Durabrand DBTV2501SM Schematic

DBTV2501 SERIES A

SER VICE MANUAL

COLOR TELEVISION RECEIVER

ORIGINAL

MFR’S VERSION A

Design and specifications are subject to change without notice.

DBTV2501 SERIES A

SER VICE MANUAL

COLOR TELEVISION RECEIVER

ORIGINAL 1

MFR’S VERSION B

MFR’S VERSION

A

B

Please file this revision with the original version.

CRT

A63AHC26X

A63ADT15*08

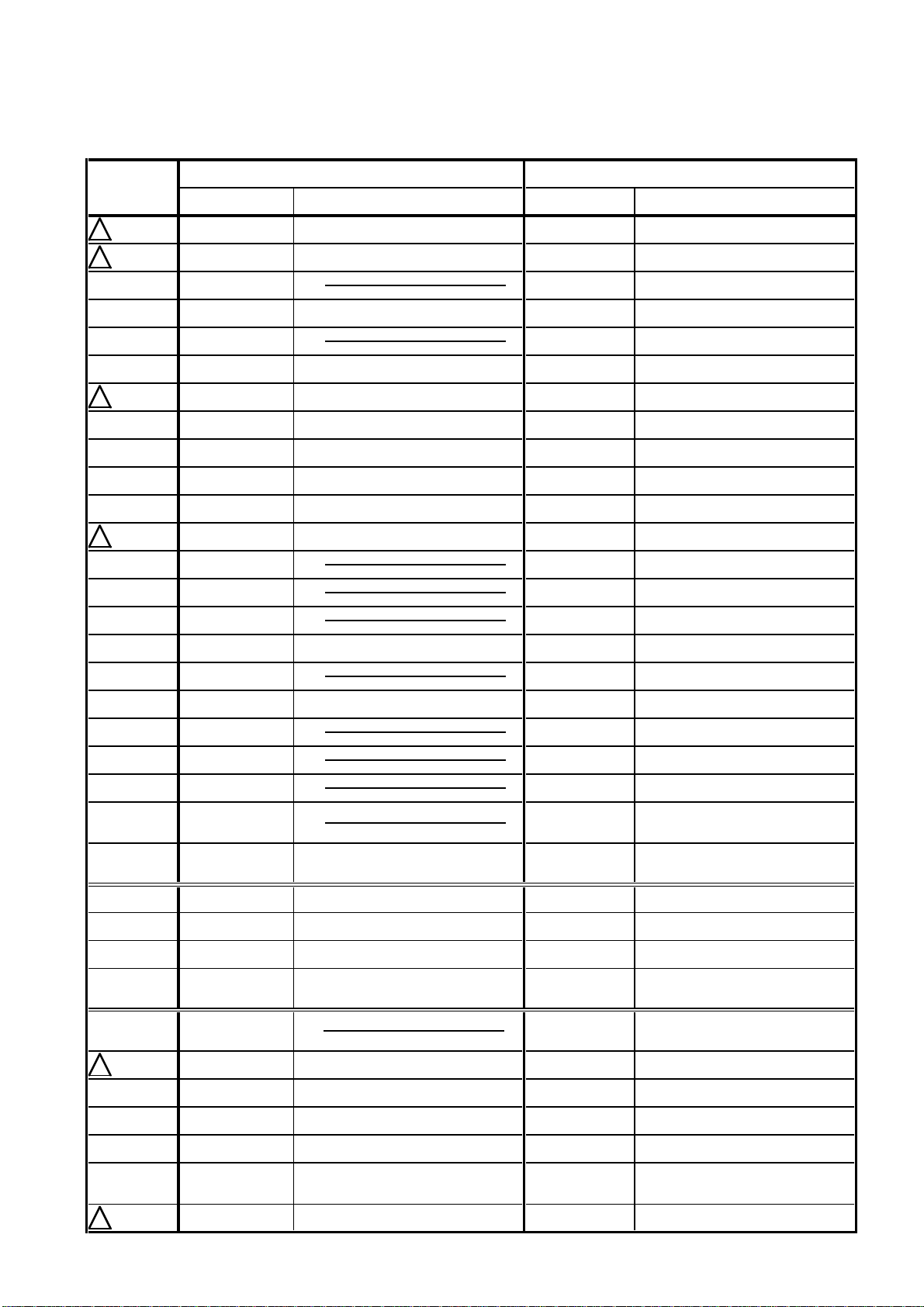

Change of CRT

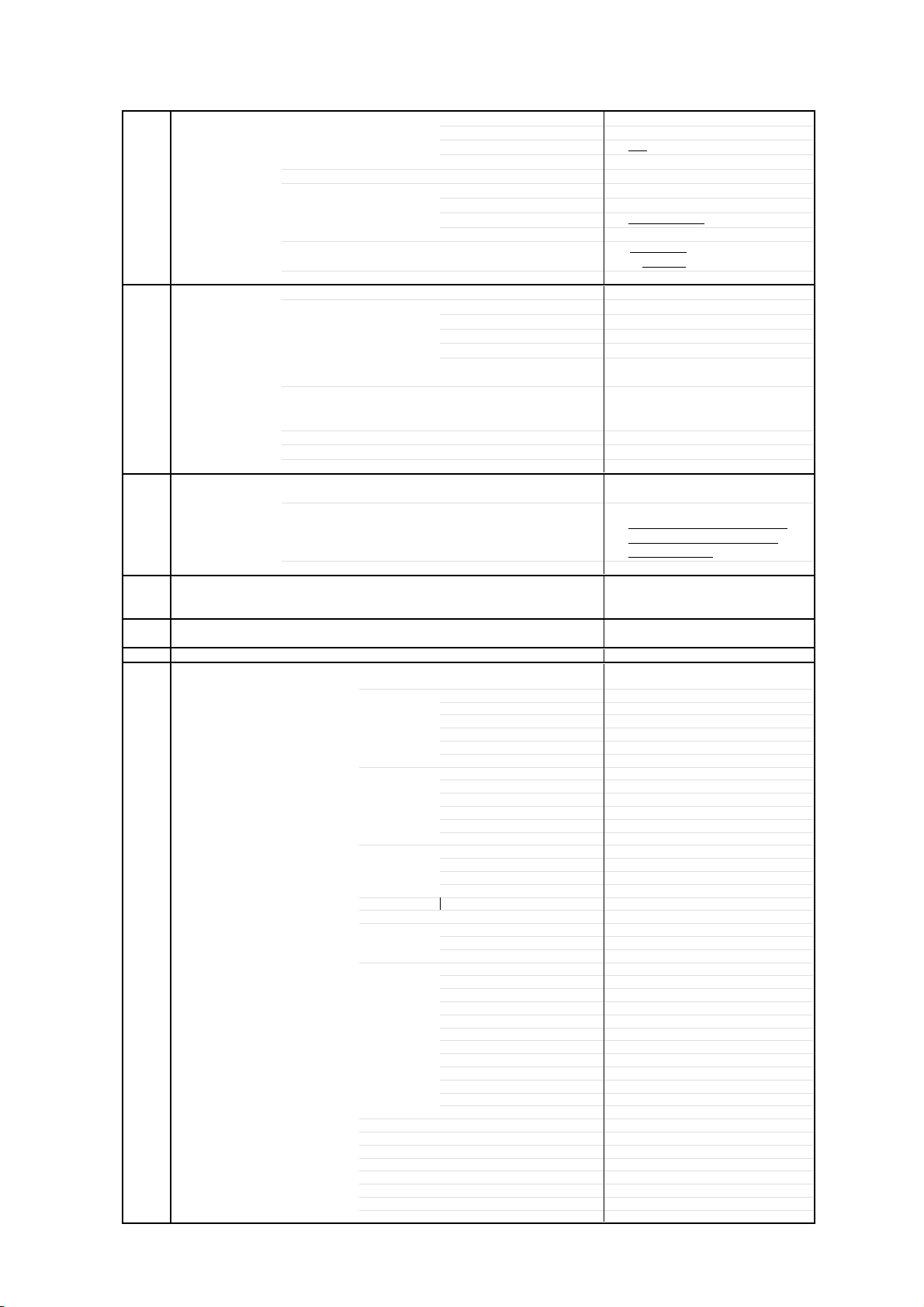

ELECTRICAL REPLACEMENT PARTS LIST

MFR'S VERSION A MFR'S VERSION B

REF. NO.

! R406 R903N8332J RC 3.3K OHM 1/8W R903N8100J RC 10 OHM 1/8W

! R408 R4X5T6183F R,METAL 18K OHM 1/6W R4X5T6273F R,METAL 27K OHM 1/6W

R410 R002T2821J RC 820 OHM 1/2W

R411 R002T2561J RC 560 OHM 1/2W R002T2102J RC 1K OHM 1/2W

R412 R002T2271J RC 270 OHM 1/2W

R413 R002T2681J RC 680 OHM 1/2W DEL

! R415 R3X181471J R,METAL OXIDE 470 OHM 1W DEL

R416 R0L2U2102J RC 1K OHM 1/2W DEL

R418 R002T4223J RC 22K OHM 1/4W R002T4273J RC 27K OHM 1/4W

R419 R002T4182J RC 1.8K OHM 1/4W R002T4122J RC 1.2K OHM 1/4W

R420 R002T4103J RC 10K OHM 1/4W R002T4682J RC 6.8K OHM 1/4W

! R429 R6558A1R8J R,FUSE 1.8 OHM 2W R6558A2R7J R,FUSE 2.7 OHM 2W

R432 R002T2821J RC 820 OHM 1/2W

R433 R002T2271J RC 270 OHM 1/2W

R438 R002T2151J RC 150 OHM 1/2W

R553 R903N8182J RC 1.8K OHM 1/8W R903N8472J RC 4.7K OHM 1/8W

PART NO. DESCRIPTION PART NO. DESCRIPTION

R613 R002T4473J RC 47K OHM 1/4W

R638 R903N8103J RC 10K OHM 1/8W R903N8822J RC 8.2K OHM 1/8W

C401 C0JTB0512K CC 100 PF 500V B

C427 E50HU5100M CE 10 UF 50V

C444 C0JLYR713K CC 0.001 UF 2KV YR

VR401 V1163H3BTC

PCB010 A3K004G01A MAIN PCB ASS'Y TMA501A A3K004I010K

C809 CS0KW04W2M CC 820 PF 50V W CS0KW04U2M CC 680 PF 50V W

C810 CS0KW04S2M CC 560 PF 50V W CS0KB04Q2K CC 470 PF 50V B

C811 CS0KW04U2M CC 680 PF 50V W CS0KW04S2M CC 560 PF 50V W

PCB110 A3K004G11G CRT PCB ASS'Y TCA358A A3K004I110K

CD804 06CU34002A

! DY801 027M062505 DY 7M062505 DEL

K001 129A000010 WEDGE 8115529 DEL

K002 129A000010 WEDGE 8115529 DEL

VOLUME,SEMI FIXED

EVNCYAA03BE3

MAIN PCB ASS'Y (VERSION B)

TMA501A

CRT PCB ASS'Y (VERSION B)

TCA358A

CORD CONNECTOR

SM1198-002-1A

K003 129A000010 WEDGE 8115529 DEL

MG801 026A062704

! V801 0984250502 CRT A63AHC26X 0984250503 CRT W/DY A63ADT15*08

MAIN PCB's and CRTPCB's are not interchangeable.

MAGNET,CONVERGENCE

29MMSTAR

DEL

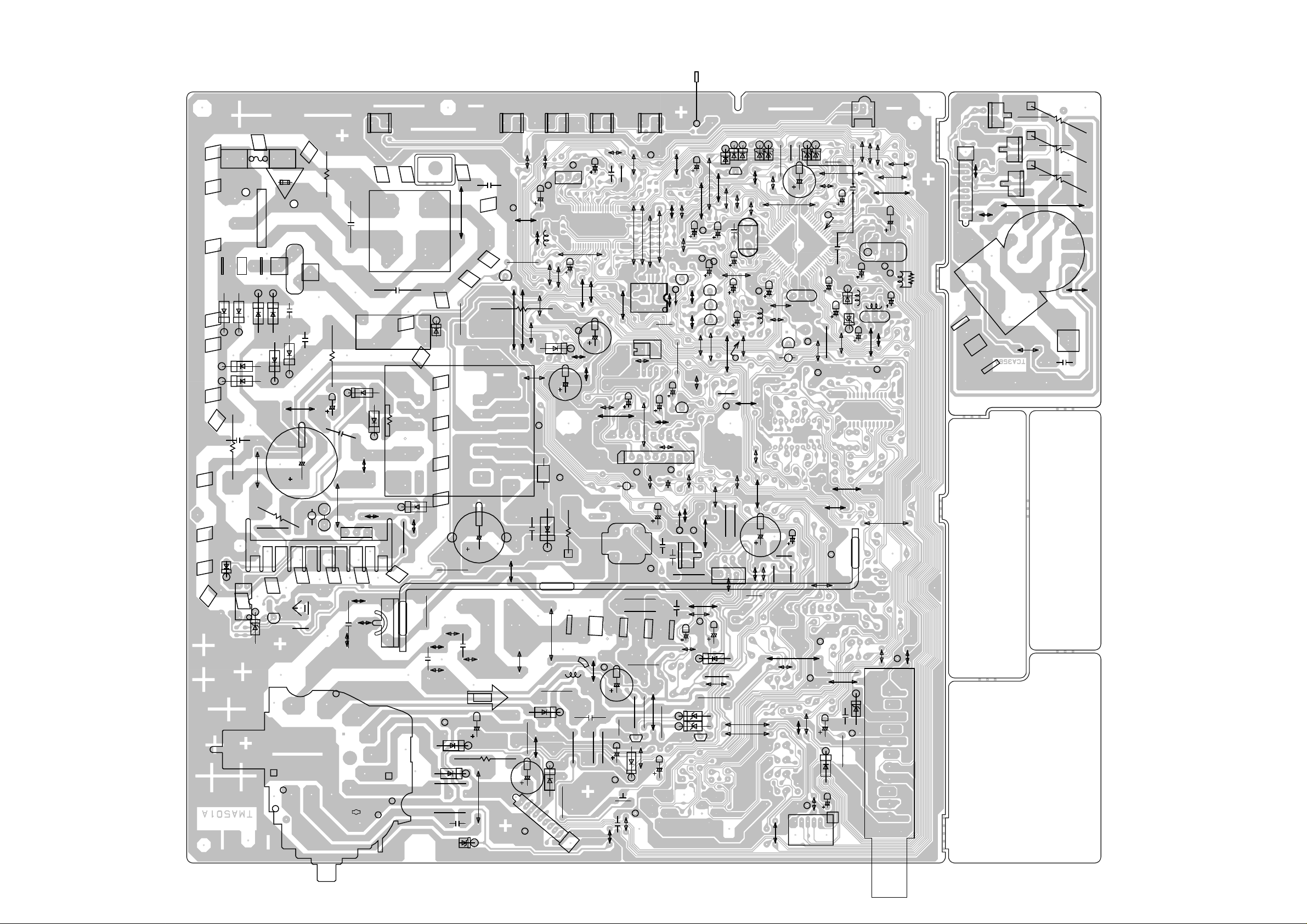

PRINTED CIRCUIT BOARDS

(MFR'S VERSION B)

MAIN/CRT (INSERTED PARTS)

SOLDER SIDE

FH501

S501A

CP502

D501

R501

D518

F501

D511

D502

D513

C532_1

W140

D528

_A_V

6.3A125VOR250V

PH003

TH501_1

C502_1

D504

D512

D517

D503

W137

R542

R506

IC506

VR502

Q507

R514

S501B

R543

R500

C503_1

R505

C507_1

HS501

FB401

PH004

C514

B502

C510

W139

C443_2

W141

D521

IC501

W143

C505_2

RY501

D506

W138

Q401

W142

SW105

W812

T501

D515

C506_2

R502

L501

R503

W820

R427

C444

D408

D410

W897

W891

R431

R422

D516

R554

W133

C401

W121

W132

D405

R523

C437

C404

C530

R429

W136

SW104

Q504

R517

C521_1

W131

W843

D407

C448_1

W120

R515

W129

R421

C118

W119

W128

D514

C517

CP802A

W123

W147

W124

B504

SW103

W118

W127

W146

S101Y

W122

D510

L406

R428

L101

W117

W134

D411

X101

W072

TP402

CP401_1

R433

C115

W827

W125

R440

C416

R412

SW102

C122

W809

C501_1

W107

R445

W099

W088

HS401

R409

W084

W114

C124

W817

C531_1

W828

W087

R653

T401

C435_2

VR401

C709

R118

R424

D413

SW101

W083

W078

CP351_1

C352_1

R432_1

R410

R411

C433

R408

Q403

W115

W077

W074

IC199

C357

W858

IC351_1

W103

C446

R405

W144

W075

R623

C360

W086

W859

C353_4

C439

W150

W085

W098

S801Y

C440

C430_1

R401

C434

W076

W073

Q603

Q351

Q402

W108

S801X

W801

R354

R446

CD806B

C613

W080

W844

C638_2

W802

W835

W152

W110

C427_1

Q101

C640

W836

C645_2

Q605

W096

W840

W105

R002

D611

W082

Q604

Q601

W092

W109

R438

D402

D401

W081

W090

W101

R436

IC401

C414

Q608

C622

R359

D607

W079

S802Y

W111

D403

D604

W863

C625

C627

C647

W829

W825

R407

W066

W064

L608

W094

R420

W862

W069

W113

D606

W810

X602

W813

W041

D608

W864

W030

C418

W059

R641

C612

C635

W031

R418

W051

W061

W010

Q606

W151

R648

R613

CF603

R632

C417

R417

R419

W065

D610

S802X

W067

W062

CP601

D609

W012

C605

W058

C002

D605

R625

C624_1

W022

W034

W048

W014

R612

C003

D601

W027

W036

R001

C004

R606

R631

C603

C659_2

CF601

C606

D602

D001

OS101

W020

C628

L606

C632

W019

L607

W029

TU001

W018

W011

C601

CF604

W023

W032

W013

W052

W015

L601

C604

W804

R604

CP802B

W003

S101X

W857

CP805

Q803

Q801

Q802

TP023

W004

R806

TP024

R804

TP022

R802

W002

R807

R805

R803

J801

W005

CP806

C802

ABC D E F GH

8

7

6

5

4

FROM/TO MICON/TUNER

3

2

1

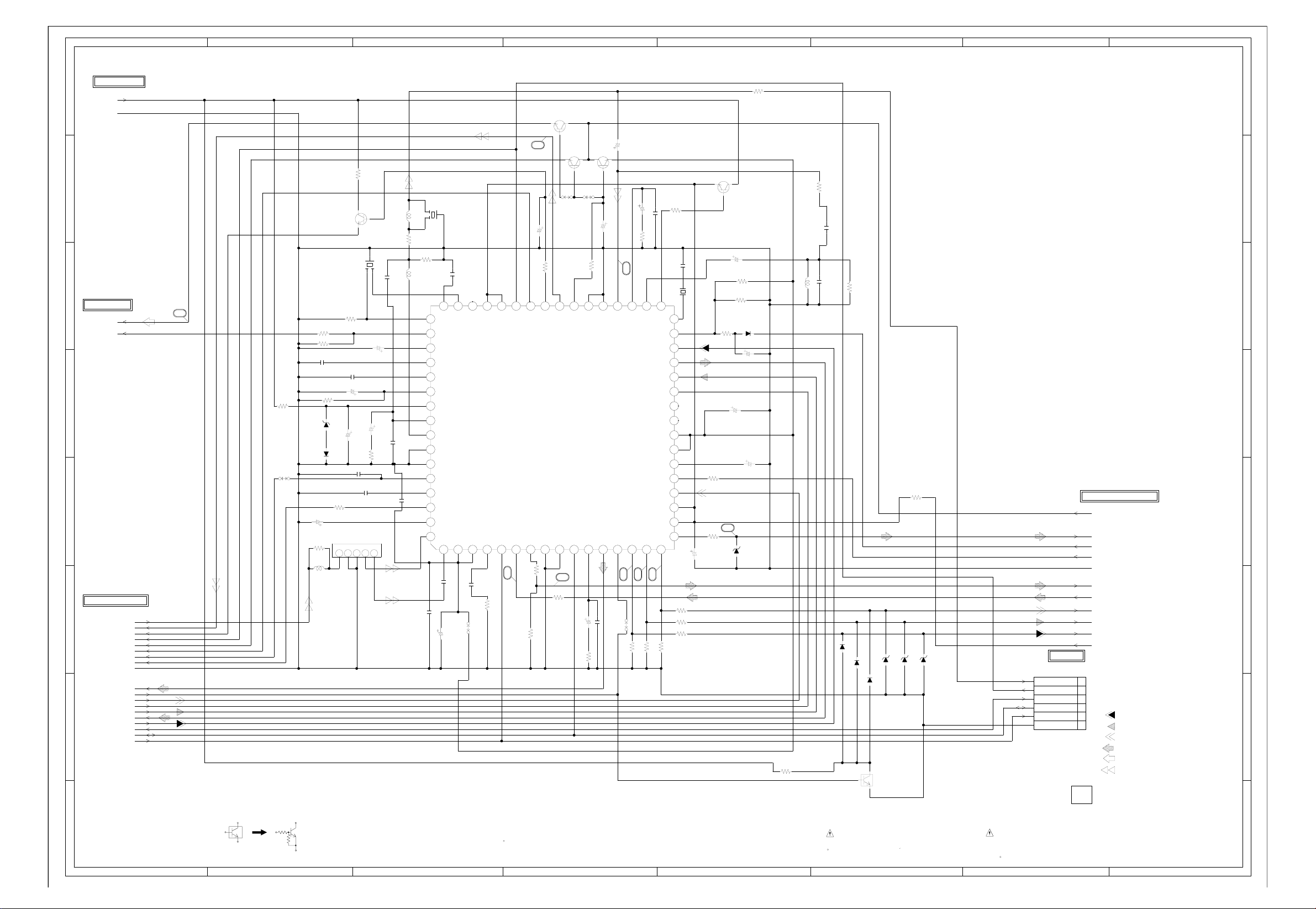

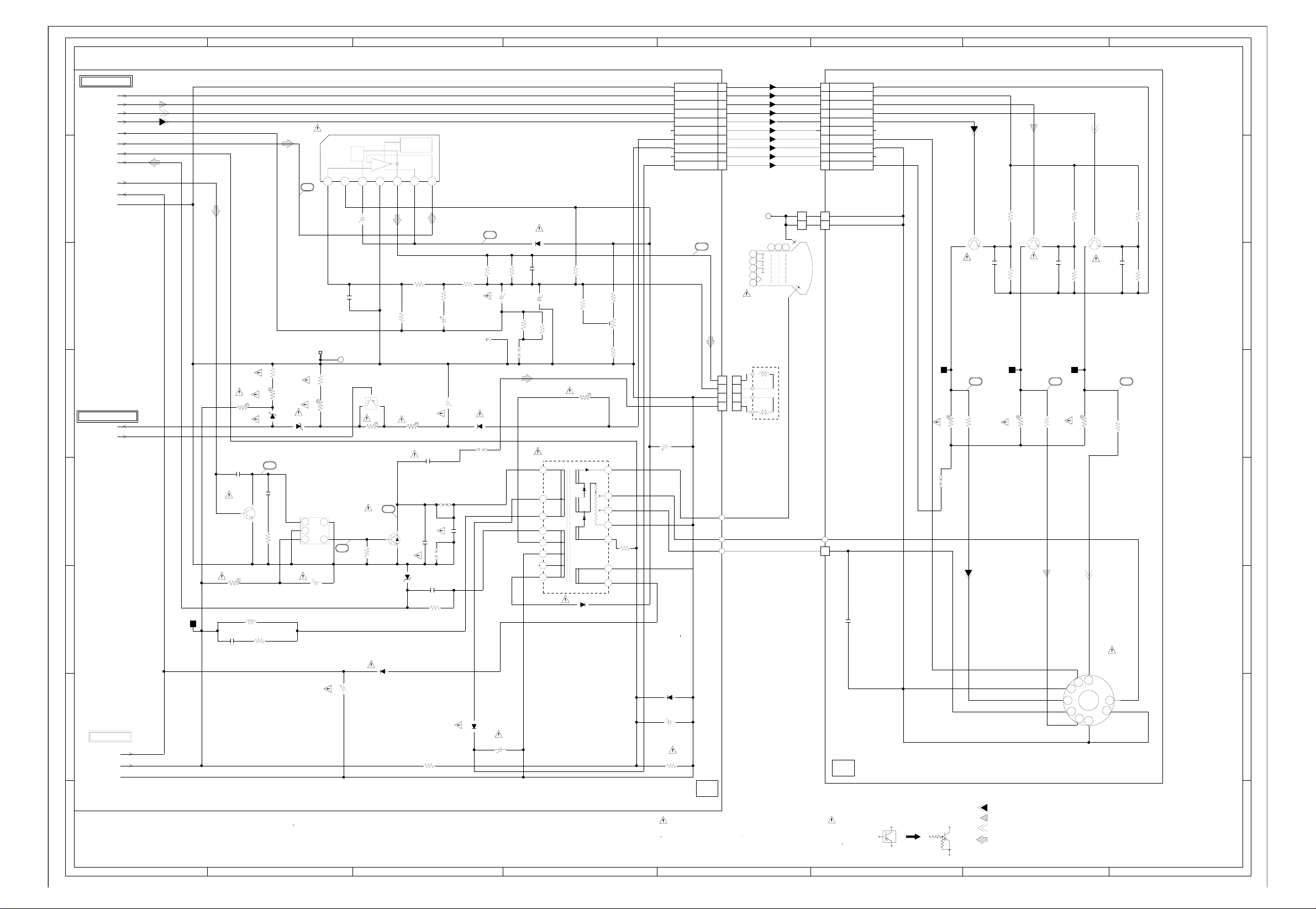

CHROMA SCHEMATIC DIAGRAM

FROM/POWER

AT+10V

GND

R623

120 1/4W

CF604

L607

R622

100P SL

15uH

68

L606

22P CH

TPSRA4M50C00-A0

R615

470

2.2uH

2.3

3.0

2.3

NC

3.8

3.1

9.2

3.0

2.6

0

0

0

2.9

1.8

2.9

1.8

C628

0.01 F

C636_1

NC

08.28.2

49

AUDIO OUT ACL/ABCL

50515253545556575859

AUDIO BYPASS

EXT AUDIO IN

FM DIRECT OUT

VIF VCO F/B

VREG Vcc

VIF APC FILTER

VIF VIDEO OUT

VIF GND

AFT OUT

6061626364

QIF IN

RF AGC OUT

RF AGC FILTER

1 10111213141516

2

1.5 5.0 5.0 2.7 4.9 6.2 6.2 0 0 4.9 3.5 4.9 4.9 4.0 4.0 4.8

C634

0.01F

0.001 B

10006.3V YK

C601

VIF Vcc

C639_1

W810

3

0.01 F

R624

Hi Vcc

46 SW REG CONT

47 LIMITER IN

48 IF AGC

49 QIF OUT

64 VIF IN (1)

1 VIF IN (2)

H VCO F/B

SCL

5

8

2K

INTELLIGENT MONI

FBP IN

6

10.64.8

5.5

Q603

5V REG

KTC3203_Y

CF603

SFSH4.5MCB

C656_1

TO/ SOUND

STEREO+5V

AUDIO_OUT

IF G.OUT

Y_VIDEO

AT+5V R.OUT

SYNC

TUNER+5V CLAMP

RESET

AFT

AGC

GND

HD

POWER

OSD_B

OSD_BLK

OSD_G

VD

OSD_R

I2C_OFF

SDA

SCL

5

C658_1 0.001 Y

R632

100 1/2W

W817

R612

R611

R618 10M

D602

D601

C606

0.2250V KA

R604

2.2K

L601

1.2uH

R634 10K

5.6K 1/4W

10K

C623_3 0.0033 Y

C632 2.250V KA

MTZJ8.2B

C605

4716V KA

C624_1

R609

1SS133

C621 0.01 F

C626_1

0.001 Y

R606

10K

SAW FILTER

CF601

SAFGP45M7VHCZR

OUTOUT G IN IN

12345

C604

150V KA

0.4750V KA

330

C659_2

470P B

C618

5V REG

Q601

KTC3203_Y

4.97 7.6

6

C635 4716V KA

R635 100

MCU RESET

5.7V REG OUT(FOR CPU)

CHROMA IC

IC601

M61206FP

H OUT

DEF

789

2.2K

R601

R626

10K

1K

R602

5.6

5V REG

Q604

2SD734

7.6

4.97

5.6

W801 W802

5v REG

Y SW OUT

34 EXT C in

33 8.7V REG OUT

32 X’TAL

17 V OUT

16 B OUT

SDA

9

C603 150V KA

R605

5V REG

Q605

KTC3203_Y

7.6

5.6

C640

27

R629

0003.45.54.83.98.22.32.9

VIDEO/CHROMA GND

AFC FILTER

INV FBP OUT

C607 0.01 F

5.6K

150V KA

C627

4.97

C625

4716V KA

7

TV/Y IN

VIDEO CHROMA Vcc

V RAMP FEEDBACK

R OUT

POWER ON CONT

11 12 13

W844

R614 2.2K

150V KA

R633

2.02.9

CHROMA APC FILTER

V PULSE OUT

FAST BLK

SPOT KILLER

fsc OUT

V RAMP CAP

STRAT UP Vcc

G OUT

R619 2.2K

R639

100

C622 0.015 M

8.2K

C616

X602

8.83.3

333435363738394404142434445464748

3.5

2.6

0

R IN

30 31 32

5.0

0

G IN

0

7.3

0

5.0

5.0

5.6

2.5

0

B IN

20 21 22 23 24 25 26 27 28 29

8.2

8.2

4.5

17 18 19

R627 100

R630 100

R631 100 1/4W

R625

2.2K 1/4W

(MAIN PCB)

15.08.2

8.8

Q606

KTC3203_Y

C647

15P CH

3.579545MHz

NC

NC

C612

R641

22K 1/4W

R648

100 1/4W

100010V YK

R638 8.2K

R646 27K

R642

6.8K

C645_2

4716V KA

10

D610

REG

150V KA

D605

11E1-EIC

C638_2

R645

10

3316V KA

C613

150V TF

MTZJ6.8B

(MFR’S VERSION B)

220

R647

C651_1

33P SL

C650_1

220P B

L608 6.8uH

D604

R653

560 1/2W

R650 1K

1SS133

4.9

D607

1SS133

D611

0

0

D609

1SS133

SWITCHING

DTC114ES

MTZJ9.1B

Q608

47K 1/4W

D608

R613

D606

MTZJ9.1B

MTZJ9.1B

TEST POINT

TKC-M06X-A1

VIDEO

INT.MONI

IIC_OFF

SDA

SCL

GND

CAUTION: DIGITAL TRANSISTOR

NOTE:THIS SCHEMATIC DIAGRAM IS THE LATEST AT THE TIME

OF PRINTING AND SUBJECT TO CHANGE WITHOUT NOTICE

THE DC VOLTAGE AT EACH PART WAS MEASURED

NOTE:

WITH THE DIGITAL TESTER WHEN THE COLOR BROADCAST

WAS RECEIVED IN GOOD CONDITION AND PICTURE IS NORMAL.

CRITICAL FOR SAFETY,USE ONES

DESCRIBED IN PARTS LIST ONLY

ARESINCE THESE PARTS MARKED BYCAUTION:

DANGEREUSES AN POINT DE VUE SECURITE

N’UTILISER QUE CELLS DECRITES

DANS LA NOMENCLATURE DES PIECES

ETANTLES PIECES REPAREES PAR UNATTENTION:

ABC D E F GH

FROM/TO DEFLECTION/CRT

FBT+8V

V_OUT

ABCL

V_FEEDBACK

GND

H_OUT

H_SYNC

B.OUT

CP601

6

5

4

3

2

1

PCB010

TMA501

R.SIGNAL

G.SIGNAL

B.SIGNAL

DEFLECTION SIGNAL

AUDIO SIGNAL

TUNER VIDEO SIGNAL

8

7

6

5

4

3

2

1

ABC D E F GH

FROM/TO CHROMA

8

V_FEEDBACK

7

6

5

FROM/TO MICON/TUNER

X-RAY_TEST

4

3

2

FROM POWER

1

CLAMP

G.OUT

B.OUT

R.OUT

V_OUT

ABCL

H_SYNC

H_OUT

FBT+8V

GND

R401

100K+-1%

X-RAY

C439

SL

22P500V

H.DRIVE

Q402

2SC2621

0.3

R440

3.3K 5W

+B

TP402

FBT+8V

+B

GND

NOTE:THIS SCHEMATIC DIAGRAM IS THE LATEST AT THE TIME

OF PRINTING AND SUBJECT TO CHANGE WITHOUT NOTICE

THE DC VOLTAGE AT EACH PART WAS MEASURED

NOTE:

WITH THE DIGITAL TESTER WHEN THE COLOR BROADCAST

WAS RECEIVED IN GOOD CONDITION AND PICTURE IS NORMAL.

C416

200V PP

0.027

L406

18uH

8.2

27.0

0

R428

C440

R446

1/2W

R405

D401

15

R404

B

0.0022500V

1/2W

4.7K

1K

22K+-1%

HZ27-1L

D402

HZ11B1L

IC401 LA78041V-OUT IC

PUMP

UP

+

AMP

-

1234567

14

HS401

763WAA0104

5013001

345

T401

C446

R406

R408

1160V YK

CH012102

10

27K +-1%

12

16

C404

GNDVCC

03.9 26.1 2.2 13 26

C414

10035V YK

C408_1

150PSL

R417

CD806B

X-RAY TEST SW.

16.0

9.6 16.1

H.OUTPUT

2SD2499(LBOEC1)

47016V YK

THE RESISTOR MARKED F IS FUSE RESISTOR.NOTE:

THE ALUMI ELECTROLYTIC CAPACITOR MARKED NP

IS NON POLAR ONE.

R424

12K +-1%

Q401

R427

100 1/4W

AU02A-EIC

D408

17

114.0

0

KRA104MAT

0

THERMAL

PROTECTION

R418

27K 1/4W

12K1/4W

Q403

R409

6.2K +-1%

D405

3.9

C437

0.56200V

C443_2

C401

MTZJ6.2B

100P500V B

R422

6.8K 1/2W

R445

100K

R419

C417

FHS

MPP

0.011.25KV

1/2W

C434

W897

W891

1.2K1/4W

4.750V

C444

DEFLECTION/CRT SCHEMATIC DIAGRAM

CP802A

NC

C433

47035V YK

D413

11E1-EIC

C435_2

0.1100V MHE

R421

220K 1/4W

ARESINCE THESE PARTS MARKED BYCAUTION:

B2013H02-10P

GND

CLAMP

G.OUT

B.OUT

R.OUT

NCNC

HEATER

GND

NC

180V

19

PCB010

TMA501

6.8K

KA

22100V YK

R420

0.0012KV YR

R432_1

1/4W

D411

AU02A-EIC

W843

D410

18

820 1/2W

C418

S801Y

AU02A-EIC

C448_1

10250V YK

R410

1000

25V

820 1/2W

YK

R407

W840

D403

11E1-EIC

C430_1

C427_1

2.2 1/2W

112.0

128.0

128.0

0

0

0

0

NC

0.3

MKT

0.022100V

R411

1K 1/2W

1050V KA

R438

R436

2.2 1/2W

R429

2W

2.7

FB401

3225010F

COL

1

VIDEO

6

B+

2

AFC

9

HEA

TER

10

GND

8

E12

4

E25

3

D407 AU02A-EIC

CRITICAL FOR SAFETY,USE ONES

DESCRIBED IN PARTS LIST ONLY

150 1/2W

(W106)

GND

ABL

GND

E8

R412

R433

HV

F

S

11

7

3.9K 1/4W

0

8

-27.0

5

2701/2W

VR401

EVNCYAA03BE3

2701/2W

R431

GND

CLAMP

G.OUT

B.OUT

R.OUT

HEATER

GND

180V

1

2

3

4

5

6

7

8

9

10

CD804

SM1198-002-1A

4

3

2

1

CP401_1

TS-80P-04-V1

S101

CD805

SM1098-009-1A

CD806A

CH012102

11

B

6

G

8

R

10

9

V801

A63ADT15*08

4

3

2

1

DANGEREUSES AN POINT DE VUE SECURITE

N’UTILISER QUE CELLS DECRITES

DANS LA NOMENCLATURE DES PIECES

(MAIN PCB)

10

1

2

175

FOCUS

SCREEN

CP806

005P-2100

CP802B

B2013H02-10P

1

2

3

4

5

6

7

8

9

CP805

A2361WV2-2P

1

2

1

PCB110

TCA358

ETANTLES PIECES REPAREES PAR UNATTENTION:

(MFR’S VERSION B)

GND

CLAMP

G.OUT

B.OUT

R.OUT

HEATER

GND

180V

C802

GND

CLAMP

G.OUT

B.OUT

R.OUT

NC

NC

HEATER

GND

NC

NC

180V

0.0012KV B

CAUTION: DIGITAL TRANSISTOR

TP022

W857

R803

3.2

RED OUT

Q801

2SC4217

2W

R802

12K

R

R809 4.7K

2.7

GREEN OUT

560P W

C811_1

390

R813

TP023

20

1/4W

2.7K

R807

R.SIGNAL

G.SIGNAL

B.SIGNAL

DEFLECTION SIGNAL

3.2

Q803

2SC4217

2W

12K

R814 4.7K

2.7

R806

GB

C810_2

22

101.6

2.7K 1/4W

99.6

95.498.4100.6

470P B

R816

TP024

R805

6.4

0

9

8

7

BLUE OUT

390

10

6

3.2

2.7

Q802

2SC4217

2W

12K

CVT3275-5102

96.4

11

5

J801

8

7

R811 4.7K

680P W

C809_1

R815

390

6

21

5

R804

2.7K 1/4W

4

3

F

0

1

2

1

ABC D E F GH

SPEC.NO.

O/R NO.

M3K0-04I

A173518

SERVICING NOTICES ON CHECKING

As for the places which need special attentions,

they are indicated with the labels or seals on the

cabinet, chassis and parts. Make sure to keep the

indications and notices in the operation manual.

2. AVOID AN ELECTRIC SHOCK

There is a high voltage part inside. Avoid an

electric shock while the electric current is

flowing.

3. USE THE DESIGNATED PARTS

The parts in this equipment have the specific

characters of incombustibility and withstand

voltage for safety. Therefore, the part which is

replaced should be used the part which has

the same character.

Especially as to the important parts for safety

which is indicated in the circuit diagram or the

table of parts as a mark, the designated

parts must be used.

PUT PARTS AND WIRES IN THE

4.

ORIGINAL POSITION AFTER

ASSEMBLING OR WIRING

There are parts which use the insulation

material such as a tube or tape for safety, or

which are assembled in the condition that

these do not contact with the printed board.

The inside wiring is designed not to get closer

to the pyrogenic parts and high voltage parts.

Therefore, put these parts in the original

positions.

5. TAKE CARE TO DEAL WITH THE

CATHODE-RAY TUBE

In the condition that an explosion-proof cathoderay tube is set in this equipment, safety is

secured against implosion. However, when

removing it or serving from backward, it is

dangerous to give a shock. Take enough care to

deal with it.

6. AVOID AN X-RAY1. KEEP THE NOTICES

Safety is secured against an X-ray by considering about the cathode-ray tube and the high

voltage peripheral circuit, etc.

Therefore, when repairing the high voltage peripheral circuit, use the designated parts and

make sure not modify the circuit.

Repairing except indicates causes rising of high

voltage, and it emits an X-ray from the cathoderay tube.

7.PERFORM A SAFETY CHECK AFTER

SERVICING

Confirm that the screws, parts and wiring which

were removed in order to service are put in the

original positions, or whether there are the

portions which are deteriorated around the

serviced places serviced or not. Check the

insulation between the antenna terminal or

external metal and the AC cord plug blades.

And be sure the safety of that.

(INSULATION CHECK PROCEDURE)

1.

Unplug the plug from the AC outlet.

2.

Remove the antenna terminal on TV and turn

on the TV.

3.

Insulation resistance between the cord plug

terminals and the eternal exposure metal

[Note 2] should be more than 1M ohm by

using the 500V insulation resistance meter

[Note 1].

4.

If the insulation resistance is less than 1M

ohm, the inspection repair should be

required.

[Note 1]

If you have not the 500V insulation

resistance meter, use a Tester.

[Note 2]

External exposure metal: Antenna terminal

HOW TO ORDER PARTS

Please include the following informations when you order parts. (Particularly the VERSION LETTER.)

1. MODEL NUMBER and VERSION LETTER

The MODEL NUMBER can be found on the back of each product and the VERSION LETTER can be

found at the end of the SERIAL NUMBER.

2. PART NO. and DESCRIPTION

You can find it in your SERVICE MANUAL.

IMPORTANT

Inferior silicon grease can damage IC's and transistors.

When replacing an IC's or transistors, use only specified silicon grease (YG6260M).

Remove all old silicon before applying new silicon.

A1-1

CONTENTS

SERVICING NOTICES ON CHECKING......................................................................................................

HOW TO ORDER PARTS ...........................................................................................................................

IMPORTANT................................................................................................................................................

CONTENTS .................................................................................................................................................

GENERAL SPECIFICATIONS ....................................................................................................................

DISASSEMBLY INSTRUCTIONS ...............................................................................................................

SERVICE MODE LIST.................................................................................................................................

CONFIRMATION OF USING HOURS.........................................................................................................

NOTE FOR THE REPLACING OF MEMORY IC ........................................................................................

ELECTRICAL ADJUSTMENTS ..................................................................................................................

MAJOR COMPONENTS LOCATION GUIDE .............................................................................................

BLOCK DIAGRAM ......................................................................................................................................

PRINTED CIRCUIT BOARDS

MAIN/CRT...........................................................................................................................................

SCHEMATIC DIAGRAMS

MICON/TUNER..................................................................................................................................

CHROMA ...........................................................................................................................................

DEFLECTION/CRT ............................................................................................................................

POWER .............................................................................................................................................

SOUND ..............................................................................................................................................

WAVEFORMS .............................................................................................................................................

MECHANICAL EXPLODED VIEW ..............................................................................................................

MECHANICAL REPLACEMENT PARTS LIST ..........................................................................................

ELECTRICAL REPLACEMENT PARTS LIST ............................................................................................

A1-1

A1-1

A1-1

A2-1

A3-1~A3-4

B-1, B-2

C-1

C-1

C-1

D1-1~D2-1

D3-1

E-1, E-2

F-1~F-4

G-1, G-2

G-3, G-4

G-5, G-6

G-7, G-8

G-9, G-10

H-1, H-2

I-1

J1-1

J2-1, J2-2

A2-1

GENERAL SPECIFICATIONS

G-1 TV CRT CRT Size / Visual Size 25 inch / 626mmV

G-2 Tuning Broadcasting System US System M

G-3 Power Power Source AC 120V AC 60Hz

G-4 Regulation Safety UL /CSA

G-5 Temperature Operation +5oC ~ +40oC

G-6 Operating Humidity Less then 80% RH

G-7 On Screen Menu Yes

System CRT Type Normal

Deflection 100 degree

Magnetic Field BV/BH +0.45G/0.18G

Color System NTSC

Speaker 2Speaker

Position Front

Size 1.5 x 2.7 Inch

Impedance 4 ohm

Sound Output MAX 0.75 + 0.75 W

10%(Typical) 0.5 + 0.5 W

NTSC3.58+4.43 /PAL60Hz No

System Tuner and System 1Tuner

Receive CH Destination Ohers

Tuning System F-Synth

Input Impedance VHF/UHF 75 ohm

CH Coverage A - I, J - W, W+1 - W+84

Intermediate Picture(FP) 45.75MHz

Frequency Sound(FS) 41.25MHz

FP-FS 4.50MHz

Preset CH

Stereo/Dual TV Sound

Tuner Sound Muting Yes

DC

Power Consumption at AC

110 W at AC 120 V 60 Hz

Stand by (at AC) 8 W at AC 120 V 60 Hz

Per Year -- kWh/Year

Protector Power Fuse Yes

Radiation FCC /DOC

X-Radiation DHHS/HWC

Storage -20oC ~ +60oC

Display Menu Type Character

Picture Yes

Contrast Yes

Brightness Yes

Color Yes

Tint Yes

Sharpness Yes

Audio No

Bass No

Treble No

Balance No

BBE On/Off No

Stable Sound On/Off No

CH Set Up Yes

TV/CATV Yes

CH Program Yes

Add/Erase Yes

Language Yes

V-chip Yes

CH Label No

Favorite CH No

Color Stream DVD/DTV No

Control Level Yes

Volume Yes

Brightness Yes

Contrast Yes

Color Yes

Tint (NTSC Only) Yes

Sharpness Yes

Tuning No

Bass No

Treble No

Balance No

Back Light No

Stereo,Audio Output,SAP No

Video No

Color Stream No

Channel(TV/Cable) Yes

CH Label No

Sleep Timer Yes

Sound Mute Yes

V-chip Rating Yes

2 - 69, 4A, A-5 - A-1,

No

No

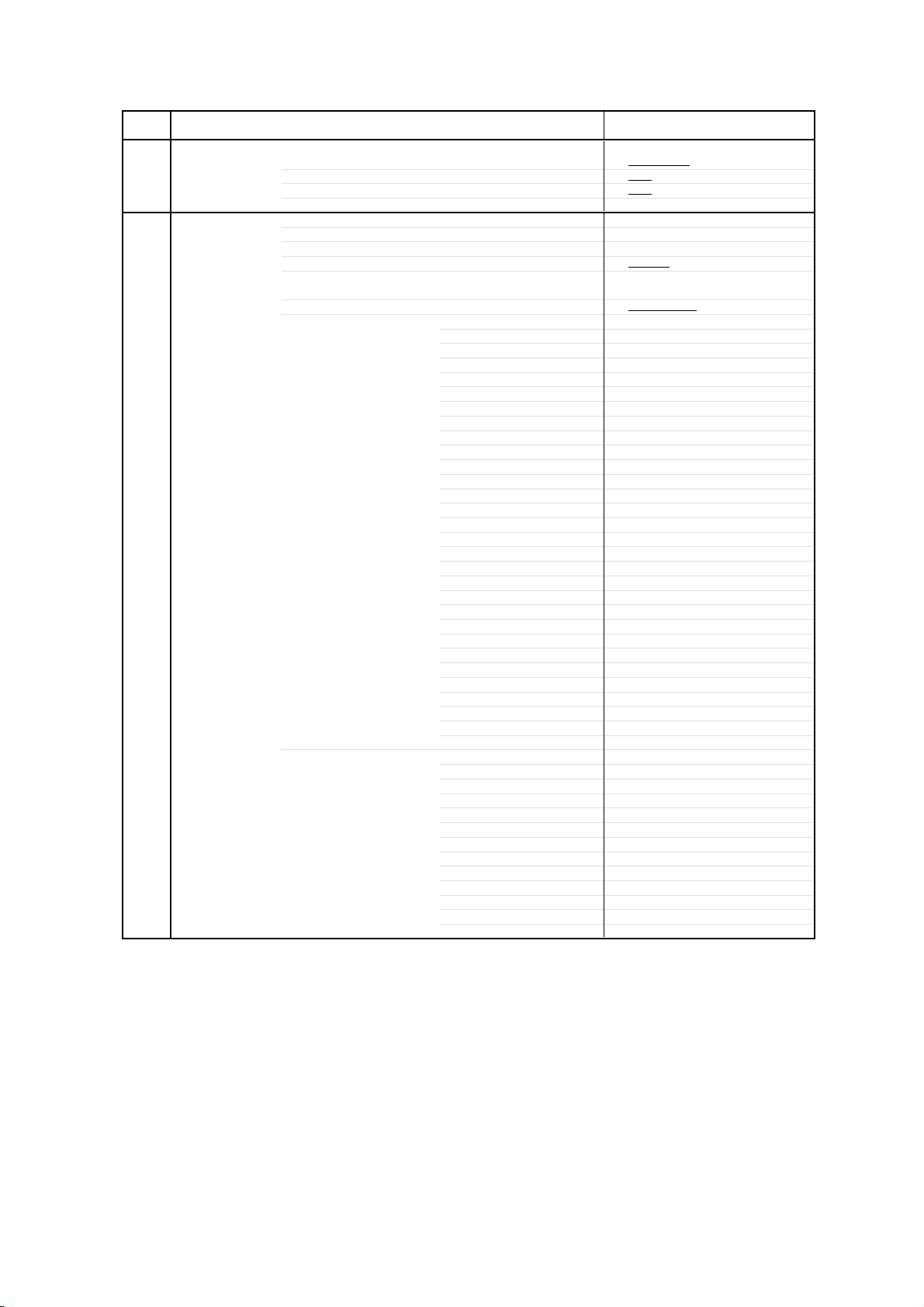

A3-1

GENERAL SPECIFICATIONS

G-8 OSD Language English French Spanish

G-9 Clock and Sleep Timer Max Time 120 Min

Timer Step 10 Min

On/Off Timer Program(On Tim / Off Tim) No

Wake Up Timer No

Timer Back-up (at Power Off Mode) more than -- Min Sec

G-10 Remote Unit RC-DW

Control Glow in Dark Remocon No

Format NEC

Custom Code 86-05 h

Power Source Voltage(D.C) 3V

Total Keys 26 Keys

Keys Power Yes

Multi Brand Keys CH Up(VCR) No

OSD Language Setting English

UM size x pcs UM-4 x 2 pcs

1 Yes

2 Yes

3 Yes

4 Yes

5 Yes

6 Yes

7 Yes

8 Yes

9 Yes

0 Yes

100 No

CH Up Yes

CH Down Yes

Volume Up Yes

Volume Down Yes

TV/Caption/Text Yes

CH1/CH2 Yes

TV/Video(TV/AV) No

CH RTN/CH ENT(Quick View) Yes

Sleep Yes

RE Call(Call) Yes

Reset Yes

Menu Yes

Enter Yes

Mute Yes

Exit No

MTS(Audio Select) No

Set + Yes

Set - Yes

CH Down(VCR) No

Pause/Still No

TV/VCR(VCR) No

Code No

FF No

Rew No

Rec No

Play No

Stop No

TV No

VCR No

Cable No

A3-2

Loading...

Loading...