Page 1

- 1 -

D

K

A

E

U

N

Apppplliiccaattiioonn

A

Noottee

N

Intelligent Assembly Solutions

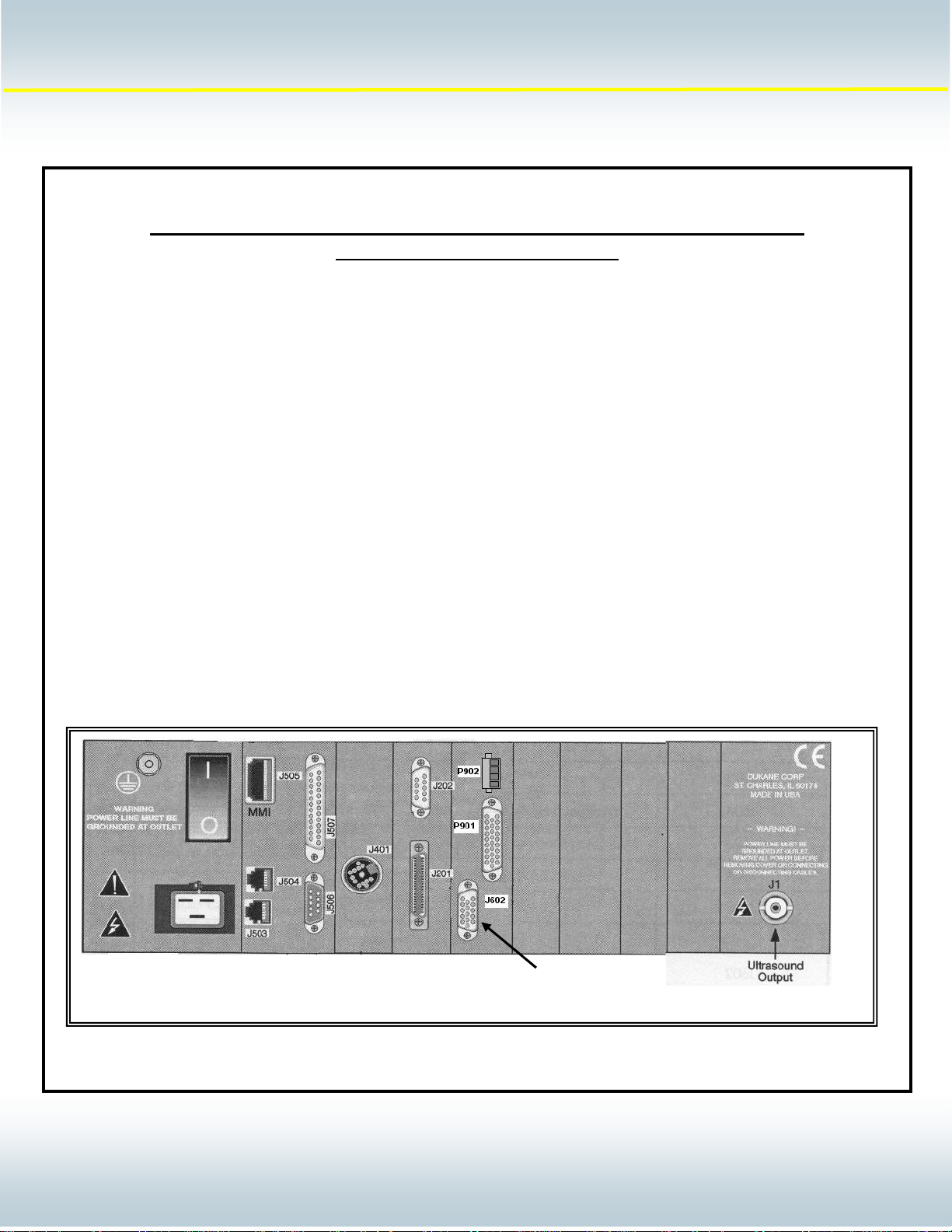

The DPC 4 welding system offers several features that are intended to communicate with automation. These features

allow the automation to control and respond to events that occur during the welding process. This document will provide

guidelines that will help you interface automation to a DPC welding system per Dukane Corporation’s requirements.

Information within this document is intended to supplement the information in the DPC 4 manual (Dukane part # 403-557).

Automation Interface Requirements for J602 Basic I/O Interface

of a DPC 4 Welding System

Note: Early production models of the DPC IV welding system referred to J602 as the User I/O interface. The

functionality of the Basic I/O Interface and the User I/O Interface are identical. Only the name has changed.

Application Note Topics:

• The J602 Pin assignments

• The 200-1203 Basic Interface Cable

• Status Output Signal Descriptions

• Status Output Interface Examples

• System Input Signal Descriptions

• System Input Interface Examples

Basic I/O

Interface

AN400

© Dukane Corporation 2004. All rights reserved.

Dukane Corporation

2900 Dukane Drive Saint Charles, IL 60174 USA

Phone (630) 797-4900 FAX (630) 797-4949

http://www.dukane.com/us

11101

1

Page 2

- 2 -

D

K

A

E

y

d

)

)

d

U

N

Apppplliiccaattiioonn

A

Noottee

N

Intelligent Assembly Solutions

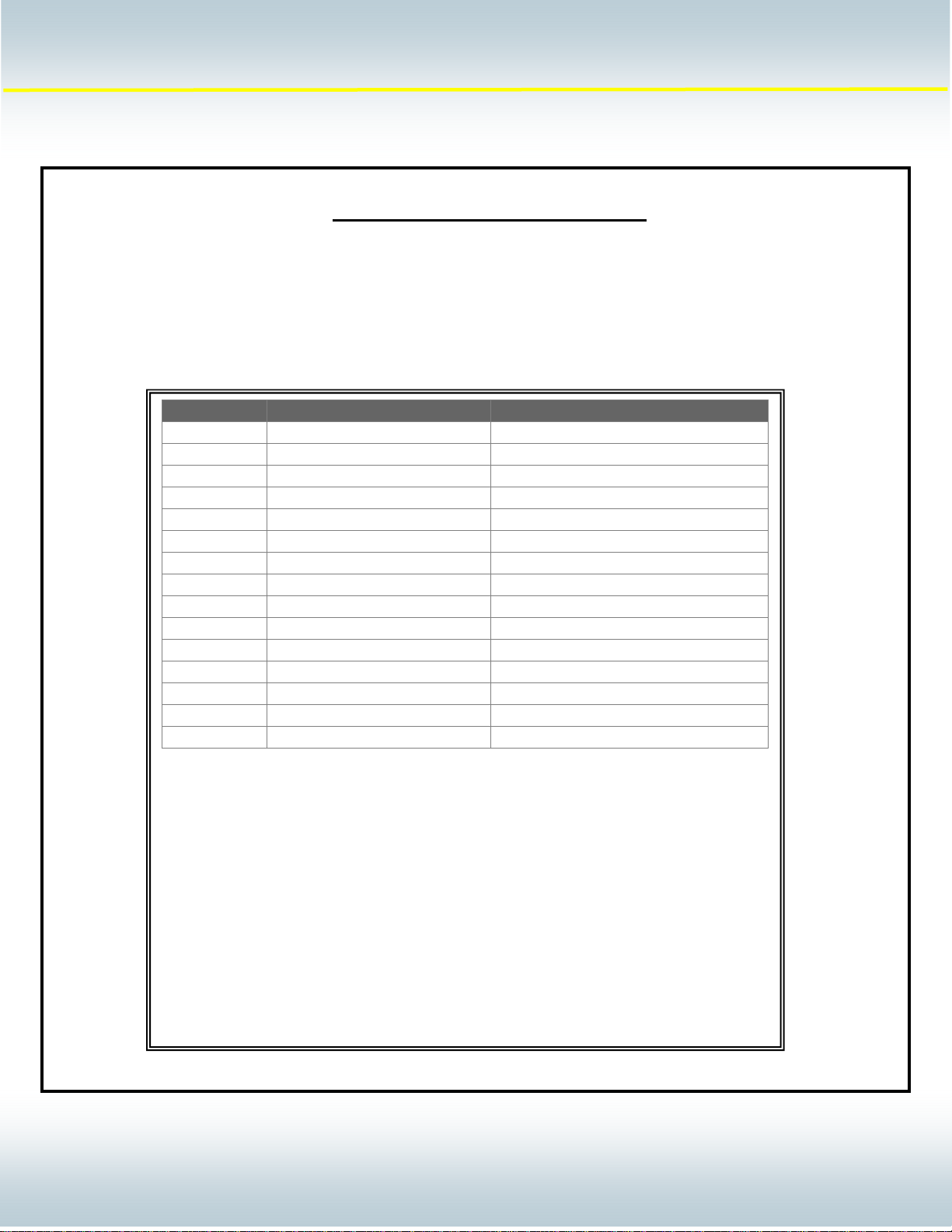

The J602 User Interface connector is the primary communications link between the DPC IV and user automation

equipment. This connector provides status signals that can be used to monitor DPC weld data analysis resu lts as well

as timing issues related to the processing of the weld sequence. It also provides the automation with dedicated

communication lines that allows the automation to control the beginning and the end of a welding sequence.

Pin Number DPC Signal Name DPC Signal Type

1 Power Suppl

2 Groun

3 Bad Part Output

4 Suspect Part (see note #2

5 Good Part Output

6 Ready (see note #1

7 Isolated Output Common Common Pin for Output Signals

8 Automation Input Input

9 Automation Stop N/C Input

10 Automation Stop N/O Input

11 Hand Probe Press Inhibit Input

12 Input Common Common Pin for Input Signals

13 Groun

14

15 Ground Detect Input

Note #1: This input can be reconfigured in the DPC IV menu choices to activate during

the following weld sequence event:

In Cycle

Sonics On

In Hold

Note #2: This input can be reconfigured in the DPC IV menu choices to activate during

the following weld sequence event:

Network Active

Sonics On

Note: Please refer to the Hardware Setup section of the DPC IV manual for details on

reconfiguring pin 4 or pin 6 to the required status output signal.

J602 User Interface Connector

+22 VDC (0.5 amp max)

Power Supply Return

Output

Output

Power Supply Return

AN400

© Dukane Corporation 2004. All rights reserved.

Dukane Corporation

2900 Dukane Drive Saint Charles, IL 60174 USA

Phone (630) 797-4900 FAX (630) 797-4949

http://www.dukane.com/us

22102

2

Page 3

- 3 -

D

K

A

E

U

N

Apppplliiccaattiioonn

A

Noottee

N

Intelligent Assembly Solutions

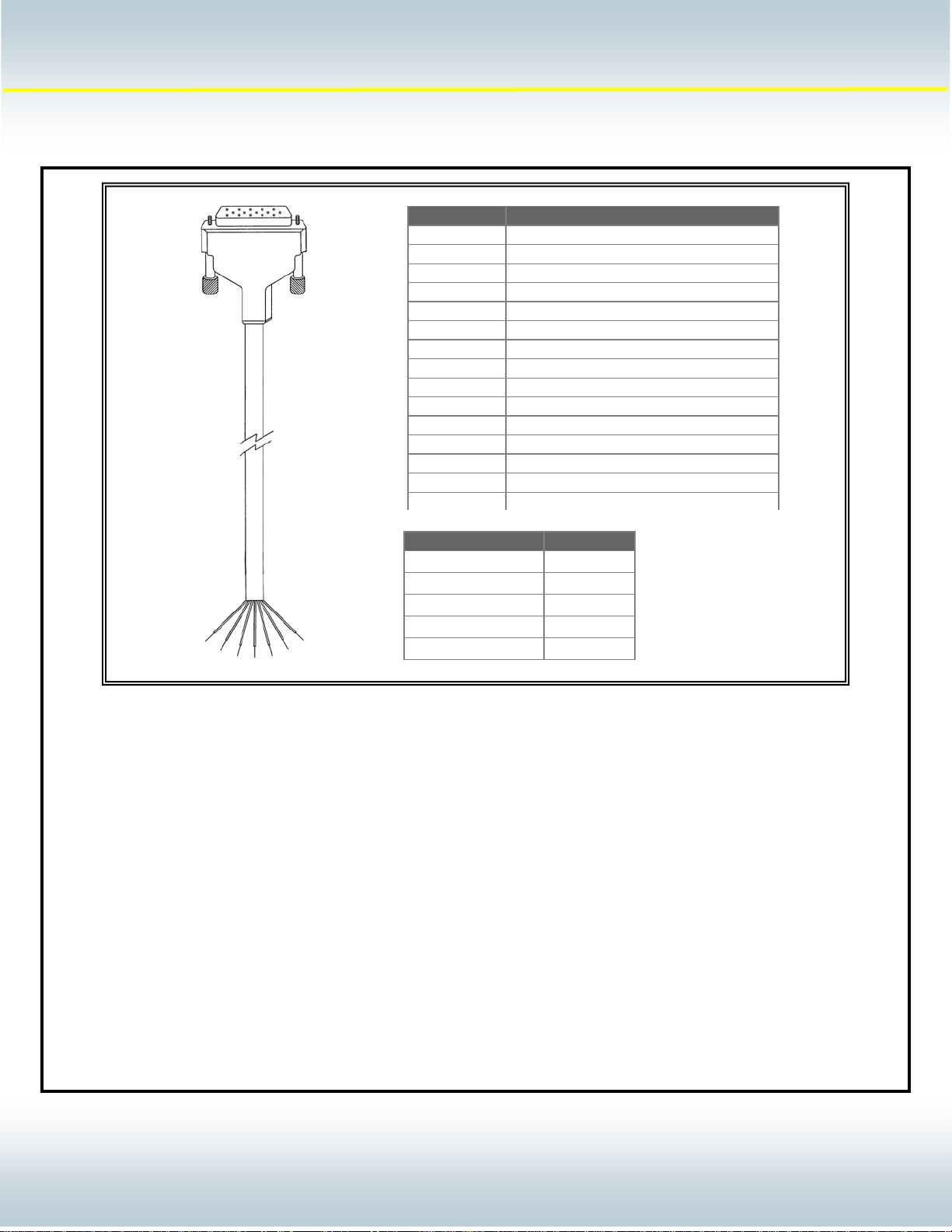

Status Output signals for the J602 Connector:

There are four status output signals available on the J602 connector. Each of these outputs are driven by a solid state

relay that creates a switch closure between the specified output pin and the Output Common pin. These pins can be

configured within the DPC software menus to provide a signal that accommodates the requirements of most automation

interface equipment. The available configurations for these output signals are:

Note: Please refer to the Hardware menu section of the DPC IV manual for further information on these features.

Active High Outputs – This setting will produce a closed switch condition between the spe cified outp ut pin and

the Output Common pin when the output signal is activated. (Factory default setting)

Active Low Outputs - This setting will produce an open switch condition between the specified output pin and

the Output Common pin when the output signal is activated.

Maintained Outputs - This setting will produce an output signal that is maintained from the completion of a

welding cycle until the beginning of the next welding cycle activation. (Factory default

setting)

Pulsed Outputs - This setting will produce an output signal that is pulsed a single time for 100 mS as the

end of the welding cycle.

Pin # Conductor Color

1 Red

2 Black

3 Blue / Black

4 Green / White

5 Blue / White

6 Red / Black

7 White / Black

8 White

9 Orange

10 Blue

11 Orange / Black

12 Red / White

13 Green Black

14 Black / White

15 Green

Part Number Length

200-1203 10 FT

200-1203-15 15 FT

200-1203-20 20 FT

200-1203-25 25 FT

200-1203-30 30 FT

AN400

© Dukane Corporation 2004. All rights reserved.

Dukane Corporation

2900 Dukane Drive Saint Charles, IL 60174 USA

Phone (630) 797-4900 FAX (630) 797-4949

http://www.dukane.com/us

33103

3

Page 4

- 4 -

D

K

A

E

U

N

Apppplliiccaattiioonn

A

Noottee

N

Intelligent Assembly Solutions

Status Output Signal Descriptions:

Bad Part Output – (J602 pin 3) This status output will activate when the data acquired during the welding sequence

exceeds one of the user defined boundaries within the Bad Part Limits portion of the user setup.

Please refer to the Process Limits section of the DPC IV manual for further details on selecting

and setting up a Bad Part Limit window.

Good Part Output - (J602 pin 5) This status output will activate when the data acquired during the welding sequence

does not exceed any of the user defined boundaries within the Bad Part Limits portion of the user

setup. Please refer to the Process Limits section of the DPC IV manual for further details on

selecting and setting up a Bad Part Limit window.

Suspect Part Output - (J602 pin 4) This status output will activate when the data acquired during the welding sequence

exceeds one of the user defined boundaries within the Suspect Part Limits portion of the user

setup. Please refer to the Process Limits section of the DPC IV manual for further details on

selecting and setting up a Suspect Part Limit window.

In Cycle (J602 pin 4 redefined) - This status output will activate when the welding cycle begins. If

the status outputs have been set for maintained, In Cycle will deactivate when the Hold portion of

the welding cycle has completed. Please refer to the Hardware Setup section of the DCP IV

manual for further details on redefining J602 pin 4.

Sonics On (J602 pin 4 redefined) – This status output will activate when the DP C produces the

ultrasound welding signal that creates motion in the transducer stack assembly. Activation of this

signal will occur during the Weld, Scrub, and Afterburst portions of the weld cycle. Please refer to

the Hardware Setup section of the DCP IV manual for further details on redefining J602 pin 4.

In Hold (J602 pin 4 redefined) – This status output will activate when the DPC is processing the

Hold portion of the welding cycle. Please refer to the Hardware Setup section of the DCP IV

manual for further details on redefining J602 pin 4.

Ready Output - (J602 pin 6) This status output will activate at the completion of the Hold portion of the welding

sequence. It should be noted that the activation of the Afterburst feature and the return of the

pneumatic press to the home position will occur after the activation of the Ready Output status

signal. Please refer to the Process Control section of the DPC IV manual for further information

on the activation and use of the Afterburst feature. In addition please refer to the Hardware Setup

section of the DCP IV manual for further details on redefining J602 pin 6.

Network Active (J602 pin 6 redefined) – This status output will activate when the DPC is an active

node on a DPC network. Please refer to the Network section of the DPC IV manual for further

details on setting up a DPC network. Please refer to the Hardware Setup section of the DCP IV

manual for further details on redefining J602 pin 6.

Sonics On (J602 pin 6 redefined) – This status output will activate when the DPC produces the

ultrasound welding signal that creates motion in the transducer stack assembly. . Please refer to

the Hardware Setup section of the DCP IV manual for further details on redefining J602 pin 6.

AN400

© Dukane Corporation 2004. All rights reserved.

Dukane Corporation

2900 Dukane Drive Saint Charles, IL 60174 USA

Phone (630) 797-4900 FAX (630) 797-4949

http://www.dukane.com/us

44104

4

Page 5

- 5 -

D

K

A

E

y

U

N

Apppplliiccaattiioonn

A

Noottee

N

Intelligent Assembly Solutions

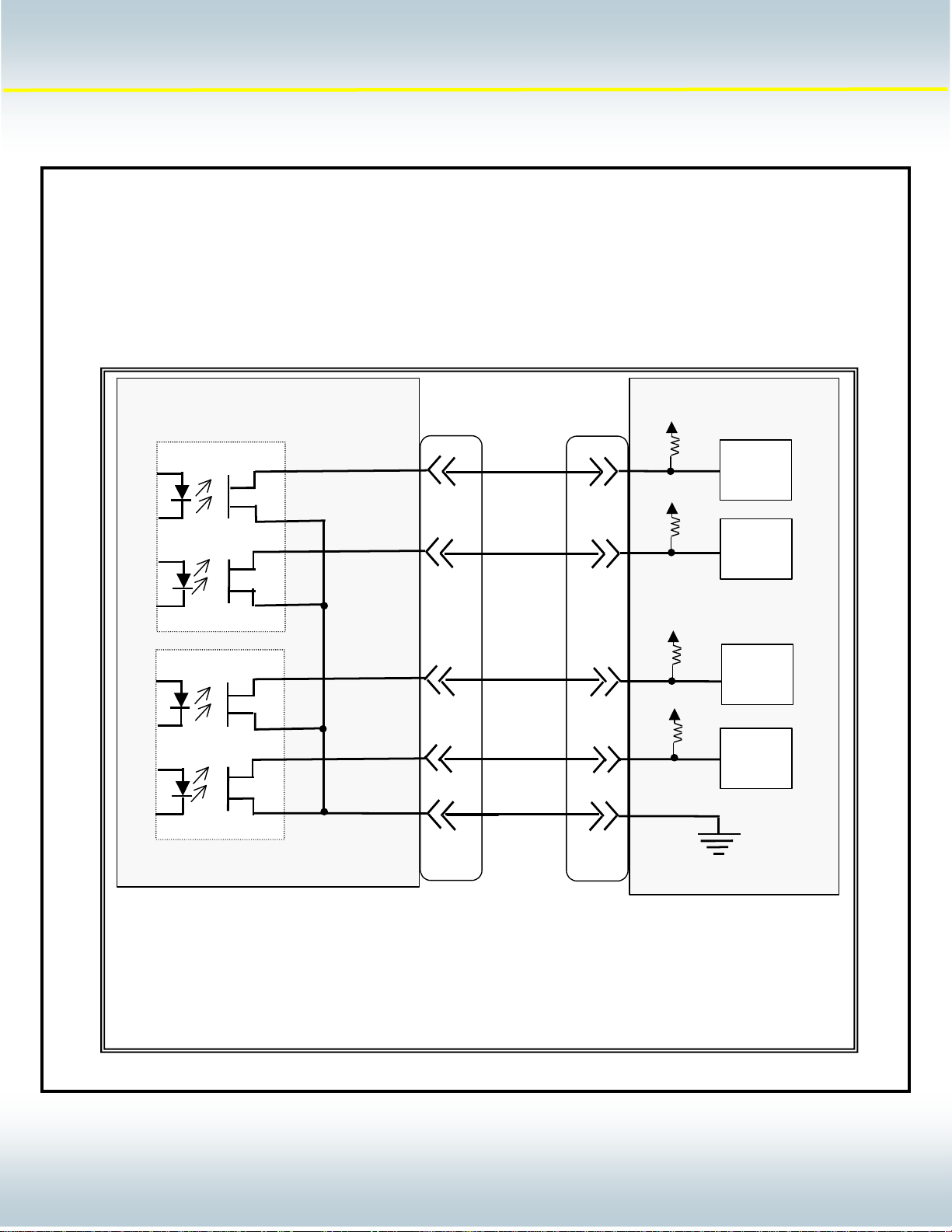

The DPC status output pins can be configured to adapt to several types of automated devices. The ratings for the DPC

Status output pins are:

Maximum Voltage Rating = +24 VDC

Maximum Current Rating = 100 mA

Status Output Interface Examples:

DPC IV

Bad Part

Suspect

Part

3

4

+ 24 VDC

Input

Device

Input

Device

AN400

Good Part

Read

Output

Common

DPC IV status output configuration for use with a PLC requiring sinking inputs.

5

6

7

J602

200-1203

Cable

Input

Device

Input

Device

PLC

© Dukane Corporation 2004. All rights reserved.

Dukane Corporation

2900 Dukane Drive Saint Charles, IL 60174 USA

Phone (630) 797-4900 FAX (630) 797-4949

http://www.dukane.com/us

55105

5

Page 6

- 6 -

D

K

A

E

U

N

Apppplliiccaattiioonn

A

Noottee

N

Intelligent Assembly Solutions

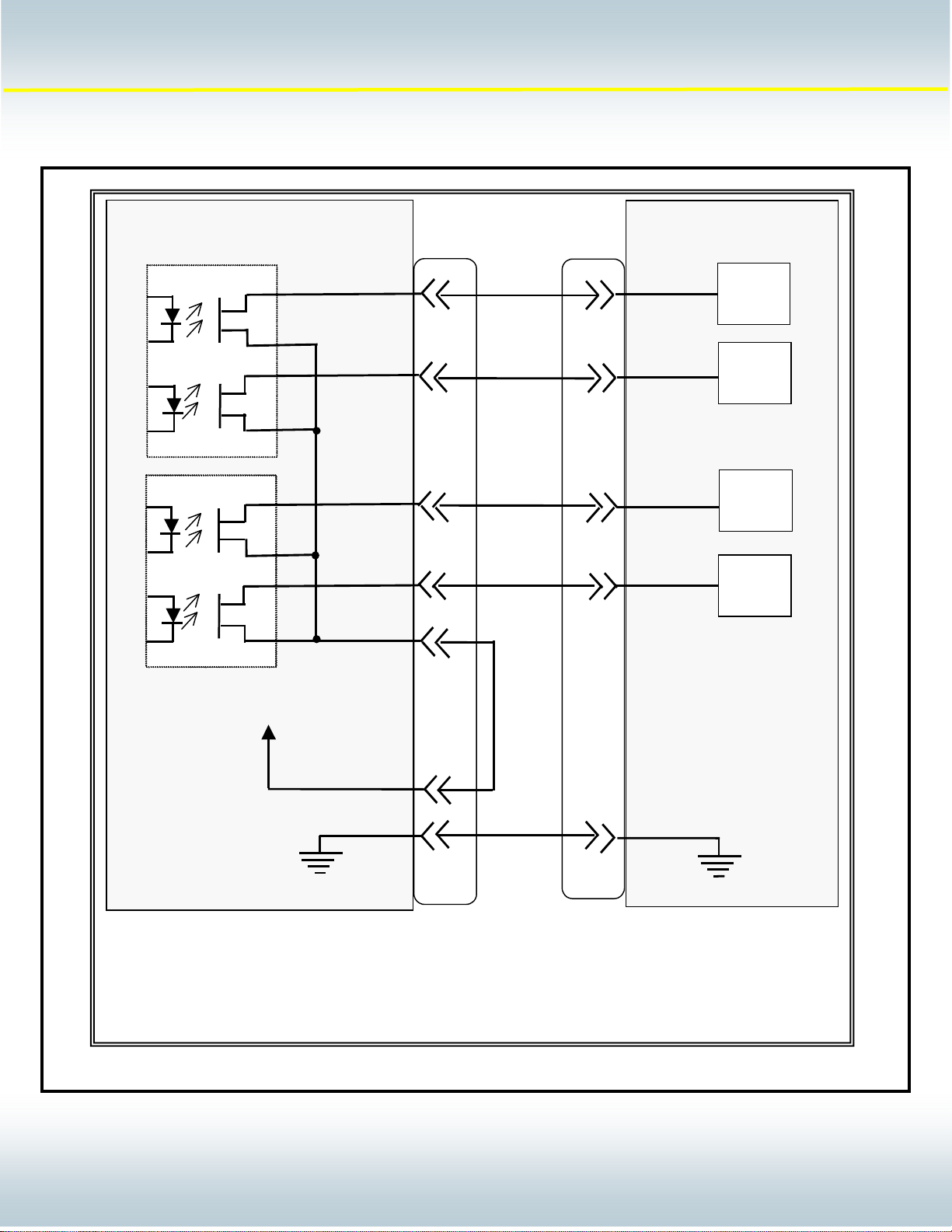

DPC IV

Bad Part

Suspect

Good Part

Part

AN400

3

4

5

Input

Device

Input

Device

Input

Device

Ready

Output

Common

+ 22 VDC

Power Supply

Ground

DPC IV status output configuration for use with a PLC requiring sourced inputs.

6

7

J602

Input

Device

1

2

PLC

200-1203

Cable

© Dukane Corporation 2004. All rights reserved.

Dukane Corporation

2900 Dukane Drive Saint Charles, IL 60174 USA

Phone (630) 797-4900 FAX (630) 797-4949

http://www.dukane.com/us

66106

6

Page 7

- 7 -

D

K

A

E

y

y

U

N

Apppplliiccaattiioonn

A

Noottee

N

Intelligent Assembly Solutions

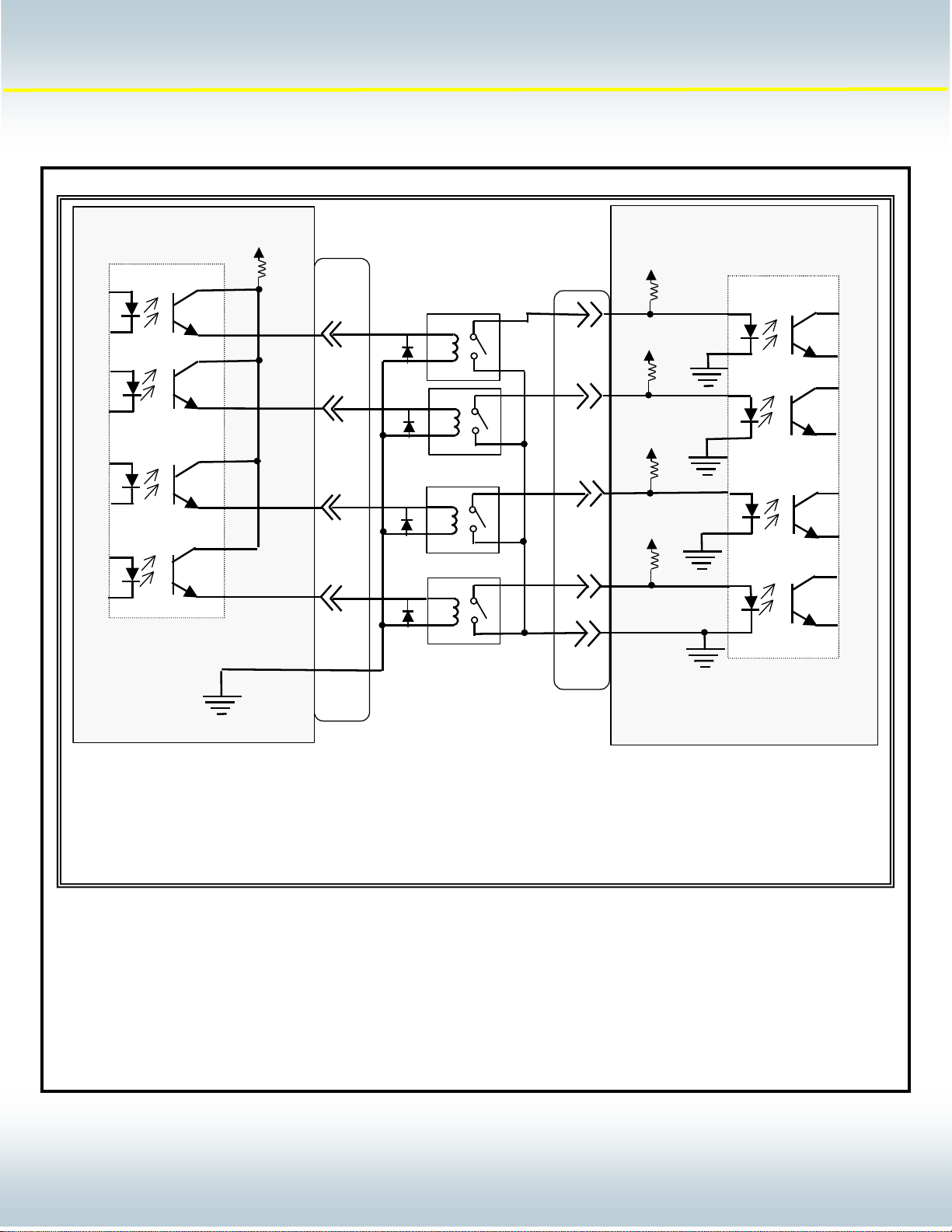

DPC IV

Good Part

Bad Part

Suspect

Part

AN400

3

Customer

Device

4

Customer

Device

5

Customer

Device

J602

6

Customer

7

1

2

200-1203

Cable

Device

Read

Output

Common

+ 22 VDC

Power Supp l

Ground

DPC IV status output configuration for use when either isolation is required or

the customer device exceeds the maximum ratings of the DPC outputs.

© Dukane Corporation 2004. All rights reserved.

Dukane Corporation

2900 Dukane Drive Saint Charles, IL 60174 USA

Phone (630) 797-4900 FAX (630) 797-4949

http://www.dukane.com/us

77107

7

Page 8

- 8 -

D

K

A

E

U

N

Apppplliiccaattiioonn

A

Noottee

N

Intelligent Assembly Solutions

System Input signals for the J602 Connector:

There are four system input signals available on the J602 connector. Each of these inputs are configured as sinking

inputs ( Do not apply voltage to the J602 inputs).

Automation Input - (J602 pin 8) This system input signal is activated by an external dry contact closure to the DPC

Ground pin on J602 pin2). The minimum duration for the activation of this input is 100 mS. The

maximum duration of this input is determined by the duration of the weld cycle. This input should

be deactivated before the end of the weld cycle to avoid an error condition (Associated Error: #

212 Auto Active at Cycle Start). Please refer to the Initiate Mode section of the DPC IV manual

for details on the activation and use of the Auto Initiate mode.

Automation Stop N/O- (J602 pin 9) This system input signal is activated by an external dry contact closure to the DPC

Ground pin on J602 pin2). The minimum duration for the activation of this input is 100 mS.

Activation of this input will end the welding cycle and deactivate all valves in the press. This

system response will continue until the contact closure to the DPC ground is removed. Weld

cycles that have been stopped due to the activation of this input will not be counted in the part

count value displayed on the DPC. Please refer to the Initiate Mode section of the DPC IV

manual for details on the activation and use of the Automation Stop mode (Auto Abort).

Automation Stop N/C- (J602 pin 10) This system input signal is activated by an removing an external dry contact closure

to the DPC Ground pin on J602 pin2). The minimum duration for the activation of this input is 100

mS. Activation of this input will end the welding cycle and deactivate all valves in the press. This

system response will continue until the contact closure to the DPC ground is replaced. Weld

cycles that have been stopped due to the activation of this input will not be counted in the part

count value displayed on the DPC. Please refer to the Initiate Mode section of the DPC IV

manual for details on the activation and use of the Automation Stop mode (Auto Abort).

Hand Probe Press Inhibit - (J602 pin 11) This system input is activated by an external dry contact closure to the DPC

Ground pin on J602 pin2). The minimum duration for the activation of this input is 100 mS.

Activation of this input is intended to configure the DPC for a probe system functionality. It will

deactivate all valves for the press during a welding cycle. This system response will continue until

the contact closure to the DPC ground is removed.

AN400

© Dukane Corporation 2004. All rights reserved.

Dukane Corporation

2900 Dukane Drive Saint Charles, IL 60174 USA

Phone (630) 797-4900 FAX (630) 797-4949

http://www.dukane.com/us

88108

8

Page 9

- 9 -

D

K

A

E

A

A

A

U

N

Apppplliiccaattiioonn

A

Noottee

N

Intelligent Assembly Solutions

The DPC system inputs are configured for a dry contact closure activation. The following connection diagram indicates

how to interface automation to the system inputs.

System Input Interface Examples:

PLC

200-1203

Cable

8

9

+ 24 VDC

uto Initiate

utomation Stop

N/O

AN400

10

utomation Stop

11

Hand Probe

2

Output

Common

DPC IV system input configuration for use when customer equipment provides contact

closure signals with not voltage.

J602

Press Inhibit

DPC IV

© Dukane Corporation 2004. All rights reserved.

Dukane Corporation

2900 Dukane Drive Saint Charles, IL 60174 USA

Phone (630) 797-4900 FAX (630) 797-4949

http://www.dukane.com/us

99109

9

Page 10

- 10 -

D

K

A

E

A

A

A

/C

U

N

Apppplliiccaattiioonn

A

Noottee

N

Intelligent Assembly Solutions

PLC

+ 24 VDC

200-1203

Cable

AN400

DPC IV

+ 24 VDC

8

uto Initiate

9

utomation Stop

N/O

10

utomation Stop

N

11

2

Output

Common

DPC IV system input configuration for use when customer equipment sources

voltage to the DPC inputs.

Hand Probe

Press Inhibit

J602

© Dukane Corporation 2004. All rights reserved.

Dukane Corporation

2900 Dukane Drive Saint Charles, IL 60174 USA

Phone (630) 797-4900 FAX (630) 797-4949

http://www.dukane.com/us

10101010

10

Loading...

Loading...