Page 1

®

ASSEMBL

ASSEMBL

Y AND OPERA

Y AND OPERA

TION MANU

TION MANU

AL

AL

www

www

.duratrax.com

.duratrax.com

™

DTXZ1115 for DTXD98**Entire Contents Copyright © 2006

Page 2

YYOU

OU

WILL

WILL

NEED

NEED

ALKALINE BATTERIES

AIR FILTER OIL

DTXC2465

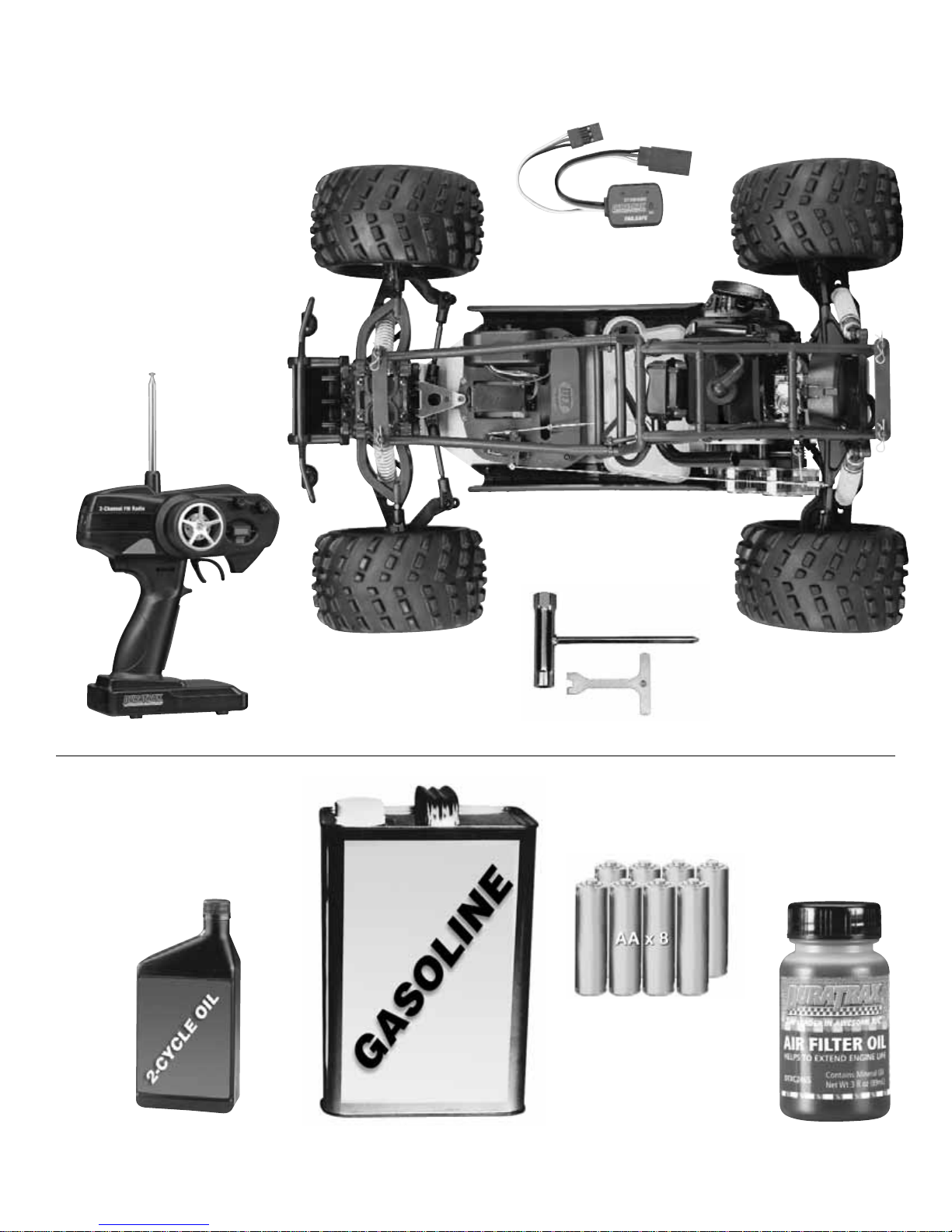

ITEMS

ITEMS

INCLUDED

INCLUDED

The following items are included:

Chassis

Body

Fail Safe Unit (Installed)

Decal Sheet

Transmitter

Transmitter Antenna

Receiver Antenna Tube

Receiver Battery

Receiver Battery Charger

Exploded View/Parts Listing

Tools

2

GASOLINE

2-CYCLE OIL

Page 3

SAFETY PRECA

SAFETY PRECA

UTIONS

UTIONS

When the safety precautions are followed, the

FireHammer MT will provide years of

enjoyment. Use care and good sense at all

times when operating this radio controlled

truck. Failure to use this vehicle in a safe,

sensible manner can result in injury or damage

to property.Y ou and y ou alone must insure that

the instructions are carefully followed and all

safety precautions are obeyed.

• Do not operate the FireHammer MT near

people. Spectators should be behind the

driver or at a safe distance away from

the vehicle.

• Water can cause the electronics to short

out and can cause permanent damage.

• Always turn on the transmitter before

turning on the receiver.

• Fully extend the transmitter antenna

before operating your vehicle.

• Before turning on your radio system,

check to make sure that no one else is

running on the same frequency.

• The engine and exhaust produce quite a

bit of noise.Do not run this vehicle when

or where it can disturb others.

• The engine and exhaust can become

very hot. Avoid touching any of these

parts during use and until they have

cooled down.

• Gasoline is extremely flammable. Keep

it away from open flame, excessive heat

or sparks. Do not smoke while operating

the FireHammer MT.

• This engine was designed for R/C

vehicles and should not be used for any

other purpose.

• The engine emits harmful fumes just

like real vehicles. Do not operate this

model indoors.

• Avoid running the truck in cold weather.

The plastic and metal parts can become

brittle at low temperatures. In addition,

grease and oil become thick, causing

premature wear and poor performance.

SPECIFICA

SPECIFICA

TION AND

TION AND

DESCRIPTION CHANGES

DESCRIPTION CHANGES

All pictures, descriptions and specifications

found in this instruction manual are subject to

change without notice.DuraTrax maintains no

responsibility for inadvertent errors in this

manual. Visit www.duratrax.com for the

latest updates and information for your model.

STRESS-TECH

STRESS-TECH

™

™

PPARARTS

TS

GUGUARANTEE

ARANTEE

We have engineered the FireHammer MT to

take the rough and tumble abuse that makes

R/C trucks fun. We are so confident of the

quality and durability of the Stress-Tech plastic

parts that we will replace any Stress-Tech

plastic part you break during the first 12

months you own the truck. Just send in the

part to us and we will send you a FREE

replacement. Please see the FireHammer MT

parts list for the items covered under the

Stress-Tech guarantee.

To receive your free replacement part

please send the following to the Hobby

Services address listed under the warranty.

❏ 1.The broken part must be included.

❏ 2.The part number and description of

the broken part.

❏ 3.Copy of your dated invoice or

purchase receipt.

❏ 4.Your name, phone number and

shipping address.

WWARRANTY

ARRANTY

• DuraTrax guarantees this kit to be free

from defects in both material and

workmanship at the date of purchase.

DuraTrax will warranty this kit for 90 days

after the purchase date. DuraTrax will

repair or replace, at no charge, the

incorrectly made part.

• Make sure you save the receipt or in voice

you were given when you bought your

model! It is your proof of purchase and

we must see it before we can honor the

warranty. Further, DuraTrax reser ves the

right to change or modify this warranty

without notice.

• In that DuraTrax has no control over the

final user assembly or material used for

final user assembly, no liability shall be

assumed nor accepted for any damage

resulting from the use by the user of the

final user-assembled product.By the act of

using the user-assembled product, the

user accepts all resulting liability.

•

The engine is under a limited warranty for

3 years. DuraTrax warrants this engine to

be free from defects in materials and

workmanship for a period of three years

from the date of purchase. During that

period, DuraT rax will, at its option, repair or

replace without service charge any

product deemed defective due to those

causes. You will be required to provide

proof of purchase date (receipt or invoice).

•

This warranty does not cover damage

caused by crash, abuse, misuse,

alterations or accident. Damaged caused

by customer disassembly, tampering, use

of substandard fuel, use of incorrect

accessories (spark plug, etc) or any use

of the engine for which it is not specifically

intended will automatically void the

warranty of the engine.If there is damage

resulting from these causes within the

stated warranty period, DuraTrax will, at

its option, repair or replace it for a service

charge not greater than 50% of the

current retail list value.Be sure to include

your daytime telephone number and email address in case we need to contact

you about your repair.

•

Under no circumstances will the purchaser

be entitled to consequential or incidental

damages.This warranty gives you specific

legal rights and you may also have other

rights, which vary from state to state.

•

If you attempt to disassemble or repair this

unit yourself, it may void your warranty.

To return your FireHammer MT for repairs

covered under warranty you should send

your truck to:

Hobby Services

3002 N. Apollo Drive Suite 1

Champaign, Illinois 61822

Attn: Service Department

Phone: (217) 398-0007 9:00 am-5:00 pm

Central Time M-F

E-mail:

hobbyservices@hobbico.com

www.hobbyservices.com

If the buyer is not prepared to accept the

liability associated with the use of this

product, the buyer is advised to return

this kit immediately in new and unused

condition to the place of purchase.

REP

REP

AIR SER

AIR SER

VICE

VICE

Repair service is available anytime.

• After the 90 day warranty, you can still

have your FireHammer MT repaired for a

small charge by the experts at DuraTrax’s

authorized repair facility, Hobby Services.

• To speed up the repair process, please

follow the instructions listed below.

❏ 1. Under most circumstances return the

ENTIRE vehicle. The exception would

be sending in a Stress-Tech part. See

the instruction under the StressTech Guarantee.

❏ 2.Make sure the transmitter is turned off,

all of the batteries are removed and

the fuel tank is completely empty.

❏ 3. Send written instructions which include: a

list of all items returned, a THOROUGH

explanation of the problem, the service

needed and your phone number during

the day. If you expect the repair to be

covered under warranty, be sure to

include a proof of date of purchase (your

store receipt or purchase invoice).

THINGS

THINGS TTOO

KNO

KNO

W

W

3

Page 4

FINISHING

FINISHING

THE FIREHAMMER MT

THE FIREHAMMER MT

• Disconnect the receiver battery lead from the

ON/OFF switch lead.

• Plug the charger (included) into an electrical

outlet.

• Plug the battery into the charger.

• Charge the battery.

• Install eight “AA” batteries into transmitter, making sure the polarity is correct.

• Insert the antenna into the top of the transmitter and tighten.

• Turn the transmitter on and check the battery light.

• If both LEDs light up, the batteries are acceptable. If only the red LED lights

up, immediately replace the batteries.

4

TRANSMITTER PREPARATION

R

STTH

N

ST

TH

AA

–

AA

+

AA

–

AA

+

CHARGING THE RECEIVER BA TTER Y

+

–

AA

–

+

AA

+

–

AA

–

+

AA

+

–

+

–

INCLUDED

CHARGER

RECEIVER

BATTERY

LEAD

Page 5

ANTENNA MOUNT

ANTENNA TUBE

RECEIVER

ANTENNA

WIRE

ANTENNA CAP

• Uncoil and straighten the antenna wire.

• Route the receiver antenna wire through

the antenna tube.

• Install the tube into the antenna mount.

• Install the antenna cap onto the top of the

antenna tube to hold the assembly in place.

• The air filter comes pre-oiled.However, after runs in dusty conditions, clean and re-oil the foam element.

• Remove the air filter top and foam element.

• Clean the foam using soap and water.

• Apply air filter oil (DTXC2465) onto the foam element, squeezing the element until it is completely coated

with the oil. TIP! Placing the element in a plastic bag will help keep your hands clean.

• Remove any excess oil with a paper towel.

• Reinstall, making sure the filter is properly seated on the base.

5

RECEIVER ANTENNA INSTALLATION

DO NOT CUT

ANTENNA WIRE!

X

AIR FILTER MAINTENANCE

AIR FILTER

FOAM

ELEMENT

BASE

AIR FILTER

TOP

Page 6

RADIO SYSTEM CHECK

• Fully extend the transmitter antenna.

• Turn the transmitter on, then turn the receiver on.

• Turn the transmitter wheel to the right—the front wheels should turn to the right. If not, move the steering servo reverse switch.

• When running, adjust the steering trim so the truck tracks straight.

• Pull the throttle trigger to make sure the carburetor opens fully and the throttle linkage functions properly without binding.

• Adjust the throttle trim until the carb is at the idle position. Always adjust idle speed with the idle stop screw on the carb, not

the throttle trim.

• Push the trigger and roll the truck to make sure the brakes are applied.

• Decal the body to your liking. Use the

photos on the box as a reference.

• Install the body onto the chassis using

four body clips.

6

ON/OFF

ANTENNA

SERVO

REVERSING

STTH

STEERING

TRIM

R

N

THROTTLE

TRIM

ST

TH

DUAL

RATE

THROTTLE

BRAKE

CHECK THE RADIO SYSTEM

FOR PROPER FUNCTION

!

BEFORE EACH RUN

BODY INSTALLATION

Page 7

BEFORE OPERATION:

•

Prepare only the amount of gasoline needed.

•

If the engine was just run, make sure you allow enough time for it

to cool down before you run it again.Also, wipe off any residue the

engine may have blown on the FireHammer MT.

•

Fuel the FireHammer MT with the adequate gasoline mix.

ENGINE BREAK IN:

•

To break in your FireHammer MT engine, you need to run the

engine for two tanks of fuel with a fuel mixture that contains a

25:1 (4%) fuel/oil ratio (5oz. per 1 gallon).

•

Do not adjust the high-speed needle on the carburetor to break

in the engine. If you do so, carbon will accumulate in the spark

plug and making ignition difficult.

•

Do not run at full power for extended periods of time while

breaking in your engine.

•

Run the FireHammer MT with the body off for break in.

RUNNING THE FIREHAMMER MT AFTER BREAK IN:

•

Once the engine is broken in, use 40:1 (2.5%) fuel/oil mix

(3.2oz. per 1 gallon).

ENGINE ADJUSTMENTS:

•

Always make high and low speed needle adjustments with the

engine shut off.

•

Always make small adjustment to the needles to prevent overadjustment.

•

To lean the engine, make a clockwise adjustment to the desired

needle.

•

It is not necessary to change the needle settings if the engine

is running smoothly. Normally only the high speed needle will

need adjustment from time to time, and only a small amount.

IDLE ADJUSTMENT:

Do not confuse the idle screw with the low speed needle. The idle

screw physically adjusts how much the carb uretor v alv e can close.The

low speed needle adjusts the gasoline to air mixture when the engine

is running at low rpm. If your engine appears to work correctly except

that the low rpm are not as low as you want them to be, then adjust the

idle screw .If your engine behaves erratically at lo w rpm, then adjust the

low speed needle.When adjusting, turn the screw about 1/8th of a turn

each time.A dirty plug will make it difficult to adjust the idle rpm.

PRECAUTIONS

•

Do not use silicone fuel tubing on the model. The gasoline will

attack it. Use vinyl or neoprene rubber fuel line.

•

Make sure the fuel line is not against the cylinder head. The

heat from the head can damage the fuel tubing.

•

The engine will be hot after being run. Allow the engine to

thoroughly cool before touching it.

•

Do not leave fuel in the tank or lines while transporting.

FUELING THE FIREHAMMER MT

1.

Unscrew the fuel cap from the fuel tank.

2. Pour the proper fuel mixture into the fuel tank.

3. Thread the fuel cap back into the fuel tank, making sure that the

fuel cap is thoroughly tightened.

4. Wipe off any fuel that may have spilled onto the truck during the

fueling process with an old towel.

STARTING THE FIREHAMMER MT

1. Tur n on the transmitter and then the receiver.

2. Check the throttle and steering to make sure they are

functioning properly.

3. Prime the engine.Push the primer button until you start to see fuel

in it. Note: Do not press the primer after you start to see fuel.

This will flood the engine and cause it to be hard to start.

4. Rotate the choke lever to the closed position.

5. T ug on the recoil until the engine starts.(The engine should start

after a few pulls). It may be necessary to slightly open the

throttle to get the engine to start.

6. Once the engine star ts, return the throttle to neutral and open the

choke back up. Note: If you do not open the choke after the

engine starts, it will probably die quickly.

SHUTTING THE FIREHAMMER MT OFF

To stop the engine press the red shut off switch on the engine.We

recommend that you familiarize yourself with the switch and what

the easiest way is to get to it with the body on.This way you are

not fumbling around to find it in case of an emergency.

SPARK PLUG

The recommended spark plug is a DuraTrax NGK CMR 7H Spark

Plug (DTXG3100).To avoid improper operation or possible engine

damage, do not use any other type of spark plugs. The plug gap

should be .025" to .030" (if the plug gap is incorrect, adjust it with

a spark plug gapping tool, wash it with gasoline and allow it to dry

completely before you reinstall the plug into the engine).

RRUNNING

UNNING

THE

THE

ENGINE

ENGINE

PREP

PREP

ARE

ARE

THE

THE

ENGINE

ENGINE

7

LOW

SPEED

HIGH

SPEED

IDLE

CHOKE

CLOSED

CHOKE

OPEN

Page 8

FAIL SAFE SET-UP

The fail safe is designed with a signal fail safe and a battery fail safe.

If the receiver loses contact with the transmitter, the fail safe will set

the throttle to the designated position and the red LED will be

constantly lit.If the battery goes below the preset v oltage, the f ail saf e

will set the throttle to the designated position and the red LED will be

constant and the green LED will flash. If this occurs, shut the

FireHammer MT off and recharge the receiver battery before running

the model again.

The fail safe should be set from the factory, but we recommend that

you double check it before running the FireHammer MT.

1. Check that the fail safe is functioning properly before starting

the engine.

2. With the receiver on, advance your throttle on the transmitter.

Then shut off the transmitter and see if the throttle servo moves

to the desired position (idle).

3. Turn on the radio system and make sure the throttle is positioned

at idle. Press and hold the “SET” button for 2 seconds.

BEFORE EACH RUN

1.Check to make sure that all screws are tight and there are not

any screws missing.

2.Check that the transmitter and receiver batteries are not low.

3.Check that all of the moving parts of the FireHammer MT move

freely and do not bind.

4.Check for broken or damaged parts. Replace any broken or

damaged parts before running the FireHammer MT. Running of

the FireHammer MT with broken or damaged parts could result

in damage to other parts.

5.Check to make sure that all wires are properly connected and secure.

AFTER EACH RUN

1. Clean any large globs of dirt or debris from the chassis and

moving parts.

2. Drain any remaining gas from the tank.

3. Check for any broken or damaged parts.This way parts may be

replaced before the next run.

AFTER EVERY 10 RUNS

1. Check to make sure that the bearings are free of dirt and debris

and roll smoothly.

2. Check the shocks for leakage.If the shocks have leaked any shock

fluid out, you should properly refill the shocks for best performance.

3. Make sure the ser vo saver does not bind.This will help prevent

stripping of the servo during running. Clean as needed.

4. Check for proper gear mesh between the spur gear and the

pinion gear.

When tuning the FireHammer MT, make sure that you have equal

lengths from one side to the other on the shocks, camber rods and

steering rods. Also, make sure to have the shock pre-load

adjusters at the same setting from left to right.They do not have to

be the same front to rear.

CASTER

Caster refers to the angle which the

kingpin is at in relation to the surface

when viewed from the side.0-degrees of

caster means that the kingpin is straight

up and down.

CAMBER

Camber refers to the angle at which the

tire and wheel ride in relation to the

ground when viewed from the front or rear .

Negative camber is when the tire and

wheel lean inward and positive camber is

when the tire and wheel lean outward.

Typically you want 0 to -2 degrees of

camber. Never put in positive camber.

Make sure that both sides are equal.

FRONT AND REAR TOE-IN AND TOE-OUT

Toe-in and toe-out refers to the angle

at which the tire is at when view from

above. Toe-in increases stability

under acceleration. However, toe-in

also decreases steering when

entering a corner. Toe-out will

increase steering into corners, but will

decrease the overall stability during

acceleration.The front typically is set-up with 0 to -2 degrees of toe-in.

RIDE HEIGHT

The ride height of the FireHammer MT affects how it jumps and

handles.The r ide height of the FireHammer MT is adjustable through

the threaded pre-load adjusters on the shock bodies.To measure the

ride height of the FireHammer MT, set the truck up as if you are ready

to run. Push the front of the truck down all of the way and release it.

When the truck returns the front arms should be parallel with the

surface.The rear ride height is set up the same except that the drive

shafts are parallel with the surface. Lowering the front ride height will

increase steering response due to more weight on the front wheels.

Lowering the rear ride height will increase rear traction and reduce

steering response due to more weight on the rear wheels.

REAR SHOCK ADJUSTMENT

Moving the tops of the shocks in will result in more traction in the

corners and smoother handling over the bumps. Moving the tops

of the shocks out will give the truck more steering and better ability

to handle large jumps.

SHOCK OILS

Thinner shock oil makes the shock react faster, but makes the

truck less stable and may cause the truck to bottom out over large

jumps. Thicker shock oil makes the truck smoother over large

jumps and in straights, but less reactive over rough sections.

TUNING

TUNING

GUIDE

GUIDE

MAINTENANCE

MAINTENANCE

TIPS

TIPS

Wheels pointed towards each other

1˚ Toe-In

1˚ 1˚

Loading...

Loading...