Page 1

DXL SERIES II

CAST IRON GAS FIRED BOILERS

Models

DXL-50

DXL-75

DXL-100

DXL-125

DXL-150

DXL-1 70

DXL-200

FOR FORCED HOT WATER

INSTALLATION, OPERATION &

MAINTENANCE MANUAL

An ISO 9001-2008 Certified Company

An ISO 9001-2008 Certified Company

Tested For 100 psi.

ASME

Working Pressure

Manufacturedby:

ECRInternational,Inc.

2201 Dwyer Avenue, Utica NY 13501

web site: www.ecrinternational.com

P/N 2400009041, Rev. B [09/2012]

Page 2

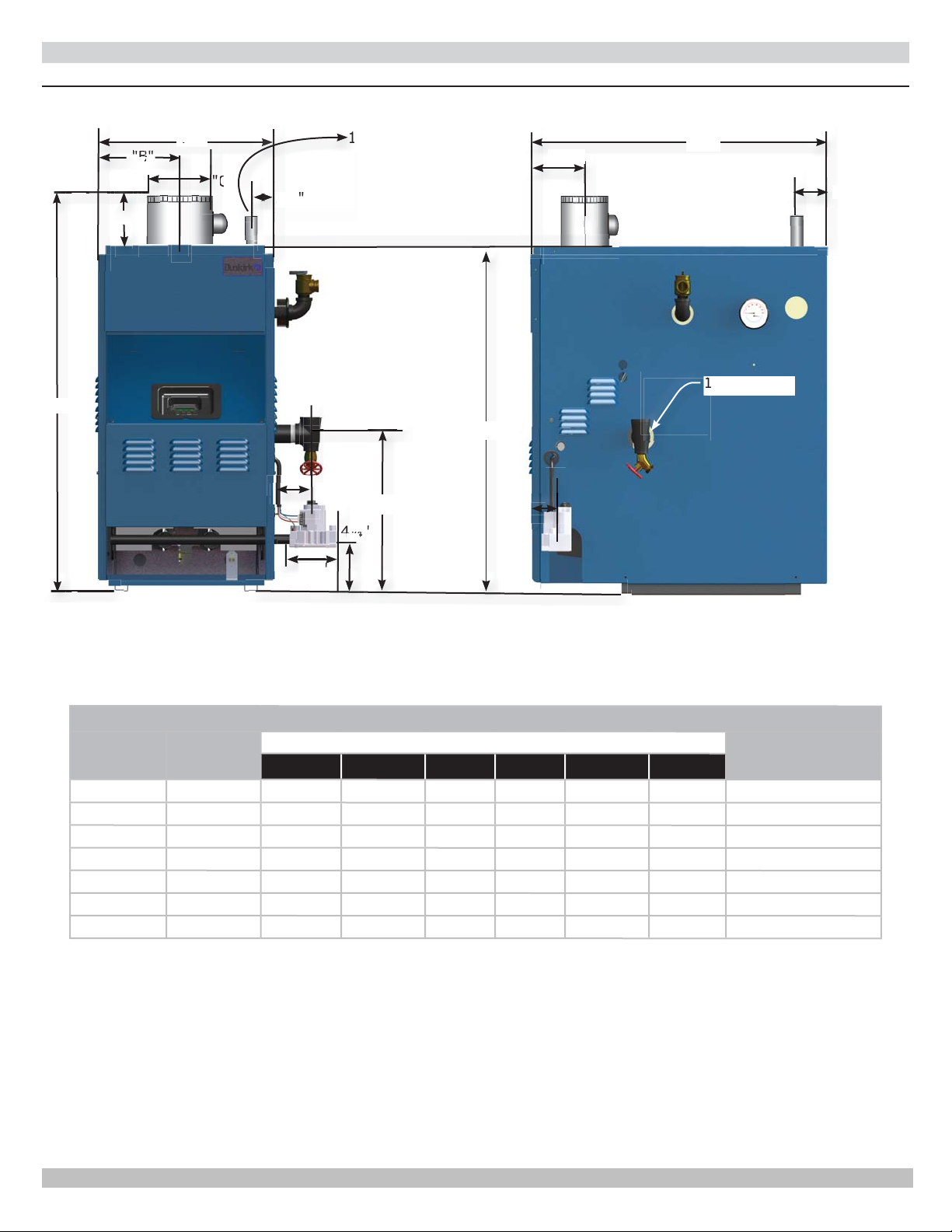

4½"

¼¼

¼

C

A

4

Figure 1 - Dimensions

1- DIMENSIONS

"E"

"F"

"B"

"A"

"C"

3½""½

4¼"

4½"

1¼" Supply

14"

4¼"

27"

5½"

3"

1¼" Return

"D"

2½"

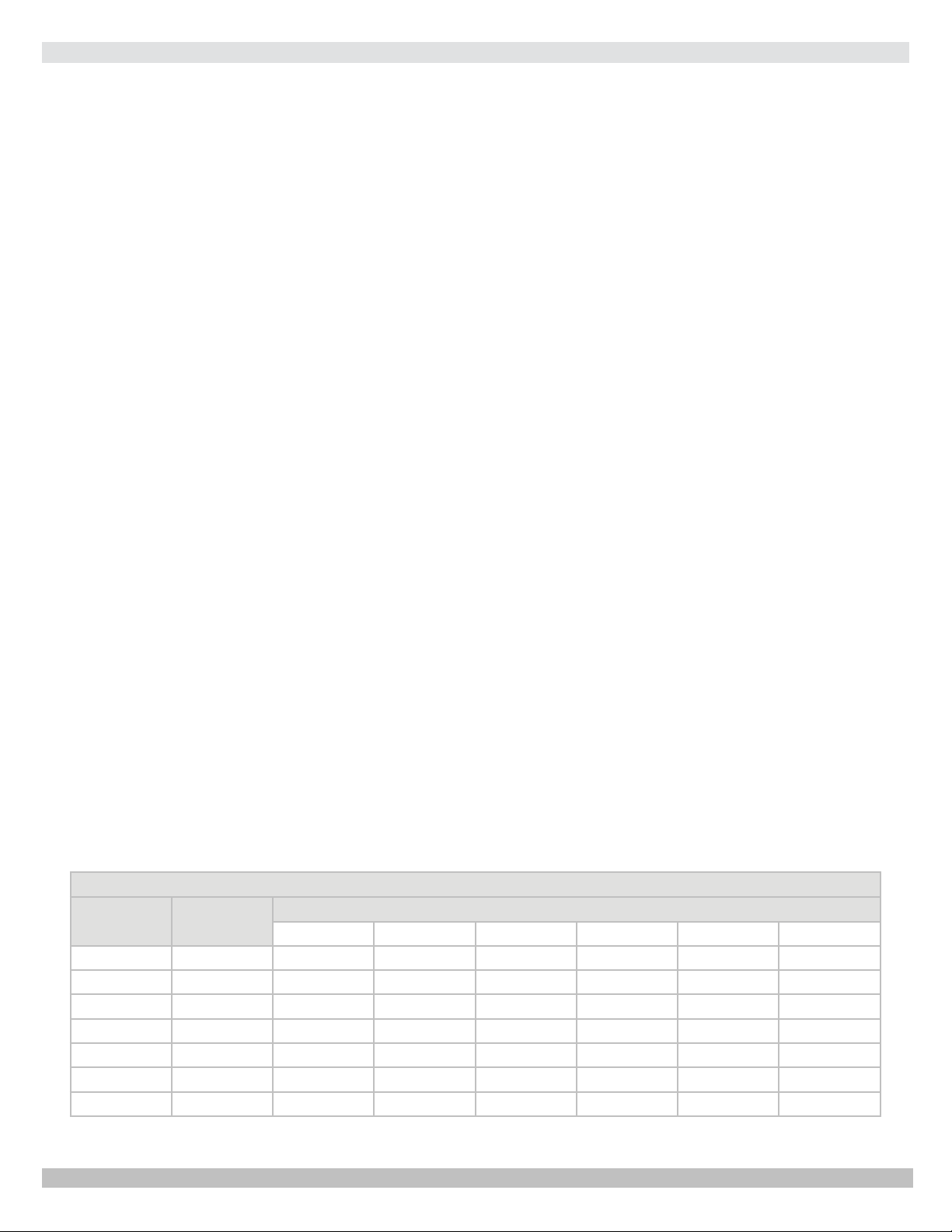

Table 1 - Dimensions

Boiler No.

50 ½" 11⅛"5½" 4" 30¾"

75 ½" 15 7½" 5" 30¾" 36¾" 6" 1¼"

100 ½" 15 7½" 6" 30¾" 37¼" 6½" 1¼"

125 ½" 18⅞"9½" 6" 30¾" 37¼" 6½" 1¼"

150 ½" 18⅞"9½" 7" 30¾" 37¾" 7" 1¼"

170 ½" 22¾"11½" 7" 30¾" 38¾" 7" 1¼"

200 ½" 22¾"11½" 8" 30¾" 38¾" 8" 1¼"

Natural Gas

Inlet*

ABCDEF

Dimensions

36¾"

Pump size Supply &

Return Tappings

6" 1¼"

2

Page 3

2 - SAFETY SYMBOLS & WARNINGS

!

1- Dimensions .....................................................2

2 - Safety Symbols & Warnings .............................3

3 - Ratings & Data - Natural Gas & Propane Gas ...... 4

4 - Installation Procedure .....................................5

5 - Ventilation & Combustion Air ............................ 6

6 - Supply And Return Piping ................................7

7 - Vent Installation ........................................... 12

8 - Vent System Modifi cation ............................... 12

9 - Vent Damper Installation & Instructions ........... 13

10 - Connecting Gas Service ............................... 14

11 - Electrical Section ........................................ 15

12 - Wiring Diagram - Intermittent Ignition ........... 16

13 - Lighting Instructions ................................... 18

14 - Sequence Of Operation ................................ 19

15 - General Instructions .................................... 19

16 - Checking Gas Input Rate To Boiler ................. 21

17 - Setting The Control ..................................... 22

17 - System Start-Up ......................................... 23

17 - Limit Control Troubleshooting ...................... 24

18 - System Troubleshooting ............................... 25

Parts, Kits and Accessories.................................. 27

Warranty .......................................................... 33

Check Out Certifi cate ......................................... 35

Safety Symbols & Warnings

The following defi ned symbols are used throughout this

manual to notify the reader of potential hazards of varying

risk levels.

KEEP THIS MANUAL NEAR BOILER

RETAIN FOR FUTURE REFERENCE

IMPORTANT: Read the following instructions

COMPLETELY before installing!!

WARNING

!

Fire, explosion, asphyxiation and electrical shock

hazard. Improper installation could result in death

or serious injury. Read this manual and understand

all requirements before beginning installation.

WARNING

!

Keep boiler area clear and free from combustible

materials, gasoline and other fl ammable vapors

and liquids.

DO NOT obstruct air openings to the boiler room.

Modifi cation, substitution or elimination of factory

equipped, supplied or specifi ed components may

result in personal injury or loss of life.

TO THE OWNER - Installation and service of this

boiler must be performed by a qualifi ed installer.

TO THE INSTALLER - Leave all instructions with

boiler for future reference.

When this product is installed in the

Commonwealth of Massachusetts the installation

must be performed by a Licensed Plumber or

Licensed Gas Fitter.

!

DANGER

Indicates a hazardous situation which, if not avoided,

WILL result in death or serious injury

!

WARNING

Indicates a hazardous situation which, if not avoided,

could result in death or serious injury.

!

CAUTION

Indicates a hazardous situation which, if not avoided,

could result in minor or moderate injury.

NOTICE

Used to address practices not related to personal

injury.

3

Page 4

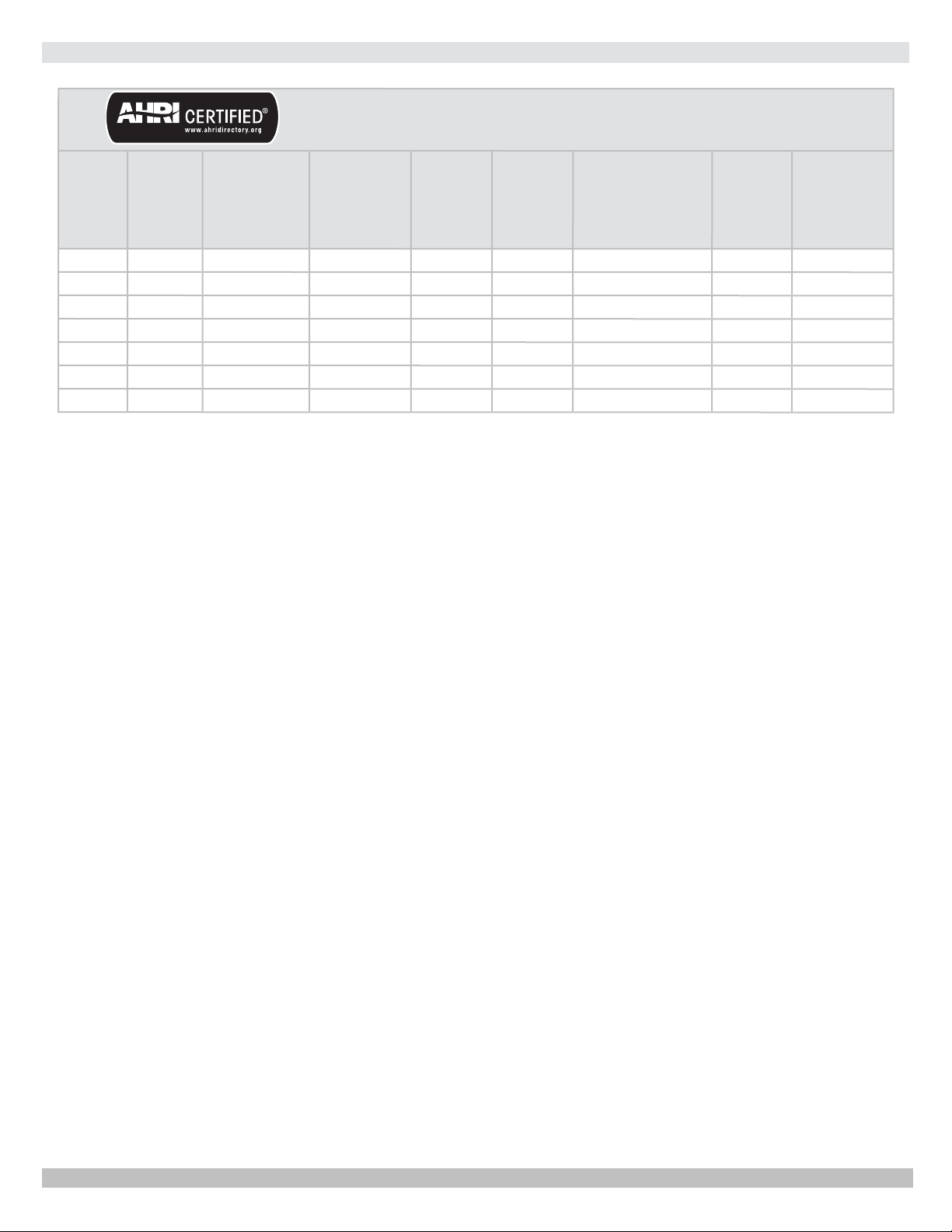

3 - RATINGS & DATA - NATURAL GAS & PROPANE GAS

Table 2 - Ratings and Capacities

(2)

Boiler

No.

(1)

Input

Mbh

(1)

Heating

Capacity

Mbh

Net AHRI

Rating

Water

Mbh AFUE

No.

of

Burners

Recommended

50 50 42 37 83.5 1 15 2.4 45,000

75 75 63 55 83.1 2 15 4.0 67,500

100 100 83 72 83.0 2 30 4.0 90,000

125 125 104 90 82.0 3 30 5.6 112,500

150 150 124 108 83.0 3 30 5.6 135,000

170 170

139

121 82.0 4 30 7.2 153,000

200 200 165 143 82.0 4 30 7.2 180,000

EXPLANATORY NOTES

-- All boilers are design certifi ed for installation on noncombustible fl oor.

(3)

Air Cushion

Tank

Water

Content

(Gals.)

High

Altitude

Input

-- For installation on combustible fl oors use combustible fl oor kit.

-- Recommended chimney height 20 feet. In special cases where conditions permit, chimney height may be

reduced to 10 feet. Refer to the latest revision of NFGC part 11.

-- Electric service to be 120 Volts, 15 Amps, 60 Hz.

-- The MEA number for the this boiler is 19-79-E.

(1) Input rating for sea level to 2,000 ft. (610m) above sea level.

United States, over 2000 ft (610m) above sea

level. Reduce input rate 4% for every 1000 ft (304m) above sea level.

(2) Net AHRI Water Ratings shown based on piping and pickup allowance of 1.15. Consult manufacturer

before selecting boiler for installations having unusual piping and pickup requirements, such as

intermittent system operation, extensive piping systems, etc.

For forced hot water systems where boiler and all piping within area to be heated, boiler may be selected

on basis of its heating capacity.

(3) Tank sized for non-ferrous baseboard or radiant panel systems. Increase size for cast iron baseboard and

radiation.

STANDARD EQUIPMENT: Boiler Jacket, Cast Iron Boiler Battery, Combination High Limit/Low Water Cutoff

Control, Intermittent Electric Ignition Pilot System, Vent Damper Relay, Temperature/Pressure Gauge, Circulator

With Return Piping To Boiler, Main Gas Burners, Gas Control (Includes Automatic Gas Valve, Gas Pressure

Regulator, Intermittent Pilot, Safety Shutoff, Pilot Flow Adjustment, Pilot Filter), A.S.M.E. Relief Valve, Drain Valve,

Spill Switch, Rollout Switch, Combination Gas Control, Automatic Vent Damper. Not Shown Are: Wiring Harness,

Thermocouple, Non-linting Safety Pilot.

4

Page 5

4 - INSTALLATION PROCEDURE

!

WARNING

Improper installation, adjustment, alteration, service

or maintenance could result in death or serious

injury

.

1.

Installation must conform to requirements of authority

having jurisdiction or, in absence of such requirements,

to the National Fuel Gas Code, ANSI Z223.1/NFPA 54.

2.

Where required by authority having jurisdiction,

installation must conform to the Standard for Controls

and Safety Devices for Automatically fi red Boilers,

ANSI/ASME CSD-1.

3.

Boiler series is classifi ed as Category I. Vent

installation shall be in accordance with "Venting of

Equipment ," of the National Fuel Gas Code, ANSI

Z223.1/NFPA 54, or applicable provisions of local

building codes.

4.

Boiler has met safe lighting and other performance

criteria with gas manifold and control assembly on

boiler per latest revision of ANSI Z21.13/CGA 4.9.

5.

Boiler shall be installed such that gas ignition system

components are protected from water (dripping,

spraying, rain, etc.) during appliance operation and

service, (circulator replacement, condensate trap,

control replacement, etc.).

6.

Locate boiler on level, solid base as near chimney as

possible and centrally located with respect to heat

distribution system as practical.

7.

Allow 24 inches (610mm) at front and right side for

servicing and cleaning.

8.

When installed in utility room, door should be wide

enough to allow largest boiler part to enter, or to

permit replacement of another appliance such as water

heater.

!

WARNING

Fire hazard. Do not install boiler on combustible

fl ooring or carpeting. Failure to follow these

instructions could result in death or serious injury.

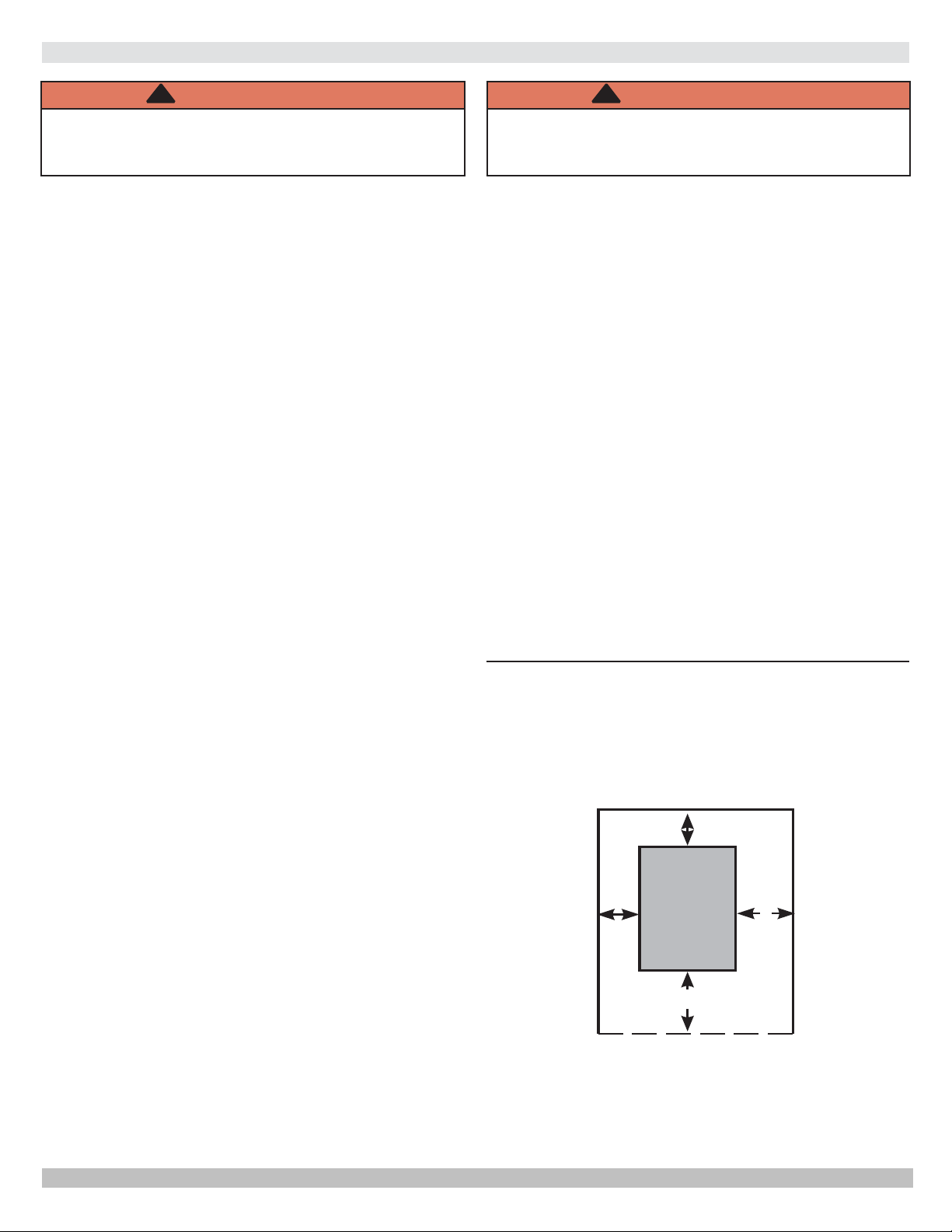

9.

FOR INSTALLATION ON NON-COMBUSTIBLE

FLOORS ONLY - For installation on combustible

fl ooring special base must be used. (See Replacement

Parts Section.) Boiler can not be installed on

carpeting. Minimum clearances to combustible

construction are:

TOP ....................................18 IN. (457mm)

FRONT .........................................ALCOVE *

FLUE CONNECTOR ................. 6 IN. (152mm)

REAR ................................... 4 IN. (102mm)

CONTROL SIDE ..................... 9 IN. (229mm)

OTHER SIDE ........................... 3 IN. (76mm)

HOT WATER PIPING ................ Per Local Code

NOTE: Greater clearances for access should supersede fire

protection clearances.

* Defi nition of Alcove is three sided space with no wall in

front of boiler. ANSI standard for alcove is 18 inches from

front of appliance to leading edge of side walls as shown

below.

Figure 2 - Clearance to Combustibles

Minimum Clearances to Combustible

Construction (as seen from above)

4"

3"

BOILER

Front

9"

18"

5

Page 6

5 - VENTILATION & COMBUSTION AIR

Provide combustion air and ventilation air in accordance

with the section “Air for Combustion and Ventilation,” of

the National Fuel Gas Code, ANSI Z223.1/NFPA 54, or

applicable provisions of local building codes.

Provide make-up air where exhaust fans, clothes dryers,

and kitchen ventilation equipment interfere with proper

operation.

National Fuel Gas Code recognizes several methods

of obtaining adequate ventilation and combustion air.

Requirements of the authority having jurisdiction may

override these methods.

• Engineered Installations. Must be approved by

authority having jurisdictions.

• Mechanical Air Supply. Provide minimum of 0.35

cfm per Mbh for all appliances located within space.

Additional requirements where exhaust fans installed.

Interlock each appliance to mechanical air supply

system to prevent main burner operation when

mechanical air supply system not operating.

• All Indoor Air. Calculate minimum volume for all

appliances in space. Use a different method if

minimum volume not available.

о Standard Method. Cannot be used if known air

infi ltration rate is less than 0.40 air changes per

hour. See Table 3 for space with boiler only. Use

equation for multiple appliances.

3

Volume ≥ 50 ft

x Total Input [Mbh]

о Known Air Infi ltration Rate. See Table 3 for

space with boiler only. Use equation for multiple

appliances. Do not use an air infi ltration rate

(ACH) greater than 0.60.

Volume ≥ 21 ft3/ACH x Total Input [Mbh]

о Refer to National Fuel Gas Code for opening

requirements between connection indoor spaces.

• All Outdoor Air. Provide permanent opening(s)

communicating directly or by ducts with outdoors.

о Two Permanent Opening Method. Provide opening

commencing within 12 inches of top and second

opening commencing within 12 inches of bottom

enclosure.

Direct communication with outdoors or

communicating through vertical ducts. Provide

minimum free area of 1 in

2

per 4 Mbh of total

input rating of all appliances in enclosure.

Communicating through horizontal ducts.

Provide minimum free area of 1 in2 per 2

Mbh of total input rating of all appliances in

enclosure.

о One Permanent Opening Method. Provide opening

commencing within 12 inches of top of enclosure.

Provide minimum clearance of 1 inch on sides

and back and 6 inches on front of boiler (does not

supersede clearance to combustible materials).

о Combination Indoor and Outdoor Air. Refer to

National Fuel Gas Code for additional requirements

for louvers, grilles, screens and air ducts.

• Combination Indoor and Outdoor Air. Refer to

National Fuel Gas Code for application information.

National Gas and Propane Installation Code Requires

providing air supply in accordance with:

• Section 8.2 and 8.3 when combination of appliances

has a total input of up to and including 400 Mbh (120

kW).

• Section 8.4 when combination of appliances has total

input exceeding 400 Mbh (120 kW).

• Refer to Natural Gas and Propane Installation Code

for specifi c air supply requirements for enclosure

or structure where boiler is installed, including air

supply openings and ducts.

Table 3 - Ventilation & Combustion Air

Input Mbh

Standard

Method

50 2500 10500 5250 3500 2625 2100 1750

75 3750 15750 7875 5250 3938 3150 2625

100 5000 21000 10500 7000 5250 4200 3500

125 6250 26250 13125 8750 6563 5250 4375

150 7500 31500 15750 10500 7875 6300 5250

170 8500 35700 17850 11900 8925 7140 5950

200 10000 42000 21000 14000 10500 8400 7000

Known Air Infi ltration Rate Method ACH (Air Changes Per Hour)

0.1 0.2 0.3 0.4 0.5 0.6

6

Page 7

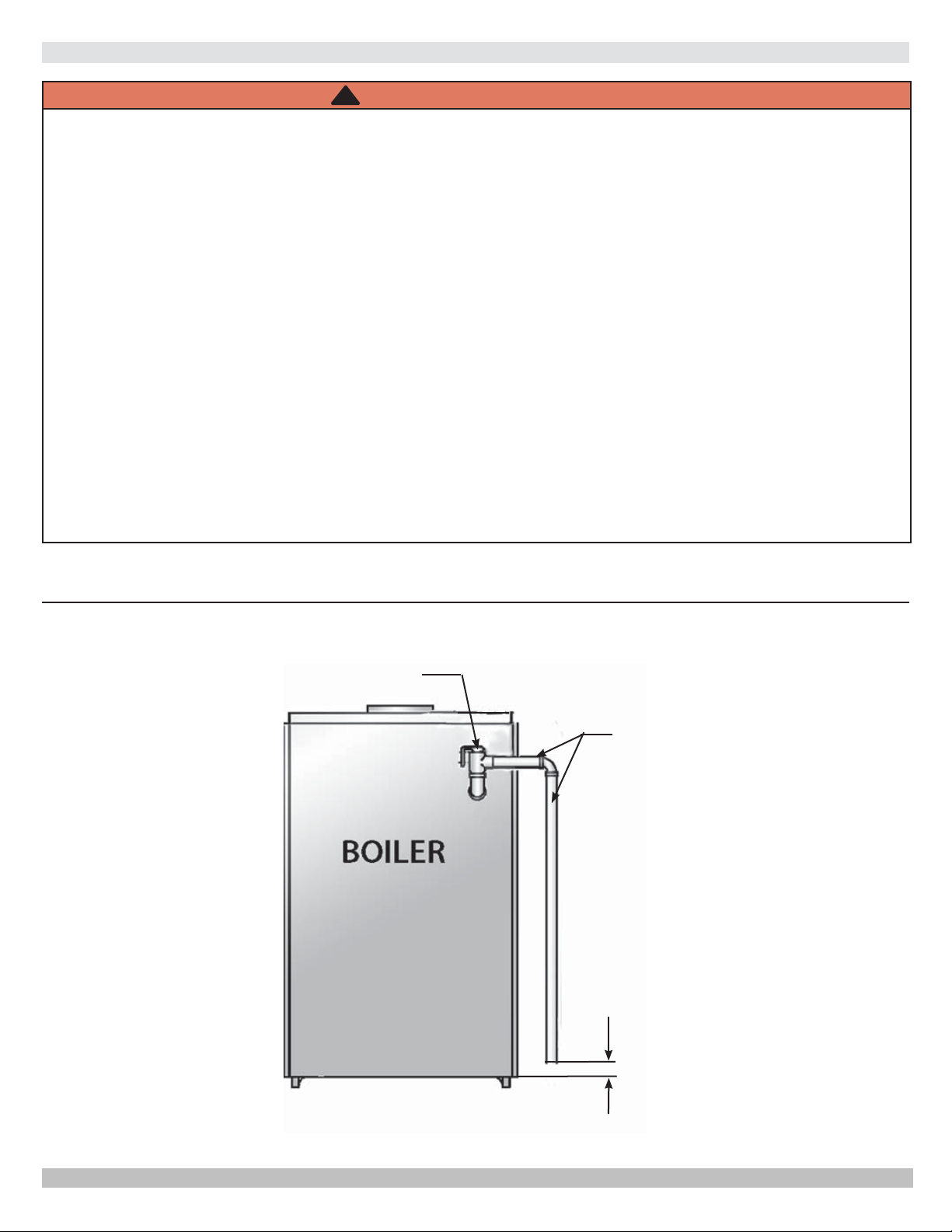

6 - SUPPLY AND RETURN PIPING

!

WARNING

Burn or Scald Hazard. Discharge line shall be installed to relief valve outlet connection to avoid burns,

scalding, or water damage due to discharge of steam and/or hot water during operation.

Discharge line shall:

• Connect to relief valve outlet and piped down to safe point of disposal. Check local codes for maximum

distance from fl oor or allowable safe point of discharge.

• Be of pipe size equal to or greater than that of the relief valve outlet over the entire length of discharge

line.

• Have no intervening shutoff valve between safety relief valve and discharge to atmosphere (do not plug

or place any obstruction in discharge line.

• Terminate freely to atmosphere where any discharge will be clearly visible and at no risk of freezing.

• Allow complete drainage of the valve and the discharge line.

• Be independently supported and securely anchored to avoid applied stress on the relief valve.

• Be as short and straight as possible.

• Terminate with plain end (not threaded).

• Be constructed of material suitable for exposure to temperatures of 375°F (191°C); or greater.

Refer to local codes and appropriate ASME Boiler and Pressure Vessel Code for additional installation

requirements.

Figure 3 - Safety Relief Valve

RELIEF VALVE

DISCHARGE

LINE

Check local

codes for

maximum

distance

from fl oor

or allowable

safe point of

discharge.

7

Page 8

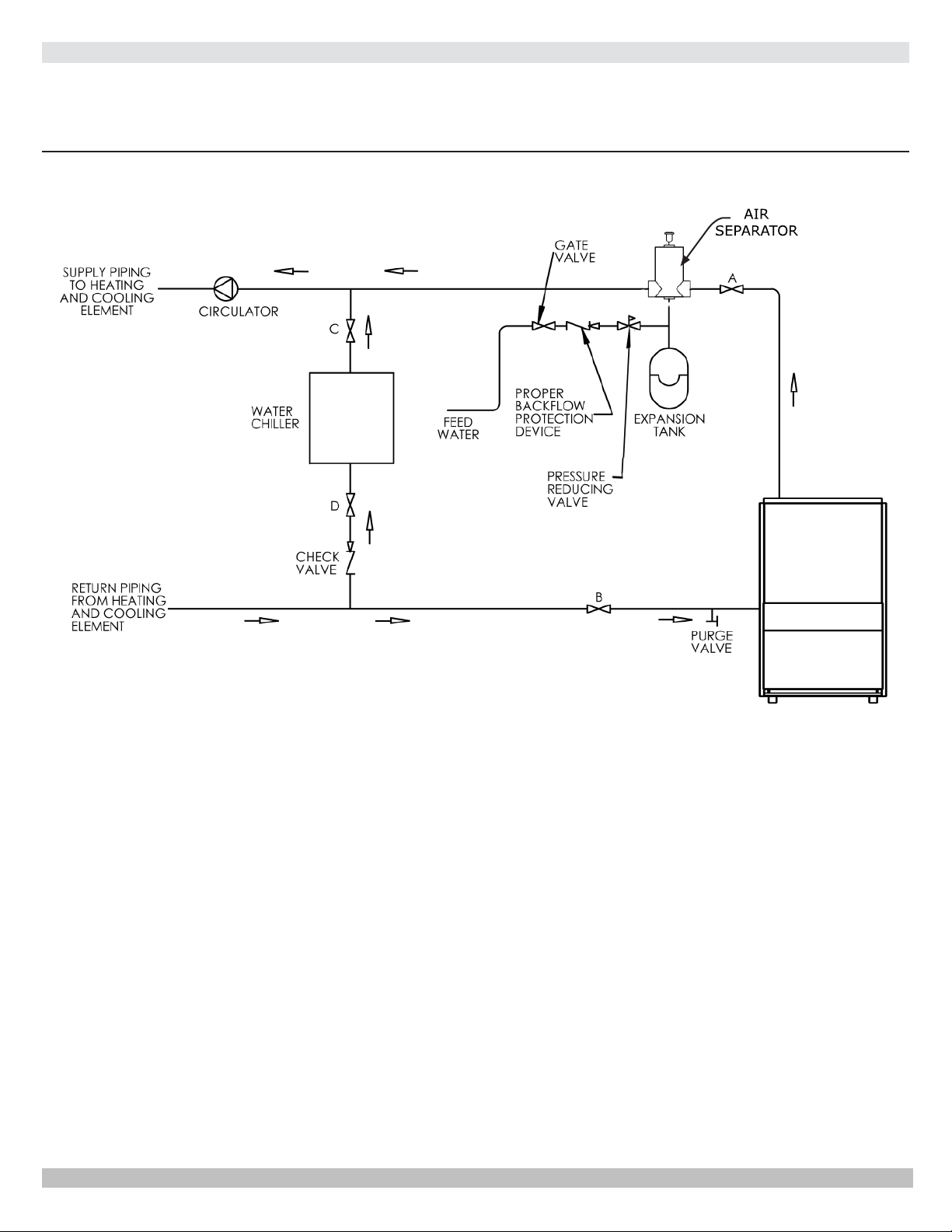

6 - SUPPLY AND RETURN PIPING

IMPORTANT: Circulators in the following illustrations are mounted on the system supply side, but

mounting on the system return side is also acceptable practice.

Figure 4 - Circulators Mounted on Supply System, Boiler Used In Confi guration to Chiller System.

See Special Conditions, Page 9

1.

Boiler, used in connection with a refrigeration system,

must be installed so chilled medium is piped in parallel

with boiler with appropriate valves to prevent chilled

medium from entering boiler. See Figure 4 .

2.

Boiler piping system of hot water boiler connected to

heating coils located in air handling units where they

may be exposed to refrigerated air circulation must be

equipped with fl ow control valves or other automatic

means to prevent gravity circulation of boiler water

during cooling cycle.

3.

Hot water boilers installed above radiation level or

as required by authority having jurisdiction must be

provided with a low water cut-off device.

4.

When a boiler is connected to a heating system that

utilizes multiple zoned circulators, each circulator must

be supplied with a fl ow control valve to prevent gravity

circulation.

5.

Hot water boilers and system must be fi lled with water

and maintained to a minimum pressure of 12 psi.

6.

Bypass piping is an option which gives the ability to

adjust the supply boiler water temperature to fi t the

system or the condition of the installation. This method

of piping, however, is not typically required for baseboard heating systems. Typical installations where

bypass piping is used are as follows:

A. This method is used to protect boilers from con-

densation forming due to low temperature return

water. Generally noticed in large converted gravity systems or other large water volume systems.

Figure 5 & 6, Page 9.

B. These methods are used to protect systems using

radiant panels and the material they are encased in

from high temperature supply water from the boiler

and protect the boiler from condensation.

NOTE#1: When using bypass piping, adjust

valves V1 & V2 until desired system temperature

is obtained.

NOTE#2: Bypass loop must be same size piping

as the supply and return piping.

8

Page 9

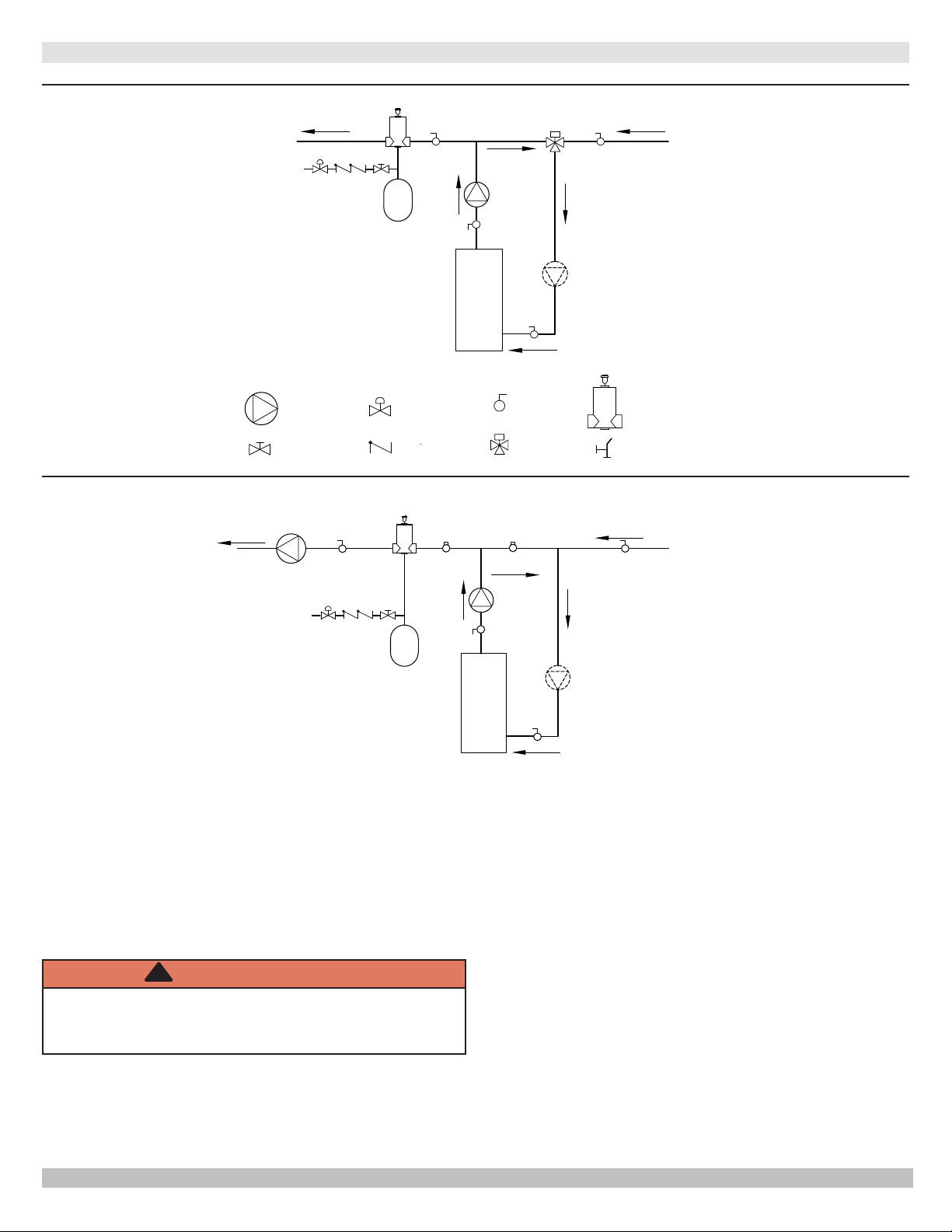

6 - SUPPLY AND RETURN PIPING

Figure 5 - Bypass Piping Automatic Mixing Valve

TO SYSTEM

WATER INLET

EXPANSION

TANK

FROM SYSTEM

CIRCULATOR

SHUT-OFF

VALVE

PRESSURE

REDUCER VALVE

CHECK VALVE

BOILER

BALL VALVE

3 WAY MIXING

VALVE

ALTERNATE

CIRCULATOR

LOCATION

AIR SEPARATOR

HOSE BIB

Figure 6 - Bypass Piping - Fixed Low Temp Only Manual Mixing Valve

TO SYSTEM

WATER INLET

SYSTEM

CIRCULATOR

EXPANSION

TANK

V2V1

BOILER

FROM SYSTEM

ALTERNATE

CIRCULATOR

LOCATION

7. Installation using circulators and zone valves are

shown in Figure 7, 8, 9 and 10 Pages 10, and 11. For

further piping information refer to AHRI Installation

and Piping Guide.

!

WARNING

Burn and scald hazard. Safety relief valve could

discharge steam or hot water during operation.

Install discharge piping per these instructions.

8. Install discharge piping from safety relief valve. See

Warning, Page 7.

9

Page 10

6 - SUPPLY AND RETURN PIPING

Figure 7 - Single Zone System With DHW Priority

Figure 8 - Multi Zone System With Circulators And DHW Priority

10

Page 11

6 - SUPPLY AND RETURN PIPING

Figure 9 - Multi Zone System With Zone Valves And DHW Priority (With Circulator)

Figure 10 - Multi Zone System With Zone Valves And DHW Priority (With Zone Valve)

11

Page 12

7 - VENT INSTALLATION

WARNING

!

Boiler and venting installations shall be performed

by a qualifi ed expert and in accordance with the

appropriate manual. Installing or venting boiler

or other gas appliance with improper methods or

materials may result in serious injury or death due

to fi re or to asphyxiation from poisonous gases such

as carbon monoxide with is odorless and invisible.

!

WARNING

Do not connect boiler to any portion of mechanical

draft system operating under positive pressure.

1.

The vent pipe must slope upward from the boiler not

less then ¼ inch for every 1 foot (21mm/m) to vent

terminal.

2.

Horizontal portions of the venting system shall be

supported rigidly every 5 feet and at the elbows. No

portion of the vent pipe should have any dips or sags.

3.

This boiler series is classifi ed as a Category I. Vent

installation shall be in accordance with "Venting of

Equipment," of the National Fuel Gas Code, ANSI

Z223.1/NFPA 54, or applicable provisions of the local

building codes.

4.

Inspect chimney to make certain it is constructed

according to NFPA 211. The vent or vent connector

shall be Type B or metal pipe having resistance to heat

and corrosion not less than that of galvanized sheet

steel or aluminum not less than 0.016 inch thick (No.

28 Ga).

5.

Connect fl ue pipe from draft hood to chimney. Bolt or

screw joints together to avoid sags. Flue pipe should

not extend beyond inside wall of chimney. Do not

install manual damper in fl ue pipe or reduce size of

fl ue outlet except as provided by the latest revision of

ANSI Z223.13.. Protect combustible ceiling and walls

near fl ue pipe with fi reproof insulation. Where two or

more appliances vent into a common fl ue, the area of

the common fl ue must be at least equal to the area

of the largest fl ue plus 50 percent of the area of each

additional fl ue.

8 - VENT SYSTEM MODIFICATION

When an existing boiler is removed from a common

venting system, the system is likely to be too large for the

proper venting of the appliances sill connected to it. If

this situation occurs, the following test procedure must be

followed:

REMOVAL OF BOILER FROM VENTING SYSTEM

At the time of removal of an existing boiler, the following

steps shall be followed with each appliance remaining

connected to the common venting system placed in

operation, while the other appliances remaining connected

to the common venting system are not in operation.

1.

Seal an unused opening in the common venting

system.

2.

Visually inspect the venting system for proper size and

horizontal pitch and determine there is no blockage or

restriction, leakage, corrosion and other defi ciencies

which could cause an unsafe condition.

3.

Insofar as is practical, close all building doors and

windows and all doors between the space in which the

appliances remaining connected to the common venting

system are located and other spaces of the building.

Turn on clothes dryers and any other appliance not

connected to the common venting system. Turn on

any exhaust fans, such as range hoods and bathroom

exhausts, so they operate at maximum speed. Do

not operate a summer exhaust fan. Close fi replace

dampers.

4.

5.

6.

7.

Place in operation the appliance being inspected. Follow

the lighting instructions. Adjust thermostat so appliance

will operate continuously.

Test for spillage at the draft hood relief opening after

5 minutes of main burner operation. Use the fl ame of

a match or candle, or smoke from a cigarette, cigar or

pipe.

After it has been determined that each appliance

remaining connected to a common venting system

properly vents when tested as outlined above, return

doors, windows, exhaust fans, fi replace dampers and

any other gas burning appliances to their previous

condition of use.

Any improper operation of the common venting system

should be corrected so the installation conforms with

the National Fuel gas Code, ANSI Z223.1/NFPA 54.

When re-sizing any portion of the common venting

system, the common venting system should be re-sized

to approach the minimum size determined using the

appropriate tables in Chapter 13 of the National Fuel

Gas Code, ANSI Z223.1/NFPA 54.

12

Page 13

9 - VENT DAMPER INSTALLATION & INSTRUCTIONS

DAMPER INSTALLATION

NOTE: Refer to Figure 10 for steps 1-6.

Figure 11 - Damper Motor Wiring

Vent Damper

Vent Outlet

DAMPER INSTRUCTIONS

Figure 12 - Vent Damper Placement

Damper Motor

1.

Place vent damper on or as close to vent outlet of

boiler as possible. See Figure 12 .

2.

Remove vent damper motor cover.

3.

Feed damper wire harness connector through bracket

hole on damper motor frame.

4.

Tighten locknut onto damper wire harness connector.

5.

Plug damper connector into socket on damper motor

frame.

6.

Replace damper motor cover and wire damper. See

Figure 11 .

1.

Verify only boiler is serviced by vent damper. See

Figure 12 .

2.

Clearance of not less than 6 inches between vent

damper and combustible material must be maintained.

Additional clearance should be allowed for service of

vent damper.

3.

Vent damper must be in the open position when

appliance main burners are operating.

4.

Vent damper position indicator must be in a visible

location following installation.

5.

The thermostat's heat anticipator must be adjusted to

match the total current draw of all controls associated

with boiler during heating cycle.

13

Page 14

10 - CONNECTING GAS SERVICE

!

!

CAUTION

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use

any phone in your building.

• Immediately call your gas supplier from a

neighbor’s phone. Follow gas supplier’s

instructions.

• If you cannot reach your gas supplier, call the fi re

department.

Figure 13 - Gas Piping

General

• Use piping materials and joining methods acceptable

to authority having jurisdiction. In absence of such

requirements of National Fuel gas Code, ANSI Z223.1/

NFPA 54

• Size and install gas piping system to provide suffi cient

gas supply to meet maximum input at not less than

minimum supply pressure. See Table 5 .

• Support piping with hooks straps, bands, brackets,

hangers, or building structure components to prevent or

dampen excessive vibrations and prevent strain on gas

connection. Boiler will not support piping weight.

• Use thread (joint) compound (pipe dope) suitable for

liquefi ed petroleum gas.

• Install fi eld sourced manual main shutoff valve, ground

joint union, and sediment trap upstream of gas valve.

See Figure 13 .

Table 5 - Gas Pressure

Natural Gas Propane

Min. Supply Pressure 5" w.c. 11" w.c.

Max. Supply Pressure 13.5" w.c. 13.5" w.c.

Manifold Pressure 3.5" w.c. 10.5" w.c.

MAXIMUM CAPACITY OF PIPE IN CUBIC FEET OF GAS/HOUR

(Gas Pressure = 0.5 psig or less, Pressure Drop = 5 in. w/c)

Table 4 - Pipe Sizes

Length of

Pipe (Feet)

10 175 360 680 1400

20 120 250 465 950

30 97 200 375 770

40 82 170 320 660

60 66 138 260 530

80 57 118 220 460

100 50 103 195 400

For additional information refer to the National Fuel Gas

Code Handbook.

Nominal Iron Pipe Size

½” ¾” 1” 1¼”

!

DANGER

Fire Hazard. Do not use matches, candles, open

fl ames, or other methods providing ignition source.

Failure to comply will result in death or serious

injury.

Leak Check Gas Piping

Pressure test boiler and gas connection before placing

boiler in operation.

•

Pressure test over 1/2 psig (3.5 kPa). Disconnect

boiler and its individual gas shutoff valve from gas

supply system.

•

Pressure test at 1/2 psig (3.5 kPa) or less. Isolate

boiler from gas supply system by closing manual gas

shutoff valve.

•

Locate leakage using gas detector, noncorrosive

detection fl uid, or other leak detection method

acceptable to authority having jurisdiction. Do not

use matches, candles, open fl ames, or other methods

providing ignition source.

•

Correct leaks immediately and retest.

14

Page 15

11 - ELECTRICAL SECTION

!

WARNING

Electrical shock hazard. Turn OFF electrical power

supply at service panel before making electrical

connections. Failure to do so could result in death

or serious injury.

Electrical Wiring

See wiring diagrams on the following two pages for

details.

Electrically bond boiler to ground in accordance with

requirements of authority having jurisdiction. Refer to

National Electrical Code, ANSI/NFPA 70.

Thermostat Installation

1.

Thermostat should be installed on an inside wall about

four feet above the fl oor.

2.

NEVER install a thermostat on an outside wall.

3.

Do not install a thermostat where it will be affected

by drafts, hot or cold pipes, sunlight, lighting fi xtures,

televisions, a fi replace, or a chimney.

4.

Check thermostat operation by raising and lowering

thermostat setting as required to start and stop the

burners.

5.

Instructions for the fi nal adjustment of the thermostat

are packaged with the thermostat (adjusting heating

anticipator, calibration, etc.)

15

Page 16

12 - WIRING DIAGRAM - INTERMITTENT IGNITION

Figure 14 - Intermittent Electronic Ignition Control (240009076)

!

WARNING

Modifi cation, substitution or elimination of factory

equipped, supplied or specifi ed components may

result in personal injury or loss of life.

16

Page 17

12 - WIRING DIAGRAM - INTERMITTENT IGNITION

Figure 15 - Intermittent Electronic Ignition Control (240009076)

17

Page 18

!

13 - LIGHTING INSTRUCTIONS

!

WARNING

If you do not follow these instructions

exactly, a fi re or explosion may result

causing property damage, personal injury

or loss of life.

• This appliance is equipped with an ignition device

which automatically lights burner. Do NOT try to

light this burner by hand.

• Before operating smell all around appliance area

for gas. Be sure to smell next to fl oor because

some gas is heavier than air and will settle to the

fl oor.

• Use only your hand to turn the gas shutoff

valve. Never use tools. If valve will not turn by

hand, do not try to repair it, call a qualifi ed ser-

vice technician. Force or attempted repair may

result in fi re or explosion.

• Do not use this appliance if any part has

been under water. Immediately call a quali-

fi ed service technician to inspect appliance and to

replace any part of control system and any gas

control which has been under water.

OPERATING INSTRUCTIONS FOR INTERMITTENT

PILOT SYSTEM

1.

STOP! Read the safety information to the left.

2.

Set the thermostat to lowest setting.

3.

Turn off all electric power to the appliance.

4.

This appliance is equipped with an ignition device which

automatically lights the pilot. Do not try to light the

pilot by hand.

Figure 16 - Intermittent Pilot

NOTICE

Before lighting any type of pilot burner (standing or

intermittent), verify the hot water boiler and system

are full of water to minimum pressure of 12 psi in

the system, also verify system is vented of air. Set

operating control of thermostat to “below” normal

setting. Refer to following appropriate lighting

instruction.

LIGHTING PROCEDURE FOR BOILER WITH

INTERMITTENT PILOT SYSTEM

For Your Safety, Read Before Operating!!

A. This appliance is equipped with an ignition device

which automatically lights the pilot. Do not try to light

appliance by hand.

!

CAUTION

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switches; do not use

any phone in your building.

5.

Turn gas control knob clockwise to “OFF.”

6.

Wait (5) minutes to clear out any gas. If you then smell

gas, STOP! Follow “What To Do If You Smell Gas” in the

safety information to the left. If you don’t smell gas, go

on to the next step.

7.

Turn gas control knob counterclockwise to “ON.”

8.

Turn on all electric power to the appliance.

9.

Set thermostat to desired setting.

10.

If the appliance will not operate, follow the instructions

“

To Turn Off Gas To Appliance

service technician or your gas supplier.

TO TURN OFF GAS TO THE APPLIANCE

1.

Set the thermostat to lowest setting.

2.

Turn off all electric power to the appliance if service is

to be performed.

3.

Push in gas control knob slightly and turn clockwise

to "OFF." DO NOT FORCE.

4.

Call qualifi ed service technician.

” , and call qualifi ed

• Immediately call your gas supplier from a

neighbor’s phone. Follow the gas supplier’s

instructions.

• If you cannot reach your gas supplier, call the fi re

department.

18

Page 19

14 - SEQUENCE OF OPERATION

Thermostat actuates on call for heat,

completing circuit to control. Completed

circuit to control will fi rst activate circulator

and damper which will close end switch inside

damper. Completes circuit to ignition system,

ignition takes place.

In event boiler water temperature exceeds

high limit setting on boiler mounted high limit

control, power is interrupted between control

system and ignition system. Power remains

off until boiler water temperature drops below

high limit setting. Circulator continues to

operate under this condition until thermostat is

satisfi ed.

In event fl ow of combustion products through

boiler venting system becomes blocked, blocked

vent safety switch shuts main burner gas off.

Similarly, if boiler fl ue-way becomes blocked,

fl ame rollout safety switch shuts main burner

gas off. See Figure 17 . If either of these

conditions occur, do not attempt to place boiler

back into operation. Contact certifi ed service

agency.

Integral Draft

Hood

Burner

Door

Burners

Orifi ces

Figure 17 - Blocked Vent Safety Switch, Roll-

out Safety Switch

Blocked Vent

Safety Switch

Rollout Switch

4 Section Boiler

Rollout Switch

2,3,5

Section Boiler

Manifold

Base

Jacket Base

Panel

15 - GENERAL INSTRUCTIONS

Before seasonal start-up, have a certifi ed service agency

check boiler for soot and scale in fl ues, clean burners and

check gas input rate to maintain high operating effi ciency.

!

WARNING

This procedure should be followed to clean fl ue gas

passageways:

1.

Label all wires prior to disconnection when servicing

controls. Wiring errors could cause improper and

dangerous operation.

Verify proper operation after servicing

Service agency will verify system is fi lled with water to

minimum pressure and open air vents, if used, to expel any

air accumulated in the system. Check entire piping system

and, if any leaks appear, have them repaired.

Circulators need to be checked and maintained.

Refer to circulator manufacturer's instructions.

Inspect venting system at the start of each heating

season. Check vent pipe from boiler to chimney for signs of

deterioration by rust or sagging joints. Repair if necessary.

Remove vent pipe at base of chimney or fl ue and using a

mirror, check vent for obstruction and verify vent is in good

working order.

Boiler fl ue gas passageways may be inspected by a light

and mirror. Remove burner door. See

Place trouble lamp in fl ue collector through draft relief

opening. With mirror positioned above burners, fl ue gas

passageways can be checked for soot or scale.

Figure 20, Page 20

2.

3.

4.

5.

6.

When cleaning process is complete, restore boiler

components to their original position. Use IS-808 GE

silicone (available from distributor) to seal around fl ue

collector and boiler castings.

.

Remove burners from combustion chamber by raising

burners up from manifold orifi ces and pulling toward

front of boiler. See

Disconnect vent pipe from draft hood.

Remove top jacket panel.

Remove combination fl ue collector and draft hood from

boiler castings by loosening nuts on hold down bolts

located on each side of collector. See

Place sheet of heavy paper or similar material over

bottom of base and brush down fl ue passageways. Soot

and scale will collect on paper and is easily removed

with the paper.

With paper still in place in base, clean top of boiler

castings of boiler putty or silicone used to seal between

castings and fl ue collector. Verify chips are not lodged

in fl ue passageways.

Figure 17

.

Figure 17 .

19

Page 20

15 - GENERAL INSTRUCTIONS

Make visual check of main burner and pilot fl ames at start

of heating season and again in mid-season. Main burner

Figure 20 - Combustion Chamber

fl ame should have well defi ned inner blue mantel with

lighter blue outer mantel. Check burner throats and burner

orifi ces for lint or dust obstruction.

See Figures 17 and 19

BURNERS

.

Figure 18 - Gas Burner Flame

Pilot fl ame should envelop ⅜ to ½ inch of tip of pilot

Figure 19 - Gas Burner Pilot

thermocouple, ignition/sensing electrode or mercury

sensor. See

GAS VALVE

ORIFICES

Figure 19 .

To adjust pilot fl ame, remove pilot adjustment cover screw

and turn inner adjustment screw counterclockwise to

increase or clockwise to decrease pilot fl ame.

Be sure to replace cover screw after adjustment to prevent

possible gas leakage. See Figure 14, Page 16 .

Burners and pilot should be checked for signs of corrosion,

rust or scale buildup.

Area around boiler must be kept clear and free of

combustible materials, gasoline and other fl ammable

vapors and liquids.

Free fl ow of combustion and ventilating air to boiler and

boiler room must not be restricted or blocked.

Inspect fi eld sourced low water cutoffs annually, or as

recommended by low water cutoff manufacturer. Flush

fl oat type low water cutoffs per manufacturer's instructions.

Employ a qualifi ed service agency to make annual

inspection of boiler and heating system. They are

experienced in making the inspections outlined above,

and, in event repairs or corrections are necessary, trained

technicians can make the proper changes for safe operation

of the boiler.

20

Page 21

16 - CHECKING GAS INPUT RATE TO BOILER

ce

cess G

O

rating Control

ated I

de

ler

• Adjust gas input to boiler by removing protective cap on

pressure regulator

increase input and counterclockwise

,

and turning screw clockwise to

to decrease

input.

• Manifold pressures are taken at outlet side of gas

valve.

• To check for proper fl ow of natural gas to boiler, divide

input rate shown on rating plate by heating value of

gas obtained from local gas company. This determines

number of cubic feet of gas required per hour.

• With all other gas appliances off, determine fl ow of gas

through meter for two minutes and multiply by 30 to

get hourly rate.

• Make minor adjustments to gas input as described

above.

• Change burner orifi ces if fi nal manifold pressure

Burner Access

varies more than plus or minus 0.3 inches water

column from specifi ed pressure.

• Primary air adjustment is not necessary, therefore

air shutters are not furnished as standard

equipment.

Figure 21 - High Limit Control Location

High Limit and

Operating Control

Located Inside Boiler

Door

nsi

Boi

• Air shutters can be furnished on request where

required by local codes or conditions.

CHECK SAFETY CONTROL CIRCUIT. Test ignition

system safety shutoff device after placing boiler in

operation.

1.

Pilot: With main burner operating, turn pilot gas

adjusting screw clockwise until pilot gas is

turned off. Within 90 seconds main gas control closes,

shutting off gas to main burner.

2.

High Limit Control: Remove cover and note

temperature setting. Decrease this setting to minimum

and operate boiler. When the boiler water temperature

exceeds the control temperature setting, the control

will open the circuit, closing the automatic main gas

valve. See Figure 21 .

Gas Valve

21

Page 22

17 - OPERATING THE BOILER - SETTING THE CONTROL

Wiring An Indirect Water Heater

SETTING

When installing with indirect water heater, signal from

indirect must be separated from heating zone signals and

wired appropriately.

If you choose not to separate indirect signal from heating

zones, Economy Feature should be turned off to insure

boiler supplies adequate temperature to heat the indirect

tank.

Setting The Control

Settings can be checked using the TEST/SETTINGS Button.

See page 23 for details.

Setting The High Limit

The high limit is factory set at 190°F. To adjust, turn

HI TEMP dial A until desired setting is displayed.

(Setting range: 130°F - 220°F)

Setting The Low Limit

Low limit is designed to maintain temperature in boiler

suitable for domestic hot water. Low limit is factory set to

OFF. Prior to adjusting, remove the jumper (not equipped

on all units) B.

Then turn LO Temp dial C clockwise until desired

temperature is displayed. For Proper operation, low

temperature limit setting should be at least 10° below high

Temperature

Limit Setting

(130°-220°F)

Factory 190°F

Economy Dial

1,2,3,4,5,HI)

limit setting. For cold start operation, low limit must be

turned OFF. If low limit temperature cannot be set above

140°F, remove jumper B. (Setting range: OFF or 110°-

200°F).

Dynamic Display

Setting The Economy Feature

Economy Feature is factory set for 1 zone heating

system. To adjust, turn the ECONOMY dial D until the

number displayed equals the number of heating zones.

The Economy Feature conserves fuel by reducing boiler

temperature. If heating system is unable to supply needed

heat to the house, Economy dial should be turned to lower

setting (example: In a three zone house, turn dial to 2 or

1). Conversely, if boiler provides adequate heat, added

fuel savings can be achieved by selecting a higher setting

(example: 4 or 5). If heating and indirect water heater

signals were not separated when wiring control, Economy

Feature should be turned OFF to insure boiler supplies

adequate temperature to heat the indirect tank.

Activation Thermal Pre-Purge (Optional)

Activation of this feature is not recommended for boiler

supplying domestic hot water.

Fuel Smart HydroStat has a Thermal Pre-Purge feature to

maximize effi ciency. When activated, control will purge

higher boiler temperatures down to 135°F at start of any

thermostat call and supply the latent energy in the boiler

to the heating zone that is calling. During the purge cycle,

the display will indicate Pur. If the heat is not suffi cient to

satisfy the thermostat, control will energize burner. Feature

works with single and multi-zone heating systems utilizing

circulators or zone valves. No change in wiring is needed.

To Activate Thermal Pre-Purge

Push and hold the TEST/SETTINGS button for 20 seconds.

Display will read Pur On. To deactivate this feature, push

and hold button a second time for 20 seconds. Display will

read Pur OFF.

Disables economy function. Will allow boiler to fi re

OFF

LO

1

2

3

4

5

HI

High

(OFF or LO,

Jumper

Temperature

and Real Time

Verifi cation

of Setting

Adjustments.

until hi-limit temp is reached and re-fi re with a 10°

subtractive differential.

Provides lowest level of fuel savings. Use this setting only if the house does not stay warm at higher

settings.

Recommended setting for single zone systems.

Recommended setting for Two zone systems.

Recommended setting for Three zone systems.

Recommended setting for Four zone systems.

Recommended setting for Five zone systems.

Provides highest level of fuel savings.

B

Water

Decimal Point

(Indicates heat call)

Differentials

are automatic

and will vary

based on

control settings

and boiler

temperature

Low

Temperature

Limit Setting

(OFF or 110°-

200°F) Factory

Off

Diagnostic LEDs

and Test Buttton

22

Page 23

17 - OPERATING THE BOILER - SYSTEM START-UP

System Start-up

At initial start-up, with Economy feature active, control

establishes 145°F target temperature. To test the high

limit shut-off function, Economy Dial must be turned to

OFF. Once tested, restore the Economy setting. If heating

demand is high, target will increase over time to satisfy

heat load. to reduce potential for condensing, control

will allow boiler to heat to 120°F prior to energizing the

circulator.

How Thermal Targeting Works

Thermal targeting technology analyzes thermostat activity

and continually evaluates how much heat the house

requires. When it is very cold outside, heat demand is

high and Fuel Smart HydroStat will raise boiler's target

temperature to provide needed heat to the home. When

outside temperature is milder, heat demand is lower. During

these periods, Fuel smart HydroStat will lower boiler's

target temperature saving fuel while continuing to provide

comfort to the house.

LED Legend

TARGET/HI LIMIT

Illuminates when boiler temperature has reached target

temperature or high limit setting. When economy feature

is active, the control utilizes thermal targeting technology

to operate boiler at reduced target temperatures (during

off-peak demand) or at high limit setting (during peak

demand). When boiler water temperature reaches the

target or high limit temperature, LED illuminates and

burner shuts down. Boil water continues to circulate and

heat the house as long as thermostat call continues.

The LED will stay lit until boiler temperature drops to

predetermined differential. The LED illuminates regularly

during normal operation.

BURNER

Illuminates whenever the burner is running (B1 is

powered).

Test/Settings Button

To test low water cut-off: Press and hold TEST/SETTINGS

button for 5 seconds. Display will read LCO.

LOW WATER

Illuminates if boiler is in a low water condition. Control will

prevent burner operation during this condition.

NOTICE

System must be checked by a qualifi ed heating

professional prior to resuming operation.

WARNING

!

Burn and scald hazard. Do not add water until boiler

has fully cooled. Failure to follow these instructions

could result in death or serious injury.

T-STAT

Illuminates whenever there is a call for heat from any

thermostat, zone device or indirect.

The red Low Water light should illuminate and burner circuit

(B1 and B2) should energize.

To View Current Settings: Press and release the TEST/

SETTINGS button in short intervals to sequentially display

following settings:

The display will return to boiler temperature (default) if

TEST/SETTINGS button is not pressed for 5 seconds.

23

Page 24

17 - OPERATING THE BOILER - LIMIT CONTROL TROUBLESHOOTING

Fahrenheit/Celsius Change

Control has the ability to operate in degrees Fahrenheit

(default setting) or Celsius.

To change from Fahrenheit to Celsius:

1.

Set low limit to 112°F

2.

Set high limit to 112°F

3.

Display will delay 2 seconds and then display an "F".

4.

Push the LWCO Test Button to change setting to "C".

5.

Reset the limit dials to the correct settings.

When control is in Celsius mode, a "c" appears in

temperature display as third digit whenever temperature is

below 100°C.

WARNING

!

Burn and scald hazard. Do not add water until boiler

has fully cooled. Failure to follow these instructions

could result in death or serious injury.

Table 6 - LIMIT CONTROL TROUBLESHOOTING

Temperature Display Exceeds

High Limit Setting

No Domestic Hot Water from

Tankless Coil

Boiler will Not Maintain Low

Limit Temperature

Under normal operation, boiler temperature continues to rise after control shuts off the

burner. This condition, known as "thermal stacking", results from hot boiler surfaces

continuing to release heat into the boiler.

Make sure low limit setting on Control is properly set.

If low limit setting is dialed fully counter clockwise, it shuts off the low temperature

maintenance feature.

Check for overlapping high temperature setting. If high limit setting is below low limit

setting, control will default to high limit setting.

To change from Celsius to Fahrenheit:

1.

Set low limit to 44°C.

2.

Set high limit to 44°C.

3.

Display will delay 2 seconds and then display a "c".

4.

Push the LWCO test button to change settings to "F".

5.

Re-set limit dials to correct settings.

Temperature Display Differs

from Boiler Temperature

Pressure Gauge Temperature

Reading

TSTAT Light (Green LED) is

Not On

Low Water Light (RED LED)

is On

Temperature variances can result from differing water temperatures within the boiler or

different reaction times of the two devices. If the control temperature is signifi cantly below

the temperature pressure gauge temperature, make sure the thermistor is inserted all the

way to the end of the well. DO NOT USE ANY HEAT TRANSFER PASTE OR GREASE.

The TSTAT light indicates when there is a call for heat. If a call is known to be present and

this light is on, check the wiring to the T-T terminals.

READ WARNING ABOVE. Low water condition is a serious and potentially dangerous

condition. Do not attempt to add water to a hot boiler. Allow boiler to fully cool before

adding water.

1.

If heating system is fi lled with water, pull sensor out of well and inspect it. Verify the

metal clip on the sensor is intact. This metal clip must be in contact with the inside of

the copper well in order for control to sense presence of water. Check well does not

have excessive build-up of heat transfer grease that may interfere with clip contacting

well.

2.

Remove well and examine for excessive residue build-up. Clean and re-install.

24

Page 25

18 - SYSTEM TROUBLESHOOTING

TABLE 7 - SYSTEM TROUBLESHOOTING

If installed with indirect water heater, insure end switch in relay box

No Or Insuffi cient Domestic

Hot Water

House Will Not Get Or Stay

Warm

controlling indirect water heater is properly connected to cable 2 (see

wiring diagram). This insures domestic water calls are prioritized. If cable

2 is not used, turn Economy Feature OFF.

1.

Check for air bond radiators.

2.

Check thermostat settings including het anticipator settings (common

on non-digital thermostats).

3.

Check Economy settings. Economy feature, much like outdoor reset

controls, lowers average boiler temperature, can slow or prevent

house from coming up to temperature. Move to lower setting.

25

Page 26

NOTES

Page 27

Date Service Performed Company Name & Tech Initials Company Address & Phone #

Page 28

DUNKIRK BOILERS

2201 Dwyer Avenue, Utica NY 13501

web site: www.ecrinternational.com

Loading...

Loading...