Dunkirk 3EW.65T, 3EW.65Z, 3EW.75, 3EW.75T, 3EW.75Z Installation Guide

...

Hodels

SERIES

3EW,65

3EW,75

3EWI,O0

4EW,90

4EW1,25

4EW1,50

SEW1,20

5EW1,75

OIL-FIRED CAST IRON

HOT WATER

INSTALLATION, OPERATION

& HAINTENANCE HANUAL

,?__,_g_,',,_& .......................................................

_!._,_,, ,

_',!_,._;_#_ ::::::::::::::::::::::::::::::.............

_i:_'_,_;_! ..........................................

_._,_.',_rL_

,

dS

Maximum Allowable

Working Pressure 50 psi.

Manufactured by:

ECR international, inc.

220! DwyerAwnue. Utica NY 13501

web s_te www ecnnternat/onal corn

H

P/N# 240009549, Rev B [10/2012]

Safety Notices .............................................. 2

Boiler Ratings And Capacities ......................... 3

Fresh Air For Combustion ............................... 7

System Piping .............................................. 9

Chimney And Chimney Connections .............. 16

Typical Chimney Connection ......................... 17

Electrical Connections ................................. 18

Filling The Boiler ....................................... 19

Operating The Boiler ................................. 20

Checking And Adjusting Controls .................. 23

Maintenance .............................................. 24

Oil Boiler Cleaning Instructions .................... 25

Oil Burner Cleaning ..................................... 26

Service Hints ............................................. 27

Electrical Wiring ......................................... 28

Equipment And Optional Accessories ............. 29

Introduction

Empire Water boiler is a natural draft oil fired hot water

boiler comprised of cast iron sections. Empire Water

boiler is available with 3, 4, or 5 cast iron sections. These

sections are held together by cast iron push nipples.

Empire Water boiler is capable of firing #2 fuel oil from

0.65 gph up to 2.00 gph. All packaged boilers include a

swing door, Honeywell limit, temperature and pressure

gauge, safety relief valve, drain valve, flue brush, and extra

boiler tap for expansion tank or air elimination.

Boiler installation shall be completed by qualified agency.

Become familiar with symbols identifying

potential hazards.

This is the safety alert symbol. Symbol alerts you

to potential personal injury hazards. Obey all safety

messages following this symbol to avoid possible injury or

death.

Indicates a hazardous situation which, if not avoided,

WILL result in death or serious injury

Indicates a hazardous situation which, if not avoided,

could result in death or serious injury.

CAUTION

Indicates a hazardous situation which, if not avoided,

could result in minor or moderate injury.

Used to address practices not related to personal

injury.

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii!!!_i;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;ii;_i_!

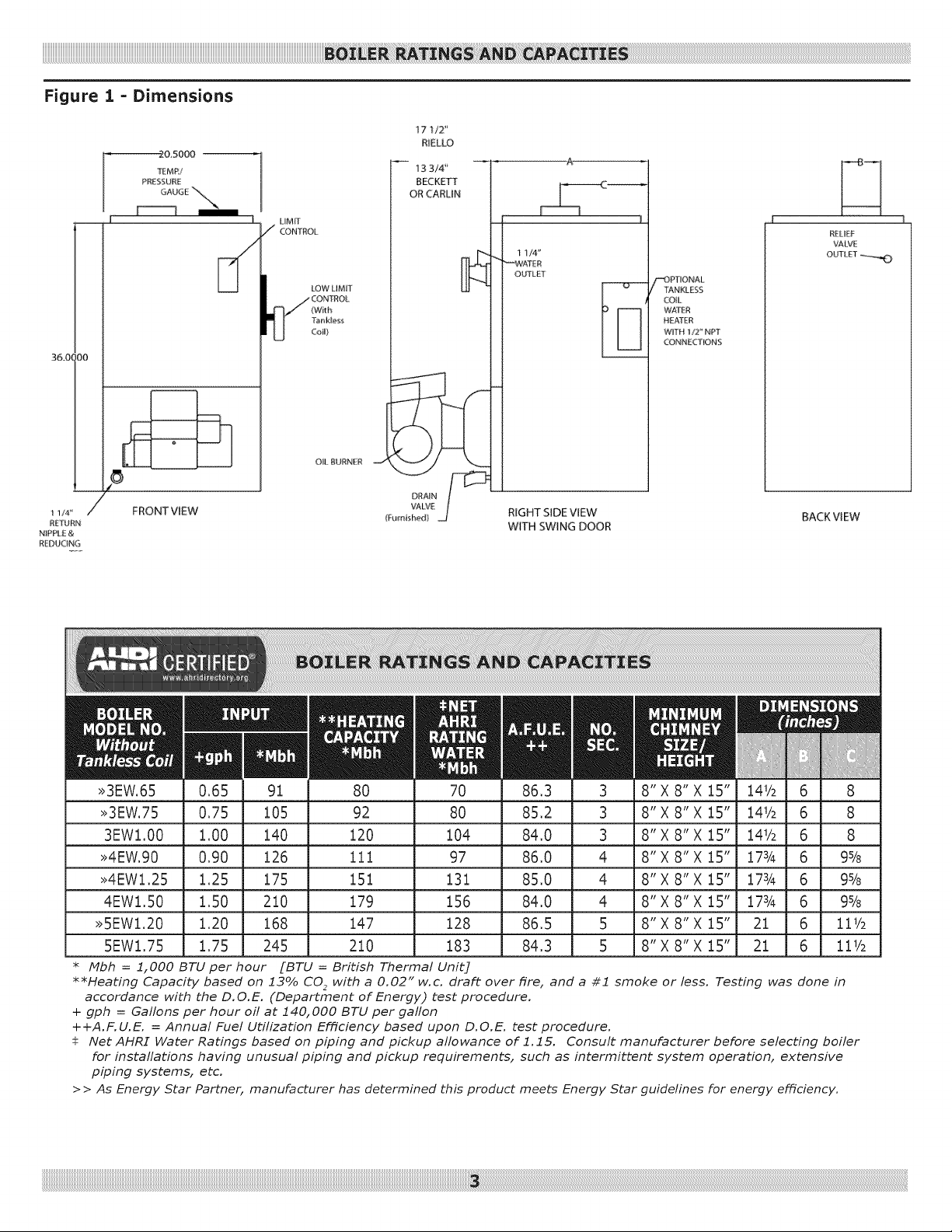

Figure 1 = Dimensions

2&5000 --

TEMR/

PRESSUiqE

GAUGE "_'_

36.01 iO0

I

LIMIT

/ CONTROL

I_/CO NTROL

LOW LIMIT

(With

Tank_ess

CoiU}

O&BURNER

17 1/2"

RIELLO

13 3/4'

BECKETT

OR CARLiN

1 1/4"

_,#,,#ATER

OUTLET

"_)PTIONA L

I"ANKLESS

COIL

WAT£R

HEATER

WITH 1/2" NPT

CONNE£T_ONS

RELIEF

VALVE

OUTLET_

DRAIN

VALVE

(Furnished)

RIGHT SIDE VIEW

WITH SWING DOOR

8" X 8" X 15"

8" X 8" X 15"

8" X 8" X 15"

8" X 8" X 15"

8" X 8" X 15"

8" X 8" X 15"

8" X 8" X 15"

8" X 8" X 15"

I 1/4 '_

REIURN

N_PP_ E &

REDUCING

/_' FRONT VIEW

>>3EW.65 80 70 86,3

>>3EW.75 92 80 85,2

3EW1.00 120 104 84,0

>>4EW.90 111 97 86,0

>>4EWl,25 151 131 85,0

4EWl.50 179 156 84,0

>>5EWl.20 147 128 86,5

5EWl.75 210 183 84,3

* Mbh = 1,000 BTU per hour [BTU = BHtish Thermal Unit]

**Heating Capacity based on 13% CO2 with a 0.02" w.c. draft over fire, and a #1 smoke

or less. Testing was done in

accordance with the D.O.E. (Department of Energy) test procedure.

+ gph = Gallons per hour off at 140,000 BTU per gaflon

++A.F.U.E. = Annual Fuel Utilization Efficiency based upon D.O.E. test procedure.

Net AHRI Water Ratings based on piping and pickup allowance of 1.15. Consult manufacturer before selecting boiler

for instaflations having unusual piping and pickup requirements, such as intermittent system operation, extensive

piping systems, etc.

> > As Energy 5tar Partner, manufacturer has determined this product meets Energy 5tar guidelines for energy efficiency.

BACKVIEW

This boiler has been designed for residential

installations. Tf used for commercial applications,

all jurisdictional requirements must be met. This

may require wiring and/or piping modifications.

Manufacturer is not responsible for any changes to

the original design.

1, Read the Owner's Manual for Safe Operation. Failure

to follow rules for safe operation and instructions can

cause malfunction of boiler and result in death, serious

bodily injury, and/or property damage.

2, Check your local codes and utility requirements before

installation. Installation must be in accordance with

their directives, or follow NFPA 31 Installation of Oil

Burning Equipment, latest revision.

3, Before servicing, allow boiler to cool. Always shut off

any electricity and oil to boiler when working on it,

4, Inspect oil line and connections for leaks.

5, Be certain oil burner nozzle is the size required. Over-

firing will result in early failure of the boiler sections.

This will cause dangerous operation.

6, Never vent this boiler into enclosed space. Always vent

to outside. Never vent to another room or inside a

building.

7, Be sure there is adequate air supply for complete

combustion.

8. Follow regular service and maintenance schedule for

efficient and safe operation.

9. Keep boiler area clean and free of combustible material,

gasoline and other flammable vapors and liquids.

10. Oil burners are not do-it-yourself items. This

boiler must be installed and serviced by qualified

professionals using combustion test instruments,

Burn and scald hazard. Safety relief valve could

discharge steam or hot water during operation.

Tnstall discharge piping per these instructions.

11.

Be aware when piping the safety relief valve if system

pressure exceeds safe limit of 30 pounds per square

inch, the safety relief valve will automatically lift

open. Lifting of the safety relief valve can discharge

large quantities of steam and hot water, which may

damage the surroundings. Before installing the safety

relief valve read the manufacturer's instructions and

maintenance section of the manual on safety relief

valves.

12.

Installation and sizing of the expansion tank must

consider heating systems total water volume,

temperature, boiler initial fill pressure, and system

arrangement. Improperly installed and sized expansion

tank may result in frequent lifting of the safety

relief valve or other heating system problems. For

proper installation, sizing, and maintenance of the

expansion tank follow guidelines established by tank

manufacturer.

13. Expansion tank performance and life expectancy can

be hindered by overfilling the boiler. Recommend initial

fill pressure of 10-12 psig. For higher fill pressures

expansion tank's air charge will need to be increased to

match fill pressure. Consult manufacturer's guidelines

for sizing and selection.

14. Purging the heating system of air and gases when

first putting boiler into service is critical for proper

circulation and quiet performance. Once air and gases

are purged, for boiler installations using float type

vents, air vents should be closed for normal operation.

If air is heard or noticed by loss of heat, purge system

and open vents for short period of time.

DO NOT USE GASOLINE CRANKCASE DRJ_ININGS

OR ANY OIL CONTAINING GASOLINE,

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiLi:i!6!i_ i_i_!!_iii!_!!i!!i!!i!!i!!i!!i_i!i_ii¸i:¸i_iiiiiiiiiiiiii_ii!i_ii6i!i_!:i:_ii_i_ii_i_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:il

Complete Prior To Installing Boiler.

A.

Verify you have selected the right size boiler with

proper capacity. AHRI rating of boiler selected 2.

should be greater than or equal to calculated peak

heating load (heat loss) for building or area(s)

served by boiler and associated hot water heating 3.

systems. See boiler rating and capacity table

previously listed in this manual. Any heat loss

calculations used should be based on approved

methods.

B. Boiler must be supplied with proper oil supply

and oil piping, sufficient fresh combustion air, and

suitable electrical supply.

C. Boiler must be connected to suitable venting system

and piping system adequate to distribute heating

load.

D. Properly locate and install thermostat for heating

system control.

Any doubts as to requirements, check with local authorities

and obtain professional help where needed. OPERATING

INSTRUCTIONS, FINAL CHECKS AND ADJUSTMENTS, and

MAINTENANCE sections in this manual are vital to the

proper and safe operation of the heating system.

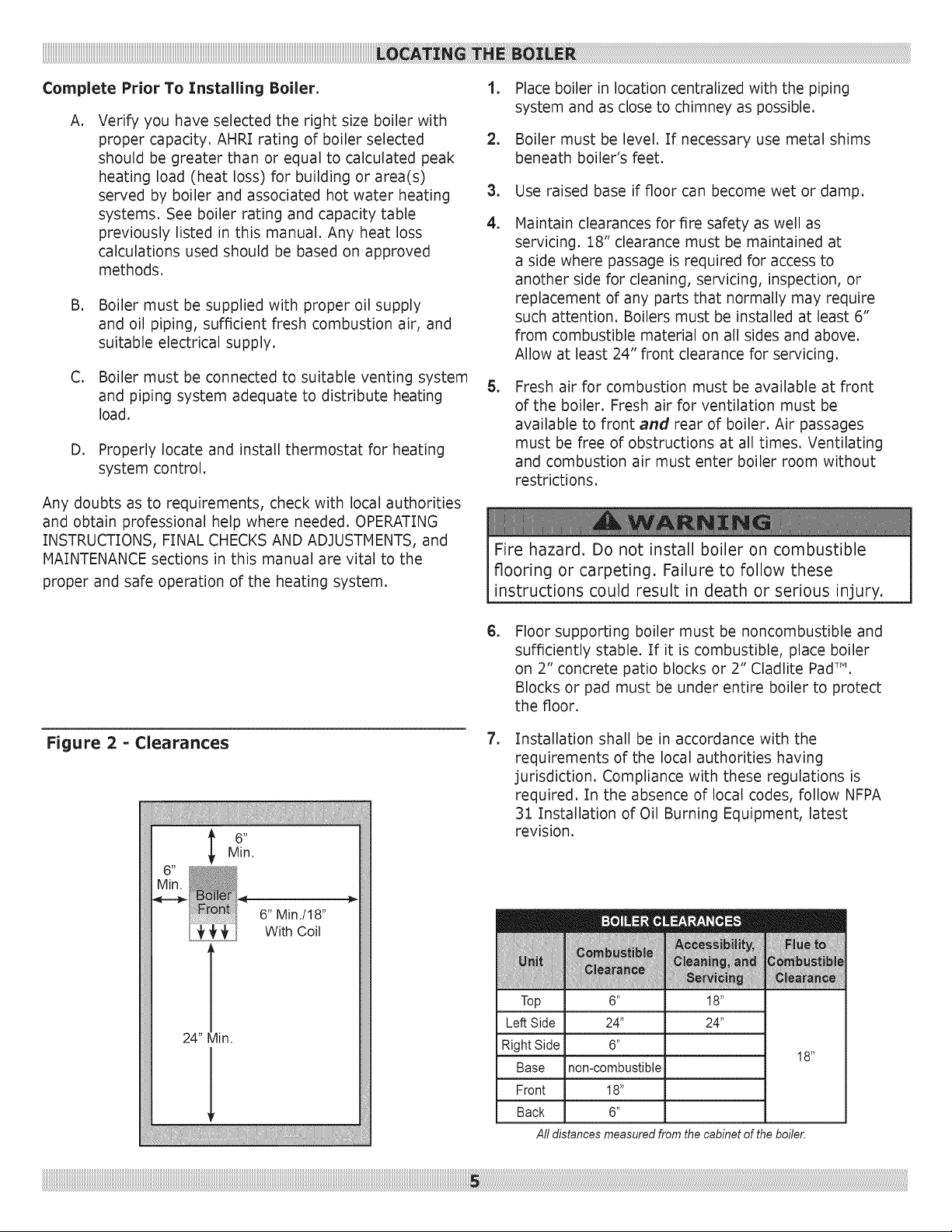

1,

Place boiler in location centralized with the piping

system and as close to chimney as possible.

Boiler must be level. If necessary use metal shims

beneath boiler's feet,

Use raised base if floor can become wet or damp.

4,

Maintain clearances for fire safety as well as

servicing. 18" clearance must be maintained at

a side where passage is required for access to

another side for cleaning, servicing, inspection, or

replacement of any parts that normally may require

such attention. Boilers must be installed at least 6"

from combustible material on all sides and above.

Allow at least 24" front clearance for servicing.

,

Fresh air for combustion must be available at front

of the boiler. Fresh air for ventilation must be

available to front and rear of boiler. Air passages

must be free of obstructions at all times. Ventilating

and combustion air must enter boiler room without

restrictions.

Fire hazard. Do not install boiler on combustible

flooring or carpeting. Failure to follow these

instructions could result in death or serious injury.

Figure 2 = Clearances

24" Min.

6" Min./l 8"

With Coil

,

Floor supporting boiler must be noncombustible and

sufficiently stable. If it is combustible, place boiler

on 2" concrete patio blocks or 2" Cladlite PadT",

Blocks or pad must be under entire boiler to protect

the floor.

, Installation shall be in accordance with the

requirements of the local authorities having

jurisdiction. Compliance with these regulations is

required. In the absence of local codes, follow NFPA

31 Installation of Oil Burning Equipment, latest

revision.

Top

Left Side

Right Side

Base

Front

Back

All distances measured from the cabinet of the boiler.

6 _

24"

non-combustible

18"

6"

18 _

24"

18 _

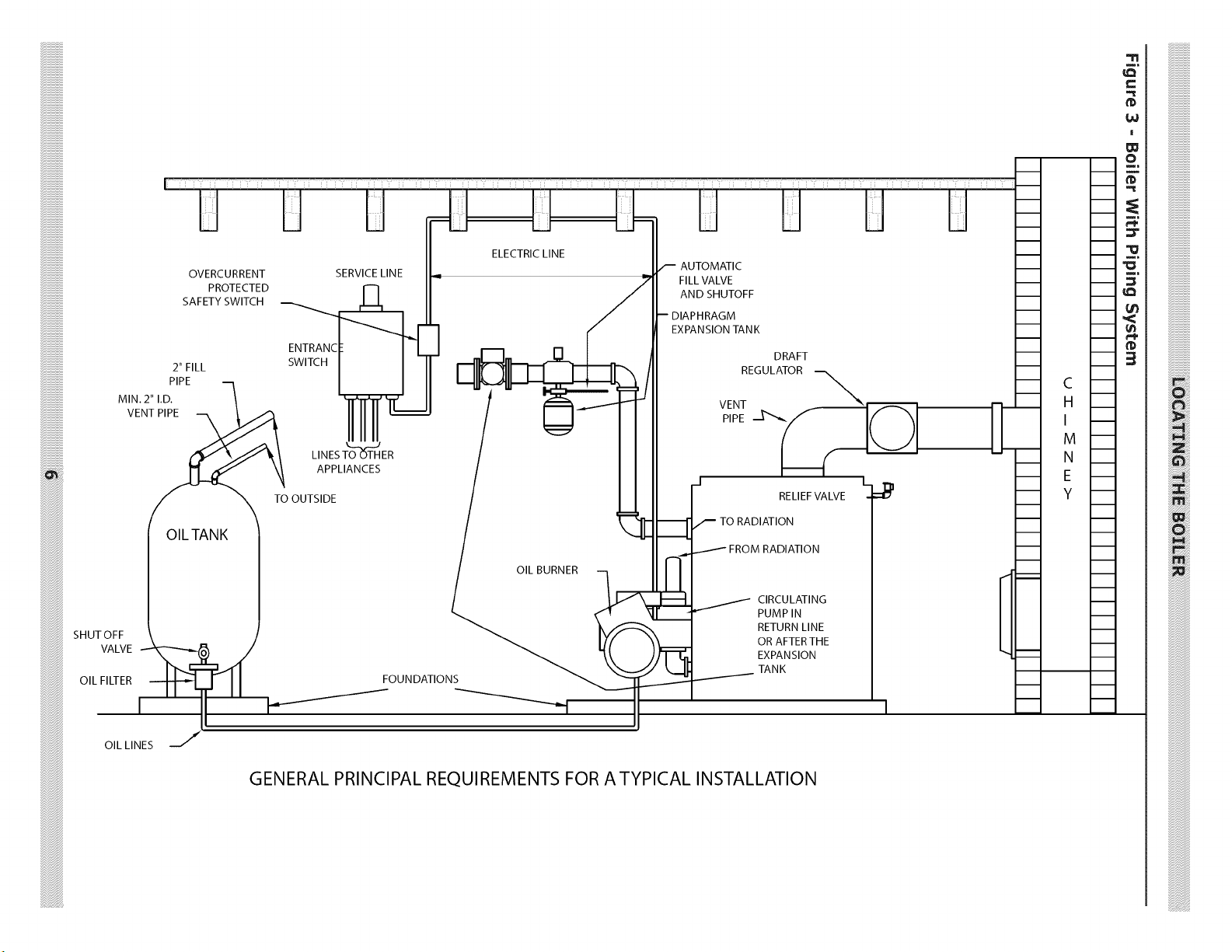

MIN. 2" I.D.

VENT PIPE

OVERCURRENT

PROTECTED

SAFETY SWITCH

2" FILL

PIPE

ENTRANq

SWITCH

LINESTO

APPLIANCES

SERVICE LINE

ELECTRIC LINE

FILL VALVE

AND SHUTOFF

DIAPHRAGM

EXPANSION TANK

REGULATOR

VENT

PIPE

DRAFT

"11

m_

c

w

I

SHUT OFF

VALVE

OIL FILTER

OIL LINES J

OILTANK

TO OUTSIDE

TO RADIATION

OIL BURNER

FOUNDATIONS

RELIEFVALVE

CIRCULATING

PUMP IN

RETURN LINE

OR AFTER THE

EXPANSION

TANK

GENERAL PRINCIPAL REQUIREMENTS FOR A TYPICAL INSTALLATION

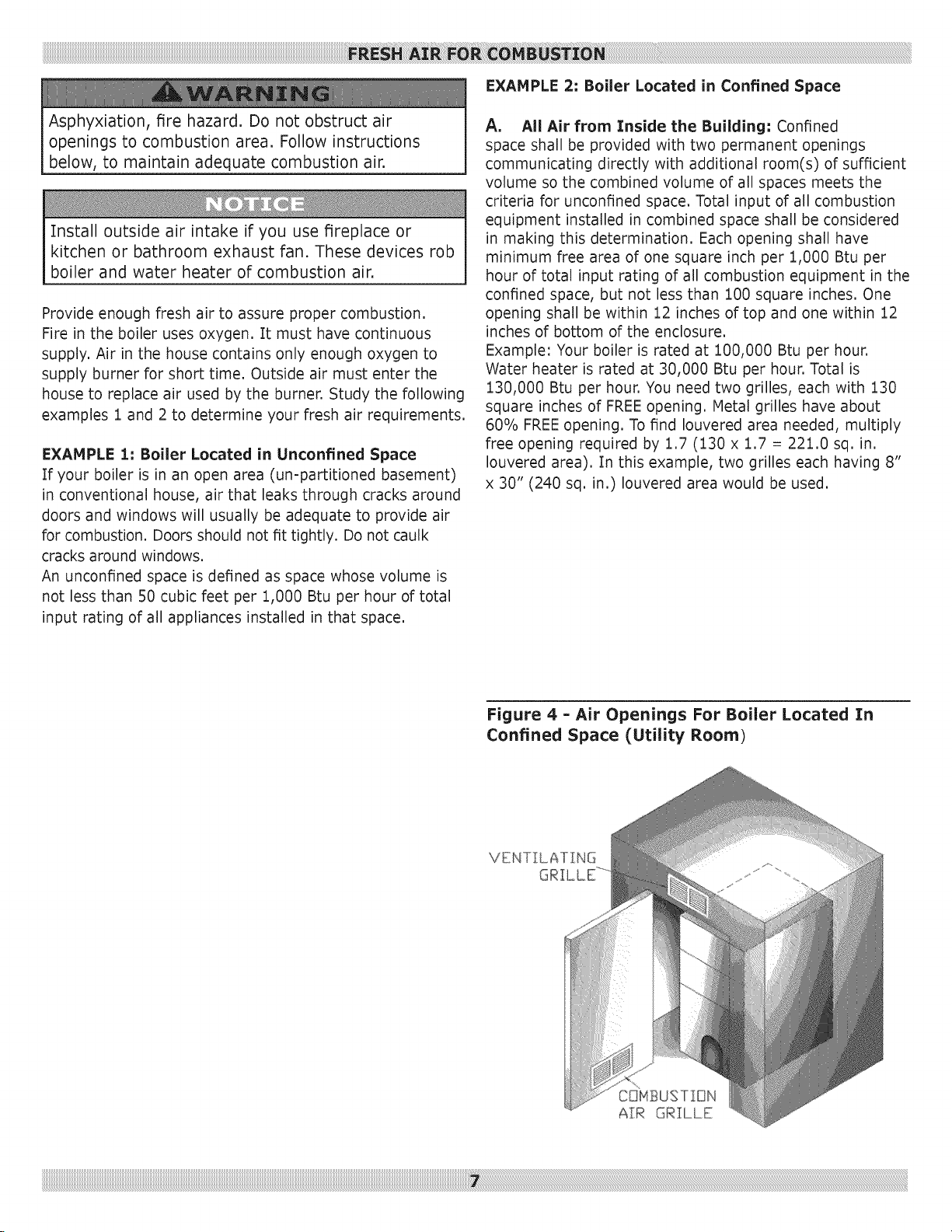

EXAMPLE 2: Boiler Located in Confined Space

Asphyxiation, fire hazard. Do not obstruct air

openings to combustion area. Follow instructions

below, to maintain adequate combustion air.

Install outside air intake if you use fireplace or

kitchen or bathroom exhaust fan. These devices rob

boiler and water heater of combustion air.

Provide enough fresh air to assure proper combustion.

Fire in the boiler uses oxygen. It must have continuous

supply. Air in the house contains only enough oxygen to

supply burner for short time. Outside air must enter the

house to replace air used by the burner, Study the following

examples 1 and 2 to determine your fresh air requirements.

EXAMPLE 1: Boiler Located in Unconfined Space

If your boiler is in an open area (un-partitioned basement)

in conventional house, air that leaks through cracks around

doors and windows will usually be adequate to provide air

for combustion. Doors should not fit tightly. Do not caulk

cracks around windows.

An unconfined space is defined as space whose volume is

not less than 50 cubic feet per 1,000 Btu per hour of total

input rating of all appliances installed in that space.

A, All Air from Inside the Building: Confined

space shall be provided with two permanent openings

communicating directly with additional room(s) of sufficient

volume so the combined volume of all spaces meets the

criteria for unconfined space. Total input of all combustion

equipment installed in combined space shall be considered

in making this determination. Each opening shall have

minimum free area of one square inch per 1,000 Btu per

hour of total input rating of all combustion equipment in the

confined space, but not less than 100 square inches. One

opening shall be within 12 inches of top and one within 12

inches of bottom of the enclosure.

Example: Your boiler is rated at 100,000 Btu per hour,

Water heater is rated at 30,000 Btu per hour, Total is

130,000 Btu per hour, You need two grilles, each with 130

square inches of FREEopening. Metal grilles have about

60% FREEopening. To find Iouvered area needed, multiply

free opening required by 1.7 (130 x 1.7 = 221.0 sq. in.

Iouvered area). In this example, two grilles each having 8"

x 30" (240 sq. in.) Iouvered area would be used.

Figure 4 - Air Openings For Boiler Located In

Confined Space (Utility Room)

VENTILATING

B,

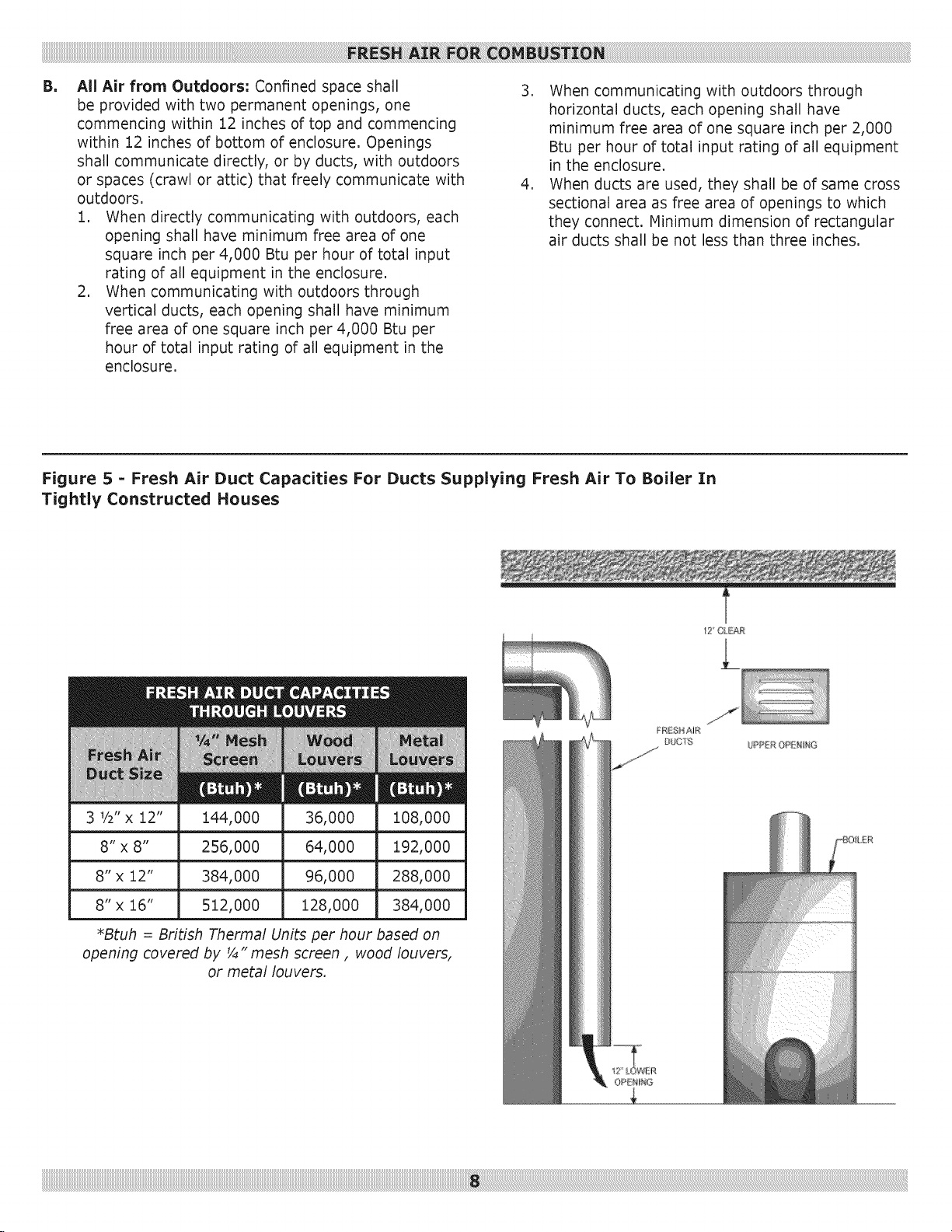

All Air from Outdoors: Confined space shall

be provided with two permanent openings, one

commencing within 12 inches of top and commencing

within 12 inches of bottom of enclosure. Openings

shall communicate directly, or by ducts, with outdoors

or spaces (crawl or attic) that freely communicate with

outdoors.

1. When directly communicating with outdoors, each

opening shall have minimum free area of one

3. When communicating with outdoors through

horizontal ducts, each opening shall have

minimum free area of one square inch per 2,000

Btu per hour of total input rating of all equipment

in the enclosure.

4. When ducts are used, they shall be of same cross

sectional area as free area of openings to which

they connect. Minimum dimension of rectangular

air ducts shall be not less than three inches.

square inch per 4,000 Btu per hour of total input

rating of all equipment in the enclosure.

2. When communicating with outdoors through

vertical ducts, each opening shall have minimum

free area of one square inch per 4,000 Btu per

hour of total input rating of all equipment in the

enclosure.

Figure 5 = Fresh Air Duct Capacities For Ducts Supplying Fresh Air To Boiler In

Tightly Constructed Houses

3 V2"x 12" 144,000 36,000 i08,000

8" x 8" 256,000 64,000 192,000

8" x 12" 384,000 96,000 288,000

8" x 16" 512,000 128,000 384,000

*Btuh = British Thermal Units per hour based on

opening covered by _" mesh screen, wood louvers,

or metal louvers.

12" CL£A£

,

Installation of boiler for new heating system,

Install all of radiation units (panels, radiators,

baseboard, or tubing) and supply and return mains

first. After all heating system piping and components

have been installed, make final connection of system

piping to boiler. It is recommended to mount circulating

pump on supply side piping, such that it pumps away

from expansion tank. Refer to figures on next pages.

,

Equip hot water boiler installed above radiation

level with low water cut off device. Periodic inspection

is necessary, as is flushing of float type devices, per

low water cut off manufacturer's specific instructions.

,

Packaged boiler is set up with 1¼" NPT supply

and return piping from front of boiler. Boiler supply

and return piping can be moved to rear of boiler. Boiler

should not be piped return line to front, supply line

to rear, or vice versa, will cause boiler water to short

circuit heat exchanger. Piping connections may require

additional fittings and parts.

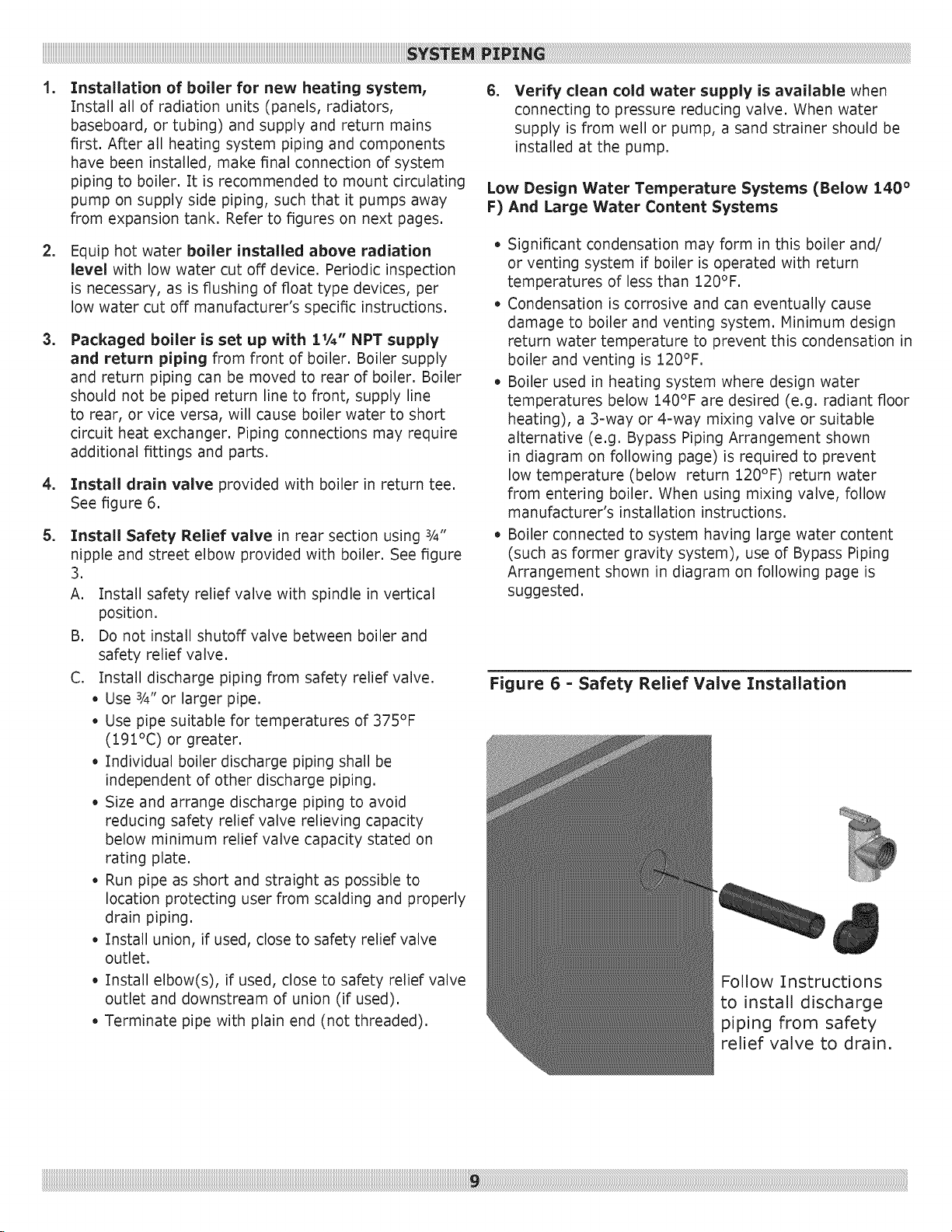

,

Install drain valve provided with boiler in return tee.

See figure 6.

,

Install Safety Relief valve in rear section using ¾"

nipple and street elbow provided with boiler. See figure

3.

A. Install safety relief valve with spindle in vertical

position.

B. Do not install shutoff valve between boiler and

safety relief valve.

C. Install discharge piping from safety relief valve.

• Use 3/4"or larger pipe.

• Use pipe suitable for temperatures of 375°F

(191°C) or greater.

• Individual boiler discharge piping shall be

independent of other discharge piping.

• Size and arrange discharge piping to avoid

reducing safety relief valve relieving capacity

below minimum relief valve capacity stated on

rating plate.

• Run pipe as short and straight as possible to

location protecting user from scalding and properly

drain piping.

• Install union, if used, close to safety relief valve

outlet.

• Install elbow(s), if used, close to safety relief valve

outlet and downstream of union (if used).

• Terminate pipe with plain end (not threaded).

,

Verify clean cold water supply is available when

connecting to pressure reducing valve. When water

supply is from well or pump, a sand strainer should be

installed at the pump.

Low Design Water Temperature Systems (Below 140 °

F) And Large Water Content Systems

• Significant condensation may form in this boiler and/

or venting system if boiler is operated with return

temperatures of less than 120°F.

• Condensation is corrosive and can eventually cause

damage to boiler and venting system. Minimum design

return water temperature to prevent this condensation in

boiler and venting is 120°F.

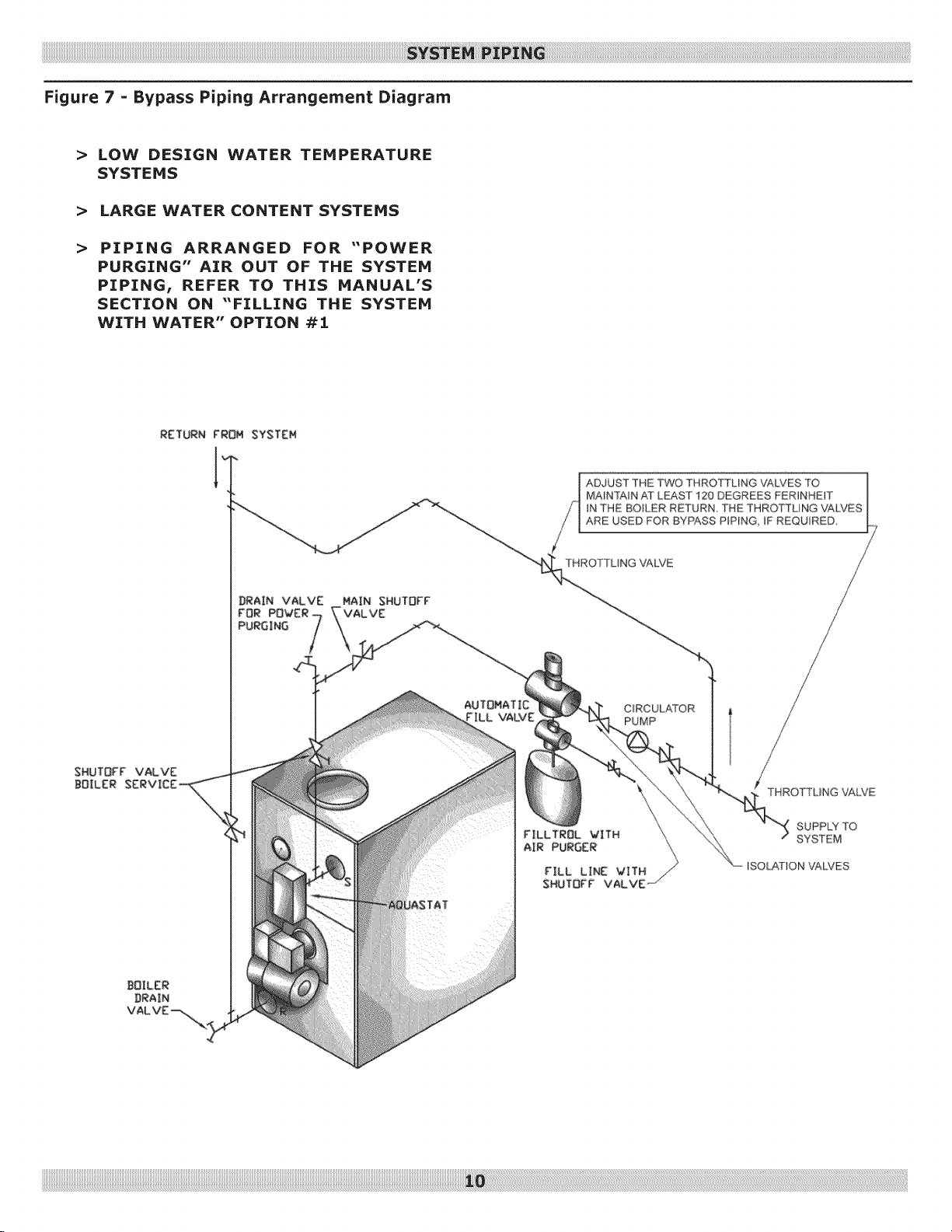

• Boiler used in heating system where design water

temperatures below 140°F are desired (e.g. radiant floor

heating), a 3=way or 4=way mixing valve or suitable

alternative (e.g. Bypass Piping Arrangement shown

in diagram on following page) is required to prevent

low temperature (below return 120°F) return water

from entering boiler. When using mixing valve, follow

manufacturer's installation instructions.

• Boiler connected to system having large water content

(such as former gravity system), use of Bypass Piping

Arrangement shown in diagram on following page is

suggested.

Figure 6 = Safety Relief Valve Installation

Follow Instructions

to install discharge

piping from safety

relief valve to drain.

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii_!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i!!i_ii!ii!il!_!!i!

Figure 7 = Bypass Piping Arrangement Diagram

> LOW DESIGN WATER TEMPERATURE

SYSTEMS

> LARGE WATER CONTENT SYSTEMS

> PIPING ARRANGED FOR "POWER

PURGING" AIR OUT OF THE SYSTEM

PIPING! REFER TO THIS MANUAL'S

SECTION ON "FILLING THE SYSTEM

WITH WATER" OPTION #i

SHUTOFF VALVE

BOILER

AUTOMATIC

rILL VALVE

ADJUST THE TWO THROTTLING VALVES TO |

MAINTAIN AT LEAST 120 DEGREES FER_NHE_T

iN THE BOH_ER RETURN THE THROTTUNG VALP_ES

ARE USED FOR BYPASS PIPING, IF REQUIRED

THROTTLING VALVE

FILLTROL VITH

AIR PURGER

|

1

CIRCULATOR

PUMP

THROTTUNG VALVE

SUPPLY TO

SYSTEM

ISOL,AS_ON VALVES

Loading...

Loading...