Duke HDC3, HDC6 SERVICE MANUAL

DRY CHANNEL

MODELS

HDC3/HDC6

Service Manual

Please read this manual completely before attempting

to install, operate or service this equipment

This document is prepared for trained Duke service technicians. It is not to be used by anyone not

properly qualied to perform these procedures.

This Service Manual is not all encompassing. If you have not been trained on servicing this product,

be sure to read the manual completely before attempting servicing. Be sure all necessary tools, test

equipment, and skills are available. Those procedures for which you do not have the proper skills

and test equipment must be performed only by a qualied Duke trained service technician.

This manual is Copyright © 2011 Duke Manufacturing Company. All rights reserved.

Reproduction without written permission is prohibited. Duke is a registered

trademark of the Duke Manufacturing Company.

Duke Manufacturing Company

2305 N. Broadway

St. Louis, MO 63102

Phone: 314-231-1130

Toll Free: 1-800-735-3853

Fax: 314-231-5074

www.dukemfg.com

P/N 219217B

Service Manual for Dry Channel HDC3/HDC6 Units

IMPORTANT WARNING AND SAFETY INFORMATION

WARNING

READ THIS MANUAL THOROUGHLY BEFORE OPERATING, INSTALLING, OR

PERFORMING MAINTENANCE ON THE EQUIPMENT.

WARNING

FAILURE TO FOLLOW INSTRUCTIONS IN THIS MANUAL CAN CAUSE PROPERTY

DAMAGE, INJURY OR DEATH.

WARNING

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS OR

LIQUIDS IN THE VICINITY OF THIS OR ANY OTHER APPLIANCE.

WARNING

DO NOT OPERATE THIS EQUIPMENT WITHOUT PROPERLY PLACING AND

SECURING ALL COVER AND ACCESS PANELS.

CAUTION

Observe the following:

• Provide and maintain adequate minimum clearances from all walls and combustible materials.

• Provide and maintain adequate clearance for air openings.

• Keep the equipment area free and clear of combustible material.

• Operate equipment only on the type of electricity indicated on the specication plate.

• Retain this manual for future reference.

2

Service Manual for Dry Channel HDC3/HDC6 Units

TABLE OF CONTENTS

IMPORTANT SAFETY INSTRUCTIONS ...........................................................................2

INTRODUCTION ...............................................................................................................4

GENERAL ....................................................................................................................4

MODEL DESIGNATIONS ............................................................................................5

MAIN FEATURES .............................................................................................................. 6

RELAY BOX .................................................................................................................6

CONTROL DISPLAY ...................................................................................................6

COMPONENT REPLACEMENT .......................................................................................7

TOOLS REQUIRED.....................................................................................................7

CONTROL DISPLAY ...................................................................................................7

CONTROL BOARD OR MYLAR COVER .................................................................... 7

RELAY BOX .................................................................................................................8

Main Power On/Off Switch ....................................................................................8

Solid State Relays .................................................................................................9

24 Volt Step-Down Transformer ........................................................................... 9

CHANNEL ASSEMBLY .............................................................................................. 10

TESTING AND TROUBLESHOOTING ........................................................................... 11

COMPONENT TESTING ........................................................................................... 11

Primary Power Check .......................................................................................... 11

Fault Conditions ................................................................................................... 11

24 Volt Step-Down Transformer ..........................................................................12

Heater Element and Hi-Limit Thermostat ............................................................12

RTD ...........................................................................................................................13

SEQUENCE OF OPERATION ........................................................................................14

TROUBLESHOOTING CHART ....................................................................................... 15

WIRING DIAGRAM .........................................................................................................16

3

Service Manual for Dry Channel HDC3/HDC6 Units

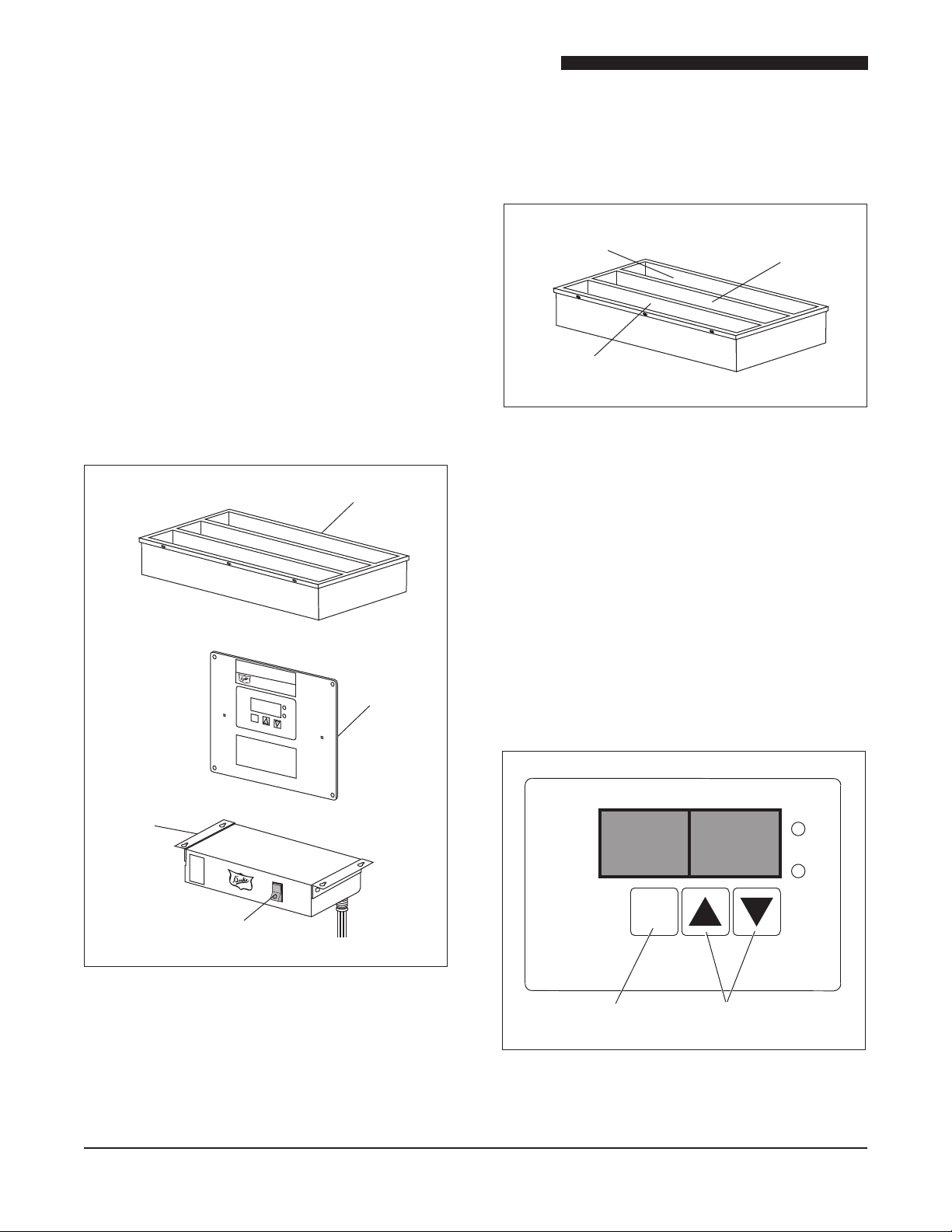

On/O

Function Control

Button

Select

Buttons

DISPLAYDISPLAY

HEAT ON

READY

Relay

Box

Display

Box

I

DRY CHANNEL TEMPERATURE

PROG

Tub

Main Power

ON/OFF Switch

Channel 3

Zones 3A & 3B

Channel 1

Zones 1A & 1B

Channel 2

Zones 2A & 2B

INTRODUCTION

GENERAL

The Duke HDC3 Dry Channel unit maintains the

factory set point temperature on 3 channels (front,

back, and center). The Duke HDC6 Dry Channel

unit maintains the factory set point temperature

on 6 channels. Each channel has an A and B

zone. The Main Power On/Off Switch is located

on the Relay/Control Box (herein after referred to

as Relay Box). A display panel will cycle through

the temperature of each channel followed by fault

messages if a fault is detected.

The display temperature will be the average of

the two zones.

Figure 2. Channels and Zones

Pressing the ON button on the Control Display

activates the display. Pressing the up arrow

will cycle through the six temperature zones,

displaying the actual temperatures. Pressing

the down arrow will cycle through the set point

temperature for each channel. The factory set

point temperature is 275°F. The HEAT ON LED

will indicate an activated relay in any zone. The

READY LED is activated when all zones reach

the set point temperature. A fault message will

be displayed to indicate any zone that does

not reach the set point temperature within 45

minutes of power up.

4

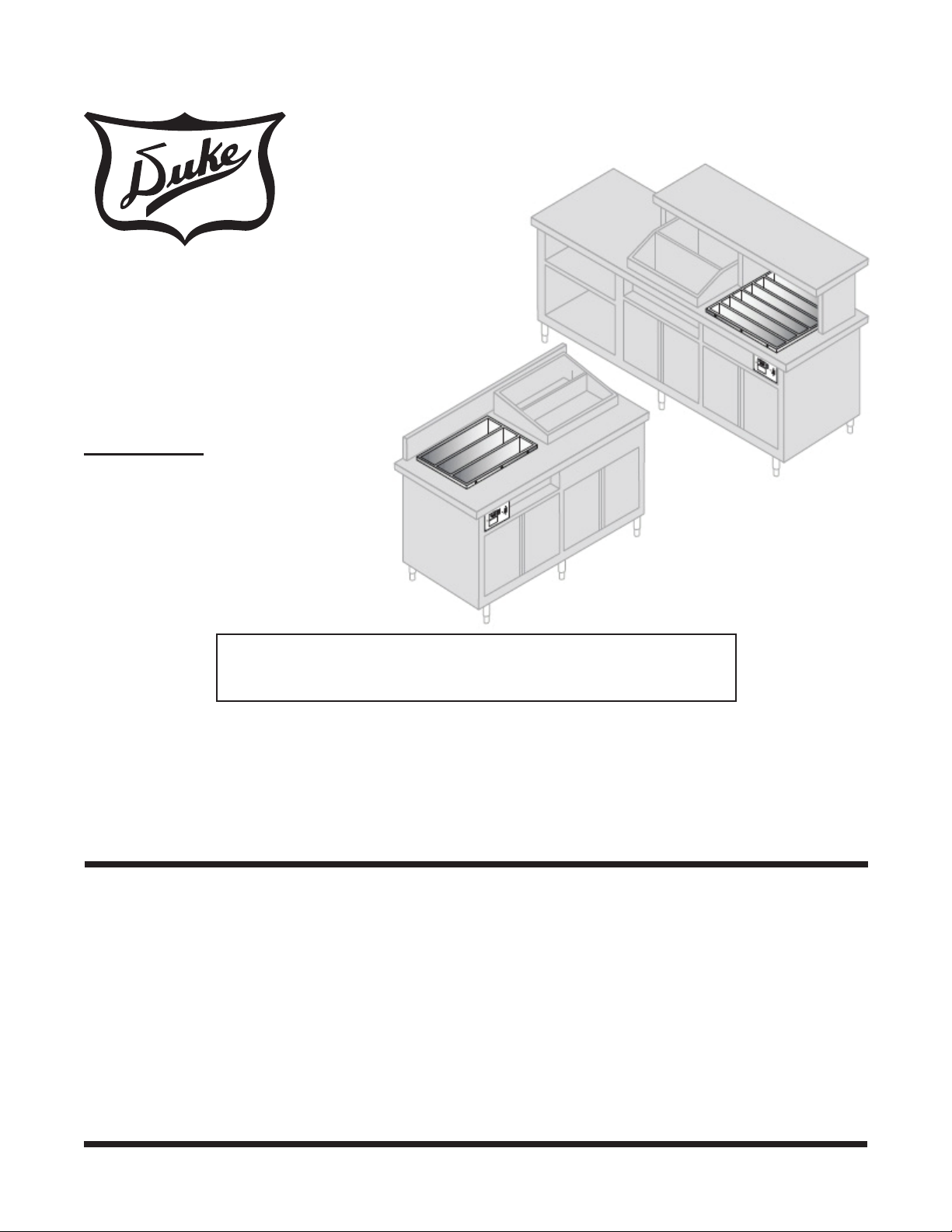

Figure 1. Dry Channel Major Components

Figure 3. Control Display

Service Manual for Dry Channel HDC3/HDC6 Units

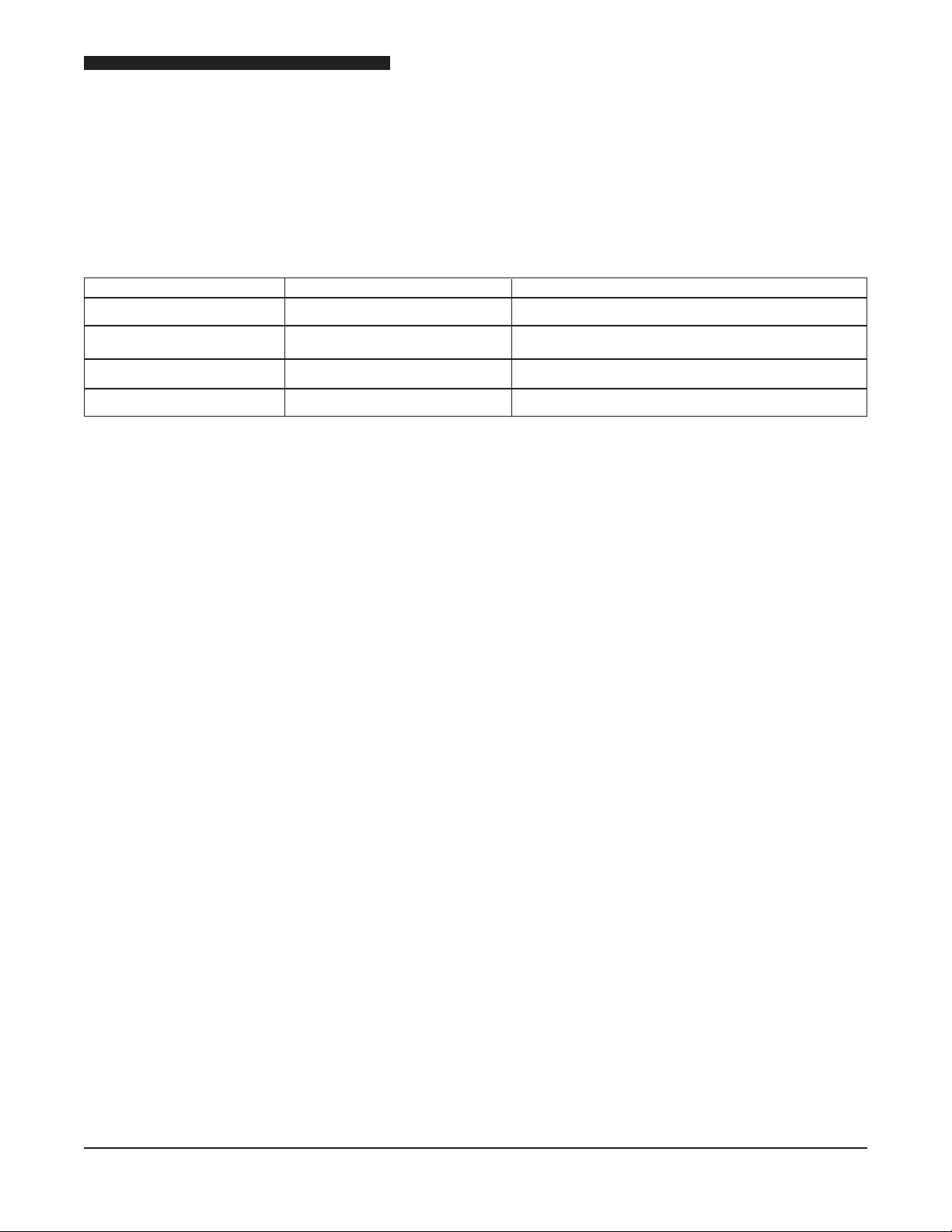

MODEL DESIGNATIONS

The following chart lists the different model designations and provides information on the weight and

electrical requirements.

TABLE 1. MODEL SPECIFICATIONS

MODEL NO. SHIPPING WT. ELECTRICAL SPECIFICATIONS

HDC3-37.5-208 160 lbs (59.7 kg) 208VAC, 10.1A, 2100W, 50/60Hz

HDC-37.5-240 160 lbs (59.7 kg) 240VAC 8.8A, 2100W, 50/60Hz

HDC6-37.5-208 315 lbs (117.6 kg) 208VAC, 20.1A, 4200W, 50/60Hz

HDC6-37.5-240 315 lbs (117.6 kg) 240VAC, 17.5A, 4200W, 50/60Hz

5

Service Manual for Dry Channel HDC3/HDC6 Units

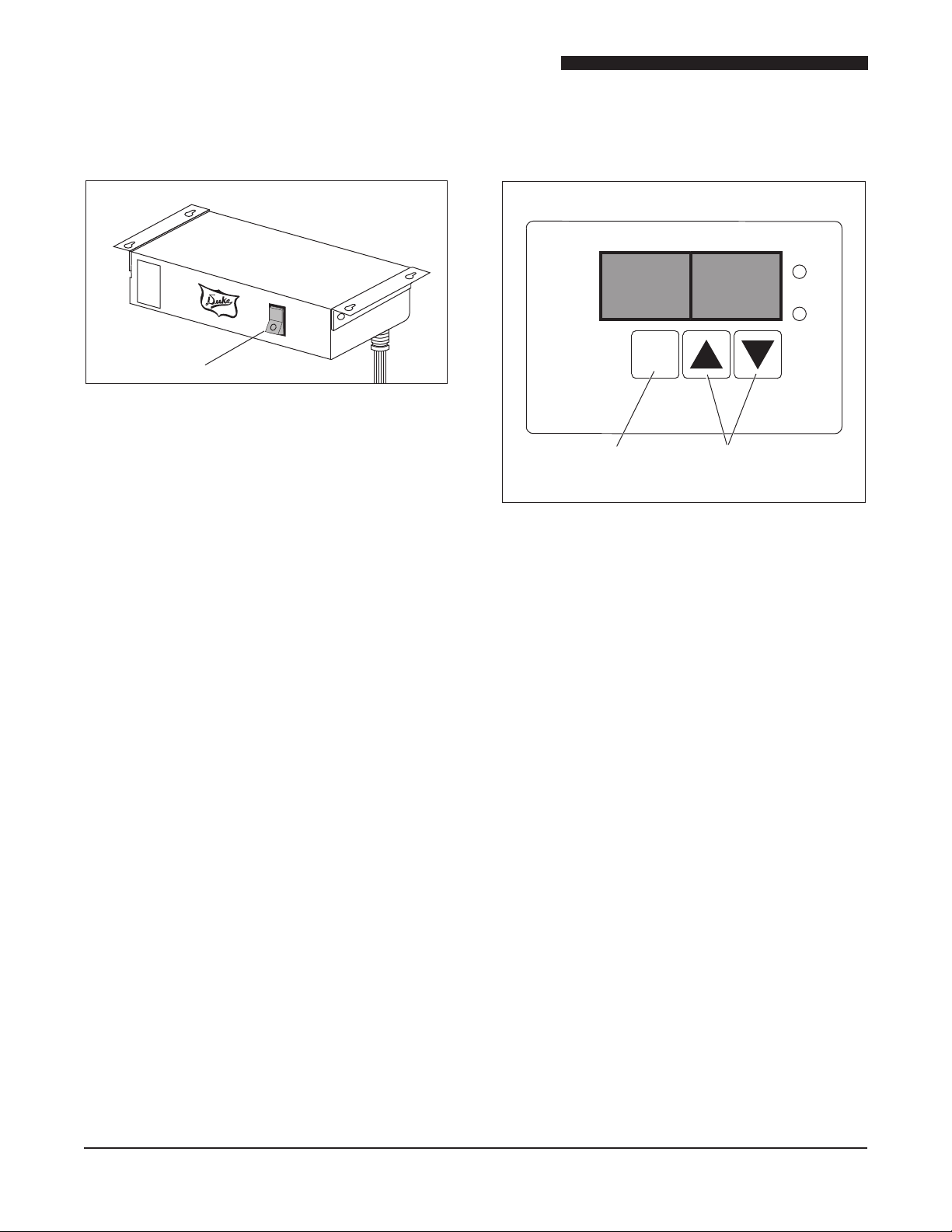

Main Power

On/Off Switch

I

On/O

Function Control

Button

Select

Buttons

DISPLAYDISPLAY

HEAT ON

READY

MAIN FEATURES

RELAY BOX

Figure 4. Relay Box

The Main Power On/Off Switch is located on

the lower right side of the Relay Box. This is a

lighted double pull single throw (DPST) switch

rated at 20 Amperes. The Relay Box houses a 24

Volt Step-Down Transformer and six Solid State

Relays (SSR).

CONTROL DISPLAY

Figure 5. Control Display

The display provides a readout of actual

temperature, set point temperature and fault

conditions.

The control board inside the Control Display

maintains the temperature of all three channels.

Each channel has an A & B zone. The control board

monitors each zone’s temperature and activates a

relay to supply power to the heater for that zone.

When the ON/OFF button is pressed, the display

cycles through the temperature of each channel.

If a fault is detected, the fault code is displayed.

The displayed temperature will be the average of

the two zones associated with that channel.

6

Loading...

Loading...