Duro-Last Rock-Ply Membrane User Manual

A

1

1

A

r

DATA SHEET

Advantages:

Duro-Last

excellent choice for projects requiring a long lasting,

aesthetically appealing roofing membrane. The

membrane is available in prefabricated sections or as

roll goods. The complete line of Duro-Last custom

prefabricated accessories is compatible with the

Rock-Ply membrane.

Description:

®

50 mil Rock-Ply® membrane is an

DURO-LAST

®

ROCK-PLY® MEMBRANE

Rock-Ply membrane is composed of PVC film

laminated to both sides of a reinforcement fabric

(scrim).

PVC Film - Proprietary thermoplastic PVC

formulation of resins, plasticizers, stabilizers,

biocides, flame retardants, and U.V. absorbents. The

same PVC film is used on both sides of the scrim.

Rock-Ply PVC film above scrim – 21 mils

Dark Gray PVC film below scrim – 17 mils

Scrim - An 18 x 14 polyester fabric construction

composed of 840 x 1000 denier threads provides

superior tear and puncture resistance. The polyester

thread is treated to prevent wicking.

Total Thickness – 50 mil, nominal.

Weight – 0.29 lb. per sq. ft.

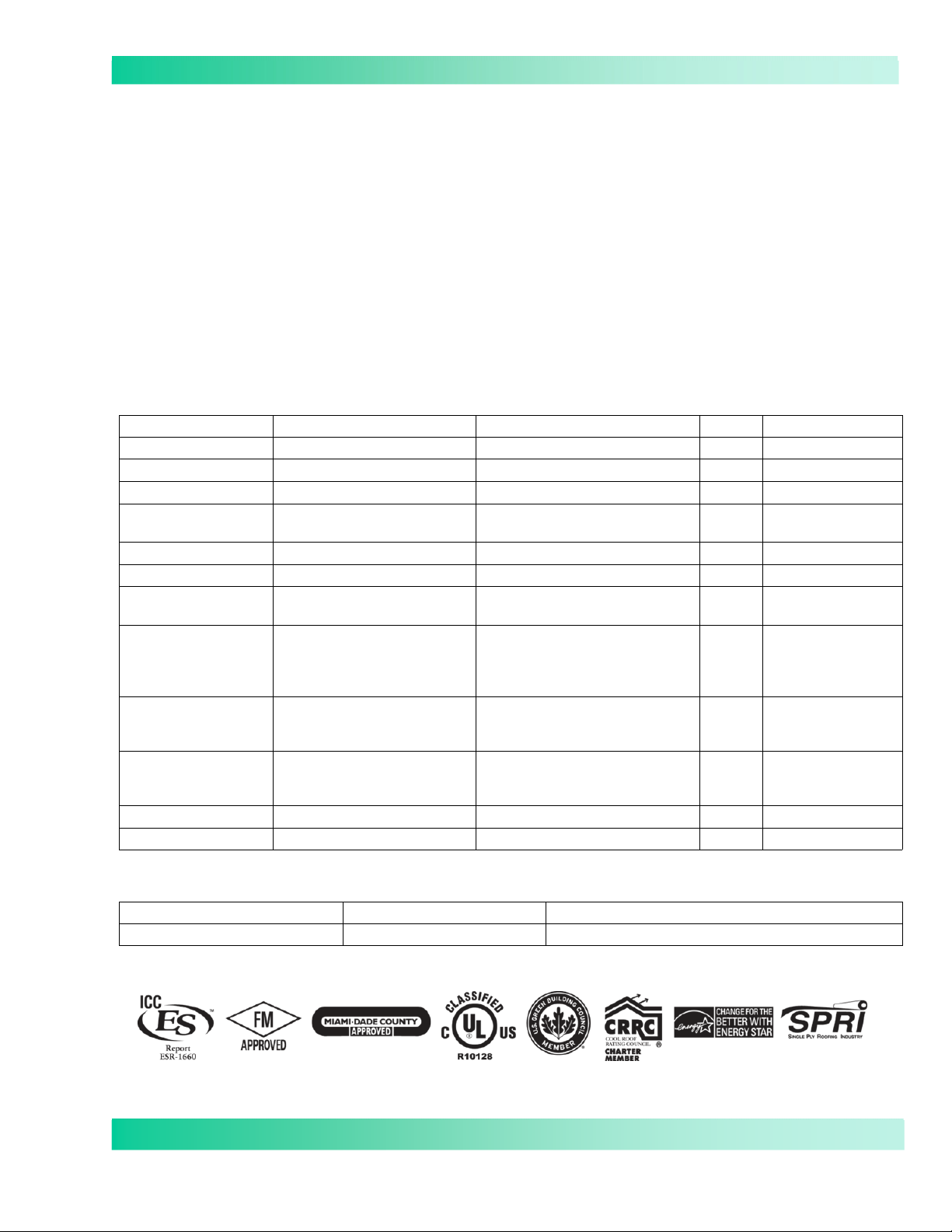

Available Configurations:

Prefabricated Sections – Rock-Ply is available in

prefabricated sections up to 2,000 sq. ft. with a

maximum 80 ft. in either dimension.

Cool Roof Rating Council (CRRC)

Rock-Ply

Duro-Last’s CRRC Product ID: 0610.

Solar

Reflectance

Initial 3-yr Initial 3-yr Initial 3-yr

0.30 0.27

Thermal

Emittance

0.87 0.90 31 28

1

Solar Reflective

Index (SRI)

Warranty:

The following warranties are available for projects

utilizing Rock-Ply membrane. Contact Duro-Last for

warranty details.

vailable Warranties

10 Yea

15 Year

20 Year

NDL

High Wind Hail High Wind + Hail

Material Only Residential

NDL

High Wind 15 + 5 15 + 5 Material

Pro-Rated Material Only Residential

Material Only

Roll Good – Typical Dimensions

Width

64 inches 100 ft. 533 sq. ft. 155 lb. 483 sq. ft.

48 inches 100 ft. 400 sq. ft. 116 lb. 350 sq. ft.

32 inches 100 ft. 267 sq. ft. 77 lb. 216 sq. ft.

16 inches 100 ft. 133 sq. ft. 39 lb. 83 sq. ft.

Assuming 6 inch overlap.

Length

(max.)

Roll

Area

Approx.

Weight

pprox.

Coverage

1

Codes and Standards:

Underwriters Laboratories (US & Canada),

FM Approvals, ICC-ES (ESR-1660), Canadian

Construction Materials Centre (CCMC 13299-L),

State of Florida, Miami-Dade County, Texas

Department of Insurance (TDI).

Storage:

Store rolls on their sides and on pallets. Use tarps

to keep rolls dry.

www.duro-last.com

“Duro-Last”, “World’s Best Roof”, “Rock-Ply” and “Duro-Bond” are registered marks owned by Duro-Last, Inc. 2/25/2013

800-248-0280

1 of 2

ROCK-PLY® MEMBRANE

1

Membrane Attachment:

Mechanically Fastened – Rock-Ply membrane may be mechanically attached to a variety of roof deck and wall

materials. An appropriate slip sheet or cover board may be required. Refer to the Duro-Last Mechanically

Fastened Systems Specification for system requirements.

Duro-Bond

®

System – The Duro-Bond system (inductive weld) may be used to attach Rock-Ply membrane.

Refer to the Duro-Last Duro-Bond System Specification for system requirements.

Adhered – Rock-Ply membrane may be adhered to a variety of properly prepared roof decks, walls, cover

boards and insulations including Duro-Guard™ ISO products, DensDeck

®

Prime Roof Board and SECUROCK

Gypsum-Fiber Roof Board. Refer to the Duro-Last Adhered Systems Specification for system requirements.

Physical Properties:

Rock-Ply membrane has been subjected to the tests required by ASTM 4434 “Standard Specification for Poly

(Vinyl Chloride) Sheet Roofing” and has been classified as a Type III, internally reinforced sheet. The results of

each test as well as typical values are listed below.

Physical Property Test Method ASTM 4434 Requirement Result Typical Value

Overall Thickness

Breaking Strength1

Elongation1

Seam Strength

Tear Strength1

Low Temp. Bend

Heat Aging

Accelerated Aging

Dimensional Stability1

Water Absorption

Static Puncture

Dynamic Puncture

Typical values are shown for both machine and cross machine directions. The machine direction results are listed first.

ASTM D751

ASTM D751 Grab Method

ASTM D751 Grab Method

ASTM D 751 Grab Method

ASTM D751 Procedure B

ASTM D2136

ASTM D3045

ASTM G154

(formerly G53)

ASTM D1204

ASTM D570

ASTM D5602

ASTM 5635

0.045 in.

200 lbf./in.

15%

292 lbf x 328 lbf

(75% of Breaking Strength)

45 lbf

Must Pass at – 40 F

Conditioned for 56 days in oven

maintained at 176 F

5,000 hour total test time.

Irradiance level of 0.68 W/m2-nm.

Cycle: 8 hour at 145 F,

4 hour condensation at 122 F

Conditioned for 6 hours in oven

maintained at 176 F.

Allowable change: ≤ 0.5%

Immersed in water at 158 F

for 168 hours.

Allowable Weight Change: ≤ 3%

33 lbf

14.7 ft-lbf (20 J)

PASS 50 mil, nominal

PASS

PASS

PASS 417 lbf

PASS

PASS PASS

PASS PASS

PASS PASS

PASS

PASS 1.7%

PASS 56 lbf

PASS

390 lbf x 438 lbf1

31% x 31%1

132 lbf x 163 lbf1

-0.30% x -0.45%1

14.7 ft-lbf (20 J)

Additional Tests

Fungi Resistance

Moisture Vapor Transmission

ASTM E96, Proc. B, Method A < 0.22 U.S. Perms

ASTM G-21 No Sustained growth or discoloration

®

www.duro-last.com

“Duro-Last”, “World’s Best Roof”, “Rock-Ply” and “Duro-Bond” are registered marks owned by Duro-Last, Inc. 2/25/2013

800-248-0280

2 of 2

Loading...

Loading...