Dunkirk DPFO-3T, DPFO-4T, DPFO-9T, DPFO-5T, DPFO-3 Installation Manual And Operating Instructions

...Page 1

EV SERIES CAST IRON PRESSURE-FIRED

WET BASE HOT WATER BOILERS

DUNKIRK BOILERS

85 Middle Rd.

Dunkirk, NY 14048

www. ecrinternationaL com

Page 2

P/N# 14683010, Rev. 3.1 [09/05] • Printed in USA. Made In USA

Boiler Ratings and Capacities ............................. 4

Rules for Safe Installation and Operation ............ 8

Indoor Boiler Installation .................................... 10

Jacket Assembly (Indoor Boilers) ...................... 11

System Piping (Indoor Boilers) .......................... 12

Weatherproof (Outdoor) Boiler Installation ........ 23

Normal Sequence of Operation ......................... 30

Lighting Instructions for Gas Burners ................ 30

Typical Vent Safety Switch Installation .............. 32

Maintenance ...................................................... 34

Service Hints and Troubleshooting .................... 36

Repair Parts ...................................................... 37

KEEP THIS MANUAL NEAR BOILER

BETA!N EOB EUTUBE BBEEBENCE J

The following defined symbols are used throughout

this manual to notify the reader of potential hazards

of varying risk levels.

ndJcates a potential hazardous situation J

hJch, if not avoided, MAY result in minor orJ

oderate injury. It may also be used to alert J

gainst unsafe practices. 3

cMoPORTANT: Read the following instructions'%}

MPLETELY before insta!!ingH j

/9""ii7", '

',4:dy,,

C.S.A. Certified

For Natural Gas Or Propane

¢@@

Tested For 100 LBS

ASME

Working Pressure

Page 3

FIG, 1 - INDOOR BOILER DIMENSIONS

L

i 0

REA_

±

81DE 5_OE

INDOOR OIL-FIRED HOT WATER BOILERS

62 54 87.6 88.40

DPFO-3T 129 I12 82.9 83.77 I1"

80 70 87.5 88.35

DPFO-4T 14_A''

169 I47 83.3 84.24

99 86 87.5 88.31

DPFO-5T 17½"

208 I82 83.8 84.72

117 I02 87.5 88.26

DPFO-7T 24"

250 217 84.3 85.20

154 134 87.4 88.15

DPFO-9T 30½"

324 282 __5) __(5)

DPFO-3 .45 56 48 87.5 88.22 5" I1"

.90 105 91 82.8 83.19

DPFO-4 1.605 74 64 87.5 88.23

159 I38 83.3 83.91 6" 14_A"

DPFO-5 I!#0 93 81 87.5 88.23 6" 17½"

199 I73 83.9 84.63

DPFO-7 1.05 130 I13 87.6 88.24 7" 24"

2.35 276 240 __(5) __(5)

1.35 167 I46 87.6 88.26

DPFO-9 3.00 353 307 __(5) __(5) 8" 30½"

Firing rates of 2.00 gph or less use a Beckett Model AFG oil burner Firing rates over 2.00 gph use a Beckett Model CF375 oil burner. Optional Riello 40 Series

oil burners also available.

Page 4

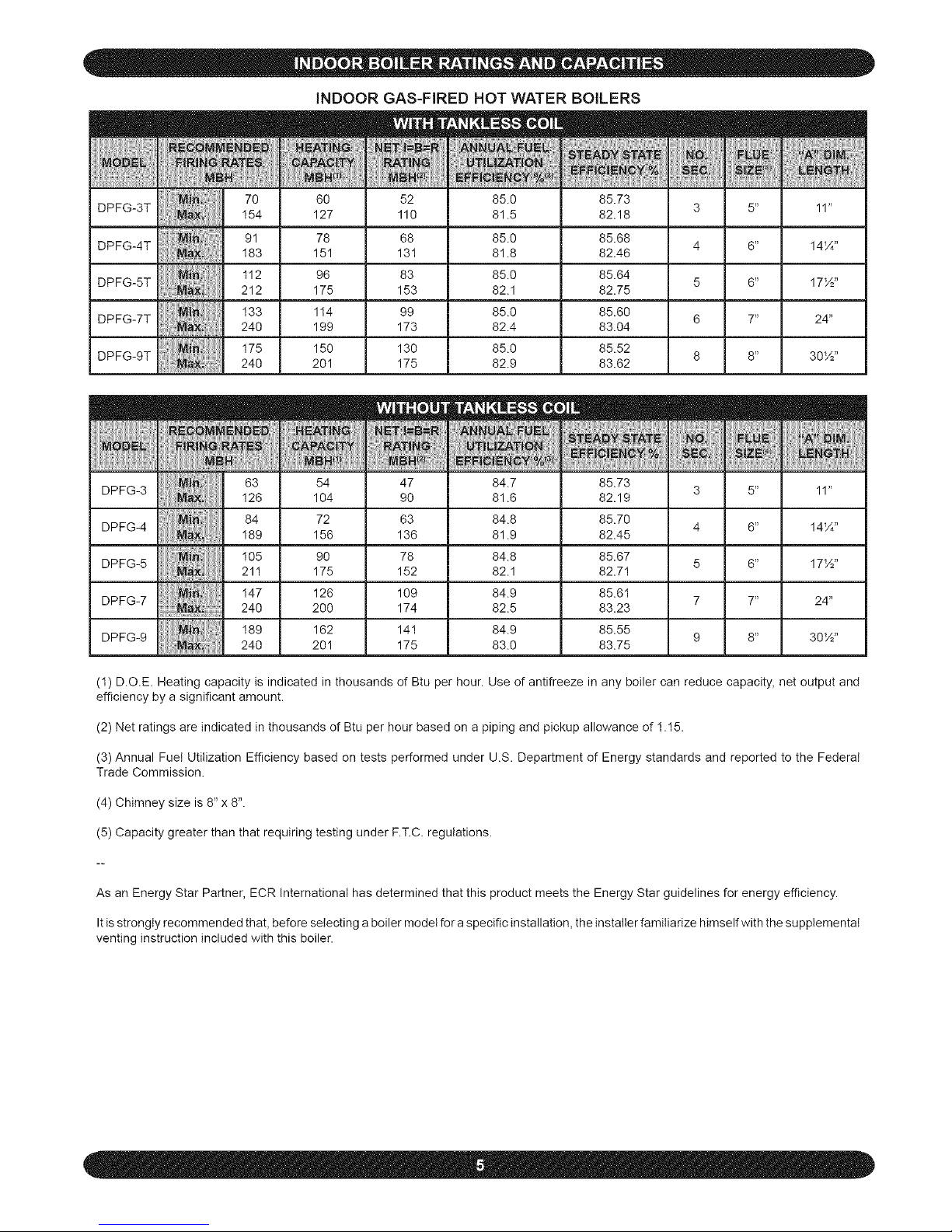

iNDOOR GAS-FIRED HOT WATER BOILERS

70 60 52 85.0 85.73

DPFG-3T 11"

I54 127 110 81.5 82.18

91 78 68 85.0 85.68

DPFG-4T 14¼"

I83 151 131 81.8 82.46

I12 96 83 85.0 85.64

DPFG-5T 17½"

212 175 153 82.1 82.75

I33 114 99 85.0 85.60

DPFG-7T 24"

240 199 173 82.4 83.04

I75 150 130 85.0 85.52

DPFG-9T 30½"

240 201 175 82.9 83.62

63 54 47 84.7 85.73

DPFG-3 3 5" 11"

I26 104 90 81.6 82.19

84 72 63 84.8 85.70

DPFG-4 4 6" 14¼"

I89 156 136 81.9 82.45

105 90 78 84.8 85.67

DPFG-5 5 6" 17½"

211 175 152 82.1 82.7I

I47 128 109 84.9 85.61

DPFG-7 240 200 174 82.5 83.23 7 7" 24"

189 162 141 84.9 85.55

DPFG-9 9 8" 30½"

240 201 175 83.0 83.75

(1) D.O.E. Heating capacity is indicated in thousands of Btu per hour. Use of antifreeze in any boiler can reduce capacity, net output and

efficiency by a significant amount.

(2) Net ratings are indicated in thousands of Btu per hour based on a piping and pickup allowance of 1.15.

(3) Annual Fuel Utilization Efficiency based on tests performed under U.S. Department of Energy standards and reported to the Federal

Trade Commission.

(4) Chimney size is 8" x 8".

(5) Capacity greater than that requiring testing under F.T.C. regulations.

As an Energy Star Partner, ECR International has determined that this product meets the Energy Star guidelines for energy efficiency.

Itis strongly recommended that, before selecting a boiler model for a specific installation, the installer familiarize himself with the supplemental

venting instruction included with this boiler.

Page 5

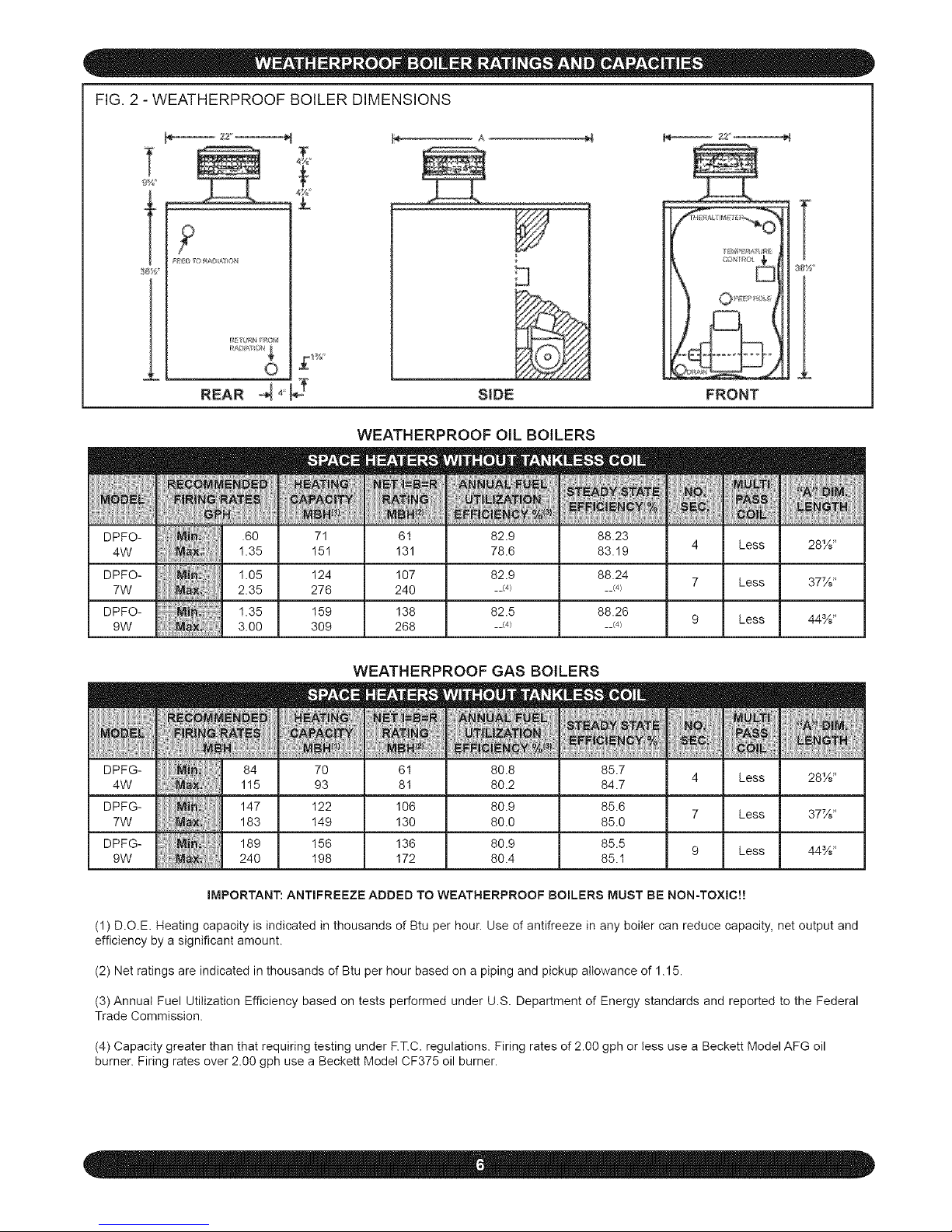

FIG, 2 - WEATHERPROOF BOILER DIMENSIONS

T

t

L

2Z_

?

REAR _ _'_

SIDE FRONT

T

38Y_

l

DPFO-

4W

DPFO-

7W

DPFO-

9W

DPFG-

4W

WEATHERPROOF OIL BOILERS

.60 71 61 82.9 88.23

1.35 I51 I31 78.6 83.19

1.05 I24 I07 82.9 88.24

2.35 276 240 __(4) __<4)

1.35 159 138 82.5 88.26

3.00 309 268 __(4) __<4)

m

NO.

_EC.

4

7

9

DPFG-

7W

DPFG-

9W

WEATHERPROOF GAS BOILERS

70 61 80.8 85.7

93 81 80.2 84.7

I22 I06 80.9 85.6

I49 I30 80.0 85.0

I56 I36 80.9 85.5

I98 I72 80.4 85.1

m

NO,

4

7

9

m

'MULTI:

PASS1

,6:O1_i

Less

Less

Less

28½"

37½"

44%"

iMPORTANT: ANTIFREEZE ADDED TO WEATHERPROOF BOILERS MUST BE NON-TOXIC!!

(1) D.O.E Heating capacity is indicated in thousands of Btu per hour. Use of antifreeze in any boiler can reduce capacity, net output and

efficiency by a significant amount.

(2) Net ratings are indicated in thousands of Btu per hour based on a piping and pickup allowance of 1.15.

(3) Annual Fuel Utilization Efficiency based on tests performed under U.S. Department of Energy standards and reported to the Federal

Trade Commission.

(4) Capacity greater than that requiring testing under F.T.C. regulations. Firing rates of 2.00 gph or tess use a Beckett Model AFG oil

burner. Firing rates over 2.00 gph use a Beckett Model CF375 oil burner.

Page 6

The optional DES is to be used in conjunction

with the EV boiler for indoor installations requiring

through the wall venting, The DES is designed as

an integral part of the EV boiler, eliminating the

need for a power venter.

_iiiiii_iii_i_iiiIHi_iiiiiijiiii_i_iiii_i1iii_i_iiiIiii_iiiiit_iiiiii_i_iiii_i_i_iii!iiI_i_!iiii!!iiii1iii

3 sections FDVS 4 4" 6W'

4 to 9 sections FDVS 6 6" 8½"

Oil boiler DES kits include an oil burner with

adjustable post purge timer and solenoid valve.

For through the wall venting, this post purge burner

must be used in place of the standard burner that is

furnished with the boiler.

Selection of boiler size should be based upon "Net

I=B+R Rating MBH being equal to or greater than

the calculated heat loss of the building.

These boilers are low pressure sectional cast

iron boilers constructed and hydrostatically tested

for a maximum working pressure of 50 psi in

accordance with A.S.M.E. (American Society of

Mechanical Engineers) Section IV Standards for

cast iron heating boilers. They are capacity rated

in accordance with the code of the Hydronics

Institute.

These boilers operate on #2 Heating Oil, Natural

Gas, or Propane Gas, with the proper burner.

IMPORTANT

Standard indoor EV Series boilers are furnished

as knockdown boilers and are shipped as four

components (w/o DES) or five components (with

DES) are shown below:

• basic boiler assembly (oil and gas identical)

• boiler jacket (oil and gas identical)

• accessory kit (oil and gas identical)

• burner (oil or gas, without post purge)

• DES parts (include post purge oil burner for

oil-fired burners)

Weatherproof (outdoor) EV Series boilers are

furnished as knockdown boilers only and are

shipped as five components as shown below:

• basic boiler assembly (oil and gas identical)

• weatherproof boiler jacket (oil and gas

identical)

• exhaust cap, pipe, and weather collar (oil

and gas identical)

• accessory kit (oil and gas identical)

• burner (oil or gas)

On knockdown oil burners, the oil burner nozzle

is not included. Correctly sized nozzle must be

installed prior to startup.

Indoor oil-fired models DPFO (3, 4, 5, 3T, 4T,

5T) without direct exhaust system are available

as packaged boilers, in which case an oil burner

nozzle for one of three specified firing rates wilt

be factory installed in the oil burner.

Gas boilers, knockdown or packaged, may be

ordered to have their burners equipped for either

natural or propane gas with the proper flame

retention head and orifice to match the input

specified by the purchaser. However, a boiler

drawn from the stock of a wholesale distributor will

normally be equipped with a burner with a G-O

flame retention head and an orifice to fire natural

as in the minimum input range of a G-O head.

,J

Page 7

• Read the installation manual before beginning

the installation. Failure to follow the rules for

safe operation and the instructions can cause a

malfunction of the boiler and result, serious bodily

injury, and/or property damage.

• Check your local codes and utility requirements

before installation. The installation must be in

accordance with their directives, or, in their absence,

follow NFPA Installation Codes and good industry

practice.

• Before servicing, allow boiler to coot. Always shut

off any electricity and oil to boiler when working on

it. This will prevent any electrical shocks or burns.

• Inspect oil lines and connections for leaks.

• Be certain oil burner nozzle or gas orifice is size

required. Over-firing will result in early failure of

the boiler sections. This will cause dangerous

operation.

• Never vent this boiler into an enclosed space.

Always vent to the outside. Never vent to another

room or inside a building.

• Be sure there is adequate air supply for complete

combustion.

• Follow a regular service and maintenance

schedule for efficient and safe operation.

• Keep boiler area clean and free of combustible

material, gasoline, and other flammable vapors

and liquids.

• Proper through-the-walt venting requires use of

complete DES (oil-fired units only).

• Oil and gas burners are not do-it-yourself items.

This boiler must be installed and serviced by

qualified professionals using combustion test

instruments.

• Be aware when piping the relief valve if the

system pressure exceeds the safe limit of 30 Ibs.

per square inch, the relief valve will automatically

open. Lifting of the relief valve can discharge large

quantities of steam and hot water, which may

damage the surroundings. Before installing the

relief valve, read the manufacturer's instructions

and the maintenance section of the manual on

relief valves.

Page 8

• Frequent and mysterious lifting of the relief valve

may be a sign of an improperly sized expansion

tank. Installation and sizing of the expansion tank

must consider the heating system's total water

volume, temperature, boiler initial fill pressure, and

system arrangement. For proper installation and

maintenance follow the guidelines established by

ECR and the manufacturer.

• Expansion tank performance and life expectancy

can be hindered by overfilling the boiler. ECR

recommends an initial fill pressure of 10 - 12 psig.

For higher fill pressures, the expansion tank's air

charge will need to match the fill pressure. Consult

the manufacturer's guidelines for sizing and

selection.

• Purging the heating system of air and gases

during the boiler's initial commissioning is critical

for proper circulation and quiet performance. Once

the air and gases are purged, for boiler installations

using float type vents, the air vents should be closed

for normal operation. If air is heard or noticed by a

loss of heat, purge the system and open the vents

for a short period of time.

- iAc o ,o.Ai

This boiler has been designed for residential

installations. If used for commercial applications,

all jurisdictional requirements must be met. This

may require wiring and/or piping modifications.

The manufacturer is not responsible for any

changes to the original design.

DO NOT USE GASOLINE CRANKCASE

DRAININGS OR ANY OIL CONTAINING

k..GASOLINE"

Check to be sure you have the right size boiler

before starting the installation. See rating and

capacity tables on preceding pages. Check the

rating plate on the right side of the boiler.

You must see that the boiler is supplied with the

proper fuel, fresh air for combustion, and a suitable

electrical supply. Also, the boiler must be connected

to a suitable venting system and an adequate piping

system. Finally, a thermostat, properly located, is

needed for control of the heating system. If you

have any doubts as to the various requirements,

check with local authorities and obtain professional

help where needed.

These installation instructions are vital to the proper

and safe operation of the heating system. Take the

time to be sure they are carefully followed.

lways keep the manual fuel supply valve shut I

if the burner is shut down for an extended r

eriod of time. J

THE PUMP PRESSURE OF THE STANDARD

BECKETT BURNER IS SET AT 140 PSI.

The output of the burner nozzle will be 18% greater than rated.

.40

.50

.60

.65

.75

.85

1.00

1.10

1.20

1.25

1.35

1.50

1.65

1.75

2.00

2.25

2.50

.47

.59

.71

.77

.89

1.01

1.18

1.30

1.42

1.48

1.60

1.77

1.95

2.07

2.37

2.66

2.96

Page 9

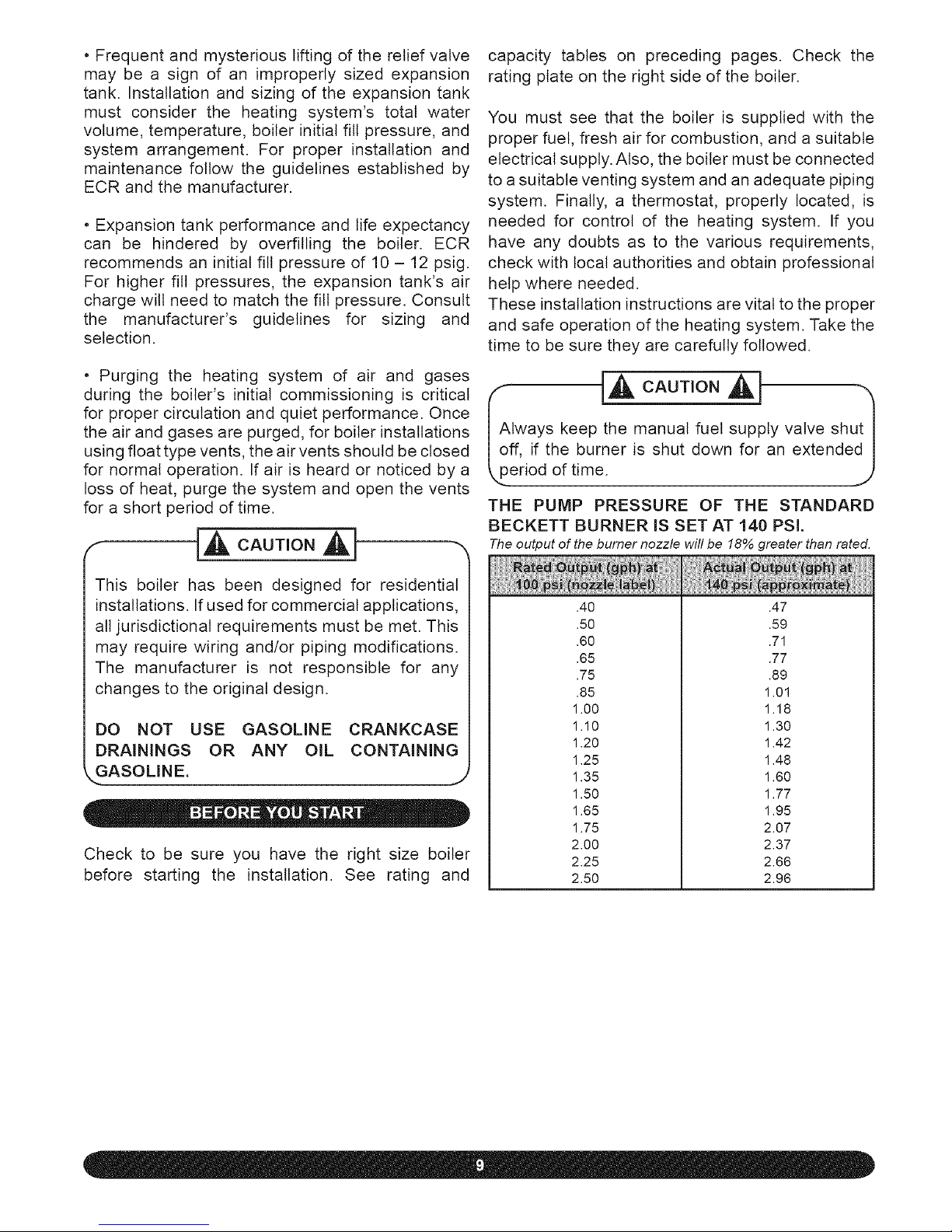

FIG. 3 - GENERAL REQUIREMENTS FOR ATYPICAL INSTALLATION

k.....

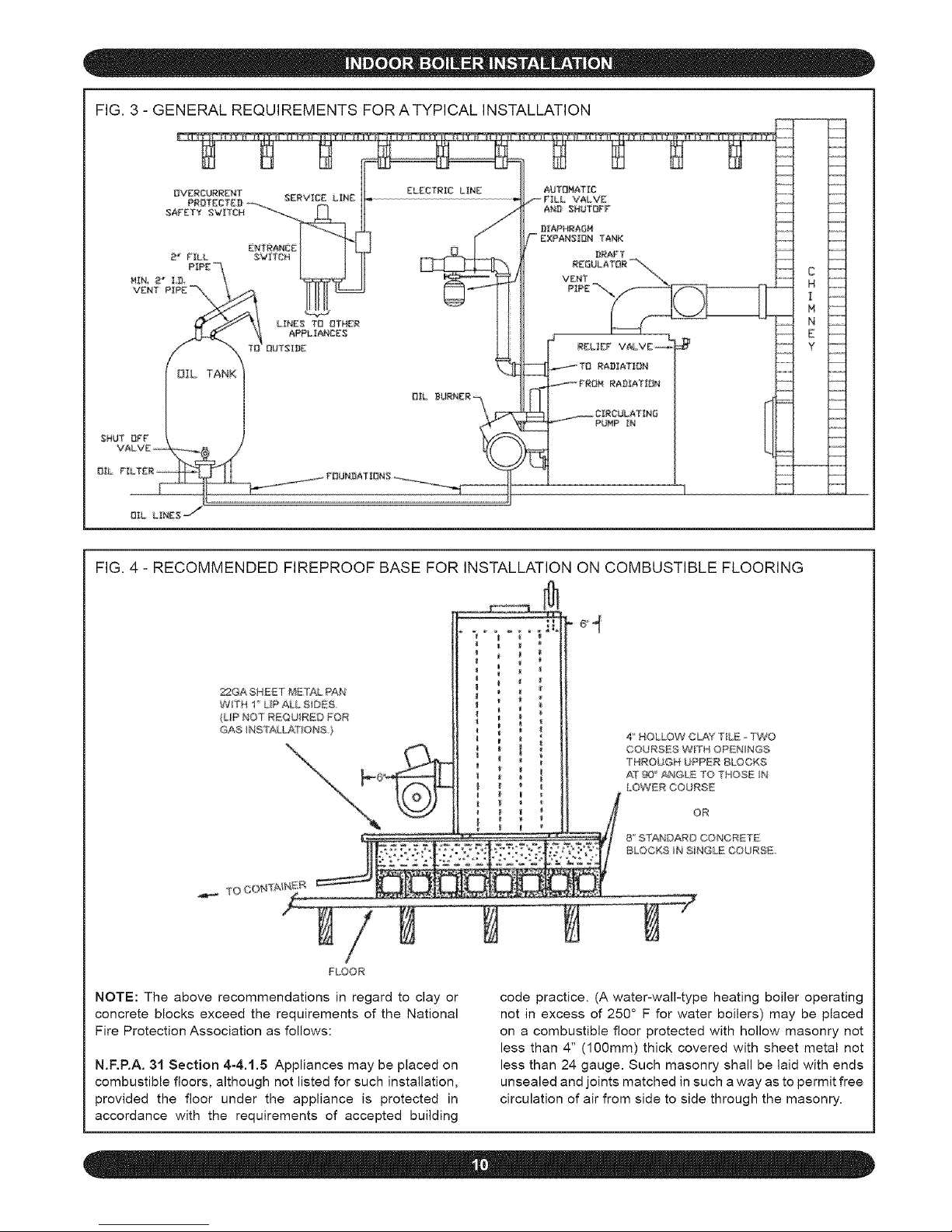

FIG. 4 - RECOMMENDED FIREPROOF BASE FOR INSTALLATION ON COMBUSTIBLE FLOORING

2"2GASHBET METAL PAN

WTH I LIPAU.SiDES

(LIP NOT R_QU_R_D POR

GAS _NS_ALL#_I"ONS )

|

4" HOLLOW C_<f T_LE _ TWO

COURSES WTH OPENINGS

THROUGH 8PPER BLOCKS

AT 9Q _ ANGLE TO THOS_ IN

LOW£R COURS_

OR

8" BTANDAR@ C©NCRET_

BLOCKS N B_NGLE COURSE

/

FLOOR

NOTE: The above recommendations in regard to clay or

concrete blocks exceed the requirements of the National

Fire Protection Association as follows:

N.F.RA. 31 Section 4-4.1.5 Appliances may be placed on

combustible floors, although not listed for such installation,

provided the floor under the appliance is protected in

accordance with the requirements of accepted building

code practice. (A water-wall-type heating boiler operating

not in excess of 250 ° F for water boilers) may be placed

on a combustible floor protected with hollow masonry not

less than 4" (100mm) thick covered with sheet metal not

less than 24 gauge. Such masonry shall be laid with ends

unsealed and joints matched in such a way as to permit free

circulation of air from side to side through the masonry.

Page 10

ote:PleaseseetheseparateVentingInstructionforflue%I

zelimitationandotherinformationonventing.FordirectI

xhaustsystems,thetotalrunofhorizontalfluepipemustJ

otexceed6'andthetotalrunofverticalfluepipemustnotJ

xceed10'(oil-firedunitsonly), j

1. Place boiler at a location as centralized to the

piping system and as close to the chimney or vent

terminal as possible to minimize condensation. At

input rates up to 1.75 gph (245,000 Btu/hr), the

supply and return from radiation may be piped on

the same end of the boiler. At higher rates, it is

recommended that the supply be piped from the

rear of the boiler and the return be piped from the

front of the boiler. Coordinate jacket installation

with piping. See "Jacket Assembly Instructions"

and "Piping Diagrams" in this manual for more

information.

2. See Figure 4 for installation on combustible

flooring. If necessary, place metal shims beneath

feet to ensure a level unit.

3. Accessibility clearances must take precedence

over fire protection clearances. Allow at least 24"

for servicing at the tankless and burner sides of the

unit. Allow at least 18" at a side where passage is

required for access to another side for servicing.

A 6" clearance from combustible material on all

sides and the top is recommended. 18" clearance

is necessary between smoke pipe and nearest

combustible material. See NFPA 31, latest revision,

for safe methods to reduce clearances where

necessary. NFPA publications are available at

Battery Park, Quincy, MA 02269.

CONSULT FIRE AUTHORITIES

J

FOR LOCAL REQUIREMENTS

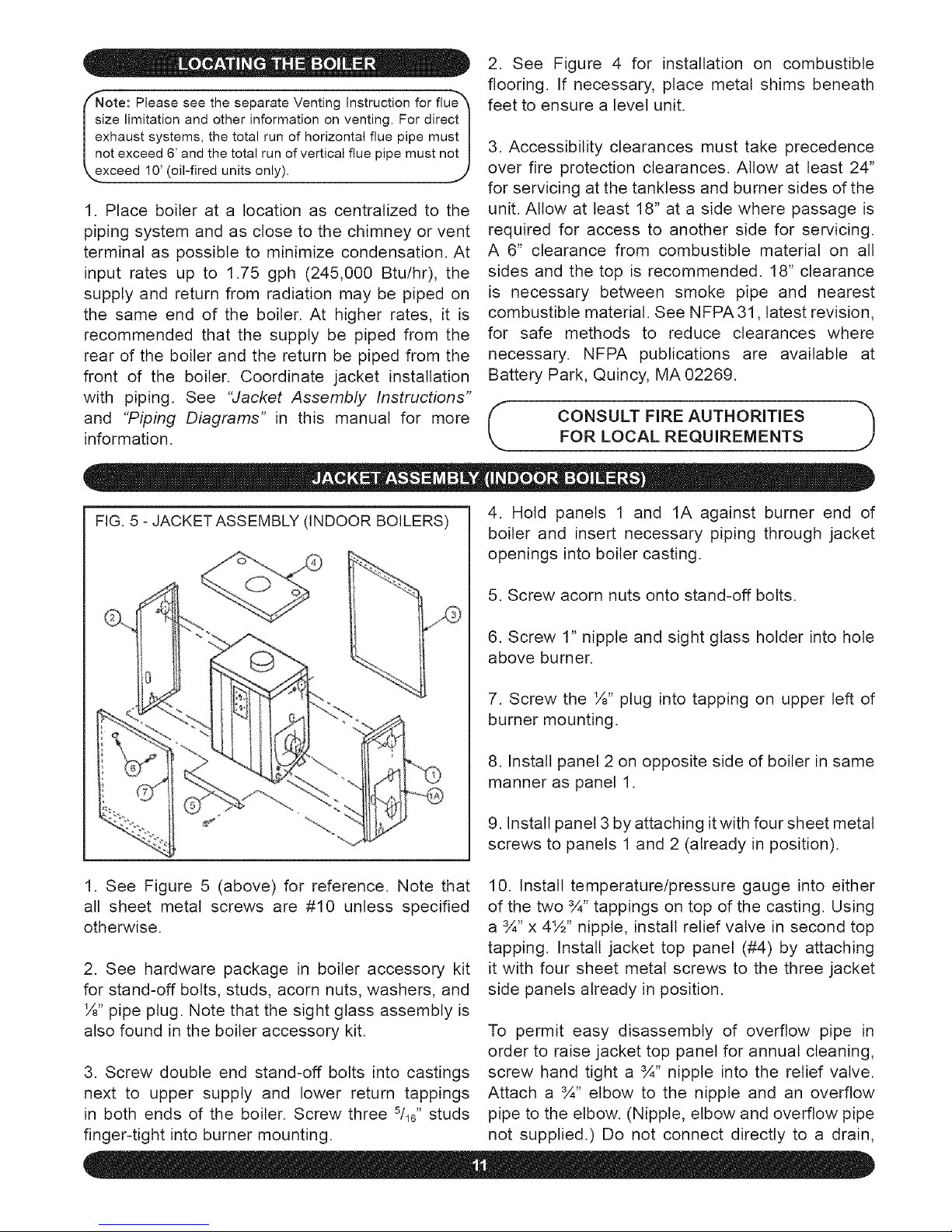

FIG. 5 - JACKETASSEMBLY (INDOOR BOILERS)

4. Hold panels 1 and 1A against burner end of

boiler and insert necessary piping through jacket

openings into boiler casting.

5. Screw acorn nuts onto stand-off bolts.

6. Screw 1" nipple and sight glass holder into hole

above burner.

7. Screw the ½" plug into tapping on upper left of

burner mounting.

8. Install panel 2 on opposite side of boiler in same

manner as panel 1.

9. Install panel 3 by attaching it with four sheet metal

screws to panels 1 and 2 (already in position).

1. See Figure 5 (above) for reference. Note that

all sheet metal screws are #10 unless specified

otherwise.

2. See hardware package in boiler accessory kit

for stand-off bolts, studs, acorn nuts, washers, and

½" pipe plug. Note that the sight glass assembly is

also found in the boiler accessory kit.

3. Screw double end stand-off bolts into castings

next to upper supply and lower return tappings

in both ends of the boiler. Screw three Sll?' studs

finger-tight into burner mounting.

10. Install temperature/pressure gauge into either

of the two 3A" tappings on top of the casting. Using

a 3A"x 4½" nipple, install relief valve in second top

tapping. Install jacket top panel (#4) by attaching

it with four sheet metal screws to the three jacket

side panels already in position.

To permit easy disassembly of overflow pipe in

order to raise jacket top panel for annual cleaning,

screw hand tight a 3A" nipple into the relief valve.

Attach a 3A" elbow to the nipple and an overflow

pipe to the elbow. (Nipple, elbow and overflow pipe

not supplied.) Do not connect directly to a drain,

Page 11

butleaveanair gap.Noshutoffof anydescription

shallbeplacedbetweenthe safetyreliefvalveand

the boiler, or on dischargepipes betweensuch

safetyvalvesand the atmosphere.Installationof

the safetyreliefvalve shallconformto the ANSI/

ASMEBoilerand PressureVesselCode,Section

IV.The manufactureris not responsiblefor any

waterdamage.

Ifpreferred,oneof thetop tappingsmaybe used

foran airventandthe reliefvalvemaybeinstalled

in an upper 1½"side tappingof the castingwith

a bushing,nipple,andstreetelbow.Valvespindle

mustbevertical.

11.Installangleiron(#5)openedgeup to panels

1 and 2 on the remainingexposedside of the

boilernearfloor level.Angleiron is attachedwith

twosheetmetalscrewsto theinsideof theturned

edgesofpanels1and2.

12. Install knobs (#6) on door panel (#7) using #8

machine screws. Install door panel by resting lower

edge inside angle iron (#5) and snapping top sides

into place.

1. Antifreeze added to boilers must be non-toxic,

and must of a type specifically intended for use

in closed hydronic heating systems. Under no

circumstances should automotive antifreeze be

used.

2. Use of antifreeze in any boiler may reduce

capacity by 10% or more and increase fuel

consumption. Tanktess coil performance will fall as

concentration of antifreeze is increased. See below

for water volumes of boilers and piping.

3. Because antifreeze forms slush rather than hard

ice, it is safe to protect only to 10 degrees above

coldest temperature anticipated provided slush

formed can move towards expansion tank.

BOILER WATER VOLUMES

DPF-3 7 DPF-3T 10

DPF-4 9 DPF-4T 12

DPF-5 11 DPF-5T 14

DPF-7 15 DPF-6T 16

DPF-9 19 DPF-8T 20

PiPiNG WATER VOLUMES

Divide total length of piping in feet by appropriate factor

below to determine volume in gallons.

½" 82.5 63.5

¾" 40.0 36.0

1" 23.3 22.2

1%" 15.3 12.8

1½" 10.8 9.5

2" 6.2 5.8

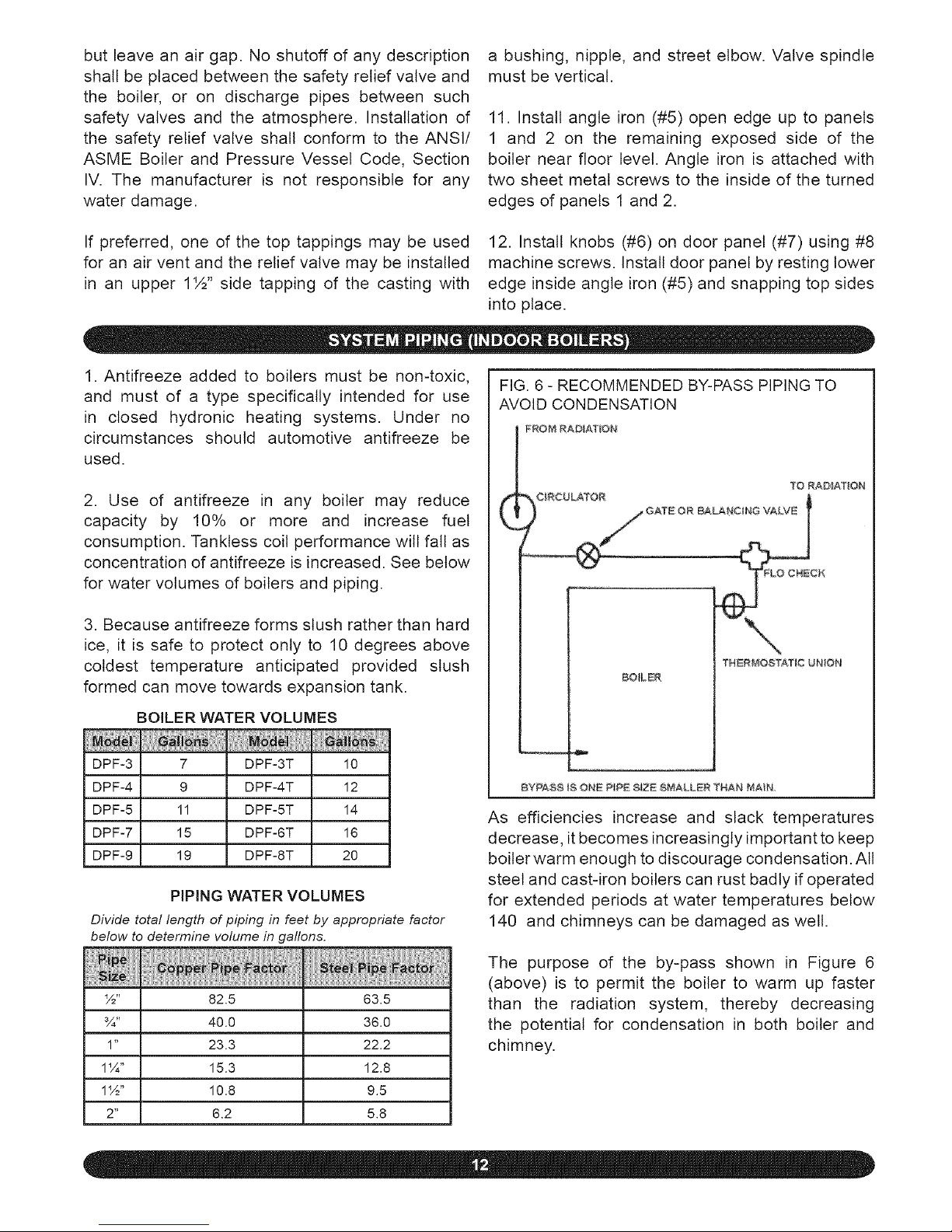

FIG. 6 - RECOMMENDED BY-PASS PIPING TO

AVOID CONDENSATION

FROM RADiATiON

(

?O RADIATION

TNERMOSTA, T_C UNION

BO_LER

BYPA@8 IS ONE P_PE @IZE @_IALLER THAN MA_N

As efficiencies increase and slack temperatures

decrease, it becomes increasingly important to keep

boiler warm enough to discourage condensation. All

steel and cast-iron boilers can rust badly if operated

for extended periods at water temperatures below

140 and chimneys can be damaged as well.

The purpose of the by-pass shown in Figure 6

(above) is to permit the boiler to warm up faster

than the radiation system, thereby decreasing

the potential for condensation in both boiler and

chimney.

Page 12

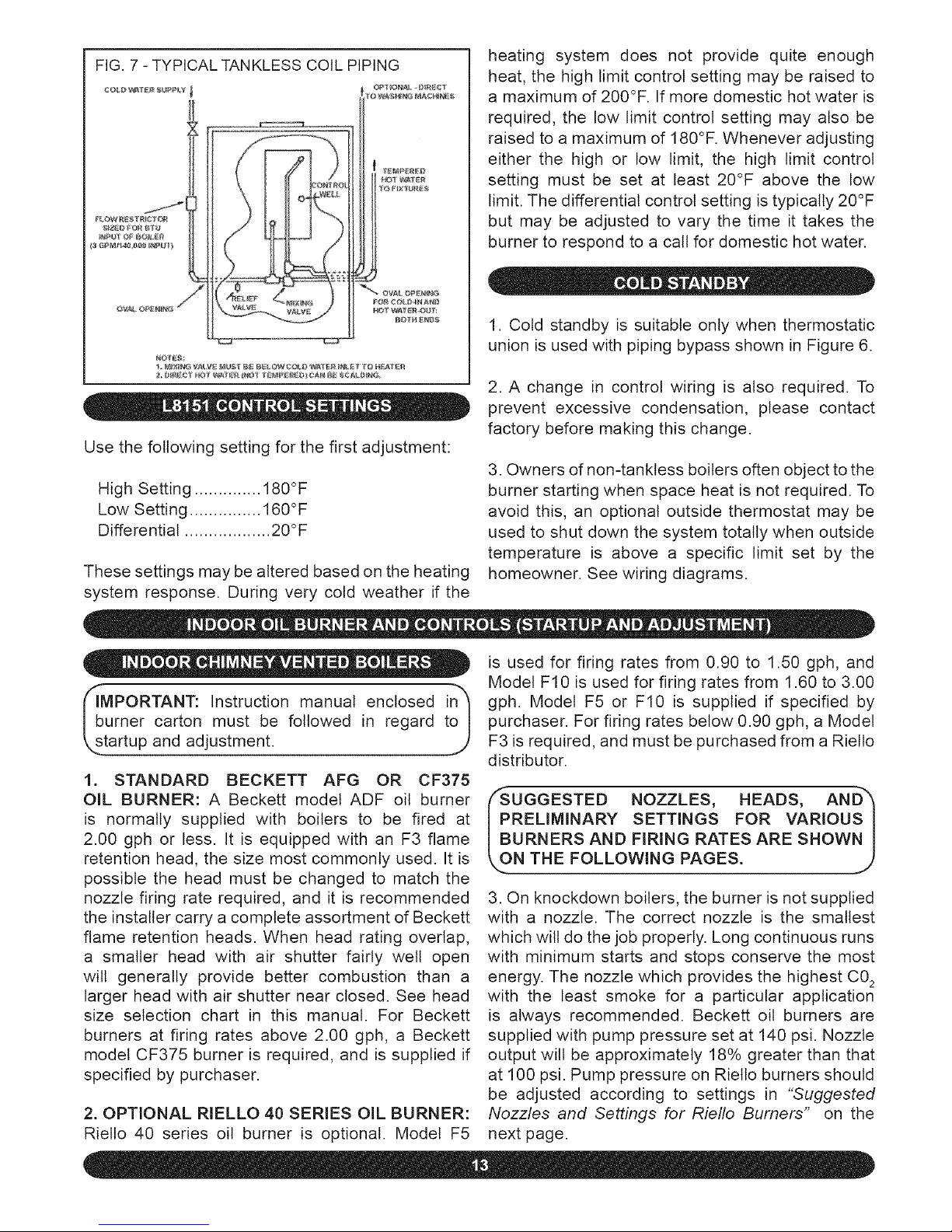

FIG.7-TYPICALTANKLESSCOILPIPING

II

Use the following setting for the first adjustment:

High Setting .............. 180°F

Low Setting ............... 160°F

Differential .................. 20°F

These settings may be altered based on the heating

system response. During very cold weather if the

heating system does not provide quite enough

heat, the high limit control setting may be raised to

a maximum of 200°F. If more domestic hot water is

required, the low limit control setting may also be

raised to a maximum of 180°F. Whenever adjusting

either the high or low limit, the high limit control

setting must be set at least 20°F above the low

limit. The differential control setting is typically 20°F

but may be adjusted to vary the time it takes the

burner to respond to a call for domestic hot water.

1. Cold standby is suitable only when thermostatic

union is used with piping bypass shown in Figure 6.

2. A change in control wiring is also required. To

prevent excessive condensation, please contact

factory before making this change.

3. Owners of non-tanktess boilers often object to the

burner starting when space heat is not required. To

avoid this, an optional outside thermostat may be

used to shut down the system totally when outside

temperature is above a specific limit set by the

homeowner. See wiring diagrams.

_sb,MPORTANT: Instruction manual enclosed i!_

umer carton must be followed in regard t

tartup and adjustment.

1. STANDARD BECKETT AFG OR CF375

OIL BURNER: A Beckett model ADF oil burner

is normally supplied with boilers to be fired at

2.00 gph or less. It is equipped with an F3 flame

retention head, the size most commonly used. It is

possible the head must be changed to match the

nozzle firing rate required, and it is recommended

the installer carry a complete assortment of Beckett

flame retention heads. When head rating overlap,

a smaller head with air shutter fairly well open

will generally provide better combustion than a

larger head with air shutter near closed. See head

size selection chart in this manual. For Beckett

burners at firing rates above 2.00 gph, a Beckett

model CF375 burner is required, and is supplied if

specified by purchaser.

2. OPTIONAL RIELLO 40 SERIES OIL BURNER:

Riello 40 series oil burner is optional. Model F5

is used for firing rates from 0.90 to 1.50 gph, and

Model F10 is used for firing rates from 1.60 to 3.00

gph. Model F5 or F10 is supplied if specified by

purchaser. For firing rates below 0.90 gph, a Model

F3 is required, and must be purchased from a Rietto

distributor.

/'-SUGGESTED NOZZLES, HEADS, AN D"_

PRELIMINARY SETTINGS FOR VARIOUS I

BURNERS AND FIRING RATES ARE SHOWN I

,..ON THE FOLLOWING PAGES. J

3. On knockdown boilers, the burner is not supplied

with a nozzle. The correct nozzle is the smallest

which will do the job properly. Long continuous runs

with minimum starts and stops conserve the most

energy. The nozzle which provides the highest C0_

with the least smoke for a particular application

is always recommended. Beckett oil burners are

supplied with pump pressure set at 140 psi. Nozzle

output will be approximately 18% greater than that

at 100 psi. Pump pressure on Rietto burners should

be adjusted according to settings in "Suggested

Nozzles and Settings for Riello Burners" on the

next page.

Page 13

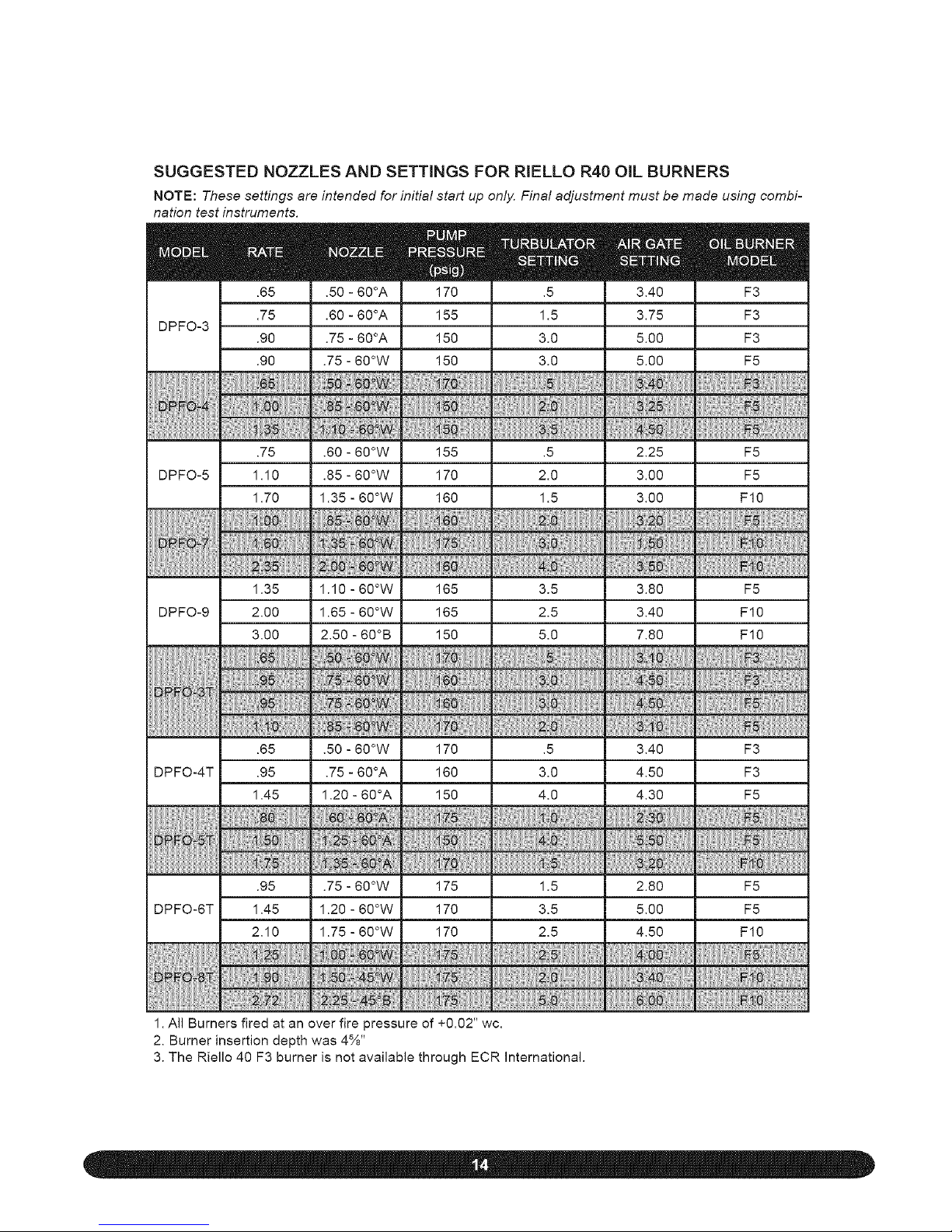

SUGGESTED NOZZLES AND SETTINGS FOR RIELLO R40 ONL BURNERS

NOTE: These settings are intended for initial start up only. Final adjustment must be made using combi-

nation test instruments.

mm

.65

.75

DPFO-3

.90

.90

.75

DPFO-5 1.10

1.70

1.35

DPFO-9 2.00

3.00

.65

DPFO-4T .95

1.45

.95

DPFO-6T 1.45

2.10

m

.50 - 60°A

.60 - 60°A

.75 - 60°A

.75 - 60°W

m

170

155

150

150

m

3.40

3.75

5.00

5.00

m

F3

F3

F3

F5

.60 - 60°W 155 .5 2.25 F5

.85 - 60°W 170 2.0 3.00 F5

1.35 - 60°W 160 1.5 3.00 F10

1.10 - 60°W 165 3.5 3.80 F5

1.65 - 60°W 165 2.5 3.40 F10

2.50 - 60°B 150 5.0 7.80 F10

.50 - 60°W 170 .5 3.40 F3

.75 - 60°A 160 3.0 4.50 F3

1.20 - 60°A 150 4.0 4.30 F5

.75 - 60°W 175 1.5 2.80 F5

1.20 - 60°W 170 3.5 5.00 F5

1.75 - 60°W 170 2.5 4.50 F10

1. All Burners fired at an over fire pressure of +0.02" wc.

2. Burner insertion depth was 4%"

3. The Riello 40 F3 burner is not available through ECR International.

Page 14

o low a firing rate can cause excessive I

ondensation within the boiler and chimney I

sutting in severe rust and corrosion. A piping by- I

ass is recommended to minimize this problem:j)

4. If Beckett AFG burner is to be fired at bess than

1.00 gph, it is possible that a low firing rate baffle

will be required. For firing rates not specified in

"Suggested Nozzles and Settings for Beckett

Burners'on the next page, see chart below in which

an "x" indicates that a baffle is necessary. See also

instruction sheet with baffle in burner carton.

F0

F3

F6

.5O X

.65 X

.75

.75 X

.85 X

.90

1.00

.85 X

.90 X

1.00

5. Using three acorn nuts, studs, and washers from

hardware package, fasten burner to mounting plate.

6. Mount L8151 control on boiler jacket above and

to the right of burner using sheet metal screws in

holes located in jacket. Wiring harness is provided.

When well is used at the rear of a larger boiler, it

might be necessary to relocate the control with

longer wiring not provided.

7. If the boiler is equipped with a tanktess coil, insert

well for the L8151 remote bulb in coil plate. Run

capillary tube through sight glass opening in jacket.

8. If a tanktess coil is not used, install 3A" well

and bulb with a bushing either in the 1½" supply

opening opposite the one used to feed radiation,

or in a reducing tee in the 1½" supply opening that

actually feeds radiation.

9. Wiring diagram is found in Figure 8. To avoid

excessive condensation, do not use a two-

stage thermostat or other fuel saving devices or

techniques without first contacting the factory.

10. Before making control adjustments, verify that

all fuel, water, and electrical connections have

been made in accordance with the regulations

of the National Fire Prevention Association, the

National Electrical Code and/or local regulations.

(See "L8151 Control Settings" in this manual for

more information.)

11. START-UP AND ADJUSTMENT: Start

and adjust burner according to manufacturer's

instructions contained in burner carton or included

with packaged boiler, and pay special attention to

the following:

a. As the name suggests, this boiler is designed

to produce the ultimate in usable heat from a

gallon of fuel oil.

b. With chamber fully warmed up, find the

highest C02 level at which zero smoke can be

maintained. Then add extra air until C02 falls off

1%. Final setting should be at least 11% C02. If

unable to obtain that reading, check for internal

oil leaks, incorrect flame retention head or a

faulty or incorrect nozzle. (See charts below.)

Draft will vary as air is adjusted. It should be left

at as cnear zero as possible at breeching.

BECKETT OIL BURNER RETENTION HEAD SELECTION

CHART

UseModel AFG Burner withAir Inlet Damper up to 2.00 gph only

F0

F3

F6

F12

F22

0.75

1.25

1.65

1.75

2.00

When a choice exists between two heads exists, the head which will

perform at or near its maximum firing rate is recommended.

NOZZLE TYPES AND SIZES

DPFO-3

DPFO-3T, DPFO-4

DPFO-4T, DPFO-5, DPFO-5T

DPF-6T, DPF-7

DPF-8T, DPF-9

80° Hollow or Solid

80° Hollow or Solid

80° Hollow or Solid

70° or 80° Hollow or Solid

70° Solid

NOTE: The description of nozzle spray patterns varies between

manufacturers. The correct nozzle is that which provides the highest

C02 at the lowest smoke reading.

fComplete installation must be made in")

accordance with the requirements of Iocat I

authorities and the National Fire Protection I

/

.Association.

Page 15

SUGGESTED NOZZLES AND SETTINGS FOR BECKETT AFG AND CF375 OIL BURNERS

NOTE: These settings are intended for initial start up only. Final adjustment must be made using combination

test instruments.

.65

DPFO-3 .75

.90

DPFO-5

DPFO-9

DPFO-4T

DPFO-6T

m

.60 - 80°A

.65 - 70°A

.75 - 80°B

.75 .65 - 80°A

1.10 1.00 - 80°A

1.70 1.50 - 80°A

1.35 1.20 - 70°A

2.00 1.65 - 40°B

3.00 2.50 - 60°B

.65 .60 - 80°B

1.00 .85 - 80°B

1.45 1.25 - 80°B

.95 .85 - 80°B

1.45 1.20 - 80°B

2.10 1.75 - 60°B

B

Yes

No

No

m

10

10

10

m

1

0

0

m

AFG

AFG

AFG

F3- I_A Yes 10 1 AFG

F6- I_A No 10 1 AFG

F12- I_A No 10 3 AFG

F6- 1_/8 No 10 2 AFG

SV1 - # 1 No 6.5 0 CF375

SV1 - # 5 No 10 4 CF375

F0 - 1_/8 Yes 10 1 AFG

F3- I_A No 10 1 AFG

F6- I_A No 10 2 AFG

F3- 1_/8 No 10 2 AFG

F6- 1_/8 No 10 3 AFG

SV1 - # 2 No 10 0 CF375

i i A@i

Pump pressure is set at 140 psig.

All burners fired at +.01 to .1 inches w.c. draft over fire.

Page 16

FIG. 8 - BECKETT BURNER WIRING DIAGRAM: INDOOR CHIMNEY VENTED OIL BOILERS WITH OPTION-

AL OUTSIDE THERMOSTAT

120V AC

POWER

SUPPLY

A_ 9 BLAC_

<_IgC_A'I'OR

HIGH LIMIT

INTERNAL SCHEMATIC FOR LS15]A

OPTIONAL REMOTE

.-. ,,u,J,OOT IDE

k....... _

RELAY

L J

C554A CAD CELL

Z_ PROVIDE DISCONNECT MEANS AND OVERLOAD PROTECTION AS REQUI_.

Z_ JUMPER T-T TERMINALS WHEN OUTSIDE THERMOSTAT IS NOT USED

NOTE: WHEN INDIRECT WATER HEATER IS USED, SEE MANUFACTURER'S WIRING INSTRUCTIONS

With all high efficiency boilers, care must be taken

to minimize condensation. Therefore, cold standby

is not recommended and may be used only with a

piping, bypass as shown on Figure 6. This requires

a change in control wiring. Please contact factory

prior to making that change.

When cold standby is not utilized, the homeowner

might object to the burner starting when space heat

is not required. To avoid this, an optional outside

thermostat may be used to shut down the system

when outside temperature is above a specific limit

set by the homeowner. When outside thermostat is

not used, Jumper T-T Terminals on relay.

These settings may be altered based on the heating

system response. During very cold weather if the

heating system does not provide quite enough

heat, the high limit control setting may be raised

to a maximum of 200°F. If more domestic hot

water is required, the low limit control setting may

also be raised to a maximum of 180°F. Whenever

adjusting either the high or low limit the high limit

control setting must be set at least 20°F above the

low limit. The differential control setting is typically

20°F above the low limit. The differential control

setting is typically 20°F but may be adjusted to vary

the time it takes the burner to respond to a call for

domestic hot water.

Use the following setting for the first adjustment:

High Limit Set Point..180°F

Low Limit Set Point... 160°F

Differential .................. 20°F

flnstruction manual enclosed in burner carton"_

must be followed in regard to start-up and I

t !: J

1. A Beckett model AFG post-purge oil burner

is normally supplied with boilers to be fired at

2.00 gph or less. It is equipped with an F3 flame

Page 17

retention head, the size most commonly used. It is

possible the head must be changed to match the

nozzle firing rate required, and it is recommended

the installer carry a complete assortment of Beckett

flame retention heads. When head ratings overlap,

a smaller head with air shutter fairly well open wilt

generally provide better combustion than a larger

head with air shutter near closed.

2. At firing rates above 2.00 gph, a special Beckett

model CF375 burner must be used and is supplied

if specified by purchaser.

3. Post-purge oil burners are supplied with pump

pressure set at 140 psi. Nozzle output wilt be

approximately 18% grater than that at 100 psi.

4. The burner is not supplied with a nozzle. The

correct nozzle is the smallest which will do the

job properly. Long continuous runs with minimum

starts and stops conserve the most energy. The

nozzle which provides the highest C% with the

least smoke for a particular application is always

recommended.

A WARNING A

5. Using acorn nuts, studs, and washers from

hardware package, fasten burner to mounting plate.

Do not disturb chamber when inserting firing head.

6. Mount L8151 control on boiler jacket above and

to the right of burner using sheet metal screws in

holes located in jacket. Wiring harness is provided.

When welt is used at the rear of a larger boiler, it

might be necessary to relocate the control with

longer wiring not provided.

7. If boiler has a tanktess coil, insert well for the

L8151 remote bulb in coil plate. Run capillary tube

through sight glass opening in jacket.

8. If a tankless coil is not used, install 3A" welt

and bulb with a bushing either in the 1½" supply

opening opposite the one used to feed radiation,

or in a reducing tee in the 1½" supply opening that

feeds radiation.

9. Mount overfire pressure switch at upper right

of burner on screws already in jacket. Burner will

shut down if overfire pressure reaches .35" H20 due

to a plugged flue or high wind. See "Vent Safety

Switch Installation" in this installation and operation

manual for more information.

10. Wiring diagram is found in Figure 9 (below). To

avoid excessive condensation, do not use a two-

FIG. 9 - BECKETT BURNER WIRING DIAGRAM: INDOOR DIRECT EXHAUST OIL BOILERS WITH POST

PURGE BURNER

120V

!_OWER

SL1PPLY

HIGH LLMIT

INTERNAL SCHEMATIC FOR LSISIA

IGNITION

T_NSFORMER

Z_ PROVIDE DISCOHNECT MEAHS AND OVERLOAD PROTECTION AS REQUIRED

Z_ JUMPER T_T TERMFNALS WHEN OUTSIDE THERMOSTAT IS NOT USED

NOTE: WHEN INDIRECT WATER }[EATER IS USED, SEE MAIqL_ACTURER_ WIRING INSTRUCTIONS

CAD CELL C554A

OVERFIRE

PR_SS_t,E

SWITCH

BL

Page 18

stage thermostat or other fuel saving devices or

techniques without first contacting the factory.

11. Install Gar-Ber filter as provided rather than a

standard filter between burner and oil storage tank.

12. Before making control adjustments, verify that

all fuel, water, and electrical connections have been

made in accordance with the regulations of the

National Fire Prevention Association, the National

Electrical Code, and/or local regulations.

13. STARTUPANDADJUSTMENT: Start and adjust

burner according to manufacturer's instructions

contained in burner carton or included with boiler

and pay special attention to the following:

a. As the name suggests, this boiler is designed

to produce the ultimate in usable heat from a

gallon of fuel oil.

b. With chamber fully warmed up, find the

highest CO 2 level at which zero Smoke can be

maintained. Then add extra air until CO 2falls off

1%. Final setting should be at least 11% CO 2. If

unable to obtain that reading, check for internal

oil leaks, incorrect flame retention head, or faulty

or incorrect nozzle.

14. POST PURGE TIMING: With through-the-wall

venting there is no overfire draft present after the

burner shuts down. Therefore a post purge must be

used to prevent the hot chamber from overheating

the nozzle.

The post purge timer is part of the Honeywell

intermittent primary control, which is located on the

Beckett oil burner. The post purge time has been

preset to 4 minutes but may be adjusted to 0, 2,

4, or 6 minutes by adjusting the switches on the

side of the intermittent primary control. With a stack

thermometer in place, the boiler fully warmed up

(200°F or more), and the boiler running, turn the

high limit control on the aquastat all the way down.

The burner motor should then be running with the

flame off (i.e., in post purge). Measure the time it

takes from the flame off until the stack temperature

falls to the same temperature as the boiler water.

Adjust the post purge timer to nearest time interval,

always rounding up if possible. For example, if the

time measured is 3 minutes and 20 seconds, then

set the post purge timer at 4 minutes.

Whenever the nozzle is removed for service, check

for varnish forming on the outside of the nozzle. If

carbon and varnish do not wipe off easily, increase

the post purge time.

15. LIMITED RECYCLEAND LIMITED RESET: The

Honeywell R7184P1031 interrupted-duty primary

control utilizes two safety features to protect the

boiler from being saturated with oil. Limited recycle

will allow the burner 3 attempts to ignite, if ignition

is unproven the control locks out. The control's

reset button can then be pressed. The limited reset

feature will allow the burner to be reset 3 times

before it locks out. To unlock the control requires

the reset button to be held for 30 seconds.

16. ELECTRICAL WIRING: Wiring should conform

with the latest edition of the National Electrical Code

ANSI/NFPA No. 70 in the United States and the CSA

C22.1 Canadian Electrical Code in Canada and/or

the local authority having jurisdiction. A separate

electrical circuit should be run from the entry box

with a fused disconnect switch in this circuit. Refer

to wiring diagrams for suggested circuitry and

field wiring. Wiring for zone valve installations are

furnished with zone valve packages.

_omplete installation must be made in"_

accordance with the requirements of the local I

authorities and the National Fire Protection J

k,,Association. J

With all high efficiency boilers, care must be taken

to minimize condensation. Therefore, cold standby

is not recommended and may be used only with a

piping bypass as shown in Figure 6. This requires

a change in control wiring. Please contact factory

prior to making that change. When cold standby is

not utilized, the homeowner might possibly object to

the burner starting when space heat is not required.

To avoid this, an optional outside thermostat may

be used to shut down the system totally when

outside temperature is above a specific limit set by

the homeowner.

Page 19

High Setting .............. 180°F

Low Setting ............... 160°F

Differential .................. 20°F

These settings may be altered based on the heating

system response. During very cold weather if the

heating system does not provide quite enough

heat, the high limit control setting may be raised

to a maximum of 200°F. If more domestic hot

water is required, the low limit control setting may

also be raised to a maximum of 180°F. Whenever

adjusting either the high or low limit the high limit

control differential control setting is typically 20°F

above the low limit. The differential control setting is

typically 20°F but may be adjusted to vary the time

it takes the burner to respond to a call for domestic

hot water.

Connect gas service meter to control assembly

in accordance with the latest revision of the ANSI

Z223.1 and local codes or utility. A ground joint

union should be installed for easy removal of gas

control for servicing. A drip or trap must be installed

at the bottom of a vertical section of piping at the

inlet to the boiler. A pipe compound resistant to the

action of liquefied petroleum gases must be used

on all threaded pipe connections. Check with the

local utility for location of manual shutoff valve.

shutoff valve during any pressure testing of the gas

supply piping system at test pressures equal to or

less than 0.5 psi (3.5 kPa). The boiler and its gas

connection must be leak tested before placing the

boiler in operation.

After placing the boiler in operation, the ignition

system safely shutoff device must be tested. The

method of testing must be specified in detail. A

sediment trap must be provided upstream of the gas

controls and location of manual main shutoff valve

must be outside the jacket when codes require.

1. The gas line should be of adequate size to

prevent undue pressure drop and never smaller

than the pipe size of the main gas control valve.

See chart below.

Maximum Pipe Capacity in Cubic Feet of Gas/Hour

(Gas pressure = O.5 psig or less, pressure drop = ½" w.c.)

IN

J "

1%"

Foradditionalinformationreferto Table]0-2 inPart 10 of the

NationalFuel Gas Code Handbook.

2. To check for leaks in gas piping, use a soap and

water solution or other approved method. DO NOT

USE AN OPEN FLAME.

3. The boiler and its individual shutoff valve must

be disconnected from the gas supply piping system

during any pressure testing of that system at test

pressures in excess of 0.5 psi (3.5 kPa).

nstruction manual enclosed in burner carton h

ust be followed in regard to fuel type as well I

s start-up and adjustment instructions, j/

1. BURNER HEAD/ELECTRODE ASSEMBLY: An

Adams gas burner shipped with an EV Series boiler

purchased directly from the factory will be equipped

with the proper flame retention head to match boiler

input as specified by the purchaser. However,

a boiler drawn from the stock of a wholesale

distributor will normally be equipped with a size

G-O head which might be necessary to change

to match boiler input rate. It is recommended that

the installer carry a complete assortment of heads

for this purpose. See table (below) for burner head

selection guide.

Burner Head Selection

70,000 to 110,000

110,000to 180,000

180,000 to 210,000

210,000 to 240,000

G-0

GT4

GT6

GT8

The boiler must be isolated from the gas supply 2. BURNER ORIFICE:AnAdams burner issupplied

piping system by closing its individual manual with two orifice plates, one attached to each end of

Page 20

FIG. 10 -ADAMS GAS BURNER HEAD SPECIFICATIONS

GT4 GT6 GT8 G-O

HEAD ASSEMBLY HEAD ASSEMBLY

_GNITNON EL_OT_OOE

_GN[_'_ON ELECTAODE

TH£ {GNITION ELECTRODE WILL ALV_#AYS BE IFa

T_ LOW_ _G_ ¸ HAND A_EA A8 _ND_CATED_

the orifice spring inside the gas manifold. Unless

specified otherwise prior to shipment from the

Dunkirk factory, the "primary" orifice plate, mounted

toward the burner head, will be sized to fire Natural

Gas at the minimum input range of a G-O head. The

"spare" orifice plate, located at the opposite end of

the orifice spring and stained red, will be that which

delivers the minimum rate for Propane Gas.

Orifice Sizing (G-0 Head Only)

70,000

80,000

90,000

100,000

110,000

3/16

#8

#3

#2

15/64

.187

.199

.213

.221

.235

5/32

#19

#16

3/16

#9

.156

.166

.177

.187

.196

Orifice Sizing (GT4, GT6, GT8 Heads)

The two orifice plates are interchangeable and the

inside diameter of either can be enlarged with a

tapered reamer to obtain a higher rate within the

burner head firing rate. See tables at left for orifice

sizing.

It is not necessary to disassemble the burner to

change or enlarge gas orifices, See orifice change

out diagram (below),

FIG. 11 - ORIFICE CHANGEOUT PROCEDURE

_ _'_/_l_ T_'_ _'TP_R _R_AR_ ¸ ©_1_ ©t_ TH_

110,000

120,000

130,000

140,000

150,000

160,000

170,000

180,000

190,000

200,000

210,000

220,000

230,000

240,000

D .246

F .257

I .272

K .281

M .295

N .300

5/16 .312

P .323

Q .332

S .350

23/64 .360

3/8 .375

25/64 .391

Z .413

#9

#3

#2

15/64

C

1/4

G

I

J

K

M

N

5/16

O

.196

.213

.221

.235

.242

.250

.260

.272

.277

.281

.295

.300

.312

.316

Orifice rates calculated at 1,000 BTU's per cubic foot of Natural

Gas and 2,500 BTU's per cubic foot of propane,

If necessary, remove the orifice cap and select

the proper (natural or propane) gas orifice plate.

Ream out the inside diameter, if necessary, using

a proper size drill to check the opening size. Mount

the orifice plate in the primary position on the orifice

spring, insert the spring assembly into the manifold

and tighten the orifice cap. Do not overtighten.

3. Using three acorn nuts, studs, and washers

from hardware package, fasten burner to mounting

plate.

4. Mount L8151 control on boiler jacket above and

to the right of burner using sheet metal screws in

holes provided in jacket. Wiring harness is provided.

When welt is used at the rear of a larger boiler, it

Page 21

might be necessaryto relocatethe controlwith

longerwiringnotprovided.

5. If a tankless coil is included in the boiler, insert the

well for the L8151 remote bulb in the coil plate. Run

capillary tube through sight glass opening in jacket.

6. If the boiler does not include a tankless coil,

install 3A"welt and bulb with a bushing either in the

1½" supply opening opposite the one used to feed

radiation, or in a reducing tee in the 1½" supply

opening that feeds radiation.

7. Wiring diagram is found in Figure 12 (below).

Optional wiring shows use of outside thermostat

to provide for total summer shutdown. To avoid

excessive condensation, do not use a two-

stage thermostat or other fuel-saving devices or

techniques without first contacting the factory.

8. Before making control adjustments, verify that

all fuel, water, and electrical connections have

been made in accordance with regulations of the

National Fire Prevention Association, The National

Electric Code and/or local regulations.

9. See control settings on next page.

10. START-UP AND ADJUSTMENT: Start

and adjust burner according to manufacturer's

instructions contained in burner carton or included

with packaged boiler and pay special attention to

the following important points:

a. As the name suggests, this boiler is designed

to produce the ultimate in usable heat from the

fuel used.

--[A WAR__.,NGA

carbon monoxide tester must be used, n

smoke tester.

b. Air Adjustment Is Not Factory Set. When

first firing burner, start with air shutter much

FIG. 12 - WIRING DIAGRAM: INDOOR CHIMNEY VENTED AND DIRECT EXHAUST GAS BOILERS WITH

OPTIONAL OUTSIDE THERMOSTAT

120!/AC PO_&rER SUPPLY

10"°"°

THERMOSTAT

FLAME PROVING ROD

13 ! I

LStSIA -- NENSE _V (GND)

[_=.J I t..Im_----- BLACK / BLACK 2DVt25V60HZ | | ] VALVE(GND) g_j._

;w_ , I(LII /l '1 II

LJW,_E _ '_ L_] EII_ _ ' I I I I J

¢ = INII

0JI -oh

_[ _A_ --- _ YELLOW/BLACK

| - I L '4 "I'ERMIN_'BOARD t I THEEMOSTATS_,_

IF ANY OF THE ORIOINAL WIRE _BURNER MOTOR O_ _1

ASSU_L]m w_rrHTim BLAC_ V_3W _ _RESS_.m_swrrc_

CONVERSION BURNER MUST

BE REPLACED. IT MUST BE REPLA(TED 3OOV

TYPE AWM 1_6°C OR EQUIVALENT,

_z

PROVIDE DISCONNECT MEANS AND OVERLOAD _ JUMPER T-T TERMINALS WHEN OUTSIDE NOTE: WHEN INDIRECT WATER HEATER IS USED. SEE

PROTEL'_.rION AS REQUIRED, THERMOSTAT 1S NOT USED MAN]._ACTURER!S WIRING INSTRUCTIONS

Page 22

nearer closed than final setting anticipated. At

70 MBH, shutter must be fully closed because

some air always by-passes shutter.

With chamber fully warmed up, find the highest

CO 2 level at which CO of tess than 30 ppm can

be maintained. Final setting should be at least

9% CO. If unable to obtain that reading, check

for air leaks, incorrect flame retention head or

for the eductor tube not centered. For chimney

vented boilers, draft wilt vary as air is adjusted.

It should be left at as near zero as possible at

breeching.

c. The correct input rate is the smallest which

will do the job properly. Long continuous runs

with minimum starts and stops conserve the

most energy.

rate that is too low can cause I

k..corrosive condensation in boiler and flue. j)

d. All orifice sizes are approximate. Actual burner

input wilt vary with heating values of gas sup-

plied locally.

e. The input for natural gas can be determined

by timing the gas meter. To vary the gas input,

install the nearest size orifice, and adjust the

pressure regulator up or down for the exact

input desired. Measure the manifold pressure at

the pressure tap on gas valve.

eOTE: Do not exceed pressure adjustment rang h

commended by the gas valve manufacturer, not less I

Ik,t,han 3" and not greater than 4" of H20. J

11. IF PUBLIC UTILITY REGULATIONS IN

YOUR COMMUNITY REQUIRE LABELING OF

THE BOILER WITH BURNER HEAD SIZE AND

FIRING RATE, PLEASE USE LABEL IN BOILER

LITERATURE ENVELOPE FOR THAT PURPOSE.

('Complete installation must be made inh

accordance with the requirements of local I

authorities and the National Fire Protection I

With all high efficiency boilers, care must be taken

to minimize condensation. Therefore, cold standby

is not recommended and may be used only with a

piping bypass as shown in Figure 6. This requires

a change in control wiring. Please contact factory

prior to making that change.

When cold standby is not utilized, the homeowner

might possibly object to the burner starting when

space heat is not required. To avoid this, an optional

outside thermostat may be used to shut down the

system totally when outside temperature is above a

specific limit set by the homeowner. When outside

thermostat is not used, jumper T-T Terminals.

High Setting - Not less than 200°F, 20°F or more

above Low Setting.

Low Setting - Not less than 180°F for best

tanktess coil output. Lower settings may be used

when tankless coil is not a factor.

Differential - 20°F typical. May be changed to

match system.

1. Place boiler at a location as centralized as

possible with the piping system and as free from

unusual wind currents as possible,

2. A level concrete or noncombustible base is

recommended with the top high enough so that

ground water and melted snow will not rise as high

as the bottom of the boiler. It is also recommended

that crushed stone or gravel surround the base to

keep shrubbery, weeds and grass at least 18" from

the boiler.

3. If necessary, level boiler with shims placed

beneath feet.

4. Accessibility clearances must take precedence

over fire protection clearances. Allow at least 24"

for servicing at the front and burner sides of the

boiler. Allow at least 18" at a side where passage is

required to another side for servicing. A 6" clearance

from combustible material on all sides and the top

is recommended.

5. Advise owner to maintain air passages free from

obstructions. Ventilating and combustion air must

enter boiler casing without restrictions.

Page 23

1. Install 1½" nipples (not supplied)or smaller

nippleswith bushingsin the two tappingsin end

of boileroppositeburner.Thesewill providefeed

to the radiationand return to the boiler. Supply

pipeshouldbelevelor riseslightlytowardairvent

inside building. See Figure 13for alternativeair

eliminationmethod.

FIG. 13 - ALTERNATIVE AI R ELIMINATION METHOD

, FLOAT VENT

E XPAr'_$_ON

SANK

2. Circulator, make-up water, expansion tank, etc.,

should be installed at a convenient location inside

the building.

a. Domestic Water Heating: See Figure 14

for piping of remote (indoor) tanktess coil or

indirect water heater. An indirect Water Heater

is recommended.

b. Without Domestic Water Heating: See

Figure 15.

3. Place control welt in top ¾" tapping near burner

end of boiler.

4. Install a ¾" street ell in remaining top tapping.

Mount relief vatve on street ell using a ¾" x 7" nipple.

Mount ¾" overflow pipe (not supplied) so that it

extends downward beside boiler casting and will be

covered by boiler jacket when jacket is in place. Do

not extend overflow pipe so near the ground that it

might become clogged with snow or ice.

5. At burner end of boiler mount theraltimeter with

1½" x ½" bushing in upper right 1½" tapping.

6. Install boiler drain with bushing in lower left 1½"

tapping.

FIG. 14 - WEATHERPROOF BOILER PIPING WITH INDOOR WATER HEATING UNIT

Page 24

FIG. 15 - WEATHERPROOF BOILER PIPING WITHOUT INDOOR WATER HEATING UNIT

STAINLESSSTEE l,I VA,VE

LI ! !

/11

1 I 't EXPANSION

l DEVICE RETURNS

_ L_ _, RECOMMENDED BYPASS _]9(_ _ _1 _

/I AND ADJUSTING VALVE H H I_

_: b WEATHERPROOF /_ (BYPASS MAY BE ONE H H H

FIG. 16 - WEATHERPROOF JACKETASSEMBLY

ONL_

7. Referring to Figure 16 (above), place panel 1

over supply and return pipe nipples.

8. Attach panels 2 and 3 to panel 1 using sheet

metal screws supplied.

10. Fasten L8151 control to upper right-hand side of

panel 4 with bulb in control welt already in place.

11. Install additional controls according to

manufacturer's instructions included and to Figures

17 (oil installation)or 18 (gas installation)on next

page.

12. Install burner according to manufacturer's

instructions with particular attention given to the

following IMPORTANT information:

a. Oil Installations: See charts (below) for firing

rate head sizing and nozzle sizing instructions,

The F3 head supplied might not be the correct

size to match the firing rate required for this

particular installation,

BECKETT RETENTION HEAD SELECTION CHART

Use Model AFG Burner up to 2.00 gph only

Max. Firing Rate .75 1.25 1.65 1.75 2.00

TYPICAL NOZZLE TYPES AND SIZES FOR BECKETT

BURNERS

DPFO-3T2W,DPFO-4W

DPFO-6T2W, DPFO-7AW, DPFO-7SW

@iii

80° Hollowor Solid

70° or80° HolloworSolid

60° or70° HolloworSolid

9. Attach panel 4 to panels 2 and 3. All Larger Models

Page 25

FIG, 17 - BECKETT BURNER WIRING DIAGRAM FOR WEATHERPROOF OIL-FIRED BOILER (SPACE HEATING)

12OV AC

POWER

SUPPLY

! i_ I SEPd_ 8O

THERMOSTAT

It#

I?? ??1

Cll_C_LATOR

/ "¢'T A

@, @

FNTEP_NAL SCHEMATIC FOR LgI51A

Z_ PROVIDE DISCONNECT MEANS AND OVERLOAD PROTIgCTIDN AS REQUIt_BD

,lUMPER T-T TERMINALS WHEN OUTSIDE TtI£RMOSTAT IS NOT U,!_D

NOTE: WHEN INDIRECT WATER HEATER IS USED, SEE MANUFACTURER'S WIRING INSTRUCTIONS

FIG. 18 - WIRING DIAGRAM FOR WEATHERPROOF GAS-FIRED BOILER (SPACE HEATING)

120V 24V 11Kl 1K2

A

PROVIDE DISCONNECT MEANS AND OVEgLOAD

PROTECTION AS REQUIRED

JUMPER T-T TERM[tqALS WHEN OUTSIDE

THERMOSTAT IS NOT USED

NOTE WHEN INDIRECT WATER HEATER IS USED_ SEE

MA]ffUFACTUP-.ER'$ WIRING INSTRUCTIONS

R_ER TERMfNAL

BOARD

30 SEC

li=,

SWITCH

BLACK TRANSFORMER LEAD

IGNITION

_9

IGNITION

ELECTRODE

Page 26

b. Gas Installations: See page 21 for head and

orifice sizing. The head supplied might not be

the correct size to match the boiler input rate

required for this particular installation.

c. Fasten burner to burner mounting plate using

three studs, washers, and acorn nuts from

hardware package. Be very careful to avoid

disturbing combustion chamber when inserting

air tube. Retention head must be set flush with

inside watt of combustion chamber.

13. Connect piping to distribution system referring to

Figure 14 for systems with domestic water heating

or to Figure 15 for systems without.

14. Verify that fuet, water, and electrical connections

have been made in conformance with all applicable

codes.

15. Fill and test boiler and systems. Weatherproof

space heating boilers require antifreeze. See

"Antifreeze" on this page for more information.

16. Cover all outdoor piping with weather-resistant

insulation.

17. Start burner according to manufacturer's

instructions and make combustion tests. It is

suggested that the short length of smoke pipe be

installed temporarily for ease in making tests. (See

startup and adjustment instructions for oil and gas

installations in this manual for more information.)

18. Referring again to Figure 16, fasten front jacket

panel (#9) in position with sheet metal screws and

install jacket top (#5).

19. Install exhaust assembly with parts 6, 7, and

8. The exhaust cap is made to spring inside the

short length of smoke pipe. A tourniquet made of

wire or a large hose clamp may be used to reduce

the diameter so that it will fit inside the pipe. Two or

three hose clamps in series may be used when a

large one is not available.

1. Antifreeze added to boilers must be non-toxic and

must be of a type specifically intended for use in closed

hydronic heating systems. Under no circumstances

should automotive antifreeze be used.

2. Use of antifreeze in any boiler may reduce capacity

by 10% or more and increase fuel consumption.

Tanktess coil performance wilt fall as concentration

of antifreeze is increased.

3. Because antifreeze forms slush rather than hard

ice, it is safe to protect only to 10 degrees above

coldest temperature anticipated provided slush

formed can move towards expansion tank.

WATERVOLUMES OF PF SERIES BOILERS

N

DPF3 7

DPF4 9

DPF5 11

DPF7 15

DPF9 19

DPF3T

DPF4T

DPF5T

DPF6T

DPFST

DPF7TT

10

12

14

16

2o

21

Divide total length of piping in feet by factor (below)

to determine water volume in gallons.

COPPER

STEEL

As boiler temperature increases, air wilt move from

top of boiler toward float vent even if lower. As

boiler temperature decreases, water will move from

expansion tank toward boiler. (See Figure 13.)

Page 27

This boiler was designed to produce the ultimate in

usable heat from a gallon of fuel oil.

With chamber fully warmed up, find highest CO 2

level at which zero smoke can be maintained.

Then add extra air until CO 2 falls off about 1%.

Final setting should be at least 11% CO 2. If unable

to obtain that reading, check for internal oil leaks,

incorrect flame retention head of faulty or incorrect

nozzle. Draft wilt vary as air is adjusted. It should

be left at as near zero as possible at breeching.

The correct nozzle is the smallest which will do the

job properly. Long continuous runs with minimum

starts and stops conserve the most energy. The

nozzle which provides the highest CO 2 with the

least smoke for a particular application is always

recommended.

A Beckett model AFG oil burner is used to fire

boilers at 2.00 gph or less. At firing rates above 2.00

gph, a Beckett model CF375 is required. A model

AFG burner shipped with your EV Series boiler

is equipped with an F3 flame retention head, the

size most commonly used. It is possible the head

must be changed to match the nozzle firing rate

required, and it is recommended the installer carry

a complete assortment of Beckett flame retention

heads. When head ratings overlap, a smaller head

with air shutter fairly well open will generally provide

better combustion than a larger head with air shutter

near closed. See head size selection chart on page

21. For firing rates under 1.00 gph. see page 18 for

information on using low firing rate baffles.

It should be recognized that the description of spray

patterns might vary between nozzle manufacturers.

In any case the nozzle recommended is that which

provides the highest CO 2with the least smoke for a

particular application.

RELIMINARY AIR SETTINGS FOR VARIOUS I

IRING RATES AND BURNERS ARE SHOWN I

N PAGE 16. 1"")

Use the following setting for the first adjustment:

High Setting .............. 180°F

Low Setting ............... 160°F

Differential .................. 20°F

These settings may be altered based on the heating

system response. During very cold weather if the

heating system, does not provide quite enough

heat, the high limit control setting may be raised to

a maximum of 200°F. If more domestic hot water is

required, the low limit control setting may also be

raised to a maximum of 180°F. Whenever adjusting

either the high or low limit the high limit control

setting must be set at least 20°F above the low

limit. The differential control setting is typically 20°F

but may be adjusted to vary the time it takes the

burner to respond to a call for domestic hot water.

Page 28

Thisboilerwasdesignedto producetheultimatein

usableheatfromthefuelused.Toadjusttheair-fuel

mixtureby eye is to waste energyunnecessarily

ahdto createundesirablegases.

!c

o not use a smoke tester with a gas burner. A I

arbon monoxide tester must be used. J

AIR ADJUSTMENT IS NOT FACTORY SET:

When first firing burner, start with air shutter much

nearer closed than final setting anticipated. (At 70

MBH, shutter must be fully closed because some

air always bypasses shutter.) With chamber fully

warmed up, find highest CO 2 level at which CO of

less than 50 ppm can be maintained. Final setting

should be at least 10% CO 2. If unable to obtain

that reading, check for air leaks, incorrect flame

retention head or educator tube not centered. CO 2

readings as high as 11% are acceptable provided

CO does not exceed 50 ppm. The correct input rate

is the smallest which wilt do the job properly. Long

continuous runs with minimum starts and stops

conserve the most energy.

n input rate that is too low may cause corrosive I

ndensa!ion in boi!er and !!ue: J

An EV Series gas boiler ordered individually from the

factory is shipped with an Adams burner equipped

with the proper flame retention head to match

the boiler input rate requested by the purchaser.

However, burners drawn from a wholesale

distributor's stock are shipped with GO heads, and

it is recommended that the installer carry a complete

assortment of Adams flame retention heads in

order to change heads when necessary to match

the boiler input rate. When head ratings overlap,

a smaller head employed with air shutter fairly

well open will generally provide better combustion

than a larger head with air shutter near closed.

The information on pages 20-21, an excerpt from

the Adams burner instruction manual, is offered to

assist in selecting the correct head and orifice for

the Adams gas burner.

Adams burners supplied from stock with EV Series

boilers are equipped with a GO flame retention

head and with two orifice plates, one inserted at

each end of the orifice spring. The primary orifice

(mounted in position ready for firing) is the smallest

at which the burner should be fired using natural

gas. The auxiliary orifice (stained red in color) is

the smallest at which the burner should be fired

with propane. The two orifices are interchangeable

according to the fuel to be used, and either should

be reamed out if a larger firing rate is desired.

Check after reaming with the proper size drill. (See

sizing charts in this manual.)

High Setting - Not less than 200°F, 20°F or more

above Low Setting.

Low Setting - Not less than 180°F for best

tankless coil output. Lower settings may be used

when tanktess coil is not a factor. Cold standby is

only suitable when thermostatic union (available

from ECR) is used with a bypass. Call factory for

instructions to change wiring.

Differential - 20°F typical. May be changed to

match system.

OTE: If public utility regulations in your community require"_

beling of the boiler with burner head size and firing rate, I

ease use label in literature envelope for this purpose. .._

The gas input for natural gas can be determined by

timing the gas meter. To vary the gas input, install

the nearest size orifice; then adjust the pressure

regulator up or down for the exact input desired.

The manifold pressure is to be measured at the

pressure tap on the gas valve.

OTE: Do NOT exceed gas valve manufacturer's"_

commended pressure adjustment range (3" minimum to !

All orifice sizes are approximate. The actual burner

input will vary with local heating values supplied.

Install, start, and adjust burner according to

manufacturer's instructions to be found in burner

carton.

omplete installation must be made in"_

ccordance with the requirements of local I

uthorities and the America Fire Protection I

ssociation, j)

Page 29

On a call for heat, the thermostat will actuate, com-

pleting the circuit to the aquastat. In turnm the circu-

lator and ignition systems are activated and ignition

will begin. In the event the boiler water temperature

exceeds the high limit setting on the boiler mount-

ed aquastat, power will be interrupted between the

aquastat and the ignition system. The power will

remain off until the boiler water temperature drops

below the high limit setting. The circulator wilt con-

tinue to operate under this condition until the ther-

mostat is satisfied.

ing the circuit to the ignition system. For oil burners

the switch wilt reset after the burner goes out post-

purge and attempt to relight. After three attempts to

light, the burner wilt go into permanent lockout.

Do not attempt to place the boiler back into op--'_

ration. Contact a qualified service agency. .i/

Should a blocked flue condition occur, the blocked

vent safety switch wilt shut the fuel to the main

burner off.

Should a blocked flue condition occur, the pres- (Do not attempt to place the boiler back into oph

sure switch will sense a drop in pressure, open- _ration. Contact a qualified service agency. .J

LT!i!!

Before operating, make certain the boiler and

system are full of water to minimum pressure

(this is usually 12 Ibs. per square inch on most

systems) and system is vented of air. See the

koperating and lighting instructions, j

1. This appliance is equipped with an ignition de-

vice which automatically lights the pilot. Do not try

to light the pilot by hand.

!AP.,

AZ))b_ _4 _4

_R_RE FOR YOUR SAFETY

ApB FOREOPERA ING

WHAT TO DO IF YOU SNELL GAS

• Do not try to light any appliance.

, Do not touchany electrical switch; do not

use any phone in your building.

, Immediately call your gas supplier from a

neighbor's phone. Follow the gas supplier's

instructions.

If you cannot reach your gas supplier, call

_the fire department.

J

2. Before operating, smell all around the appliance for

gas. Be sure to smell next to the floor because some

gas is heavier than air and will settle on the floor.

3. Use only your hand to push in or turn the gas

control knob. Never use tools. If the knob wilt not

push in or turn by hand, don't try to repair it, call a

qualified service technician.

Page 30

4. Do not use this appliance if any part has been

under water. Immediately call a qualified service

technician to inspect the appliance and to replace

any part of the control system and gas control which

has been under water.

1. STOP! Read the safety information in the user's

information manual.

2. Set thermostat to lowest setting.

3. Turn off all electric power to the appliance.

4. This appliance is equipped with an ignition de-

vice which automatically lights the pilot. DO NOT

TRY TO LIGHT THE PILOT BY HAND.

Remove the vent pipe at the base of the chimney or

flue and, using a mirror, check for obstruction.

The lever of the pressure relief valve on the boiler

should be operated periodically to make sure that

it is functioning properly. The pressure relief valve

should open before the water pressure exceeds

the 30 lb. reading on the gauge. If this pressure is

exceeded and the pressure relief valve leaks water

when the boiler is operating at normal pressures,

it should be immediately replaced. Corrosion can

build up rapidly at the valve seat and prevent its

functioning as a safety device.

,,_ WARNING ,,_

5. Turn gas control knob clockwise to "OFF."

6. Wait five (5) minutes to clear out any gas. If you

then smell gas, STOP, and follow in the safety infor-

mation "What To Do If You Smell Gas." If you don't

smell gas, go to the next step.

7. Turn gas control knob counterclockwise to

"ON ."

8. Turn on all electric power to the appliance.

9. Set thermostat to desired setting.

10.If the appliance will not operate, follow the in-

structions "To Turn Off Gas To Appliance" (below)

and call a qualified service technician or your gas

supplier.

(See off burner instructions for nozzle and electrode setting.)

1. Check oil burner nozzle to make certain it is tight

in adapter. Burner mounting bolts should be tight.

2. Check electrode setting, as they may have been

jarred out of position during transportation.

3. Lubricate burner motor and circulator motor if re-

quired. Some circulators are water lubricated and

do not require oiling.

4. Set room thermostat to call for heat, or jump

thermostat contacts on the boiler control.

5. Open all oil line valves.

1. Set thermostat to lowest setting.

2. Turn off all electric power to the appliance if ser-

vice is to be performed.

3. Turn gas control knob clockwise to "OFF." DO

NOT FORCE.

6. Turn service switch on. Burner should start.

7. On one pipe fuel systems only, vent pump as

soon as burner starts. Allow oil to run until all traces

of air in the suction line disappear.

8. Turn "OFF" burner and install pressure gauge

port on pump.

The venting system should be inspected at the start

of each heating season. Check the vent pipe from

the boiler to the chimney for signs of deterioration

by rust or sagging joints. Repair if necessary.

9. Start burner again and check oil pressure for 140

pounds. Adjust if necessary.

DO NOT SET FIRE VISUALLY L _J

Page 31

Instruments are the only reliable method to deter-

mine proper air adjustments. An improperly adjust-

ed burner causes soot and high fuel bills because

of incomplete combustion of the fuel oil. This in turn

may require excessive boiler maintenance, service

costs, and in some instances, house cleaning or re-

decorating. A competent service mechanic should

be consulted to make the proper adjustments with a

smoke tester, CO 2indicator and draft gauge. Bacha-

rach or Dwyer test kits include these instruments.

locks out, ignition stops, motor stops and oil

valve - when used - closes. To restart, open

oil supply valve and reset safety switch.

• Ignition Failure: With burner off, close oil

supply valve and run through start-up proce-

dure, The safety switch should lock out as in

flame failure.

* Power Failure: Turn off main power supply

switch while burner is operating. When burn-

er stops, restore power and burner should

start.

A ¼" diameter slot is provided in the inspection

cover plate to take draft readings in the combustion

chamber. A ¼" diameter hole wilt be required in the

flue pipe between the boiler and barometric damper

(if used) to take draft, CO2, smoke and temperature

readings. Adjust air shutter on oil burner to obtain

a "trace" of smoke. Measure CO 2 at this point. In-

crease air adjustment to lower CO 2approximately

1%. Check to insure minimum -.02 w.c. "overfire"

draft, and zero smoke. If -.02 w.c. "overfire" draft can

not be maintained, changes and/or modifications

may be required in the venting or the chimney.

CHECK SAFETY CONTROL CIRCUIT after burner

adjustments have been made for satisfactory per-

formance.

1. High Limit Control: Remove cover and note

temperature setting. With the burner operat-

ing, decrease this setting to the minimum point.