Page 1

CONTROL MODULE

REPLACEMENT KIT #550002965

INSTRUCTIONS

CHB-100, CHB-130 and CCB-150

Kit installation shall be completed by qualied agency.

WARNING

!

Fire, explosion, asphyxiation and electrical shock hazard.

Improper installation could result in death or serious injury.

Read this instruction and understand all requirements,

including requirements of authority having jurisdiction,

before beginning installation. Installation not complete until

appliance operation veried per Installation, Operation &

Maintenance Manual provided with boiler.

1.

Follow instructions TO TURN OFF GAS TO APPLIANCE

found in Installation, Operation & Maintenance Manual.

Verify all electrical power to boiler is turned off.

WARNING

!

Electrical shock hazard. Turn OFF electrical power supply at

service panel.

2.

Remove front jacket casing per instructions found in

Installation, Operation & Maintenance Manual.

WARNING

!

Burn hazard. Verify heat exchanger has cooled or use

appropriate personal protection equipment.

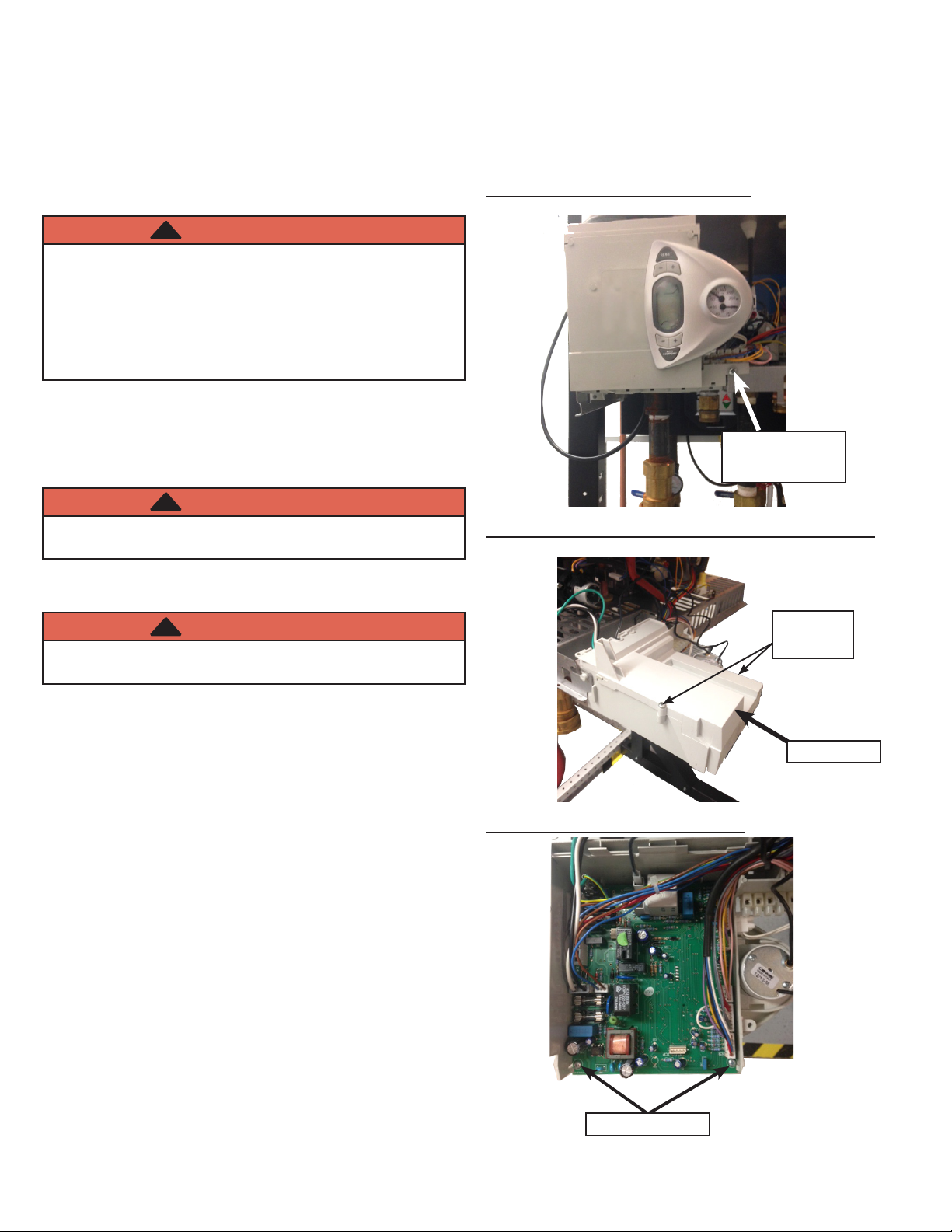

Figure 1 - Control Housing Screw

Control Housing

Screw

Figure 2 - Control Housing Folded Down on Hinge

Back Cover

Screws

3.

Remove control housing screw on lower right of control

housing. See gure 1.

4.

Slide control housing forward, it will fold down on its

built in hinge. See gure 2

5.

Remove two back cover screws. Remove back cover.

See gure 2.

6.

Disconnect all wiring connectors on control board. See

gure 3.

7.

Remove 2 screws holding board in place. Slide board

out. See gure 3.

8.

Replace board with new board, screw board in place.

Connect wiring connectors on control board. See gure 3.

9.

Replace back cover.

10.

Fold control housing up and slide back into position.

Secure with control housing screw. See gure 1.

Back Cover

Figure 3 - Screws Holding Board

Board Screws

P/N 240010533, Rev. A [07/2014]

Page 2

CONTROL BOARD REPLACEMENT KIT

11.

Remove any call for heat or hot water.

12.

Turn gas and electric power ON.

13.

Power up boiler.

14.

Congure control for proper boiler size and type.

15.

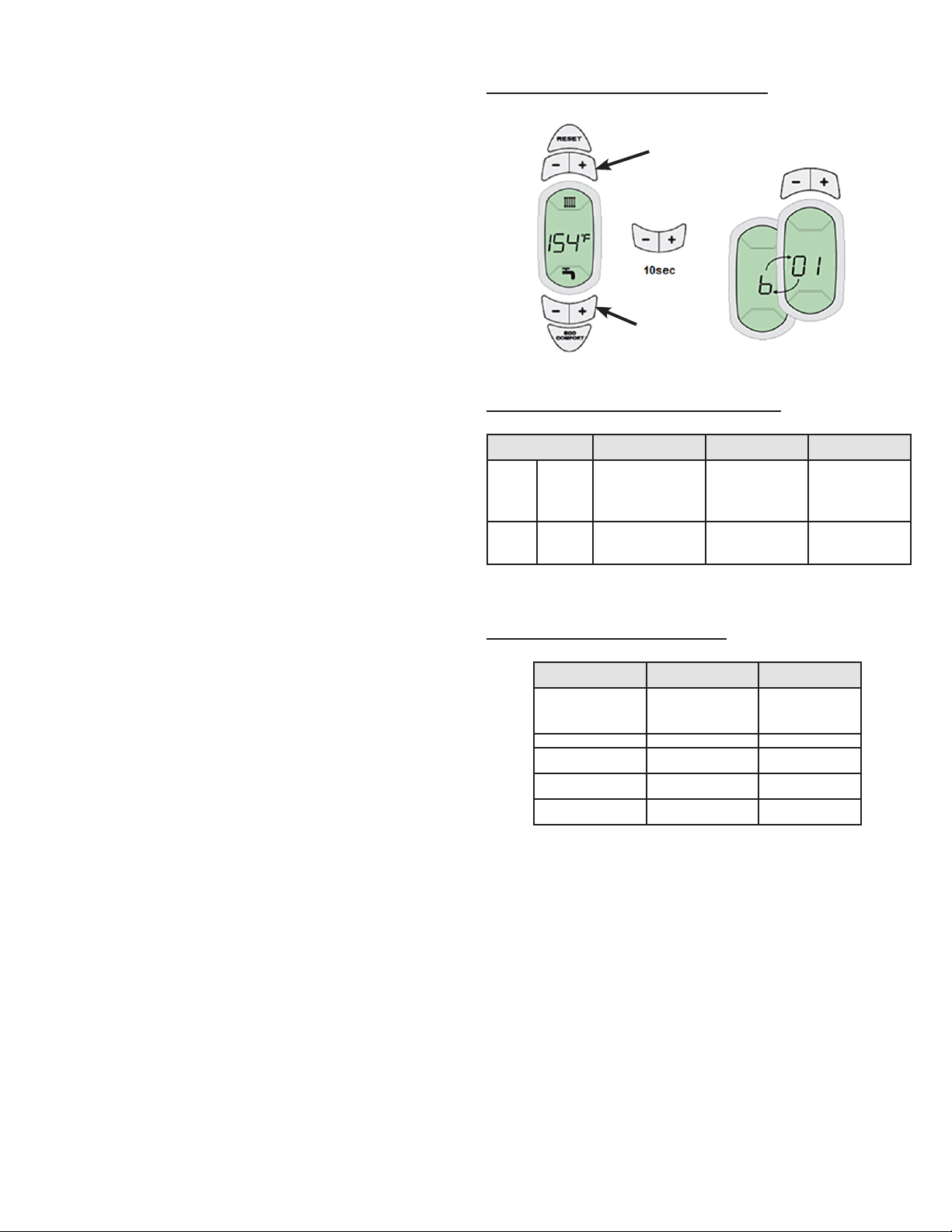

To access the Parameter “tS” menu:

• Press and hold Reset button for 10 seconds, display

will read “tS”, release button.

• Press the Reset button for 1 second, display will read

“P01”.

• Press Heating buttons to scroll the list of parameters.

Press DFHW buttons to view or change a parameter.

Two Parameters need to be set “P01 & P02” as shown

in gure 4.

16.

To access Conguration menu:

• Press DHW + & - (both) buttons and hold for 10

seconds; “b01” will appear ashing.

• Press Heating buttons to scroll Conguration list.

Press DHW buttons to view or change a setting.

Figure 4 - Enter Conguration Menu

CH

DHW

Figure 4 - Enter Parameter "tS" Menu

tS Menu CCB-150 CHB-100 CHB-130

P01

P02

Gas

Type

Boiler

Type

0=Natural

Gas; 1=LP

Gas

1 2 2

0=Natural

Gas; 1=LP

Gas

0=Natural

Gas; 1=LP

Gas

• Conguration “b01” is only one to be changed per

chart in Figure 6.

• When proper size is selected, press and hold DHW

+ & - (both) buttons for 10 seconds to exit, or turn

power off then on, or wait two minutes for auto exit.

• Boiler is now ready for operation

17.

Verify proper operation by following START UP

PROCEDURE in Installation, Operation & Maintenance

Manual.

18.

Install front jacket casing following instructions found in

Installation & Maintenance Manual.

Figure 6 - Proper Size Settings

Parameter Description Setting

b01

b01

b01

b01

Curve

Selection

CHB-100 0

CHB-130 1

CCB-150 2

Default =2

Loading...

Loading...