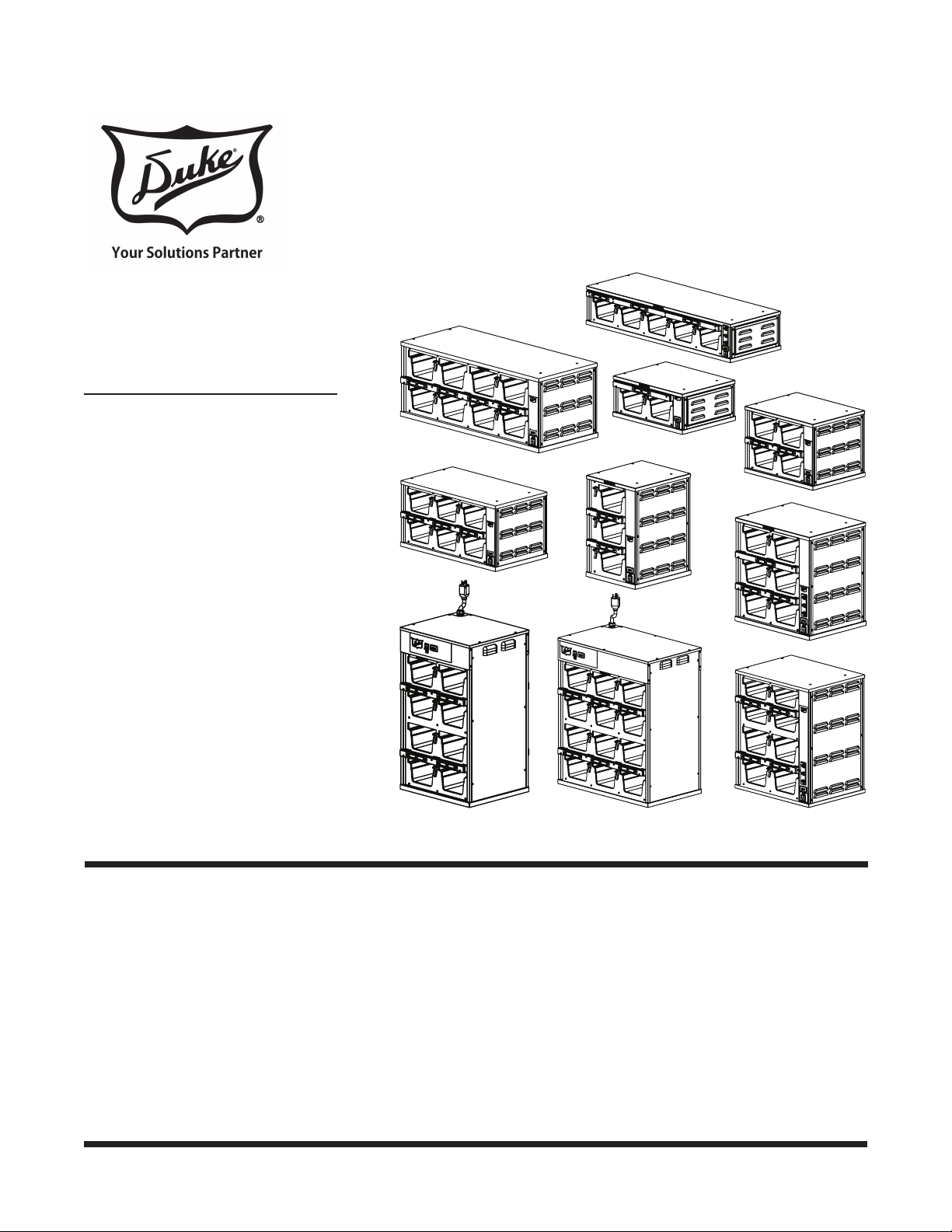

Duke FWM34-12, FWM34-15, FWM34-22, FWM34-23, FWM34-24 Installation Manual

...

PRODUCT HOLDING

CABINET

MODELS

FWM34-12 SERIES

FWM34-15 SERIES

FWM34-22 SERIES

FWM34-23 SERIES

FWM34-24 SERIES

Installation and

Operation Manual

FWM34-31 SERIES

FWM34-32 SERIES

FWM34-42 SERIES

FWM34-43 SERIES

FWM 6-42 SERIES

Please read this manual completely before attempting

to install, operate or service this equipment

This manual is Copyright © 2018 Duke Manufacturing Co. All rights reserved.

Reproduction without written permission is prohibited. Duke is a registered

Duke Manufacturing Co.

trademark of the Duke Manufacturing Co.

2305 N. Broadway

St. Louis, MO 63102

Phone: 314-231-1130

Toll Free: 1-800-735-3853

Fax: 314-231-5074

www.dukemfg.com

P/N 156224

REV V 04/20/2018

Installation and Operation of Product Holding Cabinets

2

Installation and Operation of Product Holding Cabinets

TABLE OF CONTENTS

ELECTRICAL WARNINGS ................................................................................................................4

MANUFACTURER’S INTRODUCTION .............................................................................................6

SPECIFICATIONS .............................................................................................................................7

INSTALLATION INSTRUCTIONS ...................................................................................................17

Unpacking Unit .........................................................................................................................17

Installation Codes and Standards ............................................................................................17

Unit Placement .........................................................................................................................17

Clearance Requirements ..........................................................................................................17

Earthing Instructions .................................................................................................................17

External Equipotential Bonding Terminal (Export Only)............................................................18

Stacking Units ..........................................................................................................................18

OPERATION ....................................................................................................................................19

Opening Checklist ....................................................................................................................19

Operation Instructions and Adjustments ...................................................................................19

Closing Checklist ......................................................................................................................19

Cleaning Instructions ................................................................................................................19

STAINLESS STEEL CARE ..............................................................................................................19

Cleaning ...................................................................................................................................19

Preserving & Restoring ............................................................................................................20

Heat Tint ...................................................................................................................................20

KEYPAD PROGRAMMING .............................................................................................................20

Power Up ..................................................................................................................................21

Timer Operation ........................................................................................................................21

Time Decrement .......................................................................................................................22

Menu Mode ..............................................................................................................................22

Enter Menu Mode ..............................................................................................................22

Change Meal Set ...............................................................................................................22

Display Link, Hold Time & Temperature ............................................................................23

Exit Menu Mode ................................................................................................................23

Daypart Programming (OPTION) .............................................................................................23

WEB PROGRAMMING ...................................................................................................................24

TROUBLESHOOTING ....................................................................................................................28

Electronic Control Fault Indications ..........................................................................................28

Temperature Check Procedure ................................................................................................28

Service Hot-Line .......................................................................................................................28

TABLE 1: PARTS LIST – FWM34-12, FWM34-15, FWM34-22, FWM34-23,

FWM34-32 & FWM34-32.................................................................................................................30

TABLE 2: PARTS LIST – FWM34-42 & FWM34-43 .......................................................................32

TABLE 3: PARTS LIST - FWM6-42 .................................................................................................34

WIRING SCHEMATICS ...................................................................................................................36

3

Installation and Operation of Product Holding Cabinets

ELECTRICAL WARNINGS

THIS MANUAL HAS BEEN PREPARED FOR PERSONNEL QUALIFIED TO INSTALL

ELECTRICAL EQUIPMENT, WHO SHOULD PERFORM THE INITIAL FIELD STARTUP

AND ADJUSTMENTS OF THE EQUIPMENT COVERED BY THIS MANUAL.

READ THIS MANUAL THOROUGHLY BEFORE OPERATING, INSTALLING OR PERFORMING

MAINTENANCE ON THE EQUIPMENT.

: Failure to follow all the instructions in this manual can cause

property damage, injury or death.

: Improper installation, adjustment, alteration, service or maintenance

can cause property damage, injury or death.

: (US/CAN ONLY) Electrical connections should be performed only

by a certied professional.

: Electrical and grounding connections must comply with the applicable

portions of the National Electric Code and/or all local electric codes. Failure to

comply with this procedure can cause property damage, injury or death.

: Before connecting the unit to the electrical supply, verify that the

electrical and grounding connections comply with the applicable portions of the

National Electric Code and/or other local electrical codes. Failure to comply with

this procedure can cause property damage, injury or death.

: Before connecting the unit to the electrical supply, verify that the

electrical connection agrees with the specications on the data plate. Failure to

comply with this procedure can cause property damage, injury or death.

: UL73 grounding instructions: This appliance must be connected to

a grounded, metal, permanent wiring system. Or an equipment-grounding conductor

must be run with the circuit conductors and connected to the equipment-grounding

terminal or lead on the appliance. Failure to comply with this procedure can cause

property damage, injury or death.

: Appliances equipped with a exible electric supply cord, are provided

with a three-prong grounding plug. It is imperative that this plug be connected into

a properly grounded three-prong receptacle. Failure to comply with this procedure

can cause property damage, injury or death.

: If the receptacle is not the proper grounding type, contact an

electrician. Do not remove the grounding prong from the plug. Failure to comply

with this procedure can cause property damage, injury or death.

4

Installation and Operation of Product Holding Cabinets

: Before performing any service that involves electrical connection

or disconnection and/or exposure to electrical components, always perform the

Electrical LOCKOUT/TAGOUT Procedure. Disconnect all circuits. Failure to comply

with this procedure can cause property damage, injury or death.

: Before removing any sheet metal panels or servicing this equipment,

always perform the Electrical LOCKOUT/TAGOUT Procedure. Be sure all circuits are

disconnected. Failure to comply with this procedure can cause property damage,

injury or death.

: Do not operate this equipment without properly placing and securing

all covers and access panels. Failure to comply with this procedure can cause

property damage, injury or death.

: For your safety, do not use or store gasoline or other ammable

vapors or liquids in the vicinity of this or any other appliance. Failure to comply

can cause property damage, injury or death.

: In the event of a power failure, do not attempt to operate this

appliance. Failure to comply can cause property damage, injury or death.

: This appliance is not intended for use by persons (including

children) with reduced physical, sensory or mental capabilities, or lack of experience

and knowledge, unless they have been given supervision or instruction concerning

use of the appliance by a person responsible for their safety. Children should be

supervised to ensure they do not play with the appliance.

CAUTION

Observe the following:

• Minimum clearances must be maintained from all walls and combustible materials.

• Keep the equipment area free and clear of combustible material.

• Maintain adequate clearance for air openings.

• Operate equipment only on the type of electricity indicated on the data sticker.

• Retain this manual for future reference.

5

Installation and Operation of Product Holding Cabinets

MANUFACTURER’S INTRODUCTION

The Duke Product Holding Unit was developed for extended food-holding capabilities to provide consistently high,

“just cooked” food quality.

The Duke Product Holding Unit utilizes Duke’s patented “heat sink” holding technology that provides even heat

distribution to food pans through the bottom and sides. This allows pre-cooked foods to be held for extended periods

without noticeable degradation of quality, reducing food scrap/waste.

The self contained, individually formed, sealed compartments of the Duke Product Holding Unit eliminates food odor

and taste transfer. Because the compartments are sealed and formed to the shape of the pan, no disassembly is

required for cleaning and product changes.

The unique design of the Duke Product Holding Unit allows single temperature operation for all existing product

groups. This 180°F(82°C) approved temperature is preset at the factory. This reduces the likelihood of inconsistent

performance between restaurant locations.

The Duke Product Holding Cabinet was also designed to rethermalize food product. A thermostat setting of 180°F(82°C)

minimum is required for re-thermalization. To comply with sanitation requirements do not set the temperature control

lower than 180°F(82°C) or equivalent.

: Only qualied service persons should modify control temperature presets.

SERIAL NUMBER LOCATION

The Serial Number Data Label is located on the rear of the unit, above the power cord connection. Refer to the

Serial Number Data Label for proper electrical requirements. The serial number and model number are required

when communicating with the Duke Service Department.

6

Installation and Operation of Product Holding Cabinets

SPECIFICATIONS

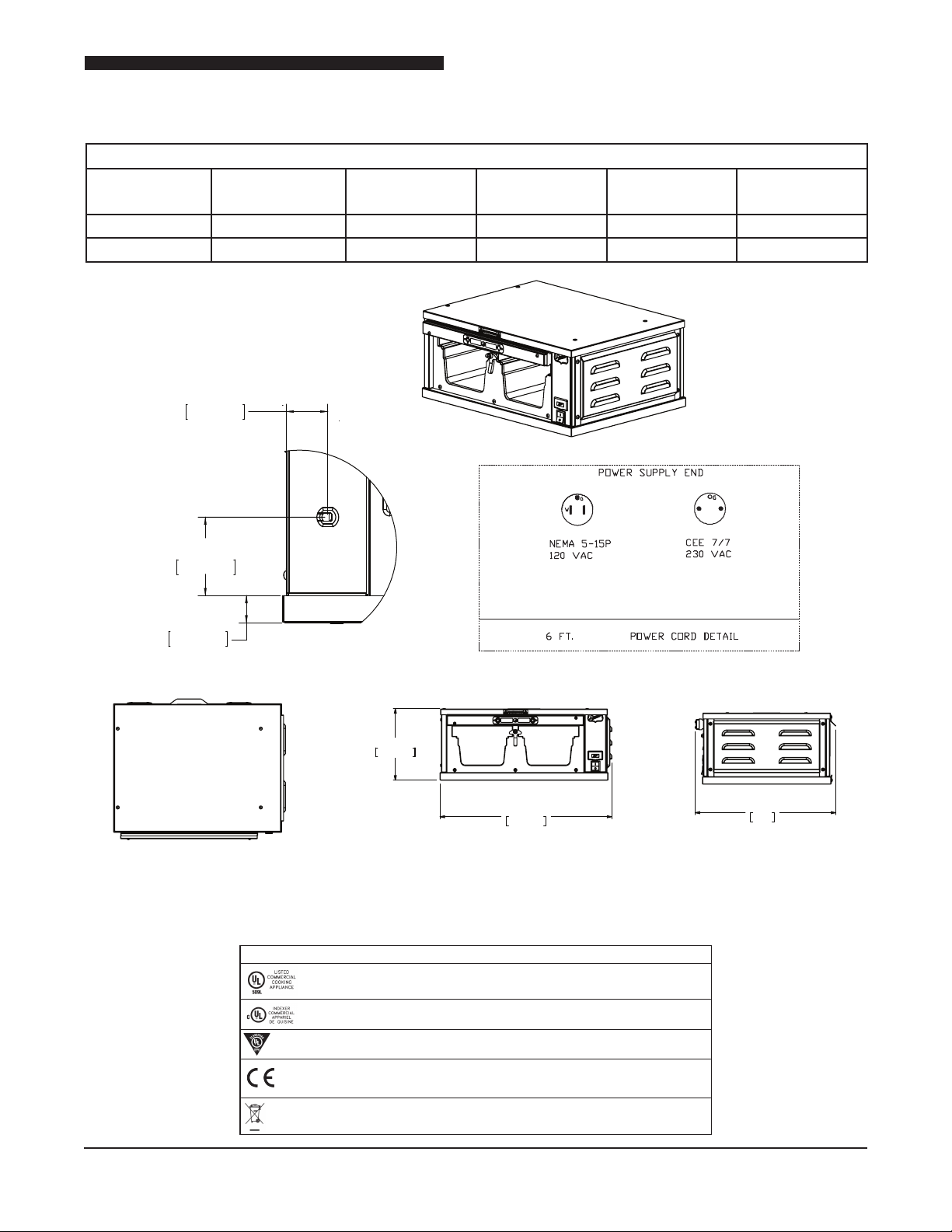

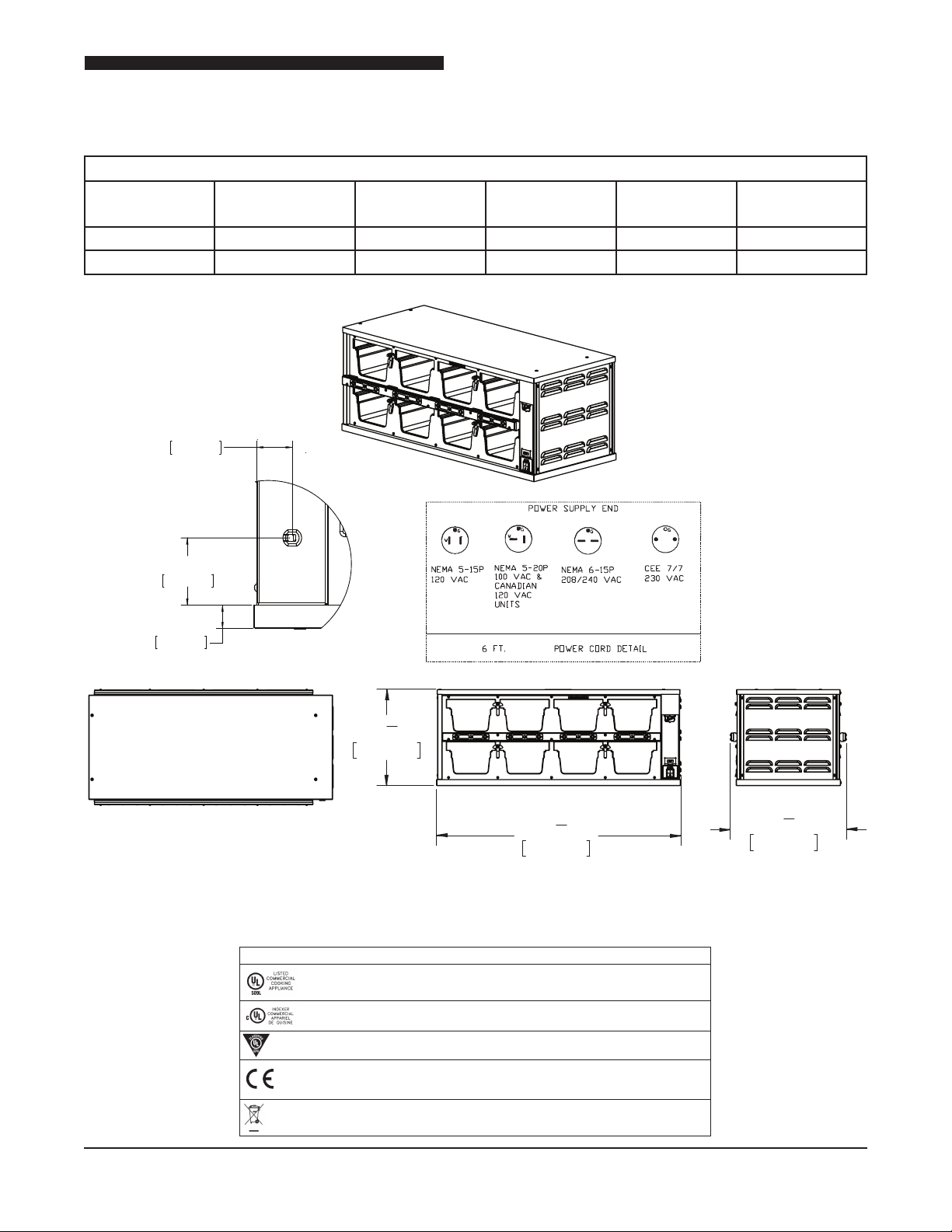

MODEL FWM34-12

MODEL SHIPPING

WEIGHT

FWM34-12-120 50 lbs (22,7 Kg) 120 400 4.0 (4,0) 60

FWM34-12-230 50 lbs (22,7 Kg) 230 600 3.0 (3,0) 50

1 3/8”

3,6 cm

AC Voltage

(V ~)

Watts

(W)

Amps

(A)

FREQUENCY

(Hz)

2 3/4”

6,9 cm

1 ”

2,4 cm

(US)

(182,9cm)

8 7/8"

22,393cm

21 1/8"

53,725cm

Compliance Declaration

Standard: UL197 File: KNGT.E17421

(GERMANY,

FRANCE AND

UK CE UNITS)

17 3/8"

ENDFRONTTOP

44cm

Standard: CSA-C22.2 No. 109 File: KNGT7.E17421

Standard: ANSI / NSF 4 File: TSQT.E157479

Directive 2006/95/EC:

EN60335 -1:2002, A1, A2, A11, A12

EN 60335-2-49:2003

WEEE RoHS Directive 2002/96/EC

Directive 89/336/EEC and 2004/108/EC:

EN61000-3-2 EN 55014-1

EN61000-3-3 EN55014-2

7

Installation and Operation of Product Holding Cabinets

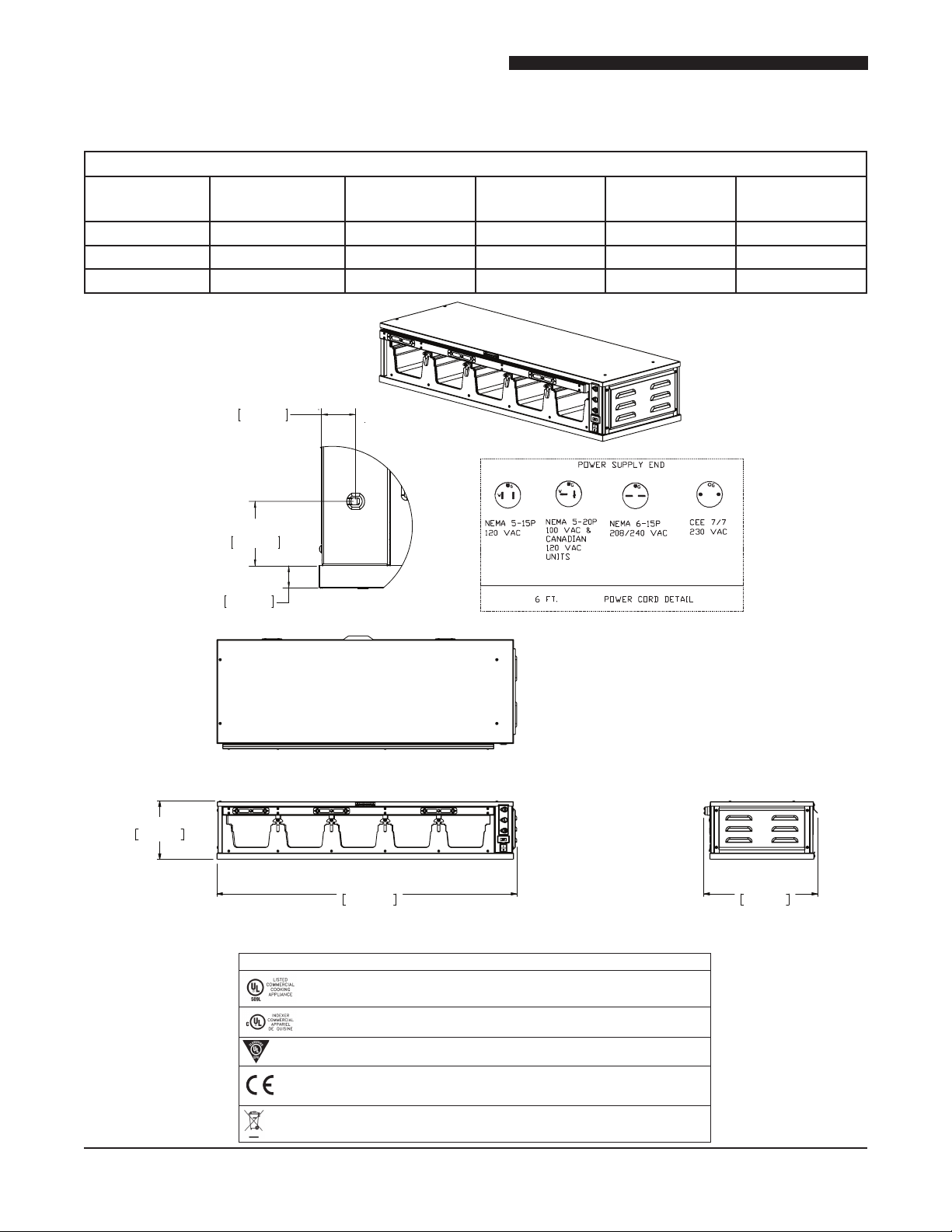

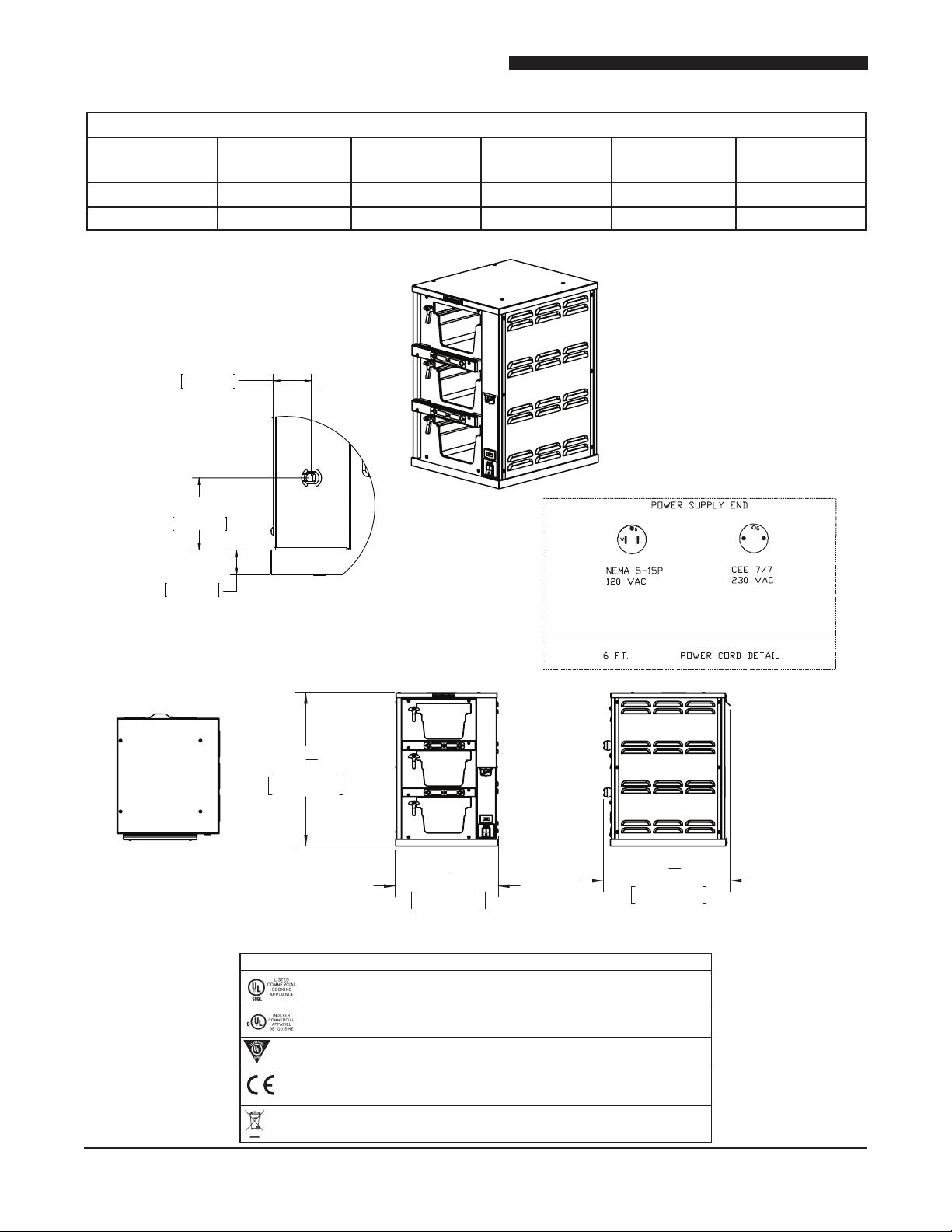

MODEL FWM34-15

MODEL SHIPPING

WEIGHT

FWM34-15-120 100 lbs (45,5 Kg) 120 1000 8.3 (8,3) 60

FWM34-15-208 100 lbs (45,5 Kg) 208 1500 7.2 (7,2) 60

FWM34-15-230 100 lbs (45,5 Kg) 230 1500 6.5 (6,5) 50

1 3/8”

3,6 cm

AC Voltage

(V ~)

Watts

(W)

Amps

(A)

FREQUENCY

(Hz)

8 7/8"

22,494cm

2 3/4”

6,9 cm

1 ”

2,4 cm

(US) (US/CAN)

(182,9cm)

(GERMANY,

FRANCE AND

UK CE UNITS)

TOP

45 5/8"

115,881cm

43,900cm

17 1/4"

ENDFRONT

Compliance Declaration

Standard: UL197 File: KNGT.E17421

Standard: CSA-C22.2 No. 109 File: KNGT7.E17421

Standard: ANSI / NSF 4 File: TSQT.E157479

Directive 2006/95/EC:

EN60335 -1:2002, A1, A2, A11, A12

EN 60335-2-49:2003

WEEE RoHS Directive 2002/96/EC

Directive 89/336/EEC and 2004/108/EC:

EN61000-3-2 EN 55014-1

EN61000-3-3 EN55014-2

8

Installation and Operation of Product Holding Cabinets

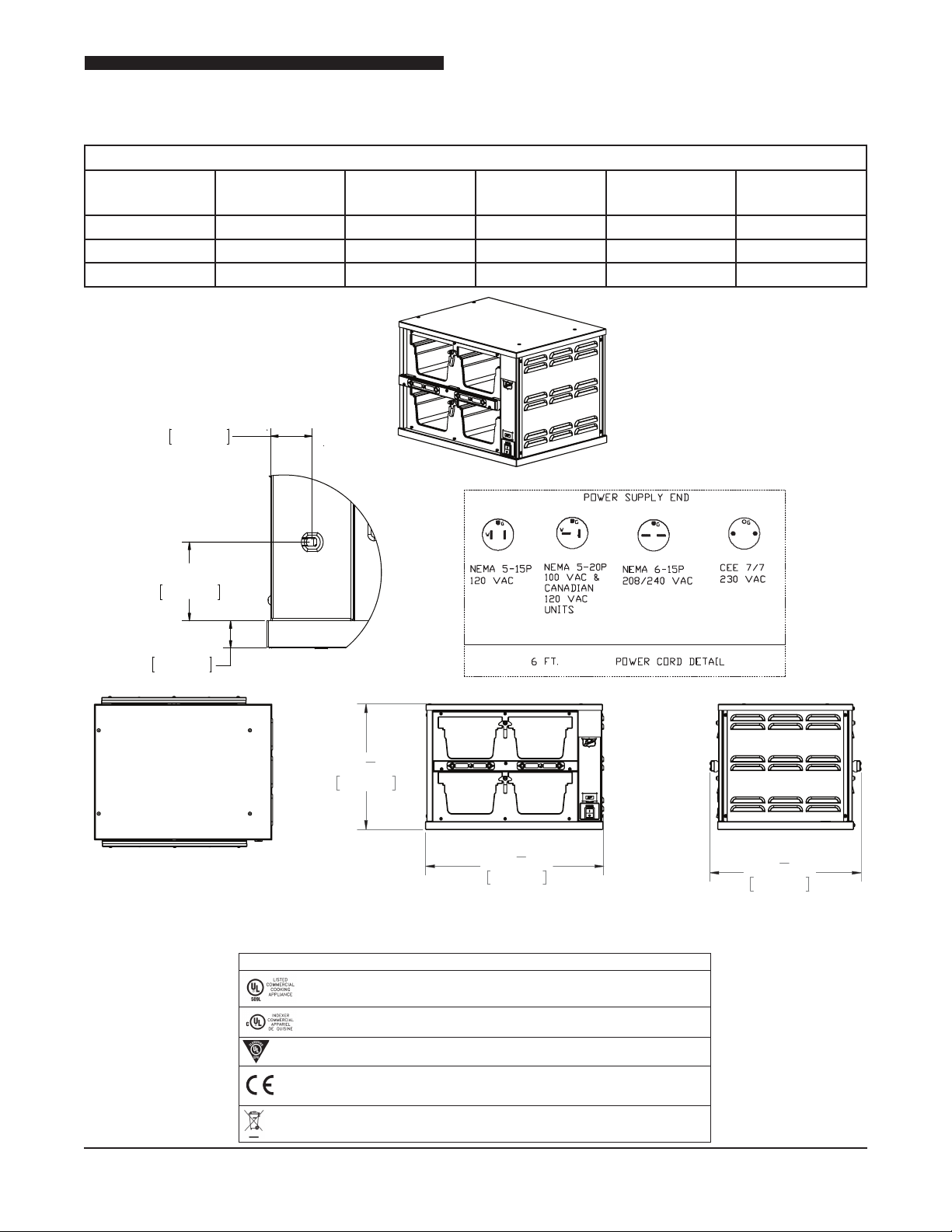

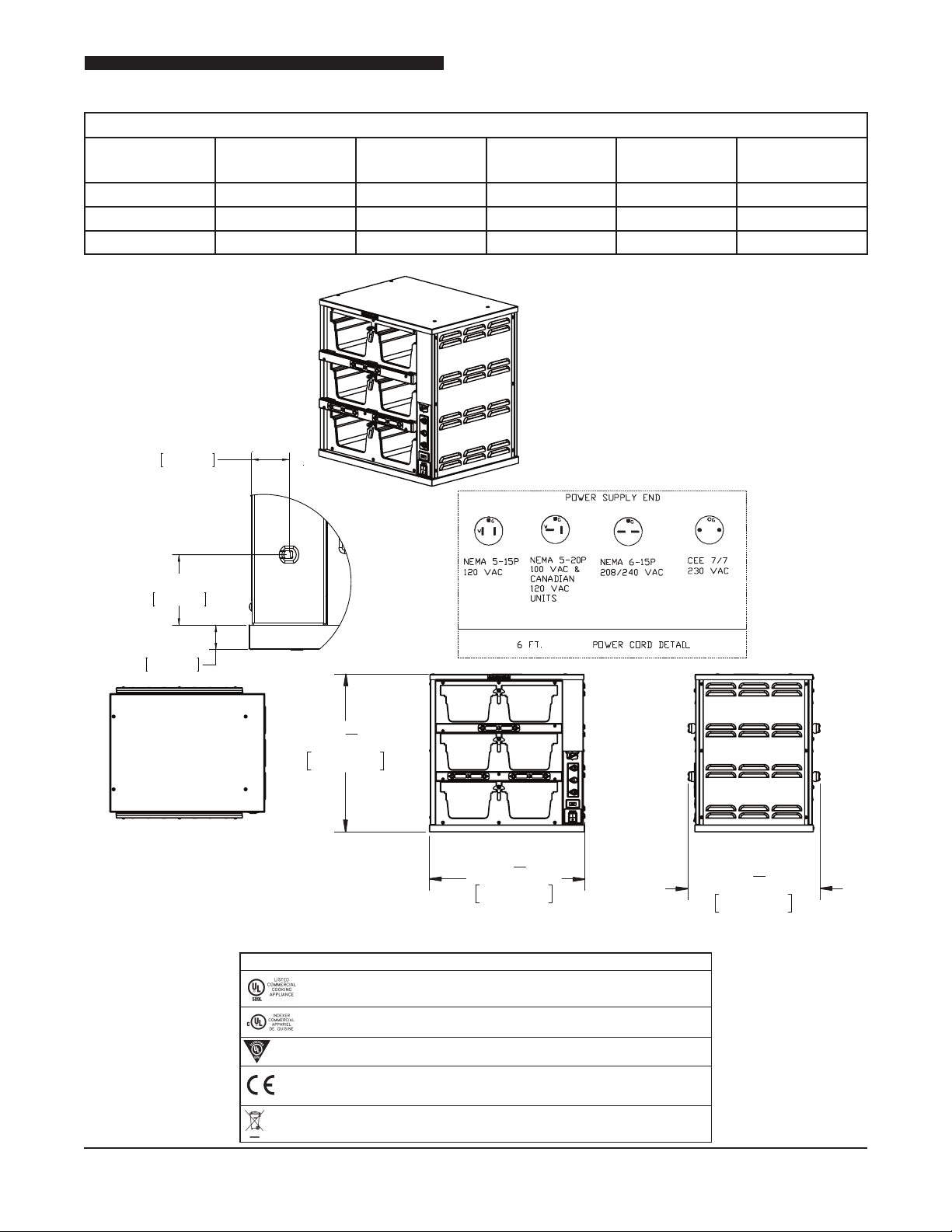

MODEL FWM34-22

MODEL SHIPPING

WEIGHT

FWM34-22-120 91 lbs (41,4 Kg) 120 800 7.0 (7,0) 60

FWM34-22-208 91 lbs (41, 4Kg) 208 1200 6.0 (6,0) 60

FWM34-22-230 91 lbs (41, 4Kg) 230 1200 5.0 (5,0) 50

AC Voltage

(V ~)

Watts

(W)

Amps

(A)

FREQUENCY

(Hz)

1 3/8”

3,6 cm

TOP

2 3/4”

6,9 cm

1 ”

2,4 cm

(US) (US/CAN)

5

"

14

8

37,196cm

3

"

20

4

52,776cm

Compliance Declaration

Standard: UL197 File: KNGT.E17421

Standard: CSA-C22.2 No. 109 File: KNGT7.E17421

(182,9cm)

(GERMANY,

FRANCE AND

UK CE UNITS)

44,762cm

ENDFRONT

17

5

"

8

Standard: ANSI / NSF 4 File: TSQT.E157479

Directive 2006/95/EC:

EN60335 -1:2002, A1, A2, A11, A12

EN 60335-2-49:2003

WEEE RoHS Directive 2002/96/EC

Directive 89/336/EEC and 2004/108/EC:

EN61000-3-2 EN 55014-1

EN61000-3-3 EN55014-2

9

Installation and Operation of Product Holding Cabinets

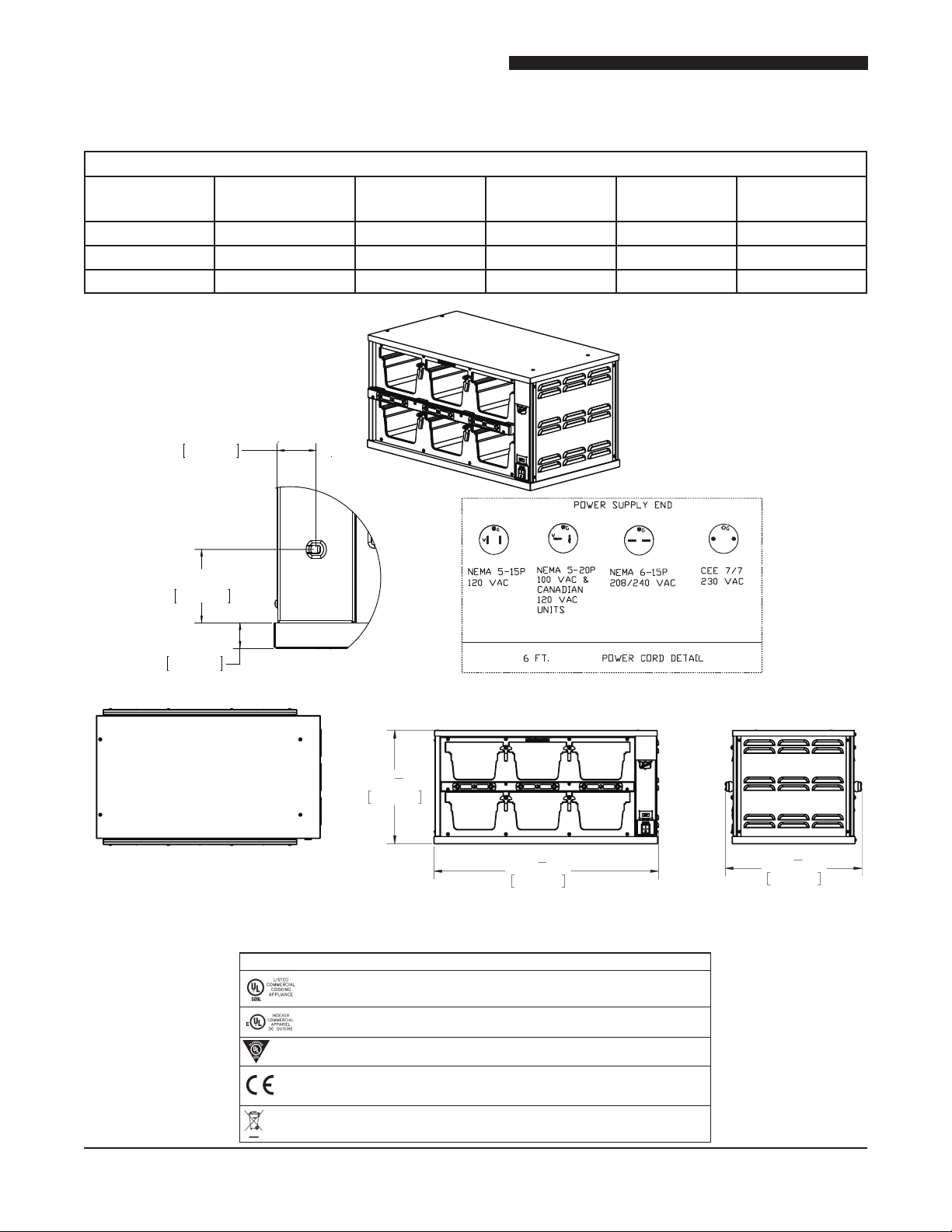

MODEL FWM34-23

MODEL SHIPPING

WEIGHT

FWM34-23-120 113 lbs (51,4Kg) 120 1200 10.0 (10,0) 60

FWM34-23-208 113 lbs (51,4Kg) 208 1800 9.0 (9,0) 60

FWM34-23-230 113 lbs (51,4Kg) 230 1800 8.0 (8,0) 50

1 3/8”

3,6 cm

AC Voltage

(V ~)

Watts

(W)

Amps

(A)

FREQUENCY

(Hz)

2 3/4”

6,9 cm

1 ”

2,4 cm

(US) (US/CAN)

(182,9cm)

5

"

14

8

37,196cm

7

"

73,495cm

Compliance Declaration

Standard: UL197 File: KNGT.E17421

Standard: CSA-C22.2 No. 109 File: KNGT7.E17421

28

8

(GERMANY,

FRANCE AND

UK CE UNITS)

17

44,762cm

ENDFRONTTOP

5

"

8

10

Standard: ANSI / NSF 4 File: TSQT.E157479

Directive 2006/95/EC:

EN60335 -1:2002, A1, A2, A11, A12

EN 60335-2-49:2003

WEEE RoHS Directive 2002/96/EC

Directive 89/336/EEC and 2004/108/EC:

EN61000-3-2 EN 55014-1

EN61000-3-3 EN55014-2

Installation and Operation of Product Holding Cabinets

MODEL FWM34-24

MODEL SHIPPING

WEIGHT

FWM34-24-120 149 lbs (67,6Kg) 120 1600 14.0 (14,0) 60

FWM34-24-208 149 lbs (67,6Kg) 208 2400 12.0 (12,0) 60

1 3/8”

3,6 cm

AC Voltage

(V ~)

Watts

(W)

Amps

(A)

FREQUENCY

(Hz)

2 3/4”

6,9 cm

1 ”

2,4 cm

(US) (US/CAN)

(182,9cm)

5

"

14

37,196cm

Standard: UL197 File: KNGT.E17421

Standard: CSA-C22.2 No. 109 File: KNGT7.E17421

8

Compliance Declaration

37

94,148cm

1

"

8

(GERMANY,

FRANCE AND

UK CE UNITS)

17

44,769cm

ENDFRONTTOP

5

"

8

Standard: ANSI / NSF 4 File: TSQT.E157479

Directive 2006/95/EC:

EN60335 -1:2002, A1, A2, A11, A12

EN 60335-2-49:2003

WEEE RoHS Directive 2002/96/EC

Directive 89/336/EEC and 2004/108/EC:

EN61000-3-2 EN 55014-1

EN61000-3-3 EN55014-2

11

Installation and Operation of Product Holding Cabinets

MODEL FWM34-31

MODEL SHIPPING

WEIGHT

FWM34-31-120 75 lbs (22,7 Kg) 120 600 6.0 (6,0) 60

FWM34-31-230 75 lbs (22,7 Kg) 230 900 5.0 (5,0) 50

1 3/8”

3,6 cm

2 3/4”

6,9 cm

AC Voltage

(V ~)

Watts

(W)

Amps

(A)

FREQUENCY

(Hz)

TOP

1 ”

2,4 cm

21

53,558cm

(US)

(182,9cm)

1

"

8

14

35,728cm

1

"

8

3

17

8

44,027cm

"

(GERMANY,

FRANCE AND

UK CE UNITS)

ENDFRONT

Compliance Declaration

Standard: UL197 File: KNGT.E17421

Standard: CSA-C22.2 No. 109 File: KNGT7.E17421

12

Standard: ANSI / NSF 4 File: TSQT.E157479

Directive 2006/95/EC:

EN60335 -1:2002, A1, A2, A11, A12

EN 60335-2-49:2003

WEEE RoHS Directive 2002/96/EC

Directive 89/336/EEC and 2004/108/EC:

EN61000-3-2 EN 55014-1

EN61000-3-3 EN55014-2

Installation and Operation of Product Holding Cabinets

TOPEND

MODEL FWM34-32

MODEL SHIPPING

WEIGHT

FWM34-32-120 113 lbs (51,4Kg) 120 1200 10.0 (10,0) 60

FWM34-32-208 113 lbs (51,4Kg) 208 1800 9.0 (9,0) 60

FWM34-32-230 113 lbs (51,4Kg) 230 1800 8.0 (8,0) 50

1 3/8”

3,6 cm

AC Voltage

(V ~)

Watts

(W)

Amps

(A)

FREQUENCY

(Hz)

2 3/4”

6,9 cm

1 ”

2,4 cm

FRONT

21

53,558cm

(US) (US/CAN)

(182,9cm)

1

"

8

20

3

"

4

52,776cm

Compliance Declaration

Standard: UL197 File: KNGT.E17421

Standard: CSA-C22.2 No. 109 File: KNGT7.E17421

(GERMANY,

FRANCE AND

UK CE UNITS)

44,762cm

17

5

"

8

Standard: ANSI / NSF 4 File: TSQT.E157479

Directive 2006/95/EC:

EN60335 -1:2002, A1, A2, A11, A12

EN 60335-2-49:2003

WEEE RoHS Directive 2002/96/EC

Directive 89/336/EEC and 2004/108/EC:

EN61000-3-2 EN 55014-1

EN61000-3-3 EN55014-2

13

Installation and Operation of Product Holding Cabinets

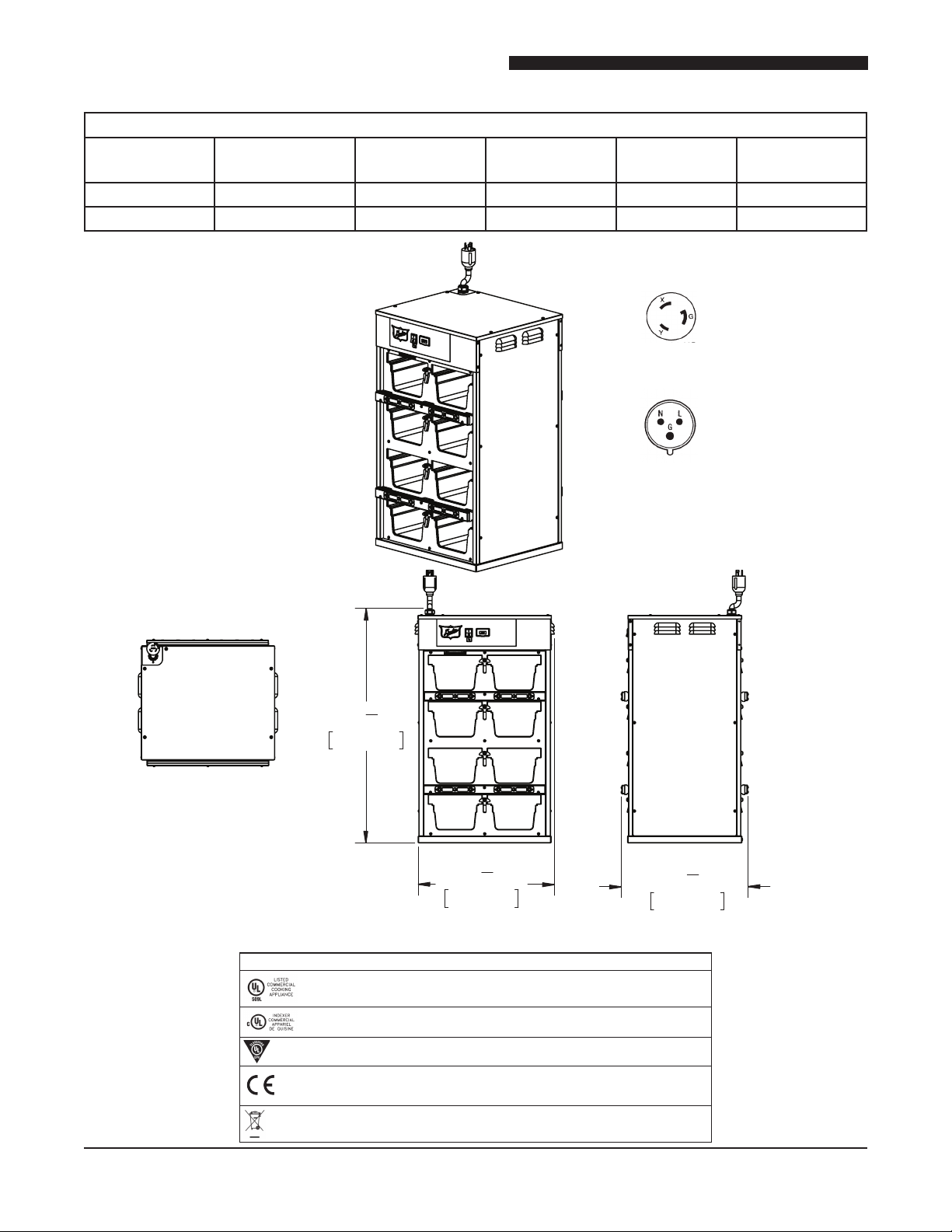

MODEL FWM34-42

MODEL SHIPPING

WEIGHT

FWM34-42-208 145 lbs (65,9Kg) 208 2400 12.0 (12,0) 60

FWM34-42-230 145 lbs (65,9Kg) 230 2400 10.0 (10,0) 50

AC Voltage

(V ~)

Watts

(W)

Amps

(A)

L6-20P

Twist Lock Plug

208V

(US/CAN)

FREQUENCY

(Hz)

FRONT

32

82,418cm

17

5

"

8

IEC 60309

3 Pin & Sleeve Plug

230V

(GERMANY, FRANCE AND UK CE UNITS)

1

"

2

7

"

18

8

47,854cm

44,769cm

14

Compliance Declaration

Standard: UL197 File: KNGT.E17421

Standard: CSA-C22.2 No. 109 File: KNGT7.E17421

Standard: ANSI / NSF 4 File: TSQT.E157479

Directive 2006/95/EC:

EN60335 -1:2002, A1, A2, A11, A12

EN 60335-2-49:2003

WEEE RoHS Directive 2002/96/EC

Directive 89/336/EEC and 2004/108/EC:

EN61000-3-2 EN 55014-1

EN61000-3-3 EN55014-2

TOPEND

Loading...

Loading...