Dunkirk 4ES1.50C, 3ES1.00C, 4ES1.75C, 4ES1.85C, 3ES1.00 Installation & Operation Manual

...

O|L-F|REDCAST |RONSTF.AM

BO|

Installation

• Operation

• RepairParts

Theseinstructionsmustbeaffixedonoradjacenttotheboiler.DUNKIRKBOILERS

DUNKIRK,NEWYORK14048- 716366-5500

MEMBER: The llydronies Institute

I/2" NPT

TANKLESS

HEATER

, o i

F , t , t i

, t , * ,

LEFT SIDE

3/4 _ NPT

_LOW UMIT

CONTROL ON

COIL PLATE

I/2" NPT

PRESSURETROL

PRESSURE GAUGE

COMBINATION

\

1-1/2" NPT

RETURN

i

FRONT

T

27"

WATER

IJNE

_l

2-I/2" NPT

SUPPLY

iq°p

i-i/2" NPT

i SKIM TAPPING

i

'L

,-V2 ° NPTi

RETURN

REAR

5/4" ASNE

POP SAFETY

VALVE

35

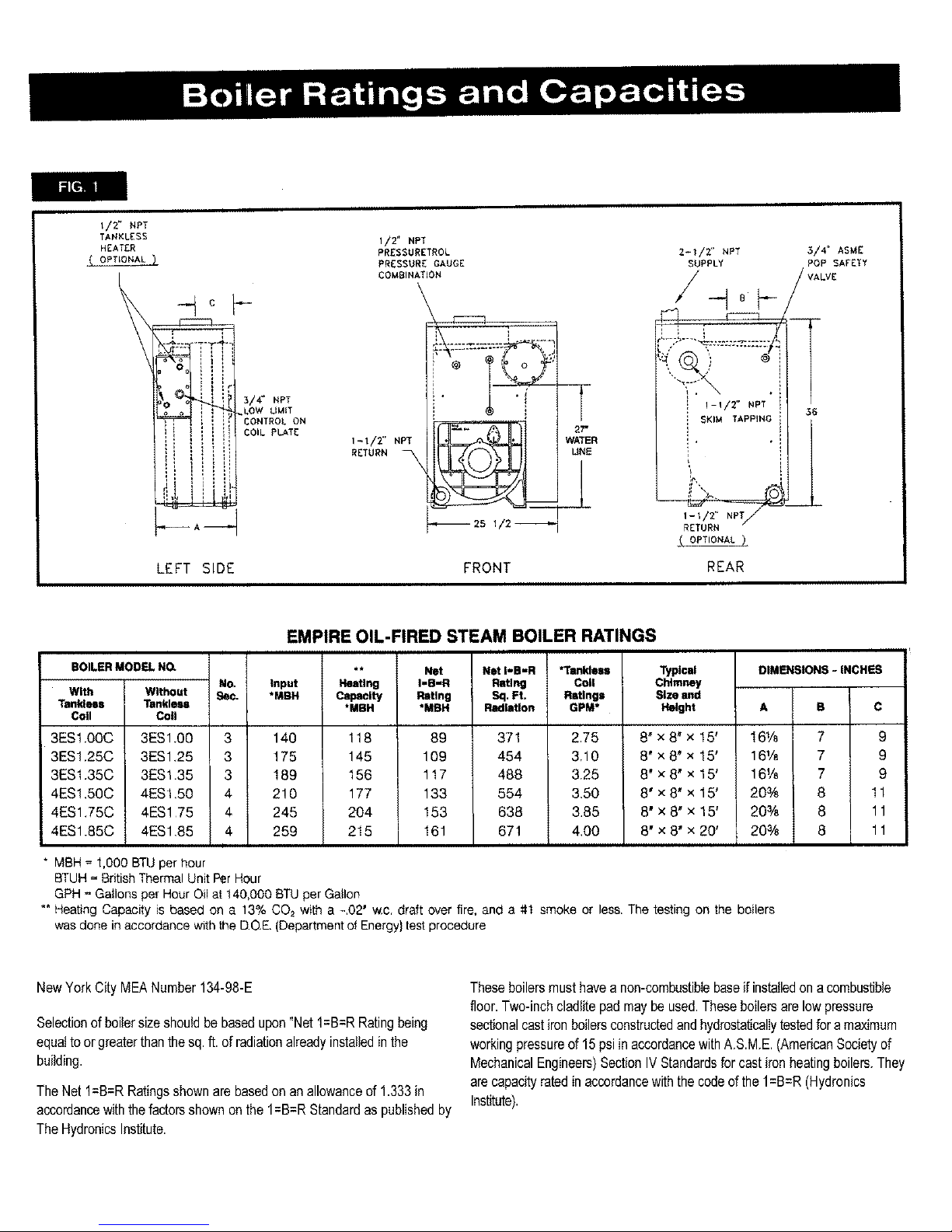

EMPIRE OIL-FIRED STEAM BOILER RATINGS

BOILER MODEL NO.

With Without

Tankless Tankless

Coil Cotl

3ESt O0C 3ES100 3

3ES1.25C 3ES1,25 3

3ES1.35C 3ES1.35 3

4ES1,50C 4ES1,50 4

4ES1.75C 4ES1 75 4

4ES1.85C 4ES1.85 4

* MBH = 1,000 BTUpet hour

No.

9ec.

Input

*MBH

140

175

189

2!0

245

259

Nesting

Capacity

*MBH

118

145

156

177

204

215

Net

I=B-R

Rating

"MBH

89

109

117

133

153

161

Not I-S-R

Rating

Sq. Ft,

Radiation

371

454

488

554

638

671

*Tonldelm

Cell

Ratings

GPM*

2.75

3,10

3.25

3.50

3.85

4,00

Typl©al

Chimney

Size and

Height

8" x 8' x 15'

8" x 8' x 15'

8" x 8' x 15'

8' x 8' x 15'

8" x 8" x 15'

8" x 8' x 20'

CIMF31SIONS- INCHES

A B C

16% 7 9

16½ 7 9

16% 7 9

20% 8 11

20% 8 11

20% 8 11

BTUH = British Thermal Unit Per Hour

GPH _ Gallons per Hour Oil at 140,000 BTU per Gallon

** Heating Capacity is based on a 13% CO2 with a -,02' w.c, draft over fire, and a #1 smoke or less. The testing on the boilers

was done in accordance with lhe DOE. (Department of Energy) test procedure

NewYorkCityMEANumber134-98-E

Selectionofboilersizeshouldbe basedupon"Net1=8=RRatingbeing

equaltoorgreaterthanthesq.ft.of radiationalreadyinstalledinthe

building.

TheNetI=B=R Ratingsshownarebasedonanallowanceof1.333in

accordancewiththefactorsshownonthe 1=B=RStandardas publishedby

TheHydronicsInstitute.

Theseboilersmusthavea non-combustiblebaseifinstalledon acombustible

floor.Two-inchcladlitepadmaybeused.Theseboilersarelowpressure

sectionalcastironboilersconstructedandhydrostaticallytestedfora maximum

workingpressureof 15psiin accordancewithA.SME. (AmericanSocietyof

MechanicalEngineers)SectionIVStandardsfor castironheatingboilers.They

arecapacityratedinaccordancewiththecodeofthe1=B=R(Hydronics

Institute).

RulesforSafeInstallationandOperation

1. Readthe Owner'sManualforSafeOperationcarefully.Failuretofollow

therulesforsafeoperationandtheinstructionscancausea malfunctionof

the boilerand result in death,_rious bodily injury, and/or property

damage.

2. Checkyourlocalcodesandutilityrequirementsbeforeinstallation.The

installationmustbeinaccordancewiththeirdirectives,orfollowNFPA31

- InstallationofOilBurningEquipment,latestrevision.

3. Beforeservicing,allowboilertocool.Nwaysshutoffanyelectricityand

oiltoboilerwhenworkingonit.Thiswillpreventanyelectricalshocksor

burns.

4. Inspectoillineandconnectionsforleaks.

5. Be certainoil burnernozzleis size required.Overfiringwill resultin

earlyfailureofthe boilersections.Thiswill causedangerousoperation.

6. Nevervent this boiler into an enclosedspace.Alwaysvent to the

outside.Neverventto anotherroomor insidea building.

7. Besurethereisadequateairsupplyforcompletecombustion.

8. Followa regutarserviceandmaintenancescheduleforefficientand

safeoperation.

9. Keepboilerareacleanandfreeofcombustiblematerial,gasolineand

otherflammablevaporsandliquids.

This boiler has been designed for residentialinstallations. If used for commercial

applications,alljurisdictionalrequirementsmustbe met.This mayrequirewiringandlor

pipingmodifications.Themanufactureris notresponsibleforany changesto the original

design.

BeforeYouStart

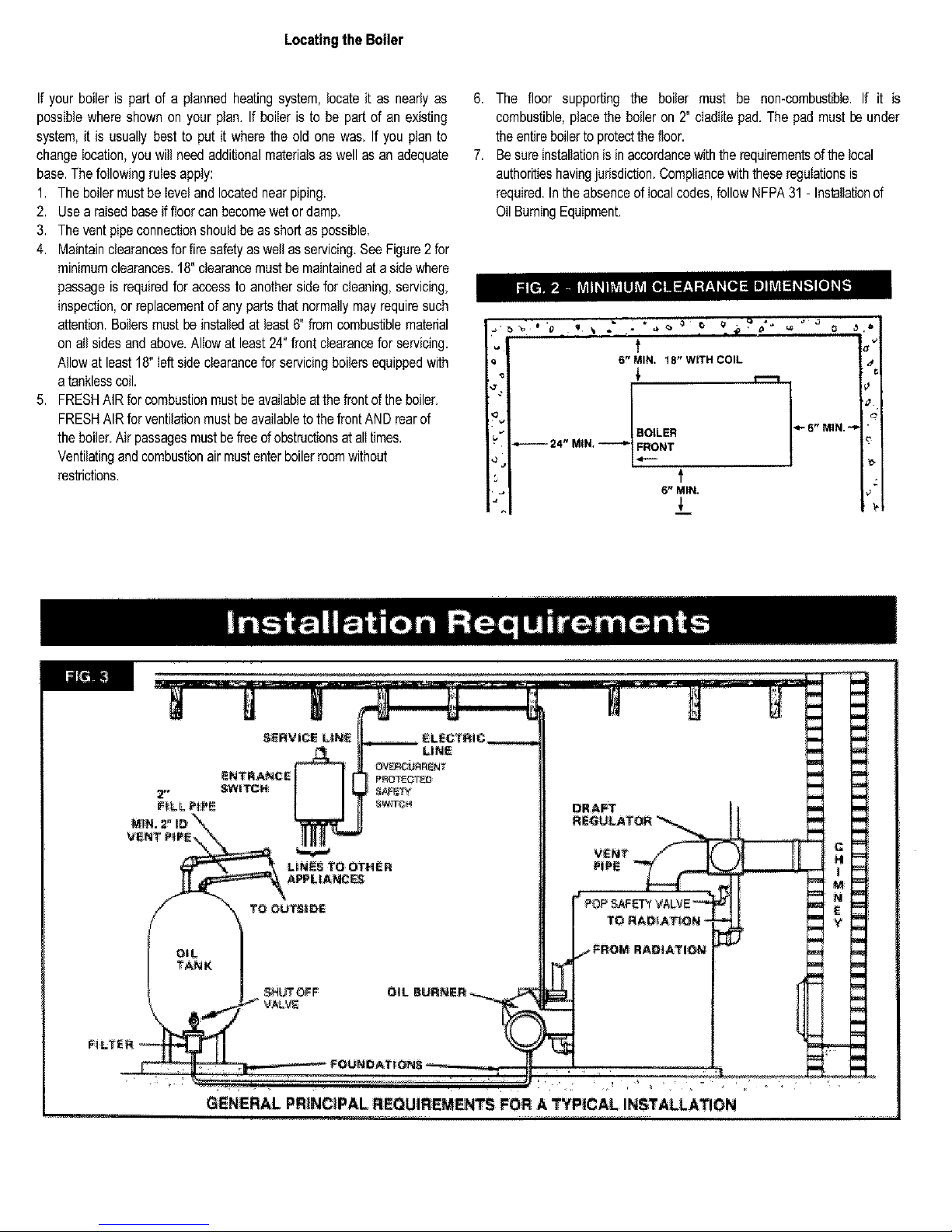

Check to be sure you have the dght size boiler beforestartingthe

installation.See ratingand capacitytableon precedingpage.Checkthe

ratingplateontheboiler.

You mustsee that theboileris suppliedwiththe properoil,freshair for

combustion,and a suitableelectricalsupply.Also, the boiler must be

connectedto a suitableventingsystemand an adequatepipingsystem.

Finally,a thermostat,properlylocated,is neededforcontrolofthe heating

system.If youhaveanydoubtsas to thevariousrequirements,checkwith

local authorities and obtain professionalhelp where needed. THE

OPERATING INSTRUCTIONSand THE FINAL CHECKS AND

ADJUSTMENTSare vitalto the properandsafe operationof the heating

system.Takethetimeto besuretheyarealldone.

Thefollowingstepsareallnecessaryforproperinstallationandsafe

operationof yourboiler.

1. LOCATINGTHEBOILER

2. OILSUPPLYANDPIPING

3. FRESHAIR FORCOMBUSTION

4. PIPINGCONNECTIONS

5. CHIMNEY& VENTPIPECONNECTIONS

6. ELECTRICALWIRING

7. THERMOSTATLOCATION

8. CHECKING&ADJUSTING

9. MAINTENANCE

Locatingthe Boiler

If yourboileris partof a plannedheatingsystem,locateit as nearlyas

possiblewhereshownon yourplan.If boileris to be partof an existing

system,it is usuallybestto put it wherethe old onewas.If youplanto

changelocation,youwill needadditionalmaterialsaswellasan adequate

base.Thefollowingrulesapply:

1. The boilermustbelevelandlocatednearpiping.

2. Usea raisedbaseiff]oorcanbecomewetordamp.

3. Theventpipeconnectionshouldbeas shortaspossible.

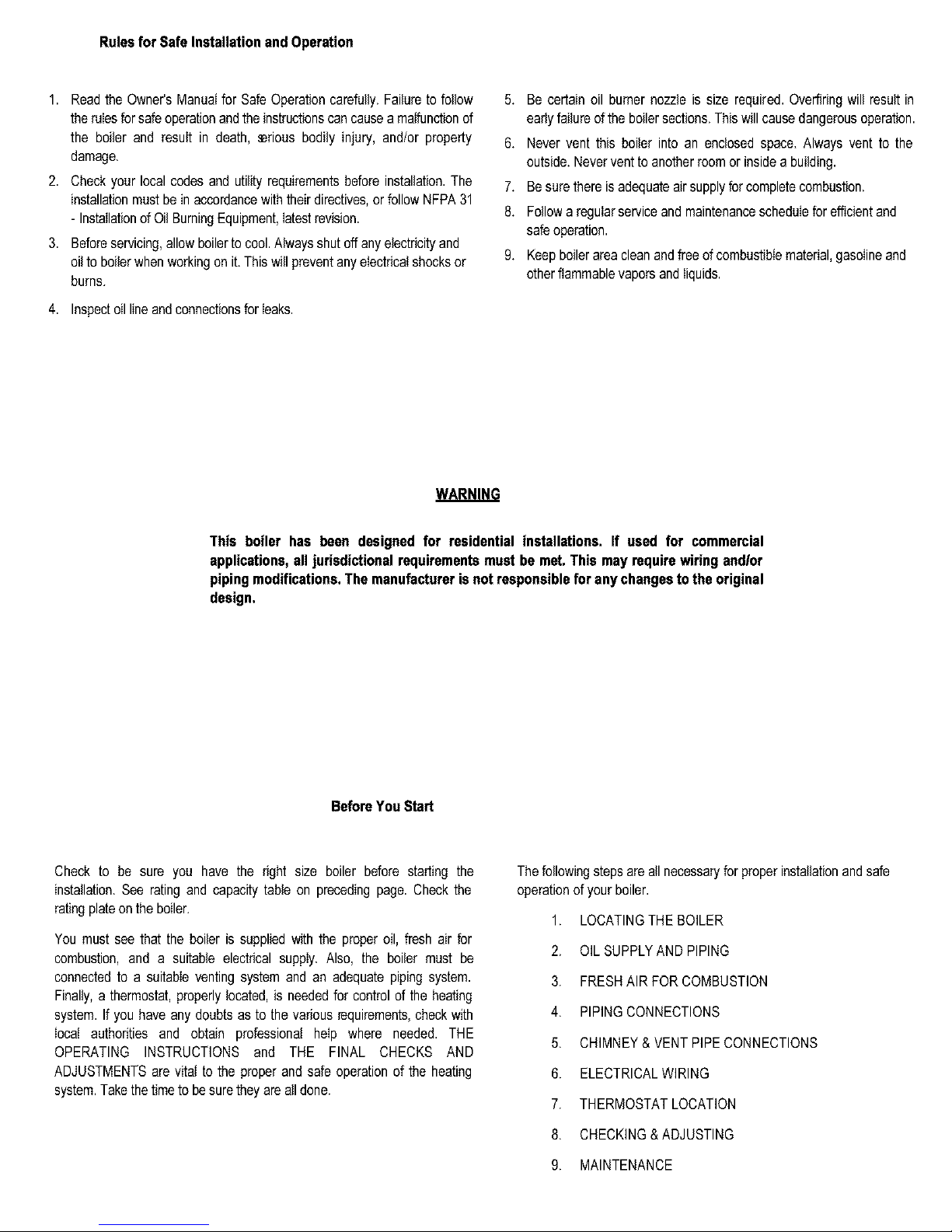

4. Maintainclearancesforfiresafetyaswellasservicing.SeeFigure2for

minimumclearances.18"clearancemustbemaintainedatasidewhere

passageisrequiredforaccessto anothersidefor cleaning,servicing,

inspection,or replacementofanypartsthatnormallymayrequiresuch

attention.Boilersmustbe installedat least6"fromcombustiblematerial

onallsidesandabove.Allowat least24"frontclearancefor servicing.

Allowat least18"leftsideclearanceforservicingboilersequippedwith

atanklesscoil.

5. FRESHAIRfor combustionmustbeavailableatthefrontoftheboiler.

FRESHAIRfor ventilationmustbeavailabletothefrontANDrearof

theboiler.Airpassagesmustbefreeofobstructionsatalltimes.

Ventilatingandcombustionairmustenterboilerroomwithout

restrictions.

6. The floor suppo_ng the boiler must be non-combustible.If it is

combustible,placetheboileron 2" cladlitepad.Thepadmustbeunder

theentireboilertoprotectthefloor.

7. Besureinstallationisinaccordancewiththerequirementsofthelocal

authoritieshavingjurisdiction.Compliancewiththeseregulationsis

required.In theabsenceof localcodes,followNFPA31- Insbtlationof

OilBurningEquipment.

Q 6" MIN. 18" WITH COIL

• _

_" 6" MIN. "

I_// . I BOILER

I-----2, .,..------IFRO.T

6" MIN.

SeRVraceL_NeLL,.------e_.ec_rRic

F_LPtFE ] I I[ s_,rrc_

GENERAL PRINCIPAL REQUiREMEnTS FOR A TYPICAL INSTALLATION

m_

Fresh Air for Combustion

WARNING

NOTE

Be sure to provide enough fresh airfor combustion. Enough air ensures

proper combustion and assures that no hazard will develop due to

the lackof oxygen.

If you use a fireplaceor a kitchenor bathroomexhaustfan,you

shouldinstallan outsideairintake.Thesedeviceswill robthe boiler

andwaterheaterof combustionair.

You must providefor enough fresh air to assurepropercombustion.The fire

in the boiler uses oxygen. It must have a continuous supply. The air in a

house contains only enough oxygen to supply the burner for a short time.

Outside air mustenter the house to replace that used by the burner. Study

foIIowingexampIes 1 and 2to determineyour fresh air requirements.

EXAMPLE 1:Boiler Located in Unconfined Space

If your boiler is in an open area (unpartitioned basement) ina conventional

house, the air that leaks through the cracks around doors and windows will

usually be adequate to provide air for combustion. The doors should not fit

tightly. Do not caulkthecracks aroundthe windows.

An unconfinedspace isdefined as aspace whose volume isnot lessthan 50

cubic feet per 1,000Btu per hour of the total inputrating of all appliances

installedin that space.

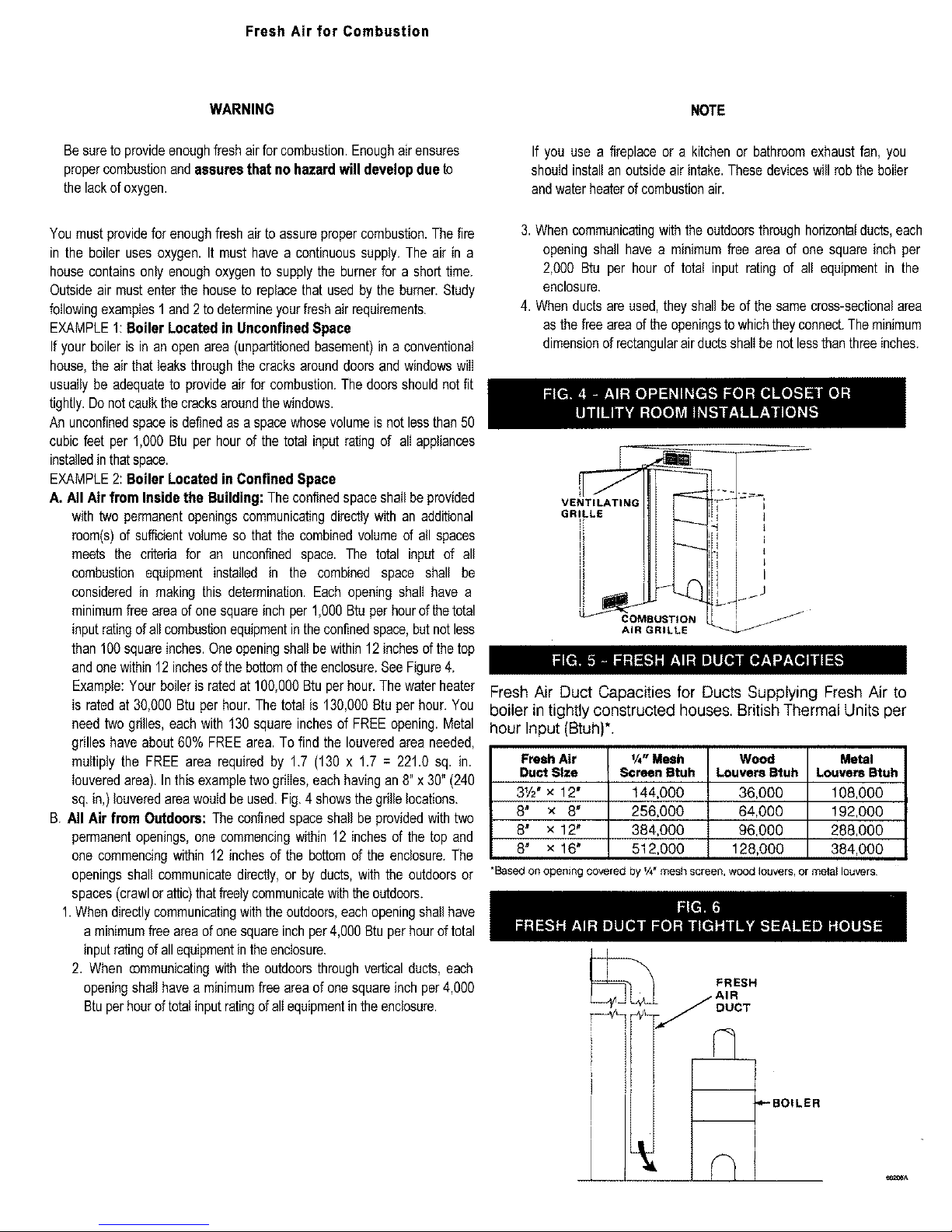

EXAMPLE 2: Boiler Located in Confined Space

A, All Air from Inside the Building: The confined space shall be provided

with two permanent openings communicating directly with an additional

room(s) of sufficientvolume so that the combined volume of all spaces

meets the criteria for an unconfined space. The total input of all

combustion equipment installed in the combined space shall be

considered in making this determination. Each opening shall have a

minimumfree area of one square inch per 1,000Btu per hourof thetotal

inputratingofall combustionequipment inthe confinedspace, but not less

than 100 squareinches. One opening shall be within 12 inches ofthe top

andonewithin 12 inchesof the bottom of theenclosure.See Figure 4.

Example: Your boiler is rated at 100,000 Btu per hour. The water heater

is rated at 30,000 Btu per hour. The total is 130,000 Btu per hour. You

need two grilles, each with 130 square inchesof FREE opening. Metal

grilles have about 60% FREE area. To find the Iouveredarea needed,

multiply the FREE area required by 1.7 (130 x 1.7 = 221.0 sq. in.

Iouvered area). In thisexample twogrilles, each having an 8"x 30" (240

sq.in,) Iouvered area would be used. Fig. 4 shows the grille locations.

B. All Air from Outdoors: The confined space shall be provided with two

permanent openings, one commencing within 12 inches of the top and

one commencing within 12 inches of the bottom of the enclosure. The

openings shall communicate directly, or by ducts, with the outdoors or

spaces (crawlor attic)thatfreely communicatewith the outdoors.

1.When directly communicatingwith the outdoors, each opening shallhave

a minimum free area of one squareinchper 4,000 Btu per hour of total

inputratingof all equipment in theenclosure.

2. When communicatingwith the outdoors through ve_cal ducts, each

opening shall have a minimumfree areaof one square inch per 4,000

Btu perhour of total input ratingof all equipmentin theenclosure.

3.Whencommunicatingwiththeoutdoorsthroughhorizontalducts,each

openingshall havea minimumfreearea of onesquareinchper

2,000 Btu per hour of totalinput ratingof all equipmentin the

enclosure.

4. Whenductsareused,theyshallbeof thesamecross-sectionalarea

asthe freeareaof theopeningstowhichtheyconnect.Theminimum

dimensionofrectangularairductsshal{benotlessthanthreeinches.

VENTILATING -'_--i

GRII.LE I

i I ' 1

i ,11 II ',

AIR GRILLE _

Fresh Air Duct Capacities for Ducts Supplying Fresh Air to

boiler in tightly constructed houses. British Thermal Units per

hour Input (Btuh)*.

Fresh Air

Duct Size

31/2"x 12"

8* x 8"

8" x 12"

8" x 16"

1/4"Mesh

Screen Btuh

144,000

256,000

384,000

512,0O0

Wood

Louvers Stuh

36,000

64,000

96,000

128,000

Metal

Louvers Btuh

108,000

!92,000

288,000

384,000

*Based on opening covered by IA" mesh screen, wood louvers, or mela{ louvers

FRESH

Boilers With Tankless Heater Coil

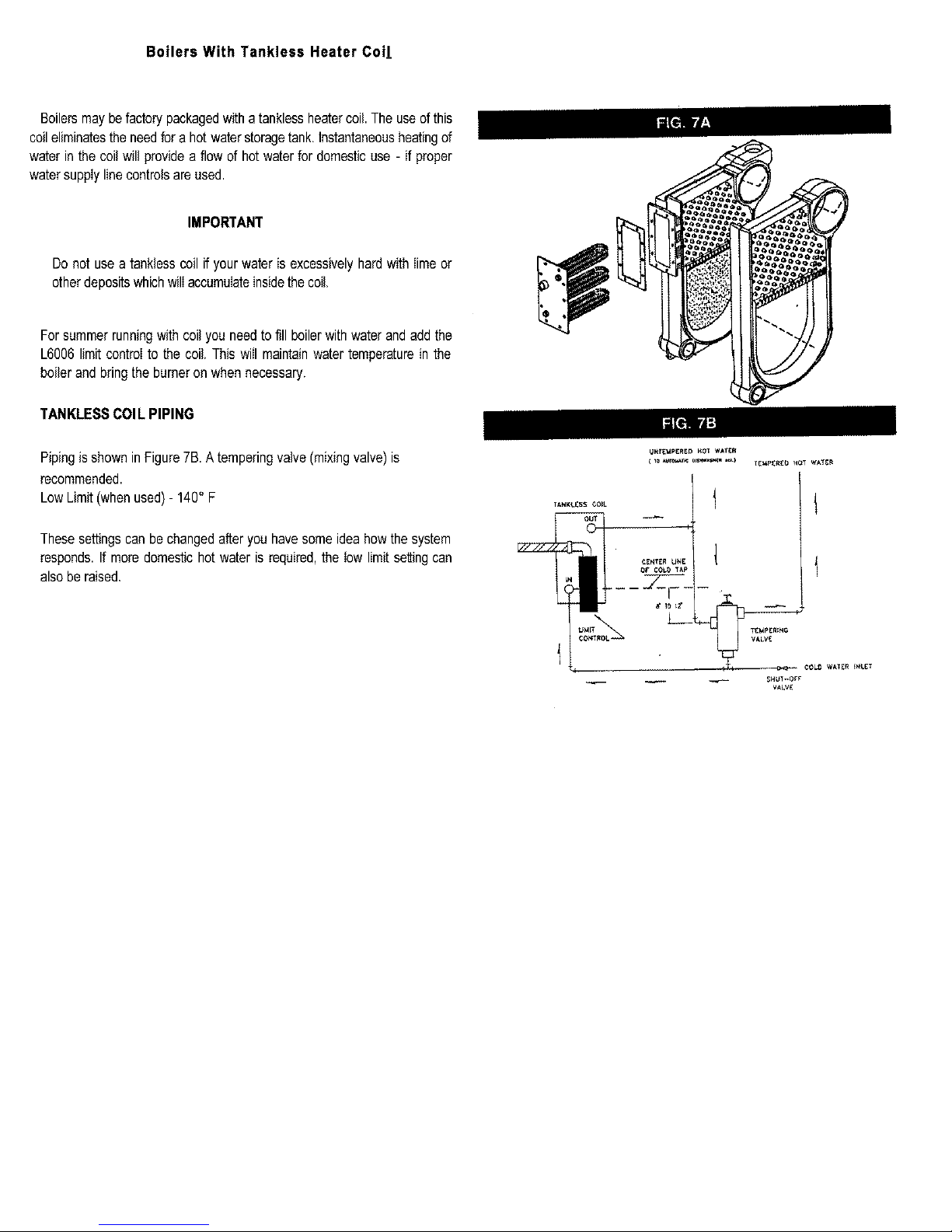

Boilersmaybefactorypackagedwithatanklessheatercoil.Theuseof this

coileliminatesthe needforahot waterstoragetank.Instantaneousheatingof

waterinthecoil willprovidea flowof hotwaterfor domesticuse- ifproper

watersupplylinecontrolsareused.

IMPORTANT

Donot usea tanklesscoilif yourwateris excessivelyhardwithlimeor

otherdepositswhichwillaccumulateinsidethecoil.

Forsummerrunningwithcoilyou needtofill boilerwithwaterandaddthe

L6006limitcontrolto the coil.Thiswill maintainwatertemperaturein the

boilerand bringtheburneronwhennecessary.

TANKLESSCOlL PIPING

PipingisshowninFigure7B.A temperingvalve(mixingvalve)is

recommended.

LowLimit(whenused)- 140° F

Thesesettingscanbechangedafteryouhavesomeideahowthe system

responds.If moredomestichotwateris required,the lowlimitsettingcan

alsoberaised.

_NT_pERE_ _OT WATER

¢OL_ WATE_ _N_ET

WLV_

Loading...

Loading...