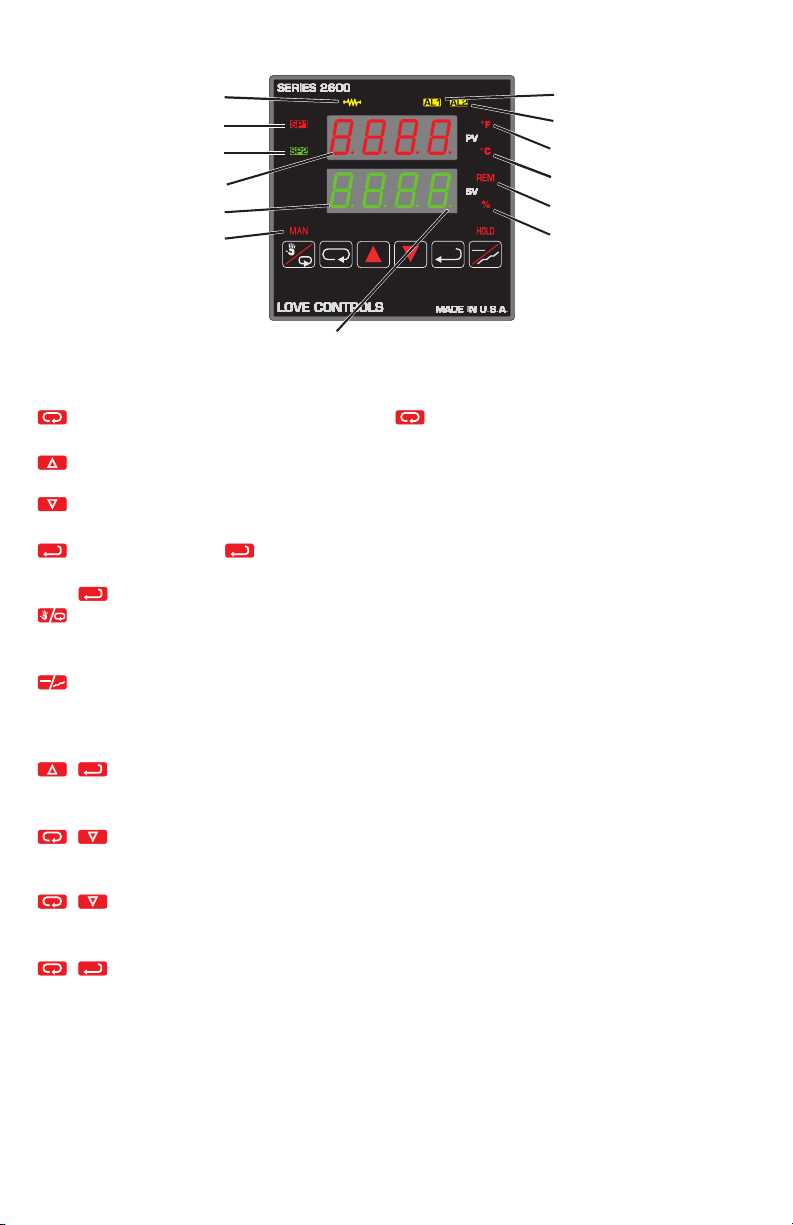

FRONT PANEL KEY FUNCTIONS

Heater Fail Lamp

Set Point 1 Lamp

Set Point 2 Lamp

Process Display

Set Point Display

Manual Indicator

Alarm 1 Lamp

Alarm 2 Lamp

°F Indicator

°C Indicator

Remote Set Lamp

Percent Lamp

The decimal point flashes when Self Tune is operating.

INDEX: Menu Navigation. Pressing the INDEX key advances the display to the

next menu item. May also be used in conjunction with other keys as noted below.

UP ARROW: Increments a value, changes a menu item, or selects the item to ON.

The maximum value obtainable is 9999 regardless of decimal point placement.

DOWN ARROW: Decrements a value, changes a menu item, or selects the item to

OFF. The minimum value obtainable is -1999 regardless of decimal point placement.

ENTER: Pressing ENTER stores the value or the item changed. If not pressed,

the previously stored value or item will be retained.The display will flash once when

ENTER is pressed.

AUTO/MANUAL: This key toggles the control output between Automatic mode and

Manual mode. Press and hold key for three seconds to activate. See section on

AUTO/MANUAL operation on page 18.

RUN/HOLD: This key toggles the Ramp/Soak program functions between Run mode

(program runs as set up), and Hold mode (program functions are suspended). Press

and hold key for three seconds to activate. See section on Ramp/Soak (page 15) for

further details.

UP ARROW & ENTER: Menu Access. Pressing these keys simultaneously

brings up the secondary menu starting at the alarm, tune, or cycle item (depending

on programming). Pressing these keys for 5 seconds will bring up the secure menu.

INDEX & DOWN ARROW: Menu navigation. Pressing these keys

simultaneously will allow backing up one menu item, or if at the first menu item they

will cause the display to return to the primary menu.

INDEX & DOWN ARROW: Alarm Reset. If an alarm condition has occurred,

press and hold these keys for three seconds to reset the alarm. Note that the alarm

condition will not reset if the alarm condition still exists.

INDEX & ENTER: ‘Global Reset’. Pressing these keys simultaneously and

holding them for 5 seconds forces a ‘warm boot’, restarting the control (similar to

turning power off and on). ‘Global Reset’ will allow recovery from errors and reset the

following menu items:

May, 2013 Page 12 of 52 949-1194 Rev. 7

Page 13

A L i H : Alarm inhibit O P E n I n P : Input error message

b A d I n P : Input error message C H E C C A L : Check calibration error

Correct the problems associated with the above conditions before using these reset keys.

More than one error could be present. Caution is advised since several items are reset at

one time.

While in the Primary or Secondary Menu, if no key is pressed for a period of 30 seconds,

the display will return to the HOME position displaying the temperature value. While in the

Secure Menu, if no key is pressed for a period of 60 seconds, the display will return to the

HOME position displaying the temperature value. Outputs are disabled (turned off) when

the Secure Menu is active.

NOTE: To move to the Primary Menu quickly from any other menu, press the

UP ARROW & ENTER keys followed by pressing the INDEX & DOWN ARROW

keys.

SECURITY LEVEL SELECTION

Four levels of security are provided. The display shows the current security level. To

change security levels change the password value using the UP ARROW and

DOWN ARROW keys and press the ENTER key. Refer to the password table

(following) for the correct value to enter for the security level desired. The SE C r menu item

security level may be viewed or changed at any time regardless of the present security

level.

To set the access level to, for example, 2 , at the S E C r menu item press the UP

ARROW key until the upper display shows the password for level 2 access, 1 1 0 1 . Press the

ENTER key. The display will blink and return with the level value, 2, in the upper

display.

The password values shown in the table cannot be altered, so retain a copy of these

pages for future reference. This is the only reference made to password values in this

instruction book.

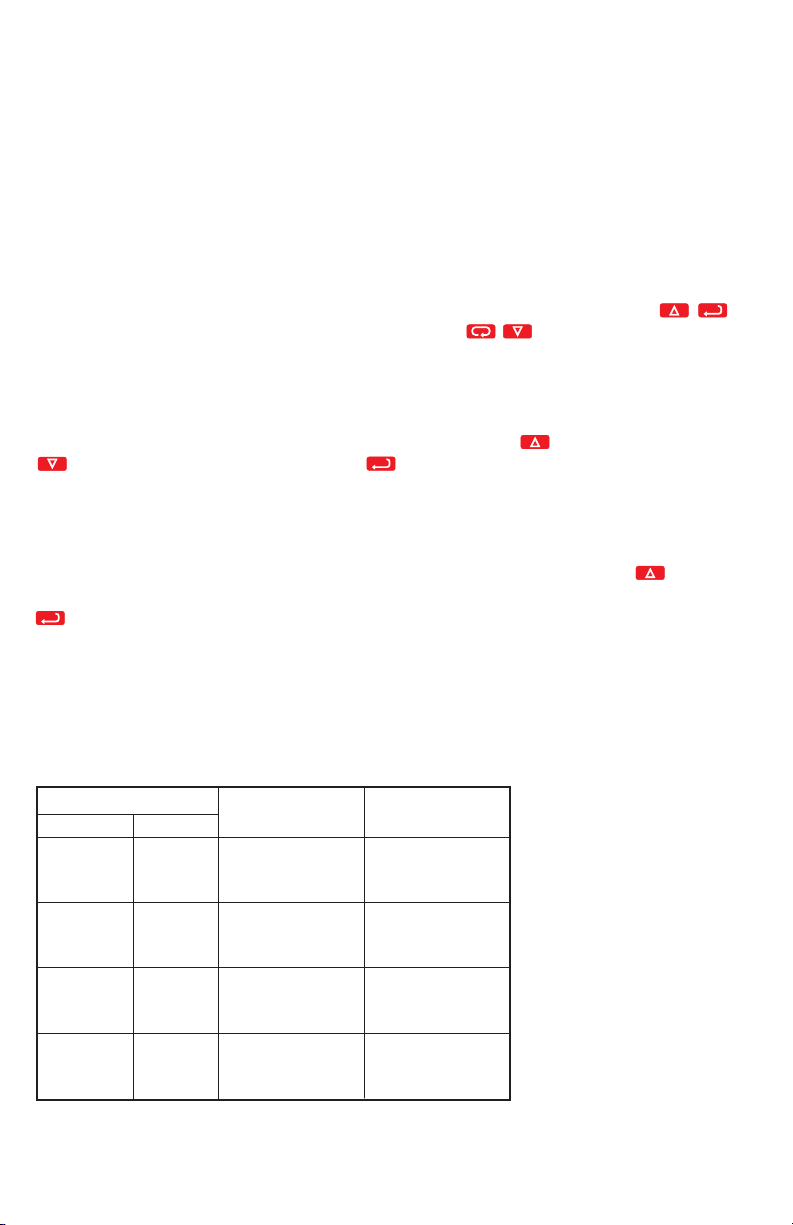

PASSWORD TABLE

Security Level

Menu

Primary

Secondary

Secure

Primary

Secondary

Secure

Primary

Secondary

Secure

Primary

Secondary

Secure

May, 2013 Page 13 of 52 949-1194 Rev. 7

Status

Locked

Locked

Locked

Unlocked

Locked

Locked

Unlocked

Unlocked

Locked

Unlocked

Unlocked

Unlocked

Displayed Value

When Viewed

1

2

3

4

Password Value

To Enter

1 1 1 0

1 1 0 1

1 0 1 1

1 1 1

Page 14

NOTATION CONVENTIONS FOR THE MENUS

Because of the number of features available in this control, information is included that

may not apply to your specific control. All usable features are included in this book, but

may not be used in your process. To increase clarity the following conventions are used:

1. Certain features, menu items, and functions shown in this book may or may not appear

on your control, depending on other menu item selections. At various places in the menus

there are notes identifying menu items that “control” or “direct” other menu items. If you

are looking for a particular menu item and can’t find it, check the menu item that is its

“control” for proper setting.

2. The “#” symbol is used in two ways. It is used inside a group of characters to indicate

which set point function (S P 1 or SP2) is being affected. It is also used before a group of

characters of a menu item to indicate that there may be more than one selection or value

for that menu item. This is used for certain repeated items such as in the Ramp/Soak

Program section.

DISPLAY CONVENTIONS

The instrument front has two four digit displays, eleven indicators, and six keys. The

diagram on page 12 shows the location of the displays and descriptors.

During normal operation the top four digit display indicates the temperature that is being

read by the sensor. The bottom display indicates the set point. When you are

programming the instrument, the bottom display indicates the Menu Item being

programmed and the top display the value selected for that Menu Item. Error messages

use both the top and bottom displays to indicate a particular error.

Each character can only be displayed with seven light segments. Alphabet characters may

look peculiar when seen presented this way. The following is an example of the ‘seven

segment alphabet’ as used in the instrument:

A B C D E F G H I J K L M N O P Q R S T U V W X Y Z

A b CdEFGHIJKLmnOPQ rSt U V U XYZ

0 1 2 3 4 5 6 7 8 9

0 1 2 3 4 567 8 9

Notice that some characters are in upper case while others are in lower case. Some look

the same (e.g. G [G] and 9 [9 ]) and must be interpreted by context. Others are close (e.g.

B [b ] and 6 [6 ]), but different. Usually, the context of the term or value will help you

determine the correct character.

May, 2013 Page 14 of 52 949-1194 Rev. 7

Page 15

THE HOME DISPLAY

The home display is the normal display while the control is operating. If no errors or

functions are active, the HOME display will indicate the Process Variable (the

temperature, pressure, flow, RH, etc., that is being measured) on the top display and the

Set Variable (Set Point 1) on the bottom.

Items that can change the HOME display are the Auto/Manual function, the Run/Hold

function, the P r o 9 function, the Pct O function, and any error message. Description of

these special displays follows.

If the Auto/Manual key is pressed, the Manual indicator lights, the “%” indicator lights,

and the home display is changed. The upper display continues to show the Process

Variable (PV), but the lower display changes to show the percentage of output in tenths of

a percent to 99.9% (0.0 to 99.9), or 100 if 100%. The display digit to the right of the

number shows a flashing letter o to indicate that the value displayed is no longer the SV,

but percent output. The SP2 percent output is indicated by the use of an overline on the

letter õ. Access to the SP 2 value is made by the INDEX key. See Auto/Manual

Operation on Page 17 for further information.

If P r o 9 is turned On, the HOME display changes the SV display from S P 1 to the Present

Set Variable as calculated by the Ramp/Soak Programmer function. See Programming

and Operation for Ramp/Soak Feature below for more information.

If P c t O (Secondary Menu) is turned On, the lower display changes to show the active

percentage of output as required to maintain S P 1 . The display is similar to the Auto/Manual

display above, except that the percent indicators (o ,õ ) do not flash, and the output is

displayed in whole percentages of output, not in tenths of a percent. If the control has both

S P 1 and SP2, the lower display will alternate between the S P 1 percent output and the SP2

percent output.

Error messages are listed on pages 41-43.

PROGRAMMING AND OPERATION FOR RAMP / SOAK FEATURE

The ramp / soak feature offers a great deal of flexibility by allowing changes in the set

point to be made over a predetermined period of time. Dwell times can be programmed,

and the alarm output relay can be programmed to open or close during any of the

segments.

Theory of Operation

The 2600 Series controls offer a very simple approach to programming a ramp. Rather

than requiring the operator to calculate an approach rate (usually in degrees per minute),

the 2600 does the calculation internally. Thus, the operator only needs to program the

target set point and the time desired to reach that point. When the ramp segment is

executed by the control, it calculates the ramp required to move the process from the

starting value (current PV) to the desired value (programmed SP) in the time allowed.

May, 2013 Page 15 of 52 949-1194 Rev. 7

Page 16

Soaks (or dwells) are ramp segments where the target set point is the same as the

beginning process value. This allows for multistage ramps without wasting intermediate

soak steps. Care must be taken, however, that the process does actually reach the soak

value before the soak time starts. If not, the next segment will calculate a slope from the

starting PV to the target SP. Depending on your process requirements, this difference

may be important. Make sure to test any program for desired results before running

production material.

Do not operate Self Tune while a ramp function is operating. The ramp function will

prevent the Self Tune from operating properly. Make sure that all tuning is set up

before operating Ramp / Soak.

Program Setup

All of the programming for the Ramp / Soak function is done in the Secondary Menu. You

may wish to work out your program on paper before going into the programmer menu

sequence.

In the Secondary Menu INDEX to P r o 9 and make sure that Pro 9 is set to OFF.

INDEX to P S E t and turn On. Press ENTER.

Skip the S t A t setting (this is discussed later) and press INDEX to 1ti .

The following items repeat in the following order: 1 t i , 1 S P , 1 A 1 and/or 1A2 (if A L 1 or AL2 in

the Secure Menu are programmed set to E U n t ), 2 t i , 2 S P , 2 A 1 ,..., 1 6 t i , 1 6 S P , 1 6 A 1 , 1 6 A 2 . To

avoid repetition each item will only be described once.

Set 1 t i to the amount of time you want for the first ramp. This value is in time units

(determined by the t b A S menu item) from 0 to 99 9 9 . Press ENTER.

Set 1 S P to the target value desired for the first ramp. This value is in actual units just like

S P 1 . If the control is programmed for temperature, then the SP displays are in temperature.

If the control is programmed for some other engineering unit, the SP is set in that unit.

Press INDEX to continue. If Alarm 1 is programmed as an event (AL 1 = EUnt), then

1 A 1 will appear. If you wish the Alarm 1 contact to function for this segment, set 1A1 for On . If

not, set for O F F . Press ENTER. When 1 A 1 is set to O n , the Alarm 1 function will be

active for the entire period set in 1 t i above.

Complete setting the segment times (2 t i ... 16ti ), segment set points (2 S P ... 1 6 S P ), and

event alarms (2 A 1 ... 16A1 ) to O n or OFF.

For unneeded or unused segments set the segment times (2 t i ... 16ti ) to 0 , and set the

segment set points (2 S P ... 16SP ) to the same value as the last active set point. A segment

alarm may be set to indicate “end of run” at the segment number you select.

May, 2013 Page 16 of 52 949-1194 Rev. 7

Page 17

The last menu item for the ramp / soak function is P E n d . P E n d determines what the control

does when the program has ended. You may choose to have the program repeat (L o o P ),

H o l d the last set point (16S P ), revert to the local S P 1 , or turn the outputs off (Oo F F ).

It is important to remember that if you want the program to repeat, you must allow the

process to return to the same condition that existed when the program first started.

Remember that the ramp function calculates the slope by drawing a line from the

beginning PV to the ramp target set point. If the PV at the end of the program is different

than the PV at the initial start, the ramp will calculate differently.

Ramp / Soak Operation

When you wish to start the program, enter the Secondary Menu and set the P r o 9 menu

item to O n . Return to the HOME position by waiting for the display to time out or by

pressing the UP ARROW & ENTER keys and then the DOWN ARROW

& INDEX keys.

The home display will read as it normally does. The HOLD indicator by the RUN / HOLD

key will be lit. To start the program press the RUN / HOLD key for three seconds. The

HOLD indicator will go out, and the program will start.

To suspend the program at any time, press the RUN / HOLD key. Press the key again

to resume.

Pressing the AUTO / MANUAL key will also suspend the program operation. The

difference is that AUTO / MANUAL also puts the control into manual mode. See Auto /

Manual Operation on page 18.

The function of the Primary Menu will change depending on the setting of the S t A t menu

item in the Secondary Menu. If S t A t is OFF then the Primary Menu is not changed.

If the S t A t menu item is set to O n , then the Primary Menu has three additional

information items added before S P 1 appears. The first INDEX item displays the time

remaining in the current segment in the top display (####), and the message t i , in the

lower display. The next INDEX item displays the total time for the active segment in the

upper display (####) and the message ##t i (1ti...1 6 t i ), in the lower display. The third

INDEX item displays the segment set value (####) in the top display, and the message

##S P (1SP...16 S P ) in the lower display. The next INDEX press resumes the normal Primary

Menu

May, 2013 Page 17 of 52 949-1194 Rev. 7

Page 18

AUTO / MANUAL OPERATION

The AUTO / MANUAL function allows you to manually adjust the output of the control. This

is normally used during process setup or start up. It can also be used for troubleshooting.

To switch from AUTO to MANUAL press the AUTO / MANUAL key and hold for three

seconds. The MANual indicator will light and the lower display will change from normal to

showing the actual output in percent. The value will be the actual percentage of output

that was active when the key was pressed. This is usually known as “bumpless transfer”.

If you wish to change the output while in manual, press the UP ARROW or DOWN

ARROW keys to change the value, and press ENTER to retain it. It is important to

remember that the value of the display is read as 0 to 100% of the full control output, NOT

the range between S1OL and S1OH or S2OL and S2OH. For example, if the set point one

output is programmed for 4 to 20 mA (S1OL=20, S1OH=100), a reading of 50% in

MANUAL represents 10 mA, not 12 mA. This allows the operator to go above and below

the output range to allow for improperly function equipment that may be connected to the

control output.

To return to AUTOmatic control, press the AUTO / MANUAL key again. The MANual

indicator will go out, and the set point will take over. However, if you want bumpless

transfer back to AUTO, slowly change the percentage of output until the process variable

matches (or at least is close) to the set point. The further away the PV is from the set

point, the greater the “bump” or upset there will be in the output.

SELF TUNE FUNCTION

Self Tune allows automatic selection of the necessary parameters to achieve best control

operation from your 2600 Series control. If you are using the control output as a simple

on-off function (Out 1 set for OnOF), none of the following will apply.

Theory of Operation

The Self Tune function calculates the Pb 1 , r E S , and r t E parameters under the P i d t u n E

selection, and the F b n d and Frt E parameters, as shown in the Secondary Menu. These

values are determined by measuring the response of the process connected to the

control. When Self Tune is started, the control temporarily acts as an on-off control. While

in this mode the control measures the overshoot and undershoot of the process, and the

period of the process (the time from peak value to the next peak value). These

measurements are collected over a period that lasts three periods of overshoot and

undershoot. The data collected over this time is then compared and calculated into final

PID and Fuzzy Logic values. The effect of Fuzzy Logic on the process is still controlled by

the F i n t (fuzzy intensity) setting. If Fin t is 0, the F b n d and FrtE will be calculated, but will

have no effect. The calculations for the PID values are the same as used in the standard

Ziegler - Nichols equations that have been recognized as standard for decades.

The only modification to the application of the Ziegler - Nichols equations is controlled by

the d F A C menu item. This menu item controls the amount of rate (derivative) that is

applied. A d F A C setting of 3 (factory default) or less allows for less damping. A dFAC

setting of 4 allows for critical damping as set forth in Ziegler - Nichols. A d F A C setting of 5

or more allows over damping of the process.

May, 2013 Page 18 of 52 949-1194 Rev. 7

Page 19

Program Setup and Operation

Do not cool the process or add heat while the tuning is occurring. In the secondary menu

set t u n E to SEL F . Skip L E r n and check to make sure that d F A C is set to the desired value.

Back up to L E r n and set to YES . The control will begin the Self Tune function. While the

Self Tune function is active, the right hand decimal point on the lower display will blink.

When Self Tune is complete, the blinking will stop.

After Self Tune is complete, the tu n E setting automatically switches to Pid. This allows

examination and / or modification of the values calculated. We recommend that you do not

change the calculated values unless you have a firm understanding of the parameters

involved and their function.

OPERATION AND PROGRAMMING OF OPTIONS

Options 924, 926, 928, Analog Remote Set Point

The analog remote set point allows the control set point to be determined by an outside

analog signal. The signal may be 0 to 10 VDC (Option 924), 0 (or 4) to 20 mADC (Option

926), or 0 to 10,000 Ohms (Option 928).

Wire the input as shown on pages 8 and 9.

To set up the analog remote set point, first determine the scale range that the analog

signal will represent. The maximum span is 11,998 degrees or counts. In the Secure Menu

set r S C L for the scale value that will be represented by the low end of the analog signal (0

Volts, 0 mA, 0 Ohms). Set rS C H for the scale value that will be represented by the high

end of the analog signal (10 Volts, 20 mA, 10,000 Ohms).

If you require a suppressed scale or input, use the following equations to determine the

proper settings for r S C L and rSC H .

K = (Highest desired scale reading - Lowest desired scale reading) / (Maximum desired

analog signal - Minimum desired analog signal).

r S C H = ((Maximum possible analog signal- Maximum desired analog signal) * K) + Highest

desired analog reading.

r S C L = Lowest desired scale reading - ((Minimum desired analog signal) * K).

Make sure that a valid analog signal is available to the control. In the Secondary Menu set

the r S P t to On. The REM indicator on the front of the control will turn on. When the control

returns to the HOME position, the displayed SV will be the value supplied from the analog

remote signal. If the analog remote signal fails or goes out of range of the S P L or SPH

settings, the control will revert to the internal S P 1 (or #SP1), and flash the error message

C H E C rSP t . If S P L or S P H are set outside of r S C L or r S C H then the error will be

suppressed, and the control will attempt to work with the remote value.

To clear the error message, change r S P t to OF F .

May, 2013 Page 19 of 52 949-1194 Rev. 7

Page 20

Option 934, 936, Isolated Analog Retransmission.

The analog retransmission option allows the Process Variable or the Set Variable to be

sent as an analog signal to an external device. The signal may be either 0 to 10 VDC

(Option 936) or 0 (or 4) to 20 mADC (Option 934). The output may be changed in the field

from one to the other by the toggle switch located on the top printed circuit board.

Wire the output as shown on page 9.

To set up the analog retransmission, first determine the scale range that the analog signal

will represent. The maximum scale is 9999°F, 5530°C, or 9999 counts. In the Secondary

Menu set P O L for the scale value that will be represented by the low end of the analog

signal (0 Volts or 0 mA). Set PO H for the scale value that will be represented by the high

end of the analog signal (10 Volts or 20 mA).

If you require a suppressed scale or output, use the following equations to determine the

proper settings for P O L and POH.

K = (Highest desired scale reading - Lowest desired scale reading) / (Maximum desired

analog signal - Minimum desired analog signal).

P O H = ((Maximum possible analog output - Maximum desired analog signal) * K) + Highest

desired analog reading.

P O L = Lowest desired scale reading - ((Minimum desired analog output) * K).

Next select whether you want the retransmission signal to follow the Process Variable or

the Set Variable. Usually the Process Variable is sent to recorders or other data

acquisition devices. Usually the Set Variable is sent to other controls to be used as an

analog remote set point. If you want the analog retransmission signal to follow the PV, in

the Secondary Menu set P O S r to InP . If you want the analog retransmission signal to

follow the SV, set P O S r to S P t .

Operation is automatic. There are no further programming steps required.

May, 2013 Page 20 of 52 949-1194 Rev. 7

Page 21

Option 948, 4-Stage Set Point.

The 4-stage set point option allows four different values to be used for SP 1 and all of the

values associated with the t u n E menu items. The control will switch to a given stage when

an external contact or contacts are made or opened across the appropriate terminals at

the rear of the control (S P S A , Set Point Switch Action, set for remote, rE), or when the

stage is selected from the Secondary Menu, S P (when SPSA is set for In t ). When the state

of a contact changes (or the stage number is changed in the Secondary Menu), the values

in use are stored and the previously stored values for the new stage are used.

Wire the input as shown on page 10.

Usually the control is configured for external switching of the stages. In this case, the

operation is usually automatic, selected by the external switches driven by the machine

logic. If it is necessary to program the stages in advance, you may select the stage to

modify with the S P menu item. When SP is changed while the S P S A is set for rE , the

selected stage is displayed for modification, but only used when the appropriate contact is

made.

Option 992, 993, 995, 996 Serial Communication.

The serial communications options allow the control to be written to and read from a

remote computer or other similar digital device. Communication is allowed either through a

RS-485 (Option 992, 996) port, or a RS-232 (Option 993, 995) port.

Wire the communication lines as shown on Page 11. Wiring for the RS-485 is run from

control to control in a daisy chain fashion with a termination resistor (120 ohms) across the

transmit and receive terminals of the last control in the chain.

Select the control address and communication baud rate with the A d d r and b A U d menu

items in the Secure Menu.

NOTE: THE BAUD RATE AND ADDRESS MENU ITEM SETTINGS WILL TAKE EFFECT

ON THE NEXT POWER UP OF THE CONTROL. BE SURE TO TURN THE POWER TO

THE CONTROL OFF AND ON BEFORE USING THE NEW BAUD RATE AND ADDRESS

VALUES.

In operation, you have the option of preventing a write command from the host computer.

To prevent the host from writing to the control change the L O r E menu item in the

Secondary Menu to L O C . To allow the host to write commands to the control set L O r E to

r E . (The host does have the ability to change the L O r E state, but it is not automatic.)

If your system depends on constant reading or writing to and from the host, you may wish

to set the No Activity Timer (n A t ) to monitor the addressing of the control. When the L O r E

is set to r E and the nAt is set to any value other than OF F , the control will expect to be

addressed on a regular basis. If the control is not addressed in the time set by the value of

n A t , then the control will display the error message C H E C L O r E . To clear the message

set L O r E to LOC .

May, 2013 Page 21 of 52 949-1194 Rev. 7

Page 22

SERIAL COMMUNICATIONS OPTIONS AND NONVOLATILE MEMORY

There are many different types of memory used in computer driven devices. The terms

RAM (random access memory) and ROM (read only memory) are a couple with which you

may be familiar.

RAM is used in computers to run programs and hold data for a short period of time. This is

the memory that is used primarily in PCs. RAM is very fast and can be read and written to

over and over again. Its major weakness is that it is erased when the power is turned off.

ROM is used in computers to hold the ‘permanent’ programming that allows a PC to start.

This memory is ‘burned in’ to the chip itself and can not be changed. Unlike RAM,

however, this memory is permanent. While it can not be changed, it can not lose its

programming when power is turned off. This is the type of memory that is used to store the

permanent programming for the control.

There is a third type of memory that is now currently used to combine the characteristics

of both RAM and ROM. This is known as EEPROM (electrically erasable programmable

read only memory). While the name may be long and somewhat cryptic, the EEPROM can

be erased and re-written many times, and yet hold the programmed data even over long

periods when the power is off. This is the type of memory that Love Controls uses to save

the settings you program in your control. The reliability and longevity of the data retention

is what allows us to guarantee a 10 year data retention without power.

In normal operation, the control uses RAM, just as any other computerized device.

Whenever you make a change to one of the parameters in the control, the set point for

example, the new value is written into the EEPROM. This way, if power goes off for

whatever reason, when power resumes, the latest settings are preserved. When power is

turned on, the data is copied from the EEPROM to the RAM to restore operation.

You might ask, “If EEPROM is such a wonderful thing, why bother with RAM?” One reason

is that is that RAM is much faster than EEPROM. Faster speed gives you better

performance in critical control functions.

Perhaps the most important reason is that RAM allows an unlimited number of writes,

while EEPROM has a limit to the number of times that it can be erased and re-written.

Current technology now sets that limit at about one million erase / write cycles. In a

dynamic control situation, it may be necessary to update RAM every few milliseconds.

EEPROM can not keep up to that pace, and, even if it could, it would be ‘used up’ in a

matter of days.

If you think about how long it would take to make a million changes to the control

programming through the front key pad, you will see that it would take a very long time to

get to use up the life of the EEPROM.

May, 2013 Page 22 of 52 949-1194 Rev. 7

Page 23

Adding one of the computer communications options (e.g. 992, 993, 995, 996) changes

the picture. The speed of computer communications is such that hundreds of instructions

can be made in less than a minute. In such a situation, the million erase / write cycles

could be used up in a couple of months causing the chip (and the control) to fail.

Usually in such a situation, the control is under close observation by the host computer. It

may not be necessary, then, to have the data written to the EEPROM, as it is ‘transitory’ in

nature (changing set points for a ramp/soak sequence for example).

Controls equipped with a Serial communications option have a menu item in the Secure

menu (S t o r ) that allows the serial communications to write to RAM (S t o r = n o ).

The factory default is ‘write to EEPROM’ (Stor = Y E S ).

If your computer system will be making frequent changes to the control, we strongly

recommend that you select the ‘write to RAM’ parameter (Stor = no ). If you are primarily

reading from the control, there is no need to change the setting.

For further information on protocols and technical information regarding computer

programming for the Serial Communications options, see our web site at http://www.lovecontrols.com/protocol.

MENU SELECTIONS

PRIMARY MENU

Press INDEX to advance to the next menu item. Press UP ARROW or

DOWN ARROW to change the value in the display. Press ENTER to retain the value.

If S t A t , (Secondary Menu), is O n , the three program status menu items shown on Page

17 will precede the following.

# S P 1 (Option 948, 4-Stage Set Point) or

S P 1 Set Point 1 Adjust, Control Point 1.

S P 2 Set Point 2 Adjust (if equipped), Control Point 2.

May, 2013 Page 23 of 52 949-1194 Rev. 7

Page 24

SECONDARY MENU

Hold UP ARROW & ENTER. Press INDEX to advance to the next menu

item. Press UP ARROW or DOWN ARROW to change the value in the display.

Press ENTER to retain the value.

If your instrument is not equipped with alarms (third character of part number is ‘0’), the

Secondary Menu starts with O u t 1 , below.

A 1 L o Alarm 1 Low: The Low Alarm point is usually set below the Set Point. May not

appear depending on A L 1 setting in Secure Menu.

A 1 H i Alarm 1 High: The High Alarm Point is usually set above the Set Point. May not

appear depending on A L 1 setting in Secure Menu.

A 2 L o Alarm 2 Low: The Low Alarm point is usually set below the Set Point. May not

appear depending on A L 2 setting in Secure Menu.

A 2 H i Alarm 2 High: The High Alarm Point is usually set above the Set Point. May not

appear depending on A L 2 setting in Secure Menu.

O u t 1 Output selection: Select O n O F , #t P , #P u L , or P r o P .

O n O F A setting of O n O F allows the control to operate in simple on/off mode.

This setting forces the control to turn off at set point, and on at the set

point plus the differential (SP 1 d ). When selected, the O u t 1 O n O F menu

item is followed by #### S P 1 d , and the t u n E , P b , r E S , O F S , and r t E

selections in the Secondary menu and the S 1 O L and S1 O H selections

in the Secure menu are suppressed.

S P 1 d Set Point On-Off Differential (hysteresis). Set for the amount of

difference between the turn off point and the turn on point.

Select 1 to 9999 (direct acting), or -1 to -9 9 9 9 (reverse

acting). This value will be negative for reverse acting set

points, and positive for direct acting outputs. The following

drawing shows output behavior for reverse and direct action.

For reverse action note how the output decreases as the input

process variable increases, e.g. heat power goes to zero as

the temperature increases to set point.

May, 2013 Page 24 of 52 949-1194 Rev. 7

Page 25

# # t P Time Proportioning Cycle Time. Select 1t P to 80tP.

1 t P A setting of 1tP is recommended for solid state outputs (SSR or

15 VDC).

2 t P to 80tP Time Proportioning Control is adjustable in 1 second

steps. Recommended for mechanical outputs (relays,

solenoids, etc.). For best contact life, a time should be selected

as long as possible without causing the process to wander.

# P u L Pulsed Time Proportioning Output: Select 1 P u L to 7 P u L . 1 P u L =

Linear and 7 P u L = most nonlinear. Changes output linearity for

use in cooling applications or for extremely fast response

processes. At the center of the proportional band, a pulse value

of 1 provides an output of one second on and one second off

(50% output). A pulse value of 2 provides an output of one

second on and two seconds off (33% output). Output at center

of band equals one second on, 2

(pulse value-1)

seconds off.

P r o P For Current (Code 5) outputs only.

The following menu items apply only if your control is equipped with a second set

point (last digit of model number is not zero). If your control does not have a second

set point, jump to the t u n E menu on the next page.

O u t 2 Output selection: Select OnOF , #t P , #P u L , or ProP.

O n O F A setting of O n O F allows the control to operate in simple on/off mode.

This setting forces the control to turn off at set point, and on at the set

point plus the differential (SP 2 d ). When selected, the O u t 2 / O n O F menu

item is followed by #### S P 2 d , and the P b 2 selection in the Secondary

menu and the S 2 O L and S2O H selections in the Secure menu are

suppressed.

S P 2 d Set Point On-Off Differential (hysteresis). Select 1 to 9999 (direct

acting), or -1 to -9999 (reverse acting). See S P 1 d on the previous

page.

# # t P Time Proportioning Cycle Time. Select 1t P to 8 0 t P .

1 t P A setting of 1tP is recommended for solid state outputs (SSR or

15 VDC).

2 t P t o 8 0 t P Time Proportioning Control is adjustable in 1 second

steps. Recommended for mechanical outputs (relays, solenoids,

etc.). For best contact life, a time should be selected as long as

possible without causing the process to wander.

May, 2013 Page 25 of 52 949-1194 Rev. 7

Page 26

# P u L Pulsed Time Proportioning Output: Select 1 P u L to 7 P u L . 1 P u L =

Linear and 7 P u L = most nonlinear. Changes output linearity for

use in cooling applications or for extremely fast response

processes. At the center of the proportional band, a pulse value

of 1 provides an output of one second on and one second off

(50% output). A pulse value of 2 provides an output of one

second on and two seconds off (33% output). Output at center

of band equals one second on, 2

(pulse value-1)

seconds off.

P r o P For Current (Code 5) outputs only.

S P (Option 948, 4-Stage Set Point) Active Set Point Stage. Select 1SP1, 2 S P 1 , 3 S P 1 ,

4 S P 1 . (See Page 21 for more detail.)

1 S P 1 Set Menu Items to display Stage 1 for view and change access. If SPSA

is set for I n t , 1 S P 1 is made active.

2 S P 1 Set Menu Items to display Stage 2 for view and change access. If S P S A

is set for Int, 2 S P 1 is made active.

3 S P 1 Set Menu Items to display Stage 3 for view and change access. If S P S A

is set for Int, 3 S P 1 is made active.

4 S P 1 Set Menu Items to display Stage 4 for view and change access. If S P S A

is set for I n t , 4 S P 1 is made active.

# S P 1 (Option 948, 4-Stage Set Point) Adjust Control Point 1 for Stage selected above.

Note: The menu items for tun E (below) are modified when Option 948 is active. Then, the

menu items are shortened or shifted right, and preceded with the stage number selected

in S P above. Each stage has its own set of tunE parameters as indicated by #t u n .

# t u n (Option 948, 4-Stage Set Point) or

t u n E Tuning Choice: Select SELF, P i d , S L O , n o r , or F A S t .

S E L F The Controller will evaluate the Process and select the PID values to

maintain good control. Active for SP1 only.

L E r n Select Y E S or no

Y E S Start Learning the Process. After the process has

been learned the menu item will revert to n o .

n o Learning will stay in present mode.

May, 2013 Page 26 of 52 949-1194 Rev. 7

Page 27

d F A C Damping factor, Select O F F , 1 to 7. Sets the ratio of Rate to

Reset for the S E L F t u n E mode. 7 = most Rate. Factory set to

3. For a fast response process the value should be lowered

(less Rate). For a slower process the value should be

increased (more Rate).

P i d Manually adjust the PID values. PID control consists of three basic

parameters, Proportional Band (Gain), Reset Time (Integral), and Rate

Time (Derivative).

# P b 1 (Option 948, 4-Stage Set Point) or

P b 1 Proportional Band (Bandwidth). Select 1 to 9 9 9 9 °F, °C, or

counts.

P b 2 Proportional Band (Bandwidth). Select 1 to 9 9 9 9 °F, °C, or

counts. Appears only if control is equipped with second set

point and O u t 2 is NOT selected as OnOF.

# r E S (Option 948, 4-Stage Set Point) or

r E S Automatic Reset Time. Select OF F , 0 . 1 to 99 . 9 minutes. Select

O F F to switch to O F S .

# O F S (Option 948, 4-Stage Set Point) or

O F S Manual Offset Correction Select OFF , 0 . 1 to 99. 9 percent.

Select O F F to switch to rES.

# r t E (Option 948, 4-Stage Set Point) or

r t E Rate Time. Select O F F , 0 . 0 1 to 9 9 . 9 9 minutes, Derivative.

S L O PID values are preset for a slow response process.

n o r PID values are preset for a normal response process.

F A S t PID values are preset for a fast response process.

P i d 2 Linkage of PID parameters between SP1 and SP2: Select O n or OFF.

O n Applies SP1 r E S , r t E , F b n d , and F r t E terms to SP2 for heat/cool

applications.

O F F SP2 functions without r E S , r t E , F b n d and FrtE.

A r U P Anti- Reset Windup Feature: Select O n or OFF.

O n When A r U P is On the accumulated Reset Offset value will be cleared to

0% when the process input is not within the Proportional Band.

O F F When A r U P is OFF , the accumulated Reset Offset Value is retained in

memory when the process input is not within the Proportional Band.

May, 2013 Page 27 of 52 949-1194 Rev. 7

Page 28

A r t E Approach Rate Time: Select OFF, 0. 0 1 to 99.9 9 minutes. The function defines

the amount of Rate applied when the input is outside of the Proportional Band.

The A r t E time and the rtE time are independent and have no effect on each

other. To increase damping effect and reduce overshoot set the approach rate

time for a value greater than the natural rise time of the process (natural

rise time = process value time to set point).

F i n t Fuzzy Logic Intensity: Select 0 to 100%. 0% is OFF (disables Fuzzy Logic). The

function defines the amount of impact Fuzzy Logic will have on the output.

F b n d Fuzzy Logic Error Band: Select 0 to 40 0 0 °F, °C, or counts. Sets the bandwidth

of the Fuzzy Logic. Set F b n d equal to PID proportional band (Pb1 ) for best

results.

F r t E Fuzzy Logic Rate of Change: Select 0 . 0 0 to 99 . 9 9 counts/second. For best initial

setting, find the counts/second change of process value near Set Point 1 with

output ON 100%. Multiply this value by 3. Set F r t E to this calculated value.

P E A The Peak feature stores the highest input the control has measured since the last

reset or Power On. At Power On PE A is reset to the present input. To manually

reset the value P E A must be in the lower display. Press the ENTER key to

reset. P E A will be reset and display the present input value.

U A L The Valley feature stores the lowest input the Instrument has measured since the

last reset or Power On. At Power On UA L is reset to the present input. To

manually reset the value U A L must be in the lower display. Press the ENTER

key. U A L will be reset and display the present input value.

P c t O Percent Output Feature: Select O n or OFF .

O n When selected O n , the HOME lower display will indicate the output of

the controller in percent. The “%” indicator lamp will light and an “o ” will

appear in the right hand side of the lower display to indicate percent

output for SP1. An “õ ” will appear on the right hand corner of the lower

display to represent percent output for SP2, if the control is so

equipped. The display will alternate between these values.

O F F Percent Output display is disabled.

May, 2013 Page 28 of 52 949-1194 Rev. 7

Page 29

P r o 9 Ramp/Soak: Select O n or OFF

O n Allows Programmed Ramp/Soak function to be started by the Run/Hold

key on the control front panel.

O F F Turns Ramp/Soak function OFF and resets program to beginning.

P S E t Programmer function set: Select On or OF F .

O F F Skip Ramp/Soak Programming. Go to next Secondary Menu Item, InPC

(next page).

O n Enable Ramp/Soak Programming.

S t A t Programmer Status Display in the Primary Menu when Prog (above) is On:

Select O n or OFF.

O F F The Primary Menu operates as normal.

O n The Primary Menu is altered to have the following items inserted before

the SP1 menu item:

#### t i time remaining in active segment

#### ##t i total time in active segment

#### ##S P segment target set point

t b A S Ramp/Soak Time Base: Select 1 _ S or 6 0 _ S .

1 _ S Ramp/Soak time base is in 1 second increments. Program time 1 t i ...1 6 t i

is measured in seconds.

6 0 _ S Ramp/Soak time base is in 60 second increments (minutes). Program

time 1 t i . . . 1 6 t i is measured in minutes.

The following items repeat in the following order: 1 t i , 1 S P , 1 A 1 and 1A2 (if A L 1 is

programmed as E U n t ), 2 t i , 2 S P , 2 A 1 , 2 A 2 ,..., 1 6 t i , 1 6 S P , 1 6 A 1 16A2 ,. To avoid repetition

each item will only be described once.

1 t i Segment Time: Select 0 to 9 9 9 9 units (minutes if tb A S is set to 60_S , seconds if

t b A S is set to 1_S ).

1 S P Segment Set Point: Set to target value desired.

1 A 1 Segment Alarm 1 Event: Select O n or OF F .

O n Alarm 1 is active during segment 1 time (1 t i ).

O F F Alarm 1 is inactive during segment 1 time (1 t i ).

1 A 2 Segment Alarm 2 Event: Select On or O F F .

O n Alarm 2 is active during segment 1 time (1 t i ).

O F F Alarm 2 is inactive during segment 1 time (1 t i ).

P E n d Program End action: Select Hold or Oo F F .

H o l d Stay at the Present Set Point (1 6 S P ).

O o F F Turn Off SP1 and SP2 Outputs at the end of the program.

L o o P Repeat program starting at 1ti.

S P 1 Revert to S P 1 value.

May, 2013 Page 29 of 52 949-1194 Rev. 7

Page 30

I n P C Input Correction: Select - 5 0 0 to 0 to 50 0 °F, °C, or counts. This feature allows

the input value to be changed to agree with an external reference or to

compensate for sensor error. Note: In P C is reset to zero when the input type is

changed, or when decimal position is changed. Factory default is 0 .

F i L t Digital Filter: Select O F F , 1 to 9 9 . In some cases the time constant of the sensor,

or noise, could cause the display to jump enough to be unreadable. A setting of 2

is usually sufficient filtering (2 represents approximately a 1 second time

constant). When the 0.1 degree resolution is selected this should be increased to

4. If this value is set too high, controllability will suffer.

L P b r Loop Break Protection: Select O F F , 1 to 9 9 9 9 seconds. If, during operation, the

output is minimum (0%) or maximum (100%), and the input moves less than 5°F

(3°C) or 5 counts over the time set for L P b r , the L O O P b A d message will appear.

This condition can also be routed to an Alarm Condition if alarms are present and

turned On (see A L b r in the Secure Menu). The loop break error can be reset by

pressing the ENTER key when at the L P b r menu item. The INDEX

& ENTER keys may also be used.

P O L (Option 934, 936, Analog Retransmission Output) Process Output Low: Select -

450°F, -260°C, or -1999 counts to any value less than PO H .

P O H (Option 934, 936, Analog Retransmission Output) Process Output High: Select

from any value greater than P O L to +9999°F, +5530°C, or 9999 counts.

P O S r (Option 934, 936, Analog Retransmission Output) Process Output Source: Select

I n P or SPt.

I n P Output follows the Process Variable (input).

S P t Output follows the Set Variable.

r S P t (Option 924, 926, 928, Analog Remote Set Point) Remote Set Point: Select On

or O F F .

O F F The control uses the value set for S P 1 .

O n The control uses the value set by the analog remote set point signal as

established by the Secure Menu items r S C L and rS C H . If the analog

signal fails, the control will display the error message C H E C rS P t and

revert to the S P 1 local value.

May, 2013 Page 30 of 52 949-1194 Rev. 7

Page 31

L O r E (Option 992, 993, 995, 996, Serial Communications) Local / Remote Status:

Select L O C or rE. Does not affect other instruments on daisy chain.

L O C The host computer is advised that remote write commands will be

rejected. Any write commands sent to this control will be rejected. All

read commands are accepted.

r E The host computer is allowed to send write commands. If the control is

not addressed within the time set in n A t (No Activity Timer in the Secure

Menu) the C H E C lor E error message will be displayed.

A d d r (Option 992, 993, 995, 996, Serial Communications) Control Address: Display

address from 1 to 3 F F for Options 992 and 993. Display address from 1 to F F for

options 995 and 996.. This number (hexadecimal, base 16) must match the

address number used by the host computer. Not settable in this menu. To

change this parameter, see Ad d r in the Secure Menu.

SECURE MENU

Hold UP ARROW & ENTER for 5 Seconds. Press INDEX to advance to the

next menu item. Press UP ARROW or DOWN ARROW to change the value in

the display. Press ENTER to retain the value.

OUTPUTS ARE DISABLED (TURNED OFF) WHILE CONTROL IS IN SECURE MENU.

S E C r Security Code: See the Security Level Selection and the Password Table in this

manual, in order to enter the correct password.

May, 2013 Page 31 of 52 949-1194 Rev. 7

Page 32

I n P Input Type: Select one of the following. Refer to the Wiring section for the proper

wiring.

J - I C Type “J” Thermocouple

C A Type “K” Thermocouple

E - Type “E” Thermocouple

t - Type “T” Thermocouple

L - Type “L” Thermocouple

n - Type “N” Thermocouple

r - 1 3 Type “R” Thermocouple

S - 1 0 Type “S” Thermocouple

b - Type “B” Thermocouple

C - Type “C” Thermocouple

P 3 9 2 100 ohm Platinum (NIST 0.00392 Ω/Ω/°C)

n 1 2 0 120 ohm Nickel

P 3 8 5 100 ohm Platinum (IEC/DIN 0.00385 Ω/Ω/°C)

1 P 3 8 1000 ohm Platinum (IEC/DIN 0.00385 Ω/Ω/°C)

C u r r DC Current Input 0.0 to 20.0 or 4.0 to 20.0 mA.

U o L t DC Voltage Input 0.0 to 10.0 or 1.0 to 10.0 volts.

d i F F DC Voltage Input -10 to +10 mV.

- - - - Reserved

O S U P Zero Suppression: Select On or O F F . Only with Current and Voltage input types.

O F F The input range will start at 0 (zero) Input.

O n The input range will start at 4.00 mA or 1.00 V.

U n i t F , C or n o n E .

F °F descriptor is On and temperature inputs will be displayed in actual

degrees Fahrenheit.

C °C descriptor is On and temperature inputs will be displayed in actual

degrees Celsius.

n o n E °F and °C descriptors will be Off. This is only available with Current and

Voltage Inputs.

d P t Decimal Point Positioning: Select 0 , 0 . 0 , 0 . 0 0 , 0 . 0 0 0 , o r . 0 0 0 0 . On

temperature type inputs a change here will alter the Process Value, SP1, SP2,

ALLo, ALHi, and InPC. For Current and Voltage Inputs all Menu Items related to

the Input will be affected.

0 No decimal Point is selected. This is available for all Input Types.

0 . 0 One decimal place is available for Type J, K, E, T, L, RTD’s, Current and

Voltage Inputs.

0 . 0 0 Two decimal places is only available for Current and Voltage Inputs.

0 . 0 0 0 Three decimal places is only available for Current and Voltage inputs.

May, 2013 Page 32 of 52 949-1194 Rev. 7

Page 33

I n P t Input Fault Timer: Select OFF, 0. 1 to 540.0 minutes. Whenever an Input is out of

range (U F L or OFL displayed), shorted, or open, the timer will start. When the

time has elapsed, the controller will revert to the output condition selected by

I n P b below. If OF F is selected, the Input Fault Timer will not be recognized (time

= infinite).

S E n C Sensor Rate of Change: Select OFF, 1 to 4 0 0 0 °F, °C, or counts per 1 second

period. This value is usually set to be slightly greater than the fastest process

response expected during a 1 second period, but measured for at least 2

seconds. If the process is faster than this setting, the S E n C b A d error message

will appear. The outputs will then be turned off. This function can be used to

detect a runaway condition, or speed up detection of an open thermocouple.

Use the INDEX & ENTER keys to reset.

S C A L Scale Low: Select 100 to 11998 counts below S C A H . The total span between

S C A L and SCA H must be within 11998 counts. Maximum setting range is -1999

to +9999 counts. For Current and Voltage inputs, this will set the low range end.

Value not adjustable for Thermocouple and RTD ranges.

S C A H Scale High: Select 100 to 11998 counts above S C A L . The total span between

S C A L and SCA H must be within 11998 counts. Maximum setting range is -1999

to +9999 counts. For Current and Voltage inputs, this will set the high range end.

Value not adjustable for Thermocouple and RTD ranges.

S P L Set Point Low: Select from the lowest input range value to S P H value. This will

set the minimum SP1 or SP2 value that can be entered. The value for SP1 or

SP2 will stop moving when this value is reached.

S P H Set Point High: Select from the highest input range value to S P L value. This will

set the maximum SP1 or SP2 value that can be entered. The value for SP1 or

SP2 will stop moving when this value is reached.

S 1 S t Set Point 1 State: Select d i r or rE .

d i r Direct Action. As the input increases the output will increase. Most

commonly used in cooling processes.

r E Reverse Action. As the input increases the output will decrease. Most

commonly used in heating processes.

May, 2013 Page 33 of 52 949-1194 Rev. 7

Page 34

If O u t 1 (Page 19) is set for ##t P , # P U L , or P r o P , then S 1 O L and S 1 O H appear. If O u t 1 is set

for O n O F , then skip to S 1 r E .

S 1 O L Set Point Output Low Limit: Select 0 to 100% but not greater than S1O H . This

item limits the lowest output value. This is useful for adding a bias to the process

when needed. Factory set to 0 for output codes 1 and 3. Factory set to 20 for

output code 5 (20% output equals 4 mA output).

S 1 O H Set Point 1 Output High Limit: Select 0 to 100% but not less than S1O L for output

codes 1 and 3. Select 0 to 102% but not less than S1O L for output code 5. This

item allows setting the maximum output limit. This is useful with processes that

are over powered. Adjustment to 102% allows setting current output to force a full

on condition for output devices which do not have bias adjustments. Factory set

to 1 0 0 for all output codes.

If O u t 1 is set for ##t P , # P U L , or P r o P , then skip to S 1 L P (next page).

If O u t 1 is set to OnO F (in the Secondary Menu), then the next three menu items can make

the S P 1 and SP1d settings act like a high or low alarm set point. See the information on

alarm settings and the cautions and warnings

that apply to them on Pages 36-37.

Note that when Set Point 1 Power Interrupt , S 1 P i is On, and Set Point 1 Reset, S 1 r E , is

programmed to H o L d , the SP1 output will automatically reset upon a power failure and

subsequent restoration, if the process is below S P 1 .

S 1 r E Set Point 1 Reset. Select O n O F or Ho L d .

O n O F Output will automatically reset when process passes back through SP1d.

H o L d Manual Reset. Reset (acknowledge) by simultaneously pressing the

INDEX & DOWN ARROW keys for 3 seconds.

S 1 P i Set Point 1 Power Interrupt. Select O n or O F F .

O n Alarm Power Interrupt is O n . Output will automatically reset on

power-up if no alarm condition exists.

O F F Alarm Power Interrupt is O F F . Output will be in the alarm condition on

power-up regardless of condition of process.

S 1 i H Set Point 1 Inhibit: Select O n or O F F .

O n Alarm Inhibit is O n . Alarm action is suspended until the process value

first enters a non-alarm condition.

O F F Alarm Inhibit is O F F .

S 1 L P Set Point Lamp: Select O o n or OoFF .

O o n Lamp ON when Output is ON.

O o F F Lamp OFF when Output is ON.

May, 2013 Page 34 of 52 949-1194 Rev. 7

Page 35

If your control is not equipped with Set Point 2, then proceed to the alarm section

(next page).

S 2 t Set Point 2 type: Select A b S or dE .

A b S Absolute S P 2 . S P 2 is independent of S P 1 , and may be set anywhere

between the limits of S P L and SPH.

d E Deviation S P 2 . S P 2 is set as a deviation from S P 1 , and allows S P 2 to

retain its relationship with S P 1 when SP1 is changed (SP 2 tracks SP1).

S 2 S t Set Point 2 State: Select dir or rE .

d i r Direct Action. As the input increases the output will increase. Most

commonly used in cooling processes.

r E Reverse Action. As the input increases the output will decrease. Most

commonly used in heating processes.

If O u t 2 is set for ##t P , # P U L , or P r o P , then S 2 O L and S 2 O H appear. If O u t 2 is set for

O n O F , then skip S 2 O L and S 2 O H .

S 2 O L Set Point Output Low Limit: Select 0 to 10 0 % but not greater than S 2 O H . This

item limits the lowest output value. This is useful for adding a bias to the process

when needed. Factory set to 0 for output codes 1 and 3. Factory set to 20 for

output code 5 (20% output equals 4 mA output).

S 2 O H Set Point 2 Output High Limit: Select 0 to 10 0 % but not less than S 2 O L for output

codes 1 and 3. Select 0 to 102% but not less than S2O L for output code 5. This

item allows setting the maximum output limit. This is useful with processes that

are over powered. Adjustment to 102% allows setting current output to force a full

on condition for output devices which do not have bias adjustments. Factory set

to 1 0 0 for all output codes.

If O u t 2 is set to OnO F (in the Secondary Menu), then the next three menu items can make

the S P 2 and SP2d settings act like a high or low alarm set point. See the information on

alarm settings and the cautions and warnings that apply to them on the next pages.

Note that when Set Point 2 Power Interrupt , S 2 P i is On, and Set Point 2 Reset, S 2 r E , is

programmed to H o l d , the SP2 output will automatically reset upon a power failure and

subsequent restoration, if the process is below S P 2 .

May, 2013 Page 35 of 52 949-1194 Rev. 7

Page 36

S 2 r E Set Point 2 Reset. Select O n O F or Hol d .

O n O F Output will automatically reset when process passes back through

S P 2 d .

H o l d Manual Reset. Reset (acknowledge) by simultaneously pressing the

INDEX & DOWN ARROW keys for 3 seconds.

S 2 P i Set Point 2 Power Interrupt. Select O n or OFF.

O n Alarm Power Interrupt is O n . Output will automatically reset on power-

up if no alarm condition exists.

O F F Alarm Power Interrupt is O F F . Output will be in the alarm condition on

power-up regardless of condition of process.

S 2 i H Set Point 2 Inhibit: Select O n or OFF.

O n Alarm Inhibit is O n . Alarm action is suspended until the process value

first enters a non-alarm condition.

O F F Alarm Inhibit is O F F .

S 2 L P Set Point 2 Lamp: Select Oon or O o F F .

O o n Lamp ON when Output is ON.

O o F F Lamp OFF when Output is ON.

ALARM TYPE AND ACTION (if alarm function is present)

Caution: In any critical application where failure could cause expensive

product loss or endanger personal safety, a redundant limit controller is

required.

When setting an alarm value for an absolute alarm (A 1 t = AbS ), simply set the value at

which the alarm is to occur.

When setting the alarm value for a deviation alarm (A 1 t = dE), set the difference in value

from the Set Point desired. For example if a low alarm is required to be 5 degrees below

the Set Point, then set A 1 L o to -5 . If a high alarm is required 20 degrees above the Set

Point, then set A 1 H i to +20. If the Set Point is changed, the alarm will continue to hold the

same relationship as originally set.

May, 2013 Page 36 of 52 949-1194 Rev. 7

Page 37

The diagram below shows the action and reset functions for both absolute and deviation

alarms.

D = 1 degree F, 1 degree C, or 1 count.

Note that when Alarm Power Interrupt, A1 P i , is programmed O n and Alarm Reset, A1 r E , is

programmed for H o l d , the alarm will automatically reset upon a power failure and

subsequent restoration if no alarm condition is present.

If Alarm Inhibit, A1 i H , is selected O n , an alarm condition is suspended upon power up until

the process value passes through the alarm set point once. Alarm inhibit can be restored

as if a power up took place by pressing both the INDEX & ENTER keys for 3

seconds.