Dunkirk 4ES1.50C, 3ES1.00C, 4ES1.75C, 4ES1.85C, 3ES1.00 Installation & Operation Manual

...Page 1

O|L-F|REDCAST |RONSTF.AM

BO|

Installation

• Operation

• RepairParts

Theseinstructionsmustbeaffixedonoradjacenttotheboiler.DUNKIRKBOILERS

DUNKIRK,NEWYORK14048- 716366-5500

MEMBER: The llydronies Institute

Page 2

I/2" NPT

TANKLESS

HEATER

, o i

F , t , t i

, t , * ,

LEFT SIDE

3/4 _ NPT

_LOW UMIT

CONTROL ON

COIL PLATE

I/2" NPT

PRESSURETROL

PRESSURE GAUGE

COMBINATION

\

1-1/2" NPT

RETURN

i

FRONT

T

27"

WATER

IJNE

_l

2-I/2" NPT

SUPPLY

iq°p

i-i/2" NPT

i SKIM TAPPING

i

'L

,-V2 ° NPTi

RETURN

REAR

5/4" ASNE

POP SAFETY

VALVE

35

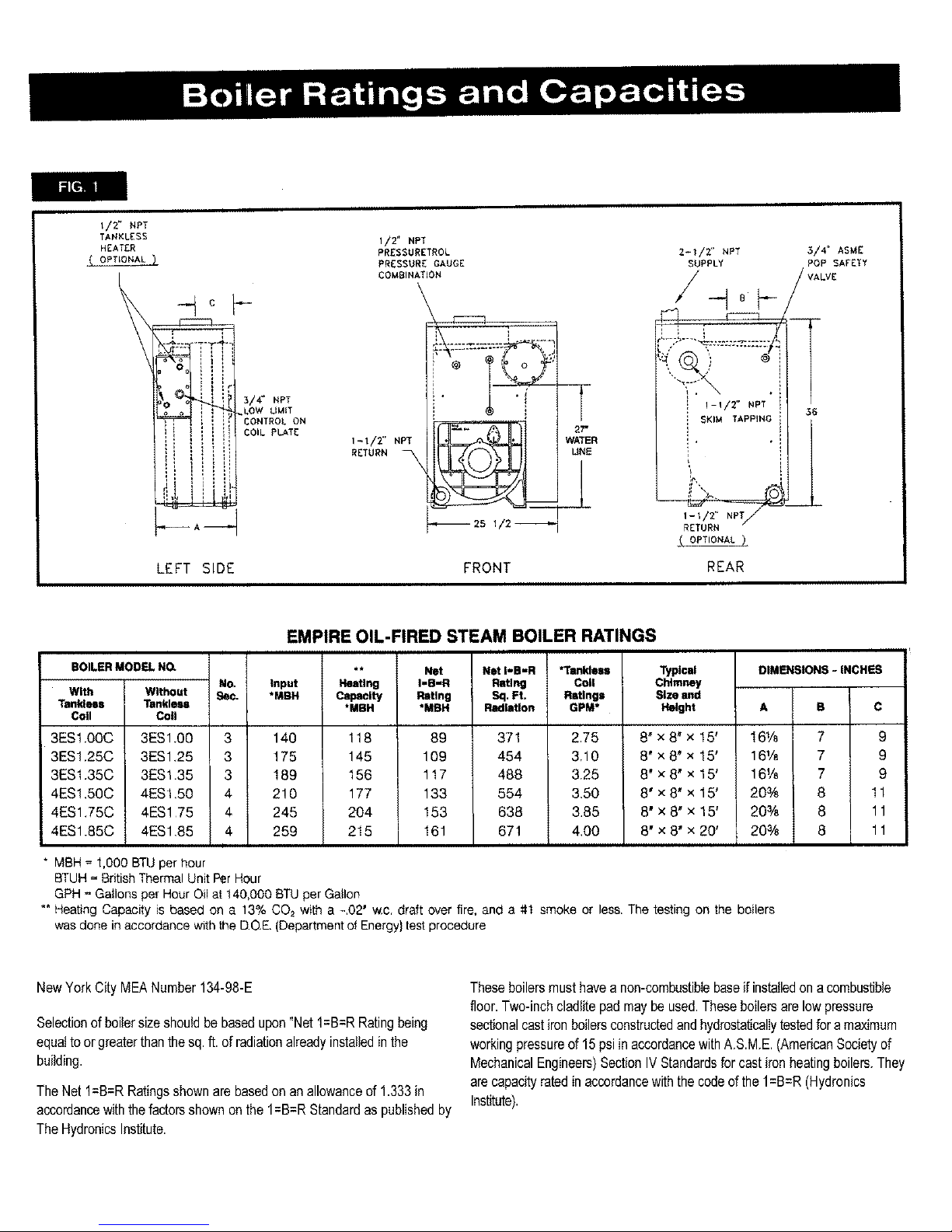

EMPIRE OIL-FIRED STEAM BOILER RATINGS

BOILER MODEL NO.

With Without

Tankless Tankless

Coil Cotl

3ESt O0C 3ES100 3

3ES1.25C 3ES1,25 3

3ES1.35C 3ES1.35 3

4ES1,50C 4ES1,50 4

4ES1.75C 4ES1 75 4

4ES1.85C 4ES1.85 4

* MBH = 1,000 BTUpet hour

No.

9ec.

Input

*MBH

140

175

189

2!0

245

259

Nesting

Capacity

*MBH

118

145

156

177

204

215

Net

I=B-R

Rating

"MBH

89

109

117

133

153

161

Not I-S-R

Rating

Sq. Ft,

Radiation

371

454

488

554

638

671

*Tonldelm

Cell

Ratings

GPM*

2.75

3,10

3.25

3.50

3.85

4,00

Typl©al

Chimney

Size and

Height

8" x 8' x 15'

8" x 8' x 15'

8" x 8' x 15'

8' x 8' x 15'

8" x 8" x 15'

8" x 8' x 20'

CIMF31SIONS- INCHES

A B C

16% 7 9

16½ 7 9

16% 7 9

20% 8 11

20% 8 11

20% 8 11

BTUH = British Thermal Unit Per Hour

GPH _ Gallons per Hour Oil at 140,000 BTU per Gallon

** Heating Capacity is based on a 13% CO2 with a -,02' w.c, draft over fire, and a #1 smoke or less. The testing on the boilers

was done in accordance with lhe DOE. (Department of Energy) test procedure

NewYorkCityMEANumber134-98-E

Selectionofboilersizeshouldbe basedupon"Net1=8=RRatingbeing

equaltoorgreaterthanthesq.ft.of radiationalreadyinstalledinthe

building.

TheNetI=B=R Ratingsshownarebasedonanallowanceof1.333in

accordancewiththefactorsshownonthe 1=B=RStandardas publishedby

TheHydronicsInstitute.

Theseboilersmusthavea non-combustiblebaseifinstalledon acombustible

floor.Two-inchcladlitepadmaybeused.Theseboilersarelowpressure

sectionalcastironboilersconstructedandhydrostaticallytestedfora maximum

workingpressureof 15psiin accordancewithA.SME. (AmericanSocietyof

MechanicalEngineers)SectionIVStandardsfor castironheatingboilers.They

arecapacityratedinaccordancewiththecodeofthe1=B=R(Hydronics

Institute).

Page 3

RulesforSafeInstallationandOperation

1. Readthe Owner'sManualforSafeOperationcarefully.Failuretofollow

therulesforsafeoperationandtheinstructionscancausea malfunctionof

the boilerand result in death,_rious bodily injury, and/or property

damage.

2. Checkyourlocalcodesandutilityrequirementsbeforeinstallation.The

installationmustbeinaccordancewiththeirdirectives,orfollowNFPA31

- InstallationofOilBurningEquipment,latestrevision.

3. Beforeservicing,allowboilertocool.Nwaysshutoffanyelectricityand

oiltoboilerwhenworkingonit.Thiswillpreventanyelectricalshocksor

burns.

4. Inspectoillineandconnectionsforleaks.

5. Be certainoil burnernozzleis size required.Overfiringwill resultin

earlyfailureofthe boilersections.Thiswill causedangerousoperation.

6. Nevervent this boiler into an enclosedspace.Alwaysvent to the

outside.Neverventto anotherroomor insidea building.

7. Besurethereisadequateairsupplyforcompletecombustion.

8. Followa regutarserviceandmaintenancescheduleforefficientand

safeoperation.

9. Keepboilerareacleanandfreeofcombustiblematerial,gasolineand

otherflammablevaporsandliquids.

This boiler has been designed for residentialinstallations. If used for commercial

applications,alljurisdictionalrequirementsmustbe met.This mayrequirewiringandlor

pipingmodifications.Themanufactureris notresponsibleforany changesto the original

design.

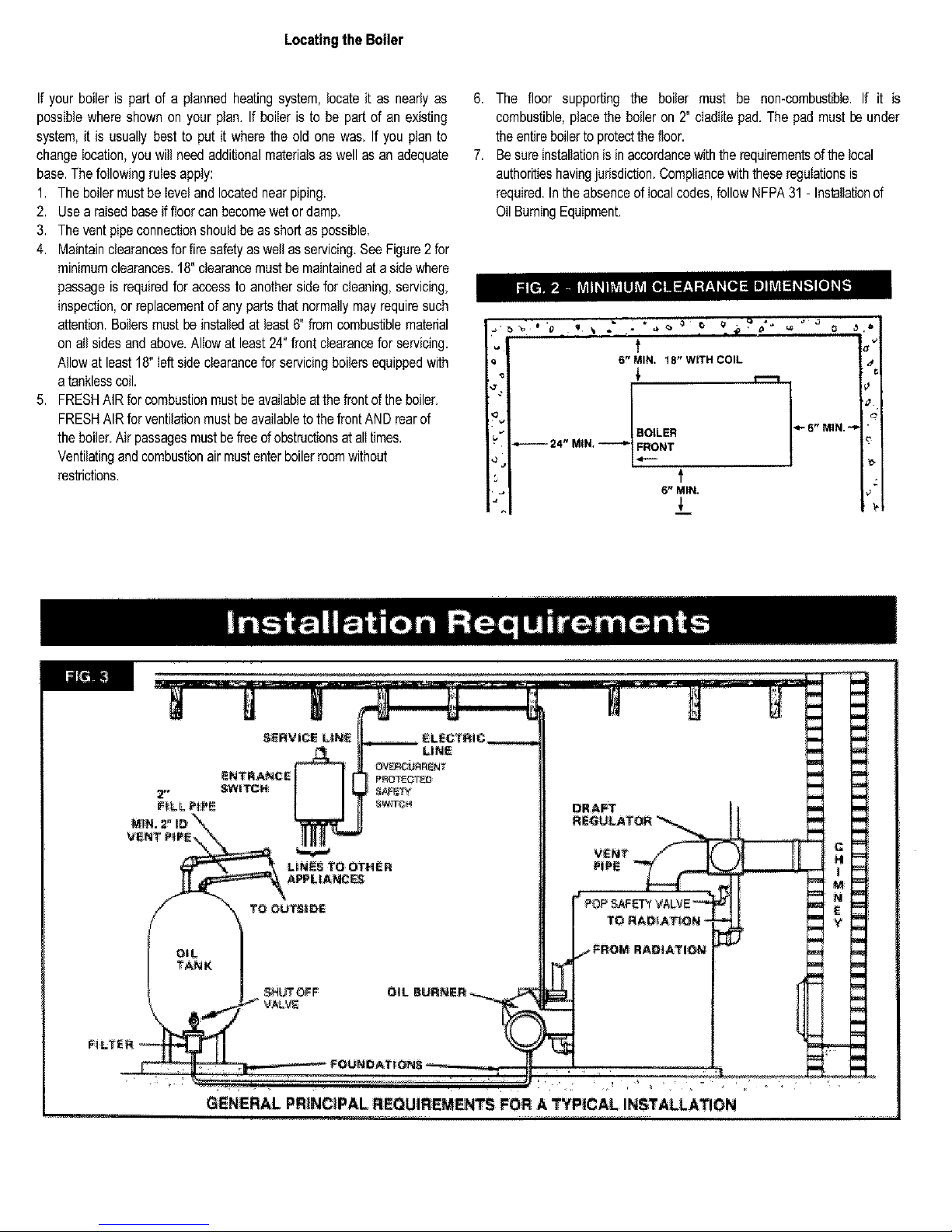

BeforeYouStart

Check to be sure you have the dght size boiler beforestartingthe

installation.See ratingand capacitytableon precedingpage.Checkthe

ratingplateontheboiler.

You mustsee that theboileris suppliedwiththe properoil,freshair for

combustion,and a suitableelectricalsupply.Also, the boiler must be

connectedto a suitableventingsystemand an adequatepipingsystem.

Finally,a thermostat,properlylocated,is neededforcontrolofthe heating

system.If youhaveanydoubtsas to thevariousrequirements,checkwith

local authorities and obtain professionalhelp where needed. THE

OPERATING INSTRUCTIONSand THE FINAL CHECKS AND

ADJUSTMENTSare vitalto the properandsafe operationof the heating

system.Takethetimeto besuretheyarealldone.

Thefollowingstepsareallnecessaryforproperinstallationandsafe

operationof yourboiler.

1. LOCATINGTHEBOILER

2. OILSUPPLYANDPIPING

3. FRESHAIR FORCOMBUSTION

4. PIPINGCONNECTIONS

5. CHIMNEY& VENTPIPECONNECTIONS

6. ELECTRICALWIRING

7. THERMOSTATLOCATION

8. CHECKING&ADJUSTING

9. MAINTENANCE

Page 4

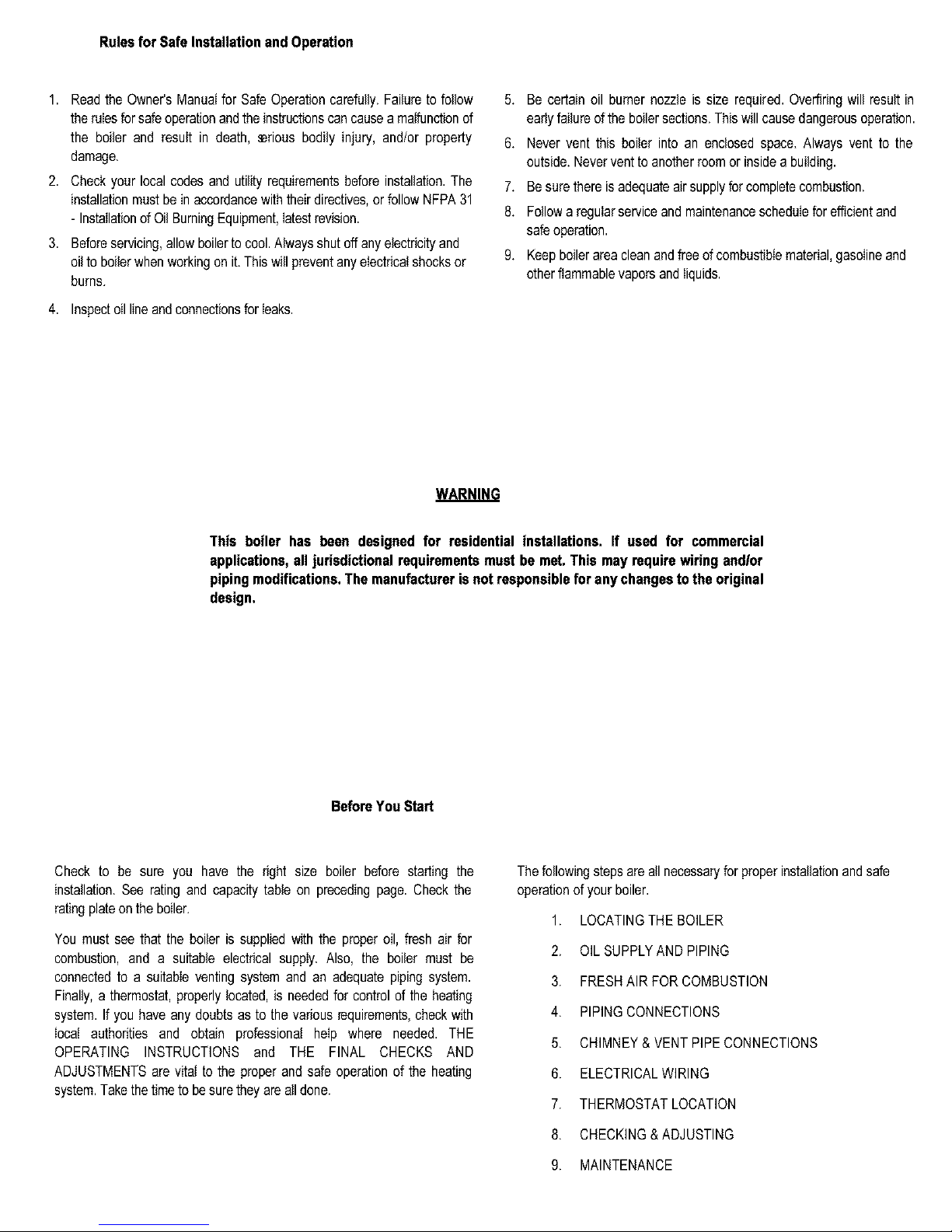

Locatingthe Boiler

If yourboileris partof a plannedheatingsystem,locateit as nearlyas

possiblewhereshownon yourplan.If boileris to be partof an existing

system,it is usuallybestto put it wherethe old onewas.If youplanto

changelocation,youwill needadditionalmaterialsaswellasan adequate

base.Thefollowingrulesapply:

1. The boilermustbelevelandlocatednearpiping.

2. Usea raisedbaseiff]oorcanbecomewetordamp.

3. Theventpipeconnectionshouldbeas shortaspossible.

4. Maintainclearancesforfiresafetyaswellasservicing.SeeFigure2for

minimumclearances.18"clearancemustbemaintainedatasidewhere

passageisrequiredforaccessto anothersidefor cleaning,servicing,

inspection,or replacementofanypartsthatnormallymayrequiresuch

attention.Boilersmustbe installedat least6"fromcombustiblematerial

onallsidesandabove.Allowat least24"frontclearancefor servicing.

Allowat least18"leftsideclearanceforservicingboilersequippedwith

atanklesscoil.

5. FRESHAIRfor combustionmustbeavailableatthefrontoftheboiler.

FRESHAIRfor ventilationmustbeavailabletothefrontANDrearof

theboiler.Airpassagesmustbefreeofobstructionsatalltimes.

Ventilatingandcombustionairmustenterboilerroomwithout

restrictions.

6. The floor suppo_ng the boiler must be non-combustible.If it is

combustible,placetheboileron 2" cladlitepad.Thepadmustbeunder

theentireboilertoprotectthefloor.

7. Besureinstallationisinaccordancewiththerequirementsofthelocal

authoritieshavingjurisdiction.Compliancewiththeseregulationsis

required.In theabsenceof localcodes,followNFPA31- Insbtlationof

OilBurningEquipment.

Q 6" MIN. 18" WITH COIL

• _

_" 6" MIN. "

I_// . I BOILER

I-----2, .,..------IFRO.T

6" MIN.

SeRVraceL_NeLL,.------e_.ec_rRic

F_LPtFE ] I I[ s_,rrc_

GENERAL PRINCIPAL REQUiREMEnTS FOR A TYPICAL INSTALLATION

m_

Page 5

Fresh Air for Combustion

WARNING

NOTE

Be sure to provide enough fresh airfor combustion. Enough air ensures

proper combustion and assures that no hazard will develop due to

the lackof oxygen.

If you use a fireplaceor a kitchenor bathroomexhaustfan,you

shouldinstallan outsideairintake.Thesedeviceswill robthe boiler

andwaterheaterof combustionair.

You must providefor enough fresh air to assurepropercombustion.The fire

in the boiler uses oxygen. It must have a continuous supply. The air in a

house contains only enough oxygen to supply the burner for a short time.

Outside air mustenter the house to replace that used by the burner. Study

foIIowingexampIes 1 and 2to determineyour fresh air requirements.

EXAMPLE 1:Boiler Located in Unconfined Space

If your boiler is in an open area (unpartitioned basement) ina conventional

house, the air that leaks through the cracks around doors and windows will

usually be adequate to provide air for combustion. The doors should not fit

tightly. Do not caulkthecracks aroundthe windows.

An unconfinedspace isdefined as aspace whose volume isnot lessthan 50

cubic feet per 1,000Btu per hour of the total inputrating of all appliances

installedin that space.

EXAMPLE 2: Boiler Located in Confined Space

A, All Air from Inside the Building: The confined space shall be provided

with two permanent openings communicating directly with an additional

room(s) of sufficientvolume so that the combined volume of all spaces

meets the criteria for an unconfined space. The total input of all

combustion equipment installed in the combined space shall be

considered in making this determination. Each opening shall have a

minimumfree area of one square inch per 1,000Btu per hourof thetotal

inputratingofall combustionequipment inthe confinedspace, but not less

than 100 squareinches. One opening shall be within 12 inches ofthe top

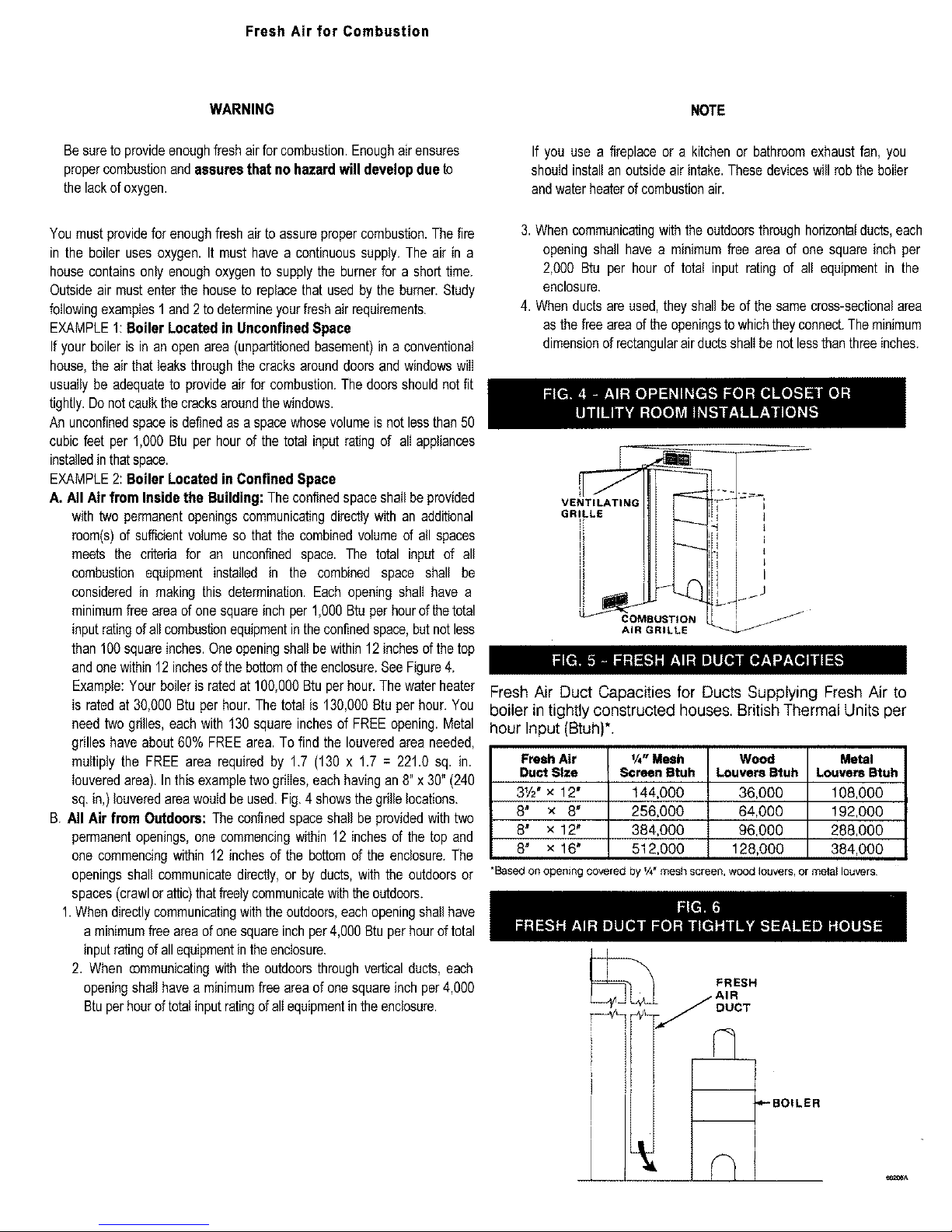

andonewithin 12 inchesof the bottom of theenclosure.See Figure 4.

Example: Your boiler is rated at 100,000 Btu per hour. The water heater

is rated at 30,000 Btu per hour. The total is 130,000 Btu per hour. You

need two grilles, each with 130 square inchesof FREE opening. Metal

grilles have about 60% FREE area. To find the Iouveredarea needed,

multiply the FREE area required by 1.7 (130 x 1.7 = 221.0 sq. in.

Iouvered area). In thisexample twogrilles, each having an 8"x 30" (240

sq.in,) Iouvered area would be used. Fig. 4 shows the grille locations.

B. All Air from Outdoors: The confined space shall be provided with two

permanent openings, one commencing within 12 inches of the top and

one commencing within 12 inches of the bottom of the enclosure. The

openings shall communicate directly, or by ducts, with the outdoors or

spaces (crawlor attic)thatfreely communicatewith the outdoors.

1.When directly communicatingwith the outdoors, each opening shallhave

a minimum free area of one squareinchper 4,000 Btu per hour of total

inputratingof all equipment in theenclosure.

2. When communicatingwith the outdoors through ve_cal ducts, each

opening shall have a minimumfree areaof one square inch per 4,000

Btu perhour of total input ratingof all equipmentin theenclosure.

3.Whencommunicatingwiththeoutdoorsthroughhorizontalducts,each

openingshall havea minimumfreearea of onesquareinchper

2,000 Btu per hour of totalinput ratingof all equipmentin the

enclosure.

4. Whenductsareused,theyshallbeof thesamecross-sectionalarea

asthe freeareaof theopeningstowhichtheyconnect.Theminimum

dimensionofrectangularairductsshal{benotlessthanthreeinches.

VENTILATING -'_--i

GRII.LE I

i I ' 1

i ,11 II ',

AIR GRILLE _

Fresh Air Duct Capacities for Ducts Supplying Fresh Air to

boiler in tightly constructed houses. British Thermal Units per

hour Input (Btuh)*.

Fresh Air

Duct Size

31/2"x 12"

8* x 8"

8" x 12"

8" x 16"

1/4"Mesh

Screen Btuh

144,000

256,000

384,000

512,0O0

Wood

Louvers Stuh

36,000

64,000

96,000

128,000

Metal

Louvers Btuh

108,000

!92,000

288,000

384,000

*Based on opening covered by IA" mesh screen, wood louvers, or mela{ louvers

FRESH

Page 6

Boilers With Tankless Heater Coil

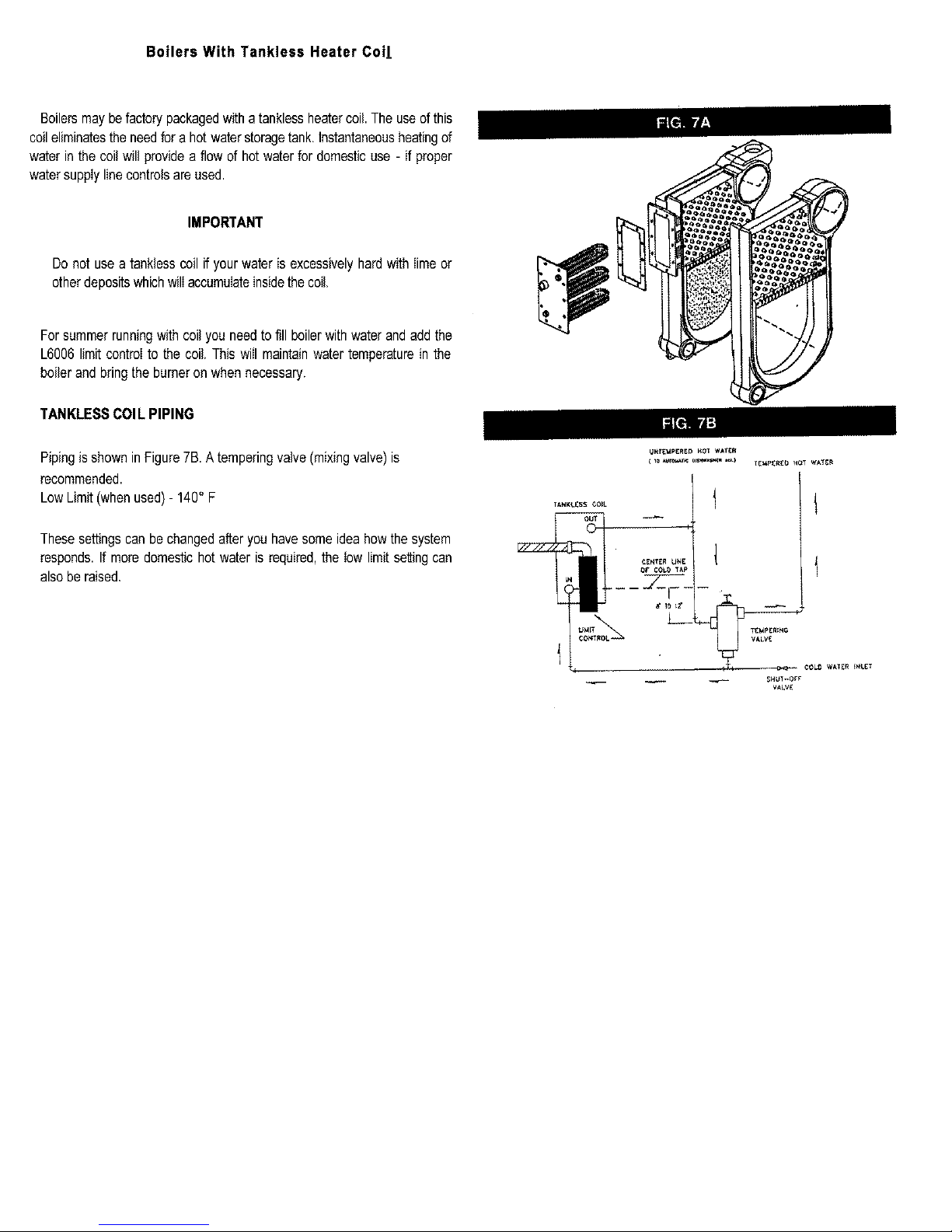

Boilersmaybefactorypackagedwithatanklessheatercoil.Theuseof this

coileliminatesthe needforahot waterstoragetank.Instantaneousheatingof

waterinthecoil willprovidea flowof hotwaterfor domesticuse- ifproper

watersupplylinecontrolsareused.

IMPORTANT

Donot usea tanklesscoilif yourwateris excessivelyhardwithlimeor

otherdepositswhichwillaccumulateinsidethecoil.

Forsummerrunningwithcoilyou needtofill boilerwithwaterandaddthe

L6006limitcontrolto the coil.Thiswill maintainwatertemperaturein the

boilerand bringtheburneronwhennecessary.

TANKLESSCOlL PIPING

PipingisshowninFigure7B.A temperingvalve(mixingvalve)is

recommended.

LowLimit(whenused)- 140° F

Thesesettingscanbechangedafteryouhavesomeideahowthe system

responds.If moredomestichotwateris required,the lowlimitsettingcan

alsoberaised.

_NT_pERE_ _OT WATER

¢OL_ WATE_ _N_ET

WLV_

Page 7

Installation-SystemPiping

Thenearboilerpiping,thatisthe pipingaroundtheboiler,mustbeconsidered

aspartofthe boilerforproperwaterlevelcontrol,andto producedrysteam.

Correctnearboilerpipingis crucialtothe properoperationoftheboilerand

theheatingsystem.Followtheserecommendationscarefully.

1.Placeboilerintheselectedlocation,as nearchimneyaspossible.

2. Installthepopsafetyvalve,usingthefurnished3/a" 90" ell,intothe3/4"

pipenippleonthebackof theboiler.Makea dischargepipe,using3/4"pipe

(notfurnished)to carrythe wateror steamto a nearbydrain.Do not

connectthe dischargepipe directlyto a drain but leavean airgap.No

shutoffofany descriptionshallbeplacedbetweenthe popsafetyvalveand

theboiler,or ondischargepipes

betweensuchsafetyvalvesandthe atmosphere.Installationof thepop

safetyvalveshallconformtotherequirementsoftheANSI/ASMEBoiler

and Pressure Vessel Code, Section IV The manufactureris not

responsibleforanywaterdamage.

3.Thisboileris equippedwithtwo 21/2"supplyconnectionson topand

two 1V2"returnconnections,oneeachon frontand backsidesof the

boiler.Unusedconnectionsmust

4.Recommendednearboilerpipingfor gravityreturnsys-temsisshown

in Figure8. Thisconfigurationusesonesupplyandonereturntapping.

Pipingoff bothboilertap-pingsis recommendedon units5 sectionand

larger.

Note:Usebothsupplytappingsonboilers5 sectionandlarger.

PtPES_E

Page 8

5.Forinstailerschoosingto usebothsupplytappings,Figure8Ashowsthe

correctwayto pipethissystem.Figure8Bshowsthewrongwaytopipe

a headerwithtworisers.

, Headersmustbe fittedwithheaderoffsetsor swingjoints, or be

equippedwith expansionjoints, so that thermalexpansionand

contractionofthe headerwillnat damagetheboiler.Headersshall

netbewelded.

, Systemtakeoffsfromtheheadermustbebetweentheequalizerand

therisertothe headernearesttheequalizer.Systemtakeoffsmust

neverbebetweentworisers.

6.Systemtakeoffsfromtheheadermustneverbe bull-headed.Ifthesteam

maingoesintwodirections,theremustbetwotakeoffsfromtheheader,

oneforeachmain.

7. All boilersingravityreturnsystemsmustbeequippedwitha Hartford

LoopasshowninFigures8and8A.

8. Whenpipingtheverticalrisersfromtheboilertotheheader,thebottom

ofthe headermustbea minimumof 24inchesabovethewaterlevel

lineantherightsideoftheboiler(i.e.51inchesabovethefloor).

9. Steamriser(s)andheadershallbe272"pipesize.

10. Equalizerlineshailbeminimum1 1/2"pipesize.

11. The boilerhasa 1V2"tappinginrearsecflanfarskimming.

_EA_{ MAINS

HART_ORO

CLOSE

N|PPLE

MAIN VENT

D_Y RETURN

M_[N

Page 9

THIS, PIPING

COMMON

tS INCORRECT

MISTAKES

TO SHOW

©

L

12. The near boilerpipingshall includea 1 1/2"ballvalveinthereturn

pipingasshowninFigure8Afarbottomblowdawnanddraining.

13. Forgravityreturnsystems,thebottomof theloweststeamcarrying

pipe,beita dryreturn,ortheendofthesteammain,mustbeatleast

28"abovethenormalwaterlevellineanthedghtsideoftheboiler.

Thisisknownas"DimensionA."

14. Forpumpedreturnsystems,followthecondensatepumporbailerfeed

pumpmanufacturer'sinstructionsforproperinstallationandhookup.

15. Inconnectingthecoldwarer supplytothewaterinletvalve,makesure

thata deanwatersupplyisavailable.Whenthewatersupplyis froma

wellor pump,asandstrainershouldbeinstalledatthepump.

FORUSEWITHCOOLINGUNITS

A.

This boiler, when used in connection with chilledwater systems,must

be installed so that the chilled water is piped in parallel with the heating

boiler. Appropriate valves must be used to prevent the chilled water

from enteringthe heating boiler(Fig. g).

B.Whenthis boileris connectedto heatingcoilslocatedin air handlingunit.,

wherethey may be exposedto refrigeratedaircirculation,the piping

systemshall be equippedwith flow controlvalves or other automatic

meansto preventgravitycirculationof theboilerwaterduringthecoolinc

cycle.

'_rd,.vE8 A & m

VALVESC & Q

_R _OUNG

Page 10

ChimneyandChimneyConnection

CHECKYOURCHIMNEY

Followlocalcodes.Inthe absenceof localcodes,followANSI/NFPA31

Installationof OilBurningEquipment,latestedition.

Thisisaveryimportantpartof yourheatingsystem.Noboiler,however

efficientitsdesign,canperformsatisfactorilyifthechimneythatservesitis

inadequate.Checkyourchimneytomakecertainthatit isthe rightsize,

properlyconstructedandinsoundcondition.

Itischeapertorebuildapoorchimneythanto payexcessivefuelbills.If

yoursisanoldmasonrychimney,a newsteellineror anew

prefabricatedchimneymaybethebestsolution.Thefollowingchartshows

recommendedminimumchimneysizesbasedonTable3andFigure6 of

theI:B:R TestingandRatingStandardfor HeatingBoilers,Sixth

Edition,June1989.

MUST BE REQUIRED MIN*

IMUM HEIGHT, MUST BE

AT LEAST 3 FT. HIGHER

THAN HIGHEST PART OF

PASSAGE THROUGH

ROOF. MUST BE AT

LEAST 2 FT. HIGHER

THAN ANY NEIGHBORING

OBJECT. MUST HAVE AN

UNOBSTRUCTED TOP

OPENING,

MUST BE AT LEAST

4 INCHES THICK -

AND BE LINED.

_l_ CHFM_ I

.60- i 30 15

13Iol 80 15

i,81o2,00 20

FIECOMMENDED MtNiMUM _IMNEY SIZES

=!:

_ER_ LNER;

_!NNqY' i_DE I_

8"×8 ' 6' 6:5_x 6_'

8' x 8" 7' , 6_f;_"× 6_!4"

[:<]re#_@:(Y)88_ee 2,#_ if,,8J3_es_ _i, ad_3 feetIocblm_qeYhe_gP4_

[_!et la Fiqure 1@t

Foradditionalchimneydesignandsizinginformation,consulttheASHRAE

1996HVACSystemsandApplicationsHand-book,Chapter30,Chimney,

GasVentandFireplaceSystems;ortheNationalStandardforChimneys,

Fireplaces,VentsandSolidFuelBurningAppliances,ANSI/NFPA211.

CHIMNEYCONNECTORANDDRAFTREGULATOR

Yourboilerrequires7"diameterchimneyconnectorpipeon 3 section,8"

diameterchimneyconnectorpipeon 4 section.Youmustalsouse a dralt

regulatorpackedwithboiler.Properlyinstalled,theregulatorwillcontrolthe

draftautomatically.Itis bettertoinstallitina horizontalsectionofthe pipe;but

itmaybeinanangledorverticalsection.Justmakecertainthatthe"top"isat

top- andthattheshortpipesectionwhichholdstheVaneishorizontal.Install

itascloseaspracticableto theboiler.

Toinstallthechimneyconnector,startatthe boilerandpreferablytakeoff

fromthefluecollectorcollarwithanelbow- theninstallthedraftregulator

next,makingit horizontal.Whentheregulatoris inplace,startatthechimney

andworkbacktotheregulator.JointhetwosectionswithaDrawband.The

horizontalpipemustslopeuptowardthechimneyatleast1/4inchperfoot.It

mustnotleakandmustbefirmlysupported.Joinsectionswithatleasttwo

sheet-metalscrews.Supporteverysecondsectionwithastovepipewire.

MINIMUMVENTPIPECLEARANCE

ALTERNATE POSITIONS

TOP

1

MUSTSLOPEUP

AT LEAST 1/

PER FOOT OF

HORIZONTALRUN

DRAWBAND

LAST PIECE

INSTALLED

I

I L

_,TIGHT. SMOOTH,

CORRECTLY SIZED.

I

I

t

I

&LEDIN

THIMBLE

TIGHT

DOOR

DRAFT REGULATOR

VANE

Woodandothercombustiblematerialsmustnotbecloserthan18"fromany BALANCEDWEIGHT

surfaceoftheventpipe.

Page 11

EquipmentandOptionalAccessories-WhatTheyDo

POPSAFETYVALVE

Youmusthavea popsafetyvalveonyourboiler.Steamexpandsasit isheated.

Ifthereisno placeforthesteamtoexpandinto,pressurewillbuildupinsidethe

boilerandsystem.Shouldthishappen,the popsafetyvalvewillautomatically

openata pre-determinedpressure.Thiswill relievethestrainontheboilerand

system.Runapipefromthesafetyvalveoutlet(pipemustbesamesizeasoutlet

andtheopenendmustnotbethreaded)toan opendrain,tuborsink,or other

suitabledrainagepointnotsubjecttofreezing.Failuretodosomaycausewater

damageorinjuryshouldreliefvalverelease.Do notcapoffthedrainlinefrom

thisvalve!Eachpopsafetyvalveisprovidedwitha liftingdevicefortestingand

shouldbetestedmonthlyduringtheheatingseason.Refertosafetyvalve

manufacturer'sinstructionspackagedwithsafetyvalve.

STEAMPRESSUREGAUGE

Everysystemshouldhaveapressuregaugeinstalledintheboiler.Thisgauge

enablesyoutomonitorthe pressureinthesystem.Ifthesafetydevicesfailtoshut

offyourboileratthepropersettings,notifyyourservicetechnicianimmediately

WATERLEVELGAUGE

Thewaterlevelin theboilercanbeseenthroughtheglasstubeinthewater

levelgaugeatsideof boiler.Correctcoldboilerwaterlevelisstampedonside

jacketpanel.Whenmakingsteam,thewaterlevelwilldroponetothreeinches.

Thewaterlevelshouldbecheckedregularly.

STEAMPRESSURECONTROL

Thesteampressurelimitcontrol(pressuretrol)shutsofftheoiltotheburnerifthe

steampressureintheboilerreachesthecut-offsetpoint(i.e.thesumofthecut-in

andthedifferentialsetpoints).Burnerretireswhenthesteampressuredropsto

thecut-insetpoint.Systempressurerequirementsarebasedonthesizeand

conditionofthepipes,andtheload.

Forgoodsystemoperation,thecut-insettingofthe pressuretrolshouldnever

be less than twicethe systempressuredrop. In a typicalsinglefamily

residencewith a cleanonepipeheatingsystemandcastiron radiation,this

meansthatthecut-inwillusuallybesetattheminimumsetting,i.e._/2psi.

Steamradiationis usuallysizedbasedon squarefeet of equivalentdirect

radiation(EDR).Thisis basedon a steampressureintheradiatorofjust less

than1 psi.Therefore,in our examplesystemfromabove,wewouldsetthe

differentialadjustmentat1psi,i.e.thesteampressurerequiredinthe radiators.

Thiswillgiveusa cut-offsetpointd 1_12psi.

Theaboveisan exampleofa typicalonepipesystem.Forlargersystemsor

othertypesofsystemssuchas two pipesystems,orsystemswithconvectors

or fan coil units,the pressuretrolsettingswill needto be determinedon a

system-by-systembasis.

The cut-insetpointisdeterminedbythesystempressuredroptothe furthest

radiatoror terminalunit.Doublethesystempressuredropasa safetyfactor,

resultinginthe rulethatthe cut-insettingshouldneverbe lessthantwicethe

systempressuredrop.

Thedifferentialset#ointis thesteampressurerequiredattheterminalheating

units.

Nowyourboilerwill operateinthe correctpressurerange.It will maintain

enoughsteampressureto sendthe steamouttothe furthestradiator,andnot

go overtheoptimumsteampressurethatisrequiredat theradiators.

67D-t LOWWATERCUT-OFF

Thefloat-typelowwatercut-offshutsofftheburnerwhenthewaterlevelis

belowasafepoint.Theburnerwillstartwhenthewaterisrefilledtoa

minimumsafelevel.

WATERFEEDER(Optional)

Awaterfeederworkswiththelowwatercut-off(LWCO)tomaintaina

minimumsafelevelofwaterforboileroperation.It'susedtokeeptheboiler

runningbycompensatingforminorevaporativesteamleaks,andtoprevent

freeze-upsif thehomeownersareawayanda returnlineshouldspringa

leak,Theautomaticwaterfeederisa safetydevice,nota

convenienceitem.Itisnotdesignedto maintaina "normal"waterline.The

waterfeederdoesnottaketheplaceofa responsiblepersonmonitoringand

maintainingthe"normal"waterline.Steamboilersrequirepersonal

attention.

Four electric water feedersare offeredby McDonnell-Millerwhichare

compatiblewiththe 67D-1LWCO.The model#101Aand #WF2-U-120

waterfeedersareusedwith120voltwiringcircuits,asfoundanthissteam

boiler.The McDonnell-Millermodel#101A-24and#WF2-U-24areused

with 24 volt circuits,whichmay be usefulin a retrofitinstallationwhich

alreadyhasa 120voltto 24volttransformer.

TheWF2-U-120and WF2-U-24(Uni-Match)waterfeedersareequipped

witha solidstateelectroniccontrolwhichfeedswaterwhensignaledbythe

LWCO.Thewaterfeedrate isfieldadaptablefar 1,2, or 4 gpm.These

waterfeedershavean adjustableslideswitchtomatchthetimingcyclean

theLWCO.Whenusinga McDonnell-MillerLWCOtheslideswitchneeds

toselectposition#1.The timingcyclecreatesaninitialdwellperiodofone

minuteto allowcondensateto be returnedto the boiler.If afterthedwell

periodthewaterhasnatreachedtheminimumsafelevelandcompletedthe

LWCOcircuit,thenwateris fedat theselectedflowratefaroneminute.The

dwellpedodistheninitiatedagainfar oneminute.Ifthewaterlevelhasstill

not reachedthe minimumsafe level,then wateris addedagain at the

selectedflowrateforoneminute.Thiscyclecontinuesuntilwaterreaches

the minimumsafe levelandthe circuitis completed.DunkirkRadiator

recommendsusingaUni-Matchwaterfeederataflawrateof1or2gpm.If

the steamboilerrequireshigherflowrateson a regularbasisa service

technicianshouldbenotified.

The1OlAwaterfeedermaybe used,howeverthewaterfeed rateistoo

high and needsto be regulatedor throttled.The IO1Awillfeedupto 6

gpm,muchgreaterthanthedesiredflowrateof 1-2gpm.Also,thereisno

dwellperiodto providea marginfor condensateto returnto the boiler.

Thesetwofactorsincreasethechancesofoverfeedingwaterto thesteam

boiler.Excessivewaterinthesteamboilerwillproducenoise

Consultthe water feedermanufacturer'sinstallationguidelinesfor more

detailson waterfeederselection,recommendedpipingarrangement,and

start up procedures. Dunkirk Radiator supports McDonnell-Miller's

recommendationtoarrangetheinstalledpipingsoa brokenuniontest can

beimplemented.

DRAINVALVE

Thismanualvalveprovidesa meansofdrainingallwaterfromtheboilerand

system.Itshouldbeinstalledinthe3/a"teewherethewatersupplyline

enterstheboiler(Fig.8).Youcanalsousethisvalveto lowerthewaterlevel

ifit istoo high.

Page 12

STEAMVENTS

Beforea steamsystemwill operateproperly,suitablesteamventsmustbe

installedin eachradiatoras wellasthe returnmain.Somesystemsrequire

steamtrapsinthereturnlineat theradiationunit.

The"Hartfordloop"isa pipingarrangementwhichmustbeincluded(Fig.8)

forproperoperationofthesteamsystem.

BOILERSWITHTANKLESSCOILSONLYFlowRegulatorandWater

TemperingValve

Ifyouhavea TanklessCoilfordomestichotwater,thesetwopartscanbe

used.Thiswillprovideyouinstantaneoushotwaterthatis neither

scaldinghotnormerelytepid.The FlowRegulatorisplacedinthecoldwater

linetothecoil.It assuresa steadyflowofwatersothatthecoilcanproperly

heatit. It prevents"spurts"of "half-heated"water.Thisisimportantwherethe

waterpressureisexcessivelyhighorvariable.TheWaterTemperingValve

is atee whichis connectedata junctionbetweenthehotwaterlinefromthe

coilandacoldwaterbranchfromthesupplyline.Itmixeshotandcoldwater

as requiredto furnisha temperedsupplyof watertothe house.Thewater

willbejustthe righttemperatureforyouruse.Thisisimportanton a steam

systemto preventscaldingtemperaturesat thefaucets.Bothpartsareself-

containedandautomatic.

Starting Your Boiler

HOWASTEAMSYSTEMOPERATES

Thewaterintheboilerisheateduntilit reachestheboilingpoint.Asthe

waterboilsit turnsintosteam.Thesteamrisesfromthetopof thewater

throughthesupplymainto theradiationunits.As it passesthroughthe

radiatorsitreleasesitsheatandcondensesintowater.Thewaterreturns

tothe boilerthroughthe returnmain.

FILLINGSYSTEMWITHWATER

Onsteamheatingsystemstheboileris partiallyfilledwithwater.Itisvery

importantto theproperoperationoftheentiresystemthatyourboilerbe

filledto theproperlevel.Thecorrectwaterlevelon coldstartconditionis

abouthalfwayupthe glasswaterlevelgaugeasmarkedon theboiler

jacket.Tofill:

1.Closetheboilerdrainvalve.

2. Openthevalvesat thetopandbottomoftheglasswaterlevelgauge.

Alsoopenthedrainvalveatthe bottomofthegauge.

3. OpenthefilIvalveandatlowwatertorunintotheboiler.

WARNING- Neverrunwater intoahotemptyboiler,

4.Allowboilertofill untilwaterrunsoutthe gaugedrainvalve.Then

closethegaugedrainvalve.

5.Continuetofillboileruntilwaterreachestheindicatedwaterline.This

Checking and Adjusting

isabouthalfwayuptheglasstube.Alwayskeepthewateratthislevel

whensystemisoff.

IMPORTANT

Skimminga newsteamboileronan existingsystemmustbedoneseveral

timesto removeall oil,greaseandsediment.Thereshouldbe a teewitha

plugpipedtothesupplylineoftheboilerinordertoproperlyskimtheboiler.

Wheneverthewaterin the glassgaugebecomesdiscolored,yourboiler

shouldbeskimmed.

Whenskimming,makesureto pipetheopenendof thetee tothefloorora

drainto preventanyonefrom beingburnedbythe steamand hotwater

whichwillbereleased.

TheFloatLowWaterCut-offshouldbe blowndownafterskimming.Following

blowdown,allowtheboilertocoolandthenaddfreshwaterslowly.

Thefloatchamberof thelowwatercut-offmustbeflushedcleanandmaintained

clearof sedimentto allowfree movementof the float.This mustbe done

frequentlyduring initial operationof the boilerand at least once per week

thereafter.Followinstructionsontagattachedto control.Neverthrottlea steam

radiatorvalve on a one-pipesystem.It mustbe fully openor fully closed.

Otherwisewaterisheldintheradiatorunits.Thiswillcauseknockingsounds.

Skimmingmayberequiredagainafterafewdaysoperation.

CHECKINGCONTROLS

To checkthe LowWaterCut-Off,turnoff powerto theboileror turnthe

thermostatdown to the lowestsetting.Drainwaterto belowthe visible

bottomof thewatergaugeglass.Turnpoweronandturnthe thermostatto

callfor heat.Whenthe boilerisequippedwiththefloattypeLWCO,theoil

burnershouldnotrunonacallfor heatwhenthewaterislow.

To check the pressurelimit, run the boileruntil the pressurereaches

systemdemand.Thenturn the pressurescrewanddropthe pressure

settinguntiltheboilershutsdown.Thiswillshowthatthe pressurelimitis

operatingproperly.

If youhaveinstalledyourown boiler,we recommendthat youcallfor an

inspectionby a servicetechnician.The peace of mind and assured

performanceare wellworththe cost involved.Hecanquicklymakethe

necessarychecksandadjustments.

OIL BURNERADJUSTMENT

Suggestednozzlesandpreliminaryburnersettingsarefoundon page20.

Referto youroil burnerownersmanualfor checkingandadjustingthe

burner.

ADJUSTOPERATINGCONTROLSInstructionsfor eachcontroland

burnerareincluded.

Betthermostatheatanticipatorat.20.Instrucfionsforthefinaladjustmentof

thethermostatarepackagedwiththethermostat.

CHECKTHERMOSTATOPERATION

Whensetabovetemperatureindicatedon the thermometer,boilerburner

shouldstart. Makecertainthe thermostatturnsoff the boilerwhenroom

temperaturereachesthe selectedsettingand startsthe boileroperating

whenroomtemperaturefallsafewdegrees.

Finally,setthethermostatforthedesiredtemperature.Specialconditionsin

yourhomeandthelocationofthethermostatwillgovernthissetting.

Page 13

MaintainingYourBoiler

Checkthe waterleveleverydayor two.Verifythe watertineshownby

operatingthe drainvalvean thegauge.Be suretop and bottom valves

on gaugeare alwaysopen so thatactualwater levelwill be shown

atalltimes,

POPSAFETYVALVE

Thisvalveshouldopenautomaticallywhenthesteampressureexceedsthe

safelimit(perinstructionspackagedwithvalve).Shoulditeverfailto open

undertheseconditions,shut downyoursystem.Havethevalvereplaced

immediately,The pop safetyvalve shouldbe testedmonthlyduringthe

heatingseason.Refertothevalvemanufactureflsinstructionspackagedwith

thepopsafetyvalve.

LOWWATERCUT-OFF

TheLowWaterCut-offwillin_rrupttheelectricalcurrenttotheburnerwhen

thewaterlinein the boilerdropsto a low level.It isveryimportanttokeep

thefloatchamberfreefromsediment,a conditionessentialto dependability.

To keep any accumulationfrom interferingwith floatactionis to "BLOW

DOWN"or flushoutthecontrolregularly.Thismustbedonetwo-threetimes

thefirstweekafterinstallationandonceaweekthereafterduringtheheating

season.Doitwhiletheboileris inoperation.Firstnotewaterlevelingauge

glass.Openblow-offvalveatbottomof control,waterwillpourout,flushing

awaysediment.Drainuntilwaterisclear,abouta pail,thenclosevalve.If

waterlevelingaugeglasshasdropped,addwaterto boilertorestorelevel.

Consultlow water cut-offmanufacturersinstructionsincludedwithboiler.

NOTE:Openingblow-offvalvecheckscut-offoperationtoo.As floatdrops

withfallingwaterlevel,burnerswillshutoff.Aftervalveisclosedandnormal

operatingconditionsarerestored,burnerswillresumefiring.

Boilersshouldnot be drainedbetweenheatingseasons.Onlywhenthe

waterin thesystembecomesdirtyshouldtheboilerbe drained,flushedor

boiledout,andrefilled.Steamboilersmaybeentirelyfilledwithwaterduring

thesummermonthsto excludeair.

CLEANINGYOURBOILER

Undernormaloperatingconditions,withthe burnersproperlyadjusted,we

recommendthat you have the flue passages,burneradjustment,and

operationof the controlschecked once each year by a Service

Technician.

Before the start of each season (orwheneversystemhasbeen

shutdownforsometime)recheckthe wholesystemforleaks...andrecheck

theboilerandventpipefor leaks.Replaceor patchanyboilersealsthatare

faulty.

BOILERFLUEPASSAGES

FluePassagesbetweensectionsshouldbeexaminedyearlyandcleaned.

Removevent pipe.Raisetoppanelof boilerandswingoutto exposeflue

collector.Removefluecollectortop. Cleanpassagewaysbetweensections

witha flexiblehandlewirebrush.Removedirtfomthebottomoftheboiler

and reassembleall parts.Be sureventpipeconnectionsto chimneyare

secureandnoobstructionsarepresent.

FOAMING,PRIMINGORSURGING

Thesetermsareusedtodescribeafluctuatingwaterline- whenwater

leavestheboiler.

Itiscausedby anycombinationofthefollowing:

1.Threadingoilandorganicmatterintheboilerwater.(Mineraloil, orcore

sanddoesnotcausesurging.)

2. Faultyquickventsthatdonot releaseairuntila sizeablepressureisbuilt

up- replace.Ifdirty,cleansothatyoucaneasilyblowthroughvalve.

3. Improperheader design - whensteamflowsinoppositedirectionof

equalizerlineon"Hartfordloop."Generallya 15"horizontalrunbetween

riserandmaintakeoffwill allowentrainedwaterto falloutofthesteam

vaporsoitcan returnto boiler.(Seepage7,Fig.8)

4.Adjustmentof steamlimitcontroltoawidedifferentialincreasesdifficultyif

quickventsare oldstyle,slow-releasingtypeor dirty.Alwayssetsteam

limitcontroldifferentialaslowaspossible.

5.Soapanddetergentscauseextremesurging-cleanthoroughlyby

skimmingtheboiler.

CAUTION

Neverrefilla hotboilerwithcoldwater-thedangerofthermalshockmay

crackasection.

CAUTION

Neverallowelectricianor oil burnermechanicsto tryouttheirwork by

turningon oil burnerfor evenonesecondunlessboileris filledto the

properoperatinglevel.

SYSTEMCHECKSAFTERFIRSTSTARTING- STEAMSYSTEMS

Readthe instructionspackagedwithyourcontrolsand makechecksand

adjustmentsaccordingly.Start the burnerand set the Thermostatfor the

desiredroomtemperature.WhenadjustingtheSteamPressurecontrol,watch

thesteamPressureGaugeanduseits pressurereading- asitwill bemore

accuratethanthecontrol.(Anydifferencebetweenthe twowillbeduetotheir

differentlocation.)

BOILERWATERTREATMENT

Inclosedhotwaterheatingsystems,negligibleamountsofmakeupwaterare

used,and watertreatmentis not required.In steam systemswherethe

systemistight,freefromleaks,andall the steamis returnedtotheboileras

condensate,theamountofmakeupwateris small.Again,watertreatmentis

notrequired.

On steamsystemswith lessthan 90% of the steambeingreturnedas

condensate,orwithveryhardor corrosivemakeupwater,treatmentmaybe

desirable.Followthe recommen-dationsof theASME(AmericanSocietyof

MechanicalEngineers)Boilerand PressureVesselCode,SectionVl, latest

version.

BETWEENHEATINGSEASONS

Boilersshouldnotbedrainedbetweenheatingseasons.Boilersinclosedhot

waterheatingsystemsmaybeleftas is.Steamboilersshouldbeentirelyfilled

withwaterduringthesummermonthsto excludeair.

Page 14

Oil Boiler/BurnerCleaningInstructions

1. ShutoffalIelectricaIpowertotheboiler/burnerandshutofffuelsupply.

2. Removethesheetmetalsmokepipefromthetopd theboiler.Inspect

pipeandchimneyfor signsofcorrosionanddeterioration.Cleanbase

ofchimney.

3. Removetopjacketpanel.

4. Removethetwobrasswingnutsholdingtheflueccllectorfop.

5. Checkthegasketontheundersideof thefluecollectorandreplaceas

necessary.

6. Removetheoil burner(threecapscrews).-OR-

Removetheoil burner/firedoorassembly(fourhex nuts).Thisis the

recommendedmethod,as it allows full accessto the combustion

chamberandlesspotentialdamagetothetargetwallduringthecleaning

process.

7. Removetheburnerdrawerassembly.Cleananysootaccumulations.

8. Replacetheburnernozzlewiththeexactsizeandtyperecommended

forus onthisboiler.

Note:Changingto adifferentfiringrate,otherthanisrecommended,ortype

of nozzlemaychangethe performanceof this boilerand/orcausea

hazardouscondition.

9. Cleanelectrodeassemblyandsetelectrodesasperburner

manufacturersrecommendations.

10.Reinstalldrawerassemblyandcheckforproperheadlocationas per

themanufacturer'srecommendations.

11.Inspectthetargetwail,blanket,andfiredoorinsulationforcrackingand

deterioration.If thereisanysignsofcrackingor deterioration,replace

beforereassemblingtheboiler.

12.Removesootfromfiresidesurfacesbybrushingdiagonallythroughthe

flue passages(see drawing).Care shouldbe taken so as not to

damagethetargetwallwiththefluebrush.

13.Carefullyvacuumsootaccumulationsfromthecombustionchamber

area,beingparticularlycarefulnottodamagethetargetwailandblanket

withthevacuum.Targetwallandblanketmustbeingoodconditionand

correctlyinstalledtoinsurepropercombustion.

\

oooooooooooo

ooooooo

%%%°°%%°2°

°j°o°2o%%%°2o°Co°2o

°°°°%02°%°o%%°°°0%%°Oo°

14. Reinstalltheburner/firedoorassembly.

15. Reinstallthefluecollectortopandsecurewiththetwobrasswingnuts.

16. ReinstalIthetopjacketpanel.Reconnectthefluepipe.

17. Inspectandcleantheoil burnerblowerwheel.

18. Oilthe burnermotor(DONOTOVEROIL}.

19.Removetheoilpumpcoverandclean/replacethepumpscreen.Carefully

reassemble.

20.Replacethefuelfilter(ifapplicable).

21.Reconnecttheelectricalandfuelsupplies.

22. Fire the burner,checkingfor propercombustionusingcombustiontest

equipment,makingadjustmentsasnecessary.

23.Insurethatallsafetycontrolsandoperatingcontrolsarefunctioning

properly.

IMPORTANTOPERATINGANDMAINTENANCEREQUIREMENTSKEEPYOURBOILERANDTHEAREAAROUNDIT

CLEANNEVERBURNREFUSEORANYMATERIALOTHERTHANTHESPECIFIEDFUELINYOURBOILERHAVEYOUR

BOILERCHECKEDEACHYEARBYAQUALIFIEDTECHNICIAN

Page 15

_u me_javowalir_o_nven_ and servi_ calls _ ch_ these potn(s _m _ c_l for _r_ce.

Bu _ler may not _ iitng at proper

re[@

Burner may be shortocyct ag,

po_r _ boile_

OonttoIs o_t of adjustment

What: to

Reset themsostat above room tem_raIu 8.

Cean all flue passages and _'he'_nt pipe,

Nave burner c_ea_d and read ueted,

C_eek _e_f_e size if there is _y doubt,

Have burner adjusted

S_ort-r_cting {too frequent off and on) of bu[ner will cause s,aoti_ _f_r ar_df

or burner bec_e dirty at frequent in_ervaJs,dter eorreotino Itre drt conditior_....

also correct _he@n_ro_setting (or other _se e#_:heehorbcV_c4i_'_gl

Check thefm_sM he_[ _ntio pa,tor_d _rre_ _tt_, if neces_ry, per ine_r_t_or_

Check o,.,_ercurreetprotection Check to _ sure power supply circuit is "ON,

Reset accordi_ to in_r_l_ie_s packed with coatro/&

Check a_icontrol term_inatsan_ w#e ioinls,

HAV_ YOUR 8_RVIC_ TECHNICIAN CHECK ANY PROBLE_ YOU ARE UNAI_LE _ CORRECT.

Page 16

COLORCODE

BK = BI_CK

BL = BLUE

W = WHITE

G = GREEN

i_ =WIRE NUT

pARTNO, - 146-34-O47

2 X 4 JUNCTION

PART NO, _45-31-O82

HANDY BOX COVER (NOT SHOWN)

PART N0. _46-61-121

LOCK-NUT (2

PART NO.

I/2" CLOSE

PART NO. 146-07-030

HONEYWELL

PRESSURETROL _

PART NO. 146-62-015

- GROUND SCREW

PART NO. 1€6-54-B02

-UNE VOLTAGE (GROUND)

• LINE VOLTAGE (NEUT. LEAD)

\

_PRESSURETROL TO LWC.O HARNESS

PART NO, 433-00-873

OIL BURNER

PRIMARY RELAY

OPTIONAL LOW LIMIT

CONTROL FOR BOILERS

WITH TANKLESS COIL

\ z z

TO 24v

THERMOSTAT

LOW VOLTAGE WiRiNG HARNESS NOT FURNISHED

L BURNER TO L.WC.O. HARNESS

PART NO - 433-00-872

LINE VOLTAGE (NOT LEAD)

#2 TERMINAL LWCO

PART NO, 433--00--874

67D-1 LW*C,O,

W_RINGTERMINAL DETAIL

'tJ

WH_E

FROM OIL BURNER

BLACK LEAD

FROM OiL BURNER

McDONNELL M_LLER

L W.C.O

PART NO. 146-26-042

4 X 4 OIL BURNER

JUNCTION BOX

Page 17

Page 18

"_p_r_ Tsr_kle_ _i_ K_t4340_14 (ir_l:_s coJ_,_8{, and b_l_)

4

L_!

Page 19

(1 _69BI0! )

Page 20

BOILER

MODEL

3ES1.00(C)

3ES1,25(0)

3ES! .35(C)

4ES1,50(C)

4ES1,75(C)

4ES1,85(0)

SUGGESTED NOZZLES AND SETTINGS

FOR BECKETT AFG-M OIL BURNER SERIES

NOZZLE ACTUAL

0,85-60°W 1.00

1,10-70°B 1.25

1,20-70°B 1.35

1,25-60°B 1.50

1,50-60°B 1.75

1.75-60°B 1.85

PUMP

PRESSURE

(psig)

!40

140

!40

140

140

140

HEAD

ADJUSTMENT

1

1

1

3

3

AIR

SHUTTER

10

10

10

I0

10

10

AIR

BAND

1

1

2

2

3

4

OIL

BURNER

MODEL

AFG-50MB

AFG-50MD

AFG-50MD

AFG-50MD

AFG-50MD

AFG-50MD

FOR RIELLO R40 OIL BURNER SERIES

ACTUAL PU M P AI R OIL

BOILER NOZZLE TURBULATOR

MODEL (DELEVAN) INPUT PRESSURE SETTING GATE BURNER

RATE (gph) (psig) SETTING MODEL

3ES1,00(C) 0.85-60°W 1.00 150 2,0 3.00 F5

3ES1,25(C) 1.00-60°W 1.25 165 2.5 3.60 F5

3ESl.35(C) 1.10-60°W 1.35 165 3.5 4.25 F5

4ES1.50(C) 1.25-60°W 1.50 160 1.5 2.60 FIO

4ES1.75(C) 1.50-60°W 1.75 145 1,5 3.25 FIO

4ES1.85(C) 1.50-60°W 1.85 160 2.0 3.40 FIO

FOR CARLIN EZ OIL BURNER SERIES

BOILER NOZZLE I HEAD

[

MODEL (DELEVAN) ! SETTING

3ES1.00(C)

3ES1,25(C)

3ES1.35(C)

4ES1.50(C)

4ES1,50(C)

4ES1,65(C)

4ES1,85(0)

0.85x70ow

1.00x70°W

1, !Ox70°W

1.25x60°W

1,25x60°W

1.35x60°W

1,50x60°W

ACTUAL

INPUT

RATE (gph)

1.00

1.25

1.35

1.50

1.50

1.65

1.85

PUMP

PRESSURE

(psig)

150

150

150

150

150

150

150

0.85-1.00

0.85-1.00

1,10-1.25

1.10-1.25

0.85-!.00

1.50

! ,50

AIR BAND

SET

POINT

0.65

0.90

1.!0

1,10

1,65

1.65

2.00

OIL

BURNER

MODEL

EZ-1 HP

EZ-1 HP

EZ-I HP

EZ-1 HP

EZ-2 HP

EZ-2 HP

EZ-2 HP

All burners fired at an over fire pressure of -0,02"wc.

Burner insertion depth of 2-1/8" allows burner tip to

be 1/4" behind insulation, I NOTE: These settings are intended for ini-

I

tial start up only, Final adjustment must be

!

made using combustion test instruments, i

Loading...

Loading...