Duro-Last Duro-Grip Weather-Tite Hurricane Force PG-1 User Manual

®

Hurricane Force

PG-1 Pump Grade

Insulation Adhesive

PRODUCT DESCRIPTION

Weather-Tite Hurricane Force PG-1 Pump Grade Insulation

Adhesive is a two component, VOC free, all purpose, low

rise, bulk packaged, polyurethane foamable adhesive that

contains no solvents and sets in minutes.

Application is quick and easy resulting in signicant

labor savings for the contractor. Hurricane Force PG-1

Insulation Adhesive is dispensed through the WeatherTite Cyclone and Cyclone II pumps or an approved low

pressure pump cart which equally mixes Part 1 and Part

2 of the adhesive, thus providing a quality, consistent

application each time.

BASIC USE

Hurricane Force PG-1 Insulation Adhesive is designed for

use as an adhesive for bonding approved roof insulations

to a building’s structural roof deck, base sheets, other

insulation boards, and smooth or graveled built-up roof

surfaces. It is dispensed in 1/2” to 3/4” (1.27cm - 1.91cm)

wide liquid beads that will quickly spread to a width of

2-3 inches. Hurricane Force PG-1 Insulation Adhesive will

expand and rise to ll minor surface irregularities.

APPROVED INSULATIONS AND SUBSTRATES

HD wood ber•

Polyisocyanurate•

Perlite•

Polystyrene•

Gypsum cover boards•

Asphaltic cover boards•

Concrete•

Gypsum•

Cemetitious wood ber•

Lightweight insulating •

concrete

Wood or steel•

Modied Bitumen •

me mb rane s and base

sheets (sanded or granule

surfaced)

Approved insulations • (mu l ti-

layer applications)

Smooth or gravel surface •

built-up roof (re-roof

applications)

FEATURES AND BENEFITS

Better Than Fasteners

No damage to structural •

decking

Eliminates fastener back out •

No noise associated with •

drilling into concrete

No unsightly fasteners on •

exposed decks

No fastener or deck corrosion•

Saves labor•

High strength•

Low Rise Foam

Eliminates •

minor surface

irregularities

No Solvents

Low odor•

VOC free•

No ame hazards•

100% solids•

APPLICATION

1. Extend quick connect spouts in Part 1 and Part 2

box packaging. When using pails stir contents before

material is poured into the holding tanks on approved

pump machine.

2. Invert box and place in tray on the Weather-Tite Cyclone

or Cyclone II pump. Box labeled Part 1 must be in area

of tray labeled “Part 1” and Part 2 in area labeled “Part

2”.

3. If pails are used ll holding tanks as recommended by

pump manufacturer. Part 1 and Part 2 must be equally

mixed. If drums are used follow all recommendations

provided by pump manufacturer.

4. Connect the black Part 1 tting to the black feed hose

tting. Connect the gray Part 2 tting to the gray feed

hose tting. Operate pump according to manufacturer’s

instructions.

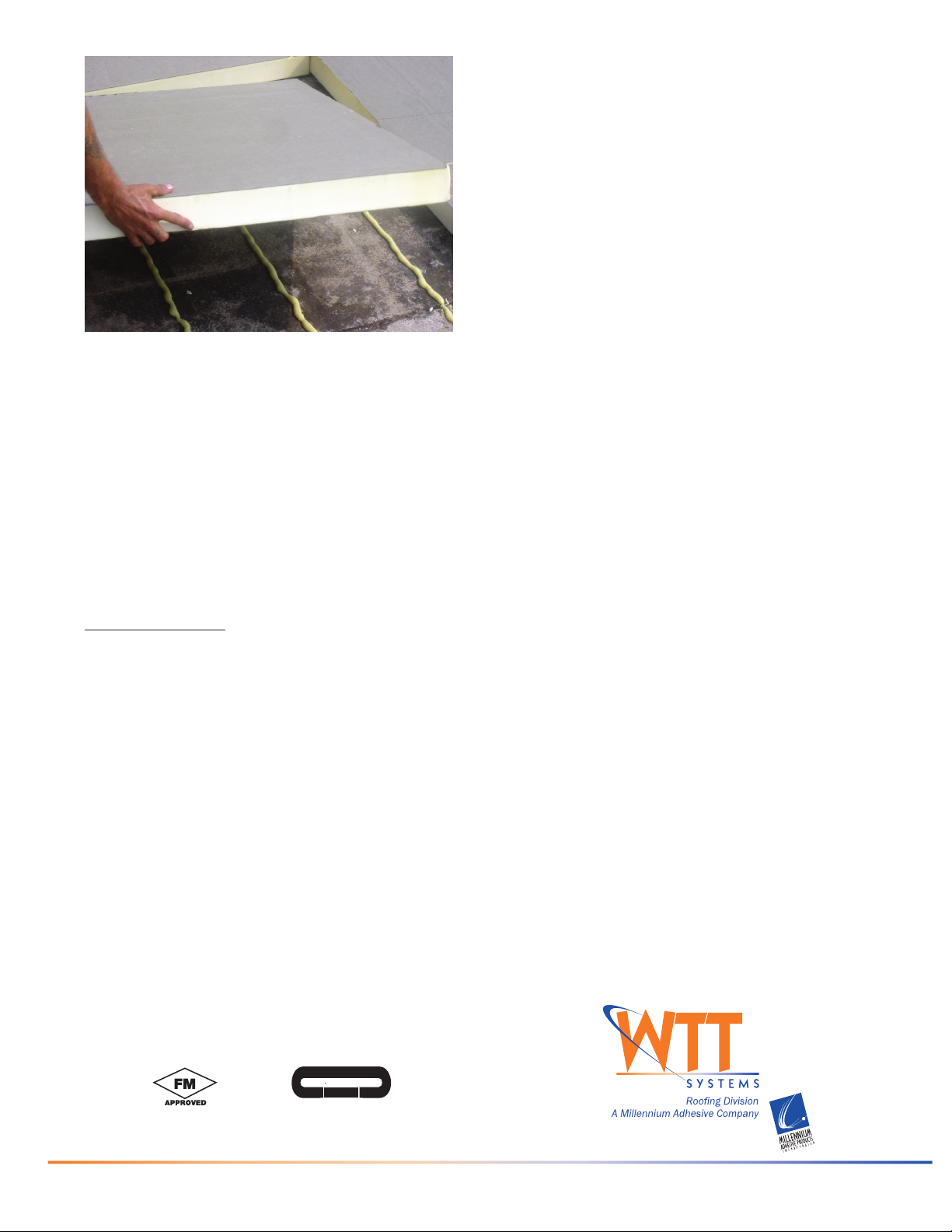

5. Apply Hurricane Force PG-1 Insulation Adhesive directly

to the substrate, using a ribbon pattern. Space beads

12” o.c., to achieve proper coverage rates for insulation

attachment.

6. Hurricane Force PG-1 Insulation Adhesive should be

approximately 70°F (22°C) when being dispensed. As

adhesive is applied, allow to begin rising, then place

insulation board into adhesive. Do not allow the adhesive

to skin over. Eliminate uneven surfaces to ensure

positive contact between the adhesive, insulation board,

and substrate.

7. Unused material can be applied at a later date. Properly

clean dispensing wand and pump unit according to

pump manufacturer’s recommendations.

For a complete list of approved substrates and insulation

types, or additional information, contact our Technical

Department.

WTT Systems - Roong Division n A Millennium Adhesive Company n 888.564.9733 n wttus.com

Weather-Tite Hurricane Force PG-1 Pump Grade Insulation

0 , $ 0 ,

'$ ' ( & 2 8 1 7 <

$3352 9 ('

"Subject to the conditions of Approval

when installed as described in the current

edition of the FM Approval Guide."

Adhesive eliminates the need for mechanical fasteners

SAFETY

Prior to working with any product, be sure to read

labels and the Material Safety Data Sheet (MSDS). Take

necessary health and safety precautions.

STORAGE

Keep temperature of contents between 45°F-95°F

(7°C-35°C). Bring temperature of material to

approximately 70°F (22°C) just before use. Do not store

in direct sunlight or high temperatures 95°F (35°C) and

higher. Store boxes valve side up.

KEEP FROM FREEZING

SURFACE PREPARATION

All work surfaces should be clean, dry, and free of dirt,

dust, debris, oils, loose and/or embedded gravel, unadhered coatings, deteriorated membrane and other

contaminants that may result in a surface that is not

sound or is uneven.

For re-cover applications apply Weather-Tite Universal

Primer prior to the application of Hurricane Force PG-1

Insulation Adhesive. For applications over fresh and/or

non-oxidized asphalt, coal tar or plastic lm membranes,

apply Weather-Tite Surface Treatment prior to the

application of Hurricane Force PG-1 Insulation Adhesive.

PACKAGING OPTIONS AND COVERAGE

Complete Kit:

Part 1 (A) - 5 gallon (18.9L) box

Part 2 (B) - 5 gallon (18.9L) box

Part 1 (A) - 5 gallon (18.9L) pail

Part 2 (B) - 5 gallon (18.9L) pail

Part 1 (A) - 50 gallon (189L) drum

Part 2 (B) - 50 gallon (189L) drum

Part “1” and Part “2” mixed through an approved low

pressure pump cart will produce the following coverage

rates:

5 gallon (18.9L) Kit: 2,000 - 2,500 sq.ft. (186m2 - 232m2)

50 gallon (189L) Kit: 20,000-25,000 sq.ft.

(18 60m2 - 2322m2)

Coverage estimates indicate total sq. ft. of insulation

attachment per kit. Rates are based on an application

pattern of 4 (four) 1/2” - 3/4” (1.27 - 1.91cm) ribbons

spaced 12” (30cm) o.c. per 4’ x 4’ (1.2m x 1.2m) insulation

board.

NOTE: A 1/2” - 3/4” (1.27cm - 1.91cm) wide uncured

adhesive bead will produce a 2” - 3” (5.08cm - 7.62cm) wide

cured adhesive bead that will rise approximately

3/4” - 1” (1.91cm - 2.54cm) above the substrate. Coverage

rates may vary when used over irregular surfaces and will

vary depending on roughness.

EQUIPMENT OPTIONS

Weather-Tite Cyclone and Cyclone II Pump machines•

Graco E-10 Reactor•

Graco Predator•

Adhesives Systems Technology GMP-075•

Adhesives Systems Technology PCH GMP-500 •

For a complete list of approved low pressure pump carts, or

additional information, contact our Technical Department.

WARRANTY

WTT Systems, LLC guarantees this product to be free

of manufactured defects for the shelf life period of 12

months from date of manufacture. All claims must be

made in writing within 12 months of the original purchase.

For detailed information regarding 10 year, 15 year or

20 year extended term system warranties, contact our

Technical Department.

LIMITATIONS

• Do not apply to a wet surface

• Not recommended for use with insulation boards larger

than 4’ x 4’ (1.2m x 1.2m)

• Do not use warped or curled insulation boards. All

insulation boards must lay at upon the roof surface

• Do not apply when temperatures are below 40°F (5°C)

Miami-Dade County, Florida

NOA No.:07-1015.02

Expiration date: 07/24/13

PG1SD0408-B

WTT Systems - Roong Division n A Millennium Adhesive Company n 888.564.9733 n wttus.com

09/08

Loading...

Loading...