Page 1

®

Page 2

TABLE OF CONTENTS

2

SAFETY PRECAUTIONS AND WARRANTY ...............3 TUNING GUIDE ..................................................8-10

PREPARE TO RUN THE 835B ............................... 4-5

ENGINE RUNNING & MAINTENANCE ......................6 REPLACEMENT PARTS ........................................34+

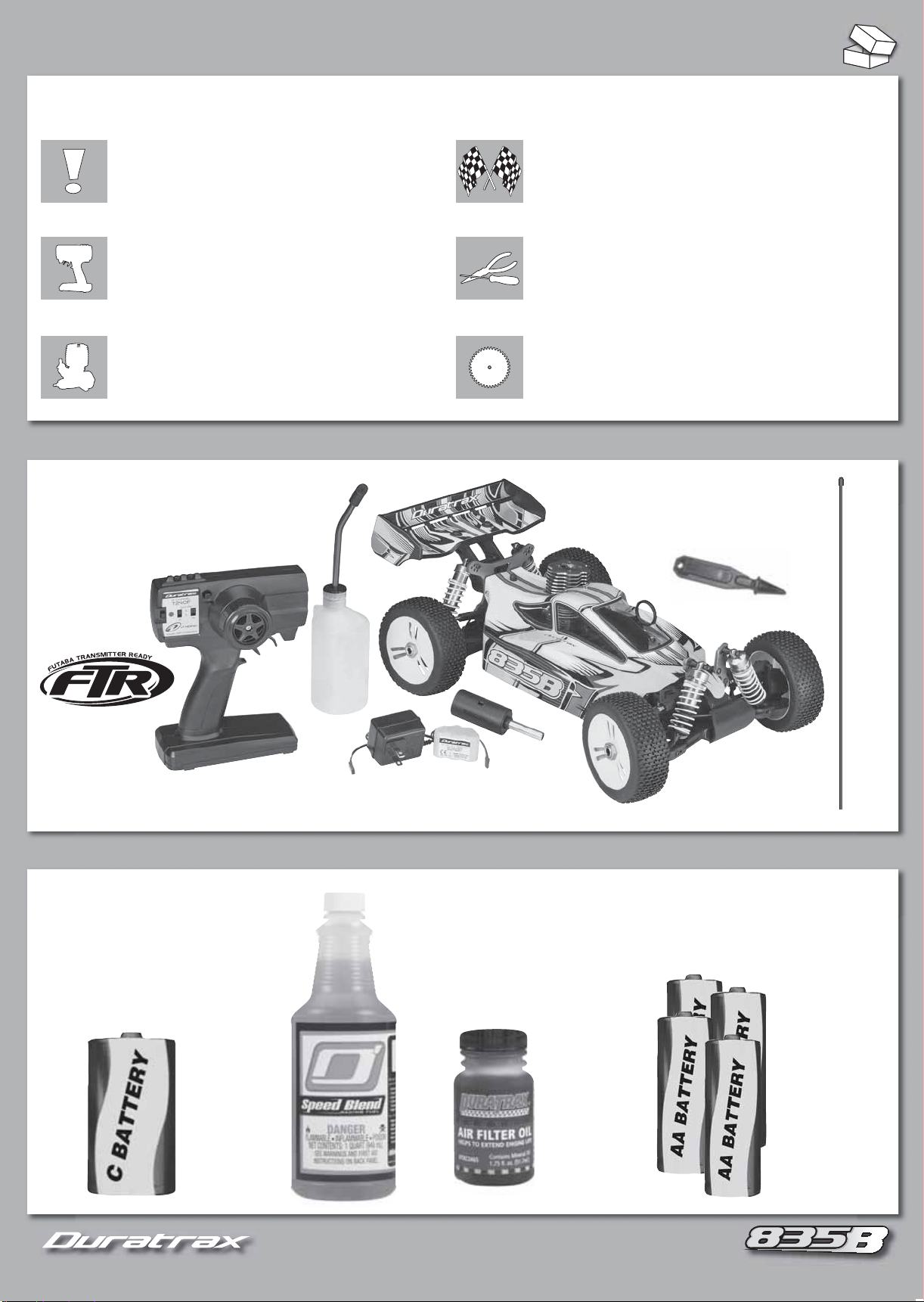

CONTENTS

™

Duratrax T240F 2.4 GHz Transmitter

Fuel

Bottle

Rx Battery

Charger

Receiver

Battery

ASSEMBLY GUIDE ........................................... 11-33

Engine Stop Tool

Glow

Starter

Chassis

Antenna

Tube

REQUIRES

“C” Alkaline

Battery

(Glow Starter)

Fuel

(ODOP4520)

“AA” Alkaline

Air Filter Oil

(DTXC2465)

2

Batteries x4

(Transmitter)

Page 3

3

SAFETY PRECAUTIONS

To prevent injury and damage to property, follow these safety precautions

when operating any radio control vehicle.

Keep all spectators a safe distance away from the vehicle.

ALWAYS turn the transmitter on before the receiver.

NEVER touch any part of the engine or exhaust as they can become very hot.

ALWAYS keep model engine fuel out of the reach of children and follow

precautions on the container.

NEVER run your model indoors. Fuel powered vehicles create harmful fumes.

NEVER smoke and avoid ignition sources when using model engine fuel.

Model engine fuel is poisonous and fl ammable. Keep away from open fl ame.

Use a mat or towel when working on your model to protect your work surface.

Do NOT run your radio control vehicle in cold weather as plastic parts

may become brittle.

WA RNING: This product contains a chemical known to the State of California to

cause cancer.

SPECIFICATIONS & DESCRIPTION CHANGES

All

information found in this manual is subject to change without notice. Visit Duratrax.com for the latest updates and information on your

model. Duratrax maintains no responsibility for inadvertent errors in this manual.

LIMITED WARRANTY

Duratrax guarantees this kit to be free from defects in

materials or workmanship for 90 days (3 years for the

engine) after the date of purchase. Duratrax will repair

or replace at no charge any incorrectly made part.

Your receipt or invoice at time of purchase is your

proof of purchase and is required for Duratrax to

honor any warranty. Duratrax reserves the right to

change or modify this warranty without notice.

For warranty repairs, contact or send to:

Hobby Services

3002 N. Apollo Drive Suite 1

Champaign, IL 61822

ATTN: Service Department

Phone: (217) 398-0007

9:00 am – 5:00 pm Central Time M-F

E-mail: hobbyservices@hobbico.com

www.hobbyservices.com

IF the buyer is not prepared to accept the liability

associated with the use of this product, buyer

is advised to return kit immediately in new and

unused condition to the place of purchase.

STRESS-TECH PARTS GUARANTEE

Stress-Tech parts are guaranteed for 12 months from the date of purchase.

Check the parts list for items covered under the Stress-Tech guarantee.

Should a Stress-Tech part break during the fi rst 12 months after purchase,

return the part to Hobby Services and we will send you a FREE replacement.

To receive your FREE replacement Stress-Tech part, include the following and

return to Hobby Services at the address above:

1. Broken part

2. Part number and description of the broken part

3. COPY of your dated purchase invoice or receipt

4. Name, phone number and shipping address

REPAIR SERVICE

Hobby Services offers repair services after the 90 day limited warranty or 12

month Stress-Tech parts replacement for a minimal charge.

Follow these instructions for your repair request:

1.

Most circumstances require the return of the ENTIRE vehicle. STRESS-TECH

requires ONLY the broken part to be returned following the instructions above.

2. Turn off the transmitter and remove the batteries.

3. Empty fuel tank on nitro vehicles.

4. Include written instructions listing

THOROUGH

phone number. IF you expect the repair to be covered under the 90 day

limited warranty, include copy of receipt or invoice with date of purchase.

description of the problem, service needed and your

ALL

items being returned with a

DAYTIME

5. Send to Hobby Services at the address above. When shipping your item(s)

to us, we recommend that you insure them and use a company that offers

tracking service (such as UPS or Federal Express).

We will carefully inspect your item and notify you of our fi ndings. You will be

advised of your options for return, repair, or replacement. Please note that

items sent back unrepaired will carry a return shipping and service charge.

Hobby Services accepts Visa®, MasterCard®, or you can send a check. We can

return the item C.O.D., but additional charges will apply.

082E

Included radio system is not fully compliant with French regulations.

TM

NiMH

3

Page 4

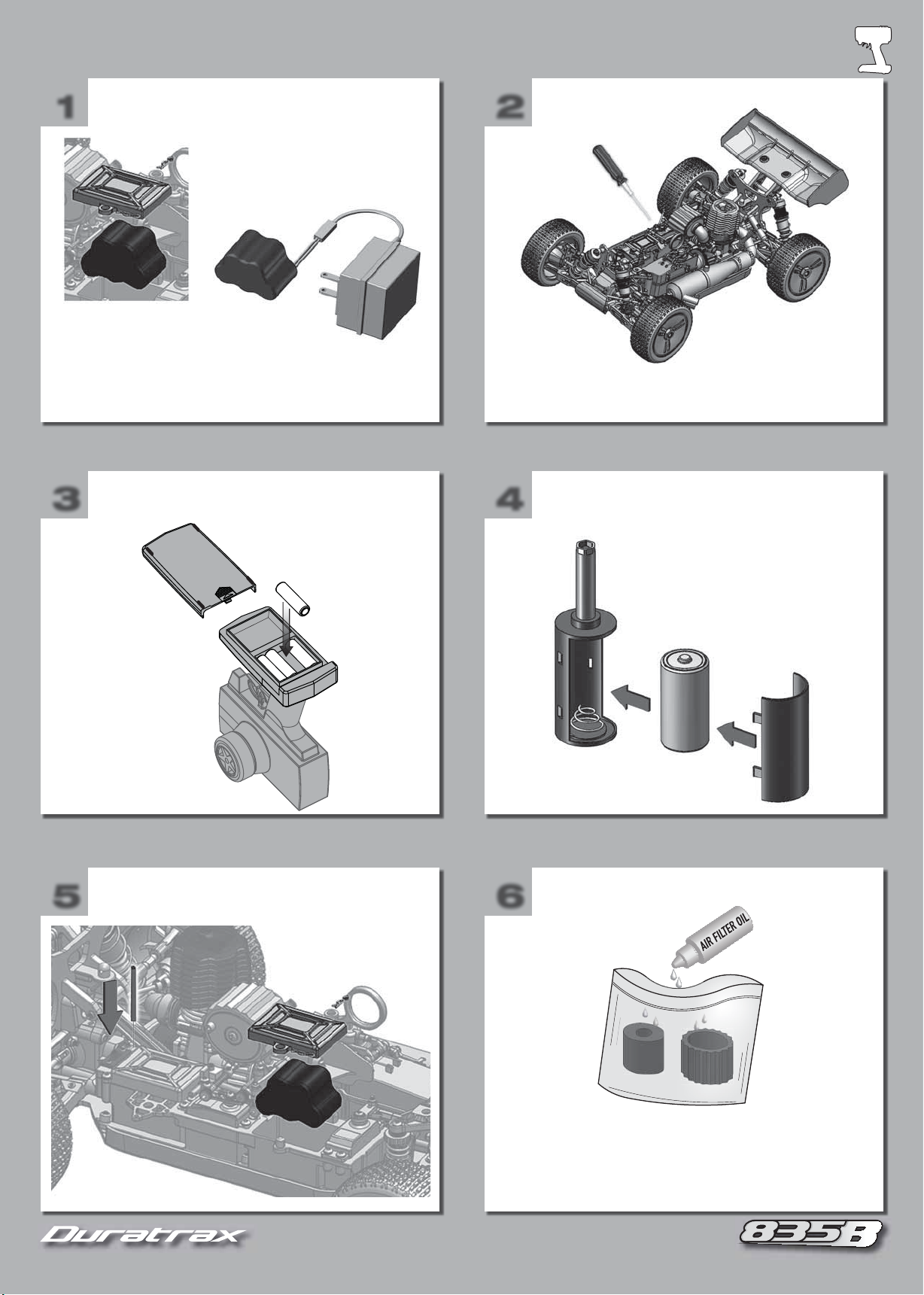

4

1

2

4

3

6

5

4

1

CHARGE THE RECEIVER

BATTERY

Remove the battery.

Allow 8 hours to fully

charge the battery.

2

CHECK SCREWS

Double-check all screws and nuts

to be sure they are tight.

3

5

INSTALL TRANSMITTER

BATTERIES

+

–

–

+

INSTALL ANTENNA TUBE

AND RECEIVER BATTERY

+

+

–

4

6

INSTALL GLOW STARTER

BATTERY

OIL AIR FILTER

Apply air filter oil (DTXC2465) onto the foam element, squeezing

s

the element until it is completely coated with the oil.

TIP! Placing the element in a plastic bag will help keep your hands clean.

s

Remove any excess oil with a paper towel.

s

4

4

Page 5

5

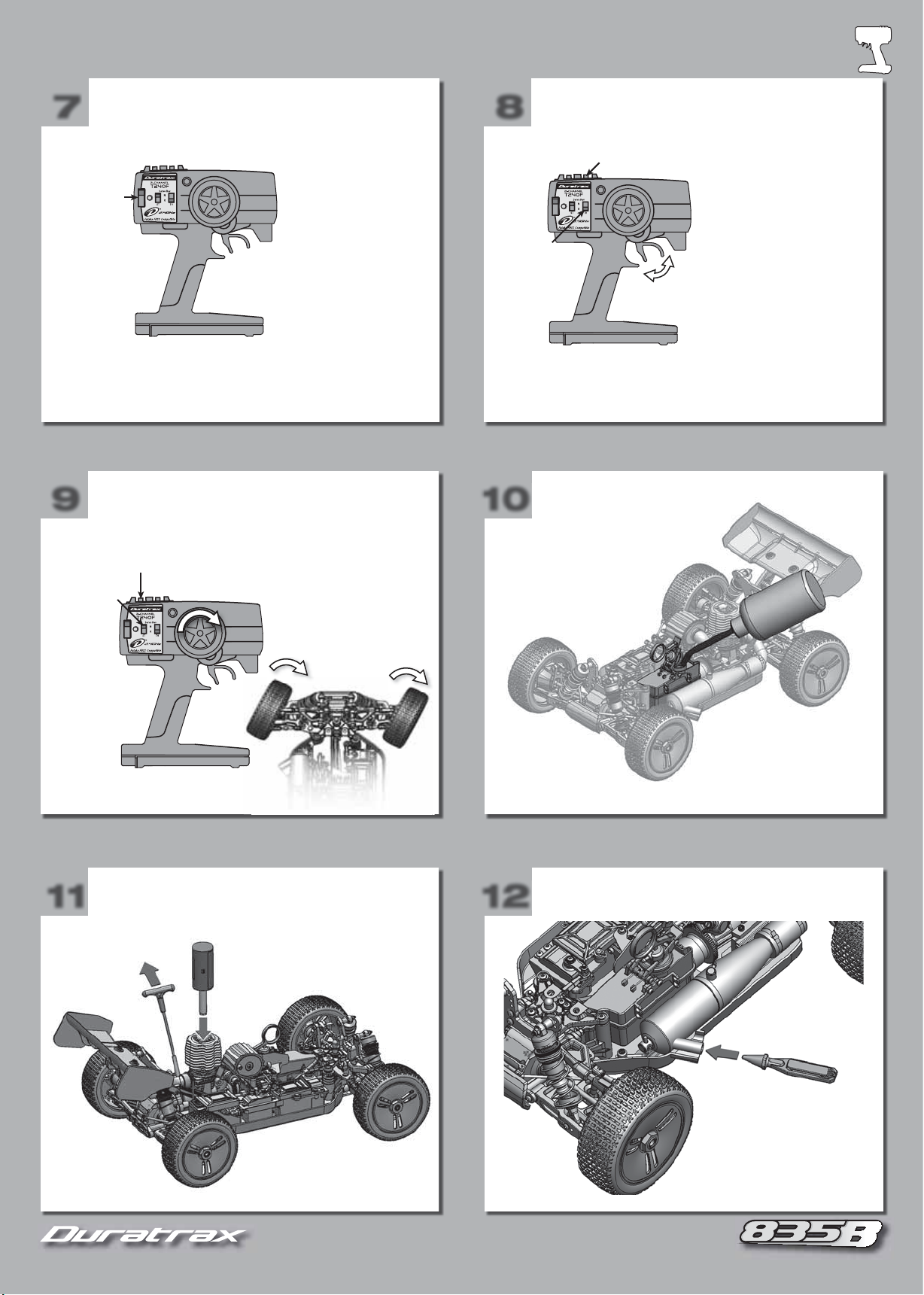

7

8

5

10

9

12

11

7

If you ever need to re-bind the receiver, turn on the system and press

and hold the bind button on the receiver until the L.E.D. turns solid green.

POWER UP TRANSMITTER CHECK THROTTLE

On/Off

2.4 GHz

Check radio operation

before each run!

8

Throttle

Reverse

Switch

Throttle Trim

Forward

2.4 GHz

Brake

Check radio operation

before each run!

9

Steering Servo

Reverse Switch

11

CHECK STEERING FUEL THE CAR

START THE ENGINE STOP THE ENGINE

Steering Trim

2.4 GHz

Check radio operation

before each run!

10

12

See page 6 for starting

and engine break-in.

To stop your 835b engine,

place the pointed end of

the engine tool into the

exhaust outlet (stinger).

This will block the exhaust

and stop the engine.

5

5

Page 6

6

BREAK-IN PROCEDURE

When starting, hold the throttle slightly open. If the engine is diffi cult to turn over, loosen glow plug 1/2-turn before starting engine (this allows

some compression to escape while allowing the engine to start). Once engine starts, tighten the glow plug.

IMPORTANT! FLOODED ENGINE:

If you are still having problems turning the engine over, it is fl ooded (too much fuel inside the engine).

1. Remove glow plug and turn vehicle upside down, pointing away from you.

2. Pull the recoil 5 times (clearing engine of fuel).

3. Replace glow plug.

4. Repeat starting engine steps.

Engine break in will be accomplished with the fi rst 5 tanks of fuel. (NOTE: Full break-in

may take up to 15 tanks.)

1. During break-in, run with the body off to keep the engine cool.

2. Keep air fi lter on at all times.

3. Run on smooth, hard surface.

4. Make sure you have extra glow plugs. Break-in puts stress on the glow plug and it may

need to be replaced.

TANK 1

Run very rich allowing fuel to carry as much oil as possible to lubricate internal engine parts.

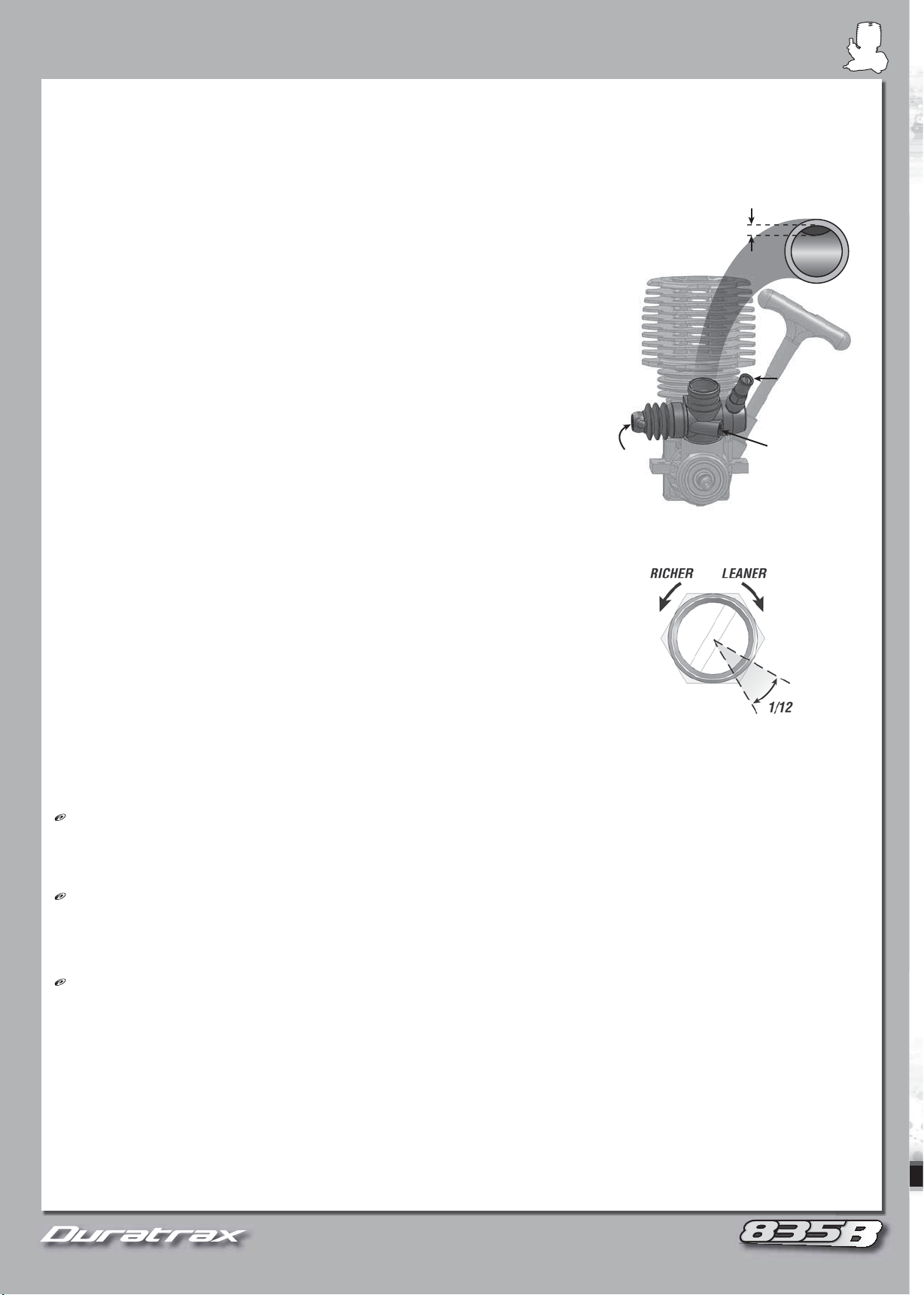

1. High Speed Needle Valve: Check this setting before running. Close the high speed

needle by rotating it clockwise until you just feel resistance, then open to 4 full turns out

(counterclockwise).

2. Run at medium speeds, slowly accelerating and decelerating.

3. If engine does not stay running consistently, increase idle speed by turning the idle stop screw clockwise.

4. DO NOT allow the tank to run out of fuel during break-in.

5. Stop engine and allow it to cool approximately 10 – 15 minutes.

TANKS 2-4

1. For each additional tank, lean high speed needle 1/12 turn from the previous tank’s setting.

2.

Stop engine, allowing it to cool approximately 10 – 15 minutes, between each tank.

TANK 5

1. Lean high speed needle an additional 1/12 turn from Tank 4 setting.

2. The engine should now be very close to fi nal tune and be broken in and ready to be performance tuned.

TUNING TIPS (Adjust only after the engine is fully broken in.)

IMPORTANT!

test the results.

High Speed Needle:

small amount of smoke. The goal is to tune the engine to make good power without overheating. Engine temperature should stay around 250°

F (132° C) using a temperature gauge (Duratrax Flashpoint

Note:

This temperature is a “guideline” only. Your engine may run

slightly warmer or cooler depending on conditions: fuel, track, and how you drive.

Low Speed Needle:

Controls fuel mixture at low throttle settings (idle). To check this setting, keep the throttle at idle and pinch the fuel line

close to the carburetor. A correct setting will increase the engine speed after 2-3 seconds and then lose speed.

• If it slows too quickly, the mixture is too lean. Open the low speed needle (counterclockwise).

• If it takes longer than 4 seconds to slow down, the mixture is too rich. Close the low speed needle (clockwise).

Idle Stop Screw:

Adjust this screw to set the idle speed so the wheels do not rotate when you lift the vehicle off of the ground. When looking

into the carburetor, the barrel should be about 1mm from fully closed.

CARE AND MAINTENANCE

1. Keep engine clean and free of dirt.

2. Do not over lean engine.

3. Run all of the fuel out of the engine before storing.

4.

Use after run oil and work it into the engine by turning the fl ywheel before storing

.

5. Do not use a fuel with a nitromethane content over 30%.

667

When starting, hold the throttle slightly open. If the engine is diffi cult to turn over, loosen glow plug 1/2-turn before starting engine (this allows

some compression to escape while allowing the engine to start). Once engine starts, tighten the glow plug.

IMPORTANT! FLOODED ENGINE:

1. Remove glow plug and turn vehicle upside down, pointing away from you.

2. Pull the recoil 5 times (clearing engine of fuel).

3. Replace glow plug.

4. Repeat starting engine steps.

Engine break in will be accomplished with the fi rst 5 tanks of fuel. (NOTE: Full break-in

may take up to 15 tanks.)

1. During break-in, run with the body off to keep the engine cool.

2. Keep air fi lter on at all times.

3. Run on smooth, hard surface.

4. Make sure you have extra glow plugs. Break-in puts stress on the glow plug and it may

need to be replaced.

TANK 1

Run very rich allowing fuel to carry as much oil as possible to lubricate internal engine parts.

1. High Speed Needle Valve: Check this setting before running. Close the high speed

needle by rotating it clockwise until you just feel resistance, then open to 4 full turns out

(counterclockwise).

2. Run at medium speeds, slowly accelerating and decelerating.

3. If engine does not stay running consistently, increase idle speed by turning the idle stop screw clockwise.

4. DO NOT allow the tank to run out of fuel during break-in.

5. Stop engine and allow it to cool approximately 10 – 15 minutes.

If you are still having problems turning the engine over, it is fl ooded (too much fuel inside the engine).

~1mm

HIGH SPEED

NEEDLE

LOW SPEED

NEEDLE

IDLE STOP

SCREW

TANKS 2-4

1. For each additional tank, lean high speed needle 1/12 turn from the previous tank’s setting.

2.

Stop engine, allowing it to cool approximately 10 – 15 minutes, between each tank.

TANK 5

1. Lean high speed needle an additional 1/12 turn from Tank 4 setting.

2. The engine should now be very close to fi nal tune and be broken in and ready to be performance tuned.

TUNING TIPS (Adjust only after the engine is fully broken in.)

IMPORTANT! Always run the engine for 1-2 minutes to warm up temperature before tuning! Only use “small” adjustments (1/12 turn at a time) and

test the results.

High Speed Needle: Controls the fuel/air mixture at high throttle settings. A properly tuned engine will accelerate smoothly and exhaust a

small amount of smoke. The goal is to tune the engine to make good power without overheating. Engine temperature should stay around 250°

F (132° C) using a temperature gauge (Duratrax Flashpoint™, DTXP3100).

slightly warmer or cooler depending on conditions: fuel, track, and how you drive.

Low Speed Needle:

close to the carburetor. A correct setting will increase the engine speed after 2-3 seconds and then lose speed.

• If it slows too quickly, the mixture is too lean. Open the low speed needle (counterclockwise).

• If it takes longer than 4 seconds to slow down, the mixture is too rich. Close the low speed needle (clockwise).

Idle Stop Screw:

into the carburetor, the barrel should be about 1mm from fully closed.

CARE AND MAINTENANCE

1. Keep engine clean and free of dirt.

2. Do not over lean engine.

3. Run all of the fuel out of the engine before storing.

4.

Use after run oil and work it into the engine by turning the fl ywheel before storing

5. Do not use a fuel with a nitromethane content over 30%.

Always run the engine for 1-2 minutes to warm up temperature before tuning! Only use “small” adjustments (1/12 turn at a time) and

Controls the fuel/air mixture at high throttle settings. A properly tuned engine will accelerate smoothly and exhaust a

, DTXP3100).

Controls fuel mixture at low throttle settings (idle). To check this setting, keep the throttle at idle and pinch the fuel line

Adjust this screw to set the idle speed so the wheels do not rotate when you lift the vehicle off of the ground. When looking

Note:

This temperature is a “guideline” only. Your engine may run

6

Page 7

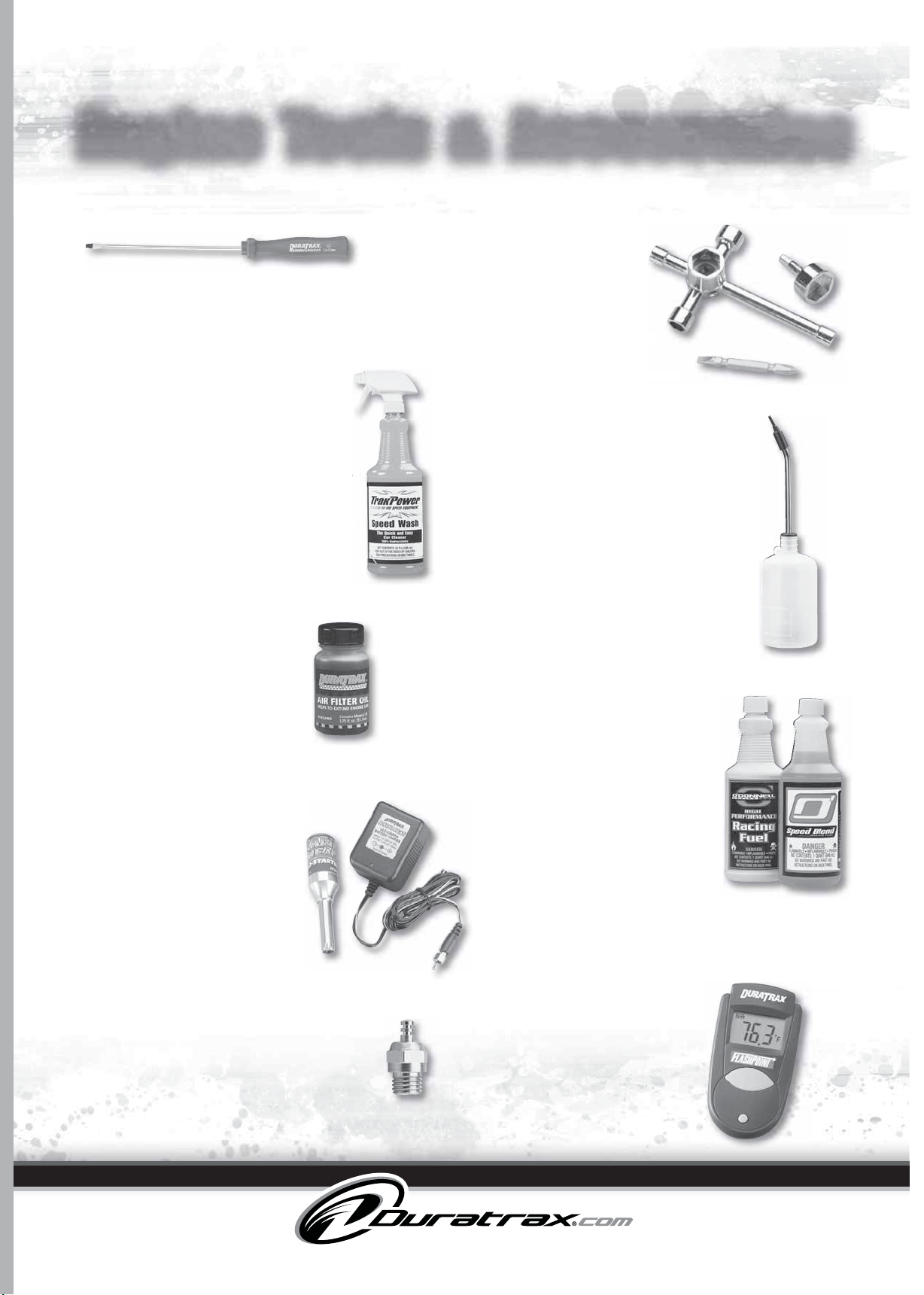

Engine Tools & Accessories

.

Engine Tuning Screwdriver

Standard slot-head screwdriver has a 120 mm

hardened steel shaft with 3.2 mm wide magnetized

tip and rubberized, hexagonal handle.

DTXR0185

™

TrakPower

Speed Wash

Nitro Cleaner

Applies with or without water and is safe

for titanium, aluminum, fiberglass, clear

coat, stainless steel, chrome, rubber,

plastic, vinyl and leather. 32 fl oz (946 mL).

TKPC8001

Air Filter Oil

Treats foam air filter elements

to increase filtering capacity

and extend engine life. Handy

1.75 fl oz (51.7 mL) bottle fits

easily into a tool box or tote.

DTXC2465

Rapid Heat

Twist-on for a secure connection

to heat your glow plug. Twist

the other way for easy removal.

Includes NiCd and AC charger.

DTXP3000

™

Glo-Starter

Deluxe Car Wrenches

Deluxe includes 6

socket head sizes

and stores up to 4

glow plugs. Ultimate

adds a slotted/Phillips

screwdriver bit and

19 mm socket for 1/8 car

wheel nuts.

DTXR1170

DTXR1175

Kwik-Pit

A squeeze on the clear plastic body

lets you control fuel flow. The 5 in

(63.5 mm) long aluminum spout

features a curved tip for no-spill refills

and a tip cap to prevent leaks. For

glow fuel only.

DTXP0125

DTXP0150

Deluxe Car Wrench

Ultimate Car Wrench

™

Fuel Bottles

250 cc (8.5 fl oz) Fuel Bottle

500 cc (17.0 fl oz) Fuel Bottle

O’Donnell Racing Fuel

Speed Blend improves fuel

economy and pushes engine

performance to the absolute

peak. Race Blend simplifies

tuning and reduces engine heat

and internal wear.

ODOP3320

ODOP3325

ODOP3330

ODOP4520

ODOP4525

ODOP4530

20% Racing Fuel Quart

25% Racing Fuel Quart

30% Racing Fuel Quart

20% Speed Blend Quart

25% Speed Blend Quart

30% Speed Blend Quart

r

rench

®

FlashPoint™ Infrared

Temperature Gauge

Glow Plugs

Hand-assembled with heat resistant coils.

Carbon Speed is medium-hot for informal

racing and sport use. Gold Racing Plug is for

higher nitro fuels and competitive driving.

DTXG3003

DTXG3005

Carbon Speed Plug

Gold Racing Plug

Just point and press for

fast, accurate, no-touch

temperature readings of

engines, motors, batteries

and more. Works in seconds

and turns off automatically

after 15 seconds of inactivity.

DTXP3100

7

Page 8

8

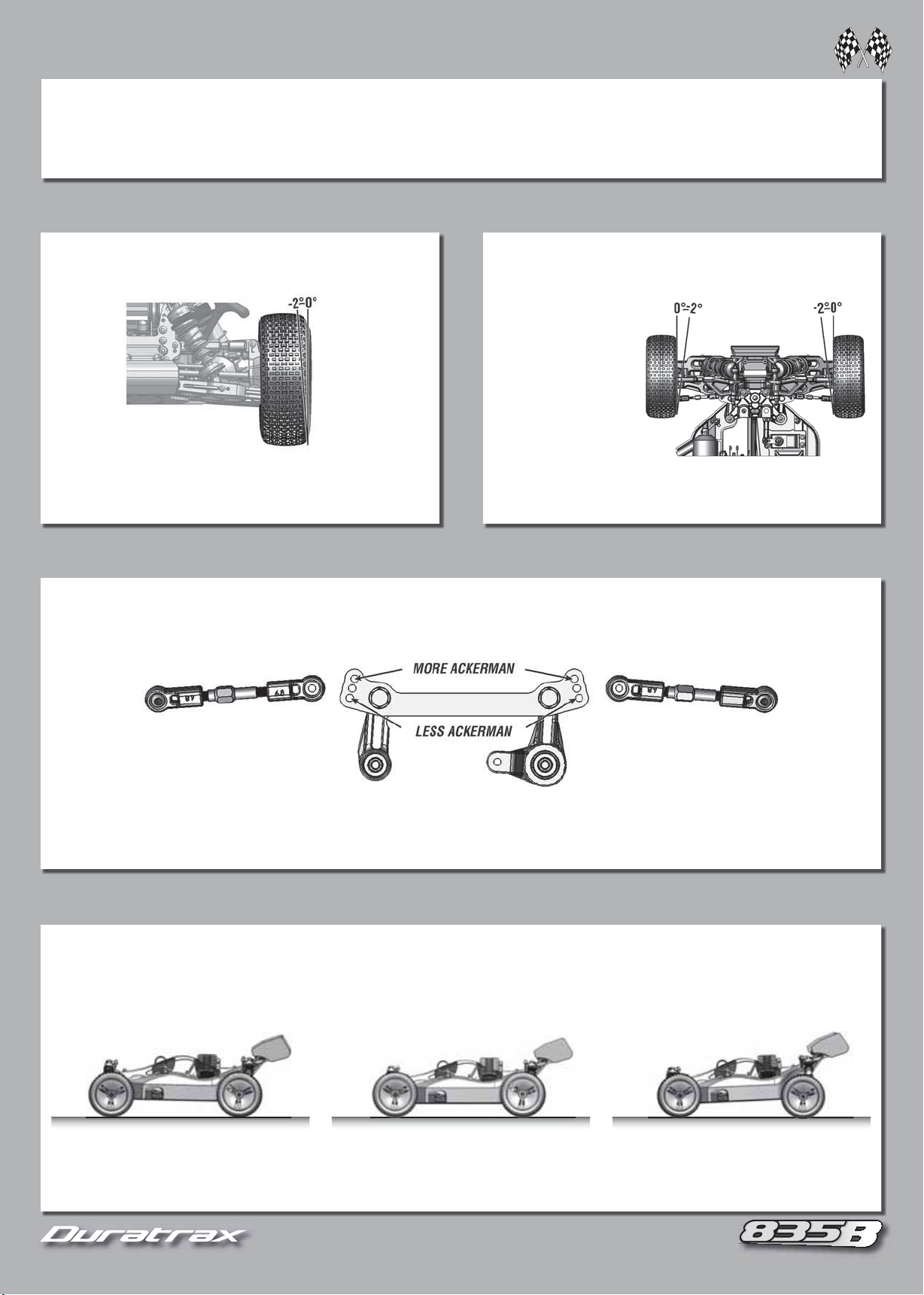

TUNING GUIDE

As a starting point, make sure your car has equal lengths on shocks, camber links and steering rods on both

sides (left and right). Front and rear do not need to be equal.

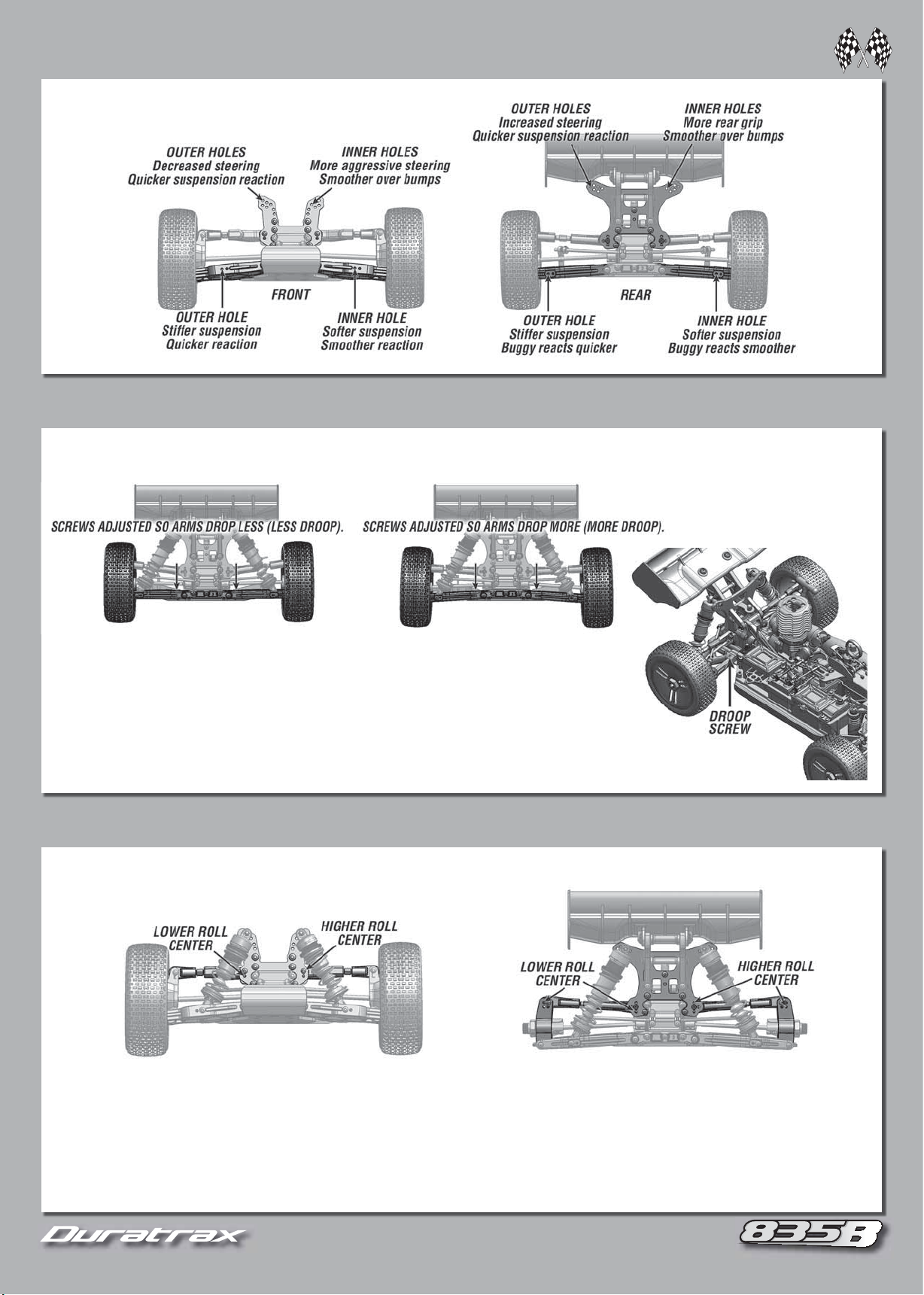

Rear Hole:

Forward Hole:

Negative Camber

Positive Camber

Toe-Out:

Toe-In:

Toe-In

8

Lower Rear:

More rear traction but reduces steering.

Lower Front:

Increases steering but can cause rear

end to lose traction.

As a starting point, make sure your car has equal lengths on shocks, camber links and steering rods on both

sides (left and right). Front and rear do not need to be equal.

CAMBER

Angle of the tire and wheel in relation to the ground when

viewed from the front.

Negative Camber =

• Improved traction while corning.

• Adds overall stability.

Positive Camber = Tire and wheel lean outward (NOT recommended).

Top of the tire and wheel lean inward (Typically 0° to -2°)

FRONT TOE-IN AND TOE-OUT

Direction the wheels point in relationship with each other,

when viewed from the front.

Toe-In: Front of the

wheels point toward each

other. (Typically 0 to -2°)

• Increased stability when

accelerating. Decreased

steering when entering

a corner.

Toe-Out: Fronts of the wheels point away from each other.

• Decreased stability when accelerating and increased steering

when entering a corner.

ACKERMAN

The difference in turning angle between the inside wheel and outside wheel in a turn.

Toe-In

Forward Hole: More initial steering into corner. Steering is

more aggressive. Better for tight technical tracks.

Rear Hole: Less initial steering into a corner. Smoother steering

response. Better for large fl owing tracks.

RIDE HEIGHT

Distance the chassis sits from the ground and how much weight is transferred when the vehicle changes speed and direction.

Rotate the collar on the shock to change ride height. Adjust left and right equally.

Lower Rear:

More rear traction but reduces steering.

Lower Front:

end to lose traction.

8

8

Increases steering but can cause rear

Page 9

9

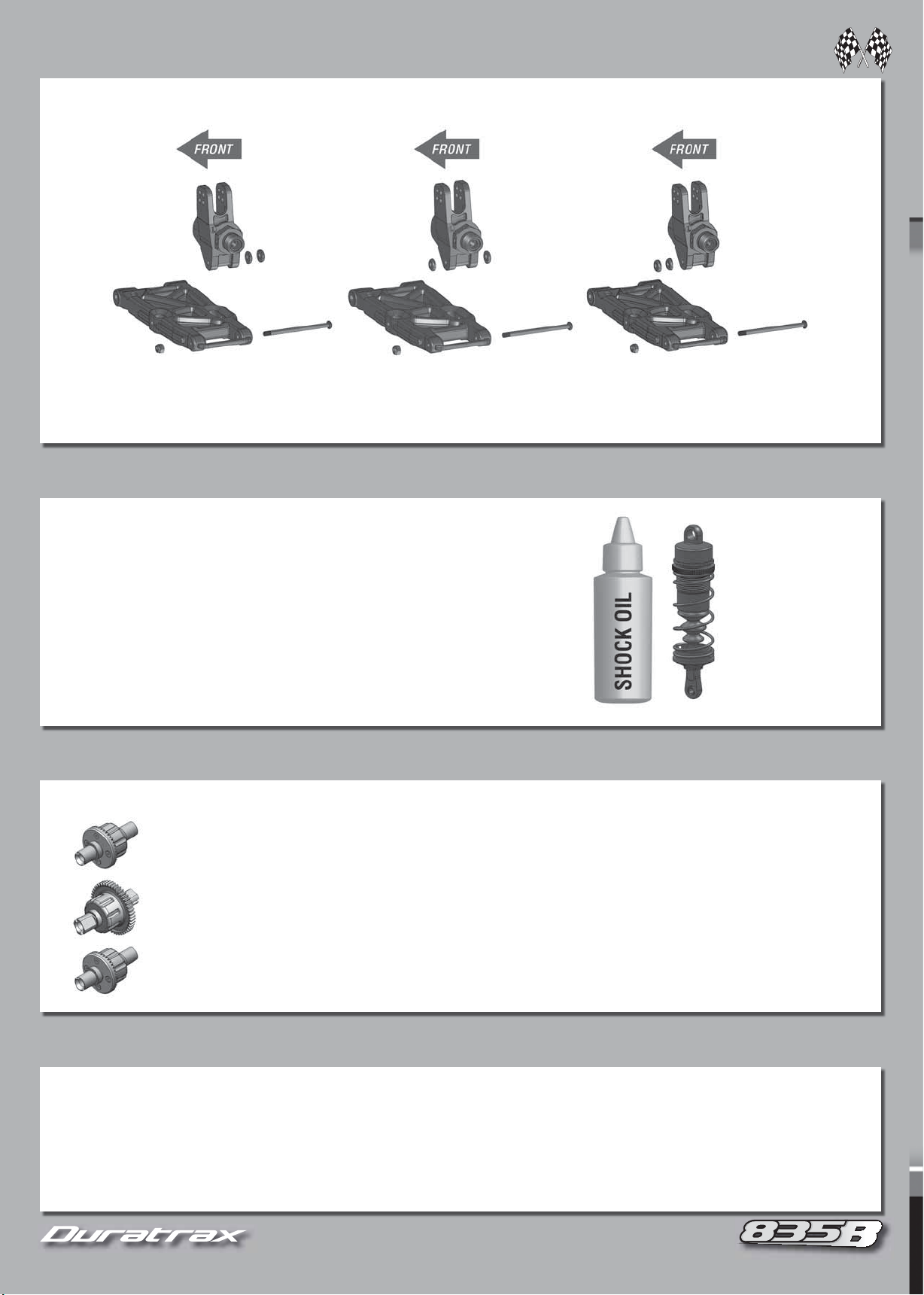

SHOCK ADJUSTMENTS

More Front Droop:

Increases chassis up travel when on throttle and decreases high speed steering,

making vehicle turn smoother. Good for low traction and bumpy surfaces.

Less Front Droop:

Decreases chassis up travel when on throttle, making steering more aggressive.

Good for high speed smooth surfaces.

More Rear Droop:

Increases chassis up travel when off throttle and under braking. Increases

steering in low speed corners and under braking.

Less Rear Droop:

Decreases steering in low speed corners, making the vehicle turn smoother.

9

Higher Roll Center:

Increases the chassis roll on the rear

of the car. Increases rear traction on-power. Decreases rear

traction during braking.

Lower

Roll Center:

Decreases the chassis roll at the rear of

the car. Decreases rear on-power traction. Reduces corner

entry steering. Increases corner exit steering.

Higher Roll Center:

Reduces chassis roll and on-power

steering. The car feels more responsive. Reduces front traction

going into corners. Good for high grip, technical tracks.

Lower

Roll Cente

Increases the chassis roll and on-power

steering. Steering is less responsive, but smoother and more

stable. Better for smooth tracks with high speed corners.

FRONT ROLL CENTER

REAR ROLL CENTER

DROOP

Distance the chassis can lift from ride height before the wheels come off the ground.

More Front Droop:

Less Front Droop:

More Rear Droop:

Less Rear Droop:

Increases chassis up travel when on throttle and decreases high speed steering,

making vehicle turn smoother. Good for low traction and bumpy surfaces.

Decreases chassis up travel when on throttle, making steering more aggressive.

Good for high speed smooth surfaces.

Increases chassis up travel when off throttle and under braking. Increases

steering in low speed corners and under braking.

Decreases steering in low speed corners, making the vehicle turn smoother.

ROLL CENTER

Point at which the vehicle rolls laterally when cornering.

FRONT ROLL CENTER

Higher Roll Center:

steering. The car feels more responsive. Reduces front traction

going into corners. Good for high grip, technical tracks.

Lower

Roll Center:r:

steering. Steering is less responsive, but smoother and more

stable. Better for smooth tracks with high speed corners.

Reduces chassis roll and on-power

Increases the chassis roll and on-power

REAR ROLL CENTER

Higher Roll Center:

of the car. Increases rear traction on-power. Decreases rear

traction during braking.

Lower

Roll Center:

the car. Decreases rear on-power traction. Reduces corner

entry steering. Increases corner exit steering.

Increases the chassis roll on the rear

Decreases the chassis roll at the rear of

9

9

Page 10

101010

Check before every run:

1. All hardware to be sure everything is tight.

2. Transmitter batteries.

3. Moving parts are free from binding.

4. Parts are not broken or damaged.

5. Wires are properly connected.

6. Remove dirt or debris from chassis and moving parts.

7. Bearings should roll smoothly.

8. Shocks should operate smoothly. Check for leakage and refi ll as needed.

9. Gear mesh between the spur and clutch gears.

WHEELBASE

Decreases off power steering. Better

through rough sections. More stable.

More on power steering.

Increases rear on power traction.

More off power steering.

Thinner:

Increased traction. Chassis transitions quicker. Increased chance of the chassis

bottoming out. Better for rough tracks

Thicker:

Decreased traction. Chassis transitions slower. Decreased chance of chassis

bottoming out. Better for smooth tracks.

FRONT:

Thinner:

Increased off power steering (too thin will make it inconsistent.) Decreased on power steering.

Thicker:

Increased stability while braking into a corner. Increased on power steering exiting a corner.

CENTER:

Thinner:

Better for rough track conditions. Causes the front to unload under acceleration. Decreases on power steering.

Thicker:

Better acceleration. Increases on power steering. Less stable. Better for smooth high bite tracks.

REAR:

Thinner:

More rear traction in the corners. Increases mid corner steering.

Thicker:

Decreases rear traction in the corners. Increases forward traction. Less mid corner steering

SHORTER WHEELBASE

MEDIUM WHEELBASE

LONGER WHEELBASE

Distance between the front and rear wheels.

SHORTER WHEELBASE

Increases rear on power traction.

More off power steering.

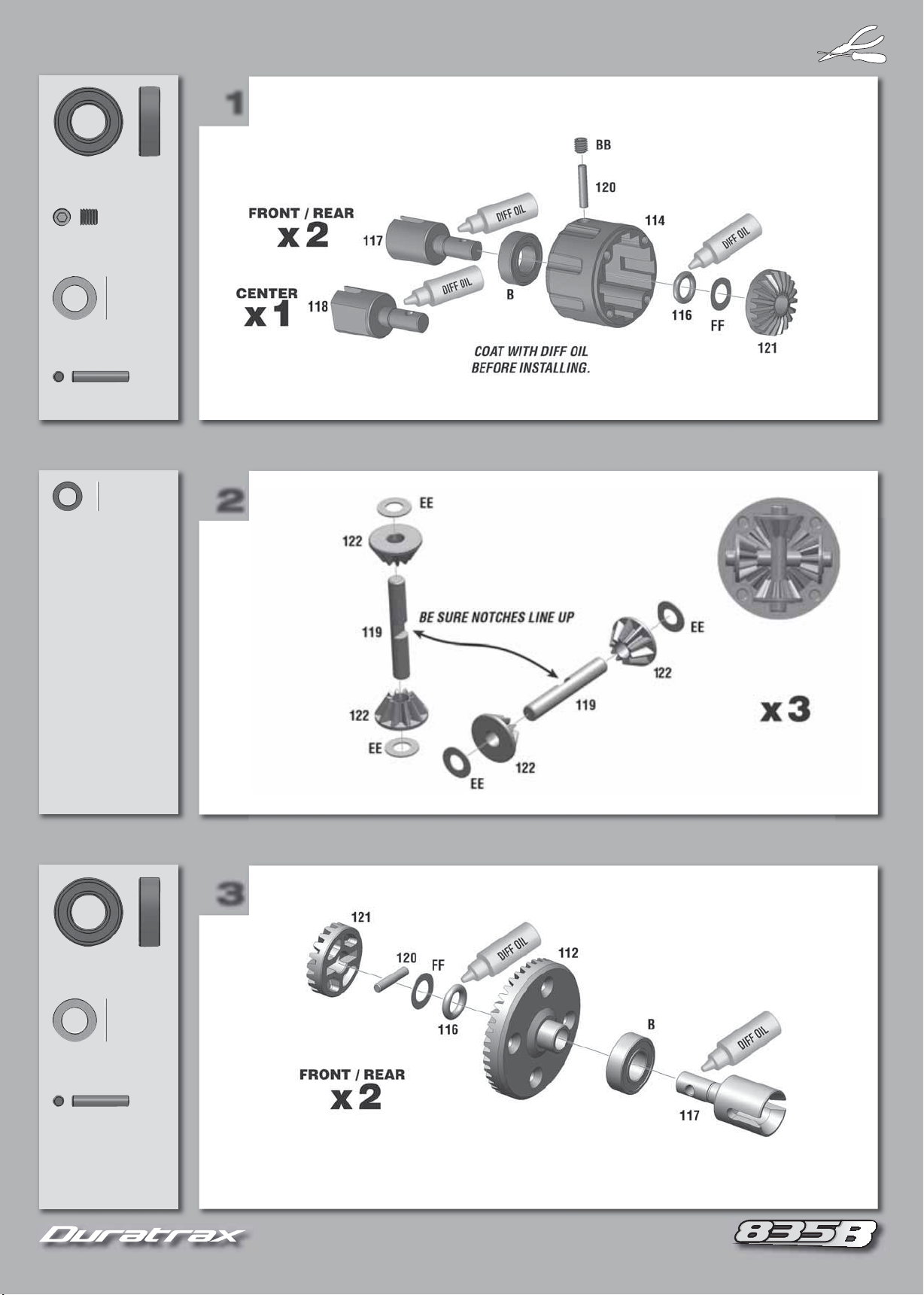

SHOCK OIL

MEDIUM WHEELBASE

LONGER WHEELBASE

Decreases off power steering. Better

through rough sections. More stable.

More on power steering.

Thinner:

bottoming out. Better for rough tracks

Thicker:

bottoming out. Better for smooth tracks.

Increased traction. Chassis transitions quicker. Increased chance of the chassis

Decreased traction. Chassis transitions slower. Decreased chance of chassis

DIFFERENTIAL OIL

FRONT:

CENTER:

REAR:

Thinner:

Thicker:

Thinner:

Thicker:

Thinner:

Thicker:

Increased off power steering (too thin will make it inconsistent.) Decreased on power steering.

Increased stability while braking into a corner. Increased on power steering exiting a corner.

Better for rough track conditions. Causes the front to unload under acceleration. Decreases on power steering.

Better acceleration. Increases on power steering. Less stable. Better for smooth high bite tracks.

More rear traction in the corners. Increases mid corner steering.

Decreases rear traction in the corners. Increases forward traction. Less mid corner steering

CHASSIS MAINTENANCE TIPS

Check before every run:

1. All hardware to be sure everything is tight.

2. Transmitter batteries.

3. Moving parts are free from binding.

4. Parts are not broken or damaged.

5. Wires are properly connected.

6. Remove dirt or debris from chassis and moving parts.

7. Bearings should roll smoothly.

8. Shocks should operate smoothly. Check for leakage and refi ll as needed.

9. Gear mesh between the spur and clutch gears.

10

Page 11

11

FOR MAINTENANCE AND REPAIRS ON YOUR 835B

FOR MAINTENANCE AND REPAIRS ON YOUR 835B

11

Page 12

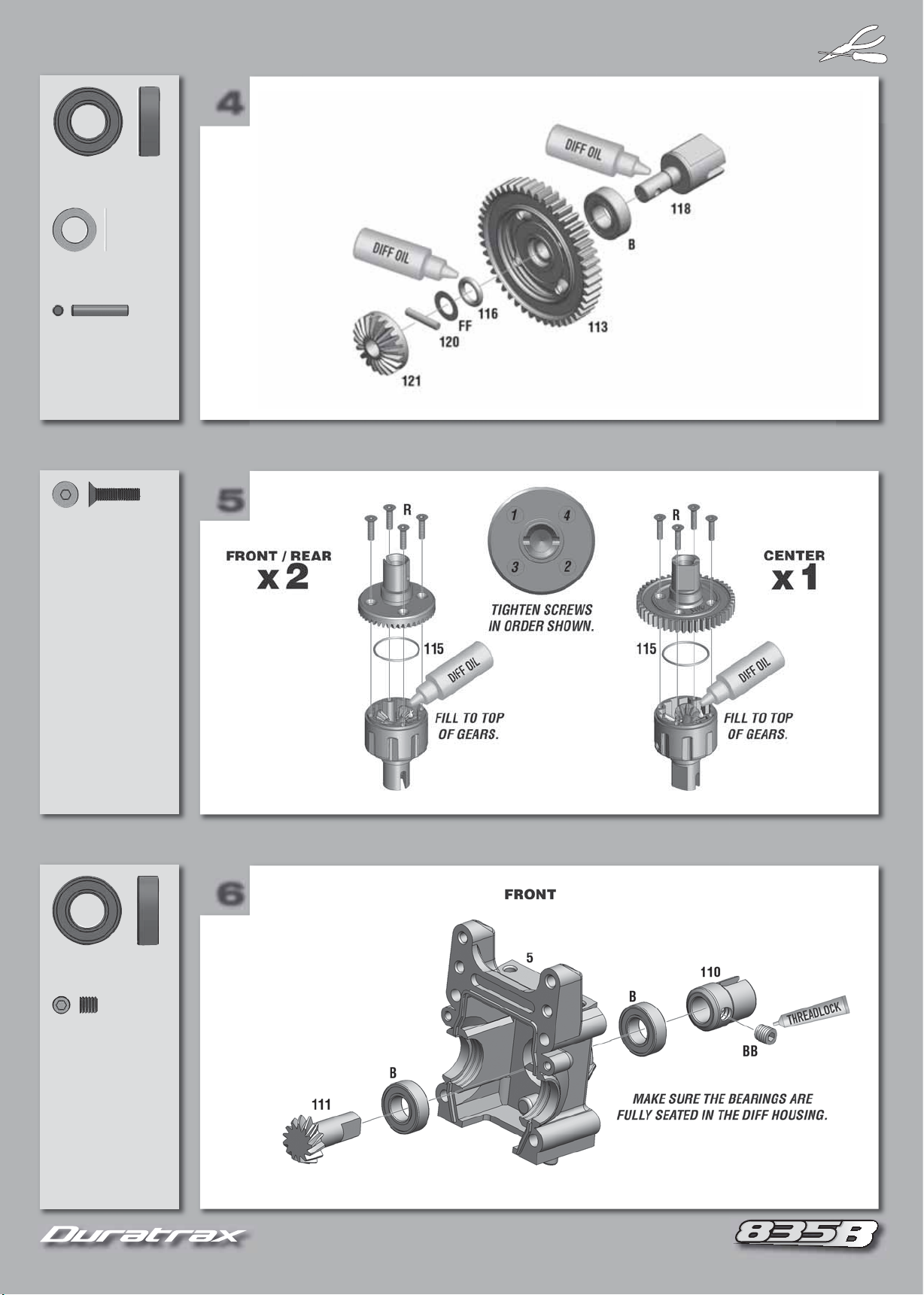

12

B (x3)

1

2

3

8x16mm

BB (x3)

4x5mm

FF (x3)

6x10mm

120 (x3)

2.5x13mm

EE (x12)

4x7mm

1

2

B (x2)

8x16mm

FF (x2)

6x10mm

120 (x2)

2.5x13mm

3

12

Page 13

131313

4

5

6

B (x1)

8x16mm

FF (x1)

6x10mm

120 (x1)

2.5x13mm

R (x12)

3x12mm

4

5

B (x2)

8x16mm

BB (x1)

4x5mm

6

13

Page 14

14

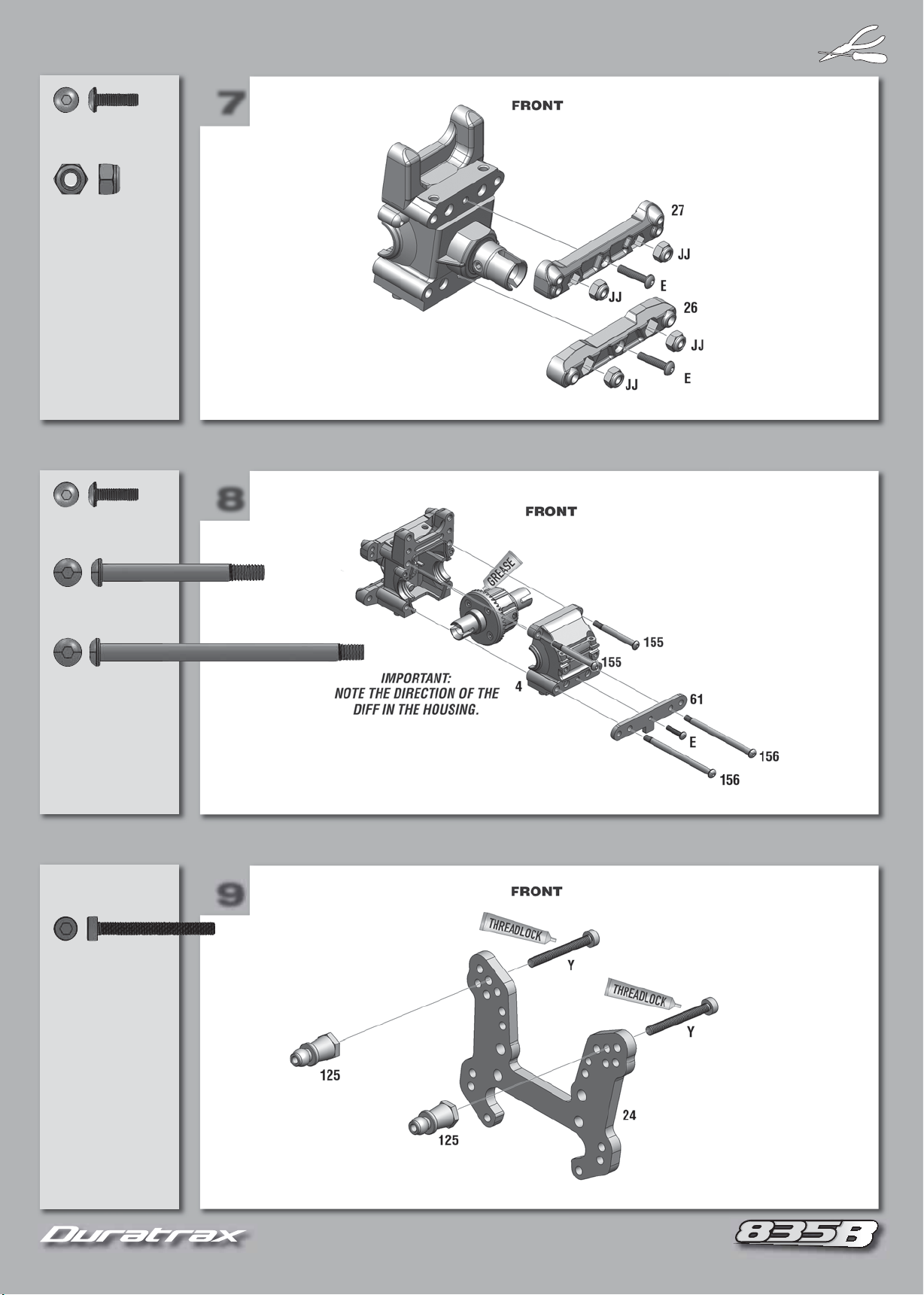

7

8

9

E (x2)

3x10mm

JJ (x4)

4mm

E (x1)

3x10mm

7

8

155 (x2)

4x37mm

156 (x2)

4x62mm

Y (x2)

3x30mm

9

14

Page 15

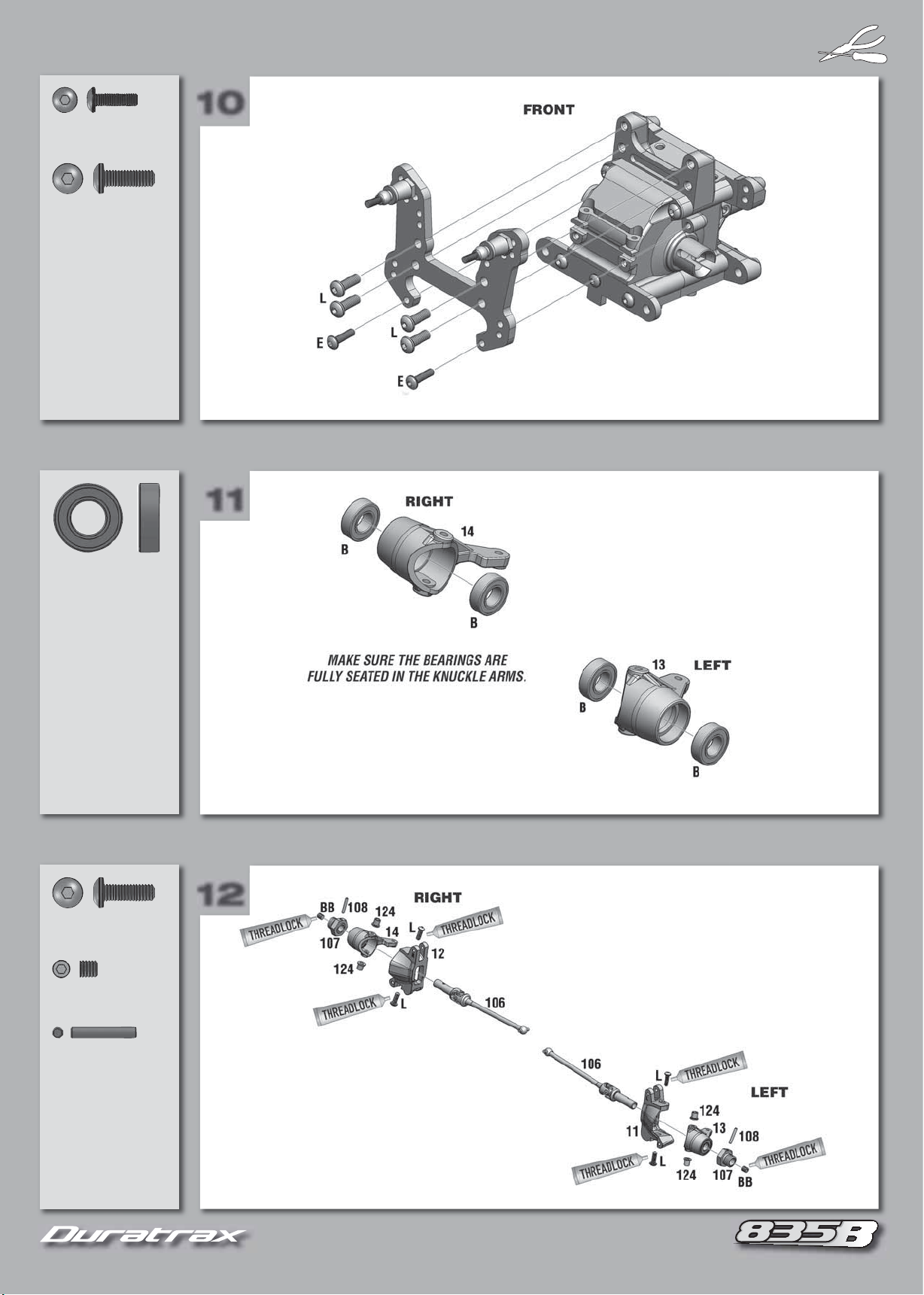

151515

10

11

12

E (x2)

3x10mm

L (x4)

4x12mm

10

11

B (x4)

8x16mm

L (x4)

4x12mm

BB (x2)

4x5mm

12

108 (x2)

2.5x16mm

15

Page 16

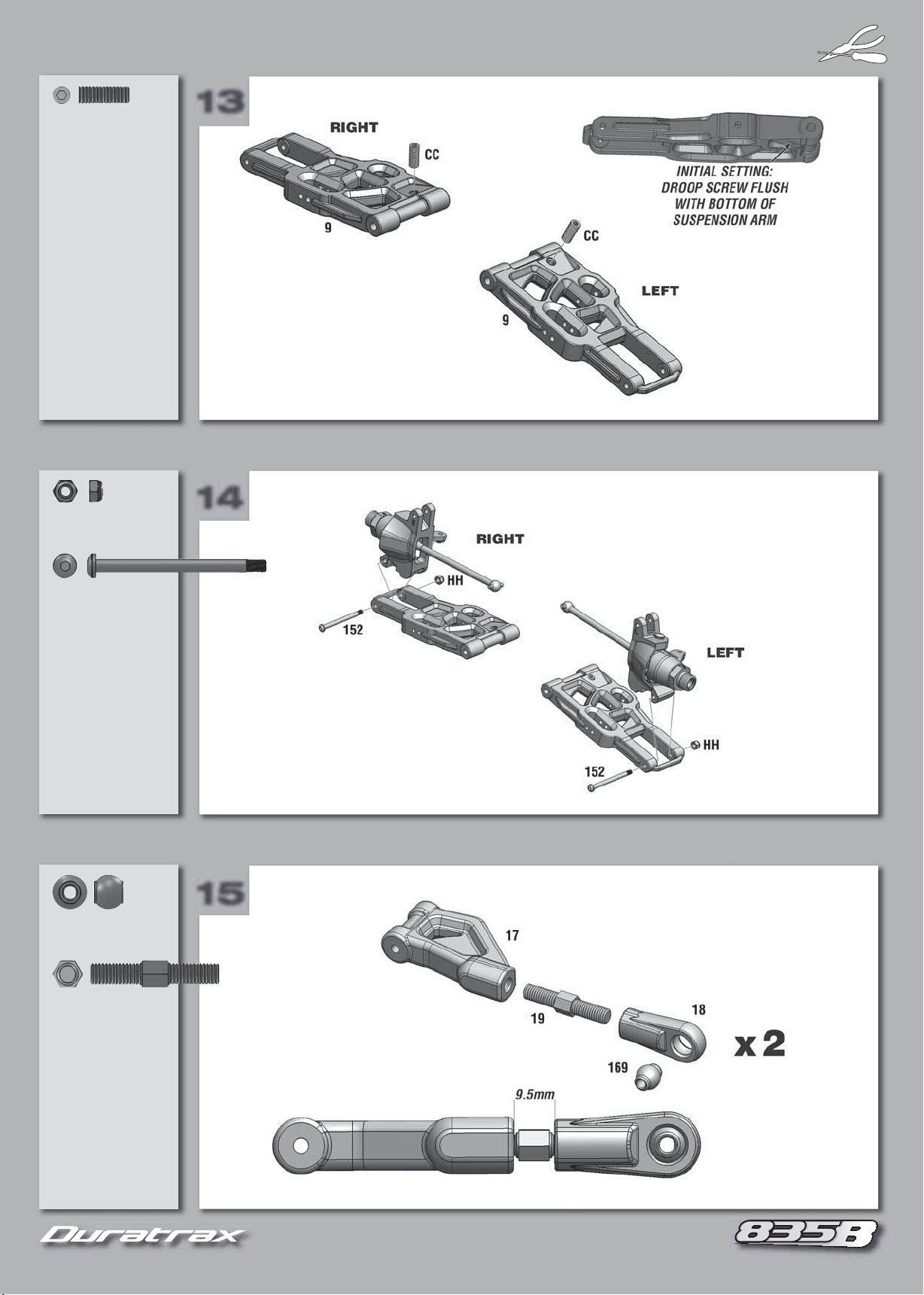

161616

14

15

CC (x2)

13

4x12mm

HH (x2)

3mm

13

14

152 (x2)

3x40mm

169 (x2)

19 (x2)

5x30mm

15

16

Page 17

17

16

17

18

K (x2)

3x22mm

HH (x2)

3mm

HH (x2)

3mm

16

17

JJ (x2)

4mm

152 (x2)

3x40mm

157 (x2)

4x70mm

AA (x2)

3x10mm

158 (x2)

18

FRONT

17

x2

Page 18

18

20

21

Z (x2)

19

3x3mm

149 (x2)

D (x2)

3x8mm

19

20

J (x2)

3x18mm

21

18

Page 19

19

23

24

B (x2)

22

8x16mm

BB (x1)

4x5mm

E (x2)

3x10mm

22

23

JJ (x4)

4mm

E (x1)

3x10mm

155 (x2)

4x37mm

24

156 (x2)

4x62mm

19

Page 20

20

26

27

25

Y (x2)

3x30mm

X (x2)

3x20mm

25

26

E (x1)

3x10mm

27

20

Page 21

21

29

30

E (x2)

28

3x10mm

L (x2)

4x12mm

28

29

B (x4)

8x16mm

BB (x2)

4x5mm

108 (x2)

2.5x16mm

HH (x2)

3mm

153 (x2)

3x45mm

30

21

Page 22

22

32

33

CC (x2)

31

4x12mm

HH (x2)

3mm

31

32

K (x2)

3x22mm

22 (x2)

5x50mm

168 (x2)

DD (x2)

3x8mm

HH (x2)

3mm

33

JJ (x2)

4mm

156 (x2)

4x62mm

22

Page 23

232323

35

36

F (x6)

34

3x12mm

34

35

M (x2)

4x20mm

AA (x2)

3x10mm

158 (x2)

36

23

REAR

x2

Page 24

24

38

39

Z (x2)

37

3x3mm

149 (x2)

D (x2)

3x8mm

37

38

J (x2)

3x18mm

39

24

Page 25

25

41

42

HH (x1)

40

3mm

154 (x1)

3x50mm

C (x4)

6x10mm

40

41

DD (x2)

3x8mm

HH (x2)

3mm

42

25

Page 26

26

44

45

T (x2)

43

4x12mm

U (x2)

4x14mm

43

44

159 (x4)

62 (x2)

4x45mm

45

26

Page 27

27

47

48

H (x4)

46

3x16mm

HH (x4)

3mm

Q (x6)

3x10mm

46

47

U (x2)

4x14mm

48

27

Page 28

28

50

51

E (x1)

49

3x10mm

F (x2)

3x12mm

L (x4)

4x12mm

49

50

R (x2)

3x12mm

HH (x2)

3mm

R (x2)

3x12mm

U (x4)

4x14mm

51

HH (x2)

3mm

28

Page 29

29

53

54

G (x4)

52

3x15mm

Z (x1)

3x3mm

52

53

F (x4)

3x12mm

54

29

Page 30

30

Z (x1)

56

57

55

3x3mm

U (x4)

4x14mm

55

56

DD (x2)

3x8mm

HH (x2)

3mm

57

30

Page 31

31

59

60

58

58

59

158 (x4)

3mm

60

31

Page 32

32

K (x2)

62

63

61

3x22mm

DD (x2)

3x8mm

HH (x2)

3mm

K (x2)

3x22mm

61

62

DD (x2)

3x8mm

HH (x2)

3mm

63

32

Page 33

33

65

66

A (x2)

64

5x10mm

64

65

V (x1)

3x10mm

DD (x1)

3x8mm

QQ (x4)

5x8x0.3mm

W (x4)

3x12mm

GG (x4)

3mm

66

33

Page 34

34

68

69

67

67

68

L (x1)

4x12mm

69

34

Page 35

35

71

72

F (x2)

70

3x12mm

70

71

Q (x2)

3x10mm

T (x1)

4x12mm

JJ (x4)

4mm

72

35

Page 36

36

74

75

73

T (x1)

4x12mm

BB (x1)

4x5mm

BB (x1)

4x5mm

73

74

MM (x4)

4x10mm

F (x8)

3x12mm

75

36

Page 37

37

77

78

E (x3)

76

3x10mm

76

77

DD (x1)

3x8mm

LL (x2)

E (x1)

3x10mm

H (x1)

3x16mm

78

P (x1)

2.6x6mm

Z (x4)

3x3mm

HH (x1)

3mm

37

Page 38

38

80

81

79

Q (x6)

3x10mm

F (x2)

3x12mm

79

80

N (x1)

3x8mm

HH (x4)

3mm

H (x2)

3x16mm

HH (x2)

3mm

81

38

Page 39

3939393939

PARTS LISTS, PARTS SETS, AND EXPLODED VIEWS

PARTS LISTS, PARTS SETS, AND EXPLODED VIEWS

39

Page 40

40

Z

t

3x3mm Set Screws

DTXC8660

G-27CX Engine

w/SG Crankshaft

DTXG0256

E7

Front Ball Bearing

DTXG0351

E8

Rear Ball Bearing

DTXG0364

E26

Carburetor Dust Boot

DTXG0404

E29

Carburetor Complete

DTXG0444

E40

E16

E17

E18

E22

Carburetor Body

DTXG0408

E36

E37

E38

Carburetor Retainer Set

DTXG0461

E18

E23

Carburetor Slide Valve

DTXG0413

E29

Carburetor O-Ring

DTXG0469

E1

E41

E34

E29

E26

E32

E30

Carburetor Gasket Set

E24

DTXG0432

E6

Connecting Rod

DTXG0474

E9

Backplate Set

DTXG0491

E2

E3

Piston/Cylinder Set

DTXG0546

E12

E16

Engine Gasket Set

DTXG0596

Backplate Screw Set

DTXG0509

E32

E31

E30

Fuel Inlet Nozzle Set

DTXG0556

E24

Low Speed Needle Set

E25

DTXG0598

Crankcase

DTXG0527

E5

E12

Head Button & Shim Se

DTXG0574

E39

Cylinder Head Screws

DTXG0610

SG Crankshaft

DTXG0539

E39

E4

Cylinder Head w/Screws

DTXG0579

E33

High Speed

Needle Socket

DTXG0618

40

Page 41

41

E35

E10

E20

E34

High Speed Needle Set

DTXG0621

E15

Start Shaft

DTXG0771

Silver Sport Glow Plug

DTXG3001

E19

One-Way Bearing

DTXG0637

E13

E14

Start Shaft Pin

DTXG0777

E11

Piston Pin Set

DTXG0646

Z

E27

Throttle Arm

DTXG0801

E21

Recoil Starter Set

DTXG0756

E41

E28

Throttle Stop Screw

DTXG0814

41

Page 42

42

ENGINE PARTS

This parts list shows the key number, part description, and

stock number for the replacement parts sets. When more

than one stock number is listed, that part is available in

multiple replacement parts sets. For contents found in each

replacment parts set, refer to the illustrated parts guide.

E1 Crankcase ..........................................................DTXG0527

E2 Cylinder Sleeve ................................................. DTXG0546

E3 Piston ................................................................ DTXG0546

E4 Cylinder Head (Blue) ......................................... DTXG0579

E5 Head Button ...................................................... DTXG0574

E6 Connecting Rod ................................................ DTXG0474

E7 Front Bearing .....................................................DTXG0351

E8 Rear Bearing ..................................................... DTXG0364

E9 SG Crankshaft ................................................... DTXG0539

E10 Piston Pin .......................................................... DTXG0646

E11 Piston Pin Retainer ........................................... DTXG0646

E12 Head Shim .................................... DTXG0596, DTXG0574

E13 Start Shaft Pin Spring ........................................DTXG0777

E14 Start Shaft Pin ....................................................DTXG0777

E15 Start Shaft ..........................................................DTXG0771

E16 Backplate Gasket ...........................DTXG0596, DTXG0491

E17 Backplate (for Recoil) .........................................DTXG0491

E18 3 x 6mm Backplate Screw ..............DTXG0509, DTXG0491

E19 One-Way Bearing ..............................................DTXG0637

E20 Recoil Starter ................................................... DTXG0756

E21 3 x 5mm Recoil Starter Screw .......................... DTXG0756

E22 Carburetor Body ............................ DTXG0408, DTXG0444

E23 Slide Valve ..................................... DTXG0413, DTXG0444

E24 Low Speed Needle O-Ring ...........DTXG0598, DTXG0432,

DTXG0444

E25 Low Speed Needle Valve .............. DTXG0598, DTXG0444

E26 Carb Dust Boot.......... DTXG0404, DTXG0432, DTXG0444

E27 Throttle Arm .................................. DTXG0801, DTXG0444

E28 Throttle Stop Screw ....................... DTXG0814, DTXG0444

E29 Carburetor O-Ring ......DTXG0469. DTXG0432, DTXG0444

E30 4 x 7.5 x .5mm Gasket .................. DTXG0432, DTXG0556,

DTXG0444

E31 Fuel Inlet Nozzle ........................... DTXG0556, DTXG0444

E32 5 x 7.5 x .5mm Gasket .................. DTXG0432, DTXG0556,

DTXG0444

E33 High Speed Needle Socket ........... DTXG0618, DTXG0444

E34 High Speed Needle O-Ring........... DTXG0621, DTXG0432,

DTXG0444

E35 High Speed Needle Valve ............. DTXG0621, DTXG0444

E36 Carburetor Retainer Pin .....................................DTXG0461

E37 3.5mm Lock Washer ..........................................DTXG0461

E38 3.5 x 5mm Carb Retainer Screw ........................DTXG0461

E39 3 x 15mm Cylinder Head Screw .... DTXG0610, DTXG0579

E40 Small Backplate O-Ring .....................................DTXG0491

E41 Throttle Stop Screw O-Ring .......... DTXG0814, DTXG0432

E35

E34

E33

E32

E28

E30

E31

E41

E22

E29

E23

E24

E26

E38

E25

E7

E37

E27

E36

E39

E4

E5

Z

E11

E1

E12

E12

E12

E2

E3

E11

E10

E6

E15

E16

E8

E17

E9

E40

E18

E13

E14

E20

E21

E19

E21

E21

42

Page 43

Tools & Accessories

43434343444444

Body Scissors & Reamer

Stainless steel blades of body scissors cut through plastics without

tearing. The reamer has a sharp tip with fluted blades to remove

debris as you cut.

DTXR1150

DTXR1151

DTXR1158

DTXR1160

DTXR1161

Pit Tech

Made of durable black

plastic, this gauge easily

and accurately measures

camber settings in 1°

increments from 10°

positive to 10° negative.

DTXR1146

Curved Tip Body Scissors

Straight Tip Body Scissors

Body Reamer

Straight Tip Body Scissors & Reamer (2-Piece Set)

Straight/Curved Tip Body Scissors & Reamer (3-Piece Set)

™

Camber Gauge

Pit Tech Tire Glue

Specially formulated to form

a lasting bond between your

wheels and rubber tires, Tire Glue

comes in two 0.5 oz (14.8 mL)

formulas: quicker-drying Thin and

slower-curing Medium.

DTXR2000

DTXR2002

Thin

Medium

Body Repair Tape

Use this flexible, open-weave

nylon mesh tape together with

Shoe Goo to repair Lexan

plastic and wood. Rolls measure

2” x 6’ (50.8 mm x 1.8 m).

DTXR1210

®

, ABS

Servo Tape

Double-sided adhesive tape

measures 1 in (25.4 mm) in width —

perfect for standard servos, as well

as many other sizes and applications.

Contains 36 in (914.4 mm) per roll.

DTXR1215

Pit Mats

The 5 x 5 in (63.5 x 63.5 mm) size is ideal for

small parts and hardware. The 29 x 19 in

(736.6 x 482.6 mm) has room for your vehicle,

heli or small plane, too. Both are made of

durable, solvent- and fuel-resistant rubber.

DTXP2045

DTXP2050

5 x 5 in Pit Mat (63.5 x 63.5 mm)

29 x 19 Pit Mat (736.6 x 482.6 mm)

Pit Tech Threadlocker

This medium-strength

threadlocking compound

prevents metal fasteners from

loosening under vibration. Each

bottle contains 0.2 oz (5.9 mL).

Not recommended for plastics.

DTXR2010

®

Shoe Goo

Clear, nonflammable Shoe Goo

compound is strong, yet flexible

when dry. It’s ideal for body

repairs, mounting servos, building

battery packs and more.

DTXC2460

II

Page 44

85

L

86

A

5x10mm Ball Bearing

DTXC1535

86

87

Air Filter Foam

DTXC6115

KK

Body Clips (Large)

DTXC6472

B

8x16mm Ball Bearing

DTXC1585

164

Antenna Tube

DTXC6161

Blue Body w/Decals

DTXC6562

N

3x6mm B/H Screw

DTXC4390

168 160 169

3mm Ball Set

DTXC6191

Orange Body w/Decals

DTXC6563

84

88

83

Air Filter Set

88

DTXC6114

LL

Body Clips (Small)

DTXC6442

Red Body w/Decals

DTXC6564

87

Yellow Body w/Decals

DTXC6565

74

75

Brake Cam Set

Z

76

DTXC6704

166

35

Clear Body w/Decals

DTXC6566

C

6x10mm Bushing

DTXC6781

77

F

34

36

45

32

31

F

33

Chassis Brace Set

DTXC6598

D

148

155

HH

5

JJ

4

156

Bulkhead/Gearbox Set

DTXC6831

3

2

79

78

Brake Disk and Pad Set

DTXC6694

23

Front Bumper

DTXC6915

1

Center Brace

DTXC6952

Center Diff Mount Set

DTXC6953

44

Side Pod Set

DTXC6970

Hard Anodized Chassis

DTXC6971

Page 45

45

DD

QQ

100

102

13T Clutch Bell

DTXC7138

104

103

Center Dogbone Set

DTXC7501

BB

110

Center Drive Joint Set

DTXC7512

Clutch Shoe Set

DTXC7163

105

Rear Dogbone Set

DTXC7502

112

R

111

116

Diff Ring & Pinion Gear

DTXC7513

101

Clutch Spring Set

DTXC7168

106

Universal Drive Shaft Set

BB

DTXC7503

114

BB

Diff Case Set

116

115

DTXC7514

Decal Set

DTXC7297

107 109 108

Drive Hex

w/Wheel Nut Set

DTXC7504

117

Front/Rear Diff

Output Joint Set

DTXC7515

118

Center Diff

Output Joint Set

DTXC7516

81

80

Engine Mount Block Set

DTXC7618

D

F

50

49

48

Q

Fuel Tank w/Mount Set

47

DTXC7821

119

EE

120

Diff Shaft Set

DTXC7517

82

Engine Mount Plate Set

DTXC7619

61

Aluminum Front

Hinge Pin Mount

DTXC7974

121

FF

122

Diff Bevel Gear Set

DTXC7518

99

Clutch Nut

DTXC7657

12

11

124

Front Hub Carrier Set

DTXC8093

93

92

Exhaust Coupler Set

DTXC7604

97

98

Flywheel and Collet

DTXC7712

16

151

15

Rear Hub Set

DTXC8094

45

Page 46

46

14

T

13

Front Knuckle Arm Set

DTXC8234

73

68

71

69

72

Z

Throttle/Brake Link Set

70

DTXC8235

HH

3mm Lock Nuts

DTXC8240

90

89

94

Exhaust Manifold Set

DTXC8291

95

Pipe Mount Set

T

DTXC8321

3x15mm H/H

Shoulder Screw

DTXC8651

AA

7

BB

123

8

96

Radio Box Set

DTXC8396

G

6

Rear Axle Set

BB

DTXC8456

K

M

155

156

152 154

Screw Pin Set

DTXC8601

157

153

Z

3x22mm B/H Screws

DTXC8652

QQ

4x20mm B/H Screws

DTXC8657

EE

3x3mm Set Screws

DTXC8660

FF

3x10mm Set Screws

DTXC8661

MM

4x10mm Motor Mount

Screws

DTXC8699

143

Shock Boot Set

142

DTXC8944

5x8x0.3mm Clutch

Bell Washers

DTXC8696

67

65

167

66

Servo Arm Set

DTXC8806

171 (x4)

170 (x4)

138 (x2)

145 (x2)

126 (x4)

Shock Parts Set

HH (x4)

140 (x4)

158 (x4)

135 (x2)

DD (x4)

139 (x8)

137 (x2)

133 (x2)

136 (x4)

132 (x2)

DTXC8945

4x7mm Washers

DTXC8697

57

6x10mm Washers

DTXC8698

53

H

55

E

56

Servo Saver Shaft,

Spring, and Adjuster

DTXC8842

54

Servo Saver

Plastic Parts Set

DTXC8843

52

129 (x4)

128 (x2)

131 (x4)

134 144

Shock Spring Set

DTXC8946

130 (x4)

141 (x4)

Shock Body Set

DTXC8947

127 (x2)

46

Page 47

47

HH

t

DD

125

Y

172

Upper Shock Mount Set

DTXC8948

24

Front Shock Tower

DTXC9292

20

169

22

21

160

Rear Upper

Suspension Arm Set

DTXC9339

Assembled Front Shocks

DTXC8982

25

Rear Shock Tower

DTXC9293

19

17

Front Upper

Suspension Arm Set

168

18

DTXC9340

Assembled Rear Shocks

DTXC8983

R

113

116

46T Spur Gear

DTXC9329

9

Front Suspension Arm Se

DTXC9341

4x8mm O-Rings

DTXC9289

30

29

27

28

26

Suspension Mount Set

DTXC9338

10

Rear Suspension Arm Set

DTXC9342

AA

64

Steering Linkage

158

DTXC9462

Z

149

148

AA

150

146

Front Sway Bar Set

DTXC9607

DD

51

T

Steering Post Set

DTXC9468

147

Z

150

149

Rear Sway Bar Set

148

AA

DTXC9608

GG

58

Steering Drag Link

DTXC9469

63

159

Tie-Rod Set

62

DTXC9634

59

60

DD

Steering Swivel Set

DTXC9477

91

Tuned Pipe

DTXC9726

38

37

3x8mm Washers

DTXC9763

Assembled

3mm Lock Washers

DTXC9764

47

Wheel & Tire Set

DTXC9795

Black Wing

w/Wing Washers

DTXC9964

Page 48

48

43

44

Wing Mount Set

F

45

DTXC9965

42

41

40

39

46

Exhaust Gasket

DTXG0658

165

6V 5-Cell 1300mAh

NIMH Receiver Battery

DTXM2040

Receiver Battery

Charger 110V

DTXP4800

P

2.6x6mm

2.6x8mm

2.6mm S/T Screw Set

2.6x10mm

2.6x12mm

DTXQ0203

BB

4x4mm

4x5mm

4x8mm

CC

4x12mm

4mm Set Screws

DTXQ0305

V

3x8mm 3x10mm

W

3x12mm

3mm H/H Screw Set

3x14mm

DTXQ0285

F

3x12mm B/H Screw Set

DTXQ5060

X

3x15mm

3x20mm

3x16mm 3x18mm

3mm H/H Screw Set

DTXQ0286

S3003 Throttle Servo

FUTM0031

Y

3x35mm3x30mm

3x40mm3x25mm

3mm H/H Screw Set

DTXQ0287

S3305 Steering Servo

FUTM0045

Fuel Tubing

GPMQ4131

U

4x14mm F/H Screws

TKPQ0123

J

3x18mm B/H Screws

TKPQ0206

Q

3x10mm F/H Screws

TKPQ0102

D

3x8mm B/H Screws

TKPQ0201

L

4x12mm B/H Screws

TKPQ0222

R

3x12mm F/H Screws

TKPQ0103

E

3x10mm B/H Screws

TKPQ0202

JJ

4mm Lock Nuts

TKPQ1004

T

4x12mm F/H Screws

TKPQ0122

H

3x16mm B/H Screws

TKPQ0205

48

Page 49

494949

Accessories

Box

49

Glow Starters 1/10 & 1/8 Universal

The all-aluminum Ultra Slim is powered

by a 1.2V, 1800mAh NiMH cell; Ultimates

with high-impact polystyrene battery

case use a larger NiCd. All include

battery and charger — and offer the

security of a Twist-and-Lock tip.

DTXP0320

DTXP0310

DTXP0315

Ultra Slim “AA” Glow Starter

Ultimate “C” Glow Starter

Ultimate “D” Glow Starter

Micro Fail-Safe

Prevents runaways due to signal

loss or low receiver battery voltage,

by reducing the throttle to a setting

you select. Works with 4- and 5-cell

NiCd and NiMH packs. Universal

connector included.

DTXM4000

Starter Box

Twin 550 motors and a durable belt

drive offer reliable starting power for

1/8 and 1/10 on- and off-road engines.

Requires either a 12V, 7Ah field battery

or two 6-cell NiCd/NiMH stick packs.

DTXP5701

Track Bags

XL Deluxe measures 27 x 14 x 12 in

(685.8 x 355.6 x 304.8 mm). 1/8 Deluxe

Hauler measures 24.5 x 23 x 19 in

(622.3 x 584.2 x 482.6 mm), and features

wheels and a handle. Both are made

of strong, lightweight nylon.

DTXP2011

DTXP2012

XL Deluxe Field Bag

1/8 Deluxe Hauler Bag

Futaba® 3PL 2.4GHz

Computer Radio

Easy to program, the 3PL includes 3

proportional channels, a fourth for

special mixing, and FHSS frequencyhopping technology to eliminate

interference. A half-ounce R2004GF

receiver is included.

FUTK1300

49

49

Page 50

505050

This parts list shows the key number, part description, and

stock number for the replacement parts sets. When more

than one stock number is listed, that part is available in

multiple replacement parts sets. For contents found in each

replacment parts set, refer to the illustrated parts guide.

# Item Description ............... Available in Stock #

1 Main Chassis ................................................DTXC6971

2 Side Pod (Left) .............................................DTXC6970

3 Side Pod (Right) ..........................................DTXC6970

4 Gearbox/Bulkhead A .....................................DTXC6831

5 Gearbox/Bulkhead B .....................................DTXC6831

6 Radio Box .....................................................DTXC8396

7 Receiver Box Lid ...........................................DTXC8396

8 Battery Box Lid .............................................DTXC8396

9 Front Susp Arm .............................................DTXC9341

10 Rear Susp Arm .............................................DTXC9342

11 Front Hub Carrier/C-Hub (Left) .....................DTXC8093

12 Front Hub Carrier/C-Hub (Right) ...................DTXC8093

13 Front Knuckle (Left) ......................................DTXC8234

14 Front Knuckle (Right) ....................................DTXC8234

15 Rear Hub (Left) .............................................DTXC8094

16 Rear Hub (Right)...........................................DTXC8094

17 Front Upper Susp Arm ..................................DTXC9340

18 Front Upper Susp Arm Ball End ...................DTXC9340

19 5x30mm Turnbuckle (Front Upper Arm) ........DTXC9340

20 Rear Upper Susp Arm Ball End (Long) ........DTXC9339

21 Rear Upper Susp Arm Ball End (Short) ........DTXC9339

22 5x50mm Turnbuckle (Rear Upper Arm) ........DTXC9339

23 Front Bumper ................................................DTXC6915

24 Front Shock Tower ........................................DTXC9292

25 Rear Shock Tower .........................................DTXC9293

26 Front, Rear Lower Susp Mount .....................DTXC9338

27 Front, Rear Upper Susp Mount .....................DTXC9338

28 Rear, Front Lower Susp Mount .....................DTXC9338

29 Rear, Rear Lower Susp Mount .....................DTXC9338

30 Rear Chassis Brace Mount ...........................DTXC9338

31 Rear Chassis Brace ......................................DTXC6598

32 Front Upper Brace ........................................DTXC6598

33 Front Chassis Brace .....................................DTXC6598

34 Center Differential Mount ..............................DTXC6953

35 Center Brace .................................................DTXC6952

36 Fuel Splash Guard ........................................DTXC6953

37 Rear Wing (Black) .........................................DTXC9964

38 Wing Washer ................................................DTXC9964

39 Lower Wing Mount (Left) ...............................DTXC9965

40 Lower Wing Mount (Right) ............................DTXC9965

41 Upper Wing Mount (Left) ..............................DTXC9965

42 Upper Wing Mount (Right) ............................DTXC9965

43 Wing Mount Support ....................................DTXC9965

44 Rear Body Mount ..........................................DTXC9965

45 Front Body Mount .........................................DTXC9965

46 Exhaust Gasket ........................................... DTXG0658

47 Fuel Tank 125cc ............................................ DTXC7821

48 Fuel Tank Mount ...........................................DTXC7821

49 Fuel Line Holder ...........................................DTXC7821

50 Fuel Tank Grommet ...................................... DTXC7821

51 Steering Post ................................................DTXC9468

52 Steering Bellcrank .......................................DTXC8843

53 Upper Servo Saver ......................................DTXC8843

54 Lower Servo Saver .......................................DTXC8843

55 Servo Saver Shaft .........................................DTXC8842

56 Servo Saver Spring .......................................DTXC8842

57 Servo Saver Adjustment Nut ........................DTXC8842

58 Steering Drag Link ........................................DTXC9469

59 Drag Link Bolt ...............................................DTXC9477

60 Drag Link Bushing ........................................ DTXC9477

61 Aluminum Front Hinge Pin Mount .................DTXC7974

62 Tie-Rod Turnbuckle .......................................DTXC9634

63 Tie Rod Ball End ...........................................DTXC9634

64 Steering Linkage Ball End ............................DTXC9462

65 Steering Servo Arm ......................................DTXC8806

66 Throttle Servo Arm .......................................DTXC8806

67 Linkage Slider A............................................DTXC8806

68 Throttle/Brake Linkage Rod ..........................DTXC8235

69 Throttle/Brake Linkage Ball End ...................DTXC8235

70 Knurled Linkage Collar .................................DTXC8235

71 Linkage Collar ...............................................DTXC8235

72 Throttle Linkage Spring ................................DTXC8235

73 Brake Linkage Spacer ..................................DTXC8235

74 Brake Cam (Long) ........................................DTXC6704

75 Brake Cam (Short) ........................................DTXC6704

76 Brake Cam Linkage Pin ................................DTXC6704

77 Brake Cam Bushing ......................................DTXC6953

78 Brake Disk ....................................................DTXC6694

79 Brake Pad .....................................................DTXC6694

80 Engine Mount Block (Left) ............................DTXC7618

81 Engine Mount Block (Right) ..........................DTXC7618

82 Engine Mount Plate ......................................DTXC7619

83 Air Filter Adapter Tube ..................................DTXC6114

84 Air Filter Mount .............................................DTXC6114

85 Air Filter Cap .................................................DTXC6114

86 Air Filter Element (Outer) ..........DTXC6115, DTXC6114

87 Air Filter Element (Inner)...........DTXC6115, DTXC6114

88 Air Filter Tie Strap .........................................DTXC6114

89 Exhaust Manifold .......................................... DTXC8291

90 Exhaust Manifold Spring ...............................DTXC8291

91 Tuned Pipe ....................................................DTXC9726

92 Tuned Pipe Coupler ......................................DTXC7604

93 Tuned Pipe Coupler Tie Strap .......................DTXC7604

94 Exhaust Manifold Plate ................................. DTXC8291

95 Tuned Pipe Mount ......................................... DTXC8321

96 Tuned Pipe Mounting Wire ............................DTXC8321

97 Flywheel Collet .............................................DTXC7712

98 Flywheel........................................................DTXC7712

99 Clutch Nut .....................................................DTXC7657

100 Clutch Shoe ..................................................DTXC7163

101 Clutch Spring ................................................DTXC7168

102 Clutch Bell (13T, Module 1) ...........................DTXC7138

103 Center Dogbone (85mm, Front) .................... DTXC7501

104 Center Dogbone (96mm, Rear) .................... DTXC7501

105 Rear Dogbone (88mm) .................................DTXC7502

106 Front Universal Drive Shaft ...........................DTXC7503

107 Drive Hex ......................................................DTXC7504

108 Drive Pin (2.5x16mm) ...................................DTXC7504

109 Wheel Nut .....................................................DTXC7504

110 Center Drive Joint .........................................DTXC7512

111 Differential Pinion Gear (13T) .......................DTXC7513

112 Differential Ring Gear (43T) ..........................DTXC7513

113 Spur Gear (46T, Module 1) ...........................DTXC9329

114 Differential Case ...........................................DTXC7514

50

Page 51

115 Differential Case O-Ring ...............................DTXC7514

116 Differential Shaft O-Ring ...........DTXC7514, DTXC9329,

DTXC7513

117 Differential Output Joint (Front/Rear) ............DTXC7515

118 Center Differential Output Joint ....................DTXC7516

119 Differential Cross Pin Shaft ........................... DTXC7517

120 Differential Output Joint Pin (2.5x13mm) ......DTXC7517

121 Differential Large Bevel Gear ........................DTXC7518

122 Differential Small Bevel Gear ........................DTXC7518

123 Rear Axle .....................................................DTXC8456

124 King Pin Bushing ..........................................DTXC8093

125 Upper Shock Mount ......................................DTXC8948

126 Upper Shock Mount Bushing ........................DTXC8945

127 Front Shock Body ..................... DTXC8947, DTXC8982

128 Rear Shock Body ......................DTXC8947, DTXC8983

129 Shock Cap ............ DTXC8947, DTXC8982, DTXC8983

130 Upper Spring Mount .................DTXC8947, DTXC8982,

DTXC8983

131 Upper Spring Mount O-Ring .....DTXC8947, DTXC8982,

DTXC8983

132 Lower Spring Mount ..................DTXC8945, DTXC8982,

DTXC8983

133 Front Shock End ....................... DTXC8945, DTXC8982

134 Front Shock Spring ................... DTXC8946, DTXC8982

135 Shock Diaphragm .....................DTXC8945, DTXC8982,

DTXC8983

136 Shock Piston .........DTXC8945, DTXC8982, DTXC8983

137 Front Shock Shaft ..................... DTXC8945, DTXC8982

138 Rear Shock Shaft ...................... DTXC8945, DTXC8983

139 Shock O-Ring .......DTXC8945, DTXC8982, DTXC8983

140 Shock O-Ring Spacer (Thin) .....DTXC8945, DTXC8982,

DTXC8983

141 Shock Seal Retainer .................DTXC8947, DTXC8982,

DTXC8983

142 Front Shock Boot ...................... DTXC8944, DTXC8982

143 Rear Shock Boot ....................... DTXC8944, DTXC8983

144 Rear Shock Spring....................DTXC8946, DTXC8983

145 Rear Shock End ........................ DTXC8945, DTXC8983

146 Front Sway Bar .............................................DTXC9607

147 Rear Sway Bar ..............................................DTXC9608

148 Sway Bar Retainer ....................DTXC9607, DTXC9608,

DTXC6831

149 Sway Bar End Pivot ..................DTXC9607, DTXC9608

150 Sway Bar Ball End ....................DTXC9607, DTXC9608

151 Rear Hub Spacer ......................................... DTXC8094

152 3x40mm Screw Pin .......................................DTXC8601

153 3x45mm Screw Pin .......................................DTXC8601

154 3x50mm Screw Pin .......................................DTXC8601

155 4x37mm Screw Pin ................... DTXC8601, DTXC6831

156 4x62mm Screw Pin ................... DTXC8601, DTXC6831

157 4x70mm Screw Pin .......................................DTXC8601

158 3mm Ball ...................................DTXC9462, DTXC8945

159 3mm Stand-Off Ball ......................................DTXC9634

160 Ball Nut .....................................DTXC6191, DTXC9339

161 Wheel............................................................DTXC9795

162 Tire................................................................DTXC9795

163 Foam Tire Insert ...........................................DTXC9795

164 Antenna Tube ................................................DTXC6161

165 6V 5-cell 1300mAh NiMH Rx Battery ......... DTXM2040

166 Fuel Line Clip ................................................DTXC6952

167 Linkage Slider B............................................DTXC8806

168 3x8mm Ball (Tall) ......................DTXC6191, DTXC9340

169 3x8mm Ball (Short) ...................DTXC6191, DTXC9339

170 Shock O-Ring Spacer (Thick) ...DTXC8945, DTXC8982,

DTXC8983

171 Shock Shaft Guide ....................DTXC8945, DTXC8982,

DTXC8983

172 4x8mm O-Ring..............................................DTXC9289

HARDWARE

A 5x10mm Ball Bearing ...................................DTXC1535

B 8x16mm Ball Bearing ...................................DTXC1585

C 6x10 Bushing ................................................DTXC6781

D 3x8mm Button Head Hex Screw ...................TKPQ0201

E 3x10mm Button Head Hex Screw .................TKPQ0202

F 3x12mm Button Head Hex Screw ................ DTXQ5060

G 3x15mm B/H Shoulder Brake Screw ............DTXC8651

H 3x16mm Button Head Hex Screw .................TKPQ0205

J 3x18mm Button Head Hex Screw .................TKPQ0206

K 3x22mm Button Head Hex Screw .................DTXC8652

L 4x12mm Button Head Hex Screw .................TKPQ0222

M 4x20mm Button Head Hex Screw ................. DTXC8657

N 3x8mm Button Head Screw ..........................DTXC4390

P 2.6x6mm Self-Tapping Screw ...................... DTXQ0203

Q 3x10mm Flat Head Hex Screw .....................TKPQ0102

R 3x12mm Flat Head Hex Screw .....................TKPQ0103

T 4x12mm Flat Head Hex Screw .....................TKPQ0122

U 4x14mm Flat Head Hex Screw .....................TKPQ0123

V 3x10mm Cap Screw .................................... DTXQ0285

W 3x12mm Cap Screw .................................... DTXQ0285

X 3x20mm Socket Head Screw ....................... DTXQ0286

Y 3x30mm Socket Head Screw ........................DTXQ0287

Z 3x3mm Set Screw .........................................DTXC8660

AA 3x10mm Set Screw ....................................... DTXC8661

BB 4x5mm Set Screw ........................................ DTXQ0305

CC 4x12mm Set Screw ...................................... DTXQ0305

DD 3x8mm Washer .............................................DTXC9763

EE 4x7mm Washer .............................................DTXC8697

FF 6x10mm Washer ...........................................DTXC8698

GG 3mm Lock Washer ........................................DTXC9764

HH 3mm Locknut ................................................DTXC8240

JJ 4mm Locknut ................................................TKPQ1004

KK Body Clip (Large) ..........................................DTXC6472

LL Body Clip (Small) ..........................................DTXC6442

MM 4x10mm Motor Mount Screws ......................DTXC8699

QQ Clutch Bell Washer (5x8x0.3mm) .................DTXC8696

Page 52

117

DD

140

170

B

BB

114

115

129

135

HH

136

137 Front

138 Rear

127 Front

128 Rear

131

130

139

171

141

142 Front

143 Rear

134 Front

144 Rear

132

133 Front

145 Rear

116

118

R

121

122

EE

120

R

R

FF

122

EE

38

H

38

57

56

53

43

158

158

M

154

51

T

H

39

K

109

54

C

55

C

41

F

HH

F

F

N

HH

65

F

AA

HH

DD

HH

64

158

F

64

C

52

C

51

T

37

R

B

113

EE

119

119

121

109

122

116

122

FF

EE

116

121

120

120

122

EE

108

FF

119

122

R

R

EE

BB

112

EE

119

121

107

14

122

R

158

R

B

150

AA

150

120

B

HH

EE

122

B

HH

148

116

124

152

DD

D

115

117

12

K

109

Z

HH

70

Z

LL

79

169

124

124

70

Z

70

73

8

LL

F

F

F

Q

79

78

G

HH

H

B

13

HH

108

FF

H

K

Z

23

124

149

D

158

157

156

L

156

148

126

155

L

HH

9

BB

125

155

61

157

114

HH

152

146

KK

B

118

KK

165

L

L

45

F

F

L

32

169

18

19

17

J

E

L

152

Y

Z

149

158

CC

U

AA

106

E

L

DD

4

HH

U

150

150

E

5

24

B

E

U

111

Y

125

126

K

158

26

L

HH

33

R

R

G

HH

JJ

27

JJ

U

CC

9

110

E

JJ

E

J

152

B

JJ

HH

17

106

HH

K

BB

11

19

103

18

L

L

E

67

P

167

67

66

68

68

H

E

DD

7

F

F

F

F

F

Q

Q

F

F

F

166

Z

77

75

76

34

U

U

3

1

B

107

BB

BB

JJ

Q

162

30

107

B

K

151

E

JJ

110

85

L

Q

QQ

V

F

50

48

Q

109

72

71

Z

F

36

35

76

68

69

E

Q

Z

U

U

Q

161

69

E

164

6

Q

Q

HH

R

77

G

74

78

79

34

Q

163

108

31

R

104

G

79

153

BB

Q

DD

49

HH

16

151

123

B

J

5

B

JJ

E

JJ

86

2

101

QQ

A

A

F

D

HH

87

100

102

D

172

CC

10

111

U

28

90

Q

101

100

50

47

48

Q

84

B

100

U

98

101

105

88

99

BB

95

97

82

T

JJ

168

150

150

4

83

T

JJ

MM

U

88

29

W

Z

GG

AA

82

149

158

U

W

JJ

157

MM

96

20

10

J

W

GG

T

MM

T

BB

147

E

CC

W

GG

81

JJ

156

MM

22

21

153

80

125

Y

157

T

126

160

DD

HH

148

91

156

159

25

105

46

DD

X

44

D

148

149

150

150

HH

94

93

63

62

158

HH

AA

172

K

92

63

HH

Z

DD

155

158

B

HH

21

123

151

F

HH

K

160

93

E

X

22

H

159

F

F

L

168

108

89

59

60

HH

Y

58

E

155

126

B

159

15

20

HH

HH

42

125

151

BB

M

DD

59

62

H

60

40

43

43

HH

107

DD

HH

63

63

159

Page 53

DTXD72Mnl

© 2012 Hobbico, Inc. All rights reserved.

Loading...

Loading...