Page 1

D248 Series

i Ln

Cast

Iron Commercial

Steam Boiler

INSTALLATION1 OPERATION &

MAINTENANCE MANUAL

'%%

"llllllllllllllllllllllllllllllllllh,,

............,,,,,..........

.....',',','........................

,,,,,,,,,,,,,,,,,,,,,,,.....

I,

,_ " ,, '........... ' ,, ,,i, I ," ,,,,,", ,,

,,,,,,,,,,,,,,,,,,,

US

Manufactured by:

ECR International, Inc.

220! Dwyer Avenue. Utica NY 13501

web site www ecnnternatlonal coin

H

P/N# 240009137, Rev B [06/2013]

Page 2

INSTALLATION MANUAL AND OPERATING INSTRUCTIONS

TABLE OF CONTENTS

Safety Symbols .................................................. 2

Boiler Ratings & Capacities .................................. 3

Rules For Safe Installation & Operation .................. 4

Locating The Boiler ............................................. 5

Combustion Air, Chimney & Vent Pipe Connection ... 5

Minimum Vent Pipe CLearance, ............................. 5

Installation ........................................................ 5

Ventilation And Combustion Air ............................ 6

Vent Installation ................................................. 8

Assembly Of Bases, Starting Section Assembly ...... 12

Attaching Draft Hoods ......................................... 13

Installing Boiler Jacket Panels .............................. 14

Control Mounting And Installation ......................... 17

Tappings ........................................................... 19

Boiler Trim, Water Trim, Water Trim Assembly ........... 19

Boiler Piping ...................................................... 20

Boilers Used With Refrigeration System .................. 20

Boiler Piping, High Limit, Pipe Sizing ...................... 20

Piping Diagrams ................................................ 21

Connecting Gas Service ...................................... 23

Electrical Wiring ................................................. 24

Installing Thermostat .......................................... 24

Adjust Thermostat Heat Anticipator ....................... 24

Stage Firing Multiple Base Boilers .......................... 24

Wiring Diagrams ................................................ 25

Operation and Service ......................................... 27

Functions & Operation, Trial/Pilot Ignition .................. 27

Main Burner Operation, System Troubleshooting ......... 27

Component & Spark Ignition Check ........................ 27

Startup & Checkout, Start system .......................... 28

Pilot Flame Adjustment, Check Burner Input ............ 28

Pilot System Troubleshooting Table ............................ 29

Checking & Adjusting ......................................... 30

Cleaning And Maintenance .................................. 31

SAFETY SYMBOLS

Indicates a hazardous situation which, if not

avoided, WILL result in death or serious injury.

Indicates a hazardous situation which, if not

avoided, could result in death or serious injury.

CAUTION

Indicates a hazardous situation which, if not

avoided, could result in minor or moderate injury.

Indicates information which should be followed to

ensure proper installation and operation.

KEEP THIS MANUAL NEAR BOILER,

RETAIN FOR FUTURE REFERENCE.

Fire, explosion, asphyxiation and electrical shock

hazard. Improper installation could result in death

or serious injury. Read this manual and understand

all requirements before beginning installation.

Page 3

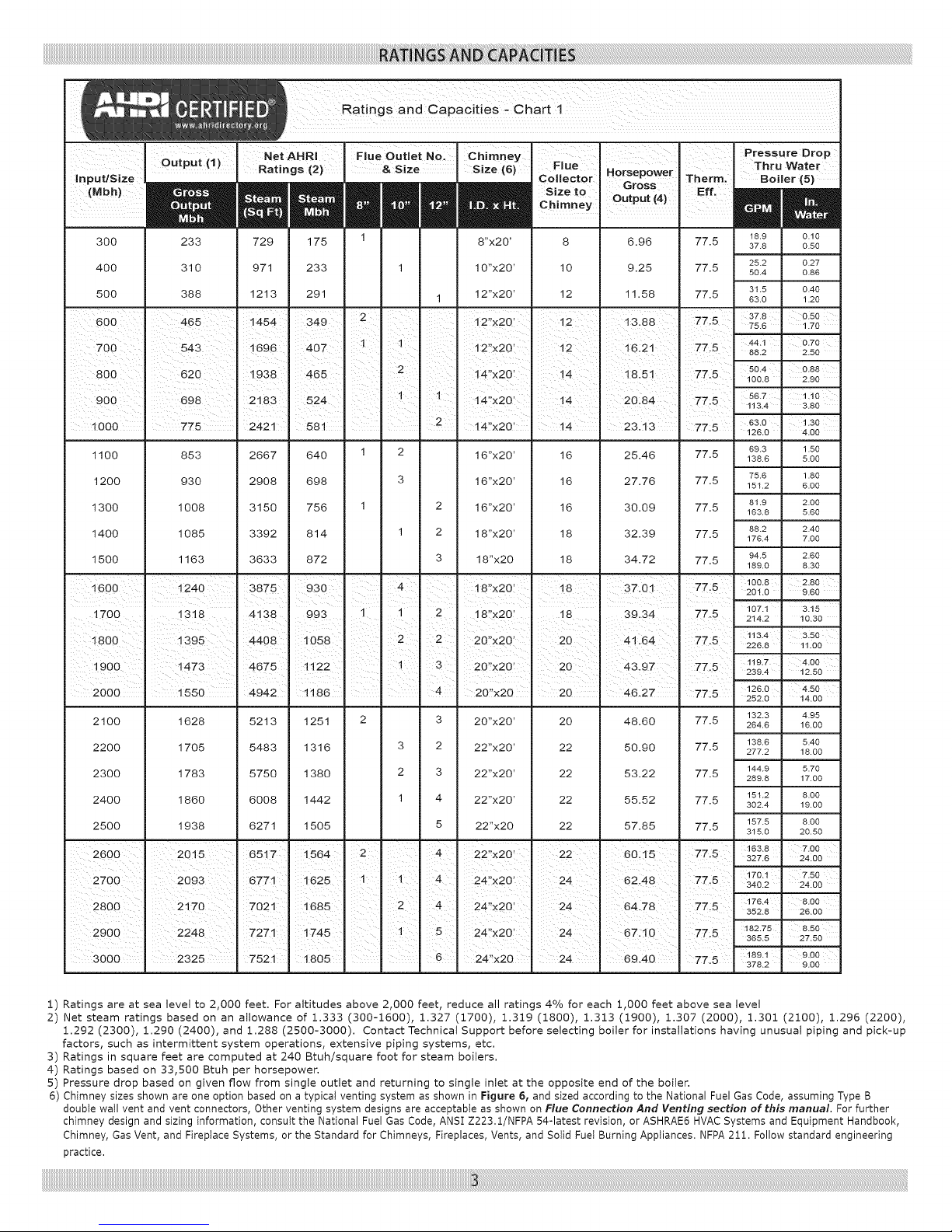

Input/size

(Mbh)

Output (1)

Net AHRI

Ratings (2)

Flue Outlet No.

& Size

Chimney

Size (6) Flue

Collector

Size to

Chimney

Horsepower

Gross

Output (4)

Pressure Drop

Therrn. Boiler (5)

Eft.

Thru Water

300 233

400 310

500 388

700 543

800 620

900

1000 775

11OO 853

1200 930

1300 1008

1400 1085

1500 1163

1700 1318

i800 i395

i900 i473

2000 1550

8"x20' 8

10"x2O' 10

12"x20' 12

12"x20' 12

12'x20! 12

14

14'x20' 14

14"x201 i4

16"x20' 16

16"x20' 16

16"x20' 16

18"x20' 18

18"x20 18

18',X2Oi i8

18!'x20' 18

20,x20' 20

20"x20!

20'!x20 20

16;21

6.96

9.25

11.58

13.88

18.51

20184

23,13

25.46

27.76

30.09

32.39

34.72

37.0i

39.34

4i]64

46.27

77.5

77.5

77.5

77;5

77.5

77.5

77.5

77:5

77.5

77.5

77.5

77.5

77.5

77:5

77.5

77:5

77.5

77:5

2100 1628

2200 1705

2300 1783

2400 1860

2500 1938

2600 . 2015

2700 2093

2800 2i70

2900

3000 2325

1) Ratings are at sea level to 2,000 feet. For altitudes above 2,000 feet, reduce all ratings 4% for each 1,000 feet above sea level

2) Net steam ratings based on an allowance of 1.333 (300-1600), 1.327 (1700), 1.319 (1800), 1.313 (1900), 1.307 (2000), 1.301 (2100), 1.296 (2200),

1.292 (2300), 1.290 (2400), and 1.288 (2500-3000). Contact Technical Support before selecting boiler for installations having unusual piping and pick-up

factors, such as intermittent system operations, extensive piping systems, etc.

3) Ratings in square feet are computed at 240 Btuh/square foot for steam boilers.

4) Ratings based on 33,500 Btuh per horsepower.

5) Pressure drop based on given flow from single outlet and returning to single inlet at the opposite end of the boiler.

6) Chimney sizes shown are one option based on a typical venting system as shown in Figure 6, and sized according to the National Fuel Gas Code, assuming Type B

double wall vent and vent connectors, Other venting system designs are acceptable as shown on Flue Connection And Venting section of this manual. For further

chimney design and sizing information, consult the National Fuel Gas Code, ANSI Z223.1/NFPA 54-latest revision, or ASHRAE6 HVAC Systems and Equipment Handbook,

Chimney, Gas Vent, and Fireplace Systems, or the Standard for Chimneys, Fireplaces, Vents, and Sotid Fuet Burning Appliances. NFPA 211. Follow standard engineering

practice.

20"x20' 20

22"x20' 22

22"x20' 22

22"x20' 22

22"x20 22

24"x20'

24'!x201

24,x20' 24

24'!x20 24

48.60

50.90

53.22

55.52

57.85

60ii5

62.48

64178

67:10

69,40

77.5

77.5

77.5

77.5

77.5

77 5

77.5

77.5

77.5

77:5

Page 4

Safety Information

iMPORTANT: Read the following

COMPLETELY before installing!!

Fire, explosion, asphyxiation and electrical shock

instructions

hazard. Improper installation could result in death

or serious injury. Read this manual and understand

all requirements before beginning installation.

When Your Boiler Arrives

When boiler arrives be sure to save and refer to

instructions,

Inspect each item received for visible damage. If any

parts are damaged, report this to freight company

immediately and request them to call and make

inspection before you make any installation. Have

inspector prepare a signed report. Send copy of

report to manufacturer.

We must have the signed inspection report of the

freight company to prove their liability.

Keep boiler area clear and free from combustible

materials, gasoline and other flammable vapors

and liquids.

DO NOT obstruct air openings to the boiler room.

Modification, substitution or elimination of factory

equipped, supplied or specified components may

result in personal injury or loss of life.

TO THE OWNER = Tnstallation and service of this

boiler must be performed by a qualified installer.

TO THE INSTALLER = Leave all instructions with

boiler for future reference.

When this product is installed in the

Commonwealth of Massachusetts the installation

must be performed by a Licensed Plumber or

Licensed Gas Fitter.

1. Never test for leaks with an open flame, Use soap suds

to check all connections, This will avoid any possibility

of fire or explosion,

2. Boiler is configured for operation with natural gas,

Over-firing will result in premature failure of boiler sec-

tions and cause dangerous operation, Verify there is

adequate gas supply piping,

3. Never vent this boiler into enclosed space, Always con-

nect boiler to chimney and vent to outside, Never vent

to another room or inside abuilding,

4. Verify there is adequate air supply for complete com-

bustion,

5. Follow regular service and maintenance schedule for

efficient and safe operation,

Read these instructions carefully before beginning

the installation to be sure all packages have been

received. ]:t is recommended that you follow the

step=by=step instructions for best assembly results.

Before discarding any packing material carefully

examine for loose parts. Also store all parts received

where they will not be lost or damaged.

CODES GOVERNING INSTALLATION

Installation must conform to the requirements of the

authority having jurisdiction or, in the absence of

such requirements, to the National Fuel Gas Code,

ANSI Z223.1/NFPA54.

Where required by the authority having jurisdiction, the

installation must conform to the standard for Controls

and Safety Devices for Automatically Fired Boilers,

ANS_/ASME CSD=I,

Installation

Boiler is designed to provide wide heating capacity range

with multiple burner modules, each equipped with its own

set of controls. For purposes of orientation, gas manifold

side of boiler is considered front. Instructions are written

for assembly of boiler starting with left side and working to

right side.

Hot water boiler installed above radiation level or as

required by the Authority having jurisdiction, must be

provided with a low water cutoff device at the time of boiler

installation.

Fire hazard. Do not install boiler carpeting. Failure

to follow these instructions could result in death or

serious injury.

6. Never install boiler on carpeting.

Page 5

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii_!i_I!E!__i!_i__i6_!_i_i_i_i_i_ii_i_ii_i_ii_i_i_iii!E_i_;E;il;Jl_ii_i_!!_il_iliiilililililil_iliiilililililil_iliiilililililil_iliiilililililil_iliiilililililil_iliiilililililil_iliiilililililil_iliiilililililil_iliiilililililil_iliiilililililil_iliiilililililil_iliiilililililil_iliiilililililil_iliiilililililil_iliiilililililil_iliiilililililil_iliiilililililil_iliiilililililil_iliiilililililil_iliiilililililil_iliiilililililil_iliiilililililil_iliiilililililil_iliiilililililil_iliiilililililil_iliiilililililil_iliiilililililil_iliiilililililil_iliiilililililil_iliiilililililil_iliiilililililil_iliiilililililil_iliiilililililil_iliiilililililil_iliiilililililil_iliiilililililil_iliiilililililil_iliiilililililil_iliiilililililil_iliiilii_

Boiler Location

Locate boiler on level, non=combustible foundation as near

to chimney or flue as possible. Allow 24 inches at front and

sides of boiler for servicing and cleaning. When installed in

utility room, the door should be wide enough to allow the

largest boiler parts to enter, or permit replacement of any

other appliance in the same room.

Tnstalling contractor must provide ventilated

foundation for boiler when installing:

• Over a room

• Over electrical wiring or cables of any kind

• Tf concrete floor is "green," or water is channeled

under concrete floor

Combustion Air

Provide combustion and ventilation air in accordance

with the section "Air for Combustion and Ventilation", of

the National Fuel Gas Code, ANSI Z223.1/NFPA 54, or

applicable provisions of the local building codes.

Chimney And Vent Pipe Connection

This is a very important part of the heating system. It must

be clean, the right size, properly constructed and in Good

Condition. No boiler can function properly with a bad

chimney. See Pages 6-::L0for specific venting instructions.

Flue pipe should be same size as draft hood outlet from boiler

to flue collector. See Chart 1 for Typical Chimney Size. Main-

rain a minimum upward slope of 1/4 inch per linear foot from

boiler to the chimney. Fasten joints together with sheet metal

screws to prevent sagging.

Minimum Vent Pipe Clearance

If the vent pipe must go through a crawl space, double

wall vent pipe should be used. Where vent passes through

a combustible wall or partition, use a ventilated metal

thimble. The thimble should be 4 inches larger in diameter

than vent pipe. If boiler is installed with single wall

galvanized type vent pipe, it must have 6 inches clearance

between its surface and any combustible material. If

UL listed type B (insulated) vent pipe is used, clearance

between it and combustible material to be as listed by pipe

manufacturer.

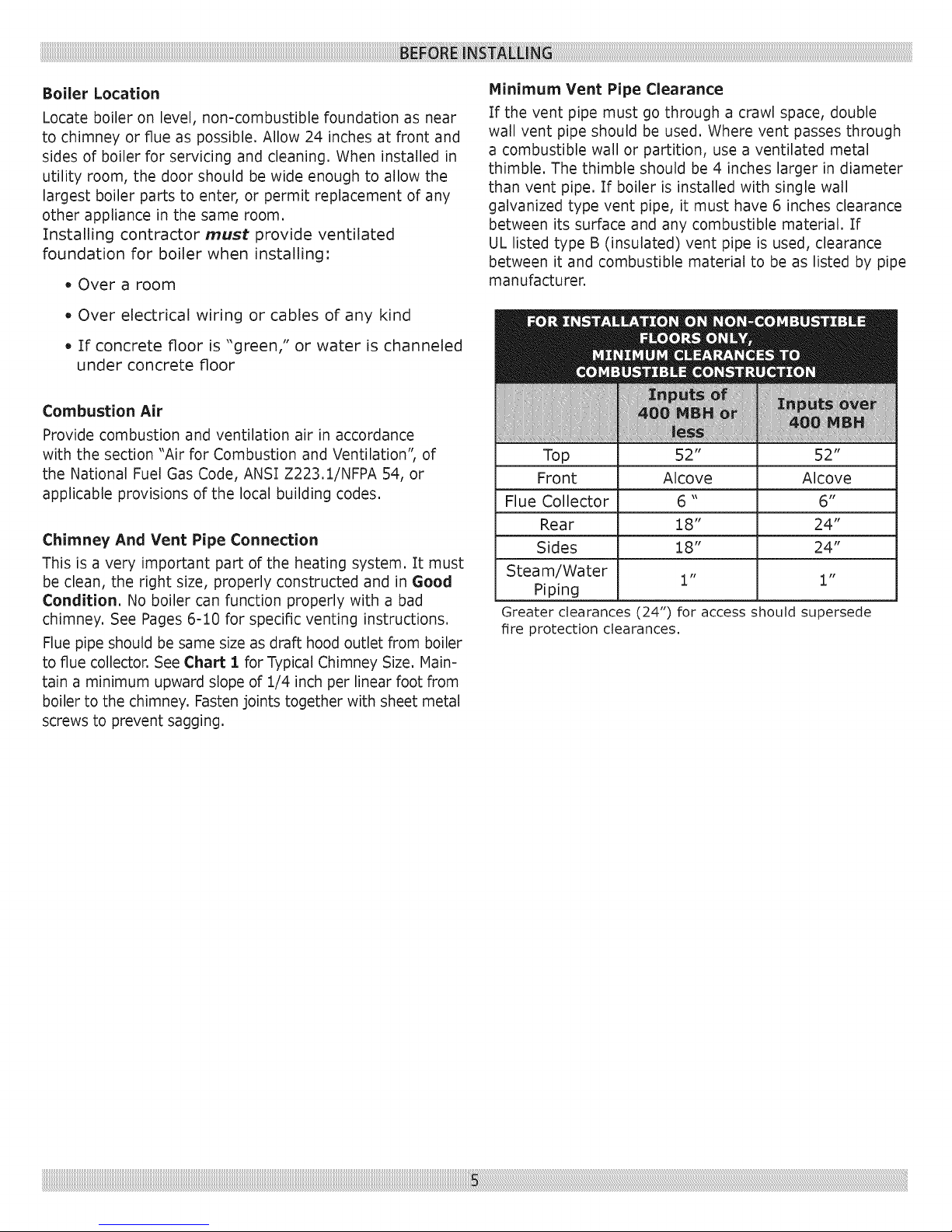

Top 52" 52"

Front Alcove Alcove

Flue Collector 6 " 6"

Rear 18" 24"

Sides 18" 24"

Steam/Water 1" 1"

Piping

Greater clearances (24") for access should supersede

fire protection clearances.

Page 6

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii !! i!!!i i ! i ii !!L! i ii iii! ! i i i i i iJ i i! :!¸:! iiiiiiiili!i :!i611 !!i !ii! ii !i itli !ii!ii6!i iiiiii

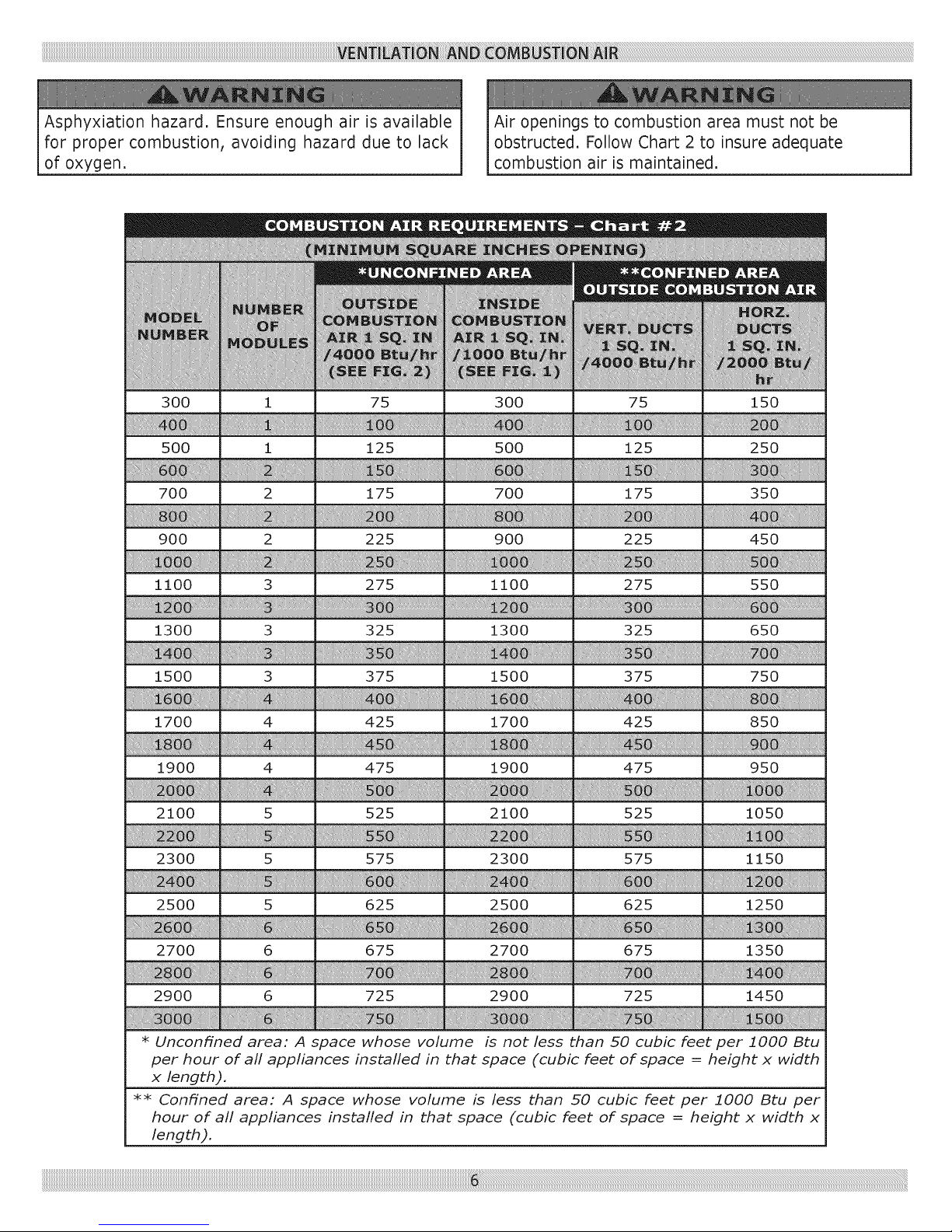

Asphyxiation hazard. Ensure enough air is available

for proper combustion, avoiding hazard due to lack

of oxygen.

300 i 75 300 75 150

500 i 125 500 125 250

700 2 175 700 175 350

900 2 225 900 225 450

ii!ii ii; i

1100 3 275 1100 275 550

Air openings to combustion area must not be

obstructed. Follow Chart 2 to insure adequate

combustion air is maintained.

1300 3 325 1300 325 650

1500 3 375 1500 375 750

1700 4 425 1700 425 850

1900 4 475 1900 475 950

2100 5 525 2100 525 1050

2300 5 575 2300 575 1150

2500 5 625 2500 625 1250

2700 6 675 2700 675 1350

2900 6 725 2900 725 1450

* Unconfined area: A space whose volume is not less than 50 cubic feetper 1000 Btu

per hour of all appliances installed in that space (cubic feet of space = height x width

x length).

** Confined area: A space whose volume is less than 50 cubic feet per 1000 Btu per

hour of all appliances installed in that space (cubic feet of space = height x width x

length).

Page 7

Figure I Figure 2

Combustion

Air

_ _, ODeninas

Y

f

Combustion Air supplied from

outside the building

Important Vent=Piping Note: Sloped vent pipe at

least 1/4" for every 1" to the vent terminal.

lo

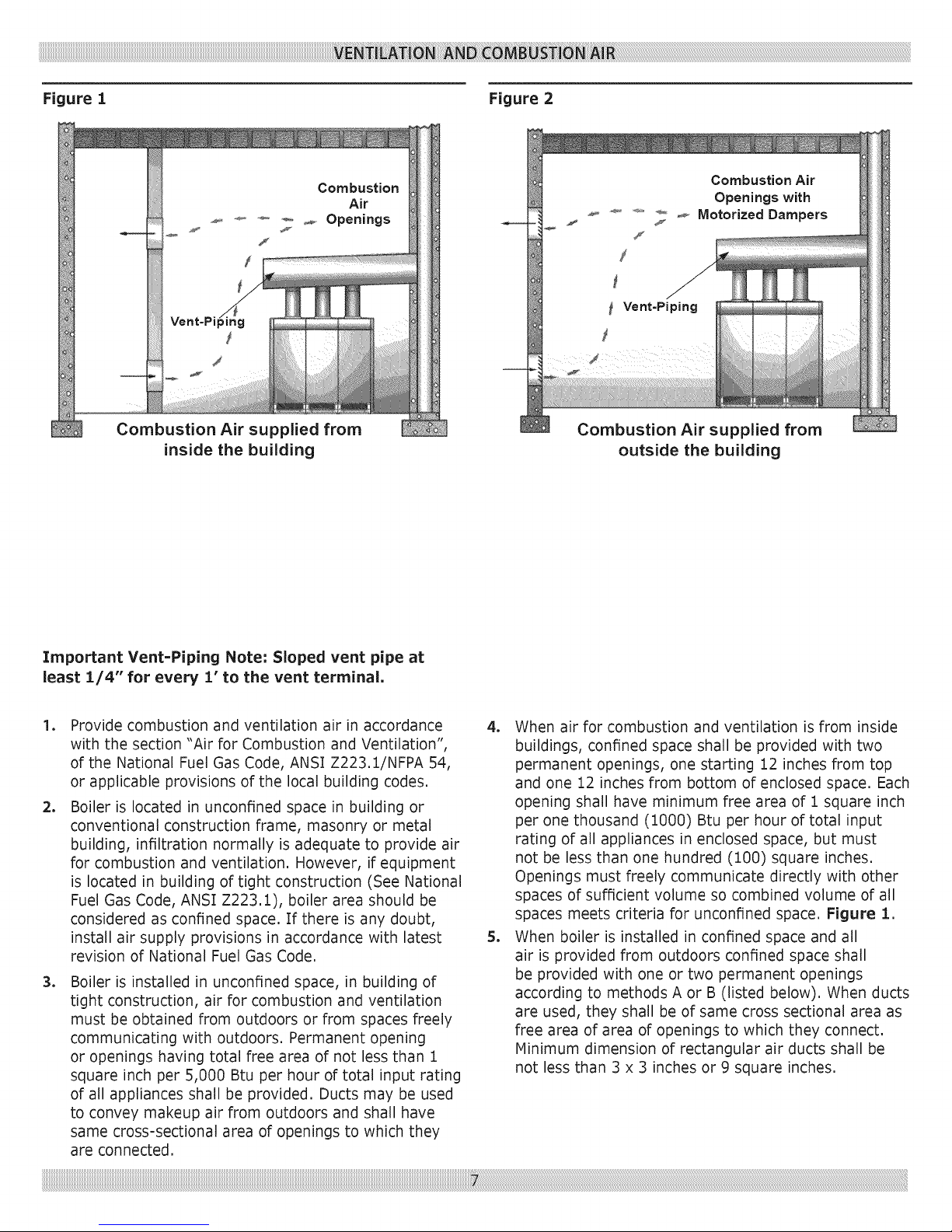

Provide combustion and ventilation air in accordance

with the section "Air for Combustion and Ventilation",

of the National Fuel Gas Code, ANSI Z223.:[/NFPA 54,

or applicable provisions of the local building codes.

2o

Boiler is located in unconfined space in building or

conventional construction frame, masonry or metal

building, infiltration normally is adequate to provide a_r

for combustion and ventilation. However, if equipment

is located in building of tight construction (See National

Fuel Gas Code, ANSI Z223.:[), boiler area should be

considered as confined space. If there is any doubt,

install air supply provisions in accordance with latest

revision of National Fuel Gas Code.

3o

Boiler is installed in unconfined space, in building of

tight construction, air for combustion and ventilation

must be obtained from outdoors or from spaces freely

communicating with outdoors. Permanent opening

or openings having total free area of not less than 1

square inch per 5,000 Btu per hour of total input rating

of all appliances shall be provided. Ducts may be used

to convey makeup air from outdoors and shall have

same cross-sectional area of openings to which they

are connected.

4. When air for combustion and ventilation is from inside

buildings, confined space shall be provided with two

permanent openings, one starting 12 inches from top

and one 12 inches from bottom of enclosed space. Each

opening shall have minimum free area of 1 square inch

per one thousand (1000) Btu per hour of total input

rating of all appliances in enclosed space, but must

not be less than one hundred (100) square inches.

Openings must freely communicate directly with other

spaces of sufficient volume so combined volume of all

spaces meets criteria for unconfined space. Figure 1.

5. When boiler is installed in confined space and all

air is provided from outdoors confined space shall

be provided with one or two permanent openings

according to methods A or B (listed below). When ducts

are used, they shall be of same cross sectional area as

free area of area of openings to which they connect.

Minimum dimension of rectangular air ducts shall be

not less than 3 x 3 inches or 9 square inches.

Page 8

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii_!i;_!ii!i_:i_i!i!ii_ilL!i!i_i_!iiiiiii!_ii!i_iilililili:ii!iili_i_i_:!_:i_!ii!i_!ii!ii!_i!i_ii_i_ii:!_!i_!_:i!i_!i!!_!iJliill_iii!i_iililili_!illjiiii!_:i_:iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii:_:_:_i_i_i_i_i_i_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_i_i:i_i:i!iiiiii

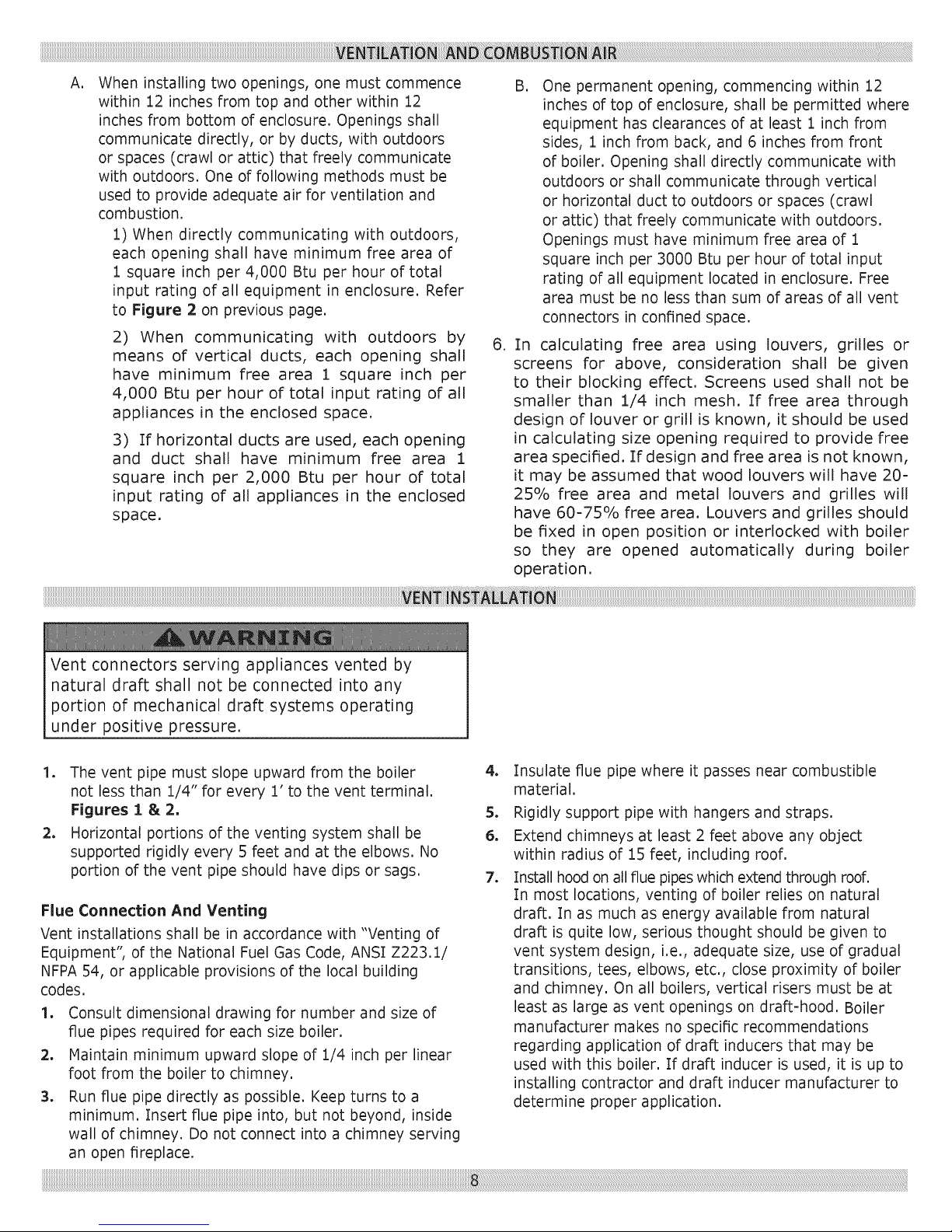

A. When installing two openings, one must commence B.

within 12 inches from top and other within 12

inches from bottom of enclosure. Openings shall

communicate directly, or by ducts, with outdoors

or spaces (:crawl or attic) that freely communicate

with outdoors. One of following methods must be

used to provide adequate air for ventilation and

combustion.

1) When directly communicating with outdoors,

each opening shall have minimum free area of

1 square inch per 4,000 Btu per hour of total

input rating of all equipment in enclosure. Refer

to Figure 2 on previous page.

2) When communicating with outdoors by

means of vertical ducts, each opening shall

have minimum free area 1 square inch per

4,000 Btu per hour of total input rating of all

appliances in the enclosed space.

3) If horizontal ducts are used, each opening

and duct shall have minimum free area 1

square inch per 2,000 Btu per hour of total

input rating of all appliances in the enclosed

space.

.

In calculating free area using louvers, grilles or

screens for above, consideration shall be given

to their blocking effect. Screens used shall not be

smaller than 1/4 inch mesh. If free area through

design of louver or grill is known, it should be used

in calculating size opening required to provide free

area specified. If design and free area is not known,

it may be assumed that wood louvers will have 20=

25% free area and metal louvers and grilles will

have 60-75% free area. Louvers and grilles should

be fixed in open position or interlocked with boiler

so they are opened automatically during boiler

operation.

One permanent opening, commencing within 12

inches of top of enclosure, shall be permitted where

equipment has clearances of at least 1 inch from

sides, 1 inch from back, and 6 inches from front

of boiler. Opening shall directly communicate with

outdoors or shall communicate through vertical

or horizontal duct to outdoors or spaces (:crawl

or attic) that freely communicate with outdoors.

Openings must have minimum free area of 1

square inch per 3000 Btu per hour of total input

rating of all equipment located in enclosure. Free

area must be no less than sum of areas of all vent

connectors in confined space.

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiU_!i_i!!_ii_iiiiiiiJ!iii_iii_!_i_ii!_ii!iL!_ii_iim:i:i!_ii_illii¸iiiiiiii¸iiiiiiii¸iiiiiiii¸iiiiiiii¸iiiiiiii¸iiiiiiii¸iiiiiiii¸iiiiiiii¸iiiiiiii¸iiiiiiii¸iiiiiiii¸iiiiiiii¸iiiiiiii¸iiiiiiii¸iiiiiiii¸iiiiiiii¸iiiiiiii¸iiiiiiii¸iiiiiiii¸iiiiiiii¸iiiiiiii¸iiiiiiii¸iiiiiiii¸iiiiiiii¸iiiiiiii¸iiiiiiii¸iiiiiiii¸iiiiiiii¸iiiiiiii¸iiiiiiii¸iiiiiiii¸iiiiiiii¸iiiiiiii¸iiiiiiii¸iiiiiiii¸iiiiiiii¸iiiiiiii¸iiiiiiii¸iiiiiiii,,

Vent connectors serving appliances vented by

natural draft shall not be connected into any

portion of mechanical draft systems operating

under positive pressure.

4_

1. The vent pipe must slope upward from the boiler

not less than 1/4" for every 1' to the vent terminal.

Figures 1 & 2,

2. Horizontal portions of the venting system shall be

supported rigidly every 5 feet and at the elbows. No

portion of the vent pipe should have dips or sags.

Flue Connection And Venting

Vent installations shall be in accordance with "Venting of

Equipment", of the National Fuel Gas Code, ANSI Z223.1/

NFPA 54, or applicable provisions of the local building

codes.

1. Consult dimensional drawing for number and size of

flue pipes required for each size boiler.

2. Maintain minimum upward slope of 1/4 inch per linear

foot from the boiler to chimney.

3. Run flue pipe directly as possible. Keep turns to a

minimum. Insert flue pipe into, but not beyond, inside

wall of chimney. Do not connect into a chimney serving

an open fireplace.

Insulate flue pipe where it passes near combustible

material.

5.

Rigidly support pipe with hangers and straps.

6.

Extend chimneys at least 2 feet above any object

within radius of 15 feet, including roof.

7.

Install hood on all flue pipes which extend through roof.

In most locations, venting of boiler relies on natural

draft. In as much as energy available from natural

draft is quite low, serious thought should be given to

vent system design, i.e., adequate size, use of gradual

transitions, tees, elbows, etc., close proximity of boiler

and chimney. On all boilers, vertical risers must be at

least as large as vent openings on draft=hood. Boiler

manufacturer makes no specific recommendations

regarding application of draft inducers that may be

used with this boiler. If draft inducer is used, it is up to

installing contractor and draft inducer manufacturer to

determine proper application.

Page 9

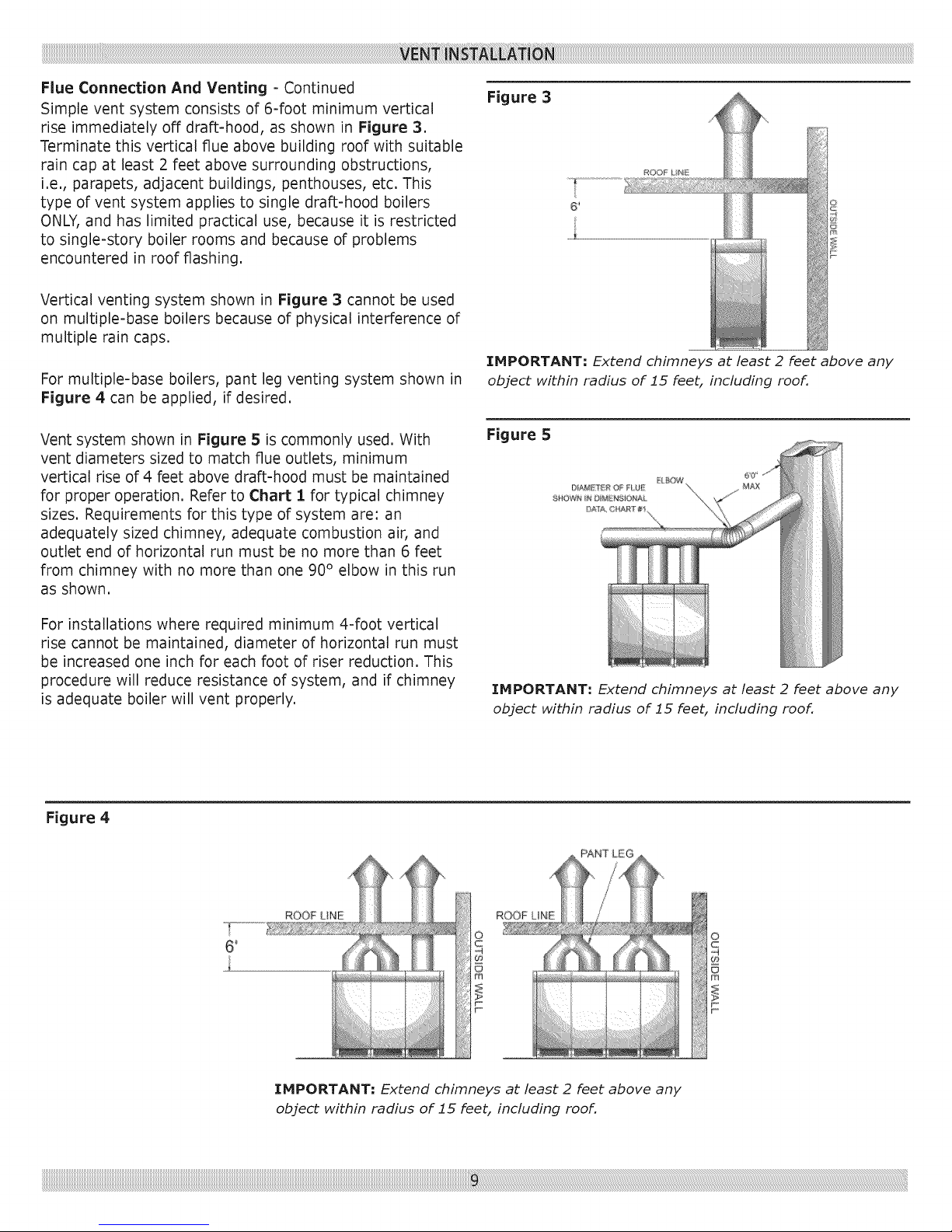

Flue Connection And Venting - Continued

Simple vent system consists of 6-foot minimum vertical

rise immediately off draft-hood, as shown in Figure 3.

Terminate this vertical flue above building roof with suitable

rain cap at least 2 feet above surrounding obstructions,

i.e., parapets, adjacent buildings, penthouses, etc. This

type of vent system applies to single draft-hood boilers

ONLY, and has limited practical use, because it is restricted

to single-story boiler rooms and because of problems

encountered in roof flashing.

Vertical venting system shown in Figure 3 cannot be used

on multiple=base boilers because of physical interference of

multiple rain caps.

For multiple=base boilers, pant leg venting system shown in

Figure 4 can be applied, if desired.

Figure 3

IMPORTANT: Extend chimneys at least 2 feet above any

object within radius of 15 feet, including roof.

Vent system shown in Figure 5 is commonly used. With

vent diameters sized to match flue outlets, minimum

vertical rise of 4 feet above draft=hood must be maintained

for proper operation. Refer to Chart 1 for typical chimney

sizes. Requirements for this type of system are: an

adequately sized chimney, adequate combustion air, and

outlet end of horizontal run must be no more than 6 feet

from chimney with no more than one 90° elbow in this run

as shown.

For installations where required minimum 4-foot vertical

rise cannot be maintained, diameter of horizontal run must

be increased one inch for each foot of riser reduction. This

procedure will reduce resistance of system, and if chimney

is adequate boiler will vent properly.

Figure 4

Figure 5

IMPORTANT: Extend chimneys at least 2 feet above any

object within radius of 15 feet, including roof.

_

IMPORTANT: Extend chimneys at least 2 feetabove any

object within radius of 15 feet, including roof.

ii

Page 10

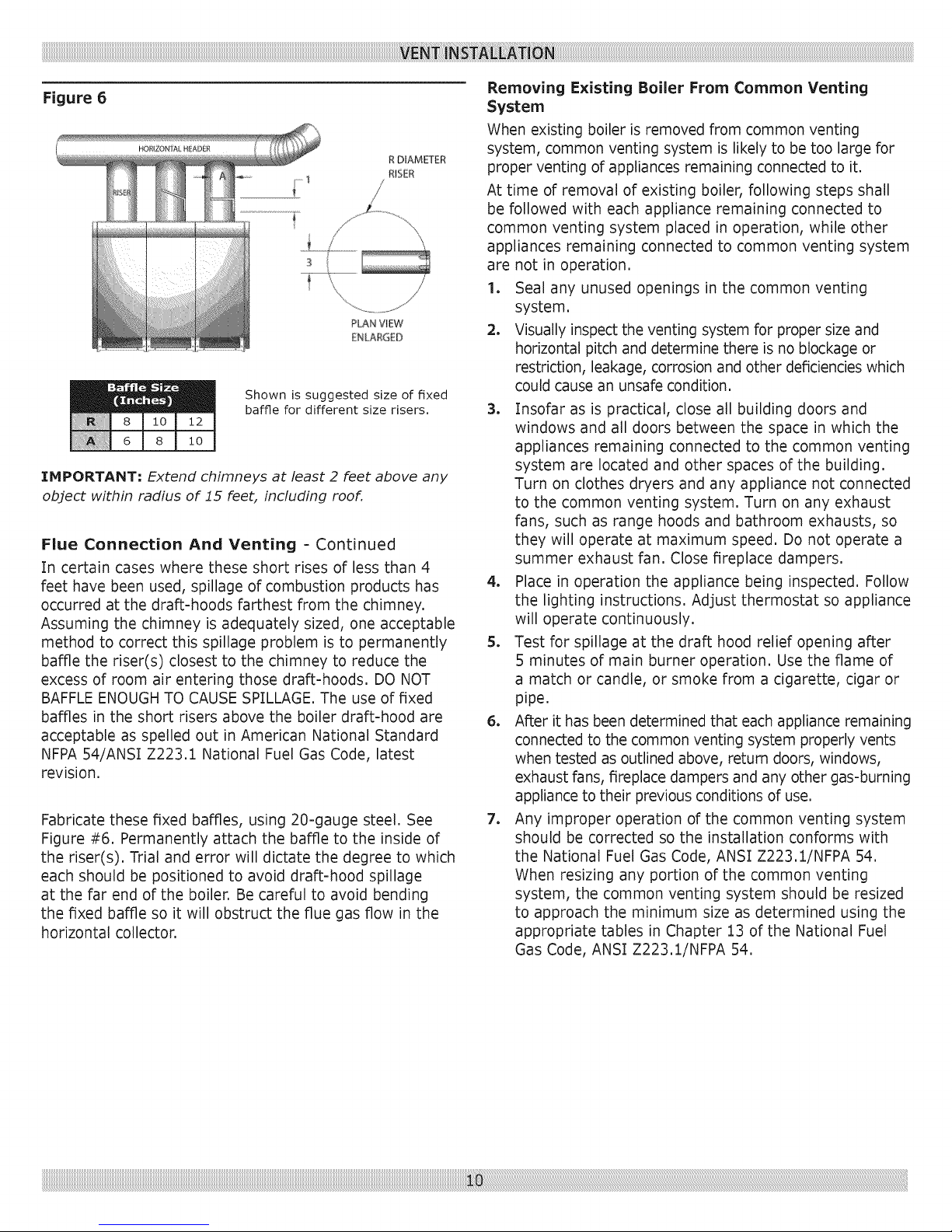

Figure 6

Shown is suggested size of fixed

baffle for different size risers.

IMPORTANT; Extend chimneys at least 2 feet above any

object within radius of 15 feet, including roof.

Flue Connection And Venting = Continued

In certain cases where these short rises of less than 4

feet have been used, spillage of combustion products has

occurred at the draft-hoods farthest from the chimney.

Assuming the chimney is adequately sized, one acceptable

method to correct this spillage problem is to permanently

baffle the riser(s) closest to the chimney to reduce the

excess of room air entering those draft-hoods. DO NOT

BAFFLE ENOUGH TO CAUSE SPILLAGE. The use of fixed

baffles in the short risers above the boiler draft-hood are

acceptable as spelled out in American National Standard

NFPA 54/ANSI Z223.1 National Fuel Gas Code, latest

revision.

Fabricate these fixed baffles, using 20-gauge steel. See

Figure #6. Permanently attach the baffle to the inside of

the riser(s). Trial and error will dictate the degree to which

each should be positioned to avoid draft-hood spillage

at the far end of the boiler. Be careful to avoid bending

the fixed baffle so it will obstruct the flue gas flow in the

horizontal collector.

Removing Existing Boiler From Common Venting

System

When existing boiler is removed from common venting

system, common venting system is likely to be too large for

proper venting of appliances remaining connected to it.

At time of removal of existing boiler, following steps shall

be followed with each appliance remaining connected to

common venting system placed in operation, while other

appliances remaining connected to common venting system

are not in operation.

1. Seal any unused openings in the common venting

system.

2. Visually inspect the venting system for proper size and

horizontal pitch and determine there is no blockage or

restriction, leakage, corrosion and other deficiencies which

could cause an unsafe condition.

3. Insofar as is practical, close all building doors and

windows and all doors between the space in which the

appliances remaining connected to the common venting

system are located and other spaces of the building.

Turn on clothes dryers and any appliance not connected

to the common venting system. Turn on any exhaust

fans, such as range hoods and bathroom exhausts, so

they will operate at maximum speed. Do not operate a

summer exhaust fan. Close fireplace dampers.

4. Place in operation the appliance being inspected. Follow

the lighting instructions. Adjust thermostat so appliance

will operate continuously.

5. Test for spillage at the draft hood relief opening after

5 minutes of main burner operation. Use the flame of

a match or candle, or smoke from a cigarette, cigar or

pipe.

6. After it has been determined that each appliance remaining

connected to the common venting system properly vents

when tested as outlined above, return doors, windows,

exhaust fans, fireplace dampers and any other gas-burning

appliance to their previous conditions of use.

7. Any improper operation of the common venting system

should be corrected so the installation conforms with

the National Fuel Gas Code, ANSI Z223.1/NFPA 54.

When resizing any portion of the common venting

system, the common venting system should be resized

to approach the minimum size as determined using the

appropriate tables in Chapter 13 of the National Fuel

Gas Code, ANSI Z223.1/NFPA 54.

Page 11

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiili¸ii_iiii6!ili!iil;Lili_!i!ii_iiiiil;!i!iii_i_lii!;ii_i!i!_!!_i_iii_!iiiiii!!i_ii_i_iii_i_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii:i!ii

Front View Left Side View

Su

38"

h AA

Top View

C D E F G H

Returr)

Supply

Floor Line

A

Flue Nutlets

ALL SUPPLY AND RETURN

CONNECTIONS ARE 4 INCH

>ply

Page 12

Base Assembly

The 300, 400 and 500 boilers are the basic models. The 300

model has (6) burners, the 400 model has (8) burners and

the 500 model has (10) burners. Combinations of the basic

models are used to assemble the 600 through 3000 models.

Refer to Chart 3 for the proper order of assembly. When two

or more bases are used to assemble the boiler, be sure the

tops of the bases are even.

The bases are fastened together with 5/16 cap bolts and

nuts. [nsert two bolts in the front posts and two in the rear

posts as shown in Figure 7A. After bases are fastened

together, install the base end panels. These end panels

must be installed before assembling sections Figure 7B.

Section Assembly

The sections may be started from either the left or right end

of the base.

Place the end section on the base with the center-line of the

section directly over the joint of the base end closure. With boilers

having two or more bases, as you progress be sure the parting

line (center-line of section) of the intermediate sections fall on

the junction of the two bases. Figure 8.

Figure 8

Important: After bases are assembled check to be sure

they are level.

Figure 7B

Bolts with nuts in

oosts

Center-line

of section

Base joint

Before beginning, clean nipples and nipple ports. Coat

nipples and nipple ports with pipe joint compound

or other good sealant and keep them clean. Figure

9.

Figure 9

/I

iiiiiiiii!iiiii!!!!_;_,

Figure 10

!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!_¸!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!!:_ii!

Page 13

Place nipples in ports taking care to seat them squarely to

prevent cocking. Figure 10.

When pulling sections together with tie rods, always insert

tie rods in holes nearest to nipple ports. Hove tie rods to

proper location, if necessary, only after sections are fully

pulled together. Oil or lubricate threads, insert tie rods

in lugs with washers under nuts and tighten uniformly

and evenly so that sections are pulled parallel as they go

together. When all sections are pulled up locate tie rods in

alternating pairs of upper and lower holes between adjacent

sections. Figure 11.

Be sure both ends of completed section assembly are

resting evenly on both ends of base.

Apply furnace cement at the joints of the sections front, top

and back. Putty should also be applied where the sections

join the base. Figure 12.

Place necessary plugs and control wells in correct locations.

Plug all other tappings, leaving air vent in top of one of

end sections, and connect water. Fill boiler with water

until it runs out the air vent. Hydrostatically test boiler in

accordance with applicable codes. Check for leaks before

continuing with assembly Drain and remove unnecessary

plugs.

Attaching Draft Hoods

Attach the draft hoods to the boiler sections after

applying boiler putty to the top of the boiler sections

where the hoods and sections meet. Use j=bolts to

attach the fronts of the draft hoods to slots in the

section flanges. Figure 13.

Figure 13

Draft hood notched

to fit over sections

g-bolt & nut

attach to front

of hood

Figure 11

Draft hood

covers

Apply turnace cement to joints on all sides or DOller.

Page 14

Installing Boiler 3acket Panels

NOTE: Jacket assembly must start at the left side of boiler,

1. Attach lower jacket end panel (left) to two Z=bars on

base end closures through two slotted holes on bottom

of jacket end panel, Use (2) #10 x 1/2"screws, Figure

14,

2. Attach middle jacket end panel (left) to lower jacket

end panel with middle laying over lower and lining up

holes, Use (5) #10 x 1/2"screws, Figure 1S.

3. Attach upper jacket end panel (left) to middle jacket

end panel with upper behind middle and lining up holes,

Use (6) #10 x 1/2"screws, Ensure bare metal plate is

inserted between casting ridge and draft hood, This will

hold panel in place, Figure 16.

4. Position top/front intermediate panel so back edge of top

hangs on adjustable clips on front of draft hood(s); left

edge hangs on bracket on left upper jacket end panel;

and right edge with integral bracket hangs on tie rod(s),

Figure 17,

5. Attach top/front intermediate panel to lower base

brackets through four slotted holes in panel, Use (4)

#10 x 1/2"screws, Figure 18.

6. On multiple base boilers, each additional top/front

intermediate panel attaches in same way (working your

way from left to right), Figure 19.

Figure 16

Figure 17

Adjustable Clip,.

Bracket

Page 15

Installing Boiler Jacket Panels - Continued

7. Attach upper jacket end panel (right) so left edge hangs

on bracket on top/front intermediate panel. Insert bare

metal plate in same manner as left panel Figure 20.

8. Attach middle jacket end panel (right) to upper jacket

end panel with middle laying over upper and tining up

holes. Use (6) #I0 x l/a" screws. Figure 21.

9. Attach lower jacket end panel (right) to middle jacket

end panel with lower behind middle and lining up holes.

Use (5) #!0 x 1if, screws, Attach lower jacket end

panel to two Z-bars on base end closures through two

slotted holes on bottom of jacket end panel. Use (2)

#10 x 1/2"screws. Figure 21B.

10. Position top of rear jacket panel(s) to draft hood baffle

flange and secure with (2) #10 x l/f, screws. Secure

bottom of rearjacket panel(s) to bracket(s) on boiler

base using (2) #10 x 1ia"screws. Figure 22.

Installing Boiler .lacket Panels - Continued

Figure 18

Figure 20

Figure 19

Figure 21A ....

Page 16

11. Attach burner door knobs with #8-32 x 1/4"screws and

#8-32 hex nuts, Slide bottom of lower access door(s)

in slots on top of manifold brackets, Figure 23,

12. Position control access jacket panel(s) so tabs slide into

slots on top/front intermediate jacket panel(s), Attach

control access jacket panel to top/front intermediate

jacket, Use (2) #10 x 1/2"screws, Figure 24,

13. Lighting Instruction Plates are provided with each

Figure 21B

boiler base. Each boiler base also includes data plate

indicating required gas type, firing rate, and gas

pressure for that base. These plates are located on

Jacket Top/Front Panels. Boilers also have rating plate

showing total Input and Output Ratings. This rating

plate is shipped in AC Carton and is to be mounted on

side Jacket End Panel by installing contractor.

14. Attach Local Code Label (not provided by

manufacturer.)

Figure 23

Figure :24

Figure 22

NOTE: The attachment of the control access jacket

panels can wait until the controls have been mounted

to the top/front intermediate jacket panels.

Page 17

Control Mounting And Installation

NOTE: Electrical controls (j-box, transformer, etc. can

be mounted on either left or right jacket end panel.

Subsequently, boiler safeties (LWCO, etc.) and their

respective piping must be mounted on opposite end of

boiler.

1. Attach j-box assembly to jacket end panel aligning with

holes in end panel, Use (4) #10 x 1/2"screws, Figure

25A,

2. Position harness and plug from j-box through opening

in jacket end panel. Figure 25B.

3. Boilers with four through six bases, require transformer

mounted externally to j-box assembly. Attach

transformer and bracket assembly to jacket end panel by

using #10 x 1/2"screws; (3) along top of bracket and (2)

along lower edge of bracket. Figure 26A. Remove cover

(2 screws) from ]-box, then remove knockout (left or

right side). Connect plug of harness from transformer to

plug on j-box. Figure 26B.

Figure 25A

4. Orient harness of control panel assembly so correct

(female) plug is toward j-box and will connect to

j-box harness. Figure 27A. Secure harness to control

panel with zip=ties and #10 x I/2" screws. Figure 27A,

Connect plugs on harnesses. Figure 27B.

5. Attach control panel to intermediate jacket panel

aligning with holes. Use (4) #10 x I/2" screws. Connect

plugs on control panel to j-box. Figure 28,

6. On multiple base boilers, mount remaining control

panels to intermediate jacket panels following steps 4

&5.

7. On each base, connect gas valve harness and pilot

spark wire to control. Figures 29A & 29B.

Figure 26A

Figure 26B

Page 18

Control Mounting And Installation

Figure 27A Figure 29A

Figure 27B

Figure 28

Figure 29B

Page 19

Illustration shows the end section and the various tap-

pings provided. Tappings are the same in both right

and left end sections.

Emml

Figure 29

F

A 4" Supply and Return Supply and

B 1/2" Gauge Glass Set

C 3/4" Drain, Left End

C 314" Drain, Right End Drain, Right

D 1/2" Plugged trol

E 1" Accessories Accessories

*F 1" Safety Valve Valve

G 3/4. Plugged or Electronic

*If openirlg F is to be used for something other than

the Safety Valve or Safety Relief Valve, or the Safety/

Relief valve is larger than 1", the Safety/Relief Valve

must be installed in the Header Piping as near the

boiler as possible

Primary LWCO and Plugged

(Probe Type) LWCO Plugged

Return

Drain, Left

End

End

Limit Con-

Safety Relief

Following controls are supplied as standard equipment.

Details of their function and operation will be found in

section on Controls and Adjustments.

C

Figure 30

B

G

B

A

E

1. Water temperature high limit control

2. Combination temperature = pressure gauge

3. Safety relief valve (30 psi)

WATER TRIM ASSEMBL Y

Locate water trim controls per chart and illustration

above.

1. Low Water Cut-Off (mounted externally) with blow-off

valve

2. High Pressure Limit Control

3. Pressure Gauge

4. Water Gauge Glass Set

5. Siphon Loop

6. Safety Valve (i5 psi..)

Assemble Steam Trim, Low Water Cut=Off, High

Pressure Limit Control, Pressure Gauge, Water Gauge

Glass Set and Siphon Loop, as shown in Figures

30. See Illustration and Chart above for location of

controls.

LO0_

CUT OF

NOTE:

WATER LEVEL

29"TO FLOOR

No shutoff of any description shall be placed between

the pressure relief valve and the boiler, or on discharge

pipes between such safety valves and the atmosphere.

Installation of the pressure relief valve shall conform

to the requirements of the ANSI/ASME Boiler and

Pressure Vessel Code, Section IV.

Page 20

When the boiler is installed in connection with a

refrigeration system, it must be piped so that the

chilled medium is piped in parallel with the heating

boiler with appropriatevalves to preventthe chilled

mediumfromenteringtheheatingsystem.Anexample

of such pipingis shownin Figure 31, Valve A and B

open for heating, closed for cooling. Valves C and D

closed for heating, open for cooling.

When hot water boilers are connected to heating

coils located in air handling units where they may be

exposed to refrigerated air circulation on the boiler

piping, the boiler piping system shall be equipped

with flow control valves or other automatic means to

prevent gravity circulation of the boiler water during

the cooling cycle.

WATER BOILER PIPING Figure 32

Supply and return connections to the hot water boiler

should be located so that the water will thoroughly

circulate throughout the entire boiler. Each installation

has a preferred piping arrangement according to the

requirements of the particular system and choice of

arrangements and sizes of headers should be decided

upon by the installer's heating engineerorwith standard

engineering practice. When using only one supply and

one return connection, return must be connected at

opposite end of boiler from flow connection, on all

boilers 600,000 Btu/hr input and larger.

PIPE SIZING

Piping connection sizes are important to control proper

water velocity at the inlet and outlet connections to

the water boiler. It is recommended that the following

pipe sizes be used for flow rates shown and that the

boiler being headered to tappings at both ends, where

one pipe connection will not be adequate to hold water

velocities below 3.33 feet per second.

35 - 50

51 - 76

77- 131

132 - 205

206 - 300

2½"

3"

4"

5"

6"

Figure 31

TO SYSTEM

A

The immersion well for the high limit control must be

mounted at flow outlet of boiler. This may be either

right or left hand. The temperature and pressure gages

should be mounted at the outlet as well, and may be

the opposite and of the high limit control.

Figure 32

SUPPLYHEADER

COMBINAT/ON

PRESSURE,

TEMPERKTURE

&AlTiTUDE

GAUGE

HGH UM_T CONTROL

PRESSURE RELIEF

VALVE

4

RETURN

HEADER

Page 21

Figure 33

CITYWATERSUPPLY

STEAM BOILERS - SERIES S

BOILER TAPPINGS ARE AVAILABLE FOR ALL CONNECTIONS SHOWN

NOTE: Mount electrical supply on opposite side.

CITYWATERSUPPLY

TORETURN

Figure 34

HcDONNELL FEEDER CUTOFF

COH BINATION

300 THRU 1500

1600 THRU 3000

FOR CLOSED HEATING SYSTEMS

DIMENSION A = 2 e 2 1/z

BOILER TAPPINGS ARE AVAILABLE FOR ALL CONNECTIONS SHOWN

WATE_R____

)- LINE _

LINET_

0

67SERIES

CUTOFF

SEPARATE McDONNEL FEEDER AND

SEPARATE McDONNEL LOW-WATER

No, 47-2" Control Mounts in

Gauge Glass Tappings

No. 51.2" Control Mounts in

1-inch Tappings

*These items available through your Distributor,

CUTOFF

300 THRU 1500 101-24V electric feeder with transformer

1600 THRU 3000 No. 51.2"

WATER BOILERS = SERIES W

WITH EXCEPTION OF NO. 764 WHICH MOUNTS IN PIPING

NOTE: Mount electrical supply on opposite side.

CITY WATER SUPPLY

McDONNELL PUMP CONTROL AND LOW-WATER

CUTOFF USED WITH CONDENSATE RECEIVER

AND ELECTRIC BOILER FEED PUMP

- for use on closed heating systems only,

FOR CLOSED HEATING SYSTEMS

DIMENSION A - 2 = 2 1/2 inches

FOR PROCESS OR PARTIAL PROCESS SYSTEMS

DIMENSION A - i = 1 1/2 inches

SUPPLY LINE

__WAT_E_R___

LINE L

NO. 150

OR

NO.93

No. 247 mechanical feeder or No,

©

NO. 764

<

@E

McDONNELL FEEDER CUT=OFF COMBINATION

ALL SIZES No. 53-2 300 THRU 1500 No. 247-2

Z

TO RETURN

1600 THRU 3000 No. 51-2"

MINIMUM

DIMENSION

29-3/4

1

't .63

McDONNELL LOW=WATER CUT=OFF

ALL SIZES No. !50

_These items available through your Distributor,

** Water supply pressure must exceed relief valve

setting by at least 20 psi.

ALL SIZES No. 63*

ALL SIZES NO, 764 _

Page 22

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii:_i_ii6!ii!i:i:Lili_!i!ii_iiii!i!!!ii_;_i_:iiiiiiii_i!i!ii!i!_!_:ii!_i__i_i_i_i_i_i_i_i__i_i_i_i_i_i_i_i__i_i_i_i_i_i_i_i__i_i_i_i_i_i_i_i__i_i_i_i_i_i_i_i__i_i_i_i_i_i_i_i__i_i_i_i_i_i_i_i__i_i_i_i_i_i_i_i__i_i_i_i_i_i_i_i__i_i_i_i_i_i_i_i__i_i_i_i_i_i_i_i__i_i_i_i_i_i_i_i__i_i_i_i_i_i_i_i__i_i_i_i_i_i_i_i__i_i_i_i_i_i_i_i__i_i_i_i_i_i_i_i__i_i_i_i_i_i_i_i__i_i_i_i_i_i_i_i__i_i_i_i_i_i_i_i__i_i_i_i_i_i_i_i__i_i_i_i_i_i_i_i__i_i_i_i_i_i_i_i__i_i_i_i_i_i_i_i__i_i_i_i_i_i_i_i__i_i_i_i_i_i_i_i__i_i_i_i_i_i_i_i__i_i_i_i_i_i_i_i__i_i_i_i_i_i_i_i__i_i_i_i_i_i_i_i__i_i_i_i_i_i_i_i__i_i_i_i_i_i_i_i__i_i_i_i_i_i_i_i__i_i_i_i_i_i_i_i__i_i_i_i_i_i_i_i__i_i_i_i_i_i_i_i__i_i_i_i_i_i_i_i__i_i_i_i_i_i_i_i__i_i_i_i_i_i_i_i__i_i_i_i_i_i_i_i__i_i_i_i_i_i_i_i__i_i_i_i_i_i_i_i__i_i_i_i_i_i_i_i_....

Figure 35

STEAM BOILER PiPiNG

STEAM

SUPPLY

STEAM CROSS

HEADER

LiNE

20°

MINo

TAPPING

FLUSH PLUGS / .HARTFORD

SAFETY VALVE SHOULD BE FTELD THSTALLED AS CLOSE AS POSSTBLE TO BO'ILER

STEAM BOZLER PZPING Figure 35

Full size steam header is recommended on all steam

systems as shown above. On Boiler Models 300, 400 and

500 full header may be eliminated and single steam header

taken off either side of boiler provided system is clean and

properly designed.

Risers should be full 4" and at least 20" in height. Use

skimmer tee as shown.

Area of Main Steam Cross Header Pipe should be equal to

or larger than total area of Steam Supply Mains leading

from Header and should never be smaller than Supply

tappings on Boiler. Return Header should be piped to both

ends of Boiler. Area of Return Header should be equal to

total area of Return Mains or larger.

Steam cross headers must be piped with swing joints, or

be equipped with slip joint connector, in order to prevent

expansion and contraction of steam header from damaging

boiler.

Each installation has preferred piping arrangement

according to requirements of particular system and choice

of arrangements and sizes of Headers should be decided

upon by installer's heating engineer or with standard

engineering practice.

WET

RETURN

L_P

Do not install shut-off or steam valve between

safety valve and boiler.

300 to 900 4" 4" 2"

1000 to 1900 4" 4" 2 1/2"

2000 to 2500 4" 4" 3"

2600 to 3000 4" 4" 4"

Page 23

• Connect gas service from meter to control assembly(s)

in accordance with ANSI Z223.1 and local codes or

utility. On multiple base boilers, connect gas service

with branch lines from common main. Individual branch

lines must be same size as inlet to gas valve. Ground

joint union should be installed in each branch line for

easy servicing of gas controls. Drip leg or trap should be

installed at bottom of vertical section of piping at inlet to

each branch line. Figure :36. Pipe compound resistant

to action of liquefied petroleum gases must be used on

all threaded pipe connections.

• Main gas supply line should be adequate to prevent

undue pressure drop, See (::hart 5 for pipe sizes for

gas mains,

• Boiler and its gas connection must be leak tested

before placing boiler in operation.

Boiler and its individual shutoff vlave must be

disconnected from gas supply piping system

during any pressure testing of that system at test

pressures in excess of 1/2psi (3.5kPa).

Boiler must be isolated from gas supply piping

system by closing its individual manual shutoff

valve during any pressure testing of gas supply

piping system at test pressures equal to or less

than 1/2 psig (3.5 kPa)

Figure 36

INSTALL MANUAL

6 ff.(183cm) OF

THE BOILER: AND

5 ff (152cm)

ABOVE THE FLOOR

BY LOCAL CODES

DRIP LEG

ro GAS CONTROL iNLET

Page 24

Electrical shock hazard. Turn OFF electrical power

supply at service panel before making any line

voltage connections. Failure to do so could result

in death or serious injury.

,_,CAUTION

Label allwires priorto disconnection when servicing

controls. Wiring errors can cause improper and

dangerous operation.

Electrical Wiring

The boiler, when installed, must be wired and electrically

bonded to ground in accordance with the requirements of

the authority having jurisdiction or, in the absence of such

requirements, with the National Electrical Code, ANSI/NFPA

70.

Tnstall a fused disconnect switch between boiler and

electrical panel in a convenient location. The wiring from high

temperature limit control should be secured to the boiler

jacket or gas piping to prevent an accidental disconnect from

controls.

All wiring to gas valves must be taped securely to the gas

supply lines or run in an appropriate conduit.

Adjust Thermostat Heat Anticipator

Suggested heatanticipatorsettingis.90amps (set

accordingly). Then follow instructions packaged with

thermostat for final adjustment, cheddng thermostat

operation. When set above temperature indicated on

thermometer, boiler burners should ignite. Make certain

thermostat(s) turns off boiler when room temperature

reaches selected setting and starts boiler operating when

room temperature falls few degrees.

Finally, set thermostat for desired temperature. Special

conditions in building and location of thermostat will

govern this setting.

Stage Firing Multiple Base Boilers

Multiple base hot water boilers are ideal for stage firing.

Many controls are available for sequencing or stage

firing multiple base hot water boilers. We offer Argo

AMB Outdoor Reset Stage Fire Control Packages that will

sequence up to eight bases, with lead boiler rotation,

adjustable reset ratio, set point boiler rotation, and

microprocessor control. This control will fire bases as

required to maintain supply water temperature at a desired

set point, which is automatically varied based on outdoor

air temperature. Consult boiler manufacturer for more

information.

Thermostat Installation

The thermostat location has an important effect on the

operation of the boiler system. Be sure to follow the

instructions included with the thermostat. Locate the

thermostat about 5feet above the floor on an inside wall. It

should be sensing average temperature.

Keep thermostat(s) at desired room temperature. If windows

are to be opened or heat is not needed, set thermostat(s)

pointer to a lower setting.

Behind Doors

Corners and Alcoves

Concealed Pipes

Fireplaces

TV Sets

Lamps

Direct Sunlight

Kitchens

Concealed Pipes or Ducts

Stairwells

Drafts

Unheated Rooms on other side of Walt

Page 25

Commercial Boiler, 1, :2 & 3 Base

COMMERCIAL BOILER,

HIGH VOLT

PDVER SUPPLY

PER NEC AND ITEMS SUPPLIED

LOCAL CODES BY INSTALLER

!GND(_) Ii (_ .... I

OVERCURRENT SERVICE DISCONNECT I

PROTECTION (RECOMMENDED) J

NEC CLASS II

LBV VOLT

1, 2

_CIRCUIT

& 3 BASE

_i PS/HL

I

_--_--7

PS/HL _ i

(DPTIONAL) i i I

MAN. RESET I I I

............" i I

r .................. J (OPTIONAL)

I r .................. "J

I

I

LWCB

{-s_i

EWF 24 V

_ BOILERBASE(S)

HO RD

VR8300M WNT _i.i u 7000 BERHC VHT _i.i u

GAS VALVE [ GAS VALVE I

WIRING -- WIRING --

)

r

'-t---TLPRIIT....

i o-_: TMFR

I _mmmm_ -- --

!r_J_'-.t

I'

[FIELD INSTALLED

RELAY

Q_

RE## _ TOADDITIONAL

WIRING SCHEMATIC

HIGH VOLT POWER SUPPLY

_Evrk--_

3_ 7 "''- ,'

LVCO

........ ..... ..... '

LVCB PS/HL PS/HL

MANUALRESET NEC CLASS IILOW

(OPTIONAL) VBLT CIRCUIT

R_'-_c

SENSOR

GNB

......... HIGH VOLT FIELD INSTALLED

i

GND

......... LOW VOLT FIELD INSTALLED

LEGEND

LWCO = LOW WATER CUT OFF

FS = FIELD SUPPLIED

HL = HIGH LIMIT

MV = MAIN VALVE

PV = PILOT VALVE

PSS = PILOT SAFETY SHUTOFF

WTS = WATER TEMPERATURE

SENSOR

EWF = ELECTRIC WATER

FEEDER

P/P = PLUG/PIN

C/S = CAP/SOCKET

TO ADDITIONAL TO ADDITIONAL

BASES BASES

LOW VOLTAGE WIRING

IGNITION

DULE

IGNITER/

Page 26

Commercial Boiler, 4, 5 & 6 Base

P/P C/S

COMMERCIAL

HIGH VOLT

PBWER SUPPLY

PER NEC AND ITEMS SUPPLIED

LOCAL CODES BY INSTALLER

DVERCURRENT SERVICE DIBCONNECTI

PROTECTION {RECOMMENDED) J

BOILER, 4,

NEC CLASS II

.__.J i i

i, ......... l.,J

LBW VOLT

CIRCUIT

5 & 6 BASE

TO ADDITIONAL

BOILER BASE(S)

,_ PS/HL

I

I LWCO

(oP%%_ !

MAN,RESETII I

............ J I '

............. J !

r ':_'-$]

I EWF 24 v

I (OPTIONAL)

HDNEY_ L

!A:_: O0#LvE _/iT_..i

WIRING SCHEMATIC

I

"-f---x. P,_,,R__....

' _._ TMFR

I r_J sE_C"@_

II

I'

i

IFIELD INSTALLED

RELAY

HIGH VOLT POWER SUPPLY

3 4

6 ,'woo

..................... g._. ,:.--_

L_#CO PS/HL PS/HL

7000 DERHC b'HT ._I _-'_u

GAS VALVE [

WIRING

4 EWF/I'--'I

2--" J

-oT

MANUAL RESET

(OPTIONAL)

SENSOR

i

,,,T,'iT,'

NEC CLASS II LOW

VOLT CIRCUIT

GND

GND

LEGEND

LWCB = LOW WATER CUT OFF

FS = FIELD SUPPLIED

PS = PRESSURE SWITCH

HL = HIGH LIMIT

PRI = PRIORITY

MV = MAIN VALVE

PV = PILOT VALVE

WTS = WATER TEMPERATURE

SENSOR

EWF = ELECTRIC WATER

FEEDER

P/P = PLUG/PIN

C/S = CAP/SOCKET

......... HIGH VOLT FIELD INSTALLED

......... LOW VOLT FIELD INSTALLED

TO ADDITIONAL TO ADDITIONAL

BASES BASES

LOW VOLTAGE WIRING

IGNITION

DULE

IGNITER/

Page 27

Control Functions And Operation

The control module performs the following basic functions:

1. Opens and closes the first (pilot) operator of the gas

valve.

2. Provides a spark for igniting pilot burner.

3. Senses the pilot burner flame.

4. Shuts off the spark after pilot flame is lit.

5. Opens and closes the second (main) operator.

These functions occur in two stages - trial for pilot ignition

and main burner operation as described below.

Trial For Pilot Ignition

On every call for heat (system start), control performs

internal safe-start check. If flame simulating condition is

present, system will not start.

During normal start, control opens first (pilot) valve

operator of gas control, which allows gas to flow to pilot

burner. At same time, electronic spark generator in control

produces 15,000 Volt spark pulse output (open circuit).

This voltage produces spark at igniter sensor rod which

ignites pilot burner. If pilot flame does not light or presence

of pilot flame is not detected back through flame=rod,

control will not open second (Main) valve operator of gas

control. Control will continue to try to ignite pilot burner

until either flame is detected or thermostat (controller) is

set down below call for heat.

System Troubleshooting

Start system by setting thermostat or controller above room

temperature and observe system response.

Establish type of system malfunction or deviation from

normal operation by using Pilot System Troubleshooting

Table, in following section.

Use table by following questions in boxes. If condition is

true (answer is yes), go down to next box. If condition is

not true (answer is no), go to box alongside.

Continue checking and answering conditions in each box

until problem and/or repair is explained. Use Component

Checks section, see below, as necessary, to perform system

checks.

After any maintenance or repair, troubleshooting sequence

should be repeated until procedure ends with normal

system operation.

Check Spark Ignition Circuit

Electronic module and step-up transformer in control provides

spark ignition at 15,000 V (open circuit). Check circuit at

control module as follows:

1. Turn off manual gas valve to prevent flow of gas.

Main Burner Operation

When pilot flame is established, flame rectification circuit is

completed to burner ground. Control flame sensing circuit

detects flame current, shuts off spark generator and opens

second (Main) valve operator to allow gas to flow to main

burners. Pilot flame ignites main burner conventionally.

IMPORTANT: Electronic control module cannot be repaired.

If troubleshooting procedure indicates malfunction in control,

control must be replaced. Intermittent Pilot systems should be

serviced only by trained, experienced service technicians.

Preliminary Check

Following visual checks should be made before

troubleshooting and after maintenance.

1. Check power switch.

2. Manual shutoff valves in gas line to boiler must be

open.

:3. Make sure all wiring connections are clean and tight.

4. Review control's normal sequence of operation.

Electrical shock hazard. Do not touch either end

of jumper or stud terminal, high voltage circuit.

Failure to follow these instructions could result in

death or serious injury.

o

Disconnect ignition cable at control stud terminal to

isolate circuit from pilot burner/igniter-sensor, and

prepare short jumper lead using heavily insulated wire,

such as ignition wire.

o

Energize control and touch one end of jumper firmly to

control ground terminal (GND). (Do not disconnect

existing ground lead.) Move free end slowly toward

stud terminal to establish spark. Pull lead wire slowly

away from stud. Note length of gap at which arcing

discontinues.

o

Arc length of 1/8 inch (3.2 mm) or more indicates

satisfactory voltage output. If no arc can be established

or maximum gap is less than 1/8 inch (3.2 mm), replace

control.

Page 28

CAUTION

WHAT TO DO IF YOU SMELL GAS

Do not try to light any appliance.

Do not touch any electrical switch; do not use any

phone in your building.

Immediately call your gas supplier from

a neighbor's phone. Follow gas supplier's

instructions.

If you cannot reach your gas supplier, call the fire

department.

Ignition Cable Check

Cable must not run in continuous contact with a metal

surface or spark voltage will be greatly reduced.

Connections to the stud terminal on the control and on the

igniter-sensor must be clean and tight. Loose connections

may not conduct a flame current even though the ignition

spark is satisfactory. Check the electrical continuity of the

cable.

NOTE: Light-off may not be satisfactory until the gas input

and combustion air have been adjusted.

Fire Hazard. Do not use matches, candles, open

flames, or other methods providing ignition source.

Failure to comply will result in death or serious

injury.

Pilot Flame Adjustment

Pilot flame should envelop 3/8 to ::[/2 inch of tip of insulated

rod on igniter-sensor. If adjustment is required, remove

pilot adjustment cover screw and turn inner adjustment

screw clockwise to decrease or counterclockwise to increase

pilot flame. Be sure to replace cover screw after adjustment

to prevent possible gas leakage.

Check Grounding

A common ground is required for the pilot burner/

igniter-sensor mounting bracket, and the GND terminal

of the control. If the ground is poor or erratic, safety

shutdown may occur occasionally even though operation is

normal at the time of the checkout. Therefore, if nuisance

shutdowns occur, be sure to check the grounding.

Startup And Checkout

NOTE: Ifany component in the system fails, the system

will not operate. If the system does not perform as

outlined in Start System, below, refer to the Pilot System

Trouble-shooting Table.

Start System

1. Turn on power to the control(s) and turn off gas

supply.

2. Check control(s) operation as follows:

A. Set the Thermostat or controller above room

temperature to call for heat.

B. Watch for spark at the pilot burner(s).

3. Turn on gas supply.

4. System should start as follows:

A. Spark will turn on and pilot gas valve will open

at once. Pilot burner(s) should ignite after gas

reaches the pilot burner(s).

B. Spark ignition should cut off when pilot flame is

established.

C. Plain gas valve should open and main burners

should ignite after gas reaches the burner ports.

Figure 41 = Proper Flame Adjustment

L

3/8T0 I/2 INCH

(9,5 TO 12.7 MILLIMETRES)

kx_ INSULATED

ELECTRODE

Ignition system safety shutoff device must be tested after

placing boiler in operation. Disconnect sensor wire from

ignition module. Burner operation should stop.

Page 29

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiliii_!i_i!iii_i!_!i_i_i!!_i_ii!i!_ii_i_!_;i_ii_i_!!!!!!!!!!!!_ii_i_iiid_!i_Ui!ili_!i_Eii!!!_!i_!_ii_i_i!_!!_i!_6_ii_Niii_i!_i!_i!_i!_ii_!i_i_!i_!Ci_ii_!_i_i_'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'ii'il_ii_i_i,,_i!

Check line voltage power, low voltage transformer, limit controller, thermostat ]

Power to module (24V module)

Spark Across Igniter/Sensor Gap.

(controller) and wiring. Also, check air proving switch on combustion air I

blower system (if used) and that vent damper (if used) is open and end switch ]

is made, ]

• On models with vent damper

plug, make sure vent damper

has not been installed, then

removed. Replace vent damper

if necessary.

• On other models, replace module.

Check ignition cable, ground wiring, ceramic insulator and gap, and correct.

Check boot of the ignition cable for signs of melting or bucking. Take

protective action to shield cable and boot from excessive temperatures.

Pilot Burner Lights?

/

Spark Stops When Pilot Lit?

Main Burner Lights?

System Runs Until Call For Heat

Ends.

|

Check that all manual gas valves are open, supply tubing and pressures are

good, and pilot burner orifice is not blocked.

Check dectrical connection between module and pilot operator on gas control.

Check for 24 vac across PV-MV/PV terminals on module. If voltage is

okay, replace gas control: if not, replace module.

Check continuity of ignition cable and ground wire.

Clean flame rod.

Check electrical connections between flame rod and module.

Check for cracked ceramic flame rod insulator.

Check that pilot flame covers flame rod and is steady and blue.

Adjust pilot flame.

If roblem ersists re lace module.

I_ Check for 24 Vac MV-MV/PV terminals. Ifno modulevoltage,

I_ Check electrical connections between module and gas control. If oka

re lace as controlor as controlo erator.

Check continuity of ignition cable and ground wire.

NOTE: If ground ispoor or erratic,shutdowns may occur occasionally even though

operation is normal at the time of chedcout.

* Check that pilot flame covers flame rod and is steady and blue.

If checks okay, replace module.

across

replace

* Check for proper thermostat (controller) operation. /

System Shuts OFF?

Troubleshooting Ends.

I

11

* Remove MVlead atmodule: if valve closes, recheck temperature controlle_

and wiring: if not, replace gas control. 1

Repeat procedure until trouble free operation is obtained. ]

!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!_!i_ii_i!_i_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i_ii_!i_!i_!!_!

Page 30

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii_ii!_ii_I!EIII!!_I!¸i_i:iiiiii!!_ii!_i!_i!_i!_i!i_ii:_¸ii:i_i!i!!!i!iii_i:i_i!Ji!i!i!_ii!!i_!i_i_!J_ii_:!_ii!_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:__!

This valve should be tested every month during periods

of boiler operation, and at the beginning and end of any

Do not exceed the Input rate stamped on the

nameplate of boiler located on End Jacket Panel.

Verify primary air supply to main burners is

properly adjusted for complete combustion.

Check Burner Input

Check boiler for proper Btu input rate.

If boiler is shut down for service, gas and electric must be

off for 5 minutes before relighting.

To check boiler for proper Btu Input proceed as

follows: With main burners operating, measure the gas

Input to the boiler by reading the meter. Be sure all other

appliances connected to the same meter are shut off.

Rate of gas flow (cu. ft. per hour) multiplied by the Btu

value of the gas should check with the Btu Input shown

on the nameplate of the boiler. If it is not within +/- 2%,

adjust Pressure Regulator to obtain the desired flow

(stem for adjustment is under the cap in the top of the

regulator). TURN CLOCKWISE TO INCREASE INPUT AND