Page 1

CAUTION!

This manual contains important information for the correct installation, operation and maintenance of the equipment

described herein. All persons involved in such installation, operation, and maintenance should be thoroughly familiar with

the contents. To safeguard against the possibility of personal injury or property damage, follow the recommendations and

instructions of this manual and keep it for further reference.

WARNING!

The equipment shown in this manual is intended for industrial use only and should not be used to lift, support, or otherwise

transport people unless authorized in writing by Duff-Norton.

Page 2

TABLE OF CONTENTS

PAGE

SECTION I

1-1

1-2

1-3

1-4

TABLE 1-4

TABLE 1-4-1

1-5

FIGURE 1-6

SECTION II

2-1

2-2

2-3

2-4

SECTION III

3-1

SECTION IV

4-1

4-2

4-3

4-4

4-5

GENERAL INFORMATION

General 3

Industrial Use Only 3

Factory Preparation 3

Specifications 3

6415 Series DC Actuator Specifications 3

6415 Series DC Super Pac Actuator Duty Cycle 3

Warranty and Warranty Repair 3

Dimensions and Specifications 4

INSTALLATION

Installation Procedures 5

Limit Switch Adjustment 5

Post-Installation Procedures 5

Potentiometer Adjustment 6

OPERATION

Operational Procedures 6

MAINTENANCE

Lubrication 7

Required Tools 7

General Procedures 7

Disassembly 7

Assembly 8

SECTION V

FIGURE 5-1

5-1

SECTION VI

6-1

FIGURE 6-1A

FIGURE 6-1B

6-2

FIGURE 6-2

6-3

ILLUSTRATED PARTS LIST

Exploded Illustration 6415 & 7415 AC Actuator 12

Parts List 13

TECHNICAL ILLUSTRATIONS

Brake Alignment 14

Brake Spring, Motor and Pinion Coupling Alignment 14

Brake Spring, Motor and Pinion Coupling Alignment 14

Limit Switch Wiring Diagram 15

Limit Switch Wiring Diagram, 6415 & 7415 Series AC Actuator 15

Limit Switch Assembly 15

Page 3

GENERAL INFORMATION

1-1. GENERAL

This manual provides instructions for the installation,

operation and maintenance of the Duff-Norton 6415 &

7415 Series AC actuator. It includes proper procedures

for the disassembly, cleaning, inspection, rebuilding and

assembly of the actuator. To ensure efficient, long,

satisfactory use of this unit, these instructions should be

followed closely.

1-2. INDUSTRIAL USE ONLY

The actuators described and illustrated in this manual

are intended for industrial use only and should not be

used to lift, support or otherwise transport people,

unless you have a written statement from Duff-Norton

Company which authorizes this actuator unit, as used in

your application, as suitable for moving people.

1-3. FACTORY PREPARATION

Each actuator is carefully assembled and tested at the

factory to ensure that the motor and the mechanical

components will function properly and that the actuator

will lift its rated load.

The brake is preset at the factory and no further

adjustment is required. With proper maintenance, this

brake prevents the actuator from self-lowering.

The actuator is pre-lubricated at the factory and thus

requires minimum maintenance.

Limit switches are checked at the factory for proper

functioning.

External wires are provided for customer

hookup. Wires are color coded as to direction of travel of

the actuator (see wiring diagram, Figure 6.2).

1-4. SPECIFICATIONS

TABLE 1-4.

SECTION 1

1-5. WARRANTY AND WARRANTY REPAIR

Subject to the conditions stated herein, Duff-Norton will

repair or replace, without charge, any parts proven to

Duff-Norton's satisfaction to have been defective in

material and workmanship. Claims must be made within

one year after date of shipment. Duff-Norton will not

repair or replace any parts that become inoperative

because of improper maintenance, eccentric loading,

overloading, chemical or abrasive action, excessive heat,

or other abuse.

Equipment and accessories not of Duff-Norton's

manufacture are warranted only to the extent that they

are warranted by their manufacturer, and only if the

claimed defect arose during normal use, applications

and service. Equipment which has been altered or

modified by anyone without Duff-Norton's authorization

is not warranted by Duff-Norton. EXCEPT AS STATED

HEREIN, DUFF-NORTON MAKES NO OTHER

WARRANTIES, EXPRESS OR IMPLIED, INCLUDING

WARRANTIES OF MERCHANTABILITY AND FITNESS

FOR A PARTICULAR PURPOSE.

If you have any questions concerning warranty

repair, please contact the Duff-Norton Company.

Authorization for return must be received from

the Duff-Norton Company before returning any

equipment for inspection or warranty repair.

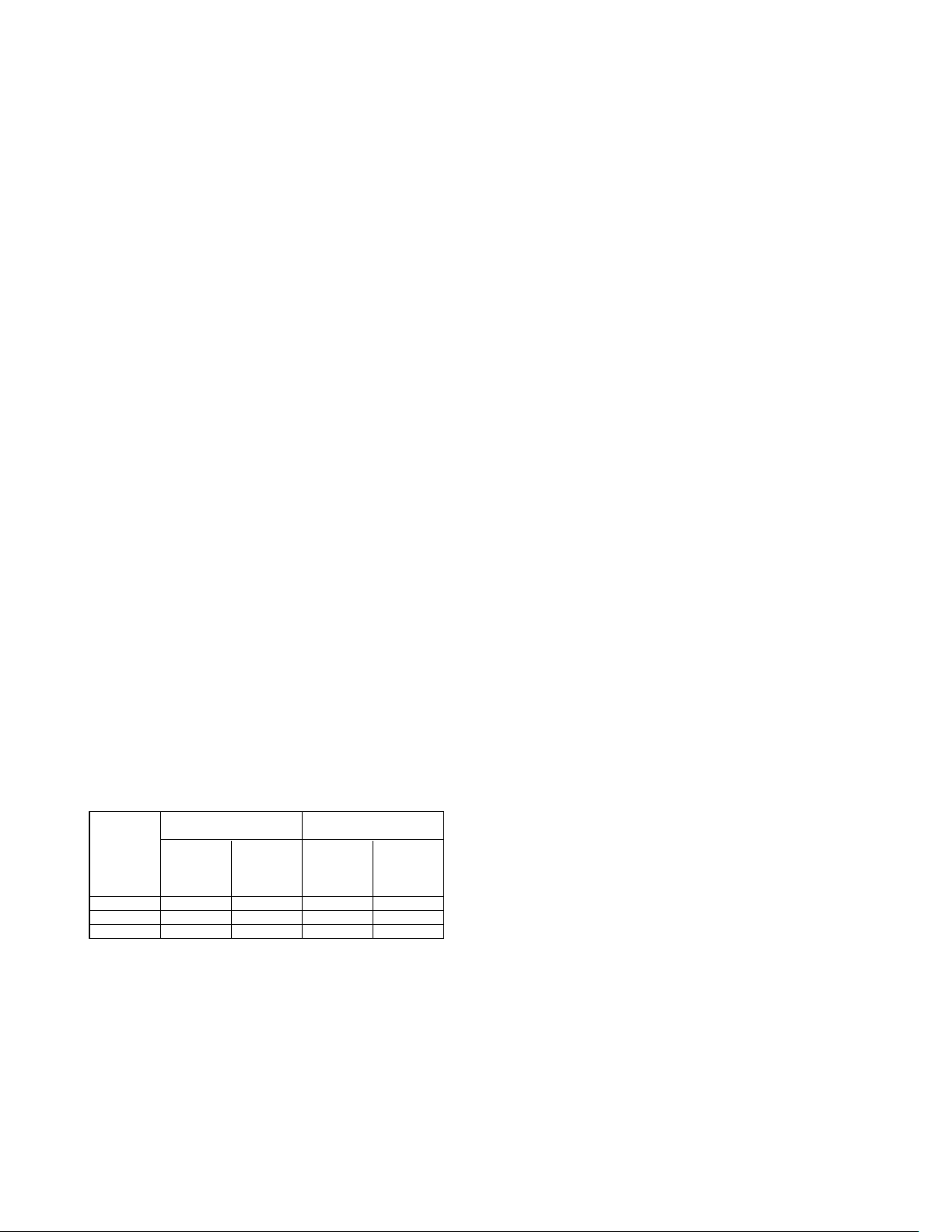

Speed

(in/min)

Applied Standard Standard Standard Standard

Load 115 Volt 220 Volt 115 Volt 220 Volt

(lbs.) Motor Motor Motor Motor

(60 Hz) (50 Hz) (60 Hz) (50 Hz)

500 52 44 5.00 1.70

1000 51 42 5.50 1.70

1500 50 41 6.20 2.00

Amps

3

Page 4

FIGURE 1-6. DIMENSIONS AND SPECIFICATIONS

WARNING:

1. Some actuator external surface temperatures may reach 230°F at or near

maximum allowable duty cycle.

2. Do not operate actuator before setting limit switches.

3. Position hooded vent to prevent moisture and dirt from entering actuator

(see instruction and maintenance sheet).

4. The actuator is not recommended for use in applications where it can be

jammed. Examples of jamming include overtraveling the limit switches and

jamming the nut and screw internally at the extreme ends of the stroke, or

driving the actuator against an immovable object and thus overloading the

actuator severely. Therefore consult Duff-Norton Engineering if jamming is

expected.

4

Page 5

INSTALLATION

2-1. INSTALLATION PROCEDURES

Use Figure 6-2 as a guide to properly attach the SPA

6415 & 7415 AC actuator to your power source.

2-2. LIMIT SWITCH ADJUSTMENT

CAUTION

Disconnect power before making any adjustments to the

limit switches.

IMPORTANT

Before attempting to set limit switch nuts by these

instructions, be certain that the red and blue motor leads

and the switch leads are connected properly per Figure

6-2. Unless leads are connected exactly as shown, the

following steps will be meaningless.

1.Setting Retracted Position

A. Do not install actuator in the intended

application at this time.

B. With nut retainer “A” installed in actuator

and the translating tube unstrained, operate

actuator toward retracted position until limit

switch nut “B” trips limit switch (see Figure 6-3).

NOTE

Translating tube may jam and rotate prior to tripping limit

switch.

SECTION II

extended centerline to centerline dimension

listed in Figure 1-6.

B. Remove nut restrainer “A” and rotate limit

switch nut “C” (see Figure 6-3) until it activates

the limit switch.

C. Replace nut restrainer “A”.

D. Install actuator in application and check the

unit's drift. Slight readjustment in switch

actuation may be attained by removing nut

restrainer “A” and (1) rotating limit switch nut

“B” to adjust retracted position or (2) rotating

limit switch nut “C” to adjust extended position

(1 notch of rotation = .05 in. of screw travel).

E. After adjusting limit switch nuts,

replace nut restrainer “A”. Operate the actuator

and readjust limit switch nuts as necessary to

achieve desired travel.

2-3. POST-INSTALLATION PROCEDURES

After actuator installation, position the air vent to prevent

moisture and dirt from entering the actuator. Vent can be

repositioned by loosening the set screw and rotating the

outer air tube into which the air vent is threaded. Spot drill

and re-tighten set screw.

If necessary, an elbow (1/8" female x 1/8" male

pipe thread) can be used for more effective positioning.

C. Rotate the translating tube by hand until

distance between the housing clevis hole

centerline and the translating tube clevis hole

centerline equals the desired closed height. This

centerline to centerline dimension is not to be

less than the retracted centerline to centerline

dimension listed in Figure 1-6. If the two clevis

end holes are not oriented as required, rotate the

translating tube no more than 1/2 turn in either

direction until they are properly oriented.

D. Install actuator in application and check drift.

Slight readjustment in switch actuation may be

attained by removing nut restrainer “A” and

rotating limit switch nut “B” (1 notch of

rotation = .05 in. of screw travel). Replace nut

restrainer, “A”.

2. Setting Extended Position

A.Restrain the translating tube against rotation

by hand. Operate the actuator, toward the

extended position, until the distance between

the housing clevis hole centerline and the

translating tube clevis hole centerline equals the

desired extended height. This centerline to

centerline dimension is not to exceed the

FOR UNITS WITH POTENTIOMETER

2-4. POTENTIOMETER INSTALLATION

1. Loosen pot locknut and remove from actuator.

2. For best accessibility, solder leads to pot at this time.

3. Limit switches should be set for extreme limits of travel

per instructions. Limit switch cam adjustments should be

made per paragraph 2 prior to potentiometer installation.

CAUTION

DO NOT ENGAGE POTENTIOMETER SHAFT GEAR

TEETH WITH PLASTIC WORM BEFORE READING

THE FOLLOWING PROCEDURE. F

ADHERE TO THE FOLLOWING PROCEDURE

COULD CAUSE DAMAGE TO THE

POTENTIOMETER.

4. Retract actuator translating tube until stopped by limit

switch.

5. a.

FOR TRAVELS UP TO 9

i. Turn pot shaft counterclockwise until

resistance between terminal SSand

CCCCWW

will be the pot’s full retracted position.

is approximately 100 ohms. This

””

(SINGLE TURN POT):

AILURE TO

5

Page 6

SECTION III

OPERATION

ii. Being careful not to turn the pot shaft, slide

it into engagement with the plastic worm and

tighten locknut.

iii. Re-check resistance. If necessary loosen

locknut slightly and twist pot to re-establish

100 ohm resistance. Pot does not have end

of travel stops, but has a 20˚ deadband

between the two ends of the resistive element.

No continuity will be measured to terminal

if the slider is in the deadband.

iv. Run actuator to full extension (do not let

tube rotate) until it is stopped by its limit

switch.

v. Check resistance between SSand

be sure the slider is still on the element and

the resistance is greater than 100 ohms. The

pot has enough rotation for 9.43 inches of

travel. (For strokes shorter than 9”, the

retracted resistance can be increased so that

pot adjustment is less critical.

b.

FOR TRAVELS GREATER THAN 9

CCCCWW

””

(MULTI-TURN POT):

i. Turn pot shaft counterclockwise until it

reaches its stop. Now turn shaft back

clockwise

ii. Without turning pot shaft, slide pot onto

engagement with the plastic worm and tighten

locknut.

iii. Starting

pot has enough rotation for 25” of actuator

travel.

6. With this set-up, potentiometer will have increasing

resistance from S to CCW (and decreasing resistance

from S to CW) as the actuator extends.

1

/4 turn.

1

/4 turn from the end, the 3-turn

to

3-1. OPERATIONAL PROCEDURES

This motor is an intermittent duty type motor. Since the

motor draws approximately the same amperage at no

load as at full rated load, it only takes 10 minutes of

cntinuous running, regardless of how light the load may

be, before the thermal overload relay cuts out. It then

takes about 10 minutes before the motor cools

sufficiently for the thermal relay to close. Make sure that

SS

the duty cycle to which the actuator is subjected is not

too severe for the motor.

Avoid using low voltage supply for the motor. All

wiring, switches etc. must be of sufficient capacity to

carry the required current.

The axis of the clevis pins should be parallel so

that the actuator can pivot without binding. The preset

brake will provide consistent braking for the actuator.

However, in the event the brake friction surfaces become

worn as indicated by excessive drift, the brake will

require rebuilding. To aid in rebuilding, a repair kit with

step by step instructions is available through Duff-Norton

Company under repair kit part number SK-6415-41. The

repair can be performed by the customer or by any

authorized repair station.

WARNING

This actuator is not recommended for use in applications

where it can be jammed. Examples of jamming include

overtraveling the limit switches and thus jamming the nut

and screw internally at the extreme ends of the stroke,

and driving the actuator against an immovable object

and thus severely overloading it. This actuator can jam a

limited number of times without damage. Therefore,

consult Duff-Norton Engineering if jamming is expected.

Do not operate actuator before setting limit

switches.

Some actuator external surface temperatures

may reach 230˚F at or near maximum allowable duty

cycle.

2-5. DIGITAL POSITION INDICATOR (DUFF-NORTON PART

NO. SK6300-4K)

The model SK6300-4K is a highly versatile, panel mount,

digital readout device that provides a very precise

indication of actuator position. It can be programmed to

display percentage, inches, or any other desired unit.

The indicator is self calibrating with no need for

measurements or calculations.

See detailed instructions with the SK6300-4K

indicator for installation and programming instructions.

Potentiometer terminal

indicator Common,

Signal Voltage Input.

CCCCWW

should be connected to

CCWW

to Excitation Voltage, and SSto

6

Page 7

MAINTENANCE

4-1. LUBRICATION

Duff-Norton recommends the use of the following

lubricant in conjunction with proper maintenance

procedures of this unit: Exxon Ronnex Extra Duty #1.

4-2. REQUIRED TOOLS

A bearing puller, press, soft jaw table clamp and

common hand tools are required for proper disassembly

and assembly.

4-3. GENERAL PROCEDURES

Duff-Norton recommends following these procedures

during disassembly and assembly:

1. Tag critical parts to facilitate reassembly.

2. Mark mating surfaces to ensure proper meshing.

3. Clean and lubricate parts as required.

4. All seals must be replaced at time of rebuild,

if damaged.

5. All screws, washers and other small common parts

must be replaced if mutilated in any way.

4-4. DISASSEMBLY

Disassemble the actuator as follows while referring to

Figure 5-1. Read instructions thoroughly before

disassembling.

NOTE

Disassembly should be accomplished on a clean cloth.

1. Clamp actuator housing (42) in vise (use soft

jaws). Unit should be in horizontal position with

outer tube (55) up.

2. Remove screws (1) from limit switch box

cover (11) and remove limit switch box cover

(11) and gasket (12).

3. Remove nut retainer (14).

NOTE

If unit has potentiometer assembly (26) and

potentiometer (26a) or gear (26b) is not damaged

proceed to Step 4.

a. Loosen nut (26c) and remove potentiometer

assembly from nut retainer (14).

b. Remove gear (26b) from potentiometer (26a).

Washer and nut do not have to be removed

from potentiometer (26a).

CAUTION

Take care not to damage potentiometer when removing

gear.

4. Remove screws (1) from capacitor box cover

(2) and remove cover (2) and gasket (3).

Remove insulation (4) from capacitor box.

5. Discharge capacitor (5). Disconnect motor (53) lead

wire terminals from capacitor (5). Remove

SECTION IV

capacitor from box.

6. Disconnect jumper wires (17 and 18) and motor (53) lead

wire terminals from switches (16). Remove jumper

wires (17 and 18) and pull motor (53) lead wires into

capacitor box.

7. Remove set screw (38) from housing (42).

8. Remove button head cap screws (7) and lock washer (8).

9. Lift cover (9) from housing (42) passing motor (53) lead

wires through hole in buttom of capacitor cavity in

cover (9). Slight tapping with soft hammer may be

necessary to overcome dowel pins (27).

10. Remove thrust washer (35) and thrust bearing (36)

from cover (9). Thrust washer (35) and thrust

bearing (36) may stay on spacer nut (37) in

housing (42) and can be removed in Step 18.

11. Remove limit switch shaft assembly, consisting of

limit switch shaft (22), limit switch nuts (23)

and worm (24), from cover (9). Allow limit

switch shaft (22) to drop out of flange bearing

(25). Tilt shaft assembly and remove from

cover (9).

NOTE

If limit switch nuts (23) or worm (24) do not have to be

replaced, proceed to Step 14.

12. Thread limit switchnuts (23) offof limit switch shaft (22)

13. Remove worm (24) from limit switch shaft (22).

NOTE

If switches (16), insulation (19) or limit switch bracket (21) do

not have to be replaced, proceed to Step 16.

14. Remove screws (20) and bracket (21) from cover (9).

15. Remove screws (15), switches (16) and insulation (19)

from bracket (21).

16. Press clevis end bushing (6) out of cover (9). If bushing

(6) is not damaged it should not be removed.

17. Remove bearing (28), bushing (34) and flange bearing

(25) from cover (9).

NOTE

Bushing (34) and flange bearing (25) should not be removed

unless they are damaged. Bearing (28) may stay on pinion

(29) and can be removed in Step 18.

18. Remove thrust washer (31) from intermediate pinion

shaft (32). Bearing (28) from pinion (29), thrust

washers (35) and thrust bearing (36) from

spacer nut (37) may have been removed in

Step 10.

19. Remove spring (61) from end of screw (62).

20. Remove intermediate cluster gear (33), intermediate

pinion shaft (32) and thrust washer (31).

7

Page 8

21. Remove socket head cap screws (45), lock washers

(46) and disassemble motor (53) from housing

(42).

WARNING

Care must be taken not to damage motor lead wires.

22. Remove “O”-Ring (52) and rubber grommet (50).

23. Disassemble outer tube (55) and slip off over

translating tube and clevis (66).

24. Remove air vent (58), wiper scraper (60) and guide

bushing (59) from outer tube (55).

NOTE

If wiper scraper or guide bushing are not damaged they

should not be removed.

25. Remove set screw (68) from spacer nut (37) and

disassemble spacer nut (37) from screw (62) by

clamping screw (62) between soft jawed vise.

WARNING

Care must be taken not to damage bearing journal of

spacer nut (37).

26. Remove output gear (39), key (40), thrust washers

(35), thrust bearing (36), and gear spacer (43).

27. Remove screw (62), translating tube and

clevis (66) and nut assembly (64).

28. Remove washer (44) from screw (62).

29. Thread screw (62) into the translating tube until the

screw bottoms out and cannot rotate farther, or

until the screw thread becomes disengaged

from the lifting nut thread (64).

30. Drive the four pins (65) just far enough into the

lifting nut (64) to clear the translating tube wall;

then remove the translating tube from the nut.

31. Remove the lifting screw (62) from the lifting nut (64).

32. Remove the four pins (65) by pressing each one the

rest of the way through the lifting nut wall.

33. Remove the stop pin (63) from the lifting screw (62)

if necessary.

34. Removing the brake (49) .(Required only if drift is

excessive. If brake removal is not necessary,

proceed to Step 35).

a. Push on the pinion(29) and coupling (47) until

it slips back enough to make the spring (49)

tang accessible.

b. Remove the spring (49) by grabbing the tang

with pliers and twisting out. (Spring must now

be replaced and can no longer be used.)

c. Remove the brake insert (51). Remove

retaining ring (48) from input pinion (29). Input

pinion (29) and bearing (30) can now be

removed from housing (42).

d. The brake inset (51) has straight knurls on its

O.D. which prevent it from rotating. Therefore,

the insert can only be removed by pulling

straight out.

e. One method of removing the insert (51) is to

use a blind hole bearing puller. This tool

expands into the internal spring cavity and pulls

against the lip of the insert (51).

35. If coupling (47) on motor (53) shaft must be

replaced, remove retaining ring (48) from motor

(53) shaft and remove coupling (47).

DISASSEMBLY IS COMPLETE.

4-5. ASSEMBLY

Assemble the actuator as follows while referring to

Figure 5-1. Read instructions thoroughly before

assembling.

NOTE

Be sure all components are clean and dry before

assembling.

1. Assemble coupling (47) on motor shaft, then install

retaining ring (48) on motor shaft.

2. Press bearing (30) on input pinion (29) (press load

should be applied to inner race of bearing to

avoid damage to bearing).

3. Press bushing (34) into housing (42).

4. Install input pinion (29) and bearing assembly (30) in

housing (42) (press load should be applied to

outer ring of bearing to prevent damage to

bearing).

5. Assemble coupling (47) on input pinion (29) and

install retaining ring (48).

6. Brake Assembly

a. Grease O.D. of spring (49) and pocket of

insert (51) (chamfered end) with Aeroshell #6

grease.

CAUTION

When using replacement parts, make sure you have

correct spring. (Part No. SK-6415-18). Red spring

designates DC unit. If your replacement spring is red,

contact your local distributor or the Duff-Norton Factory

for immediate replacement.

b. Install spring (49) into insert (51) pocket

(chamfered end).

c. Align pinion coupling (47) and spring (49) as

shown in Figure 6-1A and press insert (51) and

spring (49) assembly into housing (42)

8

(alignment must be as shown in Figure 6-1A).

Page 9

7. Press bushing (34), bushing (6) and flange bearing

(25) into cover (9).

8. Assembly of Limit Switch Components (refer to

Figure 6-3).

a. Assemble insulation (19), limit switch (16)

and screw (15) on limit switch bracket (21).

NOTE

Limit switch (16) leads should face each other. Insulation

(19) should be folded up and behind common terminal of

switches (16). See Figure 6-3.

b. Assemble limit switch nuts (23) on limit

switch shaft (22) (care should be taken not to

cross-thread nuts). Nut hubs should be facing

away from each other. See Figure 6-3.

c. Assemble worm (24) on limit switch shaft

(22). Unthreaded hub on worm should be away

from limit switch shaft (22) threads.

See Figure 6-3.

9. Assembly of Limit Switch Components in cover. Refer

to Figures 6-2 and 6-3.

NOTE

Cover (9) should be in a soft-jaw vise with limit switch

box cover up.

10. Assemble limit switch bracket (21), insulation (19)

and switch (16) assembly into cover (9) with

screws (20).

11.Assemble limit switch shaft (22), limit switch nuts

(23) and worm (24) assembly into cover (9).

Tilt shaft and insert into I.D. of bushing (34).

Then straighten and assemble shaft into flange

bearing (25).

NOTE

Worm (24) should be facing up toward flange bearing

(25). See Figure 6-3 (shaft will be loose in cover).

12. Attach red terminal wire (17) to common terminal of

left side switch (16). Attach blue terminal wire

(18) to common terminal of right side switch

(16). Feed ends of terminal wires (17) and (18)

through 5/8" dia. hole into cover (9) capacitor

box.

13. Press guide bushing (59) and wiper scraper seal (60)

into outer tube (55). (Scraper part of scraper

seal should be facing outward away from guide

bushing.)

14. Install the stop pin (63) in the end of the lifting screw

(62), taking care to center the pin in the screw.

15. Screw the lifting nut (64) on to the lifting screw (62)

with the flange end away from the stop pin (63).

16. Fill the translating tube (66) approximately 1/2 to 3/4

full with Duboise M.P.G. grease (no

substitutes).

17. Slide the translating tube over the lifting screw (66)

and on to the lifting nut (64), lining the four

holes in the translating tube up with the four

holes in the lifting nut (64). Install pins (65)

flush with translating tube O.D.

18. Assemble washer (44) and gear spacer (43) on screw

(62). Install key (40) in key groove of screw.

19. Clamp sides of housing (42) in vise (use soft jaws

with input pinion up).

20. Install screw (62), gear spacer (43), washer (44),

translating tube (66), and tube nut (64)

assembly into housing (42) through bushing

(34).

21. Apply a generous amount of Aeroshell #6 grease (no

substitutes) to thrust washers (35) and thrust

bearing (36) and assemble over gear spacer

(37).

22. Aligning keyway in output gear (39) with key (40) in

screw (62), assemble output gear (39) on screw

(counter-bore in gear facing up away from

thrust bearing).

23. Clamp screw (62) between soft jawed vise. Thread

spacer nut (37) on screw (62) and tighten

against output gear (39). Spacer nut flange

should be in counterbore of output gear. Do not

grip on bearing journal of spacer nut when

tightening spacer nut.

24. Check alignment of tapped holes in spacer nut (37)

with holes in output gear (39). Use two 9/64

dia. pins approximately 11/2" long. One pin

should drop into hole in output gear (39). If pin

does not drop into hole, tighten or loosen

spacer nut until hole is aligned and one pin

drops into hole. (Note: spacer nut should not be

rotated more than 221/2 before pin drops into

hole in gear.) It is preferable to tighten spacer

nut down instead of loosening.

25. Remove pin from aligned hole. Install half dog set

screw (68) and tighten half dog point into hole

in output gear (39). Remove remaining pin and

proceed with assembly. Note: One hole must be

in alignment to have proper assembly.

26. Lightly grease O.D. of translating tube (66) with

Duboise M.P.G. grease (no substitutes) and

assemble outer tube (55) assembly over

translating tube (66) and thread into housing

(42) (a sealing compound such as NonHardening Permatex 2 should be used on

9

Page 10

threads).

27. Insert intermediate pinion shaft (32) in housing (42)

and place thrust washer (31) over shaft (32).

Assemble intermediate cluster gear (33) on shaft

and place thrust washer (31) on top.

28. Assemble bearing (28) on input pinion (29) (press on

inner bearing ring to prevent damage to

bearing).

29. Pack housing (42) gear box cavity with Aeroshell #6

grease (no substitutes).

30. Assembly of Motor (53) to Housing (42)

a. Note location of flat on input pinion by

marking spot on the housing. See Figure 6-1B.

b. Insert grommet (50) on input pinion (29)

between coupling (47) posts and install “O”Ring (52) in cavity of insert (51).

c. Pack cavity with Aeroshell #6 grease.

d. If hole plug (54) is in rear end of motor,

remove.

e. Feed motor (53) lead wires through hole in

housing (42) lining up couplings (47) on input

pinion (29) and motor (53) shaft. (Alignment is

critical at this point. See Figure 6-1B.)

NOTE

If unit has potentiometer assembly (26) and gear (26b) does

not have to be replaced or if unit has no potentiometer

feature, proceed to Step 35.

34. Potentiometer Assembly (26)

a. If nut and washer were removed from

potentiometer, assemble washer (26d) and nut

(26c) on potentiometer (26a). Nut (26c) should

not be tightened on potentiometer (26a) face.

b. Assemble gear (26b) on potentiometer (26a)

shaft.

NOTE

Gear should be assembled with a very light press. See

sketch for required dimension of gear on potentiometer. Take

care not to damage potentiometer.

35. Assembly of Cover (9)

a. Feed motor (53) lead wires into capacitor box

cover (9). Care should be taken not to damage

lead wires. Assemble cover on housing (42),

aligning dowel pins (27) with bore in

NOTE

Input pinion (29) and motor (53) shaft flats are opposite

each other.

f. Assemble motor (53) into housing (42) . Before

assembling lock washers (46) and socket head

screws (45), hold motor firmly in place and, with

a screwdriver, turn motor shaft by using

screwdriver slot in end of motor shaft.

NOTE

Before turning motor shaft, make sure pinion shaft has

not been pushed out. It may be necessary to hold pinion

shaft down while turning motor shaft. If couplings are

properly installed, the motor can be turned freely in both

directions. If motor shaft will not turn, this is an

indication that couplings are not properly aligned and

assembly should be corrected.

g. Install lock washers (46) and socket head

screws (45).

31. Insert dowel pins (27) in housing (42) and place

gasket (41) in place over dowel pins (27).

32. Install air vent (58) in outer tube (55) ( it may be

necessary to back outer tube out in order to

install air vent or to have vent in a more

desireable position). Spot drill tube and install

set screw (33) to hold tube in place.

33. Install spring (61) into end of screw (62).

cover and flats of limit switch shaft (22) with bore

and slot in end of screw (62).

NOTE

Limit switch shaft should be able to spring up when a light

pressure with finger is applied downward on limit switch nut

and removed.

b. Install lock washers (8) and button head cap

screws (7).

c. Feed motor lead wires (red and blue small

terminal ends only) into cover switch box through

5/8” diameter hole. Install terminal of red lead wire

on normally closed terminal of left side of switch.

Install terminal of blue lead wire on normally closed

terminal of right side of switch. (Wires going to

switches should be same color.) It may be necessary

10

Page 11

to install terminals on switch terminals tabs with

needle-nose pliers and care should be taken not to

damage terminal tab or switch (see Figure 6-3).

d. Feed terminal wires, (17) red, (18) blue, fuse

jumper wire, and motor lead through 1/2"

tapped hole in cover capacitor box outside of

cover.

e. Moving wires out of the way, insert capacitor (5)

into box (termials up) and attach motor lead wire

(large connectors) to capacitor terminals. (Red on

one pair of capacitor terminals and blue on the other

pair of capacitor terminals.)

f. Insert insulation (4) and assemble gasket (3)

and cover (2) with screws (1).

g. Adjust actuator limit switch settings per

instructions in paragraph 2-2.

h. If actuator has potentiometer, refer to

position indicator installation and calibration

instructions in Paragraph 2-4.

I. Attach gasket (12) and cover (11) with screws (1).

ASSEMBLY IS NOW COMPLETE.

11

Page 12

Page 13

SECTION V

PARTS LIST FOR FIGURE 5-1

5-1. PARTS LIST

PARTS LIST FOR DUFF-NORTON ACTUATOR, 6415 & 7415 SERIES AC ACTUATOR

IInnddeexx

NNoo..

Screw

1

Cover

2

Gasket

3

Insulation

4

Capacitor – 115 V

5

Capacitor – 220 V

Bushing

6

Button Head Cap Screw

7

Lock Washer

8

Cover

9

Tapered Closure

10

Switch Cover

11

Gasket

12

Instruction Decal

13

Nut Restrainer

14

Screw

15

Switch

16

Jumper Wire (Red)

17

Jumper Wire (Blue)

18

Insulation

19

Screw

20

Limit Switch Bracket

21

Limit Switch Shaft

22

LImit Switch Nut

23

Worm

24

Flange Bearing

25

Potentiometer Assembly

26

Potentiometer

26a

Gear

26b

Nut

26c

Lock Washer

26d

Dowel Pin

27

Bearing

28

Input Pinion

29

Bearing

30

Thrust Washer

31

Intermediate Pinion Shaft

32

Intermediate Cluster Gear

33

Bushing

34

Thrust Washer

35

Thrust Bearing

36

PPaarrtt NNaammee

QQttyy..

RReeqq.. PPaarrtt NNoo..

H-2979

8

SK-6415-38

1

SK-6415-37

1

SK-6415-47

1

SK-6405-7-6

1

SK-6405-7-8

1

SK-6415-96

1

H-2986

5

S-42-9

5

SK-6415-134

1

SK-6000-46

1

SK-6415-36

1

SK-6415-35

1

SK-6905-15

1

SK-6415-136

1

H-2984

4

SK-6415-131

2

SK-6415-32-1

1

SK-6415-32-2

1

SK-6415-132

2

H-2979

2

SK-6415-137

1

SK-6415-135

1

SK-6425-9

2

SK-6905-3

1

SK-6425-11

1

††

1

††

1

SK-6415-62

1

furnished with

1

26a

1

H-5391

2

SK-6415-5

1

SK-6415-3

1

SK-2374-5

1

255K14

2

SK-6415-9

1

SK-6415-4

1

SK-6415-11

2

255K10

4

511K11

2

IInnddeexx

NNoo..

Spacer Nut

37

Set Screw

38

Output Gear

39

Woodruff Key

40

Gasket

41

Housing

42

Gear Spacer

43

Washer

44

Socket Head Cap Screw

45

Lock Washer

46

Coupling

47

Retaining Ring

48

Spring

49

Rubber Grommet

50

Insert

51

“O”-Ring

52

Motor – 115 V

53

Motor – 220 V

Hole Plug

54

Outer Tube

55

Warning Decal

56

Actuator Deal

57

Air Vent

58

Guide Bushing

59

Wiper Scraper

60

Spring

61

Screw

62

Stop Pin

63

Nut

64

Pin

65

Translating Tube & Clevis

66

Half Dog Set Screw

68

PPaarrtt NNaammee

QQttyy..

RReeqq.. PPaarrtt NNoo..

1

SK-6415-17

1

H-2594

1

SK-6415-92

1

S-23-12

1

SK-6415-7

1

SK-6415-1

1

SK-6415-91

1

H-4011

3

S-49-94

3

H-4081-P

2

SK-6415-20

2

SK-2374-8

1

SK-6415-18

1

SK-6415-29

1

SK-6415-21

1

X-6477-72

1

SK-6415-19

1

Sk-6515-96

1

1

SK-6415-111**

1

SK-6415-59

1

SK-6415-67

1

SK-2015-218

1

SK-6415-23

1

SK-6415-16

1

JF-343-3

1

SK-6415-113*

1

H-5122

1

SK-6415-15

4

H-5164

1

SK-6415-109-A*

1

H-2612

**DDeennootteess ddaasshh nnuummbbeerr iiss eeqquuaall ttoo ttrraavveell

**** DDeennootteess ddaasshh nnuummbbeerr iiss 33 ffoorr ttrraavveell.. 33 iinncchheess oorr lleessss.. OOtthheerrwwiissee ddeennootteess ddaasshh nnuummbbeerr iiss eeqquuaall ttoo ttrraavveell iinn iinncchheess..

††

OPTIONAL

Ohms/Inch Potentiometer

Travel Potentiometer (26a) Ohms Change with gear (26)

9" or less SK-3275-24 5000 530 SK6415-70-10A

over 9" SK6200-18 5000 167 SK6415-70-5A

13

Page 14

6-1. BRAKE ALIGNMENT

SECTION VI

TECHNICAL ILLUSTRATIONS

Figure 6-1A. Brake, Spring,

Motor and Pinion Coupling

Alignment

6-2. LIMIT SWITCH WIRING DIAGRAM

Figure 6-1B. Brake Spring,

Motor and Pinion Coupling

Alignment

FIGURE 6-2. LIMIT SWITCH WIRING DIAGRAM, 6415 &

7415 SERIES AC ACTUATOR

14

Page 15

6-3. LIMIT SWITCH ASSEMBLY

**MOTOR LEAD WIRE (RED) SMALL TERMINAL

* MOTOR LEAD WIRE (BLUE) SMALL TERMINAL

FIGURE 6-3. LIMIT SWITCH ASSEMBLY,

6415 & 7415 SERIES AC ACTUATOR

15

Page 16

P.O. Box 7010 • Charlotte, NC 28241-7010

Phone: (800) 477-5002 • (704) 588-4610

Fax: (704) 588-1994

Email: duffnorton@cmworks.com

www.duffnorton.com

© Yale Industrial Products, Inc., Duff-Norton Division, 2006

All rights reserved by Yale Industrial Products, Inc., Duff-Norton Division.

May not be copied in whole or in part.

Printed in the USA

ECO 98865

1M\SK6415-200\1006

Loading...

Loading...