Page 1

SUPPLEMENTAL

INSTALLATION AND OPERATING

INSTRUCTIONS

CSD-1 COMMERCIAL BOILER CONTROLS

P/N 240010413, Rev. A [12/2013]

Page 2

CSD-1 COMMERCIAL BOILER CONTROLS

WARNING

!

Fire, explosion, asphyxiation and electrical shock

hazard. Improper installation could result in death

or serious injury. Read this manual and understand

all requirements before beginning installation.

Your commercial boiler is furnished with combustion side

water or steam controls to meet our interpretation of the

American Society of Mechanical Engineers (ASME) Safety

Code for Controls and Safety Devices for Automatically

Fired Boilers, No. CSD-1.

Installation shall conform to the requirements of the

authority having jurisdiction, or, in the absence of such

requirements, to the National Fuel Gas Code, ANSI-Z223.1/

NFPA-54 (latest revision). Where required by the authority

having jurisdiction, the installation shall conform to the

American Society of Mechanical Engineers (ASME) Safety

Code for Controls and Safety Devices for Automatically Fire

Boilers, No. CSD-1.

CSD-1 controls and this installation may be subject to

approval by local inspectors. Additional parts or equipment

may be required. Consult local authorities having

jurisdiction before the installation of the boiler.

CSD-1 controls furnished with commercial boilers are

applicable to boilers with inputs above 400,000 Btu/hr.

(Models 500-1500)

Additional parts required by CSD-1 standards may be

necessary to make this boiler compliant. This supplemental

instruction manual should be used in conjunction with the

Installation, Operation and Maintenance manual for your

specic boiler.

CSD-1 Component Installation

Based on parts listed in Installation, Operation and

Maintenance manual for your particular boiler, the following

changes should be made:

Complete Boiler Material List - See Table #1: CSD-1

Complete Boiler Material List.

See Table #2: CSD-1 Component Carton Material List

for component carton material list which replaces the

corresponding list in the installation manuals.

• See Table #3: CSD-1 Electronic Ignition Base Material

• Installed locations of additional components see Figures

For CSD-1 combustion side control, light off sequence is as

follows:

1.

2.

3.

4.

A longer pilot ame recognition time is a design

feature of this module and is correct.

Gas Pressure Requirements

• Maximum allowable inlet gas pressure (natural gas

• Verify inlet gas pressure is at least 5” w.c. but no

• If gas pressure entering the building is greater than 14”

C. Also, an independent pilot gas line which includes

manual shutoff valve, pressure regulator and

safety shutoff valve, two leak test valves on

main gas valve, and manual shutoff valve located

downstream of the main gas valve are added. See

List.

1a and 1b.

Turn on power. Set thermostat to call for heat.

Ignition starts to spark and lights pilot ame.

Ignition continues sparking about 12 seconds after pilot

lights.

Main burners ignite.

NOTICE

only) to controls in CSD-1 gas train is 14” w.c. (½

psig).

greater than 14” w.c.

w.c., installing contractor must provide overpressure

protection on downstream piping to prevent buildup of

downstream pressures in excess of 14” w.c. in event

the fuel system pressure regulator fails.

Combustion Side Control :

• Models 300 and 400, no changes are required to

existing gas trains.

• Models 500 through 1500 requirements include:

A. Intermittent pilot control module is required to

have maximum 15 second pilot ame establishing

period and ability to perform safety shutdown and

lockout in event of loss of ame signal at pilot.

B. The intermittent pilot module and manual reset

switch are used to replace the existing pilot

module.

• Alternatively, gas pressure entering the building may

be reduced with additional gas pressure regulator

outdoors. If inlet gas pressure to this additional

regulator is less than 14” w.c., then overpressure

protection may not be required.

• Consult local authority(s) having jurisdiction before

installing gas supply piping to the boiler.

2

Page 3

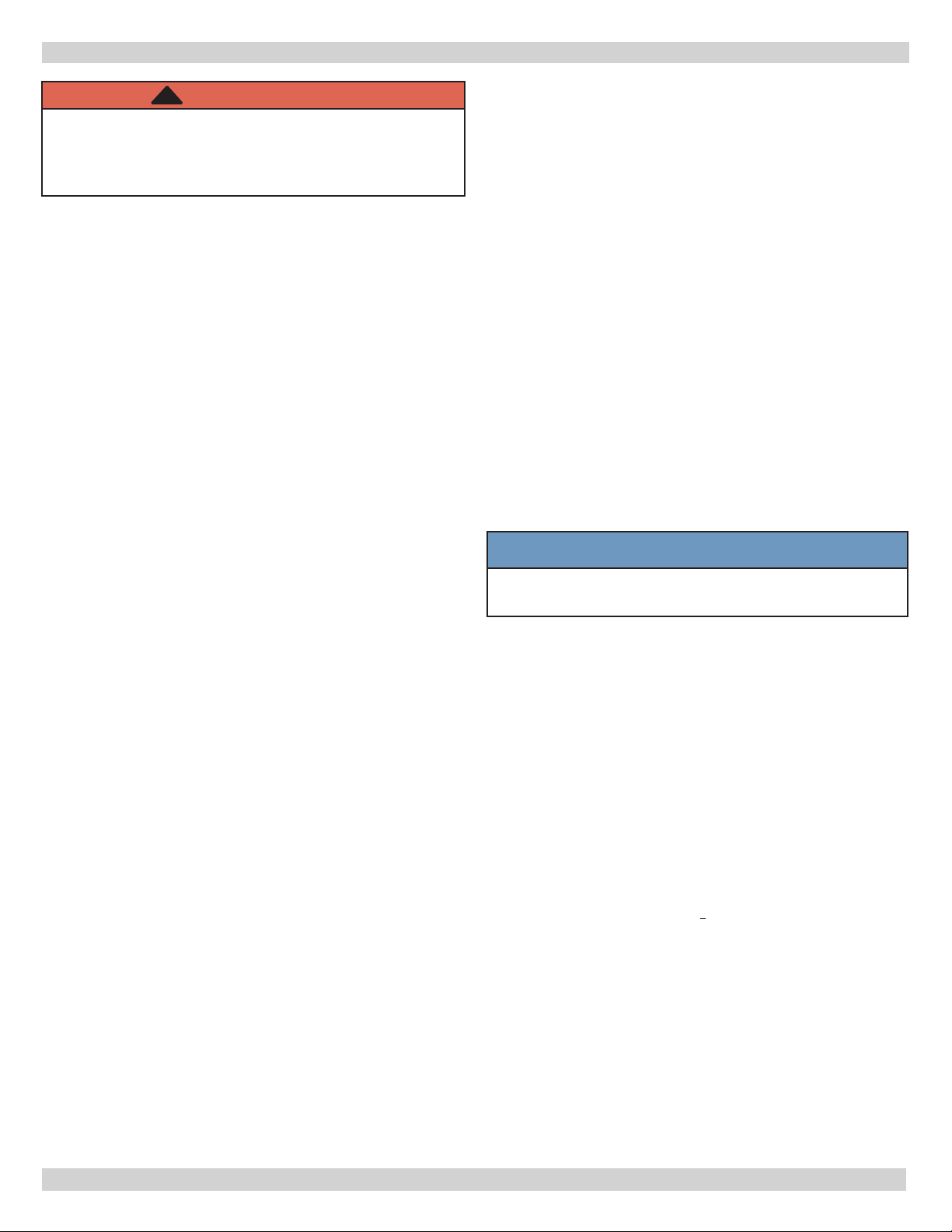

MATERIAL LISTS

Table #1: CSD-1 Complete Boiler Material List

Sections

Model

1000 1 9 1 2 SA-3 1000 1 1

1100 1 10 1 1 2 SA-3 1100 1 1

1200 1 11 1 3 SA-3 1200 1 1

1300 1 12 1 1 2 SA-3 1300 1 1

1400 1 13 1 1 2 SA-3 1400 1 1

1500 1 14 1 3 3 SA-4 1500 1 1

a. Boilers having total inputs of 400 MBH or less as complying with ANSI Z21.13 (Models 300 and 400), the standard combustion

b. There are additional parts on base assemblies for boilers having total inputs from 500 to 1,500 MBH (Models 500 to 1500)

c. For steam boilers, there is an additional CSD-1 steam trim carton for gravity or condensate pump return (Part# 41257103)

L Inner R 300 CSD-1 400 CSD-1 500 CSD-1

300 1 2 1 SA-1 300 1 1

400 1 3 1 SA-1 400 1 1

500 1 4 1 1 SA-1 500 1 1

600 1 5 1 2 SA-2 600 1 1

700 1 6 1 1 1 SA-2 700 1 1

800 1 7 1 2 SA-3 800 1 1

900 1 8 1 1 1 SA-3 900 1 1

side controls meet CSD-1 and no changes to the standard component carton are required.

to meet CSD-1. See “Table 2: CSD-1 Component Carton Material List” for details.

or an additional CSD-1 steam trim carton for boiler feed pump return (Part# 41257104). See appropriate CSD-1 Steam

Trim Carton Material List (Tables 5a and 5b) for details.

CSD-1 Component Carton

a & b

Steam

Trim

Carton

d

CSD-1

Carton

AC

Jacket

End

Panel

Carton

Base

End

Panel

Carton

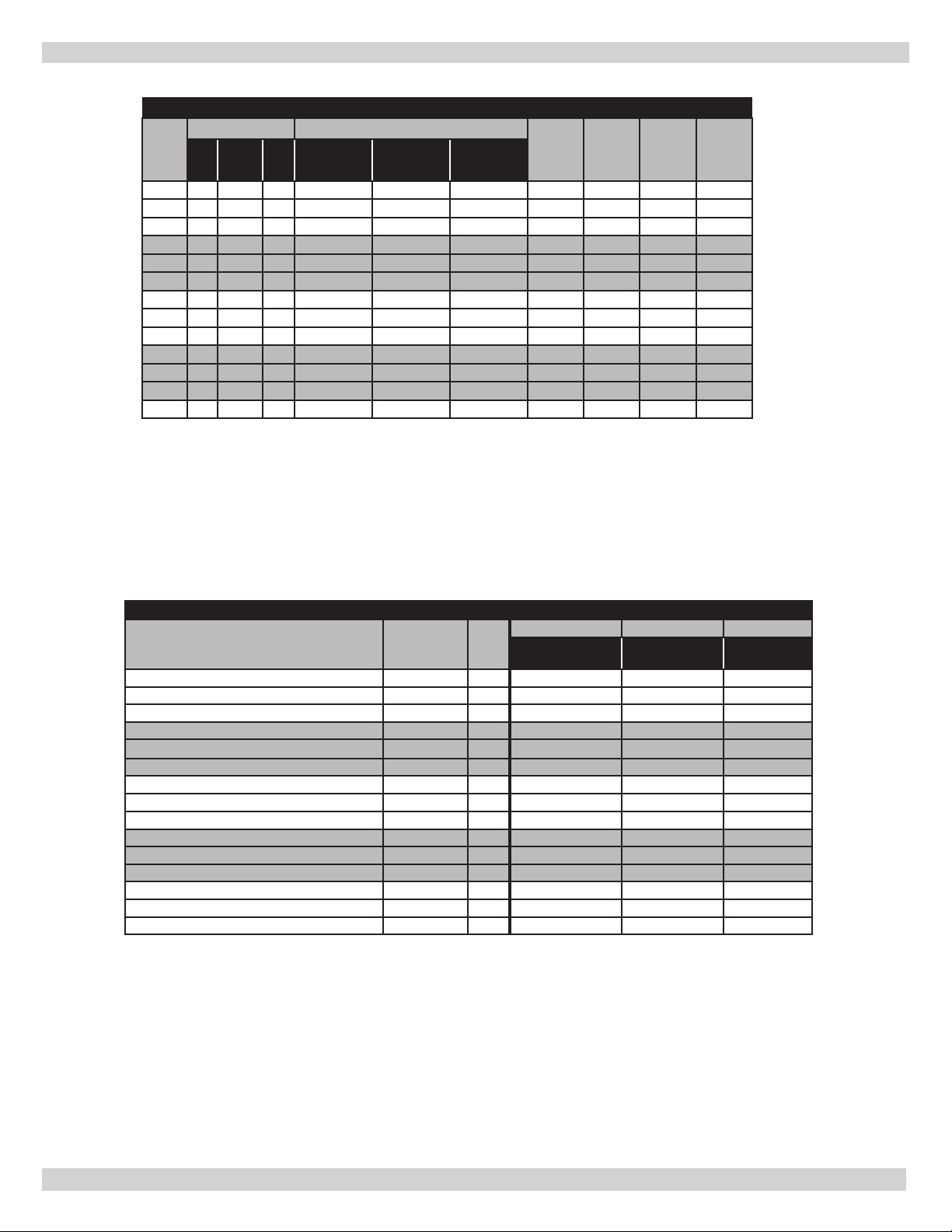

Table #2: CSD-1 Component Carton Material List

550001664 550001665 550001666

Description Stock No. Unit

300 Base Assembly CSD-1 550001670 Ea. 1

400 Base Assembly CSD-1 550001671 Ea. 1

500 Base Assembly CSD-1 550001672 Ea. 1

300 Intermediate Jacket Carton 550001673 Ea. 1

400 Intermediate Jacket Carton 550001674 Ea. 1

500 Intermediate Jacket Carton 550001675 Ea. 1

300 Draft Hood 42557113 Ea. 1

400 Draft Hood 42557114 Ea. 1

500 Draft Hood 42557115 Ea. 1

Control Panel Assembly 550001801 Ea.

Control Panel Assembly CSD-1 300/400 550001869 Ea. 1 1

Control Panel Assembly CSD-1 500 550001870 Ea. 1

Top Front Panel 300 109009216 Ea. 1

Top Front Panel 400 109009217 Ea. 1

Top Front Panel 500 109009210 Ea. 1

Boilers having total inputs of 400 MBH as complying with ANSI Z21.13 (Models 300 and 400), the standard combustion side controls

meet CSD-1 and no changes to the standard component carton are required.

300 CSD-1 400 CSD-1 500 CSD-1

3

Page 4

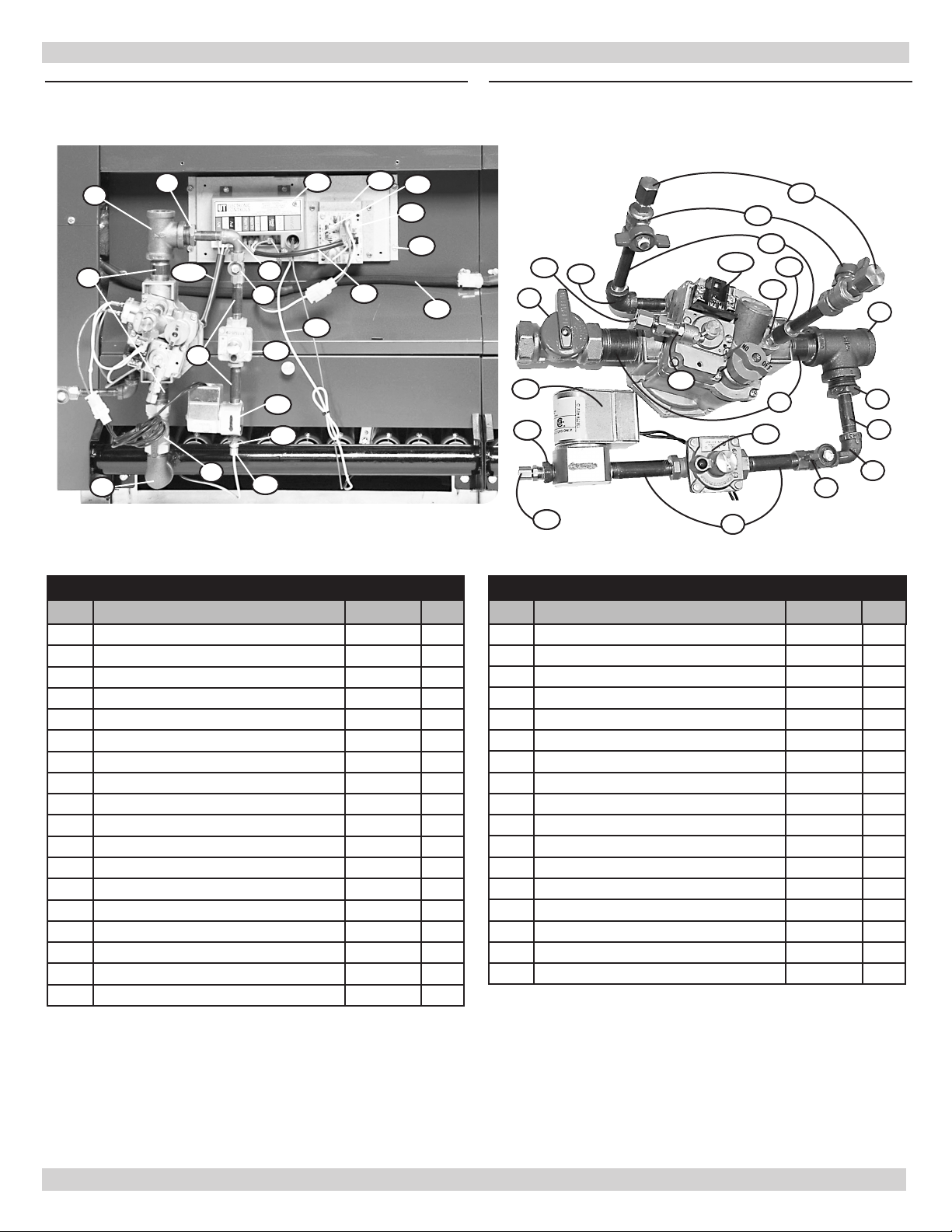

MATERIAL LISTS

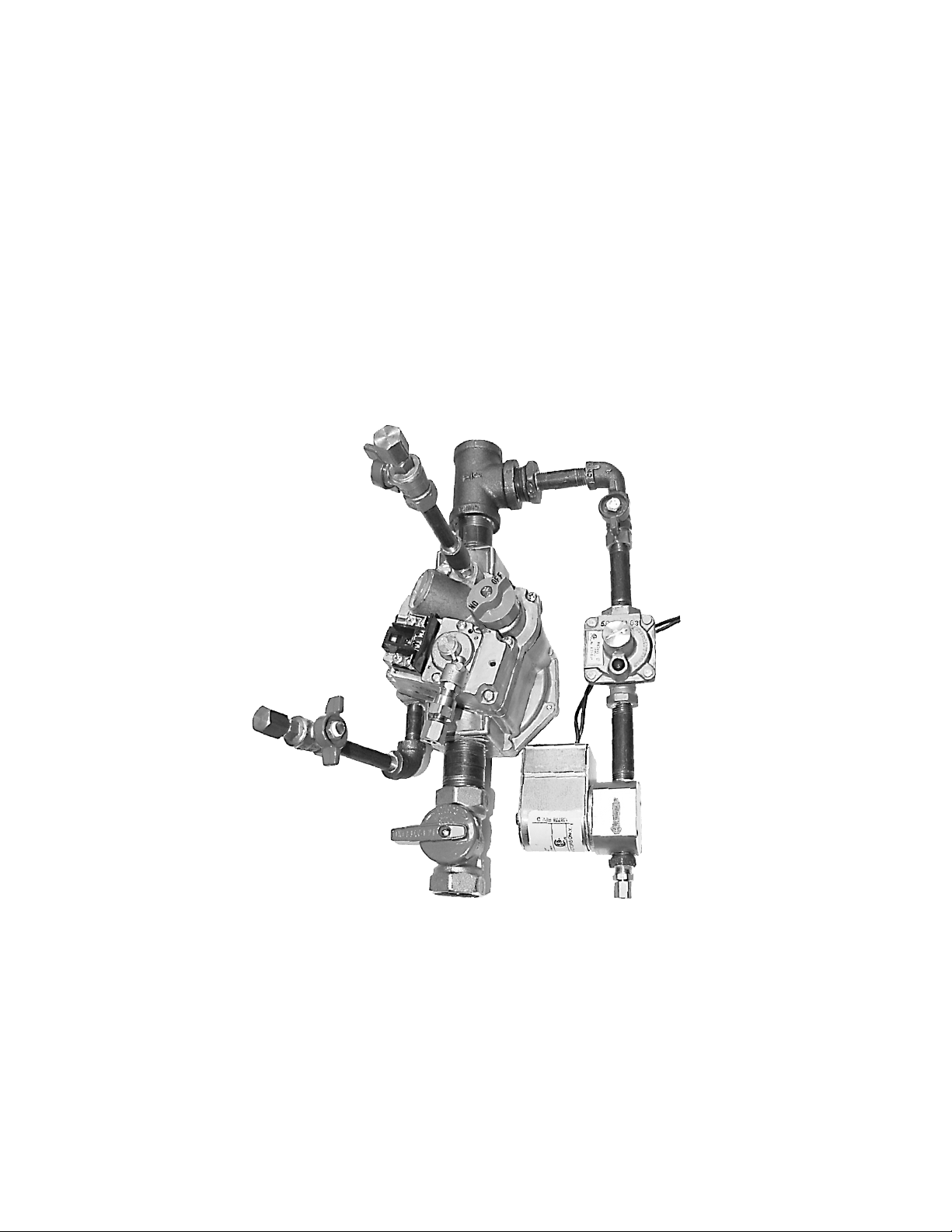

Figure 1a - CSD-1 500 Gas Train Figure 1b - CSD-1 500 Gas Train

5

14

4

15

32

16

17

3

19b

7

8

20

30

33

9

10

11

13

2

1

Table #3: CSD-1 Electronic Ignition Base Material List

Item Description Part No. Qty.

1 ¾” 90 Street Elbow Back 14693040 1

2 ¾” Manual Shutoff Valve 14657001 1

3 ¾” x 2” Nipple Black 14607201 2

4 ¾” Tee Black 14693076 1

5 ¾” x ¼” Bushing 1060002 1

6 ¼” x 2” Nipple Black 1310018 1

7 ¼” Street Elbow Black 14657007 1

8 ¼” Manual Shutoff Valve 14657002 1

9 ¼” x 2½” Nipple Black 14607000 2

10 ¼” Gas Pres. Regulator, 6” w.c. 14657004 1

11 ¼” Magnetic Valve w/Connector Assembly 43357103 1

12 ⅛” NPT x ⅛” Tube M. Connector 14657019 1

13 ¼” x ⅛” Bushing 14657008 1

14 Control STP W/Alarm 1140007 1

15 Control Mounting Panel, CSD-1 24 GA Galv 109006833 1

16 Control CSD Lockout Daughter Board 1140008 1

17 Control Mounting Panel 109006832 1

18* Screws, #8 x ⅜ Self Tap 201000001 8

12

26

25

23

11

21

24

27b

2

22

28

29

3

13

10

8

12

Table #3: Continued

Item Description Part No. Qty.

19a* Harness CSD-1 Control (300, 400) 1263016 1

19b Harness CSD-1 Control (500) 1263019 1

20 Harness CSD-1 Control 240006623 1

21 Compression Fitting, ⅛”NPT x ¼” Tube 14657025 1

22 Brass Coupling, Male ⅛” x 5/16”-24 14657024 1

23 ⅛” x 2½”” Nipple Black 14607804 2

24 ⅛” 90 Elbow (500 Only) 14657010 1

25 ⅛” Manual Shutoff Valve 14657003 2

26 ⅛” Pipe Cap 14657012 2

27a* Gas Valve, Electronic Ignition, Nat. (300, 400) 14662315 1

27b Gas Valve, Electronic Ignition, Nat. (500) 14663001 1

28 ⅛” Coupling Steel 14657013 1

29 CSD-1 Pilot Outlet Adapter 43357104 1

30 Wire Harness, Base to Base 240006732 1

31* ⅛ x 1½, Nipple, Black (300, 400 Only) 14657009 1

32 Wire Jumper, CSD-1 Board (Orange) 1263017 1

33 Ground Wire, Spark (White) 371-1-21.01 1

*Not Shown

9

4

5

6

7

4

Page 5

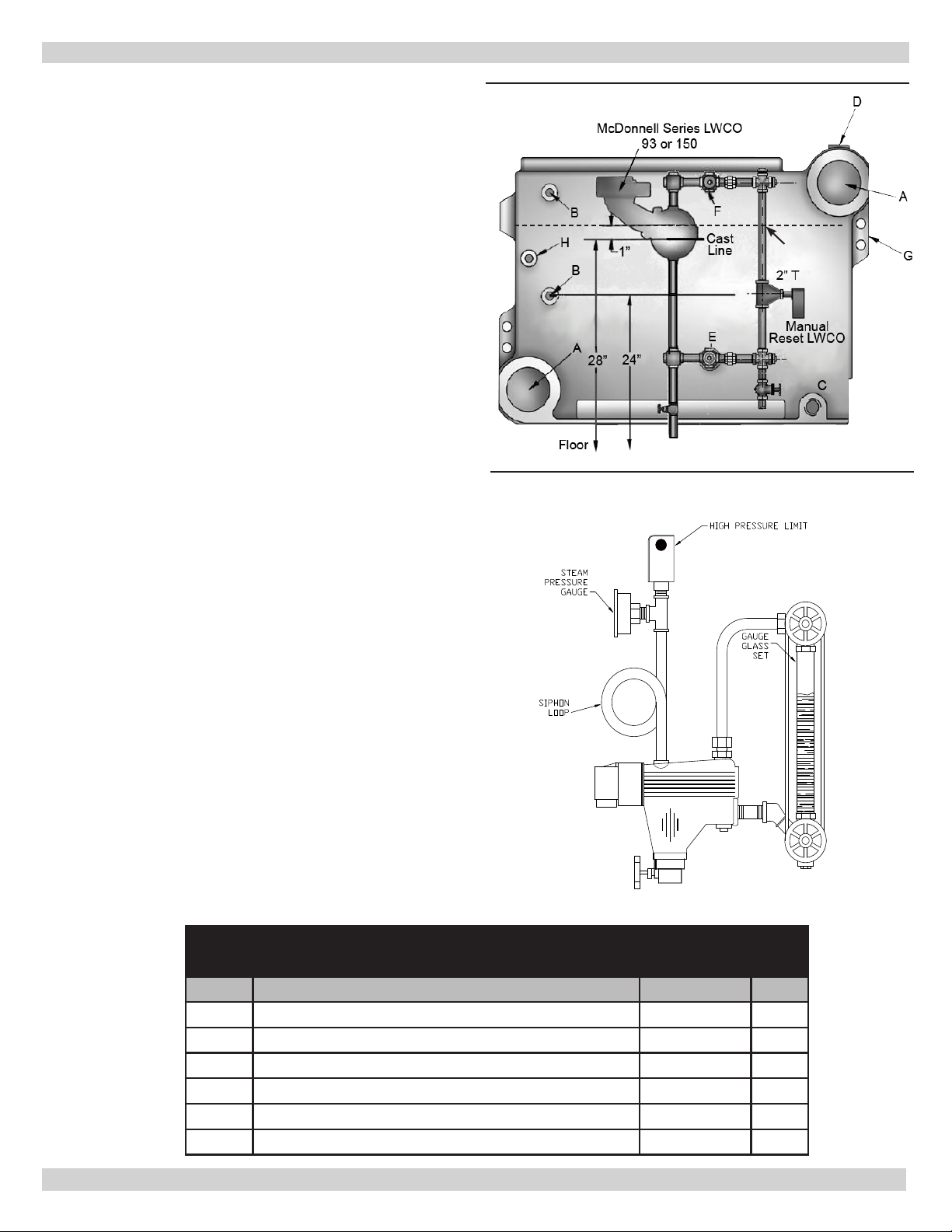

STEAM SIDE CONTROLS

Steam Side Control - Two low water cutoff devices and

two pressuretrols, one with auto reset and the second with

Figure 2 - Steam Boiler Feed Pump Return

manual reset, are required. In order to make the two

low water cutoff devices work in the appropriate

sequence, manufacture recommends locating both

devices at same end of boiler.

There are three different control systems for three different

types of condensate returns.

Identify the three different types of condensate returns:

• Gravity return - condensate is returned by gravity.

• Condensate pump return - condensate is returned

by pump(s), controlled by the water level in the

condensate receiver tank.

• Boiler Feed Pump Return - condensate is returned by

pump(s), controlled by the water level in the boiler.

Gravity Return And Condensate Pump Return

With gravity and condensate pump return, additional

control components are the same. See Table #5a and

Figure #2 for tappings.

• Tappings B & B location shown in Figure #2.

Figure 3 - Steam Gravity and Condensate Pump Return

Installation shown in Figure #3, Primary LWCO and

Pressuretrol with gauge glass set.

Normal

Water Line

• Tappings D or F (Figure #2)- Manual reset pressuretrol

and ¼” 90° brass syphon.

• Tappings E & F - Secondary LWCO (w/manual reset).

Use in conjunction with primary LWCO equipped on

boiler.

When using two LWCOs, place manual reset lower than

automatic LWCO. Water must be visible in gauge glass

when manual reset trips.

• Figure 3 shows how to raise automatic (Series 67)

LWCO 1-inch.

• Remove 1” from long side of ¼” diameter 90° brass

siphon tube.

• Remove nipple in series 67 and replace with 1 ½” long

nipple and street elbow.

• Water level control device located on condensate

receiver tank and controls condensate return pump is

not supplied.

Table #5a: CSD-1 Steam Trim Carton Material List for Gravity Return

or Condensate Pump Return (Part No. 41257103)

Item Description Part No. Qty.

1 LWCO w/Manual Reset (secondary) 240007388 1

2 Bushing, Steel or Cast 1” x 1¼” 14657016 1

3 Pressure Switch Control, Manual Reset 14662311 1

4 90° Brass Syphon, ¼” 14643004 1

5 ELB,ST,1/2”,45 DEG.BRASS 240007541 1

6 NIPPLE 1/2” X 1/2”LG BRASS 240007542 1

WATER LEVEL

29” TO FLOOR

5

Page 6

BOILER FEED PUMP RETURN

Boiler feed pump return additional parts See Table #5b.

See Figure #2 for installed locations of additional parts.

•Tappings B & B - Water gauge glass set and

pressuretrol (requires ttings 4-7 in Table #5b).

•Tapping D - Steam gauge and pressuretrol (requires

tting 8 in Table #5b).

•Tappings E & F - LWCO (auto and manual) and

pump control. Installer supply and size the steam

(top) and water (bottom) equalizing pipe lengths so

the horizontal cast line on the control body is 28”

above oor. Secondary control is 24” above the oor.

See Figure #2.

Table #5b: CSD-1 Steam Trim Carton Material List For

Boiler Feed Pump Return (Part No. 41257104)

Item Description Part No. Qty.

1 Pressure Switch Control, Manual Reset 14662311 1

2 LWCO and Pump Control (primary) 14626306 1

3 LWCO, MAN RESET, CSD-1 APRVD, SHT PROBE 240007388 1

4 90° Brass Syphon, ¼” 14643004 1

5 Brass Nipple, ½” x 3½” 14607024 2

6 Brass Tee, ½” x ½” x ¼” 14693051 2

7 Brass Coupling, ½” 14693052 2

8 Bushing, ½” x ¼” 1060001 1

6

Page 7

SEQUENCE OF OPERATION

Call For Heat

Control recognizes call for heat when power is applied

to 24V terminal on control module. Since control

receives signal from the thermostat, when call for heat is

terminated, heating cycle immediately terminates and all

control outputs will shut off.

Ignition Trial Period

Control energizes pilot gas valve and spark outputs for

ignition trial time of 12 seconds. If ame is sensed during

12 seconds of ignition trial, spark output is de-energized,

main gas valve is energized, and control enters steady heat

mode. If ame is not established within ignition trial period,

control de-energizes the spark and gas valve and operates

as described below in Ignition Failure/Re-try Sequence.

PILOT

If maximum number of ignition trials has not been

completed, control delays for 5 minute inter-purge period.

After the inter-purge, control attempts another ignition

trial. Refer back to Ignition Trial Period for details.

Steady-State Heating

Control keeps pilot gas valve and main gas valve energized

while continuously monitoring call for heat and ame

status. Control will remain in this steady-state heating

mode until power is removed by (a) thermostat satised,

(b) pressure switch opening, or (c) ame being lost.

If call for heat is satised, power is removed from control,

de-energizing pilot gas valve and main gas valve.

Ignition Failure/Re-Try Sequence

After an unsuccessful ignition trial, control checks to see

if maximum number of ignition trials (2 trials) has been

completed. If maximum number of ignition trials has been

completed, control will lockout. See Lockout (next page) for

details.

If ame is lost, control will shut off main gas valve within

one second, leave pilot gas on, and immediately start

ignition trial. Control checks to see if maximum number

of ame losses (2 per call for heat) has been reached.

If maximum number of ame losses has been reached,

control locks out. See Lockout section for details.

7

Page 8

SEQUENCE OF OPERATION

Gas Valve Sensing

If either or both the pilot and main gas valves are sensed

to be on when commanded to be off, or if no voltage

appears at gas valve output which was commanded on,

control will shut off all outputs and enter either “soft” or

“hard” lockout state. Main valve is interlocked with the pilot

valve and voltage can only be detected on main valve when

pilot valve is energized. Control locks out the rst time

as “soft” lockout, then retries after 5 minutes and enters

“hard” lockout state. Lockout should be manually reset as

described in “Lockout.”

Flame Present With Gas Off

If ame is sensed for longer than 2 seconds during a period

when gas valve should be closed, control will enter lockout.

Power Interruptions

Power interruptions less than 0.15 seconds will not

cause control to interrupt heat sequence while power

interruptions over 0.25 seconds will cause the control

to reset lockout and ignition trial counters. Power

interruptions of any duration will not cause a lockout or any

other operation requiring manual intervention.

Lockout

Controller automatically resets from rst lockout in 5

minutes. If second lockout occurs before call for heat is

satised, it will require manually resetting by depressing

red button on CSD-1 daughter board. This can be reached

with a pencil through the vent holes. A red LED will also

indicate lockout and can be seen through the vent holes.

8

Page 9

ELECTRICAL WIRE DIAGRAMS - GAS VALVE CONTROL WIRING

The suggested schematic wiring diagrams are included. Please use the appropriate one for the installation.

CSD-1 HONEYWELL VR8304M,H MAIN GAS VALVE CONTROL WIRING

9

Page 10

ALARM

CONTACTS

JUMPER

UT 1145-2

BOILER

STAT

COM

24 VAC

R

PILOT SAFETY

SHUTOFF

VALVE

BLACK

WHITE

BLUE

D D

MAIN GAS VALVE

ROBERT SHAW 7000 DE RHC

TR TH

SPARK

CABLE

TO PILOT

GREEN

SPARK

24V

GND

24V

ALARM

ALARM

PV

MV PV

MV

BLUE

WHITE

RED

YELLOW

RED

RED

CONTROL

1003-612A

WHITE

BLUE

TO CONTROL

BOX

GREEN

TO PILOT

GROUND

WHITE

GROUND

ELECTRICAL WIRE DIAGRAMS - GAS VALVE CONTROL WIRING

The suggested schematic wiring diagrams are included. Please use the appropriate one for the installation.

CSD-1 ROBERT SHAW 7000 DE RHC GAS VALVE CONTROL WIRING

10

Page 11

ELECTRICAL WIRE DIAGRAMS - CSD-1 STEAM BOILERS

WITH CONDENSATE PUMP/GRAVITY RETURN

11

Page 12

ELECTRICAL WIRE DIAGRAMS - CSD-1 STEAM BOILERS

WITH CONDENSATE PUMP/GRAVITY RETURN

3

12

Page 13

ELECTRICAL WIRE DIAGRAMS - CSD-1 STEAM BOILERS

WITH BOILER FEED PUMP RETURN

13

Page 14

ELECTRICAL WIRE DIAGRAMS - CSD-1 STEAM BOILERS

WITH BOILER FEED PUMP RETURN

3

14

Page 15

NOTES

15

Page 16

Loading...

Loading...