Page 1

Publication Part No.

SK-2463-22

Translating Tube Actuators

Model Numbers M-2464 & M-2465

Rotating Screw Actuators

Model Numbers M-2462 & M-2463

CAUTION

This manual contains important information for the correct installation, operation and maintenance of the

equipment described herein. All persons involved in such installation, operation, and maintenance should be

thoroughly familiar with the contents. To safeguard against the possibility of personal injury or property

damage, follow the recommendations and instructions of this manual and keep it for further reference.

WARNING

Improper use can result in personal injury. To avoid injury:

• Do not use actuators to lift, support, or transport people or

loads over people without written approval from Duff-Norton.

• Read all product warnings and operating instructions.

Page 2

Contents

Section I Introduction.................................................................................................................3

1-1. General...............................................................................................................3

1-2. Intended Use .......................................................................................................3

1-3. Safety Considerations.........................................................................................3

1-4. Unwarranted Applications....................................................................................3

1-5. Warranty and Warranty Repair ............................................................................3

Section II Installation ..................................................................................................................3

2-1. Motor Installation .................................................................................................3

2-2. Installation of the Actuator ...................................................................................3

2-3. Limit Switches......................................................................................................3

Section III Dimensions and Specifications...................................................................................4

3-1. Dimensions - Rotating Screw Actuators .............................................................4

3-2. Dimensions - Translating Tube Actuators............................................................4

3-3. Specifications .....................................................................................................5

Section IV Operation, Maintenance, and Inspection....................................................................5

4-1. Improper Loading ...............................................................................................5

4-2. Clevis Pins..........................................................................................................5

4-3. Lubrication ..........................................................................................................5

4-4. Inspection ...........................................................................................................5

Section V Disassembly and Assembly........................................................................................6

5-1. Lubricant.............................................................................................................6

5-2. Required Tools....................................................................................................6

5-3. General Procedures ...........................................................................................6

5-4. Disassembly - Rotating Screw Actuators (Models M-2462 and M-2463) ...........6

5-5. Assembly - Rotating Screw Actuators (Models M-2462 and M-2463)................6

5-6. Disassembly - Translating Tube Actuators (Models M-2464 and M-2465)..........8

5-7. Assembly - Translating Tube Actuators (Models M-2464 and M-2465)...............8

Section VI Illustrated Parts List ............................................................................................... ...10

6-1. General.............................................................................................................10

6-2. Parts List for Rotating Screw Actuators............................................................11

6-3. Parts List for Translating Tube Actuators (Models M-2464 and M-2465) ..........12

2

Page 3

Section I

Introduction

1-1. General

This manual provides instructions for the installation, operation, and maintenance of the Duff-Norton® Modular

Actuator. It includes proper procedures for the disassembly , cleaning, inspection, rebuilding, lubrication, and

assembly of the actuator. To ensure efficient and long,

satisfactory use of this unit, read and understand the

information herein, and follow the instructions closely.

1-2. Intended Use

The Duff-Norton® Modular Actuators described and illustrated in this manual are intended for industrial use

only and should not be used to lift, transport, or otherwise support people.

1-3. Safety Considerations

1. Avoid touching exterior surfaces of the actuator.

Surface temperatures may reach 230 ° F during

prolonged use.

2. Make certain that the electric motor used conforms

to the requirements of the actuator.

1-4. Unwarranted Applications

CAUTION

These actuators are not recommended

or warranted for use in applications involving the following activities or

conditions:

1. Lifting, supporting, or positioning of people where

a malfunction might result in bodily injury.

2. Side loading or binding of the actuator. (See Par agraph 4-1, "Improper Loading".)

NOTE

If in doubt about the suitability of the actuator for you application, consult the Duff-Norton

Engineering Department.

1-5. Warranty and Warranty Repair

Subject to the conditions stated herein, Duff-Norton will

repair or replace, without charge, any parts proven to DuffNorton’s satisfaction to hav e been defectiv e in material or

workmanship. Claims must be made within one year after date of shipment. Duff-Norton will not repair or replace

any parts that become inoperative because of improper

maintenance, eccentric loading, overloading, chemical or

abrasive action excessive heat, or other abuse

Equipment and accessories not of Duff-Norton’s manufacture are warranted only to the extent that they are

warranted by the manufacturer, and only if the claimed

defect arose during normal use, applications and service.

Equipment which has been altered or modified by anyone

without Duff-Norton’s authorization is not warranted by

Duff-Norton. EXCEPT AS STATED HEREIN, DUFFNORT ON MAKES NO OTHER WARRANTIES, EXPRESS

OR IMPLIED, INCLUDING WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE.

If you have any questions concerning warranty repair,

please consult a Duff-Norton Warehouse and Customer

Service Center for the name and address of your nearest

Duff-Norton actuator warranty repair facility.

Authorization for return must be granted b y the Duff-Norton

Company before any equipment may be returned for inspection or warranty repair.

Section II

Installation

Duff-Norton's Modular Actuator is designed to be a versatile piece of equipment which can be used in many

different applications; consequently, installation procedures will vary widely with customer requirements

2-1. Motor Installation

The Modular Actuator is designed to accept a standard

NEMA 56 frame electric motor with C-face mounting, to

be supplied by the customer. For instructions on installing the motor on the actuator, see Paragraph 5-5, steps

19-21 (these steps apply to both Rotating Screw and T ranslating Tube actuators).

2-2. Installation of the Actuator

The actuator has two bolt patterns for convenient attach-

ment of the actuator to the application: both the tw o-hole

pattern (17/32-inch unthreaded holes 4 inches apart) and

the four-hole pattern (1/2-20 threaded holes on a 2.55

inch square) can be used to bolt the actuator to a wide

variety of mounting points; the four-hole pattern will also

accept standard hydraulic type end fittings.

The lifting nut (on Rotating Screw actuators) and the clevis

end (on Traslating Tube actuators) must be restrained

against rotation in order for the actuator to lift its load.

2-3. Limit Switches

Duff-Norton recommends that limit switches be incorporated in the installation to prevent o vertravel of the actuator

in either direction and to protect the actuator against internal jamming. Duff-Norton limit switches to fit this

actuator are available at an additional cost.

3

Page 4

Section III

Dimensions and Specifications

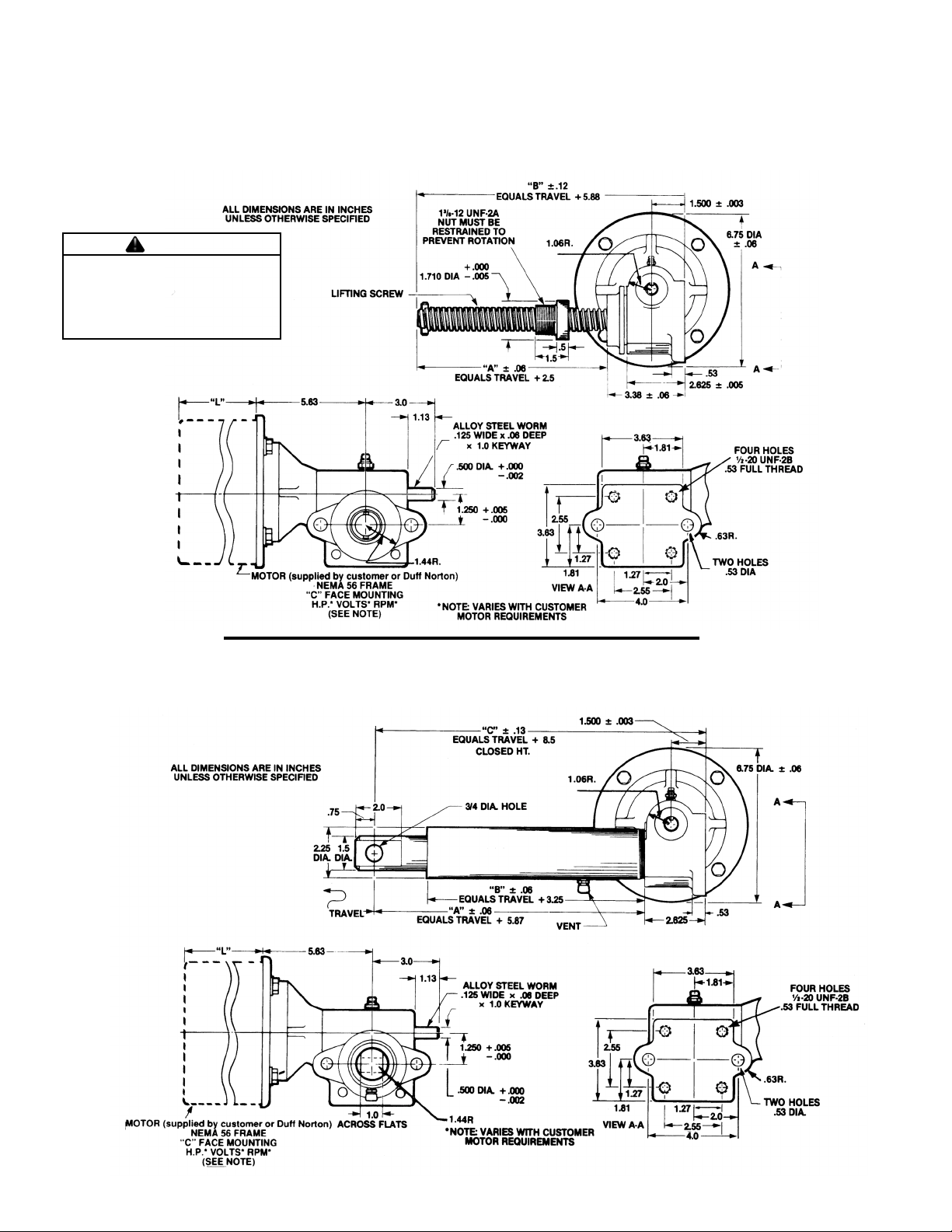

3-1. Dimensions - Rotating Screw Actuators (Models M-2462 and M-2463)

Warning

Use only replacement parts supplied

by or approved by Duff-Norton. Nonauthorized parts may be inadequate,

resulting in serious injury or death

in event of failure.

3-2. Dimensions - Translating Tube Actuators (Models M-2464 and M-2465)

4

Page 5

q

g

p

p

p

p

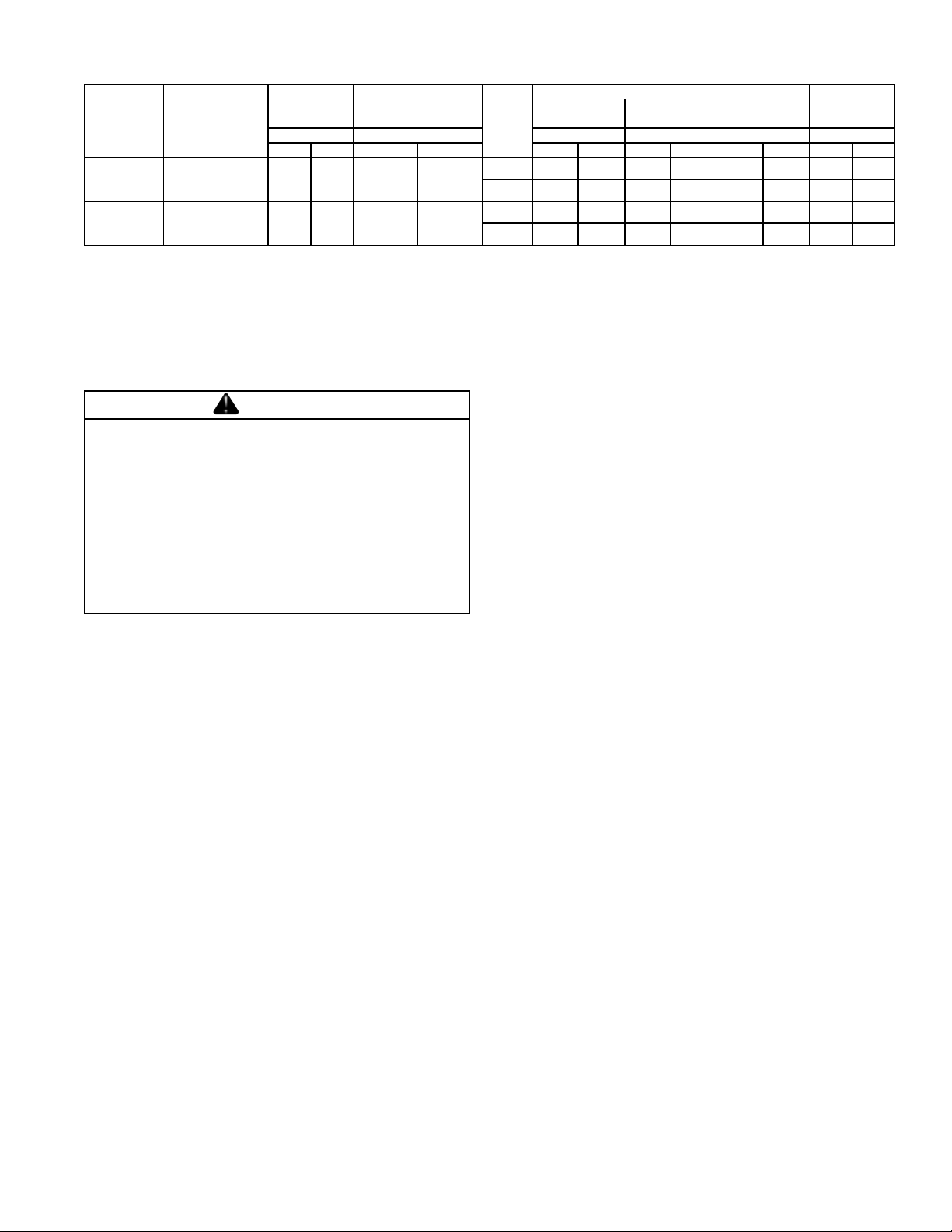

3-3. Specifications

Tor

Model No. Screw Dia.

M-2462

M-2464

M-2463

M-2465

NOTE: 1. Models M-2462 and M-2464 are self-lowering and a motor brake should be used.

.875 Dia. Acme

.25 Pitch

R.H. Double

1.0 Dia. Acme

.25 Pitch

R.H. Single

2. Models M-2463 and M-2465 may drift 0.75 in (20:1 ratio) to 2.0 in (5:1 ratio) when the motor is shut off. If this is undesirable, a motor brake should be used.

Worm/ 1"

Travel

Ratio Ratio Ratio

5:1 20:1 5:1 20:1 5:1 20:1 5:1 20:1 5:1 20:1 5:1 20:1

10 40 39 18

20 80 29

ueTurns of Liftin

lb/in @

1000 lb Load

14

Motor

RPM

1725 300 700 500 1000 700 1500 170 43

1140 450 1000 700 1500 1100 2000 114 28

1725 400 900 600 1400 900 2000 8 6 2 1

1140 600 1400 900 2000 1400 2000 57 1 4

1/3 h

Motor Motor

Rated Load

1/2 h

Ratio

3/4 h

Motor

Ratio

Section IV

Operation, Maintenance, and Inspection

4-1. Improper Loading

Warning

The actuator must NOT be subjected to side

loading or binding (i.e., a bending moment

across the actuator) at any point in its travel. It

is the responsibility of the installer to ensure

that the mounting points cannot transmit such

loading to the actuator anywhere between full

retraction and full extension. F ailure to observe

this warning will void the warranty on the actuator.

4-2. Clevis Pins

The axes of the clevis pins should be parallel so that the

actuator can pivot without binding. A few drops of oil should

be applied to the clevis pins on installation and periodically thereafter.

4-3. Lubrication

The actuator is lubricated at the factory with Shell Albida

LC EP#2 (Shell Oil Co. product code 70311). This grease

has been thoroughly evaluated b y Duff-Norton and demonstrated to provide superior actuator life. Other greases

may provide satisfactory service, with some acceleration

of wear. Only high quality, NLGI #2EP, lithium based

greases should be used.

The actuator should be lubricated periodically (see NOTE

under Paragraph 4-4, "Inspection"), using the grease fitting. On Rotating Screw actuators, the lifting screw and

nut can be lubricated by painting a light coat of grease on

the screw at a point that passes through the nut. To lubricate the lifting screw and nut on a Translating Tube

actuator, first loosen the set scre ws and unscrew the outer

tube from the housing to expose the lifting screw threads .

The actuator should be disassembled, cleaned, inspected,

and relubricated after 500,000 inches of travel under normal conditions, or earlier if the need is indicated by

inspection or by a squealing from the lifting screw and nut

area. Follow the instructions in Section V to o verhaul the

actuator.

4-4. Inspection

The actuator should be inspected periodically (see NOTE

below), with attention given to the following items:

1. Clevis ends for wear , cracks, distortion, or other degradation or damage.

2. Loose belts, screws, or other hardware on the actuator or its mounting points.

3. Limit switches (if so equipped) for proper setting and

operation.

4. Lifting screw, lifting nut, and gear set for excessive

wear or lack of lubrication (see instructions under

Paragraph 4-3, "Lubrication").

Any of the above deficiencies should be corrected bef ore

the actuator is returned to service.

NOTE

Periodic Inspection and Lubrication: The exact periods for inspection and lubrication of

the actuator cannot be predetermined because of the many variables involved, such

as frequency of operation, type and magnitude of loading, and operational environment.

Determination should be based on the user's

experience. It is recommended that the user

begin with a weekly inspection, extending the

inspection period to monthly, quarterly, or

annually, based on his weekly experience.

S

eed

in/min

Ratio

5

Page 6

Section V

Disassembly and Assembly

5-1. Lubricant

When rebuilding this actuator, use only Albida LC EP#2

grease from Shell Oil Company.

5-2. Required Tools

A bearing puller and press, a soft jaw table clamp, and

common hand tools are required for proper disassembly

and assembly of the actuator.

5-3. General Procedures

Duff-Norton recommends following these procedures during disassembly and assembly of the actuator:

1. Tag critical parts to facilitate reassembly.

2. Mark mating surfaces to ensure proper meshing.

3. Clean and lubricate parts as required.

4. Replace all seals at time of rebuild.

5. Replace any screws, washers, and other small common parts that are damaged in any way.

5-4. Disassembly - Rotating Screw Actuators (Models M-2462 and M-2463)

Disassemble the Duff-Norton® Rotating Screw Modular

Actuator as follows, referring to Figure 6-1 on page 11.

Read the instructions thoroughly before disassembling the

actuator.

NOTE

For disassembly procedures for Translating

Tube actuators, see Paragraph 5-6.

NOTE

Disassembly should be undertaken on a

clean cloth.

1. Remove the f our cap scre ws (B) with loc k w ashers

(F) that attach the motor (A) to the shell (9) flange,

and remove the motor from the shell. Half the fle xible coupling (5a) will come with the motor shaft,

and the other half (5a) will remain on the worm shaft

(4). The flexible spider (5b) may stay with either

half of the coupling.

2. Remove the set screw (5c) from the motor half of

the coupling (5a), and remove the coupling half and

the key (E) from the motor shaft.

3. Remove the pipe plug (7) and the grease fitting (8)

from the shell (9).

4. Remove the set screw (5c) from the worm half of

the coupling (5a) by inserting the set screw wrench

through the pipe plug hole.

5. Remove the coupling half (5a) and the ke y (18) from

the worm shaft (4).

When disassembling an actuator equipped with limit

switches, f ollow steps 6 and 7 below . If the actuator is not

equipped with limit switches, proceed directly to step 8.

6. Remove the two socket head cap screws (28) and

the one long hex head cap screw (26) from the limit

switch adaptor (29), and remov e the limit switch box

(D) from the limit switch adapter.

7. Remove the two half dog point sets screws (30) from

the shell (9) and remove the limit switch adapter

(29) from the shell (see NOTE below).

NOTE

It may be necessary to use heat to overcome

the adhesive in order to remove the limit

switch adapter from the shell.

8. Remove the two set scre ws (10) from the shell (9),

and unscrew the shell cap (19) from the shell.

9. Remove the shell cap, lifting screw, bearing, and

gear assembly from the shell (9).

10. Remove the retaining ring (1) from the shell (9).

11. Remov e the worm (4) by pressing on the motor end

of the worm shaft. The worm bearing (2) next to

the retaining ring (1) groove will be driven out by

the worm. The other worm bearing (2) should remain in the shell until the load bearing cup (13) has

been removed.

12. Press the worm bearing (2) off the worm (4).

13. Remove the load bearing cup (13) out of the shell

(9).

14. Remove the remaining worm bearing (2) from the

shell (9).

15. Clamp the lifting screw (17) in a vise, using soft ja ws

to prevent damage to the screw.

16. Remove the lock n ut (12), and remove the gear (14),

key (18), and spacer (15) from the lifting screw (17).

17. Remove the shell cap (19) and lifting nut (20) from

the lifting screw (17).

18. Remov e the stop pin (16) from the lifting screw (17)

if necessary.

19. Remove the two load bearing cones (13) from the

gear (14).

Disassembly of the actuator is now complete.

5-5. Assembly - Rotating Screw Actuators (Models M-2462 and M-2463)

Assemble the Duff-Norton® Rotating Screw Modular Actuator as follows, ref erring to Figure 6-1 on page 11. Read

the instructions thoroughly before assembling the actuator.

6

Page 7

NOTE

For assembly procedures f or Translating Tube

actuators, see Paragraph 5-7.

NOTE

Be sure all parts are clean and dr y before

assembling the actuator.

1. Assemble one load bearing cup (13) into the shell

(9), and the other load bearing cup into the shell

cap (19).

2. Assemble one worm bearing (2) into the motor

mounting flange end of the shell (9) (see NOTE below).

NOTE

The bearing must be installed from the opposite end of the shell.

3. Notice that one end of the worm (4) has a hole in

the center of the shaft, and one end does not. Press

the remaining worm bearing (2) on to the end of the

shaft WITH the hole.

4. Assemble the worm (4) into the shell (9) and worm

bearing (2), and then install the retaining ring (1) in

the shell.

5. Grease the two load bearing cones (13) and install

them on the worm gear (14) bearing journals.

6. Install the stop pin (16) in the end of the lifting screw

(17), taking care to center the pin in the screw.

7. Screw the lifting nut (20) on to the lifting screw (5)

with the flange end away from the stop pin (16).

8. Slide the shell cap and bearing cup assembly over

the lifting screw threads, with the bearing cup (13)

facing the turned end of the lifting screw.

9. Slip the spacer (15) over the end of the lifting screw

(17), with the flange toward the screw thread.

10. Install the ke y (18) in the ke yway in the lifting scre w

(17).

11. Slide the gear and load bearing cone assembly over

the end of the lifting screw (17).

12. Thread the lock nut (12) on to the end of the lifting

screw (17). Clamp the lifting screw between soft

jaws in a vise, and tighten the lock nut to 30 ft-lb.

13. Install the lifting screw, shell cap , and gear assembly in the shell (9), taking care to mesh the gear

teeth and the worm properly.

14. Pack the gear housing with Shell Albida LC EP#2

grease.

15. Coat the shell cap (19) threads with aluminum

antiseize compound. Thread the shell cap into the

shell (9), and torque it to 40 ft-lb. Spot drill the shell

cap thread O.D. in two places, and install the two

set screws (10). Tighten the set screws to hold the

shell cap in place.

16. Install the key (6) in the end of the worm (4) shaft

on the flange side of the shell (9), and slide a coupling half (5a) onto the worm shaft. The inside f ace

of the coupling should be flush with the worm shaft

end. Tighten the coupling set screw (5c) against

the key by inserting the set screw wrench through

the 1/8-inch pipe tap hole in the shell.

17. Install the pipe plug (7).

18. Install the grease fitting (8).

19. Install the key (E) in the motor shaft and slide the

second coupling half (5a) on to the motor shaft, with

the inside face of the coupling flush with the end of

the motor shaft. Tighten the coupling set screw

against the key to lock it in place.

20. Assemble the flexible spider (5b) on to the motor

coupling half (5c).

21. Align the motor coupling half (5a) with the worm

coupling half (5a) and assemble the motor (A) to

the shell (9), aligning the holes in the flange with

the tapped holes in the face of the motor. Make

sure that the motor is centered in the counterbore,

and then install and tighten the four 3/8-16 x 7/8

inch hex head cap screws (B) with lock washers

(F) that attach the motor to the flange. Turn the

worm shaft extension by hand to be certain that

there is no binding of the motor and the actuator.

This completes the assembly procedures for actuators not

equipped with limit switches. When assembling an actuator equipped with limit switches, continue with the

instructions below.

22. Apply two or three drops of Loc-Tite No. 35 Extra

Strength Retaining Ring Compound to the shell

bore.

If a new (replacement) limit switch adapter is being installed, follow steps 23 and 24 belo w. If a used (pre viously

spot drilled) adapter is being installed, proceed directly to

step 25.

23. Install the limit switch adapter (29) in the shell (9),

making sure that the adapter bottoms out against

the retaining ring (1). Orient the four tapped holes

in the limit switch adapter to line up with the four

motor mounting holes in the housing flange.

24. Spot drill the limit switch adapter (29) in two places

and install the two half dog point set screws (30).

Proceed directly to step 27.

25. Install the limit switch adapter (29) in the shell (9),

aligning the spot drilled holes in the adapter with

the tapped holes in the shell.

26. Install the two half dog point set screws (30).

27. Aligning the slot in the limit switch worm shaft with

the pin in the actuator worm, install the limit switch

box on the adapter (29) in the desired position.

Assembly of the actuator is now complete.

7

Page 8

5-6. Disassembly - Translating Tube Actuators (Models M-2464 and M-2465)

Disassemble the Duff-Norton® T ranslating Tube Modular

Actuator as follows, referring to Figure 6-2 on page 12.

Read the instructions thoroughly before disassembling the

actuator.

NOTE

For disassembly procedures f or the Rotating

Screw actuators, see Paragraph 5-4.

NOTE

Disassembly should be undertaken on a

clean cloth.

1. Remove the f our cap scre ws (B) with loc k w ashers

(F) that attach the motor (A) to the shell (9) flange,

and remove the motor from the shell. Half the fle xible coupling (5a) will come with the motor shaft,

and the other half (5a) will remain on the worm shaft

(4). The flexible spider (5b) may stay with either

half of the coupling.

2. Remove the set screw (5c) from the motor half of

the coupling (5a), and remove the coupling half and

the key (E) from the motor shaft.

3. Remove the pipe plug (7) and the grease fitting (8)

from the shell (9).

4. Remove the set screw (5c) from the worm half of

the coupling (5a) by inserting the set screw wrench

through the pipe plug hole.

5. Remove the coupling half (5a) and the ke y (6) from

the worm shaft (4).

When disassembling an actuator equipped with limit

switches, f ollow steps 6 and 7 below . If the actuator is not

equipped with limit switches, proceed directly to step 8.

6. Remove the two socket head cap screws (28) and

the one long hex head cap screw (26) from the limit

switch adapter (29), and remov e the limit switch box

(D) from the limit switch adapter.

7. Remove the two half dog point set scre ws (30) from

the shell (9) and remove the limit switch adapter

(29) from the shell (see NOTE below).

NOTE

It may be necessary to use heat to overcome

the adhesive in order to remov e the adapter

from the shell.

8. Remove the two set scre ws (10) from the shell (9),

and remove the outer tube (24) b y first unscrewing

it from the shell and then sliding it off over the translating tube.

9. Remove the translating tube , lifting screw, bearing,

and gear assembly from the shell (9).

10. Remove the retaining ring (1) from the shell (9).

11. Remove the w orm (4) by pressing on the motor end

8

of the worm shaft. The worm bearing (2) next to

the retaining ring (1) groove in the shell (9) will be

driven out by the worm. The other worm bearing

(2) should remain in the shell until the load bearing

cup (13) has been removed.

12. Press the worm bearing (2) off the worm (4).

13. Remove the load bearing cup (13) out of the shell

(9).

14. Remove the remaining worm bearing (2) from the

shell (9).

15. Remove the remaining load bearing cup (13) from

the outer tube (24).

16. Remov e the wiper scraper seal (22) from the outer

tube (24), and if necessary press the guide bushing (23) out of the outer tube.

17. Clamp the lifting screw (17) in a vise, using soft ja ws

to prevent damage to the screw.

18. Remove the lock n ut (12), and remove the gear (14),

key (18), and spacer (15) from the lifting screw (17).

19. Remove the two load bearing cones (13) from the

gear (14).

20. Screw the lifting scre w (17) into the translating tube

until the screw bottoms out and cannot rotate farther, or until the scre w thread becomes disengaged

from the lifting nut (19) thread.

21. (M2464) Drive the f our pins (20) just far enough into

the lifting nut (19) to clear the translating tube wall;

then remove the translating tube from the nut.

(M2465) Remove the set screw (S7-94) from the

translating tube; then remo ve the lifting nut from the

translating tube.

22. Remove the lifting screw (17) from the lifting nut

(19).

23. Remove the four pins (20) by pressing each one

the rest of the way through the lifting nut wall.

24. Remov e the stop pin (16) from the lifting screw (17)

if necessary.

Disassembly of the actuator is now complete.

5-7. Assembly - Translating Tube Actuators (Models M-2464 and M-2465)

Assemble the Duff-Norton® Translating T ube Modular Actuator as follows, ref erring to Figure 6-2 on page 12. Read

the instructions thoroughly before assembling the actuator.

NOTE

For assembly procedures f or Rotating Screw

actuators, see Paragraph 5-5.

NOTE

Be sure all parts are clean and dr y before

assembling the actuator.

1. Assemble a load bearing cup (13) into the shell (9).

Page 9

2. Assemble one worm bearing (2) into the motor

mounting flange end of the shell (9) (see NOTE below).

NOTE

The bearing must be installed from the opposite end of the shell.

3. Notice that one end of the worm (4) has a hole in

the center of the shaft, and one end does not. Press

the remaining worm bearing (2) on to the end of the

shaft WITH the hole.

4. Assemble the worm (4) into the shell (9) and worm

bearing (2), and then install the retaining ring (1) in

the shell.

5. Install the guide bushing (23) and the wiper scraper

seal (22) in the end of the outer tube (24) opposite

the threaded end.

6. Install a load bearing cup (13) in the threaded end

of the outer tube (24).

7. Grease the two load bearing cones (13) and install

them on the worm gear (14) bearing journals.

8. Install the stop pin (16) in the end of the lifting screw

(17), taking care to center the pin in the screw.

9. Screw the lifting nut (19) on to the lifting screw (17)

with the flange end away from the stop pin (16).

10. Fill the translating tube (16) approximately half full

of Shell Albida LC EP#2 grease.

11. (M2464 only) Slide the translating tube and clevis

end assembly over the lifting screw (17) and on to

the lifting nut (19), lining the four holes in the translating tube up with the four holes in the lifting nut

(19).

Press the four pins (20) into place (see CAUTION

below).

CAUTION

The pins should end up extending 1/32

inch beyond the O.D. of the translating

tube, and must NOT jam against the O.D.

of the lifting screw thread. If the pins are

pressed too far into the lifting nut, they

will bind against the lifting screw thread,

perhaps damaging the screw surface.

NOTE

The lifting nut should now rotate freely on the

lifting screw . If the nut does not rotate freely

on the screw , follo w steps 21-24 under P aragraph 5-6, "Disassembly", and then resume

"Assembly" at step 9.

12. (M2465 only) Clean any grease from the external

threads on lifting nut (SK2465-29) and from the internal threads on the translating tube and clevis end

assembly. Apply thread locker (Loctite 242) to the

external threads on the lifting nut. Screw the translating tube and clevis assembly onto the lifting n ut.

Use a drill bit to "spot" the lifting nut and install the

set screw (S7-94).

13. Slip the spacer (15) ov er the end of the lifting screw

(17), with the flange toward the lifting screw shoulder.

14. Install the ke y (18) in the ke ywa y in the lifting screw

(17).

15. Slide the gear and load bearing cone assembly over

the end of the lifting screw (17).

16. Thread the lock nut (12) on to the end of the lifting

screw (17). Clamp the lifting screw between soft

jaws in a vise, and tighten the lock nut to 30 ft-lb.

17. Install the lifting screw, translating tube, and gear

assembly in the shell (9), taking care to mesh the

gear teeth and the worm properly.

18. Pack the gear housing with Shell Albida LC EP#2

grease.

19. Make sure that a load bearing cup (13) has been

installed in the end of the outer tube (24) (see step

6). Lightly grease the O.D. of the translating tube

assembly, and slide the outer tube over the translating tube, threaded end first.

20. Thread the outer tube (24) into the shell (9), and

tighten it to 40 ft-lb. Spot drill the outer tube thread

in two places, and install and tighten the two set

screws (10) to hold the outer tube in place.

21. Install the key (6) in the end of the worm (4) shaft

on the flange side of the shell, and slide a coupling

half (5a) on to the worm shaft. The inside face of

the coupling should be flush with the worm shaft

end. Tighten the coupling set screw (5c) against

the key by inserting the set screw wrench through

the 1/8-inch pipe tap hole in the shell.

22. Install the pipe plug (7).

23. Install the grease fitting (8).

24. Install the key (E) in the motor shaft and slide the

second coupling half (5a) on to the motor shaft, with

the inside face of the coupling flush with the end of

the motor shaft. Tighten the coupling set screw

against the key to lock it in place.

25. Assemble the flexible spider (5b) on to the motor

coupling half (5c).

26. Align the motor coupling half (5a) with the worm

coupling half (5a) and assemble the motor to the

shell (9), aligning the holes of the flange with the

tapped holes in the face of the motor. Make sure

that the motor is centered in the counterbore, and

then install and tighten the four 3/8-16 x 7/8 inch

hex head cap screws (B) with loc k washers (F) that

attach the motor to the flange. Turn the worm shaft

extension by hand to be certain that there is no binding of the motor and the actuator.

9

Page 10

This completes the assembly procedures for actuators not

equipped with limit switches. When assembling an actuator equipped with limit switches, continue with the

instructions below.

27. Apply two or three drops of Loc-Tite No. 35 Extra

Strength Retaining Ring Compound to the shell

bore.

If a new (replacement) limit switch adapter is being installed, follow steps 28 and 29 below . If a used (previously

spot drilled) adapter is being installed, proceed directly to

step 30.

28. Install the limit switch adapter (29) in the shell (9),

making sure that the adapter bottoms out against

the retaining ring (1). Orient the four tapped holes

Section VI

Illustrated Parts List

6-1. General

in the limit switch adapter to line up with the four

motor mounting holes in the housing flange.

29. Spot drill the adapter (29) in two places and install

the two half dog point set screws (30). Proceed

directly to step 32.

30. Install the limit switch adapter (29) in the shell, aligning the spot drilled holes in the adapter with the

tapped holes in the shell.

31. Install the two half dog point set screws (30).

32. Aligning the slot in the limit switch worm shaft with

the pin in the actuator worm, install the limit switch

box on the adapter (29) in the desired position.

Assembly of the actuator is now complete.

This section contains exploded illustrations of DuffNorton® Rotating Screw and Translating Tube Modular

Actuators. The numbers adjacent to each of the parts on

the illustrations is the index number. On the parts listed

below, these numbers are keyed to the individual part

names.

10

Page 11

6-2. Parts List for Rotating Screw Actuators

g

g

)

g

y

g

g

g

(

)

)

)

)

)

)

)

)

Index No.

Figure 6-1

1 1 SK-2501-11

2 2 SK-2501-10

3 1 S-50-26

4 Worm 5:1 Ratio 1

5** 1 SK-2465-21

6 1 S-10-2

7 1 S-25-13

8 1 SK-974-32

9 1 SK-2465-1

10 2 S-7-10

11 1 SK-2433-19

12 1 H-3966-P

13 2 SK-2501-9

* This No. is equal to travel plus 1.

** 5a - coupling body

5b - spider

5c - set screw

Part Name

Retaining Rin

Worm Bearin

Spring Pin (Worm

20:1 Ratio 1

Flexible Couplin

Ke

Pipe Plu

Grease Fittin

Shell

Set Screw

Decal

Lock Nut

Load Bearin

Qty Req.

SK-2465-43

SK-2465-53

Part

Number

Index No.

Figure 6-1

14 Worm Gear 5:1 Ratio 1 SK-3502-4

15 1 SK-2465-17

16 1

17 1

18 1 S-10-72

19 1 SK-2463-2

20 1 SK-2463-6

26 1 S-44-157

27 3 H-4084-P

28 2 H-2201

29 1 SK-2465-11

30 2 S-52-1

Part Name

20:1 Ratio 1 SK-2502-14

Spacer

Stop

Pin

Screw (M-2463

Screw (M-2462

Key (Screw

Shell Cap (M2463

Shell Cap (M2462

Lifting Nut (M-2463

Lifting Nut (M-2462

Hex Hd. Cap Screw

Lock Washer

Soc Hd. Cap Screw

Limit Switch Adapter

Set Screws

Qty Req.

H-5122-P

SK-2465-5-*

1 SK-2464-5-*

1 SK-2462-2

1 SK-2462-6

Warning

Use only replacement

parts supplied by or approved by Duff-Norton.

Non-authorized parts may

be inadequate, resulting in

serious injury or death in

event of failure.

Part

Number

11

Page 12

6-3. Parts List for Translating Tube Actuators (Models M-2464 and M-2465)

g

g

g

g

)

g

y

g

g

Index No.

Figure 6-2

1 1 SK-2501-11

2 2 SK-2501-10

3 1 S-50-26

4 Worm 5:1 Ratio 1

5** 1 SK-2465-21

6 1 S-10-2

7 1 S-25-13

8 1 SK-974-32

9 1 SK-2465-1

10 2 S-7-10

11 1 SK-2433-19

12 1 H-3966-P

13 2 SK-2501-9

14 Worm Gear 5:1 Ratio 1 SK-3502-4

15 1 SK-2465-17

* This No. is equal to travel.

** 5a - coupling body

5b - spider

5c - set screw

Part Name

Retainin

Worm Bearin

Spring Pin (Worm

Flexible Couplin

Ke

Pipe Plu

Grease Fittin

Shell

Set Screw

Decal

Lock Nut

Load Bearin

Spacer

Rin

20:1 Ratio 1

20:1 Ratio 1 SK-2502-14

Qty Req.

SK-2465-43

SK-2465-53

Part

Number

Index No.

Figure 6-2

Pin (Stop)

16

Screw (M-2465)

17

Screw (M-2464) 1 SK-2464-5-*

18 Key (Screw) 1 S-10-72

19 Lifting Nut (M-2465) 1 SK-2465-29

Lifting Nut (M-2464) 1 SK-2415-15

20 Pin (Nut) 4 H-5164

Screw (M-2465) 1 S7-94

21 Tube & Clevis Sub-Assembly (M-2464) 1 SK-6415-109-* A

Tube & Clevis Sub-Assembly (M-2465) 1 SK-2465-31-* A

22 Wiper-Scraper Seal 1 SK-6415-16

23 Guide Bushing 1 SK-6415-23

24 Outer Tube 1 SK-6415-111-*

25 Air Vent 1 SK-2405-218

26 Hex Hd. Cap Screw 1 S-44-157

27 Lock Washer 3 H-4084-P

28 Soc. Hd. Cap Screw 2 H-2201

29 Limit Switch Adapter 1 SK-2465-11

30 Set Screws 2 S-52-1

Part Name Qty Req.

1

1

Part

Number

H-5122-P

SK-2465-5-*

Warning

Use only replacement

parts supplied by or approved by Duff-Norton.

Non-authorized parts may

be inadequate, resulting in

serious injury or death in

event of failure.

12

Page 13

Notes

13

Page 14

© 2000 Yale Industrial Products, Inc.

P.O. Box 7010

Charlotte, NC 28241-7010

Customer Service (800) 477-5002

FAX (704) 588-1994

Email: duffnorton@cmworks.com

www.duffnorton.com

SK2463-22

500/0404

ECO 97804

Loading...

Loading...