Dunkirk DXL-200 User Manual

CONVERSION KIT INSTRUCTIONS

NA TU RAL DRAFT CAST IRON SERIES II

GAS FIRED BOILERS FOR FOR CED HOT W ATER

NA TU RAL GAS TO LP CONVERSION

MGB/OMGB/MCB/D XL S IZES THR OUGH 200 MB TU

Kit #'s 55000 2 66 3 , 5 50002664, 5 50002665

WARNING

!

Conversion kit shall be installed by qualifi ed service

agency in accordance with manufacturer's instructions

and all applicable codes and requirements of authority

having jurisdiction. If information in these instructions

is not followed exactly, a fi re, explosion or production

of carbon monoxide may result causing personal injury

or loss of life. Qualifi ed service agency is responsible

for proper installation of this kit. Installation is not

proper and complete until operation of converted

appliance is checked as specifi ed in manufacturer's

instructions supplied with the kit.

Tools Required

• Flat Head Screwdriver

• 1/4” Nut Driver

• 7/16” Open Ended Wrench

• 3/16” Allen Wrench

• 18” Manometer (or dial manometer)

TABLE 1 - Kit # 550002663 550002664 550002665

Model

DESCRIPTION

Pilot Orifi ce - Spark PB00208 (1)

Orifi ce # 47 (4) # 50 (2) # 49 (4)

Label, "Nat to LP"

Conversion Plate

Liquid Sealing

Compound

Spring Kit 1272030 (1)

Instructions 240009725 (1)

50/100/

150/200

PART #

(QTY)

75 125/170

PART #

(QTY)

240004822 (1)

140010 (1)

PART #

(QTY)

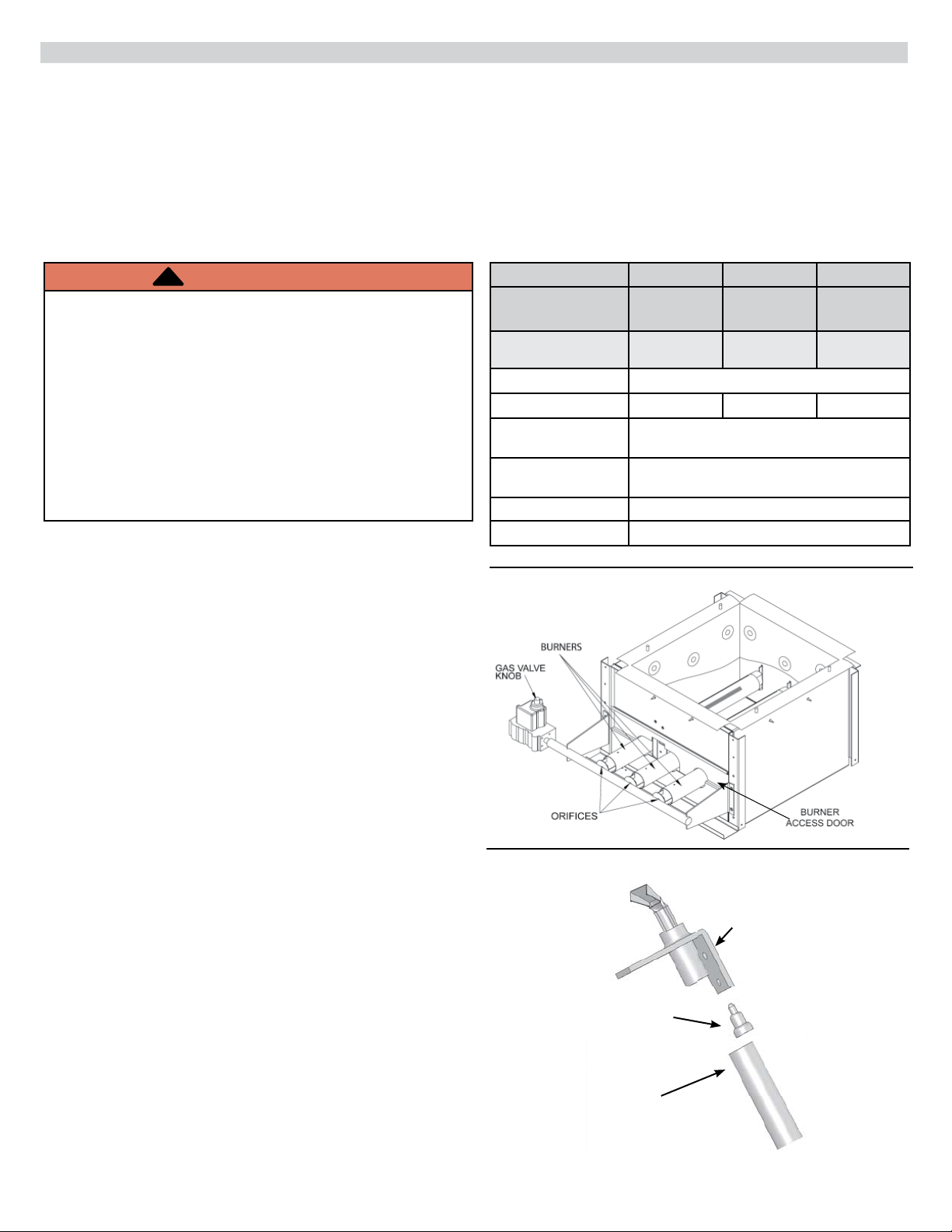

Figure 1 - Burners Assembly

Converting Boiler From Natural Gas To Propane (LP):

1.

Follow instruction TO TURN OFF GAS TO APPLIANCE.

Verify electrical power is OFF.

2.

Remove front panel.

3.

Remove burner access door.

4.

Remove main gas burner tubes. See Figure 1.

5.

Remove main burner orifi ces. See Figure 1.

6.

Install LP gas main burner orifi ces. Discard excess LP

orifi ces.

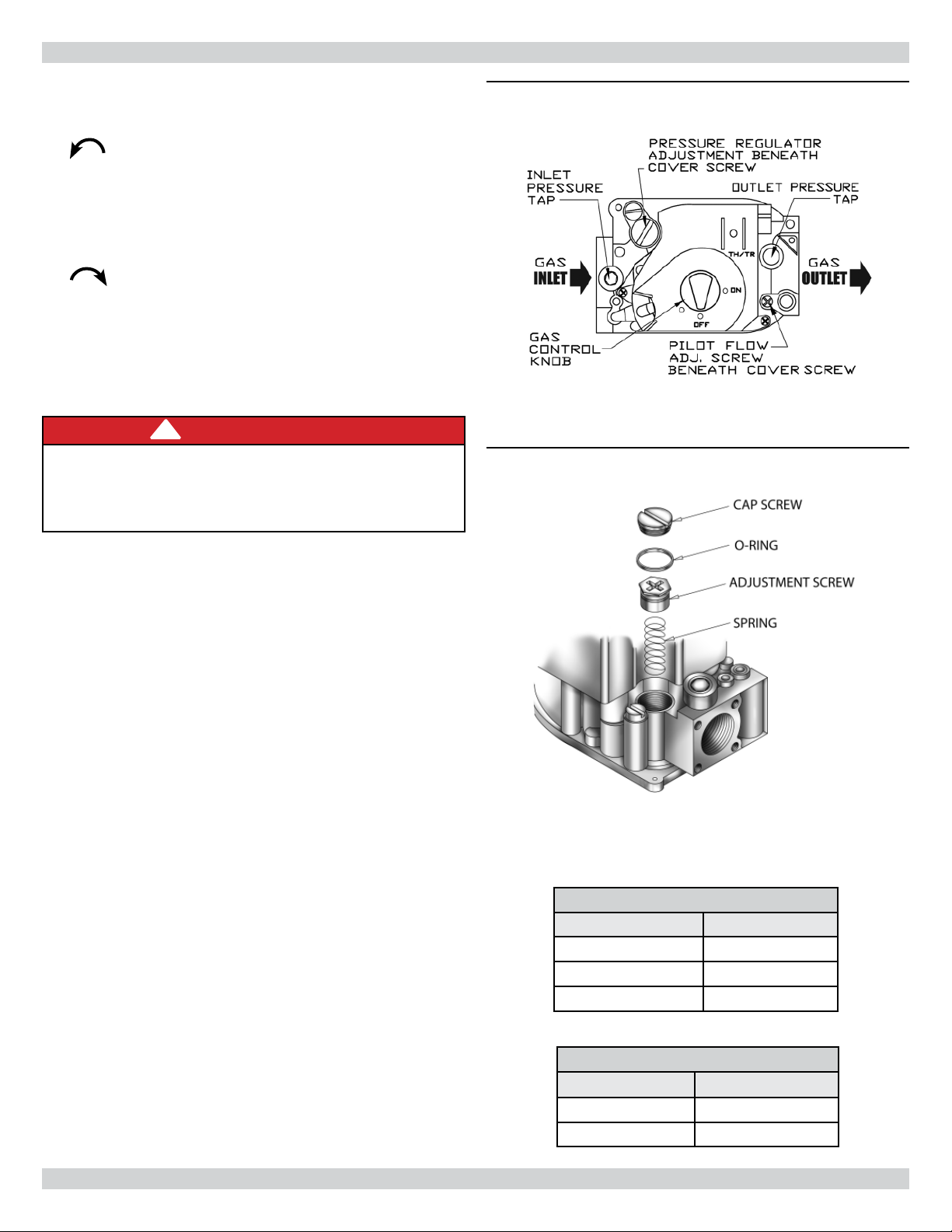

7.

Use 7/16” wrench, disconnect pilot tube from pilot. See

Figure 2

8.

Remove pilot orifi ce.

9.

Install LP gas pilot orifi ce.

10.

Apply liquid sealing compound (provided) to threads of

pilot assembly fi tting.

11.

Reattach pilot tube to pilot and securely tighten. See

Figure 2.

12.

Replace main gas burner tubes.

.

Figure 2 - Pilot Assembly

Pilot

Pilot Orifi ce

Pilot Tube

P/N 240009725, Rev. C [10/2012]

NATURAL GAS TO LP CONVERSION INSTRUCTIONS

13.

Remove cover screw from gas valve pressure regulator.

See Figure 3.

14.

Remove adjustment screw by turning counterclockwise

. See Figure 4.

15.

Remove stainless steel natural gas spring.

16.

Insert Red LP gas spring.

17.

Install new adjustment screw. Assure screw top is fl ush

with regulator top.

18.

Turn pressure regulator adjustment screw clockwise

eleven (11) complete turns. (This is starting point

for manifold pressure.)

19.

Install manometer to pressure tap on outlet side of gas

valve. See Figure 3.

NOTE: Gas inlet pressure should be between minimum

of 11” w.c. and maximum of 14” w.c.

20.

Turn electric and gas supply ON.

!

DANGER

Fire Hazard. Do not use matches, candles, open

fl ames, or other methods providing ignition source.

Failure to comply will result in death or serious

injury.

Figure 3 - Gas Valve

Figure 4 - Gas Valve Adjustment Screw

Assembly

21.

Check for gas leaks around all gas connections using

commercially available soap solution specifi cally made

for leak detection.

22.

While boiler is running adjust manifold pressure to 11”

water column by turning pressure regulator adjustment

screw. Check for CO2 and CO levels to assure proper

operation.

23.

Turn electric and gas supply OFF.

24.

Remove manometer. Replace pressure tap cover screw

securely.

25.

Install Black LP gas regulator adjustment cover screw

with o-ring. See Figure 4.

26.

Mount conversion label on gas valve (found in spring

kit).

27.

Turn electric and gas supply ON.

28.

Cycle boiler to ensure proper operation and lighting.

29.

Replace front panel.

NOTE: Complete following steps to provide proper

identifi cation for customer service or technical support

issues.

30.

Copy serial number from old rating plate to new one.

31.

Mount new rating plate adjacent to old one.

TABLE 1 - Main Burner Orifi ces

Boiler Size Orifi ce

50, 100, 150, 200 47

125, 170 49

75 50

Parts for steps 16, 17, 25, and 26 are located in

Honeywell LP gas conversion kit HW#393691 (ECR #

1272030) for VR8204, and VR8304 gas valves.

2

TABLE 2 - Propane (LP) Orifi ces

Manufacturer

ECR PB00208

Honeywell 390686-36

Part Number

Loading...

Loading...