Dukane AN200 User Manual

- 1 -

D

K

A

E

U

N

Apppplliiccaattiioonn

A

Noottee

N

Intelligent Assembly Solutions

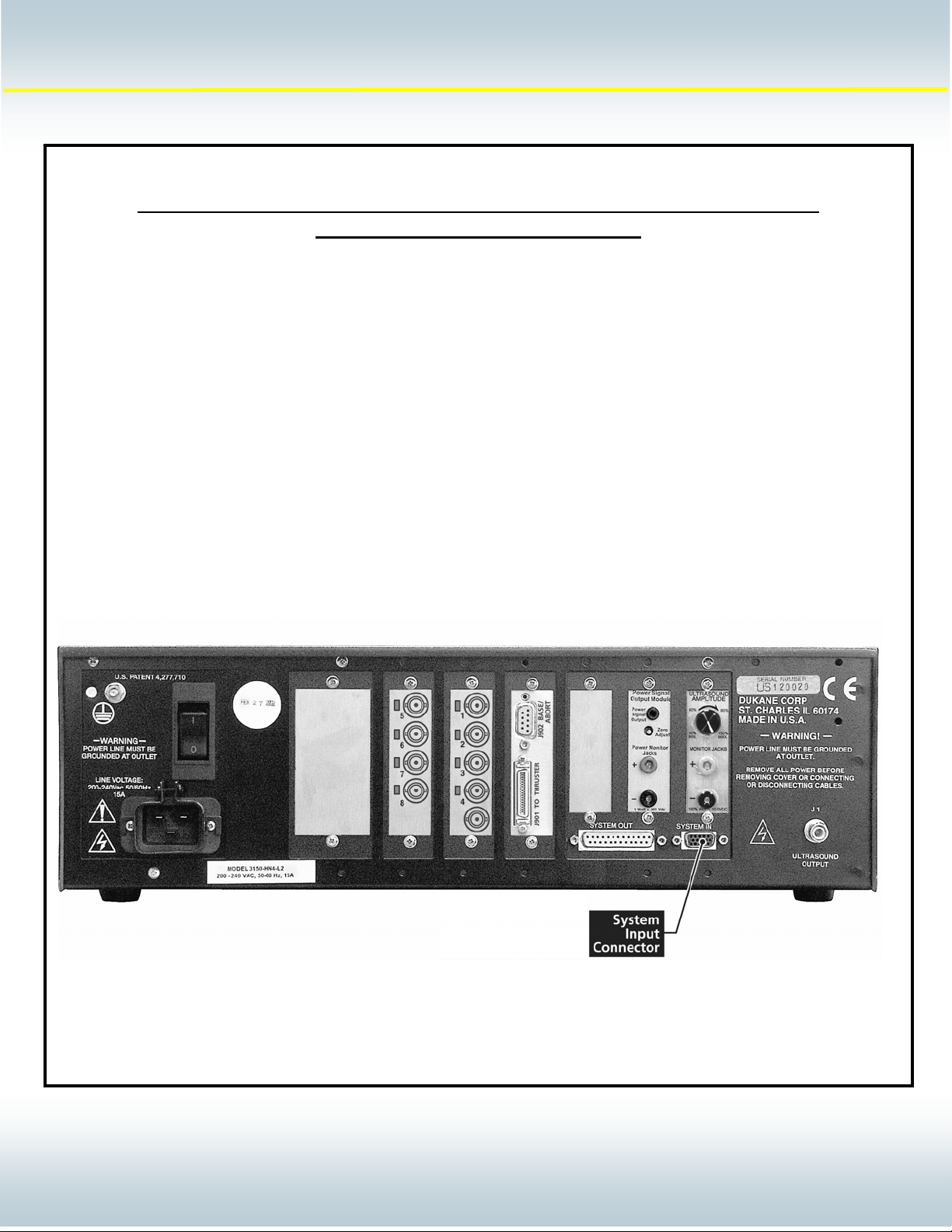

The DPC II / II+ welding system offers several features that are intended to communicate with automation. These features

allow the automation to control events that occur during the welding process. This document will provide guidelines that

will help you interface automation to a DPC welding system per Dukane Corporation’s requirements. Information within

this document is intended to supplement the information in the DPC II (Dukane part # 403-558) and DPC II+ (Dukane part

# 403-551)manuals.

Automation Interface Requirements for the System Input Interface

of a DPC II / II+ Welding System

Application Note Topics:

• The System In Connector Pin assignments

• The 200-1203 Basic Interface Cable

• System Input Signal Descriptions

• System Input Interface Examples

AN200

Rev 01

© Dukane Corporation 2003. All rights reserved.

Dukane Corporation

2900 Dukane Drive Saint Charles, IL 60174 USA

Phone (630) 797-4900 FAX (630) 797-4949

http://www.dukane.com/us

11101

1

- 2 -

D

K

A

E

y

U

N

Apppplliiccaattiioonn

A

Noottee

N

Intelligent Assembly Solutions

1

The System In interface connector is one of the primary communications links between the DPC II / II+ input port and

the user automation equipment. This connector provides the automation with dedicated communication lines that

allow the automation to control the beginning and the end of a welding sequence.

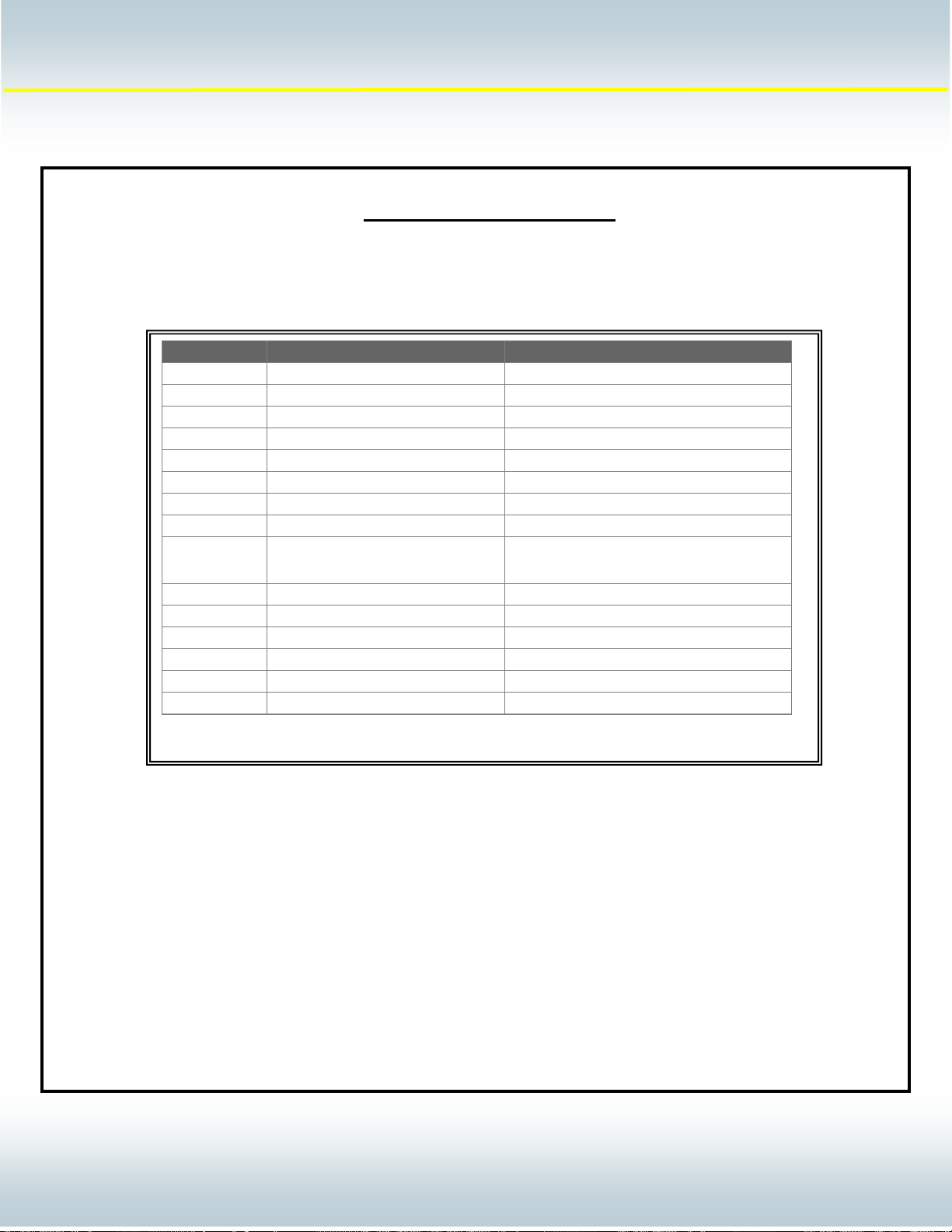

Pin Number DPC Signal Name DPC Signal Type

1 Power Suppl

2 Ground 22VDC Return

3 Isolated Operate Input Input

4 Isolated Input Common

5 Isolated Press Control

6 Not Used Not Used

7 Ground +22VDC Return

8 Non Isolated Operate Input

9 Isolated Automation Stop /

Automation End of Weld 3

10 Not Used Not Used

11 Hand Probe Press Inhibit Input

12 MPC Probe/Setup Bit 0

13 MPC Probe/Setup Bit 1

14 MPC Probe/Setup Bit 2

15 Front Panel Control Lock Input

System Input Connector

1

2

4

4

4

+22 VDC (250 mA max)

Common for pin 3, 5, 9

Input

Input

Input

Input

Input

AN200

Rev 01

Notes:

1. SH707 on the 110-3606 system I/O PCB must be configured to the JU728 position when this

common is used.

2. This input requires the optional 110-3938 press control module. Configuration of the SH901

Jumper on the 110-3938 press control module may also be required.

3. This input is configured for use as Automation End of Weld at the factory. Jumper SH704 must

be reconfigured on the 110-3606 System I/O board to permit use of the Isolated Automation

Stop feature.

4. The MPC probe bit functionality requires the optional MPC feature. The Setup bit functionality

is available on all DPC II+ systems. Please refer to the DPC manual for further details on this

feature.

© Dukane Corporation 2003. All rights reserved.

Dukane Corporation

2900 Dukane Drive Saint Charles, IL 60174 USA

Phone (630) 797-4900 FAX (630) 797-4949

http://www.dukane.com/us

22102

2

- 3 -

D

K

A

E

U

N

Apppplliiccaattiioonn

A

Noottee

N

Intelligent Assembly Solutions

AN200

Rev 01

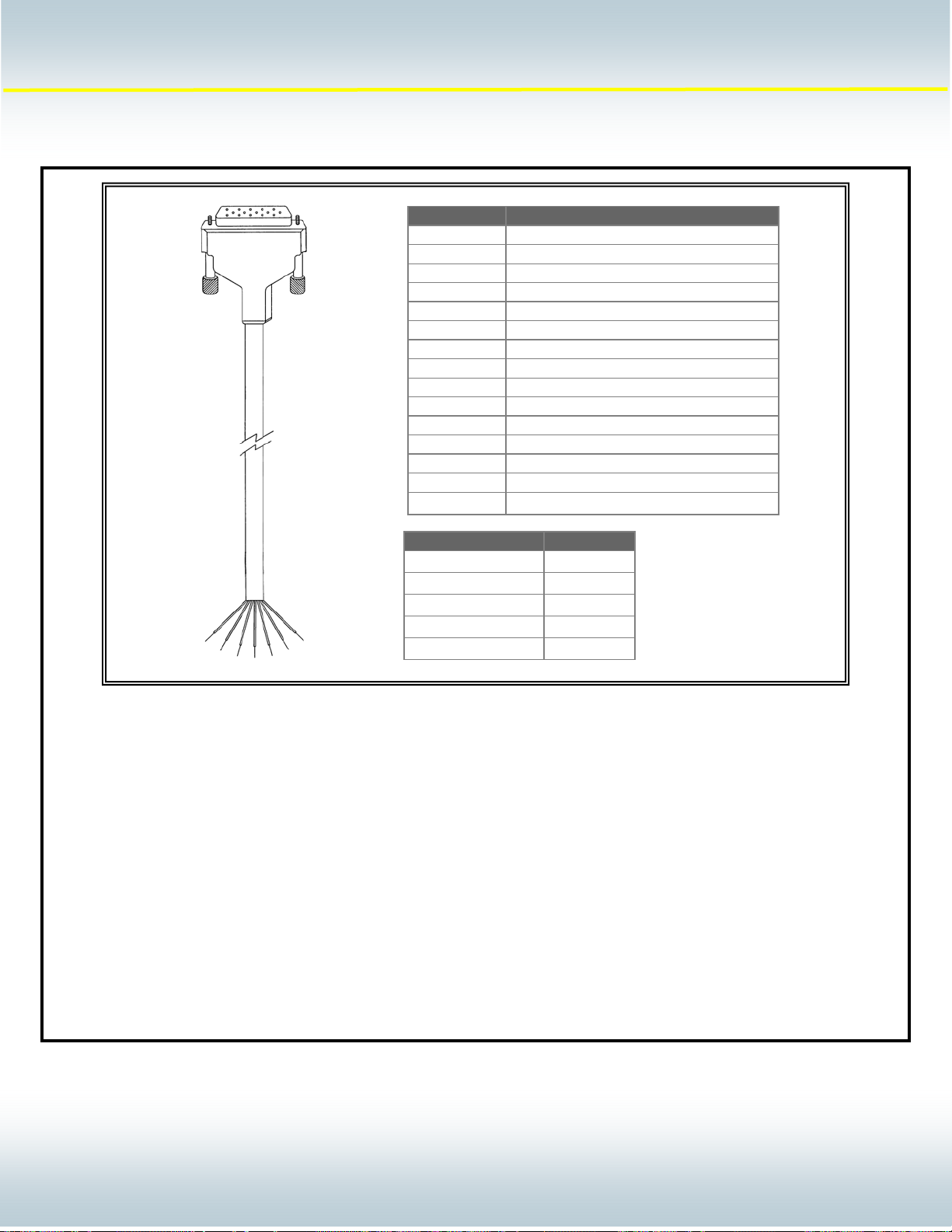

Pin # Conductor Color

1 Red

2 Black

3 Blue / Black

4 Green / White

5 Blue / White

6 Red / Black

7 White / Black

8 White

9 Orange

10 Blue

11 Orange / Black

12 Red / White

13 Green / Black

14 Black / White

15 Green

Part Number Length

200-1203 10 FT

200-1203-15 15 FT

200-1203-20 20 FT

200-1203-25 25 FT

200-1203-30 30 FT

© Dukane Corporation 2003. All rights reserved.

Dukane Corporation

2900 Dukane Drive Saint Charles, IL 60174 USA

Phone (630) 797-4900 FAX (630) 797-4949

http://www.dukane.com/us

33103

3

Loading...

Loading...