Page 1

DURO-LAST® DURO-GRIP INSULATION ADHESIVE

Description:

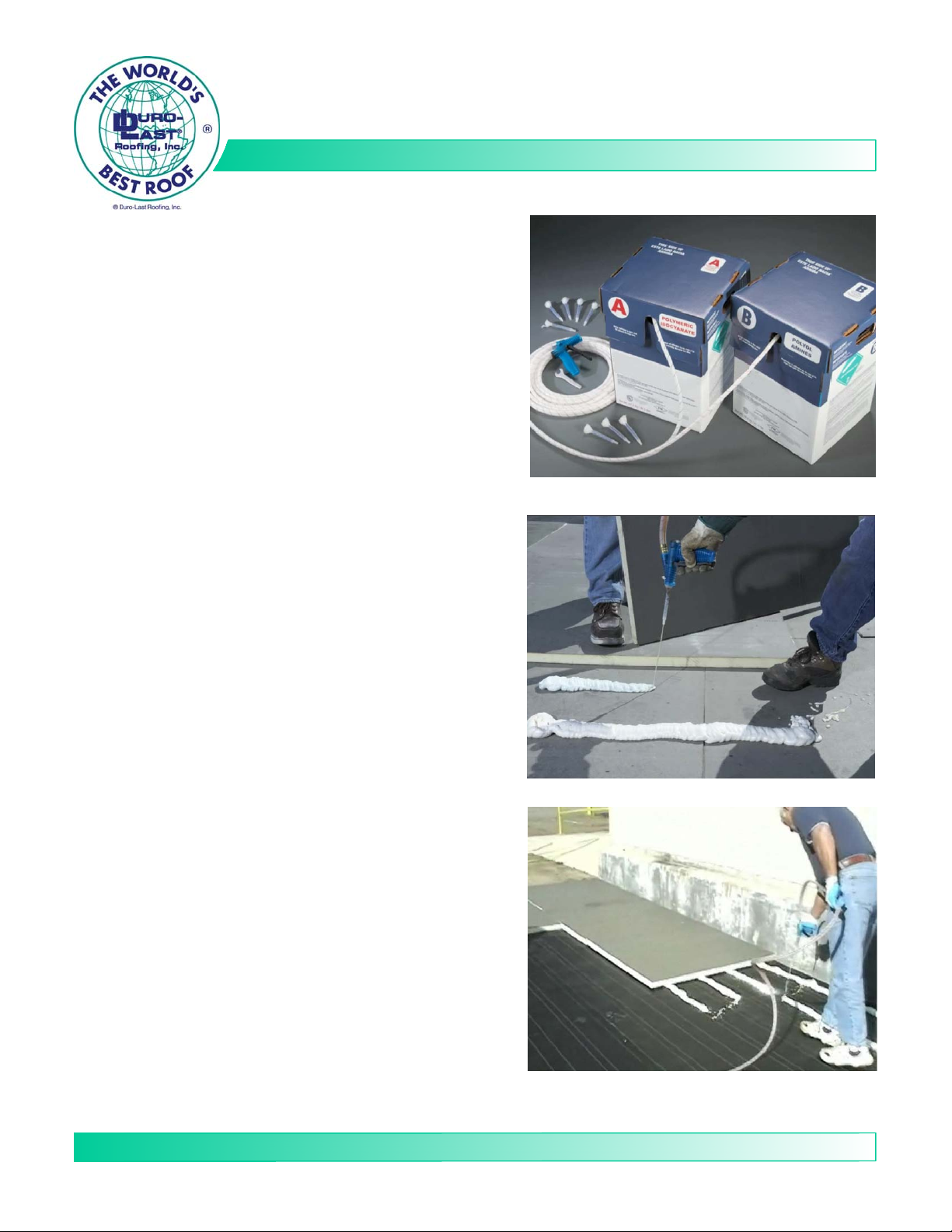

Duro-Grip™ Insulation Adhesive is a two component

elastomeric polyurethane froth adhesive designed to adhere

both insulation and cover boards to various substrates. It can

also be used to adhere insulation boards together where

multiple layers are required.

Duro-Grip is applied in bead form directly to an approved

substrate. The “A” and “B” components are dispensed from two

pre-pressurized disposable cylinders using the hose and nozzle

kit. The insulation or cover board is placed onto the adhesive

and a chemical cure takes place several minutes after

application depending on temperature and weather conditions.

DATA SHEET

Duro-Grip contains less than 250 g/L of Volatile Organic

Compounds (VOC) and meets all VOC restrictions and

regulations in the United States. See Table 1 for VOC

information.

Duro-Grip is ideal for use when mechanical fastener penetration

into the roof deck is undesirable. Duro-Grip is approved for use

with many roof deck substrates, insulation and cover boards.

Structural concrete (poured-in-place)

Structural concrete (precast)

Lightweight structural concrete (pull test required)

Insulating concrete (pull test required)

Cementitious wood fiber planks

Gypsum decks (pull test required)

Steel - 22 gauge or thicker ("B" deck profile)

Plywood and OSB

Polyisocyanurate (flat or tapered)

Expanded polystyrene (EPS, flat or tapered)

Extruded polystyrene (XPS, flat or tapered)

DensDeck Roof Board

SECUROCK Gyp sum -Fiber Board

Various aged built-up roofs (pull test required)

Vapor retarders (contact Duro-Last for approved

product list)

A/B Tank Kit, Ho se/Gun Kit, Wrench and Nozzles

Duro-Grip is applied to substrate in 2.5 inch beads

Material Safety Data Sheet:

1. Review MSDS sheets for both "A" and "B" components

before working with the product.

2. MSDS available at www.duro-last.com.

Duro-Last: The Proven Performer®

www.duro-last.com

"Duro-Last " an d " The World's Best Roof" are registered marks owned by Duro-Las t , Inc.

1 of 4

800-248-0280

May 20, 2010

Page 2

DURO-GRIP INSULATION ADHESIVE

Determining Bead Spacing:

1. Apply Duro-Grip per the "Directions for Use" section.

2. For any project located in an area with the design

wind speed greater than 120 mph or a roof deck

height greater than 100 feet, the Duro-Last

Engineering Services Department must determine

the bead spacing pattern to be used. Otherwise, use

the guidelines below.

3. The spacing between beads of Duro-Grip is less in

the perimeter area of the roof than in the main field

area to compensate for higher wind uplift pressures.

4. The width of the perimeter area is defined as the

lesser of either 40% of the building eave height or

10% of the lesser roof plan dimension, but in no case

less than 6 feet. The remainder of the roof is the field

area.

a. Perimeter area: apply beads 6 inches on center.

b. Field area: apply beads 12 inches on center.

5. Use the bead spacing above for all layers to be

applied with Duro-Grip.

6. Refer to Table 2 for the estimated coverage per each

A/B Tank Kit based on bead spacing.

Limitations:

1. Maximum size of insulation board to be attached with

Duro-Grip is 4 x 4 foot (1.2 x 1.2 m).

2. Maximum size of cover board to be attached with

Duro-Grip is 4 x 8 foot (1.2 x 2.4 m)

3. The product temperature must be between 70 °F and

90 °F (21 - 32 °C) when applied. This ensures that

the proper mixing ratio is maintained during

installation and will give the best yield per tank kit.

When the product temperature falls outside of this

range the tanks may take several hours to adjust to

an acceptable temperature. Therefore, keeping the

tanks in a warm environment overnight during cold

weather months and keeping the tanks from getting

to hot in the summer will avoid delays during

installation.

4. The substrate temperature that the product is applied

to must be at least 40 °F (5 °C) and rising.

5. Do not use during inclement weather.

6. Concrete and gypsum decks must be cured before

applying Duro-Grip.

Do not use on wet surfaces. Do not install

7.

Duro-Grip on a wet surface. Take whatever

precautions are necessary to ensure that the surface

is dry during the application and curing of the

Duro-Grip.

8. Do not use on any roof deck that shows signs of

deterioration or loss of integrity.

9. Do not use on excessively dirty or grease laden

surfaces.

10.Do not use after expiration date.

Storage and Handling:

1. The "A" and "B" containers should be stored between

45 and 95 °F (7 - 35 °C). The shelf life at these

temperatures is 18 months from the date of

production.

2. Follow instructions on the "A" and "B" boxes for

overnight and longer term storage.

TABLE 1. TYPICAL PROPERTIES - BY COMPONENT

Product

Base

Blowing Agent

Physical For m Liquid Liquid

Net Weight

(cylinder)

Specific Gravity

(77°F/25°C)

Color

Volatile Organic

Compounds (VOC)

VOC when used as

intended with both parts

Flash Point (TCC) >200 °F (> 93°C) >200 °F (> 93°C)

Auto Igniti o n

Temperature

Viscosity (77°F / 25 °C)

Mix Ratio 1.14 1

¹ Technical i n f o rmation and data should be conside re d represent ative

or typical only and should not be used for specification purposes.

TABLE 2. TYPICAL PROPERTIES - MIXED COMP O N ENTS

Proper ties Mixe d Component s

Open Time (2.5 inch bead)

Work L i fe in Mixing Nozzle

Time to Tack Free 5 - 12 minutes*

Time to Hand l ing Strength 4 - 8 minutes af ter bonding*

Time to Full Cure 24 hours

2.5 inch beads, 12 inches o.c.

(field area)

2.5 inch beads, 6 inches o.c.

(perimeter area)

* Times may be affected by temperature and weather conditions

A - Co mponent

Polymeric

Isocyanurate

134a 134a

40.0 lbs. 35.0 lbs.

1.23 1.1

Light Brown

0 g/L 135.6 g/L

>600 °F (> 315°C)

130 cps 150 cps

Coverage

¹ B - Co mponent¹

Polyol Amines

Amber To Brown

67.5 g/L

Not Determine d

1.5 - 5 minute s*

1 minute*

2,000 sq-ft per A/B T a nk Kit

1,000 sq-ft per A/B T a nk Kit

Duro-Last: The Proven Performer®

www.duro-last.com

"Duro-Last " an d " The World's Best Roof" are registered marks owned by Duro-Las t , Inc.

2 of 4

800-248-0280

May 20, 2010

Page 3

DURO-GRIP INSULATION ADHESIVE

Ordering Duro-Grip:

1. The following items are available when ordering.

a. A/B Tank Kit. (Item #1109) Each kit includes:

"A" & "B" Tank s

8 Nozzles

Wrench

Installation Instruction Sheet

b. Hose/Gun Kit. (Item #1109-001)

Order 1 for every 4 A/B Tank Kits.

c. Extra Nozzles, bag of 10 (Item #1109-002)

Directions for Use:

1. Application Surface and Temperatures:

a. For best results, all surfaces to be bonded must

be clean, dry and free from dirt, dust, oil, loose

paint, wax or grease, etc.

b. The temperature of the adhesive should be

between 70 - 90 ˚F (21 - 32 ˚C) and the surfaces

being bonded should be at 40 ˚F (4 ˚C) or above.

Temperatures outside this range may affect

bonding range, dispensability and performance of

the product.

2. Equipment Set Up:

a. There are two cylinder tanks per system: an “A”

cylinder that is RED and a “B” cylinder that is

BLUE. These two cylinders must have matching

fill dates to be used together.

b. The cylinders can only be used in the upright

position (never open the valves unless the

cylinders are upright).

c. The lids on the boxes are designed to shield the

cylinders from direct sunlight and keep the

product from getting too hot. For this reason, the

box lid should remain closed during use.

d. Using the wrench included in the nozzle pack,

connect the RED striped hose to the “A” cylinder.

e. Connect the BLACK striped hose to the “B”

cylinder.

f. Slowly open the cylinder valves and inspect the

connections for any leaks. Tighten if needed.

Fully open the valves.

g. Activate the trigger, dispensing into a proper

waste receptacle, until all the air is released from

the hoses and a good stream of both chemicals is

visible through the applicator orifices.

h. Clean residue from the output tips.

i. Attach the mixing nozzle to the applicator. Insert

the bottom tab of the nozzle into the bottom slot

of the applicator gun. Secure the top latch by

pushing towards the back of the applicator until it

www.duro-last.com

"Duro-Last " an d " The World's Best Roof" are registered marks owned by Duro-Las t , Inc.

3 of 4

“snaps” into the locked position.

3. Adhesive Test Spray:

a. When spraying for the first time or when starting

a new kit, it is recommended to trigger the gun

only ½ to ¾ open, until the desired output and

spray pattern is achieved. This controllable

metering ability is a major advantage of the gun,

allowing the user complete control of the flow rate

and spray pattern that best fits the application.

b. Apply several test shots on plastic or cardboard

before beginning the job.

Extremely Important - When spraying is stopped

c.

for more than 1 minute, the nozzle should be

removed and replaced with a new nozzle. The

chemical in the nozzle will begin to cure and will

clog the nozzle when spraying has stopped for

more than a few minutes. If the trigger is pulled

while a clogged nozzle is on the gun, the

chemical from the cylinders (which is under

pressure!) will be blocked by the clogged nozzle

and will cause a “back-up” of chemical into the

hoses, which is called a crossover . The gun will

no longer dispense chemicals in the right

proportions and the adhesive will not function

properly. This situation can be easily avoided by

simply changing nozzle when sprayi ng is stopped

for more than 1 minute.

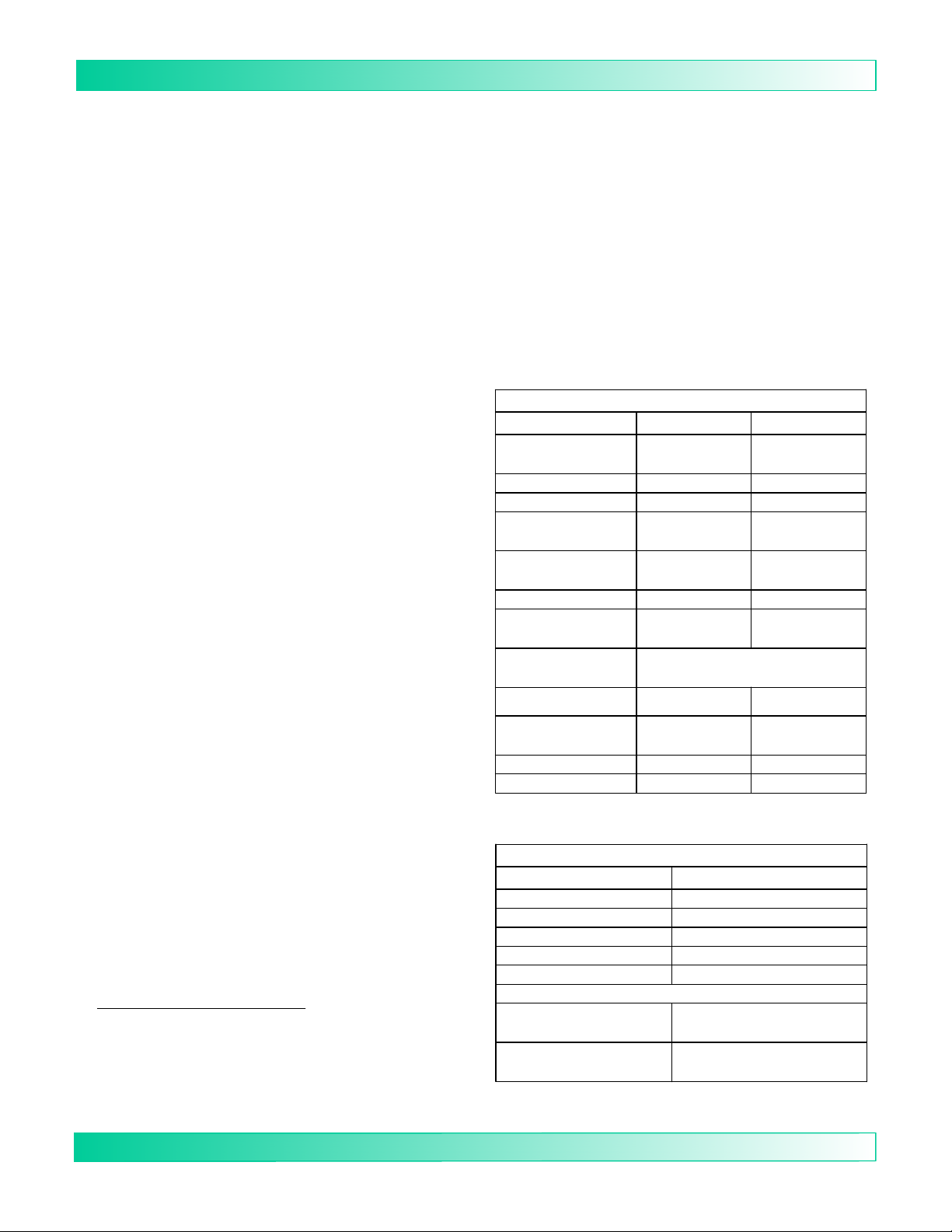

4. Adhesive Applications:

a. To dispense foam, point the applicator’s nozzle at

the surface to be sprayed, holding it

approximately 20 inches from the surface.

Squeeze the trigger and move hand at a speed

which delivers the desired adhesive pattern.

b. Refer to the "Determining Bead Spacing" section

for the spacing between beads.

c. Insulation boards are to be placed immediately

on the wet adhesive but not walked-into-place or

compressed into the adhesive until the adhesive

has begun to thicken and has started to develop

its initial bond.

d. The time involved in this process is contingent on

the ambient as well as deck surface temperature.

The chart below illustrates the approximate time

required prior to walking in or adding ballast to

the boards.

Duro-Last: The Proven Performer®

Ambient / Deck Temperature Time Before Walking In

40 - 60 °F 6 - 10 minutes

60 - 80 °F 3 - 6 minutes

80 - 100 °F 1 - 3 minutes

800-248-0280

May 20, 2010

Page 4

DURO-GRIP INSULATION ADHESIVE

e. After the adhesive has attained its initial bond

strength the boards can be walked-in and will be

compressed to the deck or substrate exhibiting

minimal slippage or movement. The boards

should be exposed to minimum traffic for at least

10-20 minutes (depending on temperature) after

they have been walked-into-place to avoid

breaking the freshly formed bond.

f. Membranes can be applied once the adhesive

has achieved sufficient bond strength to the

immediate substrate to which it is adhered. It is

recommended that the contractor inspect the

installed insulation for proper adhesion and

re-adhere any boards and/or corners that are not

adequately attached.

g. Boards that will not lay flat due to cupping,

warping or crowning, or surface irregularities of

the substrate, should have weights placed on the

boards until the adhesive has achieved adequate

adhesion to hold the boards in place.

h. When spraying stops for breaks, lunch or

overnight repeat the purging procedure in

step # 2g.

Very Important: As the hoses are exposed to the

i.

heat of the sun, especially in the summer months,

the pressure in the hoses will build up. Purging

the hoses for a few seconds prior to spraying

relieves the excess pressure and allows the

chemical to flow in the proper proportions.

b. Check the face of the gun to make sure the outlet

ports are clear and the face of the gun is free from

dirt, chemical or other debris.

c. If necessary, use a rag to remove any cured foam

or chemical from the face of the gun.

d. See Equipment Set Up directions on the previous

page.

7. Disposal Procedures:

a. Do not puncture or incinerate cylinder tanks.

b. After cylinders are empty, they must be vented.

CAUTION:Tanks will still be under pressure. Eye

protection and impervious gloves MUST be worn

during the procedure.

c. With tank valve in opposite position of use, slowly

open the tank valve, point tank AWAY from face

and allow pressure to completel y vent. CAUTION:

Empty tank could contain potential vapor toxicity

hazard. Provide adequate ventilation or

respiratory protection (consult MSDS).

d. DISPOSE OF EM P T Y CYLINDERS

ACCORDING TO APPLICABLE FEDERAL,

STATE AND LOCAL REGULATIONS.

5. Equipment Storage and Re-Use:

a. Turn the cylinder tank valves off.

b. Do not store at temperatures above 95 ˚F (35 ˚C)

or below 45 ˚F (7 ˚C).

c. The used nozzle should be left on the gun during

storage.

d. Engage the trigger safety lock.

e. Close the supply valves on both “A” and “B”

cylinders.

f. The dispensing gun is a disposable unit and is not

designed for prolonged storage or continuous

re-use. To help extend the storage life, it is

recommended to dispense a minimal amount of

foam from the gun at least once every seven days

to ensure optimum flow of chemical through the

hoses.

g. Use up the adhesive within 30 days of initial use.

h. Make certain valves are in correct position when

turning them on and when operating the unit.

6. Re-Use of Applicator Gun After Storage:

a. Before disengaging the trigger safety lock,

remove the used nozzle.

www.duro-last.com

"Duro-Last " an d " The World's Best Roof" are registered marks owned by Duro-Las t , Inc.

4 of 4

Wear eye protection and impervious gloves

Duro-Last: The Proven Performer®

800-248-0280

May 20, 2010

Loading...

Loading...