Duke HS2-22-T Installation Manual

DUAL HEATSINK

OPERATOR’S MANUAL

TM

HOLDING UNITS

MODELS

HS2-22-T

HS2-23-T

HS2-24-T

HS2-42-T

HS2-34-T

U.S. and Foreign Patents Pending

IMPORTANT INFORMATION, READ BEFORE USE.

PLEASE SAVE THESE INSTRUCTIONS.

This manual is Copyright © 2018 Duke Manufacturing Company. All rights reserved.

Reproduction without written permission is prohibited. Duke is a registered

trademark of the Duke Manufacturing Company.

Duke Manufacturing Company

2305 N. Broadway

St. Louis, MO 63102

Phone: 314-231-1130

Toll Free: 1-800-735-3853

Fax: 314-231-5074

www.dukemfg.com

REV J 04/16/2018

P/N 229201

HS2 Holding Units

Operator’s Manual

TABLE OF CONTENTS

Manufacturer’s Introduction ................................................................................................................... 3

Important Safety Instructions ................................................................................................................. 4

Installation ............................................................................................................................................. 5

Temperature Verication ........................................................................................................................ 6

Stacking Units........................................................................................................................................ 7

Proper Use Of Pan HeatSinkTM Cover & Pan Trivets ............................................................................. 7

Cleaning Guide ...................................................................................................................................... 8

HS2-T Operating Instructions .............................................................................................................. 10

HS2 Recipe Conguration Guide ........................................................................................................ 12

HS2 Recipe Download onto a USB Drive............................................................................................ 16

Downloading the Recipe to the HS2 Unit ............................................................................................ 17

Renaming Recipe Files ....................................................................................................................... 19

HS2-T Fault Displays on Timer Bars ................................................................................................... 20

Parts Lists And Illustrations ................................................................................................................. 21

HS2-2X2 Specications ....................................................................................................................... 22

HS2-2X2 Wiring Schematics ............................................................................................................... 23

HS2-2X3 Specications ....................................................................................................................... 24

HS2-2X3 Wiring Schematics ............................................................................................................... 25

HS2-2X4 Specications ....................................................................................................................... 26

HS2-2X4 Wiring Schematics ............................................................................................................... 27

HS2-4X2 Specications ....................................................................................................................... 28

HS2-4X2 Wiring Schematics ............................................................................................................... 29

HS2-3X4 Specications ....................................................................................................................... 30

HS2-3X4 Wiring Schematics ............................................................................................................... 31

2

HS2 Holding Units

Operator’s Manual

MANUFACTURER’S INTRODUCTION

The HS2 Holding Unit was developed specically to address the needs of restaurant operations and

protability. Extended hold times with improved food quality and consistency were achieved through

the innovative, top and bottom patented Duke technology HeatSink’s

TM

. This gives you the ability

to maintain gold standard sensory attributes at signicantly extended hold times while delivering

hotter food to your customers.

In addition to providing the most robust and reliable solution technically possible, we also made the

following improvements from the previous FWM PHU model:

• Changed to a more robust Duke timer bar and control system on HS2-T models

• Eliminated plastic lids and replaced with a robust Stainless Steel Pan HeatSink™ Cover for

broiled foods

• Incorporated advanced grease migration controls

• Eliminated plastic faceplate and plastic lid capture system

Throughout this manual, you will uncover more details about the benets and advantages that the

Duke HS2 will bring to your restaurant. Thank you for your purchase and as always, your feedback

is appreciated.

3

HS2 Holding Units

WARNING

CAUTION

CAUTION

Operator’s Manual

IMPORTANT SAFETY INSTRUCTIONS

Throughout this manual, you will nd the following safety words and symbols that signify important safety

issues with regards to operating or maintaining the equipment.

Indicates a hazardous situation which, if not avoided, could result in

death or serious injury.

Indicates a hazardous situation which, if not avoided, could result

in minor or moderate injury.

In addition to the warnings and cautions in this manual, use the following guidelines for safe operation of

the unit.

• Read all instructions before using equipment.

• For your safety, the equipment is furnished with a properly grounded cord connector. Do not attempt to

defeat the grounded connector.

• Install or locate the equipment only for its intended use as described in this manual.

• Do not use corrosive chemicals in this equipment.

• Do not operate this equipment if it has a damaged cord or plug, if it is not working properly, or if it has

been damaged or dropped.

• This equipment should be serviced by qualied personnel only. Contact the nearest Duke authorized

service facility for adjustment or repair.

• Do not block or cover any openings on the unit.

Indicates electrical shock hazard which, if not avoided, could result in

Indicates hot surface which, if not avoided, could result in minor or

Indicates Important Information

death or serious injury and/or equipment damage.

moderate injury.

• Do not immerse cord or plug in water.

• Keep cord away from heated surfaces.

• Do not allow cord to hang over edge of table or counter.

The following warnings and cautions appear throughout this manual and should be carefully observed.

• Turn the unit off, disconnect the power source and allow unit to cool down before performing any

service or maintenance on the unit.

• The procedures in this manual may include the use of chemical products. You must read the Material

Safety Data Sheets before using any of these products.

• The unit should be grounded according to local electrical codes to prevent the possibility of electrical

shock. It requires a grounded receptacle with dedicated electrical lines, protected by fuses or circuit

breaker of the proper rating, in accordance with all applicable regulations.

• Disposal of the unit must be in accordance with local environmental codes and/or any other

applicable codes.

• This appliance is not intended for use by persons (including children) with reduced physical, sensory

or mental capabilities, or lack of experience and knowledge, unless they have been given supervision

or instruction concerning use of the appliance by a person responsible for their safety.

4

WARNING

INSTALLATION

UNPACKING UNIT

Inspect the shipping carton and/or container, carefully

noting any exterior damage on the delivery receipt;

also note any damage not evident on the outside of

the shipping container (concealed damage). Contact

the carrier immediately and le a damage claim with

them. Save all packing materials when ling a claim.

Freight damage claims are the responsibility of the

purchaser and are not covered by the warranty.

• Follow the instructions on the Carton Box for

unpacking the unit.

• Inspect unit for damage.

• Report any dents or breakage to source of

purchase immediately.

• Do not attempt to use unit if damaged.

• Remove all materials from unit interior.

• If unit has been stored in extremely cold area,

wait a few hours before connecting power.

INSTALLATION CODES AND STANDARDS

In the United States, the HS2 must be installed in

accordance with the following:

1. State and local codes.

2. National Electrical Code (ANSI/NFPA No. 70,

latest edition) available from the National Fire

Protection Association, Batterymarch Park,

Quincy, MA 02269.

3. Vapor Removal from Cooking Equipment, (NFPA-

96, latest edition) available from NFPA.

4. Sealed to the counter upon which the equipment

is placed per NSF/ANSI 4 standard.

In Canada, the HS2 must be installed in accordance

with the following:

1. Local codes.

2. Canadian Electrical Code (CSA C22.2 No. 3,

latest edition) available from the Canadian

Standards Association, 5060 Spectrum Way,

Mississauga, Ontario, Canada L4W 5N6.

UNIT PLACEMENT

• Do not install unit next to, below or above source

of heat such as oven or deep fat fryer.

• Install unit on level counter top surface.

• Outlet should be located so that plug is

accessible when the unit is in place.

• Do not install unit in the direct path of

air-conditioned airow.

HS2 Holding Units

Operator’s Manual

The following minimum clearances must be

maintained between the warmer and any

combustible or non-combustible substance:

Unit Clearance

Right Side 2”

Left Side 2”

Rear OPEN

Floor 0”

Proper airow around unit will cool the electrical

components. With restricted airow, the unit may

not operate properly and the life of the electrical

components may be reduced. A 2” clearance is

recommended at the control side for longer control

life expectancy.

ELECTRICAL SHOCK HAZARD UNIT MUST

BE SAFETY GROUNDED, EARTHED.

DO NOT MODIFY, DEFEAT ELECTRICAL

CONNECTIONS OR ALTER PLUG.

ELECTRICAL CONNECTIONS

BEFORE CONNECTING THE

UNIT TO THE POWER SOURCE, VERIFY

THAT THE VOLTAGE AND PHASE OF

THE POWER SOURCE ARE IDENTICAL

TO THE VOLTAGE AND PHASE

INFORMATION ON THE DATA LABEL.

EARTHING INSTRUCTIONS

THE UNIT MUST BE GROUNDED. Grounding

reduces risk of electric shock by providing an escape

wire for the electric current if an electrical short

occurs. This unit is equipped with a cord having a

grounding wire with a grounding plug. The plug must

be plugged into a receptacle that is properly installed

and grounded.

Consult a qualied electrician or service agent

if grounding instructions are not completely

understood, or if doubt exists as to whether the unit is

properly grounded.

DO NOT USE AN EXTENSION CORD. If the product

power cord is too short, have a qualied electrician

install a three-slot receptacle (or the country specic

receptacle for International Units). This unit should

be plugged into a dedicated circuit with the electrical

rating as provided on the product data plate.

5

HS2 Holding Units

Operator’s Manual

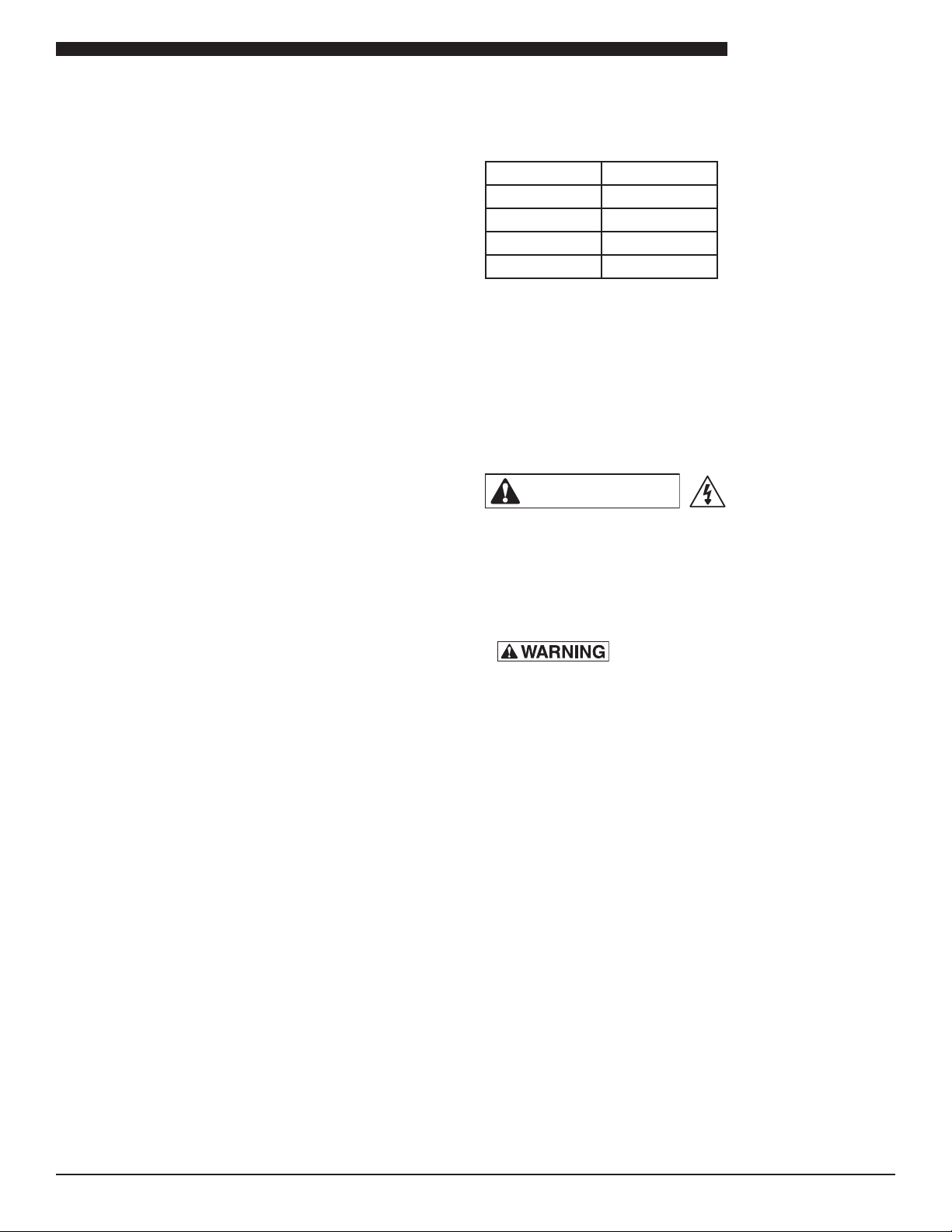

TEMPERATURE CHECK PROCEDURE

1. A digital temperature meter that has been

calibrated must be used to get an accurate

temperature reading. Use a thermocouple

surface temperature probe to measure

temperatures.

2. No pans should be in wells during the

pre-heat and temperature check. Pre-heat

the warmer for 30 minutes before taking any

temperature readings. Do not take readings

unless the cavity has been empty for 30

minutes. This will allow the temperature to

stabilize and will prevent false readings.

2X3 2T

2X3 4T

Top

OR

Bottom

Fig 1

Top

OR

Bottom

Fig 2

1

Top

OR

Bottom

Fig 3

3

2

4

3. The warmer cavity should be cleaned and

empty before the temperature is checked.

Avoid any air drafts that might ow through

the cavity.

4. Temperature readings should be taken when

standing on the front side of the unit with on/

off switch. Locate the surface temperature

probe on the bottom or top of the rst cavity.

Position the probe half way back on the heat

sink beneath the rail as shown. The top

readings should be taken on either side of the

rail half way back on the heat sink. Four wide

units require 2 readings, left and right side.

NOTE: For 2x3 four (4) zone units refer to Fig 3.

Top

OR

Bottom

Fig 4

Top

OR

Bottom

5. All temperature controls exhibit a swing in

temperature as the control cycles on and off

while regulating to the set point. The correct

calibration temperature is the average of

several readings taken over a period of 20

minutes after the warmer has been preheated. The average temperature should be

no greater than ± 10°F (± 6°C) from the set

point.

6. The allowable range of well temperatures

which can be programmed on the HS2 is

140°F-280°F (60°C-137.8°C).

6

HS2 Holding Units

Operator’s Manual

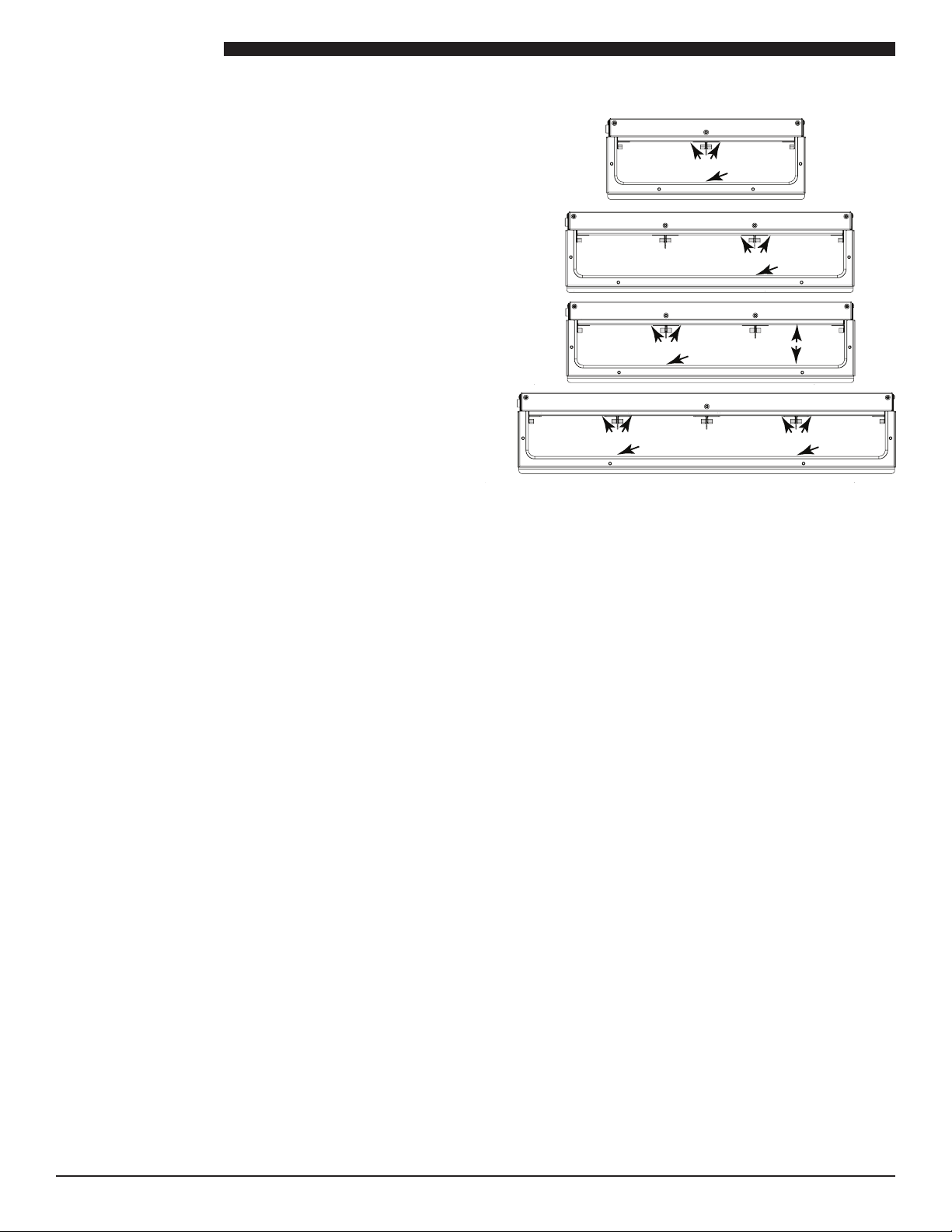

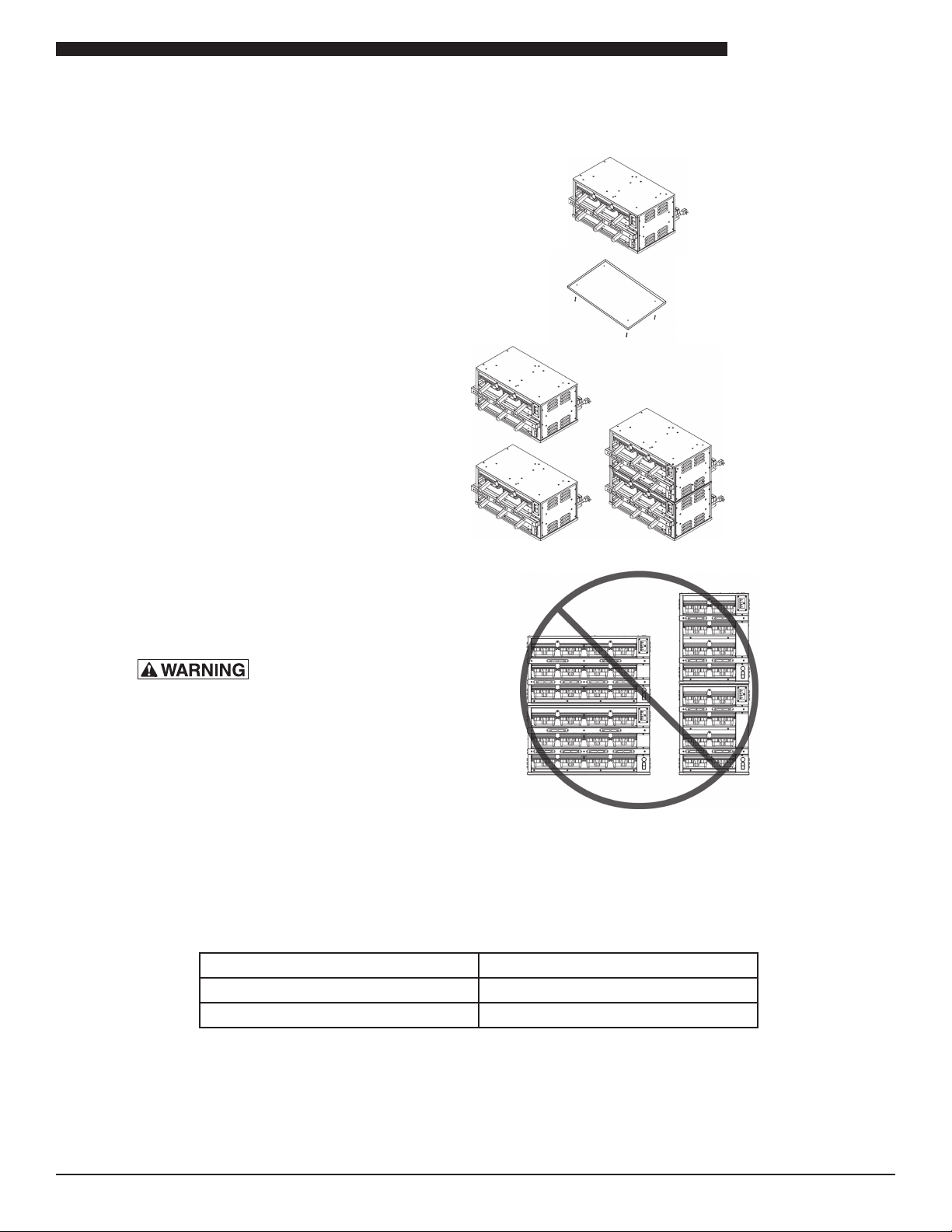

STACKING UNITS

The HS2 Holding Unit is designed to allow limited stacking capabilities. This section outlines how to safely

stack the holding unit.

Step 1

Step 2

Remove the base pan from the unit that will be on

top. The pan is held in place by four screws on the

bottom of the unit.

Place bottom unit into position then

stack the next unit on top. The top of

the lower holding unit rests inside of

the base of the upper unit.

TIP HAZARD! DO NOT

STACK HS2-42 OR HS2-34 UNITS. DO

NOT EXCEED 2 HOLDING UNITS PER

STACK. DO NOT PLACE HOLDING

UNIT STACKS ON SURFACES THAT

MAY EASILY TIP OVER.

PROPER USE OF HEATSINKTM COVERS & PAN TRIVETS

Proper usage of each is important and is outlined below:

Product Type Duke Pan Heat Sink Cover

Broiled yes

Fried no

Consult your Kitchen Operations Manual for any modications to the above based on your specic food

requirements.

7

HS2 Holding Units

CAUTION

WARNING

CAUTION

CAUTION

CAUTION

Operator’s Manual

CLEANING GUIDE

Electrical shock hazard. Do not wash with water jet or hose.

DO NOT USE CAUSTIC CLEANERS, ACIDS, AMMONIA PRODUCTS OR ABRASIVE

CLEANERS OR ABRASIVE CLOTHS. THESE CAN DAMAGE THE STAINLESS STEEL AND

PLASTIC SURFACES.

Bottom and sides of warmer wells are very hot and

cool slowly.

DAILY CLEANING

• Stainless Steel Surfaces

To prevent discoloration or rust on stainless steel

several important steps need to be taken. Stainless

steel contains 70-80% iron which will rust. It also

contains 12-30% chromium which forms an invisible

passive lm over the steel surface which acts as a

shield against corrosion. As long as the protective

layer is intact, the metal will not corrode. If the lm is

broken or contaminated, outside elements can begin

to breakdown the steel and begin to form rust or

discoloration.

Proper cleaning of stainless steel requires soft cloths

or plastic scouring pads.

Never use steel pads, wire brushes or scrapers.

Cleaning solutions need to be alkaline based or non-

chloride cleaners. Any cleaner containing chlorides

will damage the protective lm of the stainless

steel. Chlorides are also commonly found in hard

water, salts and household and industrial cleaners.

If cleaners containing chlorides are used, be sure to

rinse repeatedly and dry thoroughly upon completion.

Routine cleaning of stainless steel can be done with

soap and water. Extreme stains or grease should

be cleaned with a non-abrasive cleaner and plastic

scrub pad. It is always good to rub with the grain

of the steel. There are also stainless steel cleaners

available which can restore and preserve the nish of

the steels protective layer.

NEVER USE AN ACID

BASED CLEANING SOLUTION! MANY

FOOD PRODUCTS HAVE AN ACIDIC

CONTENT WHICH CAN DETERIORATE THE

FINISH. BE SURE TO CLEAN ALL FOOD

PRODUCTS FROM ANY STAINLESS STEEL

SURFACE. COMMON ITEMS INCLUDE,

TOMATOES, PEPPERS AND OTHER

VEGETABLES.

THE POWER MUST BE

TURNED OFF AND DISCONNECTED

AT ALL TIMES WHEN PERFORMING

MAINTENANCE OR REPAIR FUNCTIONS.

NEVER USE A HIGHPRESSURE WATER WASH FOR THIS

CLEANING PROCEDURE AS WATER CAN

DAMAGE ELECTRICAL COMPONENTS

ELECTRICAL SHOCK HAZARD.

DO NOT WASH WITH WATER JET OR

HOSE.

RECOMMENDED SUPPLIES

Cleaning Towels

Non-Scratch Scrub Pad

KAY™ Degreaser

KAY® SINK SANITIZER, KAYQUAT™ Sanitizer, or

compatible sanitizer

Early signs of stainless steel breakdown can consist

of small pits and cracks. If this has begun, clean

thoroughly and start to apply stainless steel cleaners

in an attempt to restore the passivity of steel.

8

HS2 Holding Units

CAUTION

Operator’s Manual

PROCEDURE

1. Turn unit off, unplug, and allow to cool for 30 minutes.

2. Remove all holding pans and heat sink covers. Wash, rinse, and sanitize at the 3 compartment sink.

3. Allow to air dry.

4. Spray a cleaning towel, or non-scratch scrub pad when necessary, with soapy solution or KAY™

Degreaser. Fully clean upper heat sink surfaces by hand, as well as lower heat sink surfaces.

Take care when reaching in the cabinet. Pan and lid guides present

sheet metal edges which could be sharp.

NOTE: Never spray cleaning solution directly onto the cabinet.

5. If daily cleaning is performed routinely, deeper, more aggressive, cleaning methods can be avoided. Over

longer periods of time, fried food product can accumulate and bake on to the upper heat sink surfaces of

the compartments.

6. Use a sanitizer-soaked towel and wipe out all compartments on the holding unit. Wipe top compartments

rst, and then lower compartments.

IMPORTANT: Use clean, sanitizer-soaked towels (Important: towels must be wrung out so that

they are damp and not dripping, dripping towels may harm the unit.)

DAILY INSPECTION CHECKLIST:

Make sure that:

• Unit is free of any visible food soils.

• Unit is free of grease or soils in holding compartment.

• Exterior of unit is free of smudges or soil.

• Holding pans are free of any food soil residue.

• Pans are free of damage such as cracks.

9

HS2 Holding Units

Operator’s Manual

HS2-T OPERATING INSTRUCTIONS

TO ENSURE OPTIMAL HOLD QUALITY, THE USER WOULD PRESS THE BUTTON ON THE TIMER BAR

CORRESPONDING WITH THE PAN LOCATION TO ACTIVATE A HOLD CYCLE.

THIS STARTS THE TIMER COUNTDOWN.

11 22 33

• ENSURE PROPER HEAT

SINK COVERS ARE

INSERTED INTO THE

CORRECT LOCATION

(BROILED AND MOISTURE

SENSITIVE PRODUCTS

ONLY).

1. Status LED’s: Indicates status of the pan

a. Non-Illuminated – timer is inactive – no product in pan.

b. Green – timer is active – product in pan (use 1

c. Amber – timer is active – product in pan (use next)

d. Non-Illuminated – timer active – product in pan

(use later)

e. Flashing Green – cook warning time reached

(cook more product)

ST

)

• ENSURE METAL TRIVETS

ARE INSERTED INTO

THE PANS FOR FRIED

PRODUCTS.

• UPON TURNING ON,

ALLOW THE HOLDING

UNIT TO HEAT FOR AT

LEAST 30 MINUTES OR

UNTIL THE TEMPERATURE

DISAPPEARS AND THE

TIMER BARS DISPLAY

THE PREPROGRAMMED

PRODUCT NAMES.

f. Flashing Red – product is expired (discard)

2. Arrow buttons

a. Used for starting and stopping the timer

b. Used to access menu mode

c. Indicates which pan the adjacent status LED and pan

display are linked to

3. Pan Display

a. In startup mode it will display spinning bars then

transition to PRE HEAT, and then cycle through the

bottom actual temp and top actual temp

b. Once unit reaches the recipe set points it will display

product name. (If associated recipe requires a lid

display will toggle prod name, lid.)

c. Unit will display product name and hold time remaining

(display will alternate between the two when a timer

is active)

• IF THE TIMER BARS

DISPLAY “HIGH” OR

“LOW” AT ANY TIME

AFTER THE PRE-HEAT

PERIOD, DISCONTINUE

USE OF THE AFFECTED

PAN LOCATION(S) UNTIL

THE HOLDING UNIT CAN

BE SERVICED.

10

Loading...

Loading...