Page 1

ulletin G-29

7

1

2

11

6

8

9

4

3

10

5

B

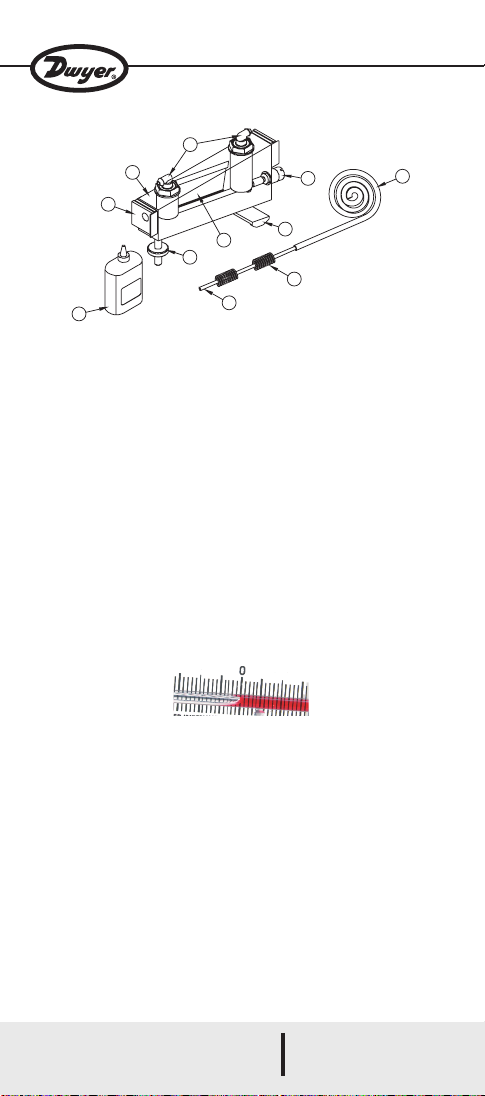

Series 170, 171 & 172 Inclined Draft Gages

Operating Instructions and Parts List

1. Gage body

2. Molded nylon rapid shut-off connector, Cat.No. A-315

3. Zero adjust screw

4. Gage stand with screw and washer

5. Scale

6. Leveling screw

7. Magneclip assembly, Cat. No. A-344

9. Spring type holder for terminal tube or thermometer, Cat. No. A-357

10. Rubber tubing, 9 ft. length, Cat. No. A-201

11. Red gage fluid, 1 oz bottle, Cat. No. A-101

TO OPERATE

1. Place gage on a horizontal surface with the gage stand

perpendicular to the body or attach to a vertical steel surface using

Magneclips.

2. Open both Nylon connectors by turning the elbows 1/2 to 3/4 turns

counterclockwise. This will vent the gage.

3. Level the gage by centering the bubble in the level vial. Use the

leveling screw on horizontal surfaces or shift the gage on vertical

surfaces when using Magneclips.

4. Turn the zero adjust screw to set the leading edge of the meniscus

on zero. Align the meniscus with its reflected image to eliminate

parallax error, as shown below.

5. If unable to adjust to zero using the zero adjust screw, add or

remove gage fluid as required. Either of the Nylon rapid shut-off

connectors must be removed to do this.

6. For draft reading, first connect one end of the rubber tubing to the

terminal tube and the other to the right hand gage connector Insert

the terminal tube either over the fire in the combustion chamber or in

the smoke pipe (stack) between the furnace and the draft control.

When reading positive pressures attach tubing to the left connector.

7. Allow a few seconds for fluid to drain and read amount of draft

directly. Adjust controls as needed.

CAUTION:

Use only Dwyer®.826 sp. gr. red gage fluid. Clean only with mild soap

and water. Other fluids, solvents or cleaning agents may damage the

gage.

Copyright 2013 by Dwyer Instruments Inc. Printed in U.S.A. 5/13

DWYER INSTRUMENTS, INC.

P.O. BOX 373

MICHIGAN CITY, IN 46360,U.S.A

Phone: 219/879-8000

Fax: 219/872-9057

www.dwyer-inst.com

e-mail: info@dwyer-inst.com

Page 2

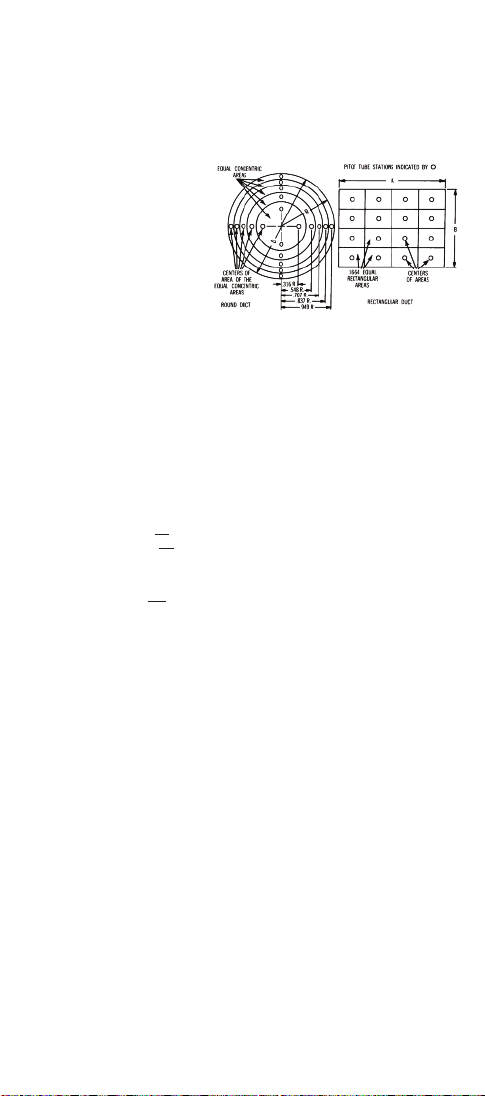

The total pressure of an air stream flowing in a duct is the sum of the static

or bursting pressure exerted upon the sidewalls of the duct and the impact

or velocity pressure of the moving air. Through the use of a pitot tube

connected differentially to a manometer, the velocity pressure alone is

indicated and the corresponding air velocity determined.

For accuracy of plus or minus 2%, as in laboratory applications, extreme

care is required and the following precautions should be observed:

. Duct diameter 4˝ (8.64 mm) or

1

greater.

2. Make an accurate traverse per

ketch at right and average the

s

readings.

3. Provide smooth, straight duct

ections 10 diameters in length

s

both upstream and downstream

from the pitot tube.

. Provide an egg crate type

4

straightener upstream from

the pitot tube.

In making an air velocity check, select a location as suggested above,

connect tubing leads from both pitot tube connections to the manometer

and insert in the duct with the tip directed into the air stream. If the

manometer shows a minus indication reverse the tubes. With a direct

reading manometer, air velocities will now be shown in feet per minute. In

other types, the manometer will read velocity pressure in inches of water

and the corresponding velocity will be found from the curves in Bulletin H-

11. If circumstances do not permit an accurate traverse, center the pitot

tube in the duct, determine the center velocity and multiply by a factor of

.9 for the approximate average velocity. Field tests run in this manner

should be accurate within plus or minus 5%.

The velocity indicated is for dry air at 70°F (21.3°C), 29.9˝ Barometric

Pressure and a resulting density of .075=/cu. ft. For air at a temperature

other than 70°F, refer to the curves in Bulletin H-11. For other variations

from these conditions, corrections may be based upon the following data:

Air Velocity=1096.7 Pv

where Pv=velocity pressure in inches of water

D=Air density in lbs/cu. ft.

Air Density=1.325 x PB

where PB = Barometric Pressure in inches of mercury

T = Absolute Temperature (indicated temperature plus 460)

Flow in cu. ft. per min. = Duct area in square feet x air velocity in ft.

In checking inlet and discharge fan and blower pressures, balancing

ventilation and dust collection systems, checking exhaust systems and

similar installations, air velocities above 700 ft. per min. (12.81 kms/hr)

can cause an appreciable error. It is recommended that the static

connection of the pitot tube or a static pressure tip be used. In using the

static pressure tip or pitot tube, the tip should be directed into the air

stream. For permanent installation, static pressure tips are recommended.

If not available, make connections, enter the duct perpendicular to the air

stream and finish off flush and smooth on the inside.

Connect the terminal tube to the minus pressure gage opening and insert

it into the combustion chamber for over fire draft reading. If a drilled port

is not available insert through fire door but seal the crack. For last pass or

smoke pipe draft, connect into the breeching on the furnace side of any

draft control or damper. To determine draft loss through the furnace, make

connection as indicated for smoke pipe draft and add a second tube,

connecting the manometer differentially to the combustion chamber.

To determine the pressure drop across an air filter, connect the

manometer differentially with one tubing from the downstream or blower

side of the filter to the right hand or minus pressure gage connection. Run

the second tubing from the upstream side of the filter to the other gage

connection. Use static pressure tips if available, with the tips directed into

the air stream, to eliminate possibility of error due to air velocity. Read the

pressure drop across the filter in inches of water and follow the filter

manufacturer’s recommendations for filter cleaning or replacement.

AIR VELOCITY

√

D

T

per minute.

STATIC PRESSURE

FURNACE DRAFT

AIR FILTER TEST

FR# 36-440380-00 Rev. 3

Loading...

Loading...