Page 1

®

™

ASSEMBLY AND OPERATION MANUAL

www.duratrax.com

Page 2

ITEMS

INCLUDED

The following items are included

with your Cliff Climber.

Chassis

Body

Decal Sheet

Transmitter (RTR Only)

Transmitter Antenna (RTR Only)

Transmitter Frequency Flag (RTR Only)

Receiver Antenna Tube

Exploded View/Parts Listing

YOU WILL

NEED

x 8

“AA” BATTERIES

ONYX™ 240 AC/DC DUAL CHARGER

DTXP4240

IF YOU HAVE THE ARR VERSION

YOU WILL ALSO NEED

• A radio system that includes transmitter, receiver and two standard servos. We

recommend the Futaba 2PL radio system (FUTK02**). For even better performance,

two high-torque servos such as Hobbico’s CS-170 (HCAM0316) can be used.

x 2

6-CELL 2/3 “A” CELL 7.2V

1200MAH NIMH STICK

DTXC2194

x 2

BATTERY ADAPTERS

(FOR CHARGING)

DTXC2210

• An electronic speed control capable of use with two 380 size motors and two 7.2-8.4V

batteries. We recommend the DuraTrax ESC-15K (DTXC1280).

• A dual servo output harness such as FUTM4130.

• Polycarbonate-compatible paint of the user’s choice.

2

Page 3

THINGS TO

SPECIFICATION AND

DESCRIPTION CHANGES

STRESS-TECH™ PARTS

GUARANTEE

KNOW

SAFETY PRECAUTIONS

When the safety precautions are followed, the

Cliff Climber will provide years of enjoyment.

Use care and good sense at all times when

operating this radio controlled crawler.

Failure to use this vehicle in a safe, sensible

manner can result in injury or damage to

property. You and you alone must insure that

the instructions are carefully followed and all

safety precautions are obeyed.

• Do not use lithium-polymer batteries with

the stock ESC unless a voltage cut-off

unit is used.

• Water can cause the electronics to short

out and can cause permanent damage.

• Always turn on the transmitter before

turning on the receiver.

• Fully extend the transmitter antenna

before operating your vehicle.

• Before turning on your radio sytem, check

to make sure that no one else is running

on the same frequency.

• Keep out of reach of children. The motors

and ESC may become hot during running.

• Never leave a battery on charge unattended.

• If the battery or the charger become hot

at any time, disconnect the battery from

the charger immediately! Failure to do

so could cause permanent damage to

the charger and battery and may cause

bodily harm.

• Do not allow water or moisture to contact

the charger.

• Do not place the charger on or near a

fl ammable object during use.

• Only use 6-cell or 7-cell “2/3 A” size

batteries in your Cliff Climber.

• Avoid running the Cliff Climber in cold

weather. The plastic and metal parts

can become brittle at low temperatures.

In addition, grease and oil become

thick, causing premature wear and poor

performance.

All pictures, descriptions and specifi cations

found in this instruction manual are

subject to change without notice. DuraTrax

maintains no responsibility for inadvertent

errors in this manual. Visit www.duratrax.

com for the latest updates and information

for your model.

WARRANTY

• DuraTrax® guarantees this kit to be

free from defects in both material and

workmanship at the date of purchase.

DuraTrax will warranty this kit for 90

days after the purchase date. DuraTrax

will repair or replace, at no charge, the

incorrectly made part.

• Make sure you save the receipt or invoice

you were given when you bought your

model! It is your proof of purchase and

we must see it before we can honor the

warranty. Further, DuraTrax reserves the

right to change or modify this warranty

without notice.

• In that DuraTrax has no control over the

fi nal user assembly or material used for

fi nal user assembly, no liability shall be

assumed nor accepted for any damage

resulting from the use by the user of the

fi nal user-assembled product. By the act

of using the user-assembled product, the

user accepts all resulting liability.

To return your Cliff Climber for repairs

covered under warranty, you should send

your truck to:

Hobby Services

3002 N. Apollo Drive, Suite 1

Champaign, Illinois 61822

Attn: Service Department

Phone: (217) 398-0007 9:00 am-5:00 pm

Central Time M-F

E-mail: hobbyservices@hobbico.com

www.hobbyservices.com

If the buyer is not prepared to accept the

liability associated with the use of this

product, the buyer is advised to return

this kit immediately in new and unused

condition to the place of purchase.

We have engineered the Cliff Climber to

take the rough and tumble abuse that makes

R/C fun. We are so confi dent of the quality

and durability of the Stress-Tech plastic

parts that we will replace any Stress-Tech

plastic part you break during the fi rst 12

months you own the crawler. Just send in

the part to us and we will send you a FREE

replacement. Please see the Cliff Climber

parts list for the items covered under the

Stress-Tech guarantee.

To receive your free replacement part

please send the following to the Hobby

Services address listed under the warranty

on the left.

❏ 1. The broken part must be included.

❏ 2. The part number and description of the

broken part.

❏ 3. Copy of your dated invoice or

purchase receipt.

❏ 4. Your name, phone number and

shipping address.

REPAIR SERVICE

Repair service is available anytime.

• After the 90 day warranty, you can still

have your Cliff Climber repaired for a

small charge by the experts at DuraTrax’s

authorized repair facility, Hobby Services.

• To speed up the repair process, please

follow the instructions listed below.

❏ 1. Under most circumstances return

the ENTIRE vehicle. The exception would

be sending in a Stress-Tech part. See the

instruction under the Stress-Tech Guarantee.

❏ 2. Make sure the transmitter is turned off,

and all of the batteries are removed.

❏ 3. Send written instructions which include:

a list of all items returned, a THOROUGH

explanation of the problem, the service

needed and your phone number during the

day. If you expect the repair to be covered

under warranty, be sure to include a proof

of date of purchase (your store receipt or

purchase invoice).

3

Page 4

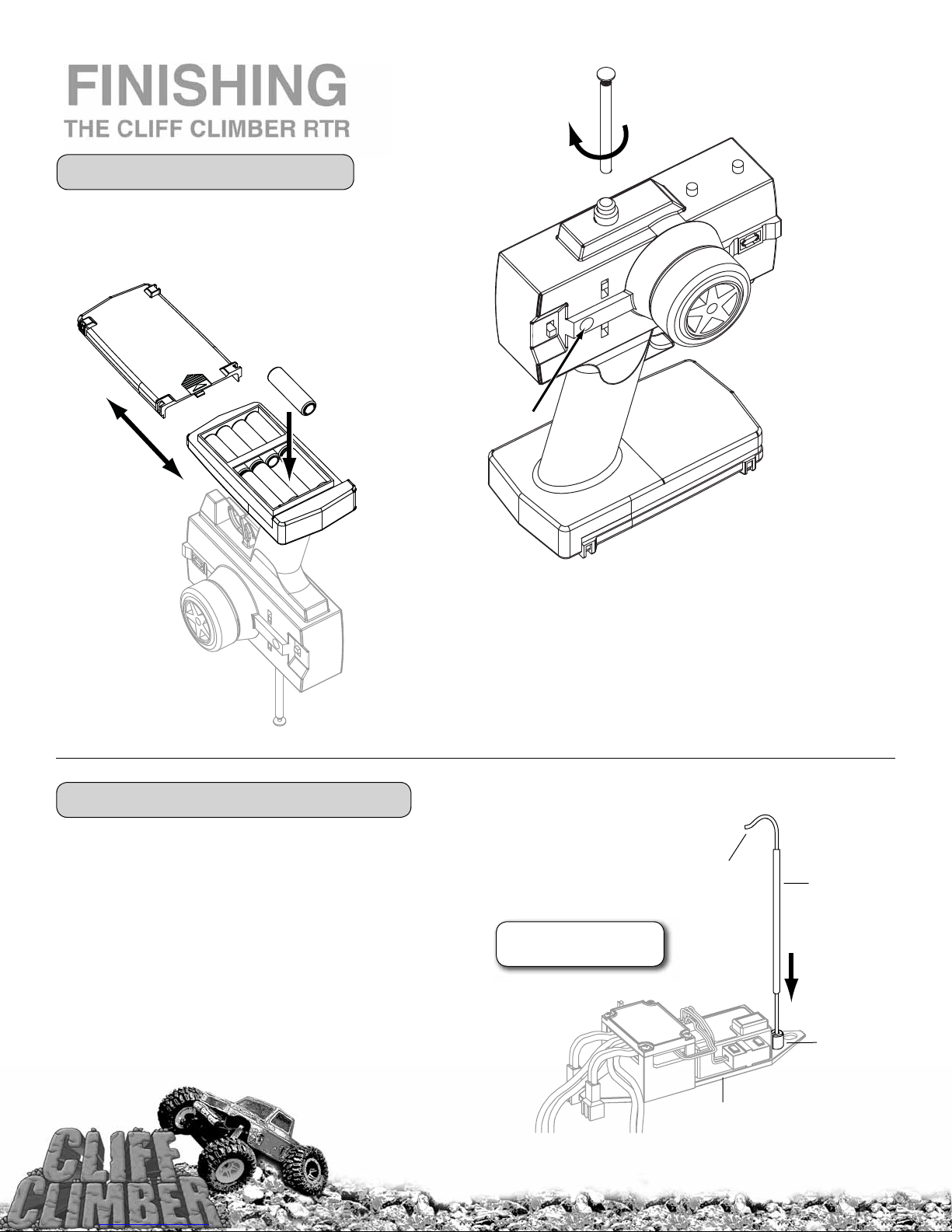

FINISHING

THE CLIFF CLIMBER RTR

TRANSMITTER PREPARATION

• Slide the batttery tray door off and install

eight “AA” batteries into transmitter,

making sure the polarity is correct.

Battery

Tray Door

+

–

–

+

–

+

–

+

+

+

–

Battery On

• Insert the antenna into the top of the transmitter and gently tighten.

• Turn the transmitter on and check the battery light. If the red light glows

RECEIVER ANTENNA INSTALLATION

• Thread the receiver antenna wire up through the

antenna tube. The antenna will be longer than the

antenna tube.

• Press fi t the antenna tube down into the molded

antenna mount on the battery strap.

• Tip: Run the antenna wire through your fi ngers to

straighten out the kinks before running it through the

antenna tube. Also, applying a small amount of soap

and water to the antenna wire will help lubricate the

wire for threading into the antenna tube.

steadily, the batteries have enough voltage. If the red light blinks, the

batteries are low and should be replaced.

DO NOT CUT THE

ANTENNA WIRE!

X

Receiver

Antenna Wire

Antenna

Tube

Antenna

Tube Mount

Battery Strap

4

Page 5

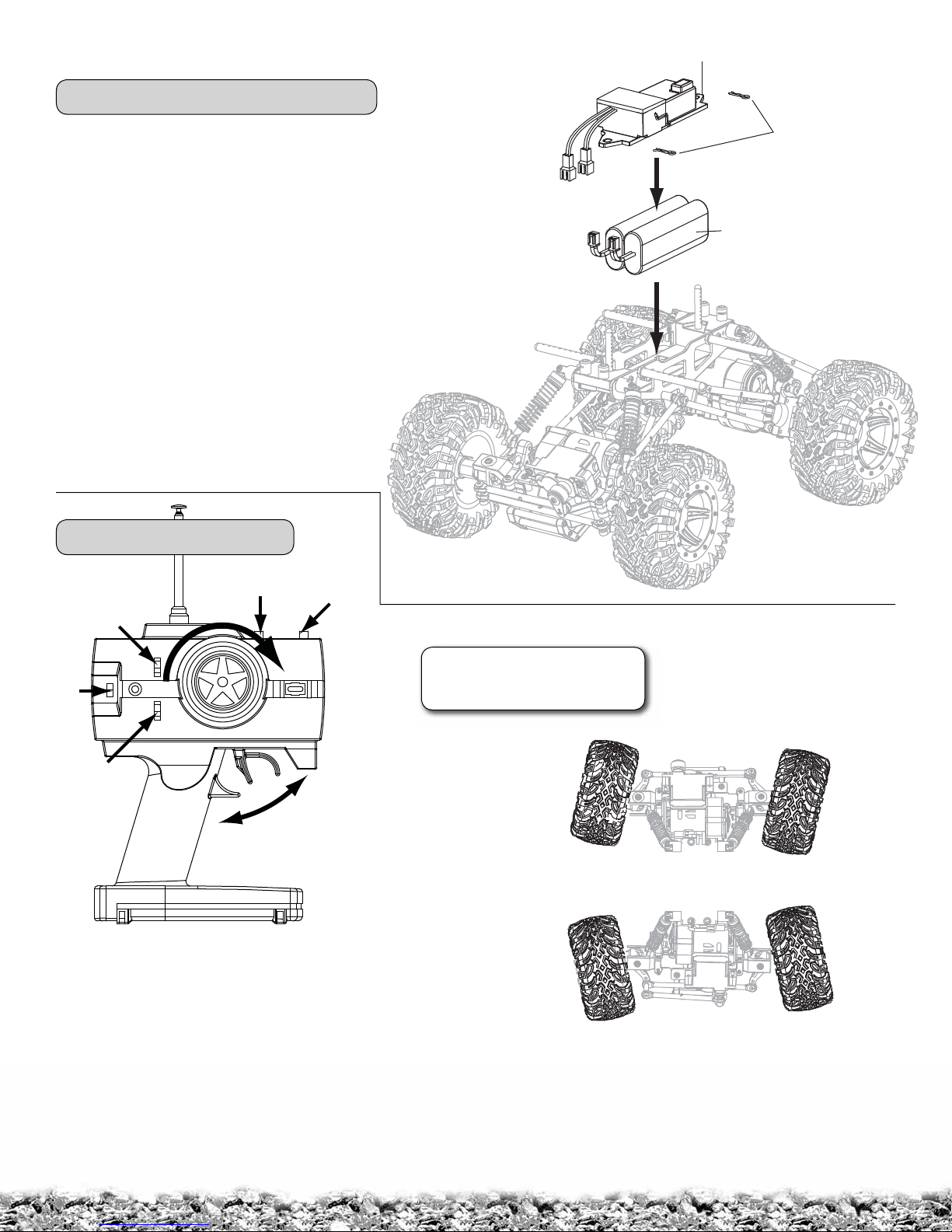

BATTERY INSTALLATION

• Remove the battery clips from the battery strap.

Battery Strap

Battery Clips

• Remove the battery strap.

• Install the 7.2V batteries (not included) into the

chassis as shown.

• Reinstall the battery strap and secure it in place

with the battery clips.

• Check that the ESC is “OFF,” and then plug the

batteries into the ESC.

RADIO SYSTEM CHECK

Steering

Servo

Reverse

Switch

On/Off

Steering

Tr i m

Throttle

Tr i m

CHECK THE RADIO SYSTEM

FOR PROPER FUNCTION

!

BEFORE EACH RUN

7.2V Batteries

Throttle

Servo

Reverse

Switch

Forward

The ESC is an autoset ESC. No programming is required.

• Turn the transmitter on and center the throttle trim.

• Turn the ESC on. Wait 2 seconds while the ESC sets itself up.

• When you pull the throttle trigger back, the red LED will fl ash

and the truck will go forward.

• When you push the throttle trigger forward, the green LED will

fl ash and the truck will go in reverse.

• At neutral, the LEDs will be on constantly.

• If the truck goes in reverse when you pull the throttle trigger,

switch the throttle reveresing switch on your transmitter.

Reverse

5

FRONT

REAR

• Turn the transmitter on. Then turn the ESC on.

• Turn the transmitter wheel to the right—the front

wheels should turn to the right and the rear wheels to

the left. If not, move the steering servo reverse switch.

• When running, adjust the steering trim so the crawler

tracks straight.

Page 6

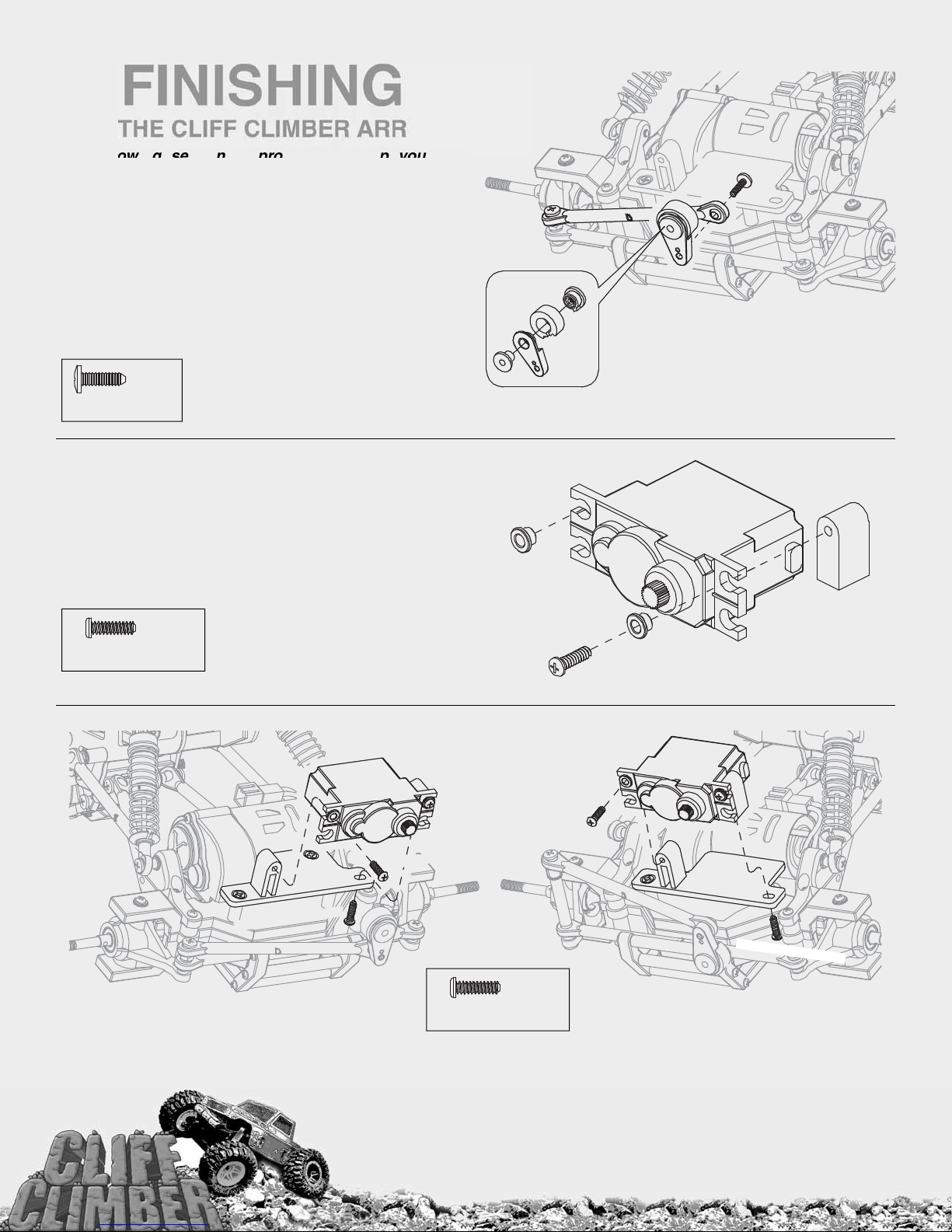

FINISHING

THE CLIFF CLIMBER ARR

The following section is provided to help you with

assembly of the almost-ready-to-run version of the Cliff

Climber. Pay extra attention to the notes and tips for

proper assembly.

• Assemble the front and rear servo saver bushings (45), arms

(44), rings (43), and adapters (42) as shown.

3x10mm

Screw

9

• Secure the assembled servo savers onto steering linkage

rods D (9) with 3x10mm screws.

...x1

3x10mm Screw

• Install a fl anged bushing (11) into the upper eye on each side

of the servos as shown.

• Using a 3x10mm S/T screw, secure a servo mounting block (41)

to the side of the servos with the output splines as shown.

...x1

3x10mm S/TScrew

45

11

42

43

44

3x10mm S/T Screw

Caution: Be sure to use the correct servo

spline adapter (42) for your servo. They

are marked for easy identifi cation:

F ➙ Futaba

H ➙ Hitec

J ➙ Airtronics/Sanwa

41

11

40

3x10mm S/T Screw

Front Rear

3x10mm S/T Screw

3x10mm S/T Screw

40

3x10mm S/T Screw

...x4

3x10mm S/TScrew

• Secure the side of the servos without the mounting blocks to

the servo tray mounts (40) using 3x10mm S/T screws.

• Secure the side of the servos with the installed mounting

blocks (41) to the bottom of the servo tray mounts (40) with

3x10mm S/T screws.

6

Page 7

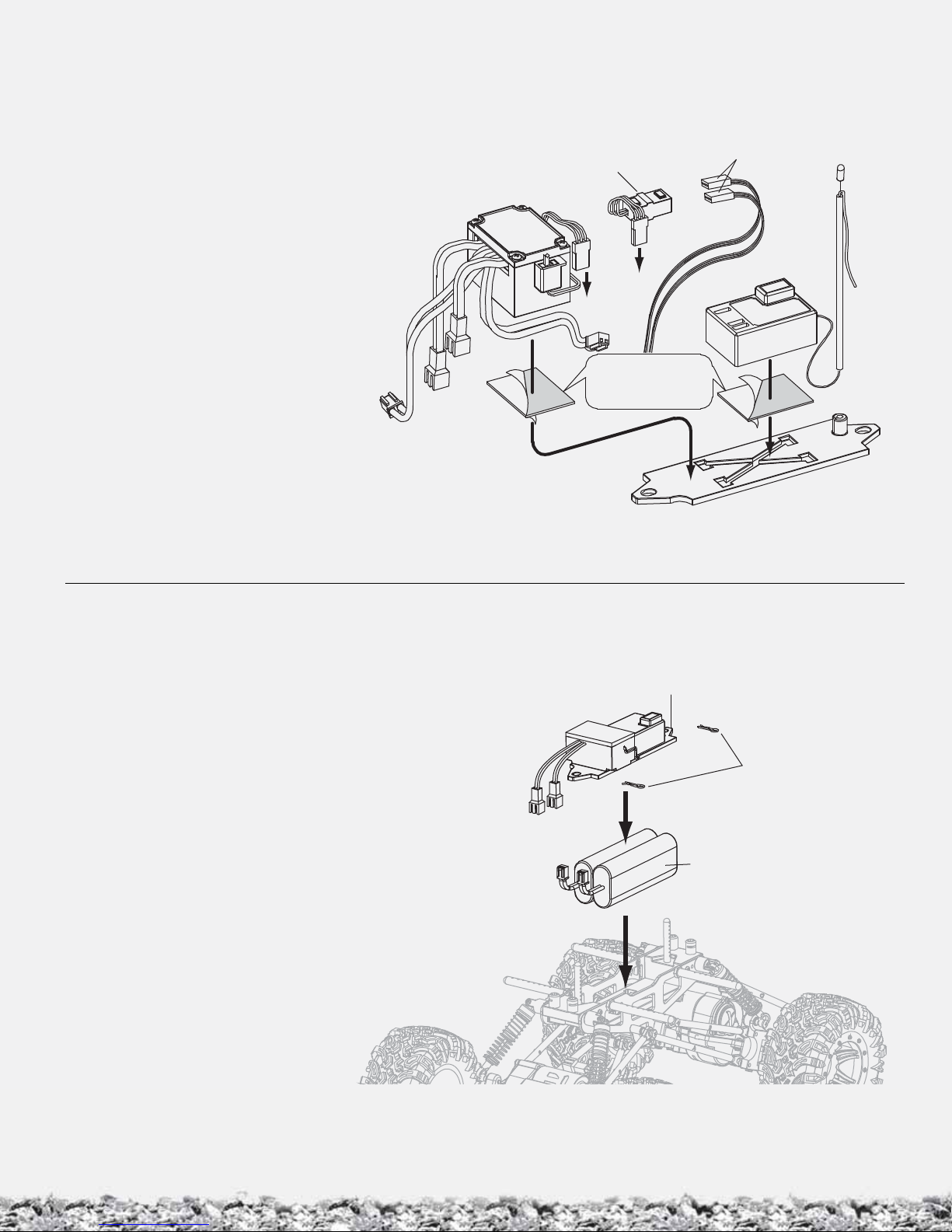

• Secure the ESC and receiver to the top

of the battery strap with double-sided

mounting tape (DTXR1215).

• Connect the ESC and receiver being

used, following the instructions that

came with the ESC and radio system.

Normally the ESC plugs into channel 2

on the receiver.

• Thread the receiver antenna wire up

through the antenna tube. The antenna

will be longer than the antenna tube.

• Connect both front and rear servo

leads into the larger plug on the servo

Y-harness (not included).

• Connect the Y-harness into channel 1

on the receiver. Mount the Y-harness

with double face tape (the location will

vary depending on the length of the

servo leads) to secure it.

ESC

Y-Harness

Ch2

Double-Sided

Ch1

Tape

Steering Servo

Leads

CH2

CH1

RX

• Remove the battery clips from the battery strap.

• Remove the battery strap.

• Install the 7.2V batteries (not included) into the

chassis as shown.

• Reinstall the battery strap and secure it in place

with the body clips.

• Check that the ESC is “OFF,” and then plug the

batteries into the ESC.

Battery Strap

Battery Clips

7.2V Batteries

7

Page 8

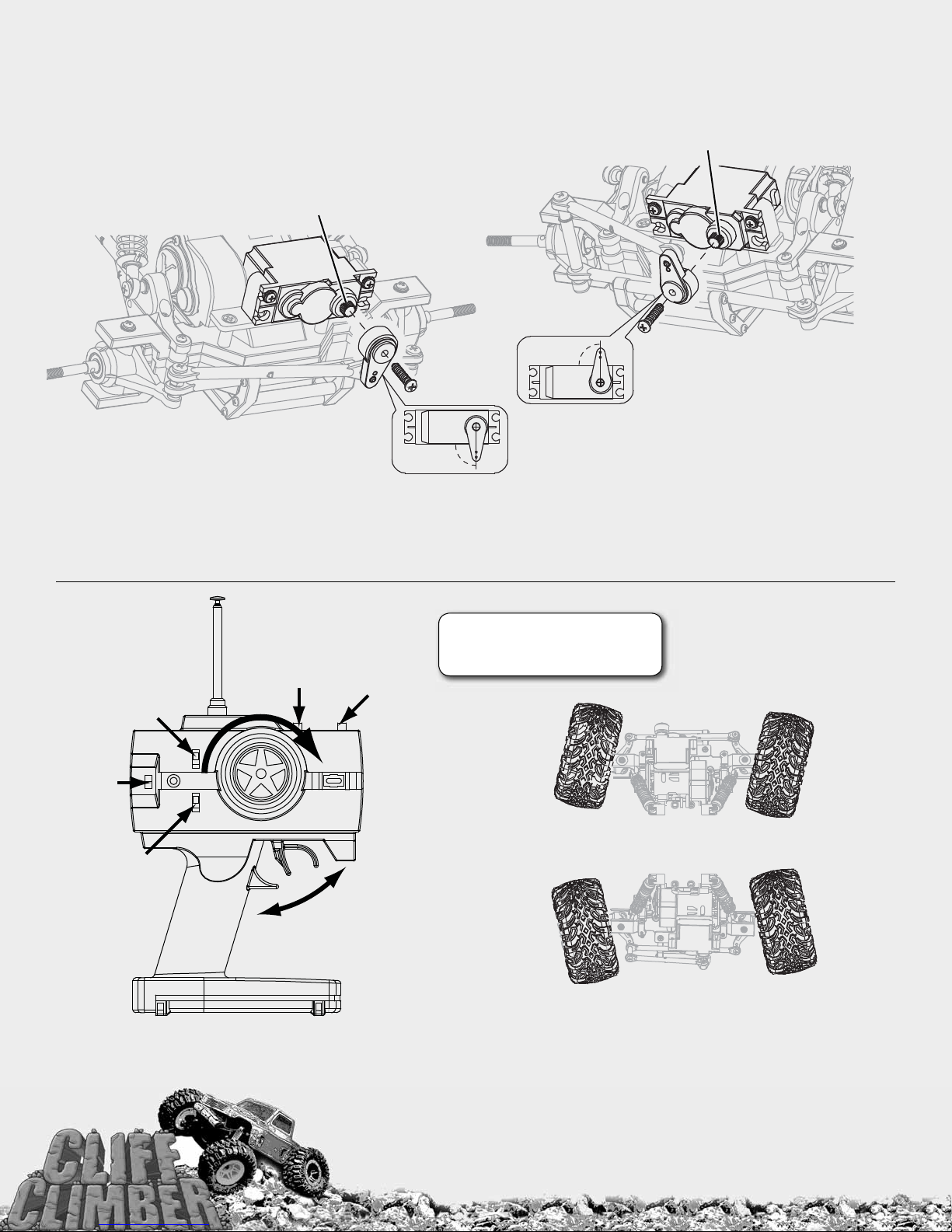

• Turn on the radio system and center the front and rear servos per the

radio system instructions.

• NOTE: You may want to unplug the motors from the ESC until you

completely set up the ESC and radio system. This will prevent a potential

“runaway” when centering the servos and attaching the linkages.

SPLINE

SPLINE

90°

Rear

Front

• Install the front servo horn onto the servo

output spline pointing down at a 90° angle.

• Secure the servo savers to the servos with the

servo horn screw that came with the servo.

Steering

Servo

Reverse

Switch

On/Off

Throttle

Servo

Reverse

Switch

Steering

Tr i m

Forward

Throttle

Tr i m

Reverse

• Install the rear servo horn onto the servo output

90°

CHECK THE RADIO SYSTEM

FOR PROPER FUNCTION

!

BEFORE EACH RUN

spline pointing up at a 90° angle.

• Secure the servo savers to the servos with the

servo horn screw that came with the servo.

FRONT

REAR

• Turn the transmitter on. Then turn the ESC on.

• Set up the ESC according to the instructions that came with your ESC.

• Turn the transmitter wheel to the right—the front wheels should turn to the right

and the rear wheels to the left. If not, move the steering servo reverse switch.

• When running, adjust the steering trim so the crawler tracks straight.

8

Page 9

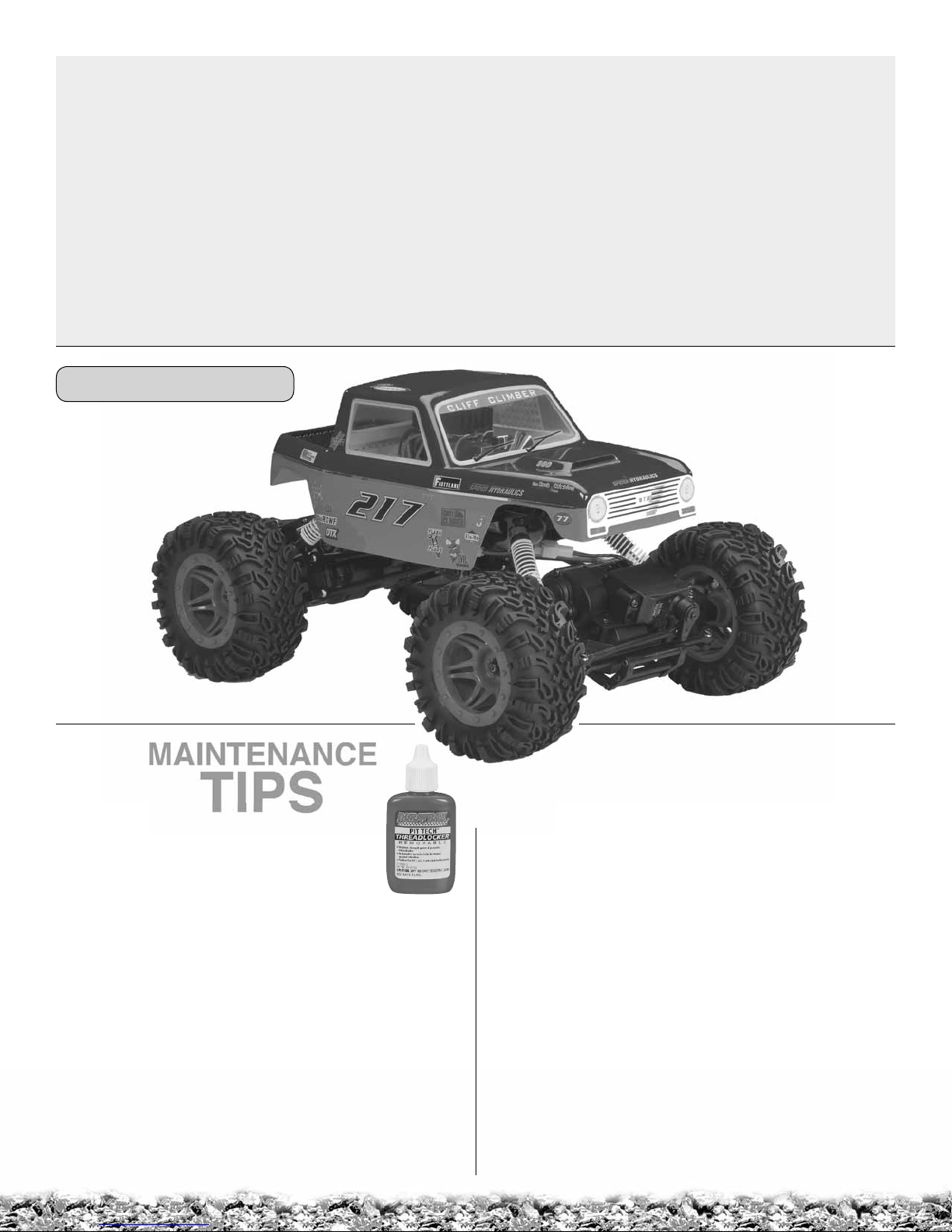

The Cliff Climber ARR body comes clear. Below are a few tips to follow when painting your Cliff Climber.

CAUTION:

• Always paint in a well-ventilated area.

• Never paint near an open fl ame.

• Wash the inside of the body out with dish soap and water. Make sure the body is thoroughly rinsed out.

• Use a quality masking tape or Hobbico® Liquid Mask to mask the inside of the body off.

• If using masking tape, make sure it is properly sealed down.

• If using Hobbico Liquid Mask, make sure to use multiple coats. Make sure not to put the liquid mask on too thick

or too thin. 2-3 medium coats work best.

• Use a new hobby blade when cutting the masking tape or liquid mask.

• Paint the inside of the body using a quality Lexan compatible paint. Spray dark colors fi rst and always back light

colors with white or silver.

• Remove the clear protective fi lm from the outside of the body.

• Decal the body to your liking. Use the

BODY INSTALLATION

photos on the box as a reference.

• Install the body onto the chassis using

four body clips.

MAINTENANCE

TIPS

Before Each Run

• Check to make sure that all screws are tight.

Always use threadlock (DTXR2010) on screws

going into metal.

• Before running, always check the condition of your radio

system batteries and replace/recharge them if necessary.

• Check to make sure that all of the Cliff Climber’s moving

parts move freely and do not bind.

• Before running, turn on the radio and make sure the servos

move easily and in the proper direction.

• Check for broken or damaged parts. Replace any that

are found before running the Cliff Climber. Running the

Cliff Climber with broken or damaged parts could result in

damage to the rest of the truck.

• Check to make sure that all wires are properly connected.

• Check that the ESC and receiver are properly secured.

After Each Run

• Clean any large globs of dirt or debris from the chassis and

moving parts.

• Check for any broken or damaged parts. This way parts

may be replaced before the next run.

• Disconnect and remove the batteries from the Cliff Climber.

After Every 10 Runs

• Check to make sure that the bushings are free of dirt and

debris, and roll smoothly.

• Check the shocks for oil leakage. Inspect the shaft and

O-rings for wear and damage. Replace if necessary. (A

shock shaft with scratches you can feel with a fi ngernail

should be replaced.)

• Check the tires to make sure they are still properly glued

to the wheels.

9

Page 10

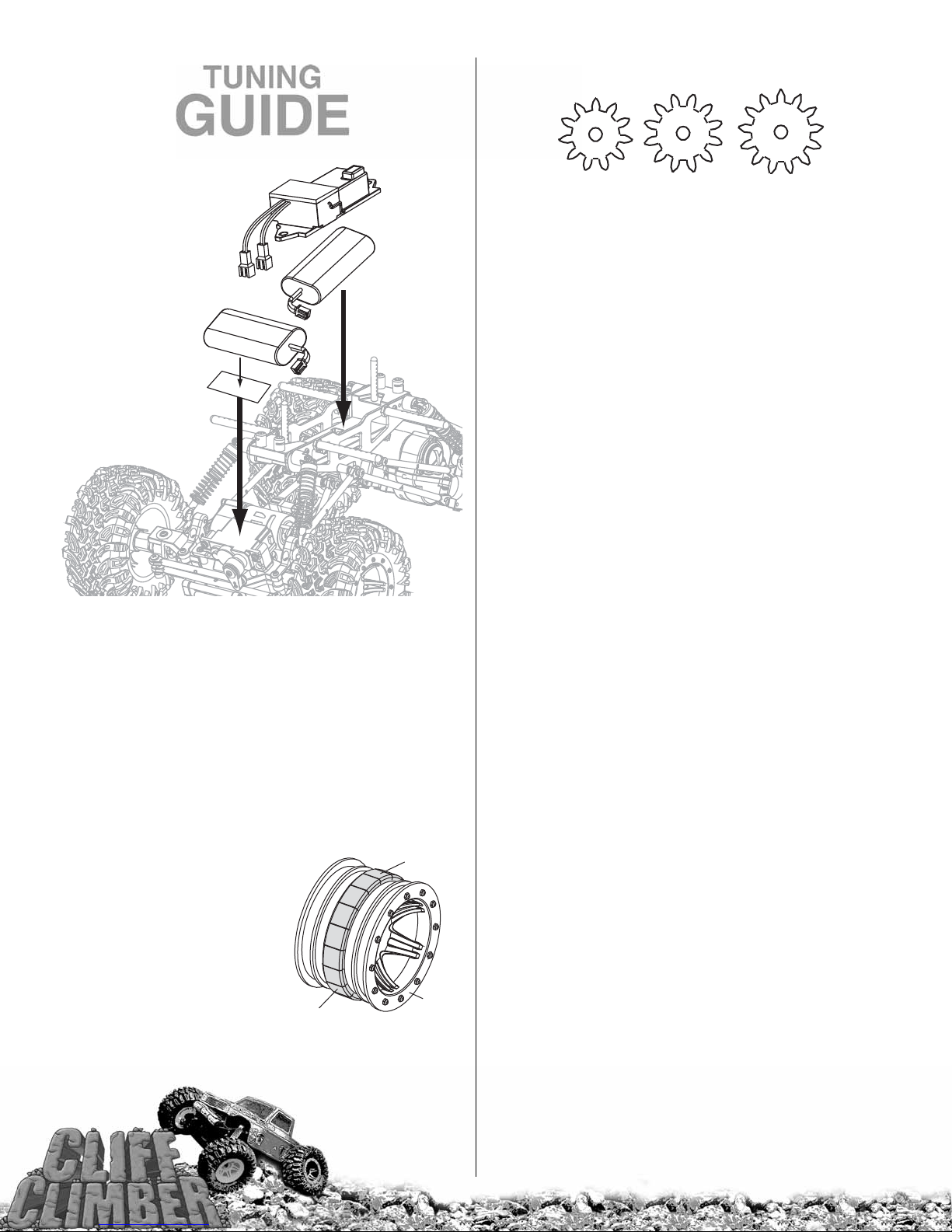

TUNING

d

l

s

PINION GEAR

GUIDE

BATTERY PLACEMENT

7.2V Battery

7.2V Battery

Hook & Loop

Material

Front

Battery placement is an easy way to improve the Cliff Climber’s

crawling capabilities. Take one of the batteries and install it on

top of the front steering servo. Lay the other battery down in

the Cliff Climber chassis. By placing the battery over the front

steering servo, you lower the center of gravity of the vehicle

and you place additional weight over the front wheels for

additional traction and better weight bias. There are a couple

of different ways to install the battery on the front steering

servo. The fi rst is by purchasing the DuraTrax optional servo

battery mount (DTXC6279). If you don’t currently have the

servo battery mount, you can use hook and loop material on

the battery and the servo.

WEIGHT

Another quick and easy way

to improve your Cliff Climber’s

crawling capabilities is to add

weight to the front rims. This

can easily be done by installing

a strip of stick-on lead weights

(available at most hobby

shops) all the way around

each of the front wheels.

Tip: Make sure the weight is

evenly placed all the way around the rim to help prevent the

wheels from being severely out of balance. This will increase

Wrap weights

evenly.

the weight over the

front wheels, increasing

traction and stability.

Segmented

Stick-On

Lead Weight

Whee

More

Torque

11 Tooth 12 Tooth

(Stock)

The Cliff Climber comes stock with a 12 tooth pinion. Optional

11 tooth (DTXC8347) and 13 tooth (DTXC8349) pinions are

also available. If you fi nd that you need a little more torque,

go down to 11 tooth pinions. If you are looking for a little more

speed from the Cliff Climber, go to 13 tooth pinions. Always use

the same size pinion on both motors. Make sure you set your

gear mesh properly if you change the pinions. You want a small

amount of play between the pinion and the gear. Too tight, and

you will damage the gears and possibly the motor and ESC. Too

loose, and you can strip the gears.

STEERING

Another way to improve the Cliff Climber’s crawling ability

is to install high torque servos. This will allow you to use

the strength of the steering servo to help maneuver around

obstacles. Another good upgrade is aluminum servo horns

(DTXM5010) on the steering servos. This will eliminate any

give in the steering allowing you to use the strength of the

servos. Caution: By removing the servo savers from the

steering servos, you increase the chances of the servo

getting damaged during use. We recommend you only use

an aluminum servo horn with metal geared servos.

For better clearance over rocks you can remove the front

and rear bumpers. Caution! This will expose your steering

linkage to impact and could cause damage to your servos.

SHOCKS

The Cliff Climber comes stock with 30 weight shock oil

installed in the shocks. We found this to be a good general

setup. Changing the shock oil can change how the Cliff

Climber crawls. This is something you will have to experiment

with, depending on what type of surface you are crawling on.

There are also optional shock springs available for the

Cliff Climber. Again, this is something that you will have to

experiment with to see what works best for you.

DTXC9112 Yellow (Medium, stock)

DTXC9156 Green (Firm)

DTXC9157 Blue (Extra Firm)

BUILDING A ROCK CLIMBER COURSE

The options for building an R/C crawling course for your Cliff

Climber are only limited by your imagination and access to

supplies. It can be as simple as stacking some books, boxes

or other general household items in your living room. You can

use rocks, wood or just anything you can stack outside to

crawl with your Cliff Climber. There are also several different

threads in the rccrawler.com forum that describe how to

build more complex crawling courses.

10

13 Tooth

More

Spee

Page 11

ce

MAINTENANCE

GUIDE

The following section is provided to help you with maintenance

following section is provided to help you with maintenan

and repairs to your Cliff Climber. Pay extra attention to the

notes and tips for proper assembly.

3x6mm

1 2

3x6mm

Bushing

..........2

3x6mm Bushing

Bushing

x2

x2

3

x2

4

10x15mm

Bushing

5x11mm

Bushing

..........2

5x11mm Bushing

..........2

10x15mm Bushing

5x11mm

Bushing

10x15mm

Bushing

x2

..........2

3x10mm Screw

3x10mm Screw

x2

3x10mm Screw

11

Page 12

5

..........2

3x10mm Set Screw

Shaft

E-Clip

..........1

4mm E-Clip

......1

2.5mm Shaft

..........2

5x11mm Bushing

6

3x10mm

Set Screw

4mm E-Clip

2.5mm Shaft

5x11mm

Bushing

3x10mm Set Screw

5x11mm

Bushing

x2

7

..........2

3x6mm Bushing

x2

x2

3x6mm Bushing

12

Page 13

8

2mm E-Clip

..........2

2mm E-Clip

9

2mm E-Clip

10

..........2

2.6x8mm Screw

..........2

3x10mm Screw

..........2

2.6mm Lock Nut

..........1

3x10mm S/T Screw

x2

3x10mm Screw

2.6x8mm Screw

x2

3x10mm S/T Screw

3x10mm Screw

2.6x8mm Screw

x2

2.6mm Lock Nut

2.6mm Lock Nut

13

Page 14

11

..........1

3x3mm Set Screw

12

2.6x20mm Screw

..........2

2.6mm Washer

3.5mm

3mm Set Screw

Apply

Threadlock

x2

.....2

x2

2.6mm Washer

2.6x20mm Screw

2.6mm Washer

Apply

Threadlock

2.6x20mm Screw

14

Page 15

The gear mesh on the Cliff Climber is adjustable. Make sure to set the

gear mesh properly to avoid damage to the gears. The gear mesh should

be set so that there is a slight amount of play between the pinion and the

gear it meshes with. Be careful not to set the mesh too loose or too tight.

13

14

x2

Check for proper

gear mesh

3x10mm S/T Screw

3x10mm S/T Screw

x2

3x10mm S/T Screw

15

2.6x10mm S/T Screw

2.6x10mm S/T Screw

2.6x10mm S/T Screw

x2

.......2

........6

2.6x10mm S/T Screw

2.6x10mm S/T Screw

2.6x10mm S/T Screw

2.6x10mm S/T Screw

15

Page 16

16

..........3

2.6x10mm S/T Screw

17

..........4

2.6x8mm Screw

2.6x8mm Screw

2.6x10mm S/T Screw

2.6x10mm

S/T Screw

x2

2.6x10mm S/T Screw

2.6x8mm Screw

2.6x8mm Screw

2.6x8mm Screw

16

Page 17

18

3x8mm Screw

..........4

3x8mm Screw

3x8mm Screw

3x8mm Screw

3x8mm Screw

19

..........4

5.8mm Ball

5.8mm Ball

5.8mm Ball

A

5.8mm Ball

B

5.8mm Ball

A

B

17

A

102mm

B

103.5mm

x4

Page 18

20

Note the direction

of the flange.

B

3x28mm Screw

3x28mm Screw

B

B

Note the direction

of the flange.

21

3x15mm Screw

Note the direction

of the flange.

3x15mm Screw

A

........4

3x28mm Screw

3x15mm Screw

B

B

3x28mm Screw

A

B

B

A

..........4

B

A

3x15mm Screw

3x15mm Screw

18

Page 19

22

Note the direction

of the flange

Note the direction

of the flange

....8

3x15mm Screw

3x15mm

Screw

3x15mm Screw

3x15mm

Screw

3x15mm Screw

Note the direction

of the flange

3x15mm Screw

3x15mm

Screw

3x15mm

Screw

Note the direction

of the flange

3x15mm Screw

19

Page 20

2.6x20mm

Shoulder Screw

23

2.6x20mm

Shoulder Screw

The shock mounts should be

able to rotate. Do not

overtighten the

mounting screws.

......4

2.6x20mm

Shoulder Screw

2.6x20mm Shoulder Screw

2.6x20mm Shoulder Screw

1.5mm E-Clip

24

..........2

1.5mm E-Clip

Oil the shock shaft and O-rings

before installing the shock shaft

to prevent damage to the O-ring

during assembly.

1.5mm E-Clip

Oil

Oil

Oil

x2

20

Page 21

25

Slowly move the shaft up

and down to remove air

bubbles. Push the shock

shaft up when installing

the shock cap. Note: Make

sure the shock piston

does not come out of

the oil when pushed up.

26

Oil

x4

27

2x10mm Screw

2x10mm Screw

Insert the

screw into

the shock

mount as

shown.

x4

..........4

2x10mm Screw

2x10mm

Screw

21

Page 22

28

5.8mm Ball

5.8mm Ball

5.8mm Ball

29

3x15mm Screw

.......2

5.8mm

Ball

..........4

5.8mm Ball

3x15mm Screw

Note the direction

of the flange.

3x15mm Screw

Note the direction

of the flange.

x2

22

Page 23

30

3x30mm

Screw

3x30mm

Screw

3x30mm Screw

Do not

overtighten.

3x30mm Screw

Do not

overtighten.

3x30mm Screw

..........4

3mm Lock Nut

31

..........3

2.6x8mm Screw

3mm Lock Nut

..........4

2.6x8mm Screw

3mm Lock Nut

3mm Lock Nut

3mm Lock Nut

x2

2.6x8mm Screw

2.6x8mm

Screw

x2

23

Page 24

32

5.8mm Ball

C

C

C

121.21mm

..........4

5.8mm Ball

5.8mm Ball

33

3x18mm Screw

...1

x2

5.8mm Ball

D

5.8mm Ball

D

87.8mm

D

x2

Front

..........1

3x10mm Screw

..........1

3mm Lock Nut

3x18mm Screw

3x10mm Screw

3mm Lock Nut

24

Page 25

Rear

34

..........1

3x10mm Screw

3x15mm Screw

3x18mm Screw

35

3x18mm Screw

......1

3x10mm Screw

..1

3x15mm Screw

36

..........1

3x10mm Screw

Front

x2

3x10mm Screw

25

Page 26

37

..........1

3x10mm Screw

Rear

38

..........1

3x10mm S/T Screw

3x10mm Screw

3x10mm S/T Screw

39

..........2

3x10mm S/T Screw

Install the servo

as shown.

3x10mm S/T Screw

3x10mm S/T Screw

Front

26

Page 27

Install the servo

as shown.

40

..........2

3x10mm S/T Screw

41

..........1

3x12mm S/T Screw

*Check for proper screw

size depending on the

servo used. The screw

for the RTR is shown.

3x10mm

S/T Screw

Rear

3x10mm

S/T Screw

Front

42

3x12mm S/T Screw

*Check for proper screw

size depending on the

servo used. The screw

for the RTR is shown.

Rear

..........1

3x12mm S/T Screw

Do not

overtighten

3x12mm S/T Screw

27

Page 28

43

3x10mm Screw

3x10mm Screw

3x10mm Screw

........4

3x10mm Screw

3x10mm Screw

44

45

Red to

batteries

Yellow

to motor

CH1

CH2

Double-Sided

Tape

To servo leads

Yellow

to motor

28

Page 29

46

47

Now’s a great time

to add weight to the

front wheels.

4mm Lock Nut

4mm

Washer

48

49

4mm Lock Nut

4mm

Washer

CA

Glue

CA

Glue

2.5mm Shaft

Caution: Don’t overflow the glue over the

tire surface.

Note the direction of the tires before gluing.

..........4

4mm Lock Nut

..........4

4mm Washer

.......4

2.5mm Shaft

2.5mm Shaft

29

Page 30

Hop-Ups Available for the Cliff Climber

Axle Tube/Gearbox

Graphite Pattern

DTXC6167

Blue Aluminum Turnbuckle (4)

Suspension Link A

DTXC9491

Blue Aluminum Turnbuckle (2)

Blue Aluminum

Knuckle Arm (2)

Suspension Link A

Bent Blue Alum Turnbuckle (4)

DTXC9489

Suspension Link C

DTXC9493

Suspension Link D

Blue Aluminum Turnbuckle (2)

DTXC9494

Other Accessories Available From DuraTrax

DTXC8230

Suspension Link B

Blue Aluminum Turnbuckle (4)

DTXC9492

7.2V 1400mAh Battery

Tire Glue

DTXR2000, Thin

DTXR2002, Med

DTXC2185

Long Nose Pliers

DTXR0300

Ultimate Driver Set

Onyx 240 Charger

DTXP4240

Battery Adapter

DTXC2210

DTXR0183

For more optional parts and accessories,

contact your hobby dealer or www.duratrax.com

30

Lead Weight

GPMQ4485

Page 31

ROCK CRAWLING

REFERENCES

For more tips and helpful information about the Cliff Climber

and R/C Crawling, go to www.rccrawler.com.

For information on rules and specifi cations for

R/C competions, go to www.usrcca.com.

31

Page 32

Entire Contents Copyright © 2008 DTXZ1123 for DTXD18** v1.0

Loading...

Loading...