Duratrax CHEVY CAMARO ZL1 Owner's Manual

N

YY

RR

G

3

110

13

32

13

2

2

Accessories

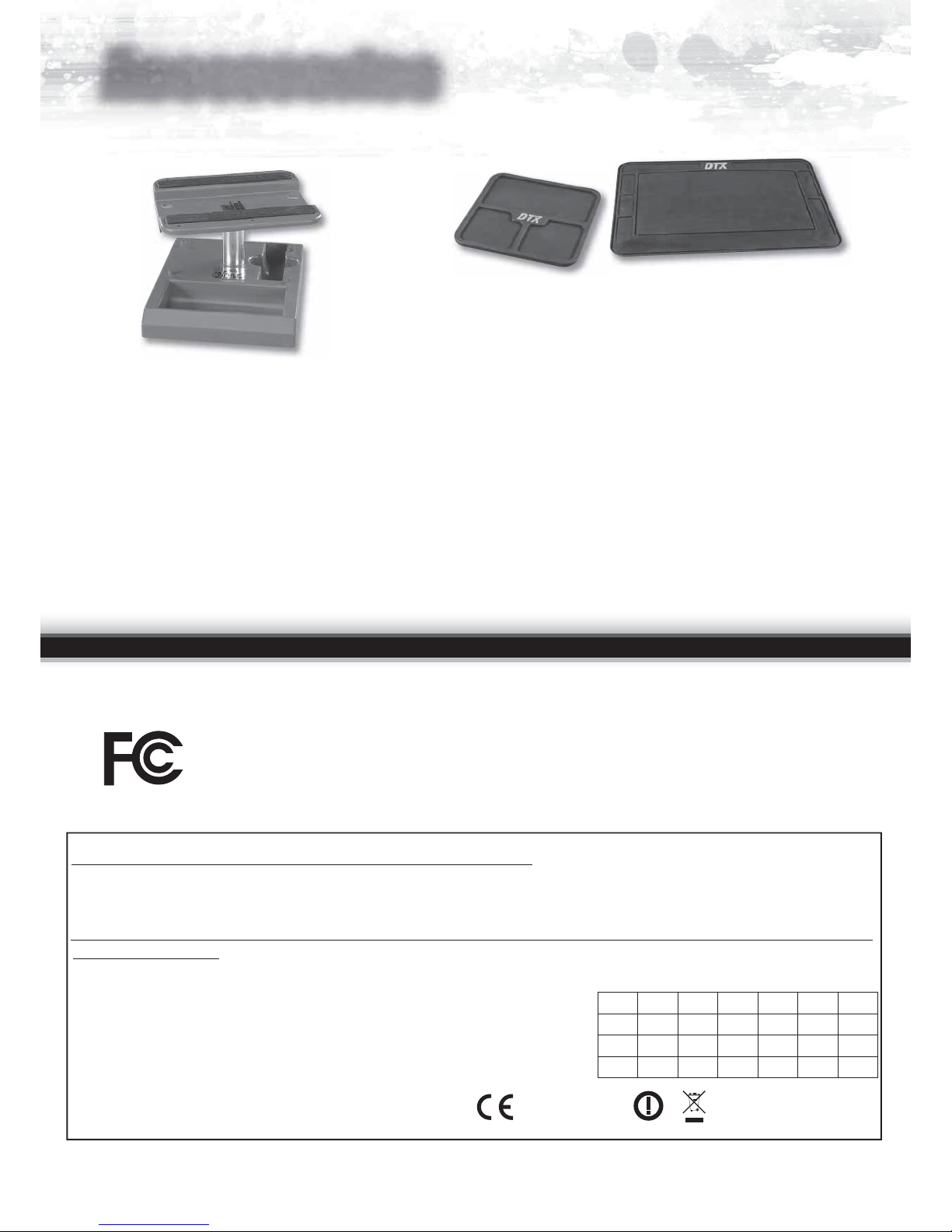

Pit-Tech™ Deluxe Car Stands

Pit Mats

Handy workstation features a rotating upper

plate with molded rubber insert grips. Base

includes an extra-large parts tray.

DTXC2370

Blue

DTXC2371

Orange

DTXC2372

Purple

DTXC2373

Green

The 5 x 5 in (63.5 x 63.5 mm) size is ideal for

small parts and hardware. The 29 x 19 in

(736.6 x 482.6 mm) has room for your vehicle,

heli or small plane, too. Both are made of

durable, solvent- and fuel-resistant rubber.

DTXP2045

5 x 5 in Pit Mat (63.5 x 63.5 mm)

DTXP2050

29 x 19 Pit Mat (736.6 x 482.6 mm)

3

3

This device complies with part 15 of the FCC rules. Operation is subject to the following two conditions.

(1) This device may not cause harmful interference.

(2) This device must accept any interference received, including interference that may cause undesired operation.

NOTE: THE MANUFACTURER IS NOT RESPONSIBLE FOR ANY RADIO OR TV INTERFERENCE CAUSED BY UNAUTHORIZED MODIFICATIONS

TO THIS EQUIPMENT. SUCH MODIFICATIONS COULD VOID THE USER’S AUTHORITY TO OPERATE THE EQUIPMENT.

FCC REQUIREMENT

CE COMPLIANCE INFORMATION FOR THE EUROPEAN UNION

Instructions for Disposal of Waste Equipment by Private Users in the European Union: This symbol on the product or its packaging indicates this

product must not be disposed of with other household waste. Instead, it is the user’s responsibility to dispose of their waste equipment by handing it over

to a designated collection point for the recycling of waste electrical and electronic equipment. The separate collection and recycling of your waste

equipment at the time of disposal will help to conserve natural resources and ensure that it is recycled in a manner that protects human health and the

environment. For more information about where you can drop off your waste equipment for recycling, please contact your local city office, your household

waste disposal service or location where you purchased the product.

Declaration of Conformity:

Product: Duratrax T240F 2.4GHz 2-Channel Tx and R240 3-Channel Rx

Item number: T240F, Equipment class: 2

The objects of the declaration described here are in conformiity with the requirements of the

specifications listed below, following the provisions of the European 2006/95/EC Low Voltage

Directive:

IEC 60950-1:2005(2nd Edition) + Am1:2009/EN 60950-1:2006 + A11:2009 + A1:2010 + A12:2011

The objects of the declaration described here are in conformity with the requirements of the

specifications listed below, following the provisions of the European R&TTE directive 1995/5/EC:

Radio: ETSI EN 300 328 V1.7.1 (2006-10)

EMC: ETSI EN 301 489-1 V1.8.1 (2008-04, Clause 9.2 and 9.3)

ETSI EN 301 489-17 V2.1.1 (2009-05)

Duratrax

c/o Hobbico, Inc.

2904 Research Road

Champaign, IL USA 61826

The associated regulatory agencies of the following

countries recognize the noted certifications to this

product as authorized for sale and use.

UK DE DK BG SE FI GR

EE LV LT PL CZ SK HU

RO SI AT IT ES PT IE

NL LU MT CY

0682

Included radio system not fully compliant with French regulations.

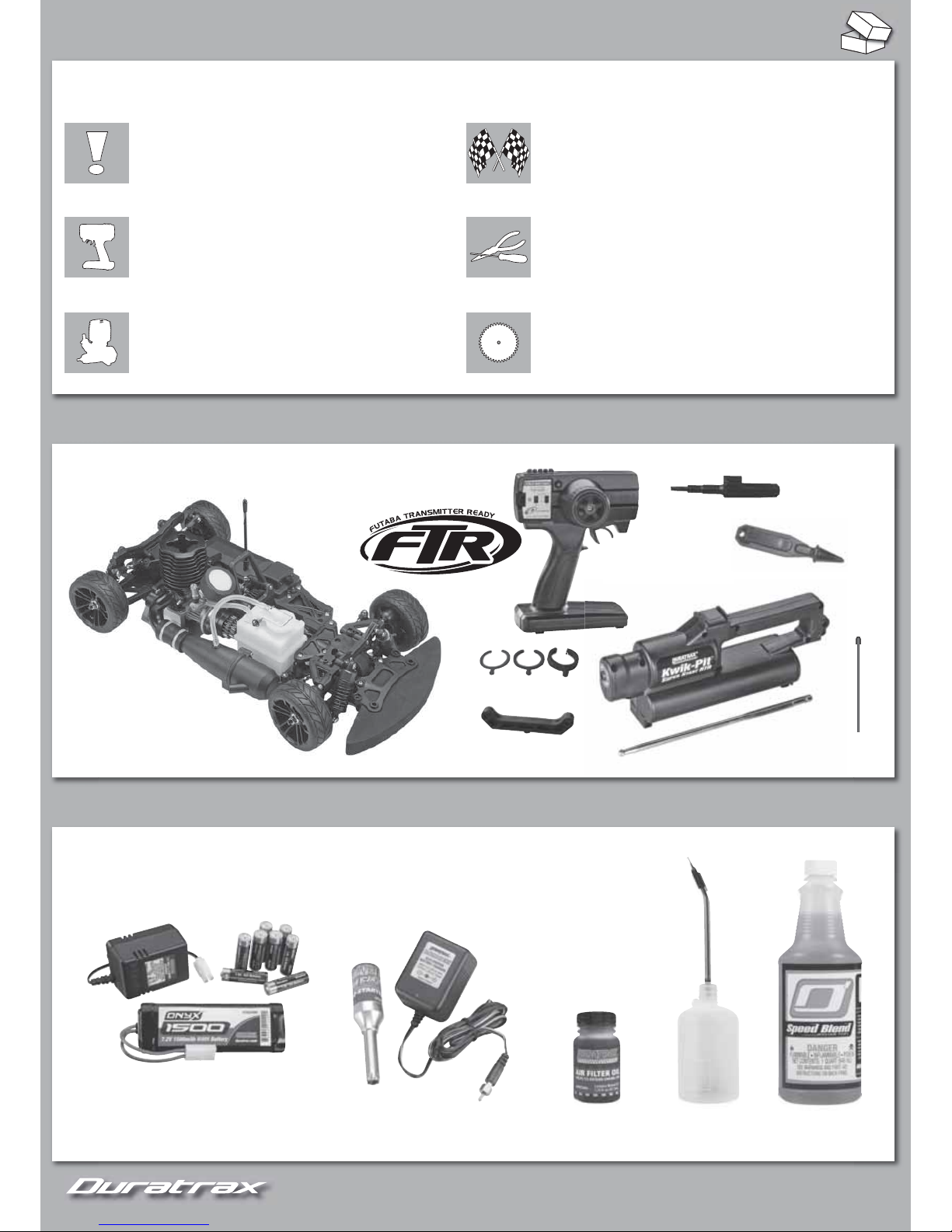

CONTENTS

Chassis

Super Start

Duratrax T240F

2.4 GHz Transmitter

™

Engine Stop Tool

Antenna

Tube

Shock Clips

x4 x4 x4

Rear Hinge Pin Mount

REQUIRES

“AA” (x8)

7.2V 6-Cell Battery Pack & Charger

(DTXP4615)

Glow Starter & Charger

(DTXP3000)

Air Filter Oil

(DTXC2465)

Fuel Bottle

DTXP0150

Fuel

(ODOP4520)

TABLE OF CONTENTS

Bind Tool

4

4

SAFETY PRECAUTIONS AND WARRANTY ....... 5 TUNING GUIDE ............................................. 10

GETTING READY TO DRIVE ............................. 6 ASSEMBLY GUIDE ........................................ 13

BREAK-IN PROCEDURE .................................8 REPLACEMENT PARTS ................................27

5

5

SPECIFICATIONS & DESCRIPTION CHANGES

ALL

information found in this manual is subject to change without notice. Visit Duratrax.com for the latest updates and information on your model.

Duratrax maintains no responsibility for inadvertent errors in this manual.

SAFETY PRECAUTIONS

To prevent injury and damage to property, follow these safety precautions when

operating any radio control vehicle.

Keep all spectators a safe distance away from the vehicle.

ALWAYS turn the transmitter on before the receiver.

NEVER touch any part of the engine or exhaust as they can become very hot.

ALWAYS keep model engine fuel out of the reach of children and follow

precautions on the container.

NEVER smoke and avoid ignition sources when using model engine fuel.

Model engine fuel is poisonous and fl ammable. Keep away from open fl ame.

NEVER run your model indoors. Fuel powered vehicles create harmful fumes.

Use a mat or towel when working on your model to protect your work surface.

Do NOT run your radio control vehicle in cold weather as plastic parts may

become brittle.

LIMITED WARRANTY

Duratrax guarantees this kit to be free from

defects in materials or workmanship for 90

days (3 years for the engine) after the date of

purchase. Duratrax will repair or replace at no

charge any incorrectly made part.

Your receipt or invoice at time of purchase

is your proof of purchase and is required for

Duratrax to honor any warranty. Duratrax

reserves the right to change or modify this

warranty without notice.

For warranty repairs, contact or send to:

Hobby Services

3002 N. Apollo Drive Suite 1

Champaign, IL 61822

ATTN: Service Department

Phone: (217) 398-0007

9:00 am – 5:00 pm Central Time M-F

E-mail: hobbyservices@hobbico.com

www.hobbyservices.com

IF

the buyer is not prepared to accept the

liability associated with the use of this product,

buyer is advised to return kit immediately

in new and unused condition to the place of

purchase.

STRESS-TECH PARTS GUARANTEE

Stress-Tech parts are guaranteed for 12 months from the date of

purchase. Check the parts list for items covered under the Stress-Tech

guarantee. Should a Stress-Tech part break during the fi rst 12 months

after purchase, return the part to Hobby Services and we will send you

a

FREE

replacement.

To receive your

FREE

replacement Stress-Tech part, include the

following and return to Hobby Services at the address above:

1. Broken part

2. Part number and description of the broken part

3. COPY of your dated purchase invoice or receipt

4. Name, phone number and shipping address

TM

REPAIR SERVICE

Hobby Services offers repair services after the limited warranty or 12 month

Stress-Tech parts replacement for a minimal charge.

Follow these instructions for your repair request:

1. Most circumstances require the return of the ENTIRE vehicle. STRESS-TECH

requires ONLY the broken part to be returned following the instructions above.

2. Turn off the transmitter and remove the batteries.

3. Empty fuel tank on nitro vehicles.

4. Include written instructions listing ALL items being returned with a THOROUGH

description of the problem, service needed and your DAYTIME phone number.

IF you expect the repair to be covered under the limited warranty, include

copy of receipt or invoice with date of purchase.

5. Send to Hobby Services at the address above. When shipping your item(s)

to us, we recommend that you insure them and use a company that offers

tracking service (such as UPS or Federal Express).

We will carefully inspect your item and notify you of our fi ndings. You will be

advised of your options for return, repair, or replacement. Please note that items

sent back unrepaired will carry a return shipping and service charge.

Hobby Services accepts Visa®, MasterCard®, or you can send a check. We can

return the item C.O.D., but additional charges will apply.

6

6

6

6

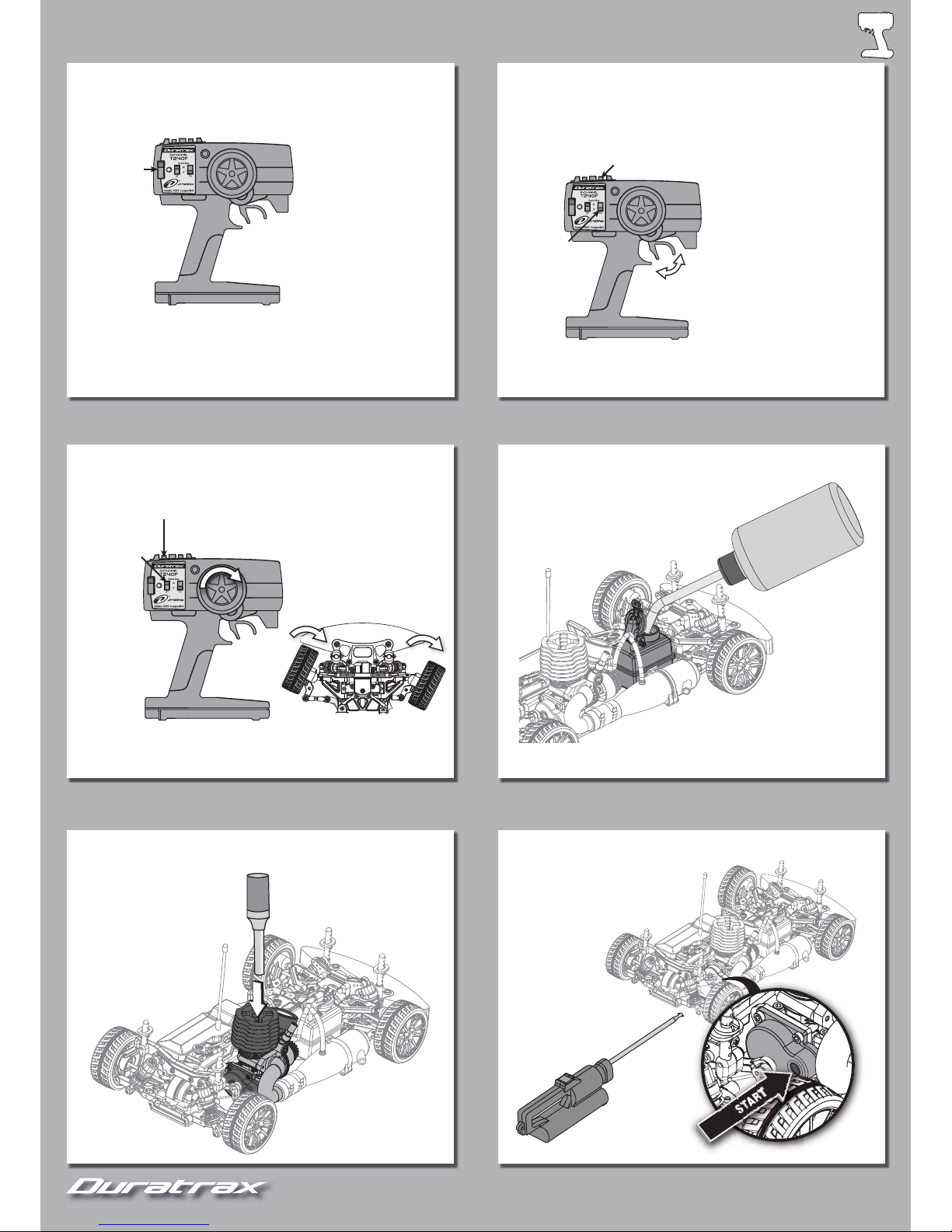

GETTING READY TO DRIVE

Follow these steps to get the radio, super start, and Camaro ready for use.

7.2V NiMH

1. CHARGE THE SUPER

START BATTERY*

2. PREPARE THE SUPER START

+

+

+

+

–

–

–

+

–

3. INSTALL TRANSMITTER

BATTERIES

4. INSTALL RECEIVER

BATTERIES

Do not cut antenna wire!

s

Apply air filter oil (DTXC2465) onto the foam element, squeezing

the element until it is completely coated with the oil.

s

TIP! Placing the element in a plastic bag will help keep your

hands clean.

s

Remove any excess oil with a paper towel.

5. INSTALL ANTENNA TUBE 6. OIL AIR FILTER

*Charger and battery not included.

7

7

Check radio operation

before each run!

On/Off

If you ever need to rebind the receiver, turn on the system

and press the bind button on the receiver using the included

binding tool until the L.E.D. turns solid green.

2.4 GHz

Forward

Brake

Check radio operation

before each run!

Throttle Trim

Throttle

Reverse

Switch

2.4 GHz

7

7

7. POWER UP TRANSMITTER 8. CHECK THROTTLE

Check radio operation

before each run!

Steering Trim

Steering Servo

Reverse Switch

2.4 GHz

9. CHECK STEERING 10. FUEL THE CAR

See page 8 for starting and

enigne break-in details.

11. ATTACH GLOW STARTER 12. START THE ENGINE

8

8

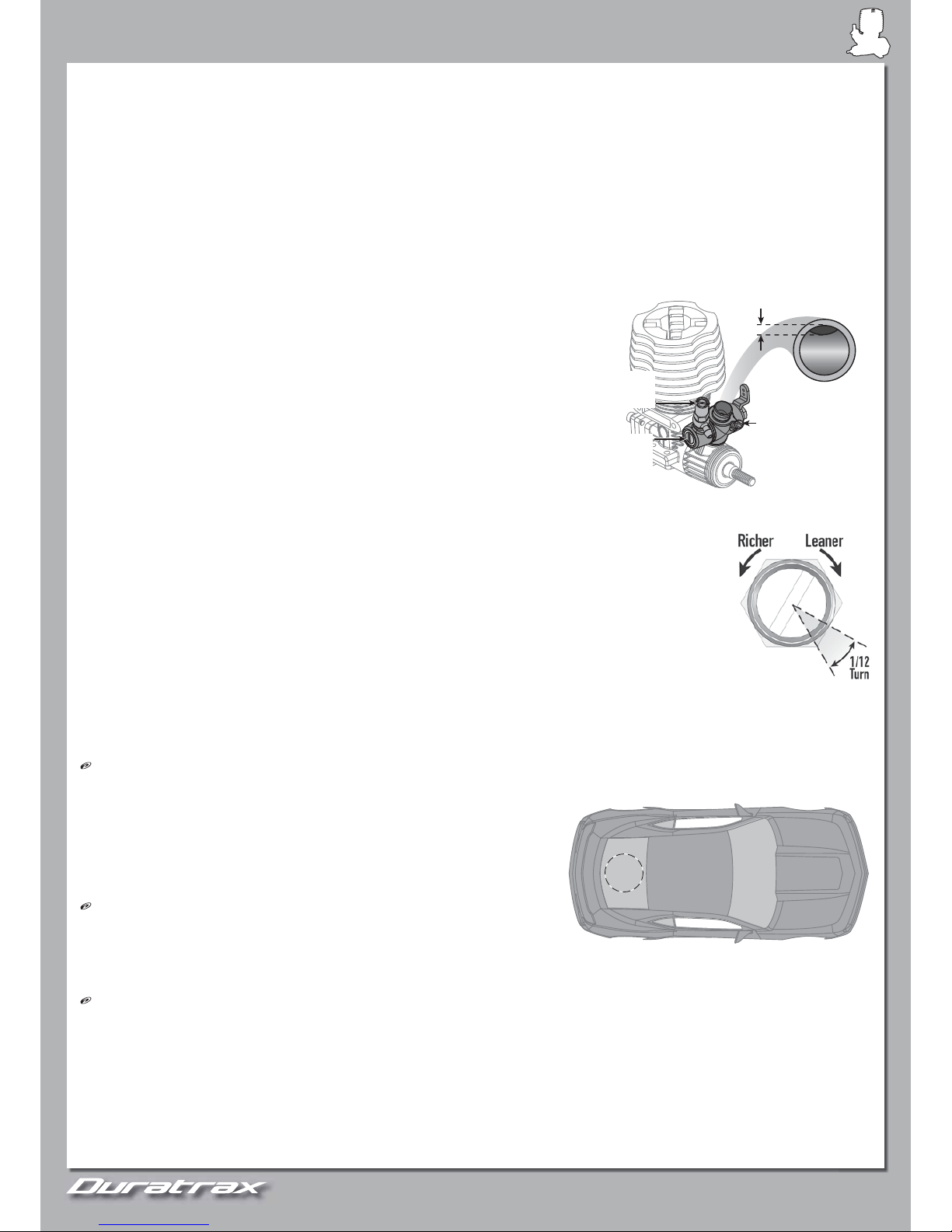

BREAK-IN PROCEDURE

When starting, hold the throttle slightly open. If the engine is diffi cult to turn over, loosen glow plug 1/2-turn before starting engine (this allows

some compression to escape while allowing the engine to start). Once engine starts tighten the glow plug.

IMPORTANT! FLOODED ENGINE:

IMPORTANT! FLOODED ENGINE: If the Super Start still is having problems turning the engine over, it is fl ooded (too much fuel inside the engine).

1. Remove glow plug and turn vehicle upside down, pointing away from you.

2. Run Super Start for 5-6 seconds (clearing engine of fuel).

3. Replace glow plug.

4. Repeat starting engine steps.

Initial engine break in will be accomplished with the fi rst 5 tanks of fuel. (Full break-in may take up to 15 tanks.)

Initial engine break in will be accomplished with the fi rst 5 tanks of fuel. (Full break-in may take up to 15 tanks.)

1. During break-in, run with the body off to keep the engine cool.

2. Keep air fi lter on at all times.

3. Run on smooth, hard surface.

4. Make sure you have extra glow plugs. Break-in puts stress on the glow plug

and it may need to be replaced.

TANK 1

TANK 1

Run very rich allowing fuel to carry as much oil as possible to lubricate internal engine parts.

1. High Speed Needle Valve: Check this setting before running. Close the high speed

needle by rotating it clockwise until you just feel resistance, then open to 3 full turns out

(counterclockwise).

2. Run at medium speeds, slowly accelerating and decelerating.

NOTE:

NOTE: It is normal for the

two speed NOT to shift during this tank.

3. If engine does not stay running consistently, increase idle speed by turning the idle stop screw clockwise.

4. DO NOT allow the tank to run out of fuel during break-in.

5. Stop engine by placing the engine tool into the exhaust outlet. Allow it to cool approximately 10 – 15 minutes.

TANKS 2-4

TANKS 2-4

1. For each additional tank, lean high speed needle 1/12 turn from the previous tank’s setting.

2.

Stop engine, allowing it to cool approximately 10 – 15 minutes, between each tank.

TANK 5

TANK 5

1. Lean high speed needle an additional 1/12 turn from Tank 4 setting.

2. The engine should now be very close to fi nal tune and be broken in and ready to be performance tuned.

TUNING TIPS (Adjust only after the engine is fully broken in.)

TUNING TIPS (Adjust only after the engine is fully broken in.)

IMPORTANT!

IMPORTANT!

Always run the engine for 1-2 minutes to warm up temperature before tuning! Only use “small” adjustments (1/12 turn at a time) and test

the results.

High Speed Needle

High Speed Needle::

Controls the fuel/air mixture at high throttle settings. A properly tuned engine will accelerate smoothly and exhaust a

small amount of smoke. The goal is to tune the engine to make good power without overheating. Engine temperature should stay around

250° F (132° C) using a temperature gauge (Duratrax Flashpoint™, DTXP3100).

Note:

Note:

This temperature is a “guideline” only. Your engine may run slightly warmer or cooler

depending on conditions; fuel, track, and how you drive.

On hot days, additional cooling may be needed. Cut a 60mm hole in the rear window to

allow more airfl ow through the body.

Low Speed Needle

Low Speed Needle::

Controls fuel mixture at low throttle settings (idle). To check this

setting, keep the throttle at idle and pinch the fuel line close to the carburetor. A

correct setting will increase the engine speed after 2-3 seconds and then lose speed.

• If it slows too quickly, the mixture is too lean. Open the low speed needle (counterclockwise).

• If it takes longer than 4 seconds to slow down, the mixture is too rich. Close the low speed needle (clockwise).

Idle Stop Screw:

Idle Stop Screw: Adjust this screw to set the idle speed so the wheels do not rotate when you lift the vehicle off of the ground. When looking

into the carburetor, the barrel should be about 1mm from fully closed.

CARE AND MAINTENANCE

CARE AND MAINTENANCE

1. Keep engine clean and free of dirt.

2. Do not over lean engine.

3. Run all of the fuel out of the engine before storing.

4.

Use after run oil and work it into the engine by turning the fl ywheel before storing

.

5. Do not use a fuel with a nitromethane content over 30%.

~1mm

Idle stop

screw

High

speed

needle

Low

speed

needle

60mm

8

8

9

9

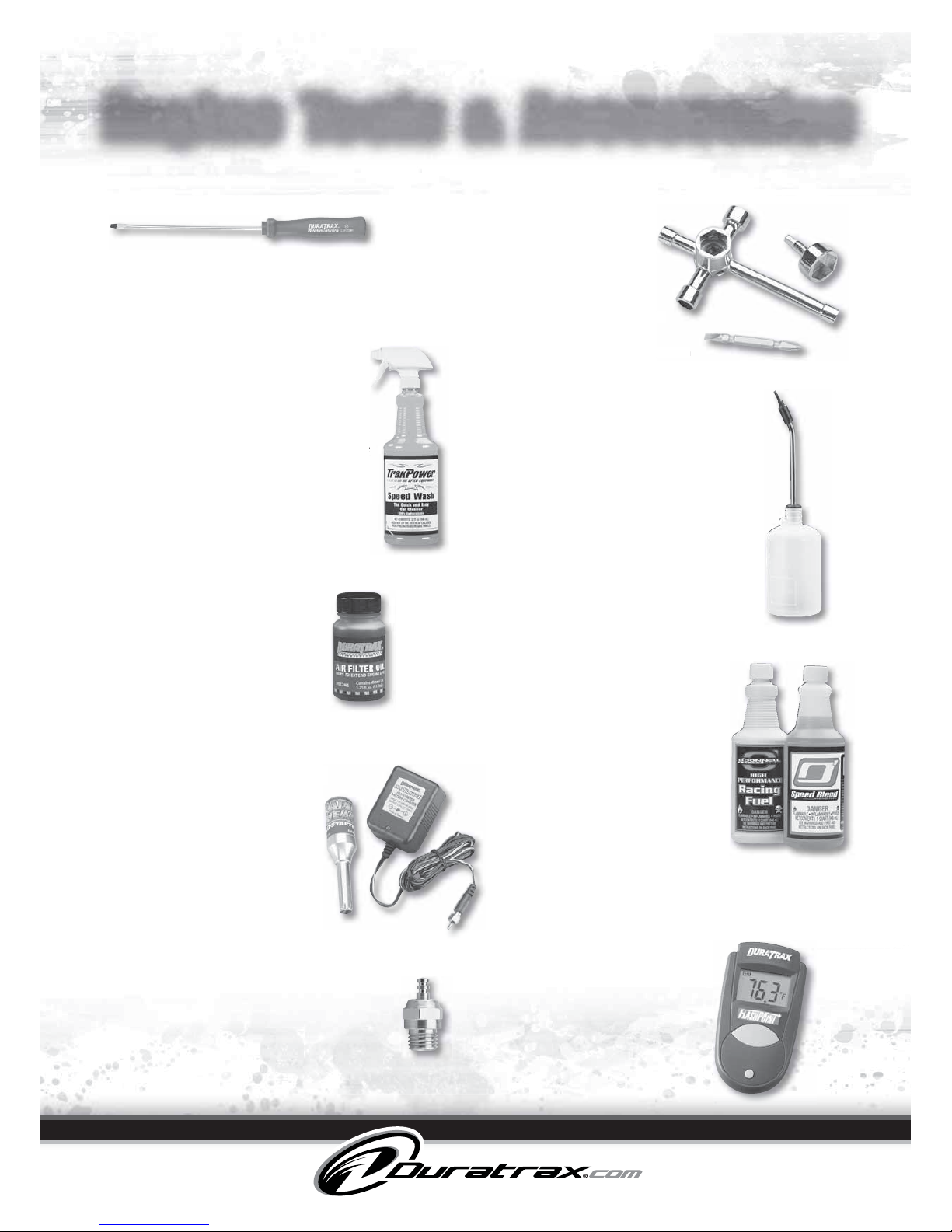

Engine Tools & Accessories

Engine Tuning Screwdriver

TrakPower

™

Speed Wash

Nitro Cleaner

Kwik-Pit

™

Fuel Bottles

Rapid Heat

™

Glo-Starter

FlashPoint

™

Infrared

Temperature Gauge

Deluxe Car Wrenches

O’Donnell Racing Fuel

®

Air Filter Oil

Standard slot-head screwdriver has a 120 mm

hardened steel shaft with 3.2 mm wide magnetized

tip and rubberized, hexagonal handle.

DTXR0185

Applies with or without water and is safe

for titanium, aluminum, fiberglass, clear

coat, stainless steel, chrome, rubber,

plastic, vinyl and leather. 32 fl oz (946 mL).

TKPC8001

A squeeze on the clear plastic body

lets you control fuel flow. The 5 in

(63.5 mm) long aluminum spout

features a curved tip for no-spill refills

and a tip cap to prevent leaks. For

glow fuel only.

DTXP0125

250 cc (8.5 fl oz) Fuel Bottle

DTXP0150

500 cc (17.0 fl oz) Fuel Bottle

Twist-on for a secure connection

to heat your glow plug. Twist

the other way for easy removal.

Includes NiCd and AC charger.

DTXP3000

Just point and press for

fast, accurate, no-touch

temperature readings of

engines, motors, batteries

and more. Works in seconds

and turns off automatically

after 15 seconds of inactivity.

DTXP3100

Hand-assembled with heat resistant coils.

Carbon Speed is medium-hot for informal

racing and sport use. Gold Racing Plug is for

higher nitro fuels and competitive driving.

DTXG3003

Carbon Speed Plug

DTXG3005

Gold Racing Plug

Deluxe includes 6

socket head sizes

and stores up to 4

glow plugs. Ultimate

adds a slotted/Phillips

screwdriver bit and

19 mm socket for 1/8 car

wheel nuts.

DTXR1170

Deluxe Car Wrench

DTXR1175

Ultimate Car Wrench

Speed Blend improves fuel

economy and pushes engine

performance to the absolute

peak. Race Blend simplifies

tuning and reduces engine heat

and internal wear.

ODOP3320

20% Racing Fuel Quart

ODOP3325

25% Racing Fuel Quart

ODOP3330

30% Racing Fuel Quart

ODOP4520

20% Speed Blend Quart

ODOP4525

25% Speed Blend Quart

ODOP4530

30% Speed Blend Quart

Treats foam air filter elements

to increase filtering capacity

and extend engine life. Handy

1.75 fl oz (51.7 mL) bottle fits

easily into a tool box or tote.

DTXC2465

.

r

rench

Glow Plugs

10

10

TUNING GUIDE

As a starting point, make sure your car has equal lengths on shocks, camber links and steering rods on both sides (left

and right). Front and rear do not need to be equal.

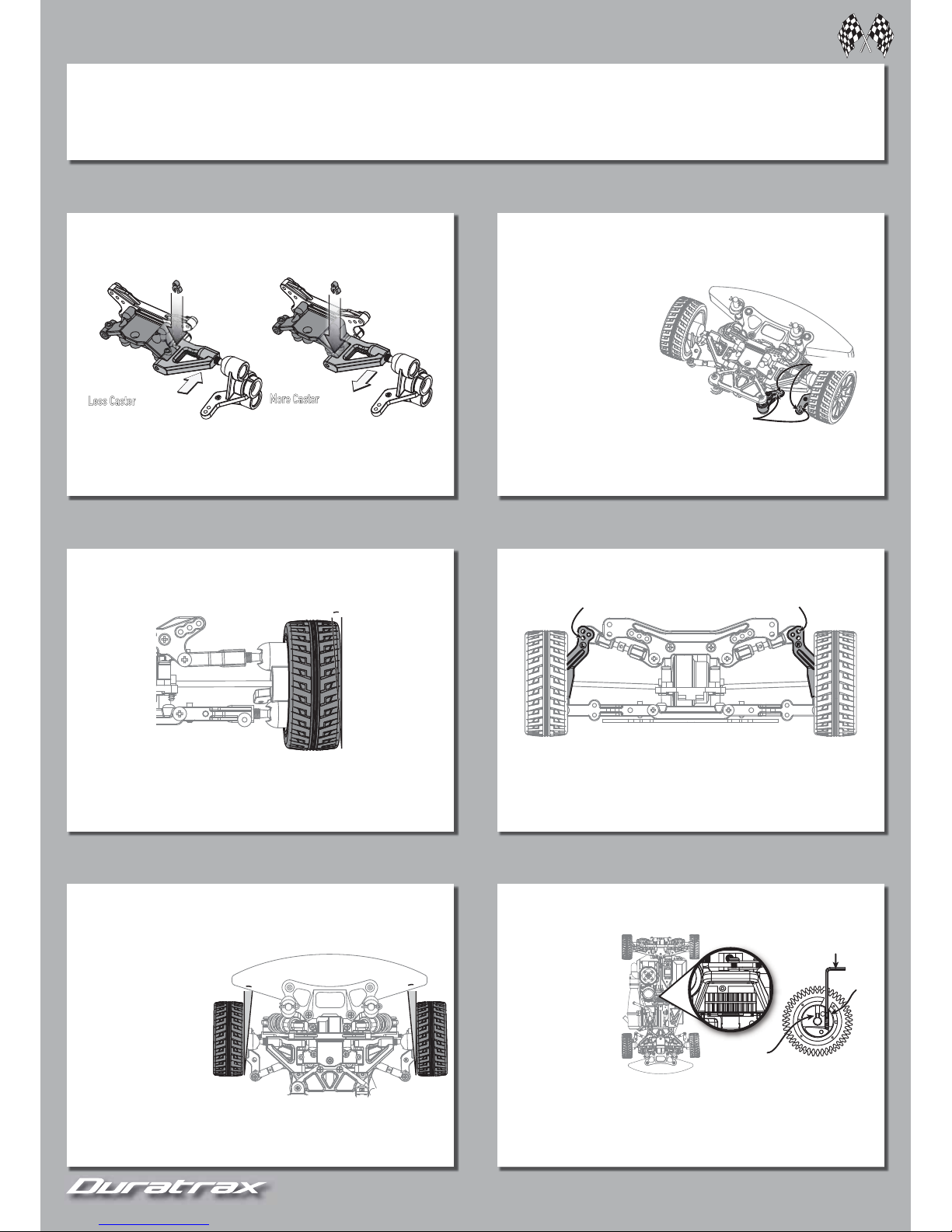

Upper Arm Spacer

Less Caster

= Arm forward

More Caster

= Arm back

Upper Arm Spacer

CASTER

Angle of the front knuckles in relation to the ground when

viewed from the side.

• Increased off power steering

when entering a corner.

• Straight line stability.

• Vehicle more responsive.

• Decreases on power steering

when entering a corner.

• Turns feel smoother.

More Ackerman

Less Ackerman

ACKERMAN

The difference in turning angle between the inside wheel

and outside wheel in a turn.

Less Ackerman

Less Ackerman =

Inside wheel turns more equal to the outside wheel.

Move steering rod forward on the knuckle or back on the bellcranks.

Less aggressive steering, smoother cornering.

Mo re Ackerman

Mo re Ackerman =

Inside wheel

turns increasing more than the

outside wheel. Move steering

rod back on the knuckle or

forward on bellcranks.

More aggressive steering,

vehicle turns more abruptly.

0°

-2°

CAMBER

Angle of the tire and wheel in relation to the ground when

viewed from the front.

Negative Camber

Negative Camber =

Tire and wheel lean inward (Typically 0° to -2°)

• Improved traction while corning.

• Adds overall stability.

Positive Camber

Positive Camber =

Tire and wheel lean outward (This is NOT recommended)

Highest roll center Lowest roll center

ROLL CENTER

Point at which the vehicle rolls laterally when cornering.

Raising Roll Center:

Raising Roll Center: Raise rear camber rod mounting location on the hub.

Increases rear on power traction and decreases rear traction during braking.

Lowering Roll Center:

Lowering Roll Center: Lower rear camber rod mounting location on the hub.

Decreases rear traction on power, reduces corner entry steering and

increases corner exit steering.

Toe-In

-

2°

-

2°

0°

0°

FRONT TOE-IN AND TOE-OUT

Direction the wheels point in relationship with each other,

when viewed from above.

Toe-Out

Toe-Out:: Fronts of the wheels point away from each other.

• Decreased stability when accelerating and increased steering when

entering a corner.

To e-In:

To e-In: Fronts of the wheels

point toward each other.

(Typically 0 to -2°)

• Increased stability when

accelerating. Decreased

steering when entering a

corner.

FRONT CUT AWAY VIEW

1.5mm hex wrench

Do not adjust

this screw!

Adjustmen

t

Screw

2-SPEED SHIFT POINT

Proper shift point helps keeps the engine within its optimum

RPM range.

Shifts too soon

Shifts too soon

(Vehicle will lose acceleration):: Turn the screw in, making

the vehicle shift later and engine rev higher before shifting.

Shifts too late

Shifts too late

(Vehicle will not hit top speed): Turn the screw out, making

the vehicle shift sooner and engine rev less before shifting.

THE ENGINE MUST BE

COMPLETELY BROKEN IN

AND UP TO OPERATING

TEMPERATURE BEFORE

MAKING SHIFT POINT

CHANGES.

IF YOU NEED TO MAKE A

CHANGE, STOP THE ENGINE!

10

10

11

11

CHASSIS MAINTENANCE TIPS

Check before every run:

1. All hardware to be sure everything is tight.

2. Transmitter batteries.

3. Moving parts are free from binding.

4. Parts are not broken or damaged.

5. Wires are properly connected.

6. Remove dirt or debris from chassis and moving parts.

7. Bearings should roll smoothly.

8. Shocks should operate smoothly. Check for leakage and refi ll as needed.

9. Gear mesh between the spur and pinion gears.

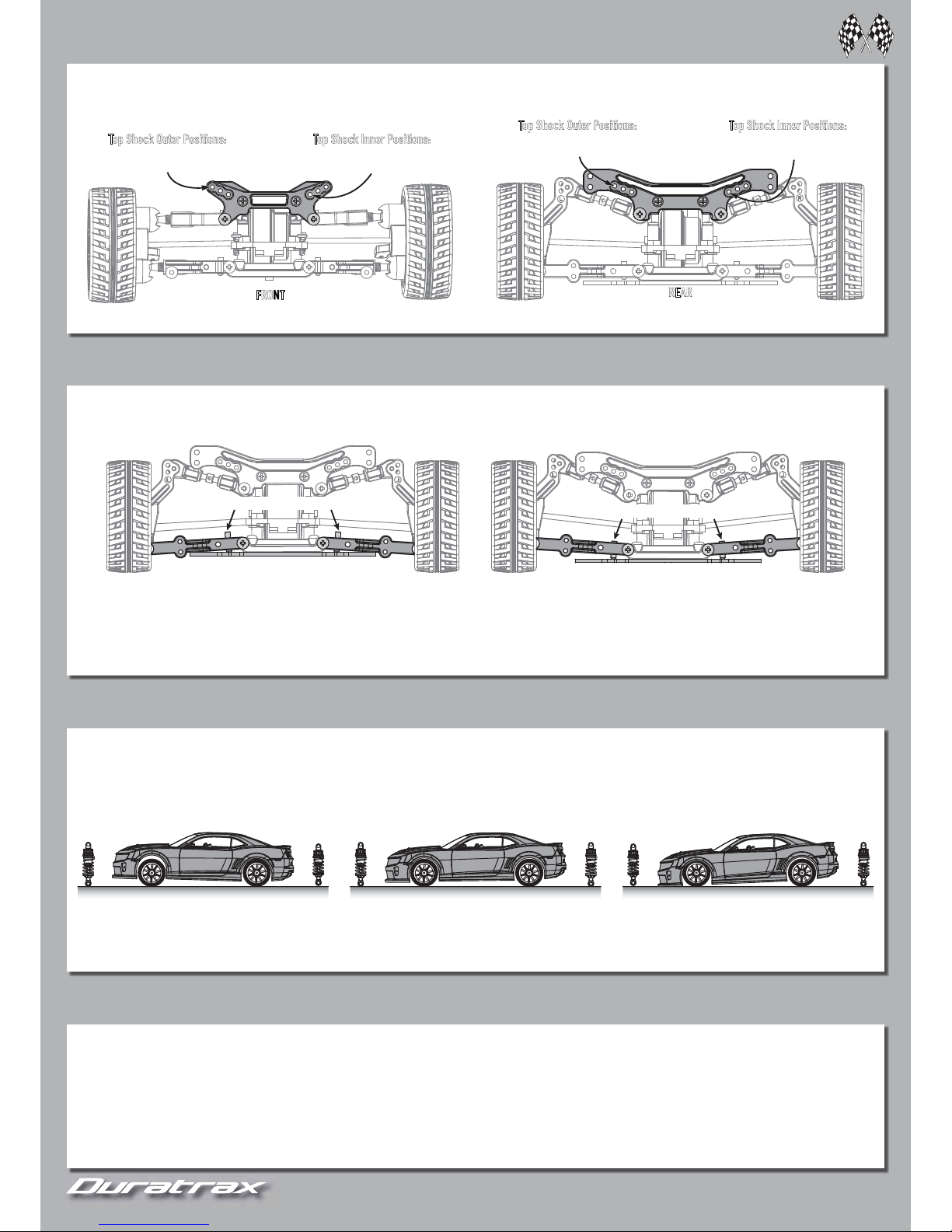

SHOCK ADJUSTMENTS

Top Shock Outer Positions:

s Decreases steering

s Quicker suspension reaction

FRONT

Top Shock Inner Positions:

s More aggressive steering

s Smoother over bumps

Top Shock Outer Positions:

s Increase steering

s Quicker suspension reaction

Top Shock Inner Positions:

s More traction in corners

s Smoother over bumps

REAR

Screws adjusted so arms drop less.

Screws adjusted so arms drop more (more droop).

DROOP

Distance the chassis can lift from ride height before the wheels come off the ground.

More Front Droop:

More Front Droop: Increases chassis up travel when on throttle and decreases high speed steering, making vehicle turn smoother. Good for low traction and bumpy surfaces.

Less Front Droop:

Less Front Droop: Decreases chassis up travel when off throttle and under braking, making steering more aggressive. Good for high speed smooth surfaces.

More Rear Droop:

More Rear Droop: Increases chassis up travel when off throttle and under braking. Increases steering in low speed corners and under braking.

Less Rear Droop:

Less Rear Droop: Decreases steering in low speed corners, making the vehicle turn smoother.

More spacers on the front shock. More spacers on the rear shock.Same number of spacers front and rear.

RIDE HEIGHT

Distance the chassis sits from the ground and how much weight is transferred when the vehicle changes speed and direction.

Lower Rear:

Lower Rear: More rear traction but reduces steering.

Lower Front:

Lower Front: Increases steering but can cause

rear end to break loose.

11

11

12

12

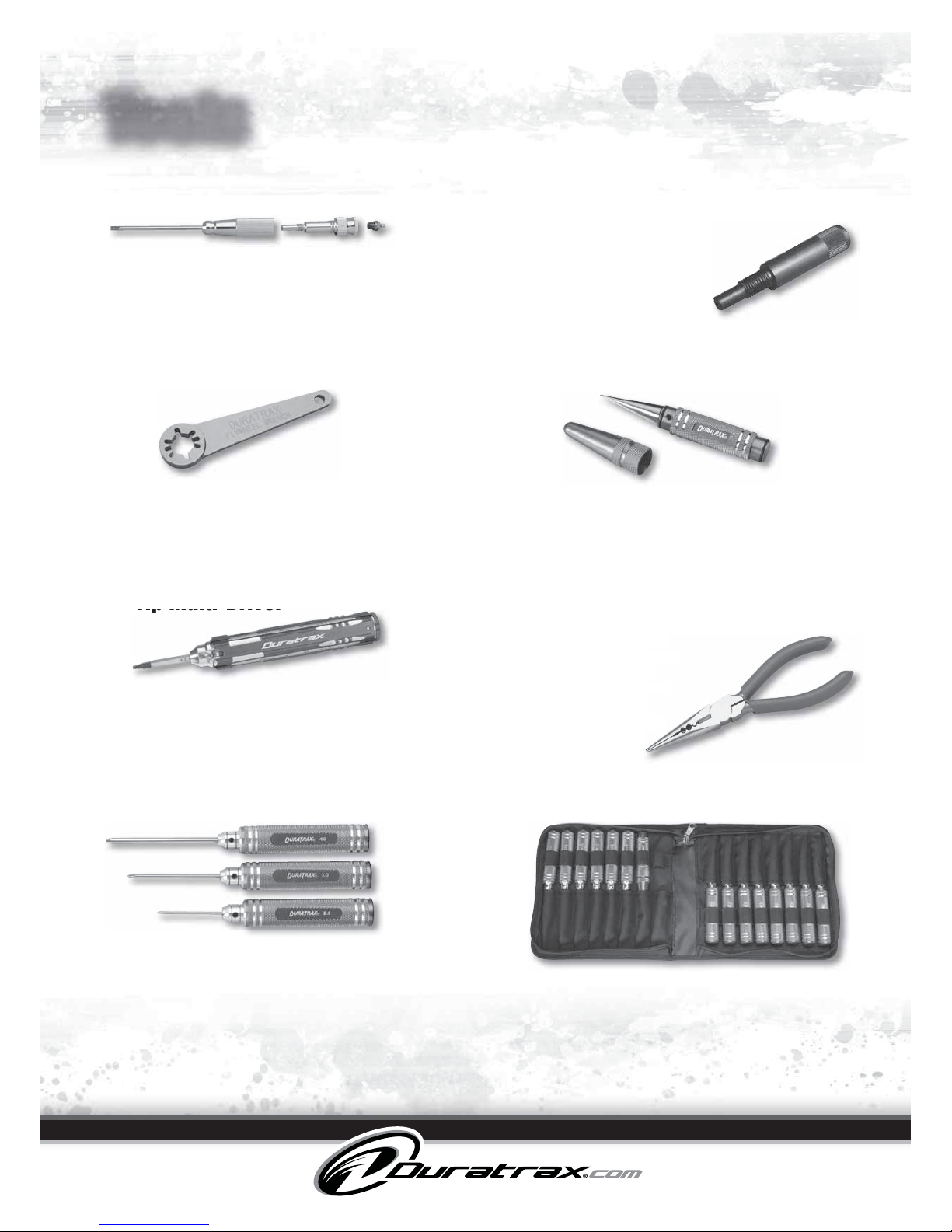

Tools

Engine Tuning Tool

Ultimate Flywheel Wrench

Ultimate Body Reamer

6” Long Nose Pliers

Tool Set and Pouch

Crankshaft Locking Tool

12-Tip Multi-Driver

Two tools for the price of one – a steel shank

screwdriver with a knurled, anodized aluminum

handle and a piston locking tool! Includes

storage space for one spare glow plug.

DTXR0187

Slotted to fit 2-, 3- or 4-pin flywheels, this

aluminum wrench safely holds the flywheel

while you tighten or loosen clutch nuts —

without stressing internal engine components.

DTXR1105

The extra-sharp point starts holes precisely

where you want them, while the knurled

aluminum handle provides a secure grip. A

snap-on cap protects the tip when not in use.

DTXR1157

Forged from chrome

alloy steel, these pliers

feature rubberized

handles and serrated

jaws for easy wire

bending, cutting and

stripping.

DTXR0300

Set includes 4 each of metric and SAE hex drivers,

3 each of slotted and Phillips screwdrivers, plus

an Ultimate Body Reamer — all organized in

a zippered, 15-pocket tool pouch (pouch also

available separately).

DTXR0400

15-Piece Ultimate Tool Set w/Pouch

DTXR0401

15-Pocket Ultimate Tool Pouch Only

Tools in these convenient sets have knurled, blue-anodized

aluminum handles; hardened steel shafts; precision-ground

tips; and tip sizes engraved onto the handles.

DTXR0179

3-Piece Ultimate Slotted Screwdriver Set (2, 3 and 4 mm)

DTXR0183

3-Piece Ultimate Phillips Screwdriver Set (2, 3 and 4 mm)

DTXR0292

4-Piece Ultimate Hex Driver Set (1.5, 2, 2.5 and 3 mm)

DTXR0297

4-Piece Ultimate Ball Driver Set (1.5, 2, 2.5 and 3 mm)

DTXR0392

4-Piece Ultimate Hex Driver Set (.050, 1/16, 5/64 and 3/32 in)

This handy tool threads into

your engine’s glow plug

socket, locking the piston

and crankshaft to prevent

them from turning while

you perform maintenance.

DTXR1100

The aluminum handles holds six shanks with 12 adjustablelength tips, suited for many different driving needs. Rotate

the end cap to select the tip you need. Tips included:

1.5 mm and 2 mm slotted; 0 and 00 Phillips; and 1.5 mm,

2.0 mm, 2.5 mm, 3.0 mm, .050”, 1/16”, 5/64”, and 3/32”.

DTXR1165

Tip Multi Driver

Ultimate Tool Sets

me

pliers

d

ed

nd

Loading...

Loading...