Page 1

,943

TMA

Thermomechanical Analyzer

-------------------------

Operator's Manual

~

REG. U.S. PATs.TM. OfF.

Page 2

Thermal Analyzers

Instrument Systems

Operator's Manual

943

Thermomechanical

Analyzer

Du Pont Company

Instrument Systems

Concord Plaza - Quillen Building

Wilmington, OE 19898

PN 943145-000, Rev. F

Issued April 1985

Page 3

INTRODOCTION

Page 4

HEATER

4/79B

943/1

Introduction

Introducing the 943 TMA

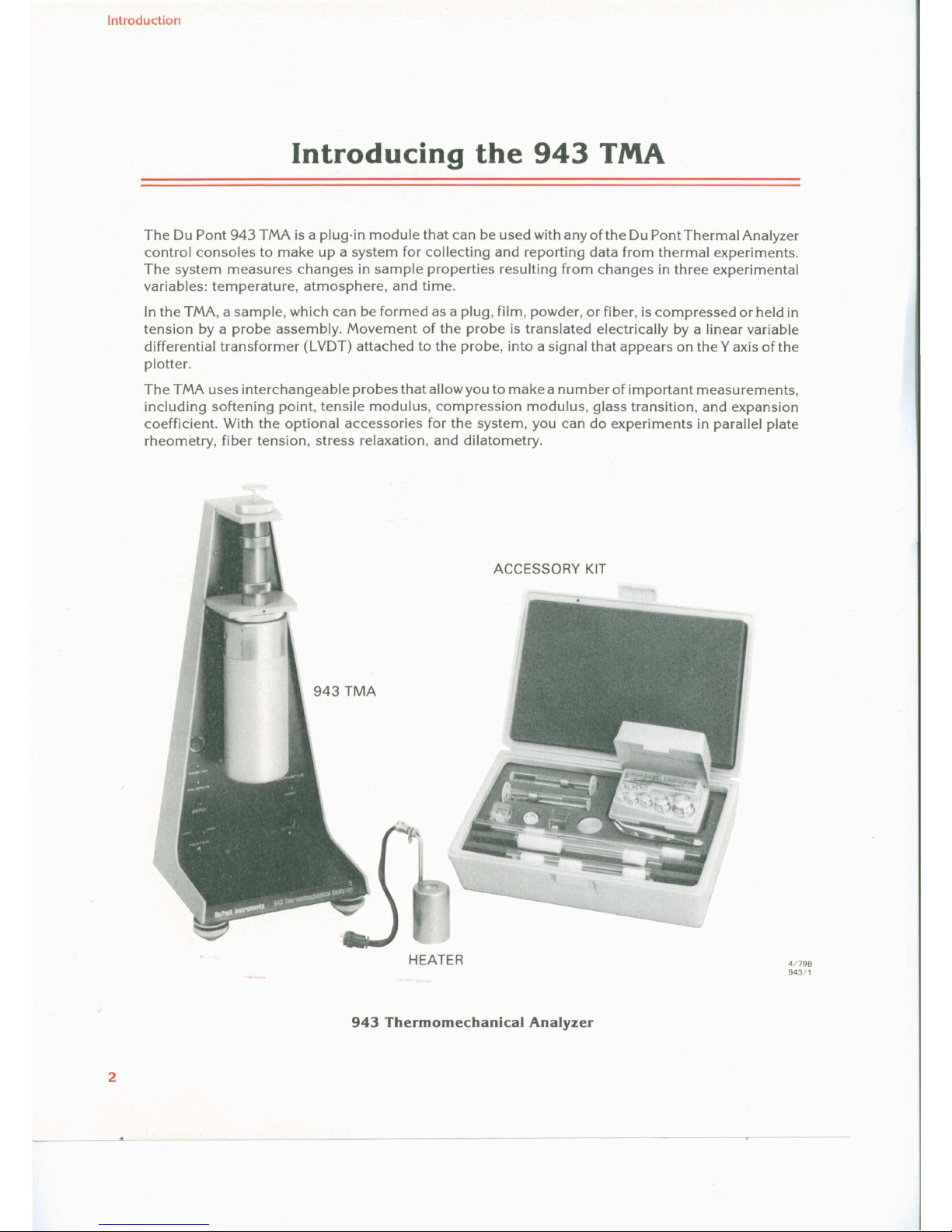

The Du Pont 943 TMA isa pluq-in module that can be used with any of the Du Pont Thermal Analyzer

contra I consoles to make up a system for collecting and reporting data from thermal experiments.

The system measures changes in sampie properties resulting from changes in three experimental

variables: temperature, atmosphere, and time.

In the TMA, a sampie, which can be formed as a plug, film, powder, or fiber, iscompressed or held in

tension by a probe assembly. Movement of the probe is translated electrically by a linear variable

differential transformer (LYDT) attached to the probe, into asignal that appears on the Y axis of the

plotter.

The TMA uses interchangeable probes that allow you to make anumber of important measurements,

including softening point, tensile modulus, compression modulus, glass transition, and expansion

coefficient. With the optional accessories for the system, you can do experiments in parallel plate

rheornetry, fiber tension, stress relaxation, and dilatometry.

ACCESSORY KIT

943 Thermomechanical Analyzer

2

Page 5

3

Introduction

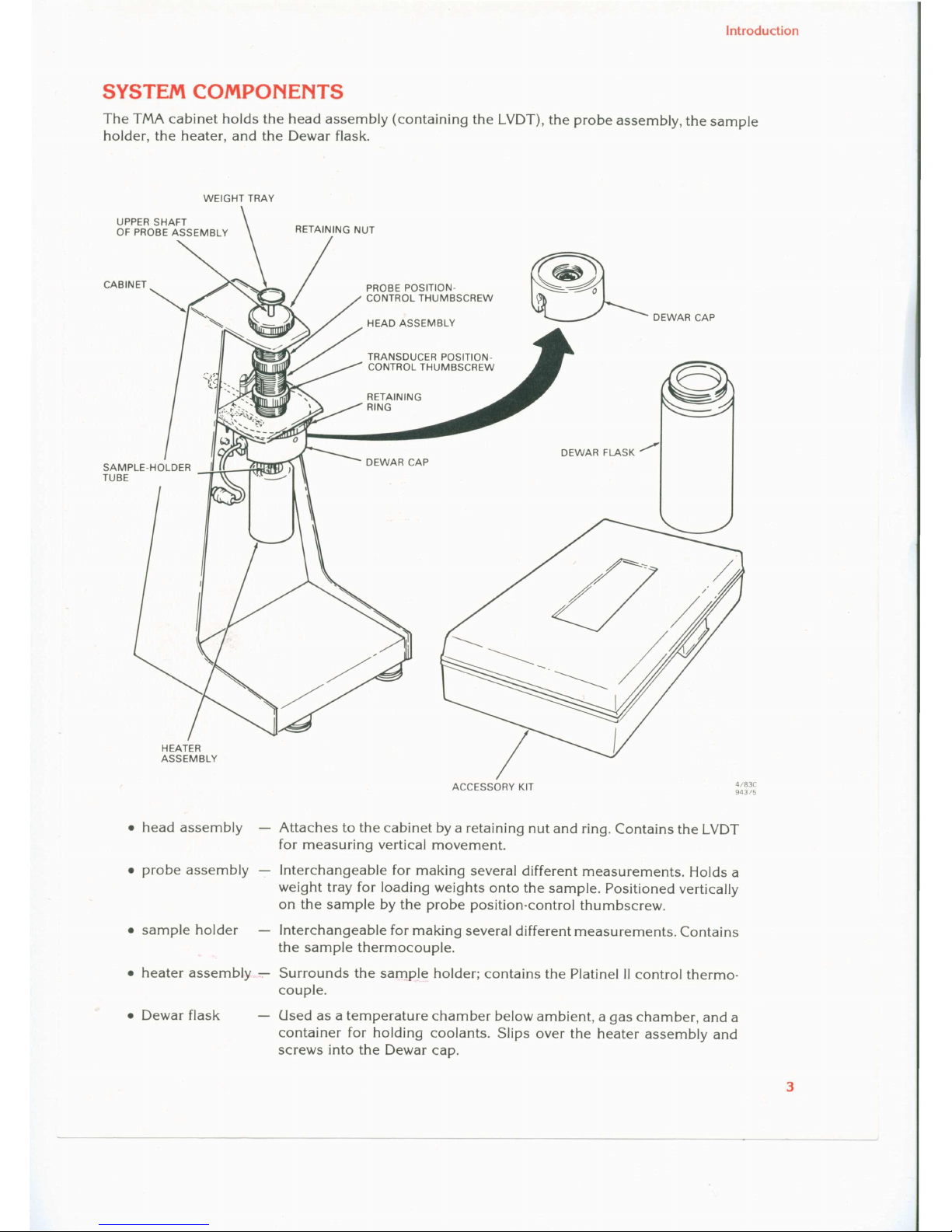

SYSTEM COMPONENTS

The TMA cabinet holds the head assembly (containing the LVDT), the probe assembly, the sampIe

holder, the heater, and the Dewar flask.

WEIGHT TRAY

UPPER SHAFT

OF PROBE ASSEMBLY

PROBE POSITION-

CONTROL THUMBSCREW

HEAD ASSEMBLY

DEWAR CAP

TRANSDUCER POSITION-

CONTROL THUMBSCREW

DEWAR FLASK ./""

HEATER

ASSEMBLY

ACCESSORY KIT

4/83C

943/5

• head assembly Attaches to the cabinet by a retaining nut and ring. Contains the LVDT

for measuring vertical movement.

• probe assembly - lnterchangeable for making several different measurements. Holds a

weight tray for loading weights onto the sampIe. Positioned vertically

on the sampIe by the probe position-control thumbscrew.

• sampIe holder lnterchangeable for making several different measurements. Contains

the sam pIe thermocouple.

• heater assembly :-:- Surrounds the sarnple holder; contains the Platinel 11control thermo-

coupIe.

• Dewar flask

Used as a temperature chamber below ambient, agas chamber, and a

container for holding coolants. Slips over the heater assembly and

screws into the Dewar cap.

Page 6

Introduction

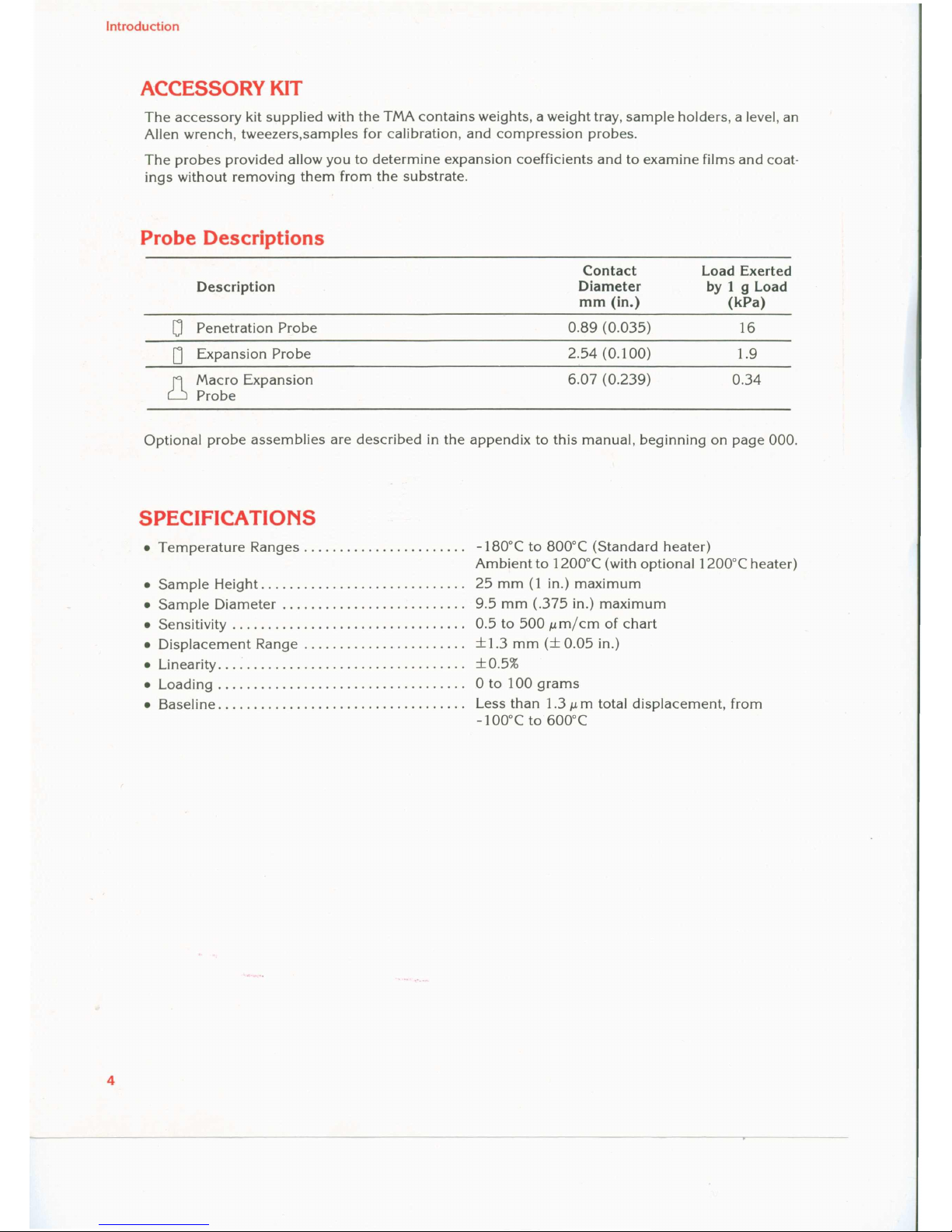

ACCESSORY KIT

The accessory kit supplied with the TMA contains weights, a weight tray, sam pie holders, a level, an

Allen wrench, tweezers,samples for calibration, and compression probes.

The probes provided allow you to determine expansion coefficients and to examine films and coat-

ings without removing them from the substrate.

Probe Descriptions

Contact

Load Exerted

Description

Diameter

by

1 9 Load

mm

(ln.)

(kPa)

0

Penetration Probe

0.89 (0.035)

16

D

Expansion Probe

2.54 (0.100)

1.9

l1

Macro Expansion

6.07 (0.239)

0.34

Probe

Optional probe assemblies are described in the appendix to this manual, beginning on page

000.

SPECIFICATIONS

• Temperature Ranges

-180

o

e to

800

0

e (Standard heater)

Ambient to

1200

0

e (with

optionallZüü'C heater)

• Sampie Height. . . . . . . . . . . . . . . . . . . . . . . . . . . ..

25

mm(1in.) maximum

• Sampie Diameter. . . . . . . . . . . . . . . . . . . . . . . . ..

9.5

mm

(.375

in.) maximum

• Sensitivity

0.5to500

Mm/cm of chart

• Displacement Range

±1.3

mm

(± 0.05

in.)

• Linearity ... :...............................

± 0.5%

• Loading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..0to

100

grams

• Baseline................................... Less than

1.3

Mm total displacement, from

-100

o

e to

600

0

e

4

Page 7

INSTALLATION

Page 8

CAUTION -----------------,

Installation

Installing the 943 System

When you receive the 943 TMA, inspect the instrument and shipping container for signs of shipping

damage, and check the parts received against the shipping list. If the instrument isdamaged, notify

the carrier and Du Pont Instruments immediately. If the instrument is intact but parts are missing,

notify Du Pont Instruments. You will find a list of Du Pont offices on the back cover of this manual.

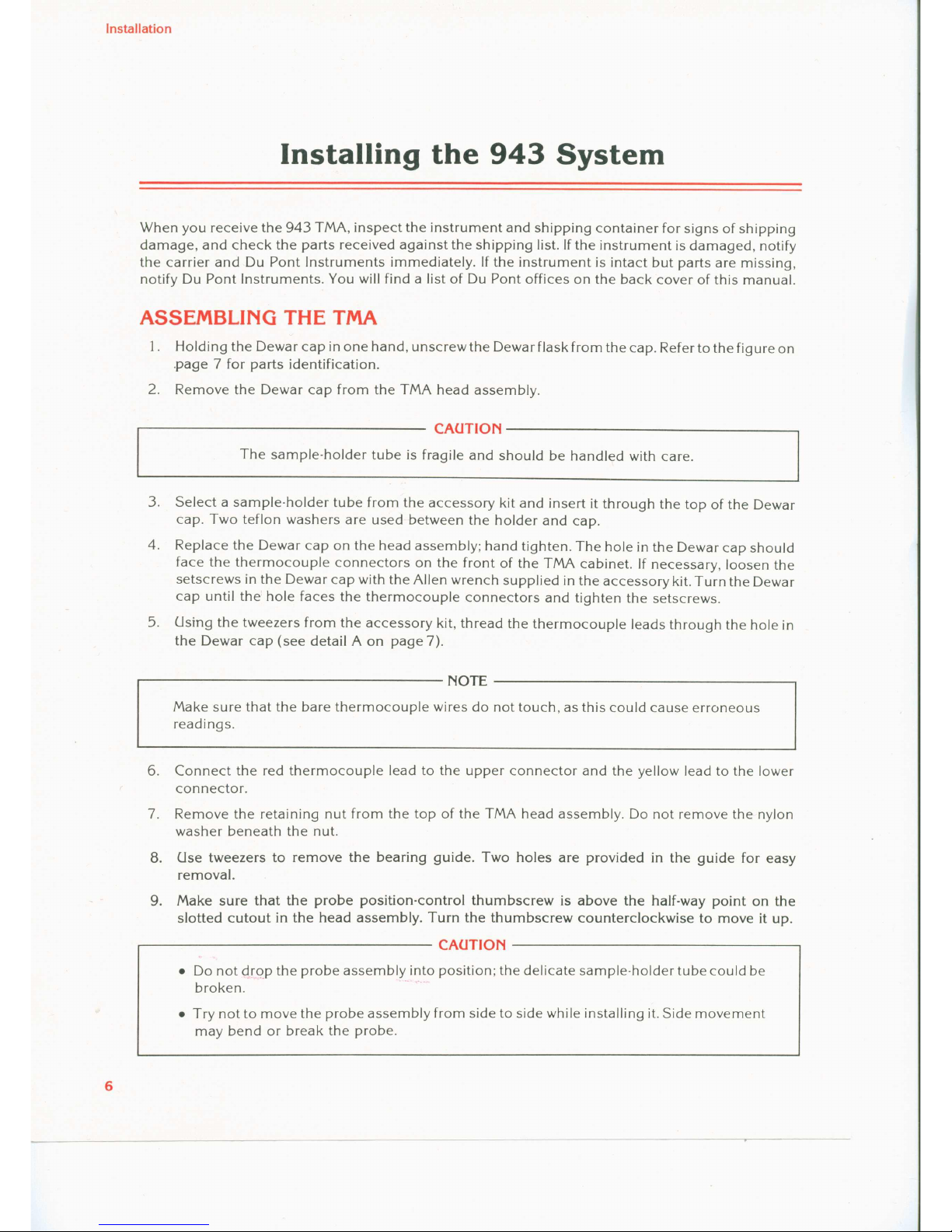

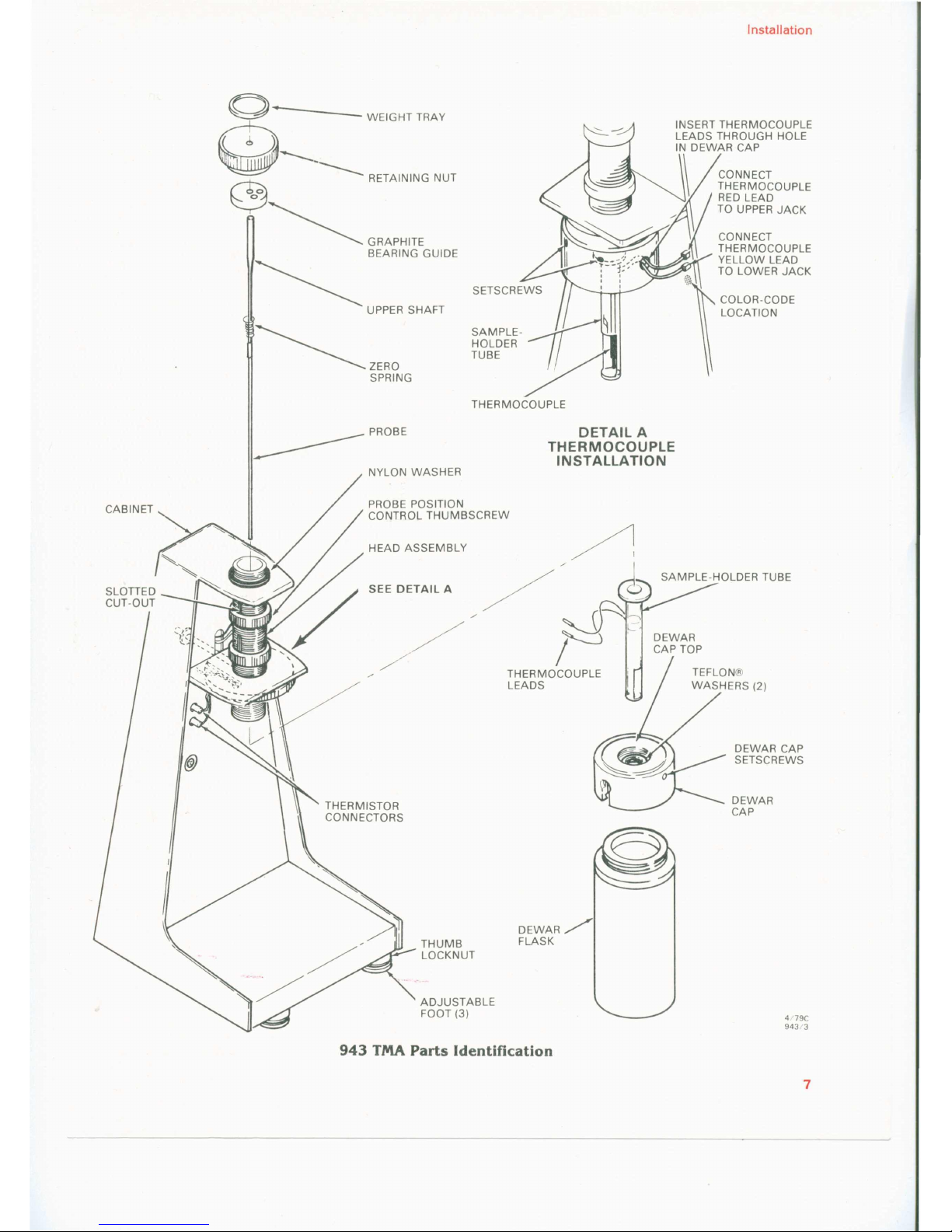

ASSEMBLING THE TMA

1. Holding the Dewar cap in one hand, unscrew the Dewarf1askfrom the cap. Referto the figure on

.page 7 for parts identification.

2. Remove the Dewar cap from the TMA head assembly.

The sarnple-holder tube is fragile and should be handled with care.

3. Select a sarnple-holder tube from the accessory kit and insert it through the top of the Dewar

cap. Two teflon washers are used between the holder and cap.

4. Replace the Dewar cap on the head assembly; hand tighten. The hole in the Dewar cap should

face the thermocouple connectors on the front of the TMA cabinet. If necessary, loosen the

setscrews in the Dewar cap with the Allen wrench supplied in the accessory kit. Turn the Dewar

cap until the' hole faces the thermocouple connectors and tighten the setscrews.

5. Using the tweezers from the accessory kit, thread the thermocouple leads through the hole in

the Dewar cap (see detail A on page7).

...----------------- NOTE ----------------,

Make sure that the bare thermocouple wires do not touch, asthis could cause erroneous

readings.

6. Connect the red thermocouple lead to the upper connector and the yellow lead to the lower

connector.

7. Remove the retaining nut from the top of the TMA head assembly. Do not remove the nylon

washer beneath the nut.

8. Use tweezers to remove the bearing guide. Two holes are provided in the guide for easy

removal.

9. Make sure that the probe position-control thumbscrew is above the half-way point on the

slotted cutout in the head assembly. Turn the thumbscrew counterclockwise to move it up.

~--------------- CAUTION ----------------,

• Do not drop the probe assembly into position; the delicate sarnple-holder tube could be

broken. .....-

• Try not to move the probe assembly from sideto side while installing it. Side movement

may bend or break the probe.

6

Page 9

o

WEIGHTTRAY

~...__________ RETAINING NUT

~

~ GRAPHITE

~ BEARING GUIDE

~ UPPER SHAFT

~ZERO

SPRING

Installation

~~~~;J~~~tJ1gS~~~~E

IN DEWAR CAP

~

CONNECT

THERMOCOUPLE

t

RED LEAD

TO UPPER JACK

.-<

CONNECT

THERMOCOUPLE

YELLOW LEAD

TO LOWER JACK

COLOR-CODE

LOCATION

SAMPLE-

HOLDER

TUBE

THERMOCOUPLE

DETAIL A

THERMOCOUPLE

INSTALLATION

PROBE

------- NYLON WASHER

PROBE POTSHIT0~NBSCREW

CONTROL

HEAD ASSEMBLY

THUMB

LOCKNUT

ADJUSTABLE

FOOT (3)

SAMPLE-HOLDER TUBE

DEWAR

CAP TOP

TEFLON®

WASHERS (2)

DEWAR CAP

SETSCREWS

DEWAR

CAP

DEWAR/

FLASK

4179C

943/3

943 TMA Parts Identification

7

Page 10

Installation

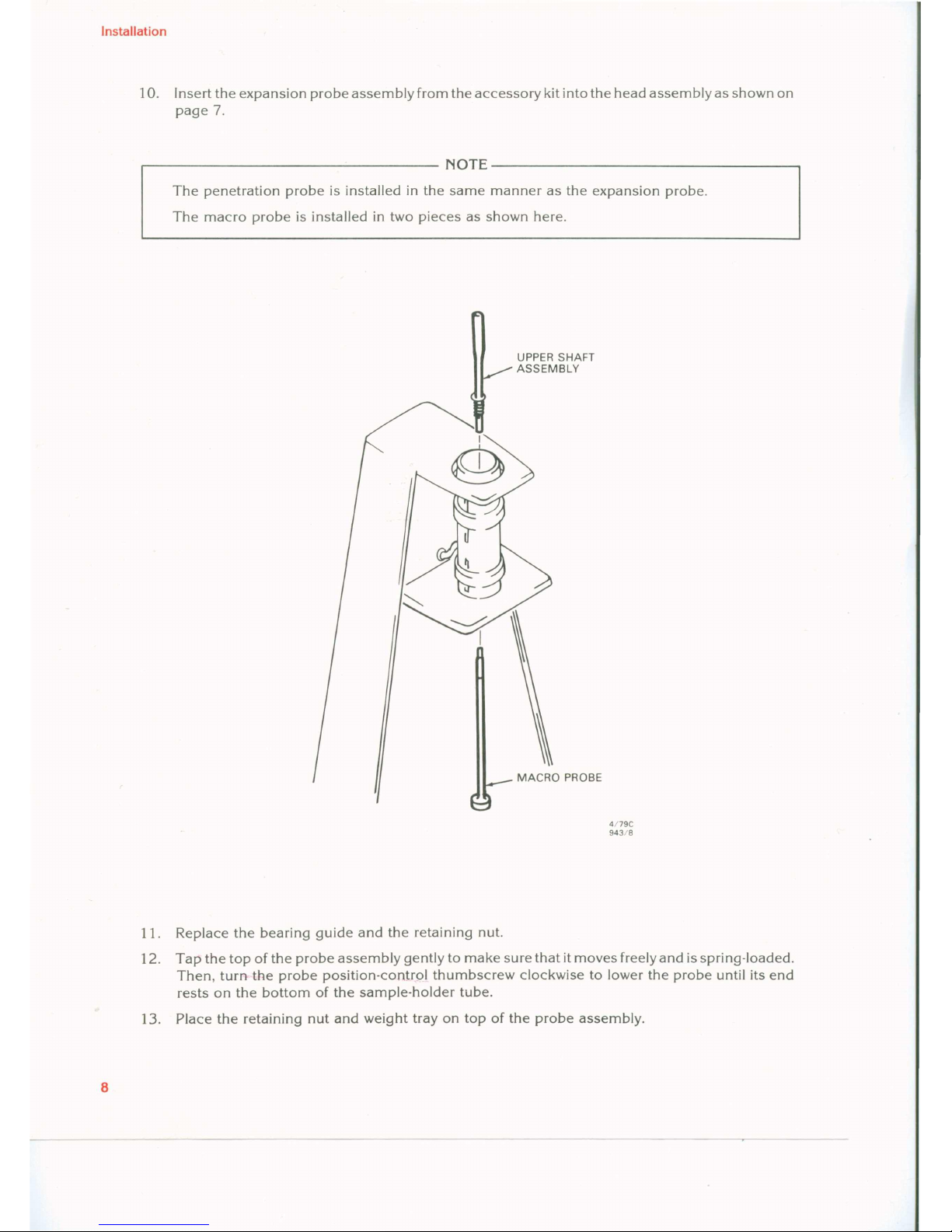

The penetration probe is installed in the same manner as the expansion probe.

The macro probe is installed in two pieces as shown here.

10. Insert the expansion probe assembly from the accessory kit into the head assembly as shown on

page 7.

r------------------------------NOTE-------------------------------.

UPPER SHAFT

ASSEMBLY

MACRO PROBE

4179C

943/8

11. Replace the bearing guide and the retaining nut.

12. Tap the top of the probe assembly gently to make sure that itmoves freely and is spring-loaded.

Then, turn the probe position-control thumbscrew clockwise to lower the probe until its end

rests on the bottom of the sam pie-holder tube.

13. Place the retaining nut and weight tray on top of the probe assembly.

8

Page 11

9

Installation

14. Place the TMA next to the programmer. The instrument should be on a vibration-free bench or

marble benchtop. Observe the following precautions:

• Do not locate the TMA near air conditioning or heating vents.

• Avoid locations where there are high levels of corrosive gases (such as sulfur dioxide or

hydrogen chloride), or where ventilation is poor.

• Avoid dusty locations and places where vibrations occur.

15. Place the level from the accessory kit on top of the weight tray. Level the TMA by adjusting the

three leveling feet on the base of the cabinet. To adjust the feet, loosen the thumb locknut for

all three feet and screw the feet into or out of the cabinet. When the instrument is level, tighten

the thumb locknuts and remove the level from the weight tray.

16. Raise the probe approximately 2 cm (1 in.) from the bottom of the sarnple-holder tube by turn-

ing the probe position-control thumbscrew counterclockwise.

17. Remove the weight tray, retaining nut, and bearing guide from the TMA.

18. Check probe alignment by looking down into the head assembly and observing the gap be-

tween the lower bearing and the probe. Ifthe probe appears to be touching the side of the head

assembly, rotate it until the gap is uniform around the probe.

19. Reinstall the bearing guide, retaining nut, and weight tray. Lower the probe until it rests on the

bottom of the sam pie-holder tube .

.------------------ CA(JTION -----------------,

Do not load the weight tray unless the probe is touching either the sample-holder tube

bottom or a sampIe.

20. Check the thermocouple connections for tightness.

HOOK-OP

To connect the 943 TMA to the programmer:

1. Make sure that the programmer power is off, and that the programmer power cord is unplugged

from the wall outlet. The 943 connector (marked ACCESSORY) is located on the back of the

unit. The cable and connector are keyed so that they can only be connected one way.

2. Connect the accessory cable from the programmer to the TMA.

3. Connect the programmer power cord to the wall outlet.

4. If you wish to use inert or reactive gases for testing, attach the external gas supply tube to

the TMA gas purge connection on the back of the instrument. The TMA is now ready for cali-

bration. Calibration procedures appear in part 3 of the manual.

Page 12

OPERATION

Page 13

Operation

Performing Routine Experiments

This section contains routine operating procedures for the 943 TMA. The section is divided into the

following parts:

• 943 Controls

• Heater Installation

• Dewar Flask Installation

• Applications Notes

• Calibration Procedures

• Routine Operating Sequence

• Subambient Operation

Specific instructions for operating the TMA with each of the optional accessories appear in the

appendix of the rnanual, beginning on page 000.

Before operating the TMA, you should have the unit instalIed and connected to a TA programmer.

943 CONTROLS

Controls for the 943 TMA are located on the front and rear panels of the cabinet. They are described

in the tables that follow.

12

Page 14

Operation

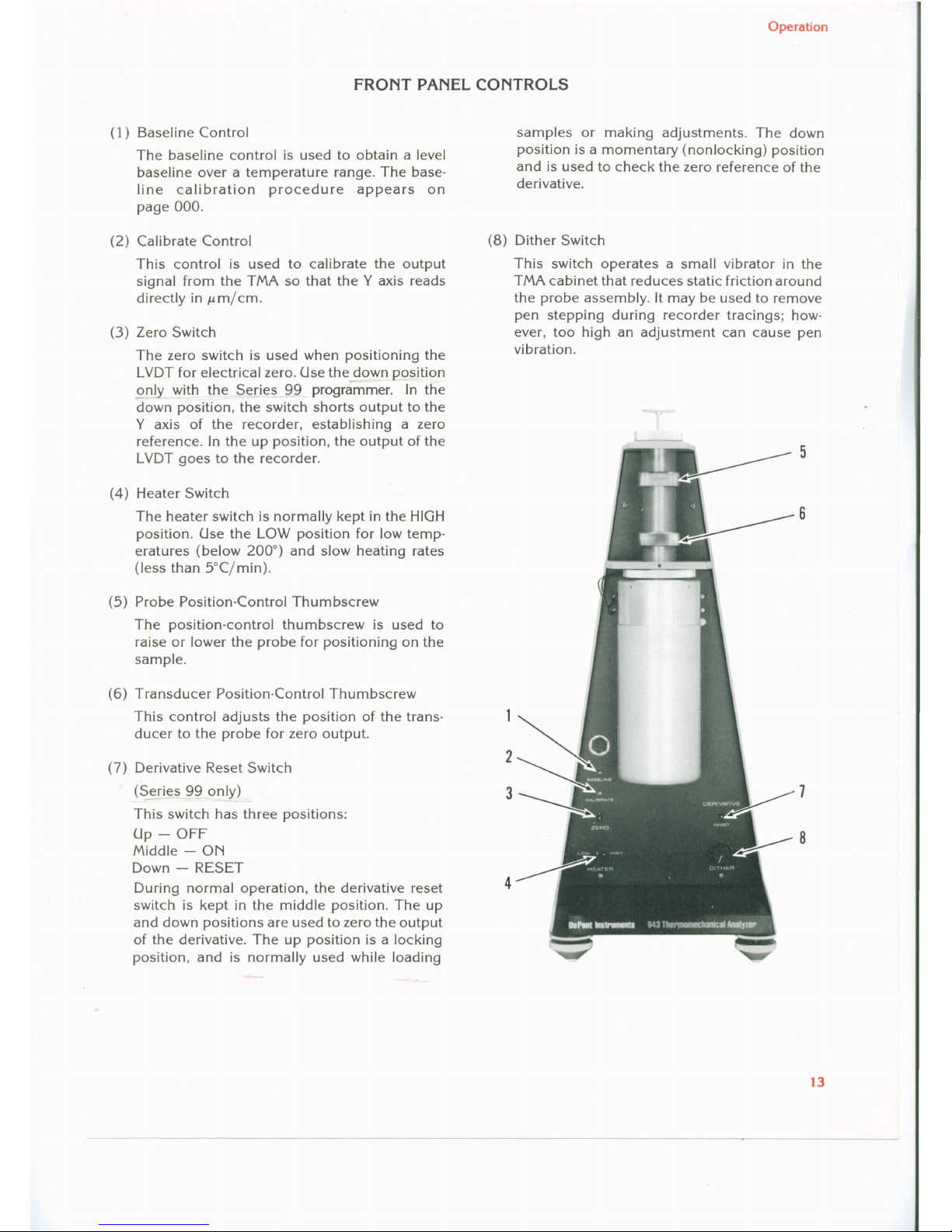

FRONT PANEL CONTROLS

(1) Baseline Control

The baseline control is used to obtain a level

baseline over a temperature range. The

base-

line calibration procedure appears on

page 000.

(2) Calibrate Control

This control is used to calibrate the output

signal from the TMA so that theYaxis reads

directly in

J.Lmjcm.

(3)

Zero Switch

The zero switch is used when positioning the

LVDT for electrical zero. Usethe down position

only with the Series

99

pragrcilTI"mer.In the

down position, the switch shorts output to the

Y

axis of the recorder, establishing a zero

reference. In the up position, the output of the

LVDT goes to the recorder.

(4)

Heater Switch

The heater switch is normally kept in the HIGH

position. Use the LOW position for low

ternp-

eratures (below 200°) and slow heating rates

(Iess than 5°Cjmin).

(5) Probe

Position-Control

Thumbscrew

The position-control thumbscrew is used to

raise or lower the probe for positioning on the

sampie.

(6) Transducer Position-Control Thumbscrew

This contral adjusts the position of the

trans-

ducer to the probe for zero output.

(7)

Derivative Reset Switch

(S~ries

99

only)

This switch has three positions:

Up - OFF

Middle - ON

Down - RESET

During normal operation, the derivative reset

4

switch is kept in the middle position. The up

and down positions are used to zero the output

of the derivative. The up position is a locking

position, and is normally used while loading

sampies or making adjustments. The down

position is a momentary (nonlocking) position

and is used to check the zero reference of the

derivative.

(8)

Dither Switch

This switch operates a small vibrator in the

TMA cabinet that reduces static friction around

the probe assembly. It may be used to remove

pen stepping during recorder tracings;

how-

ever, too high an adjustment can cause pen

vibration.

2

8

5

6

3

7

13

Page 15

(15) Derivative Ramp Zero

This control isusedto zerothe derivative output

to the recorder zero.

1/S1C

943/4

Operation

REAR PANEL CONTROLS

(14) Cal-Norrnal Switch

The normal position is used for routine oper-

ation. The cal position is used during calibra-

tion.

13

(9) Control Reference Junction

The control reference junction is used to cali-

brate the control thermocouple.

(10) Sampie Reference Junction

The sampie reference junction is used to cali-

brate the sampie thermocouple.

(11) Derivative Zero

This screwdriver adjustment zeroesthe Y axis

during calibration.

(12) Derivative Gain

The derivative gain control is a screwdriver

adjustment that is used to calibrate derivative

gain as a tirne-base function.

(13) Ramp Out Jacks

These jacks are used to connect the TMA to a

recorder or oscilloscope.

11

12

14

Page 16

15

Operation

HEATER INSTALLATION

1. Slip the heater over the sampIe holder. Insert the heater support arm all the way into the slot in

the Dewar cap.

HEATER

SUPPORT

ARM THUMB

LOCK NUT

HEATER

ASSEMBLY

TEMP. HEATER

SOCKET

I

-.."

4179A

943/26

2. Make sure that the heater does not touch the sampIe holder. If it does, adjust the heater as

folIows:

a. Vertical Adjustment

CAOTION --------------~

When performing this adjustment, hold the support arm rigid to prevent the arm from

breaking at the weId joint.

To adjust the support arm, hold the vertical part of the arm rigid and gently bend the hori-

zontal part. Bending downward will rota te the heater's vertical axis clockwise; bending

upward will rotate the heater's vertical axis counterclockwise.

Page 17

Check heater alignment whenever the sarnple-holder tube is replaced.

Operation

I

VERTICAL AXIS

5/838

943/28

b. Horizontal Adjustment

To adjust the support arm horizontally, loosen the adjustment tab locknut and screw the tab

in or out as needed. Tighten the locknut .

.----------------- NOTE ---------------,

3. Attach the heater to the Dewar cap by tightening the support arm locknut.

4. Insert the heater plug into the TMA heater socket.

16

Page 18

17

Operation

DEWAR FLASK INSTALLATION

.----------------- CAOTION -----------------,

The Dewar flask seals will melt at temperatures above 500°C.

To install the Dewar flask, tilt the flask and slip it over the heater. Then, while holding the Dewar cap in

one hand, screw the flask into the cap.

DEWAR CAP

Page 19

Operation

18

APPLICATION NOTES

The following are some notes and precautions related to applications of the 943 systems.

r----------------

WARNING

Wear protective gloves when handling the heater. The outside surface of the heater be-

comes hot during operation.

CAGTION -----------------------~

• The Dewar flask seals will melt at temperatures above 500°C.

• Do not leave the heater switch on low when heating to a final temperature above 200°C,

or at a rate faster than 5°C/min.

r-----------------NOTES ----------------,

• Between -40°C and O°C,false penetration may occur due to ice.

• To remove water from the system, thoroughly rinse the probe and sample-holder tube

with acetone and allow drying time for evaporation.

• When adjusting the thumbscrews for the TMAprobe position control and the transducer

position control, maintain approximately the same distance between them. Otherwise, a

false zero setting of theY'-axis pen may occur, or full downward travel of the probe may

be hampered.

Check the zero setting, by moving the transducer above and below the zero point, to see

if the output moves equally above and below the set point.

• Make the final adjustment of the probe assembly at a temperature below that of the low-

est transition expected in the material under investigation.

• SampIes for penetration and expansion should be as thin as possible to minimize tern-

perature gradients in the sampIe. A height of 2.5 to 5 mm (100 to 200 mils) is normal

for making expansion measurements on sam pIes having expansion coefficients in

the order of 100

J.!

m/m°C.

• Film sam pIes should be as flat as possible to prevent false penetrations due to buckling

or relaxation.

• Powdered siliea can be used both above and belowthe sampIe to level the sampIe and to

prevent lateral movement of both probe and sampIe. Powdered or finely divided silica

can be purchased from most chemical supply houses.

• SampIes can be heated and formed into cylinders and then cooled; however, doing so

may change important thermal history.

• A heating rate of 5°C/min is best for polymerie and elastometric materials.

• When searching for softening temperatures, studies of loading versus penetration are

helpful to eliminate false values of Tg.

• Temperature programs should be started weil below the temperatures of any known

transitions, since straight-line extrapolations are normally used to define transition

temperatures.

Page 20

19

Operation

CALIBRATION PROCEDORES

The 943 system must be calibrated at installation and periodically thereafter. The calibrations de-

scribed in this section include:

• Baseline Calibration

• Temperature Calibration

• Y'·Axis Static Calibration

• Y·Axis Derivative Calibration

• Y·Axis Dynamic Calibration

Baseline Calibration

The baseline should be checked as part of the initial set-up procedure and adjusted if necessary.

Afterward, it should only need adjustment after servicing.

To adjust the baseline:

I.

Prepare the TMA with a sampIe holder, probe and weight tray.

2. Adjust the probe position control so that the probe just rests on the sample-holder platforrn.

3. Place a 5 9 weight on the weight

tray,

4. Attach the heater to the TMA.

5. Set the Y(Y'}·AxisRANGE to its maximum sensitivity and adjust the Y(Y'}·AxisZERO SHIFT so

that the pen is in the center of the chart paper. Dir

r-

I

{Jwv

6. Heat at 5°Cjmin from ambient to desired upper

limit,

7.Ifthe baseline deviates from the horizontal more than 2.5 cm, adjust the BASELINE control on

the front of the TMA to bring the pen back toward the center of the

chart,

8. Repeat steps 6 and 7 until the desired baseline is achieved.

Temperature Calibration

The temperature calibration procedure is used to adjust the temperature readings of the recorder

and programmer to standard with a known melting point.

SAMPLE THERMOCOUPLE

To calibrate the sampIe thermocouple:

I.

Prepare the TMA with a sampIe holder, probe, and weight

tray,

2. Place an indium sam pIe on the sample-holder platforrn.

3. Adjust the probe position control so that the probe just touches the sarnple.

4. Place a 5 9 weight on the weight tray.

5. Attach the heater to the TMA.

6. Zero the electrical signal from the TMA, as described in the Y'·Axis static calibration on page 20.

7. Heat the indium sampIe from ambient to 170°C. Record the

scan,

8. Note the difference in inflection point from the standard (156.6). For example, 158.0°C -

156.6°C = 1.4°C_If the inflection point is not 156.6°C, proceed to Step 9.

Page 21

Operation

9. Set the system to hold isothermally at 150°C. Allow the system to equilibrate, then adjust the

SAMPLE reference junction on the back of the TMA by the difference between the actual inflec-

tion point and the standard. For example, if the inflection point recorded is 158.0°C, adjust the

SAMPLE reference junction back I.4°C. On the 1090, you can watch the adjustment on the

plasma display; on the Series 99, you will use the recorder.

When the sampie thermocouple has been corrected, leave the system set to hold isothermally

at 150°C and proceed to the Control Thermocouple Calibration Procedure.

CONTROL THERMOCO(JPLE

To set the control thermocouple:

Turn the CONTROL reference junction on the back of the TMA until the programmer indicates

150°C.

Y'

-Axis

Statle Calibration

1090 PROGRAMMER

The 1090 programmer allows direct read-out of electrical zero from the 1090 display using the

DISPLAY AXIS key. To set static calibration using the 1090:

1. Prepare the TMA with a sample-holder tube, expansion probe, and weight tray.

2. Turn the programmer on and set it to standby.

3. Adjust the TMAprobe position control so that the probe just rests on the empty sample-holder

platform.

4. Place a 5 9 weight from the accessory kit on top of the weight tray.

5. Set the DISPLAYAXIS to read signal 3 on the last line of the display. Adjust the TMAtransducer

position control until signal 3 reads zero. When you get elose to zero, you can use SIGNAL

ZERO to bring the 1090 reading to zero ..

6. Remove the 5 9 weight from the weight tray.

7. Raise the probe with the probe position control. Place the 380/-,m (15 mil) calibration shim from

the accessory kit on the sample-holder tube platform. Then, lower the probe gently until it rests

on the shim.

8. Replace the 5 9 weight on the TMA weight tray.

9. Adjust the TMA CALIBRATE control so that the displayaxis reading is equivalent to the shim

thickness.

10. Remove the weight and shim. The system is now statically calibrated.

SERIES 99 PROGRAMMER

To set static calibration using the Series 99 programmer:

1. Prepare the TMA with a sample-holder tube, expansion probe and weight tray.

2. Push the programmer POWER switch to on.

3. Set the programmer to standby.

4. Set the recorder PEN selector to LOAD.

5. Place a sheet of linear chart paper (PN 990525) on the recorder platen.

6. Set the recorder PEN selector to UP.

7. Set the recorder T-axis ZERO SHIFT selector to 0 (zero).

20

Page 22

21

Operation

8. Set the recorder Tvaxis RANGE selector to TIME.

9. Set the recorder V'-axis RANGE selector to 20 mV/ cm.

10. Adjust the TMA probe position control so that the probe just rests on the empty sample-holder

tube platform.

11. Place a 5 9 weight from the accessory kit on top of the weight tray.

12. Push and hold the recorder V'-axis ZERO switch up. Adjust the ZERO SHIFT selector so that the

V'-axis pen is positioned as a line-zero reference point, 1 cm above the bottom grid line of the

chart paper. Release the ZERO switch.

,------------------ NOTE -------------------.

When ZERO switch is released, the pen will change its position.

13. Adjust the TMA transducer position control so that the V'-axis pen is positioned to the previous-

ly established line-zero reference point, 1 cm above the bottom grid line of the chart paper.

PART NO. 990525

RUN NO. _OATE _

T-AXIS

OPERATOR PROG RATE. °C/min_

SAMPLE RANGE. mV/cm __

ATM __

c'

HEAT_CODL_ISO.

FLOW RATE .___ SHIFT,

cm _

TIME.

min/cm _

10

20

14

28

18

36

22

44

SET Y'-AXIS PEN

BASEUNE (ZERO)

1cmABOVE

BOnOM GRID UNE

6/838

943/30

Page 23

NOTE

Operation

14. To check the accuracy of the settings performed in steps 12 and 13, push the recorder Y'<axls

ZERO switch up momentarily, and while releasing it, observe the pen.lf pen movement occurs,

readjust the transducer position control slightly to raise or lower the pen. Repeat this procedure

until no pen movement is detected.

15. Remove the 5 9 weight from the TMA weight tray.

16. Obtain the 380Mm (15 mil) calibration shim from the accessory kit. Raise the probe with the

probe position control and place the shim on the sarnple-holder tube platform. Lower the probe

gently until it rests on the shim.

NOTE ----------------------------~

The Y'-axis pen will move upward.

17. Replace the 5 9 weight on the TMA weight tray.

18. Adjust the TMA CALIBRATE control so that the Y'-axis recorder pen deflection is equivalent to

the shim thickness shown. For example, the pen deflection for a 380Mm (15 mil) shim is 19

cm, starting from the baseline, which is 1 cm up from the bottom grid line.

19. Set the recorder PEN selector to LOAD, and remove the chart paper.

20. Remove the weight from the weight tray, and the shim from the sarnple-holder tube platform.

The system is now statically calibrated.

Y-axis (Derivative) Calibration

The following procedure is written for the Series 99 programmer. Ifyou have a 1090 pro-

grammer, you should not be concerned with this calibration unless you are interested in

the analog derivative signal, signal 5. To perform this procedure on the 1090, use the

DISPLAY AXIS to zero the electrical signal.

The TMA's derivative printed circuit board provides its own calibration signal. Two multiposition

controls, the function switch (CAL/NORMAL) on the rear panel and the DERIVATIVE (off/on/

RESET) on the front panel, are used selectively to control both the ramp and the derivative signals.

When the function switch is in the NORMALposition, the derivative board circuit is placed in parallel

with the LVDT output; this results in the output signal from the derivative board being the derivative

of the LVDTsignal. Ifthe function switch is placed in the CAL(lBRATE) position, the output from the

internally generated ramp signal is connected to the input of the derivative board for calibration

purposes. The two RAMP OUT jacks on the rear provide an output ramp signal.

The DERIVATIVEswitch, located on the front panel, provides two functions. When the DERIVATIVE

switch is moved to the on (center) position, the signal is the derivative function of the input signal. In

either the off (up) or RESET position (down), the switch shorts both the ramp function and the deri-

vative output.

Setup Procedure:

1.

Prior to performing the actual derivative calibration procedure, perform the Y'<axis static cali-

bration described on page 20.

2. Remove the probe assembly.

3. Place the function switch on the rear panel of the TMA to the CAL position.

22

Page 24

23

Operation

4. Power on the programmer and set it to standby.

5. Set the PEN selector to the LOAD position.

6.

Place a sheet of linear chart paper on the recorder (PN 990525).

7. Set the PEN selector to the UP position.

Calibration Procedure:

1.

Place

the

DERlvATlvE/RESET switch in the up (off) position.

2. Using the recorder ZERO switch, adjust the Y'-axis pen to the 2 cm line from the bottom of the

chart paper. This is a reference zero for the RAMP ZERO adjustment on the rear panel of the

TMA.

3. Using the recorder ZERO switch, adjust the Yaxis pen to the 20 cm line of the chart paper.

This will be the top line of the chart paper and represents the reference zero for the derivative

output.

4. Observe the movement of the Y'<axis (Iower) pen as the RAMPZERO potentiometer (15), on

the rear panel of the TMA, is adjusted. Rotate the screwdrtver-adjustable potentiometer clock-

wise to move the pen down. Adjust this zero to coincide with the previously set recorder zero.

5. Observe the movement of the

Yaxis

(upper) pen as the derivative ZERO potentiometer (11),

on the rear panel of the TMA, is adjusted. Turning the screwdriver-adjustable potentiometer

clockwise moves the pen up and counterclockwise moves the pen down. Adjust this zero to

coincide with the previously set recorder zero.

~----------------------------- NOTE ------------------------------~

Proper adjustment of the RAMPZERO and ZERO potentiometers should result invirtually

no pen movement

«

1 mm) when the recorder ZERO switch is pressed for Y' and Y.

6. After the zeroing procedure is complete, proceed to set up the derivative output calibration by

setting the recorder and TMA controls as folIows:

a. TMA

Function

Switch:

CAL position

b. Recorder

Y'·axis:

TIME BASE

50 mv/cm

(5 mll/rnin/In.)

50 mv/cm (5

rnil/In.)

0.5

min/crn

(0.5

rnin/in.)

T·axis:

Yaxis:

TIME BASE:

T·AXIS

ZERO

SHIFT:

PROGRAM:

o

STANDBY Position

Page 25

Operation

7. Start the plot by pressing the START switch on the recorder. Allow the pens to plot for approx-

imately 1 cm distance; then place the DERIVATIVE switch in the center (on) position.

8. Allow the program to run for 7 to 10 minutes; a typical plot, as shown on the following page,

results.

9. Choose an arbitrary point,

PI'

on the Y' curve. Drop a verticalline to intersect a horizontalline

drawn fromP3to

P2.

10. Measure line segments

PIP2

and

P2P3.

Substitute these values into the relationship.

Y

t

=

20 PtP

2

P2

P

3

11. Measure the distance Y2on the Ycurve. Compare it with the calculated value YI,which should

be equal to Y

2

, (to 3 significant figures).

12. Ifthe calculated value, Y

I

, is not equal to Y2, adjust the GAINpotentiometer (on the rear panel

of the TMA) cIockwise to increase deflection (Y2)and countercIockwise to decrease deflection

(Y

2

)·

24

Page 26

tn

1:!

es:.

E

=

c.

...

-<

tn

eil

I:

-

>C

...

;.

I:

-

=

0

CL.

tD

=

.,

<.

ca

I»

....

<.

tD

-

C/J

....

I»

....

;:;.

(')

w

_j

!.

m

...

<t

Q"

IT

.,

<t

I»

>

....

0

ö·

w

:s

n

:J

UJ

<t

w

~

[\J

U1

PART NO. 990525

RUN NO.___ OATE___

T-AXIS

OSC

2DD/lW/mV

TMA

1 p.m/mV

OMA

0.05 Hz/mV

O.oSdB/mV

OPERATOR

PROG RATE.

°C/min___

OTA

50mK/mV

OTG

0.1

ILm/Cmin mVl

FREQ,mV/cm

SAMPLE

RANGE. mV/ern

RANGE, mV/ern

MODE

DAMPING,

mV/cm ____

ATM

@

HEAT_COOL_ISO __

WEIGHT,mg

RANGE, mV/ern

OSCAMP,mm

FLOWRATE

SHIFT.cm

REFERENCE

SAMPLESIZE

A/ZGAIN.Ofo

TIME.

min/cm

LOAO.g

SAMPLESIZE

0

~

·r"ö

IT~

"

.~ t

1+;

'"

::1-.

:~~!rr;

.

~

,.,-;, U

,

,"

~

-~

f

~.

lllli

.'

"I.

Y2

ylCURVE

--

PI

..y

CURVE

0

~ P

3

P

2

1

2

4

3

B

12

7

14

28

23

4B

92

31

B2

124

37

74

148

25

50

100

27

54

108

29

58

11 B

33

BB

132

35

70

140

9

18

3B

13

2B

52

15

30

BO

17

34

B8

19

38

7B

21

42

84

5

10

20

1 1

22

44

o

"'0

Cb

..,

Q)

e.

o

:J

2JOOA

91OR/43

Page 27

Operation

Y'-Axis and Y-Axis (Derivative) Dynamic Calibration

For high precision dynamic measurements (e. g., determination of the coefficient of expansion),

perform the following calibration procedures:

1. Prepare the TMA with a sarnple-holder tube, expansion probe, and weight tray.

2. Perform

Y'-axis

static calibration procedures described on page 20.

3. Obtain the calibration standard (aluminum cylinder) from the TMA accessory kit. Measure its

length within±0.02 mm (±mil), using a micrometer calipers (not supplied), and note the

result. Place the aluminum cylinder on the TMA

sarnple-holder

tube platform. The aluminum

cylinder for our example measured 7.62 mm (300 mil).

4. Adjust the TMA probe position control so that the probe just rests on top of the aluminum

cylinder.

5. Obtain a 59weight from the TMA accessory kit and place it on top of the weight tray.

6. Attach the heater assembly.

7. Set the programmer to standby. (For 1090 operation follow steps 8 through 11. For Series 99

operation skip to step 12.)

1090 PROGRAMMER

8. Zero the electrical signal using the transducer position control and the displayaxis.

9. Set up a thermal run from

arnbient

to 300°C at 10°C/min. (Prepare to store the run.)

t

10. Start the calibration run. Then, press and hold the RESET switch on the TMA until the 1090

displayaxis returns to zero. Release the switch and complete the run.

11. Playback signals 3 and 5 vs. time. Then, proceed to Calculations of Y' Axis and YAxis for Deter-

mining Coefficient of expansion on page 27.

SERIES 99 PROGRAMMER

12. Place a sheet of

therrnocouple-corrected

chart paper on the recorder platen. Our example

uses O°Cto 360°C (PN 9900529) chart paper.

13. Set the recorder PEN selector to UP.

.----------------------------------------------------------------------------NOTE--------------------------------------------------------------------------,

The Y'-axis pen will move upward.

14. Turn the recorder Tvaxis RANGE and ZERO SHIFT selectors to the settings indicated on the

chart paper under the heading, "T axis."

15. Turn the recorder Y'<axis RANGE selector to 2 mV/cm.

16. Turn the recorder

Yaxis

RANGE selector to 2 mV/ cm.

17. Adjust the TMA transducer position control so that the

Yaxis

pen is 1 cm above the bottom

grid line of the chart paper.

18. Push and hold the recorder Y-axis ZERO switch up. Adjust the ZERO SHIFT selector so that the

Y-axis pen is postitioned as a line zero reference point on the top grid line of the chart paper.

Release the ZERO switch.

26

Page 28

Operation

,------------------------------- NOTE ------------------------------~

When ZERO switch is released, the pen may change its position slightly.

19. Set up a thermal run from ambient to 300°C at 10°C/min .

.------------------------------NOTE------------------------------~

The following settings are nominal. You may choose other chart papers and instrument

settings that correspond more closely to your desired experimental conditions.

20. Start the calibration scan. Then, press and hold the RESET switch on the TMAuntil the pen

returns to zero. Release the switch and allow the scan to proceed until the pen lifts and starts to

return to ambient temperature.

21. Perform Y'<axis and Yaxis (derivative) caIculations as folIows:

Calculations of Y'-Axis and Y-Axis for Determining Coefficient

of Expansion

CaIculate the Y'vaxis and Y-axis (derivative) coefficient of expansion from the expansion profile by

using the following equations. Example calculations are based on the expansion profile shown on

page 29.

a. Calculate Experimental Value

(0'

experimental) for the Coefficient of Expansion on the

Y'-axis.

Equation 1:

ß

L X Y'x ETMA x K

zr

x

L

0'

= coefficient of expansion inJ.Lm/moC(J.Lin/in°C)

ETMA = static calibration coefficient = 1 J.Lm/mV

[103J.L

in/min(in.)]

0'

=

Where:

L = sampIe length in m(in.)

ß

L = change in sampIe length in cm of chart

ß

T = change in temperature in °C CC)

Y

'

= Y-axis sensitivity in mV/cm

K = dynamic calibration coefficient (nom. 1.1 to 1.3)

Metric example:

_ (10.3 cm) (2 mV/cm) (1 J.Lm/mV) x 1 = 21.2

J.Lm/moC

0' -

(1270C) (7.62 xl0-3m)

1. Select the temperature range of interest in the experiment.The range selected for our example

is 100°C to 250°C.

2. Use the table on page 28 to select the temperature (T") value closest to (but not above) the

upper limit of the selected temperature range. For our example, the closest T'C value is 227°C.

3. Draw a horizontal line from the expansion curve at the lower limit of the selected temperature

range (100°C) until it intersects with the T'C value selected from the table (227°C). Calculate

the degrees centigrade between these points, and apply the result to equation 1 asßT. In our

example,ßT = 127°C.

4. Drawa perpendicular line from the intersection point, determined in step 3, up the T'C (22rC)

line to the Y'-axis expansion curve. Measure its length in cm (in.). Apply this measurement to

equation 1 asßL.

In our example,ßL = 10.3 cm.

27

Page 29

CaIculate the specifie ternperature and eoefficient of expansion values under

investiqa-

tion by rneans of interpolating the known values Iisted in the table,

Operation

ALUMINUM COEFFICIENT OF EXPANSION

(AMERICAN INSTITUTE OF PHYSICS HANDBOOK. [2nd edition]. 4-66 [1963])

T

~rn/rnoC

(llin./in.°C)

(aC)

-73

20.0

-23 21.9

27 23.2

77

24.1

127 24.9

227 26.4

327

28.3

427 30.7

527 33.8

r------------------------------NOTE------------------------------~

5. Apply the ealibration standard (alurninurn eylinder) length rneasurernent to equation 1 as

L.

Our exarnple rneasures 7.62 rnm.

6. Use the Y'-axis RANGE setting at whieh the sarnple sean was run, and apply this to equation 1

asy_Our exarnple used a setting of 2 rnV

lern.

28

Page 30

ETMA

AND

EOTM

CALIBRATION FACTORS

PART NO. 990529

I

w

...J

ID

<t

iI

<t

>

o

w

tr

J

(JJ

<t

w

:2

RUN NO. __ OATE

OPERATOR _

SAMPLE ~__

T-AXIS

n

o

tD

a

n

;-

:s

..

o

....

CI

'0

Dl

:s

!II

Ö

:s

'0

a

=

-

tD

•

1:

I

~

i;

111 I

I:

-

PROG RATE. "C/min _

50 mK/mV

SUPPRESSION. mg _

RANGE. mV/cm _

WEIGHT. mg _

MOOE .

RANGE.

De/em

_____lO________IRANGE. mV/cm _

DSC

DTA

200 IlW/mV

TGA

DTG

50 Ilg/mV

50 I'g/Cmln mV)

TMA

DTM

ATM_.

(u _

FLOW RATE _

HEAT __ COOL _ISO. __

SHIFT,

cm

______o_

WEIGHT. mg _

REFERENCE _

TIME.

min/cm _ _ _

!

11;

l;i:llii!III:II'fi';lj'i:Ii;CI;;lfll~I;I;";li"f':I';~

I·"'·I.,I!

i.

TOC VAlUE

FROM TABlE (227°C)

6/83E

943/6

o

"0

Cl>

..,

Cl>

.....

Ö·

;:J

l\J

1.0

Page 31

The dY (derivative) signal reads the eoeffieient of expansion direetly as displaeement

from the derivative baseline.

Operation

7. Use the TMAealibration eoefficient faetor specified on the ehart paper, and apply this to equa-

tion 1 as ETMA.The ETMAfaetor for our example is 1

f..t/mV.

8. Assurne that the value ofK(dynamie ealibration eoefficient) is equal to 1 and apply this to

equa-

tion 1 as

K.

9.

Solve equation 1 and reeord the result as0:experimental for the Y'

-axis.

The result of our

ex-

ample is 21.2

f..tm/mm°C.

b. Calculate Experimental Value

(0:

experimental) for the Coefficient of Expansion Yaxis

(derivative).

Use the following

equation

to ealeulate the experimental eoefficient of expansion value for

the Yaxis (derivative).

Equation 2:

0:

=dYxYx

EDTM

RxL

0:

=

eoefficient of expansion in

f..tm/

mOC(

f.L

in./in.°C)

EDTM=statie derivative ealibration eoefficient=0.1 m/min mV

(103f..t

in./

mil)

L

=

sampie length in m (in.)

R=program rate in °C/min (OC/min)

dY=Yaxis measurement of derivative

Where:

Metrie example:

=

(8.1 em) (2 mV/ern) (0.1 f.Lm/minmV)=21.2 f.Lm/moC

(10°C/min) (7.62x10-3m)

1. Apply the ealibration standard (aluminum eylinder) length measurement to equation 2 as

L.

Our example measures 7.62 mm.

2. Use the PROGRAMRATE setting at which the sampie sean was run, and apply this to equation

2 asR.Our example uses a setting of 10°C/min.

3.

Measure in cm (in.) the

Y-axis

(derivative) signal at the same

T'C

(227°C) value, less pen offset,

from the derivative baseline to the Y-axis expansion eurve. Apply this measurement to

equa-

tion 2 as dY. In our example, dY = 8.1 em.

~----------------------------NOTE----------------------------~

4. Apply the Y-axis RANGE setting at whieh the sampie sean was run to equation 2 as Y.Our sam-

pie uses a setting of 2 mV/ern.

5. Use the DTM ealibration eoefficient faetor specified on the ehart paper, and apply this to

equation 2 as Y. Our sampie uses a setting of 2 mV/ern.

5. Use the DTM ealibration eoefficient factor speeified on the ehart paper, and apply this to

equation 2 as EDTM. The EDTM faetor for our example is 1 f..tm/min mV.

6. Solve equation 2 and reeord the result as0:experimental for the Y-axis.The result of our exarn-

pie is 21.2

f..tm/m°C.

30

Page 32

31

Operation

c. Determine Actual Value (aActual) for the Coefficient of Expansion

Equation 3:

K

=

a

actual

a

experimental

Where:

K=dynamic calibration coefficient

a

actual=actual value of coefficient of expansion in jJ.

m/rn"

( jJ.in/in°C)

a

experimental

=

experimental value of coefficient of expansion in

m/rn''C

(jJ.in/in°C)

Example Y'-axis:

K=26.4 1.24

21.2

Example Y·axis (derivative):

K

=

26.4

=

1 24

21.2 .

1. Refer to the table and find the jJ.m/moCvalue that corresponds to the

T'C

value (227°C)

previously selected. Apply this value to equation 3 asaactual. Our example is 26.4

jJ.m/m°C.

2. Apply to equation 3 theaexperimental value for the Y'-axis previously recorded from

equation 1 step 9. The experimental value previously from our example was21.2 jJ.m/m°C.

3. Solve equation 3 to determine the dynamic calibration coefficient (K) value for the Y'

-axis,

4. Apply to equation 3 theaexperimental value for the Y-axis(derivative) previously recorded

from equation 2 step 6. Theaexperimental value previously recorded from our example was

21.2 jJ.m/m°C.

5. Solve equation 3 to determine the dynamic calibration coefficient (K) value for the Y-axis

(derivative). Calculations for the coefficient of expansion are completed. Use the deter-

mined K values as a calculation factor in subsequent experiments.

6. Detach the heater assembly, remove the weight from the weight tray, and remove the

aluminum cylinder from the sampie-holder tube.

Page 33

Before operating the TMA at subambient temperatures, read the safety precautions for

handling cryogenic material on page iv of this manual.

Operation

Routine Operating Sequence

1. Prepare the TMA with a sampie holder and probe.

2. Load the sampie into the sampie holder.

3. Turn programmer power on.

4. Adjust the probe position control so that the probe almost touches the sampie.

5. Zero the electrical signal from the TMA using the transducer position control. The 1090 willallow

you to do this using the displayaxis. Refer to the Y-AxisStatic Calibration Procedure, page 20, for

more information.

6. Connect the heater to the TMA.

7. Use the TA programmer to set up the thermal run.

Subambient Operation

The TMA can be used when programming from -100°C to 800°C (ambient to 1200°C with optional

heater). When an experiment requires heating from subambient temperatures, perform the fol-

lowing steps:

~ CAOTION---------- -.

1. Remove the TMA Dewar flask and heater assembly.

2. Prepare the TMA with a weight tray, the desired probe assembly, and the corresponding sampIe-

holder tube.

3. Place a sampie on the TMA sample-holder tube.

4. Set the programmer to ST ANDBY.

5. Adjust the probe position control so that the probe almost touches the sampie.

6. Zero the electrical signal.

7. Connect the heater plug to the TMA heater socket.

8. Set the programmer starting temperature to 30°C below the start temperature required for the

experiment.

9. Set the programmer to hold isothermally.

10. Place the Dewar flask next to the TMA and fill it with 5 cm (2 in.) of liquid nitrogen.

11. Lower the heater into the liquid nitrogen until the heater support arm rests on the top of the

Dewar flask. Replenish the Dewar flask until the programmer indicates that the start temperature

has been reached.

32

Page 34

Operation

NOTE

To prevent frost from accumulating inside the heater weil,

do not

remove the heater

assembly when replenishing the Dewar flask with liquid nitrogen. Care should be taken to

ensure that as Iittle liquid nitrogen as possible enters the heater weil. This will reduce the

amount of power applied to the heater to maintain the initial temperature.

12. Remove the heater from the liquid nitrogen, empty any liquid from the heater weil, and attach the

heater to the Dewar cap.

13. Remove liquid nitrogen from the Dewar flask, then screw the Dewar flask into the Dewar cap.

14. Enter the program parameters for the experiment.

15. Lower the probe until it touches the sampie.

16. Adjust the transducer position control back to zero.

17. Press down and release the TMA derivative reset switch.

18. Start the thermal run.

33

Page 35

MAINTENANCE

Page 36

WARNING --------------------------~

Maintenance

Keeping the 943 Working

Maintenance procedures should be performed periodically to keep the 943 in good working

condition. .

The procedures described in this section are

the custorner's

responsibility. Anyfurther maintenance

should be performed by a representative of Du Pont Instruments or other qualified service personnel.

Do not open the electronics compartment. Because of the high voltages in this instru-

ment, repair procedures requiring access to the electronics compartment must be

performed by Du Pont or other qualified service personnel.

CLEANING THE BEARING GOlDES

The surfaces of the bearing guides must be kept clean for the probe assembly to operate properly. If

the probe is sticking or moving sluggishly, clean the bearings with Freon® TF degreasing solvent (PN

102401)

using a pressurized spray can. This solvent will not harm any internal components.

~ CAOTION -,

Remember quartz parts are fragile and should be handled carefully.

Clean the bearing guides as folIows:

1.

Remove the weight tray, Dewar flask, and heater assembly.

2. Disconnect the thermocouple leads and remove the Dewar cap with the sample-holder tube.

3.

Place a piece of cloth on the TMA cabinet directly below the head assembly to catch any Freon®

drippings.

4.

Remove the retaining nut from the top of the head assembly to expose the upper bearing guide.

5.

Spray Freon® TF down into the head assembly at the point where the probe shaft meets the

bearing guide. Spray for10to15seconds. Gently move the shaft up and down while spraying

to dislodge any hidden dust particles.

6.

Wait about one minute to allow any solvent between the shaft and bearing guide to drain

and

evaporate.

7.

Spray up into the head assembly at the point where the probe shaft meets the lower bearing guide.

Again, move the shaft while spraying and allow sufficient time for the solvent to penetrate.

8.

Make sure that

the

probe is centered in each of the bearing guides to prevent binding.

9. Install the retaining nut, weight tray, sarnple-holder tube, Dewar cap, heater assembly, and Dewar

flask.

36

Page 37

37

Maintenance

NOTE

Replace the dust cover when the TMA is not in use.This will prevent dust from settling into

the bearing guides.

CLEANING THE PROBE ASSEMBLY

At the end of each experiment, check the probe assembly and the LVDT core for grease or other

residue. If the probe is dirty, clean it as folIows:

1. Clean the LVDT core and the upper probe with Freon® TF spray, or with acetone applied with a

soft brush or cloth.

2. Clean residue from the end of the quartz probe by heating it with aBunsen burner until the residue

evaporates.

r------------------------------

NOTE ------------------------------~

Small amounts of residue on the probe may be removed with acetone.

REPLACING THE SAMPLE THERMOCO(JPLE

Remove and replace the sampie thermocouple as folIows:

a. Removal

1. Remove the Dewar flask from the Dewar cap.

2. Disconnect the thermocouple leads and remove the Dewar cap from the head assembly.

4179A

943/32

Page 38

You do not have to remove the two Teflon® washers in the Dewar cap.

Maintenance

3. Hold the Dewar cap in one hand, and remove the sarnple-holder tube with the thermocouple

from the Dewar cap as shown here.

Make sure that the thermocouple leads are properly aligned with the hole in the Dewar cap for

easy removal.

~-----------------------------NOTE------------------------------~

4. Holding the sarnple-holder tube in one hand, insert ahook (which can be fashioned out of a

piece of stiffwire) into the top of the sarnple-holder tube. Remove the spring clip while holding

the thermocouple in position.

r__--------------WARNING ---------------'-----,

Excessive pressure can break the sarnple-holder tube; wear protective gloves when

removing or installing the spring clip.

38

Page 39

Maintenance

5. Use tweezers to pull the thermocouple out through the bottorn of the sarnple-holder tube.

Make sure that the thermocouple leads are properly aligned with the hole in the side of the

sarnple-holder tube when removing the thermocouple.

b. Replacement

1. Insert the thermocouple leads up through the bottorn of the sarnple-holder tube. Then, using

tweezers, pull the leads through the hole in the side of the sarnple-holder tube.

2. Position the thermocouple so that the thermocouple tip is approximately 1.5 mm (0.06 in.)

from the bottorn of the sample-holder tube. Hold the thermocouple in position and insert the

spring clip into the bottom of the sample-holder tube.

SPRING

CLIP

4 7~lA

94] 3f.

THERMOCOUPLE TIP

3. Hold the thermocouple in position and insert the hook into the top of the sarnple-holder tube.

Pull the spring clip upward to approximately 6 mm (0.25 in.) from the hole in the side of

the tube.

4. Check the position ofthe thermocouple. If it moves upward while you are installing the spring

clip, insert a wooden dowel in the top of the sarnple-holder tube and carefully push the spring

clip down (the thermocouple will also move down) until the thermocouple is in its prop-

er position.

~------------------------------- NOTE-------------------------------,

To avoid false thermocouple readings, make sure that the thermocouple tip does not touch

the sampie holder-tube. Exposed portions of the two thermocouple leads (usually atthe hole

of the holder) must not touch each other.

____________________________________ _~~- _---I

39

Page 40

4179A

943/36

Maintenance

5. Insert the sample-holder tube and thermocouple leads through the hole in the top of the

Dewar cap. Use tweezers to thread the thermocouple leads through the hole in the side ofthe

Dewar cap.

6. Replace the Dewar cap.

7. Connect the red thermocouple lead to the upper jack on the TMA and the yellow lead to the

lower jack.

\\ \

CONNECT THERMOCOUPLE

RED LEAD TO UPPER JACK

~

CONNECT THERMOCOUPLE

YELLOW LEAD TO LOWER JACK

\

\ \ 4 79A

943 37

8. Attach the heater assembly and check alignment. If adjustment is required, refer to page 15.

40

Page 41

PARTS LIST

Page 42

PARTS LIST

Page 43

Itern No. Part Nurnber

Description

Parts List

Parts for the 943. System

This section Iists replaceable parts for the 943 and its accessories.

To order replacement parts, contact the nearest Du Pont district office. A list of offices appears on the

back cover of this manual.

To ensure that you receive the correct part for your unit, be sure to include the part number and

description, as weil as the instrument type, model number and serial number.

943 TMA PARTS LIST

1

2

3

4

5

6

7

8

9

10

11

940020

940078

941024

941128

941082

941078

941086

941079

941150

941147

941136

WEIGHT TRA Y*

NYLON®WASHER

UPPER BEARING GUIDE

UPPER SHAFT ASSEMBL Y

PENETRATION PROBE ASSEMBL Y

• Lower Shaft Assembly "

EXPANSION PROBE ASSEMBLY*

• Lower Shaft Assembly

MACRO EXPANSION ASSEMBLY

• Lower Shaft Assernbly"

SAMPLE THERMOCOUPLE, CHROMEL-ALUMEL

WITH SPRING RETAINER

SAMPLE-HOLDER TUBE WITH THERMOCOUPLE

SAMPLE-HOLDER TUBE WITHOUT THERMOCOUPLE

TEFLON® WASHERS (2)

HEATER ASSEMBLY (Standard 800°C)

NEOPRENE GASKET

DEWAR ASSEMBLY INSERT

INSTRUCTION MANUAL

TMA ACCESSORY KIT

• Teflon® Demonstration Sampie

• Circular Level

• Aluminum Calibration Standard

• Balance Weights

• Tweezers

• Allen Wrench

• Accessory Kit Case

• Calibration Shim

12

13

14

15

16

17

18

19

941099

941097

940053

942050-901

942062

942058

943145

941112

942057

259534

940070

259522

259537

259521

259073

942056

"Itern included in TMA accessory kit.

42

Page 44

5,7,9

6,8,10

1"

I

12,13

15

17

Exploded Vi ew, 943 System

Parts List

l

8179A

943/38

43

Page 45

Parts List

943 TMA OPTIONAL ACCESSORIES PARTS LIST

Part Number

Description

941131

941128

941139

941145

941151-901

941133

941128

941140

941144

941038-901

943010-902

943105

943106

943107

943013-902

943015-901

943012-901

941144-901

941038-901

943118

943010-901

943105

943106

943107

943013-901

943014-901

943011-901

943016-901

203947-005

943118

941137

941128

941142

941099

941022

941148

941143

FILM TENSION PROBE ACCESSORY KIT

• Upper Shaft Assernbly"

• Film Tension Lower Probe Assembly

• Film Tension Sample-Holder Assembly

• Film Clamp Assembly Set

FIBER TENSION ACCESSORY KIT

• Upper Shaft Assernbly"

• Fiber Tension Lower Probe Assembly

• Fiber Tension Sample-Holder Assembly

• Vial of Cleaved Aluminum Balls

FIBER TENSION SPECTROMETER ACCESSORY KIT

• Load Cell Carrier

• Load Cell Adapter

• Load Cell Weight Tray

• Load Cell Assembly, Low Range

• Fiber Tension Lower Probe Assembly

• Fiber Tension Upper Shaft Assembly

• Fiber Tension Sample-Holder Assembly

• Vial of Cleaved Aluminum Balls

• Load Cell Key

STRESS RELAXATION ACCESSORY KIT

• Load Cell Carrier

• Load Cell Adapter

• Load Cell Weight Tray

• Load Cell Assembly, High Range

• Stress Relaxation Probe Assembly

• Stress Relaxation Upper Clamp Assembly

• Stress Relaxation Lower Clamp Assembly

• Allen Wrench, 238 mm (332 in.)

• Load Cell Key

DILATOMETER PROBE ACCESSORY KIT

• Upper Shaft Assernbly"

• Dilatometer Lower Probe Assembly

• Sam pie-Holder Tube with Therrnocouple"

• Aluminum Calibration Standard

• Vials of Filling Medium (2)

• Dilatometer Sam pie Vials (2)

"ltern included in TMA accessory kit.

44

Page 46

Parts List

943 TMA OPTIONAL ACCESSORIES PARTS LIST (continued)

Part No. Description

943138-901

943136-901

943133-901

943147-901

943124

943122

943123

943121

943125

943126

900902-901

900680-901

943022-901

943153-901

943139-901

940053

PARALLEL PLATE RHEOMETER ACCESSORY KIT

• Rheometer Shaft Assembly (2)

• Rheometer Sarnple-Holder Assembly (2)

• Rheometer Sample-Forming Die Set (Pellet Press)

Pellet Press Cylinder

- Pellet Press Cylinder Head

- Pellet Press Piston

- Pellet Press Base Screw

• Rheometer Alignment Cages (3)

Rheometer Parallel Plates (6)

• Indium Metal Standard

SAMPLE ENCAPSULATING PRESS

1200°C TMA HEATER ACCESSORY

• Heater Assembly

• Water Cooling Jacket

• Teflon Washers (3)

"ltern included in TMA accessory kit.

45

Loading...

Loading...