Duff-Norton 528AMJ, 126AMJ, 536AMJ, 528CMJ, 144AMJ Operating And Maintenance Instructions With Parts

...

Table of Contents

Section I Introduction

1-1. General

1-2. Construction

1-3. Technical Specifications and Operational Characteristics

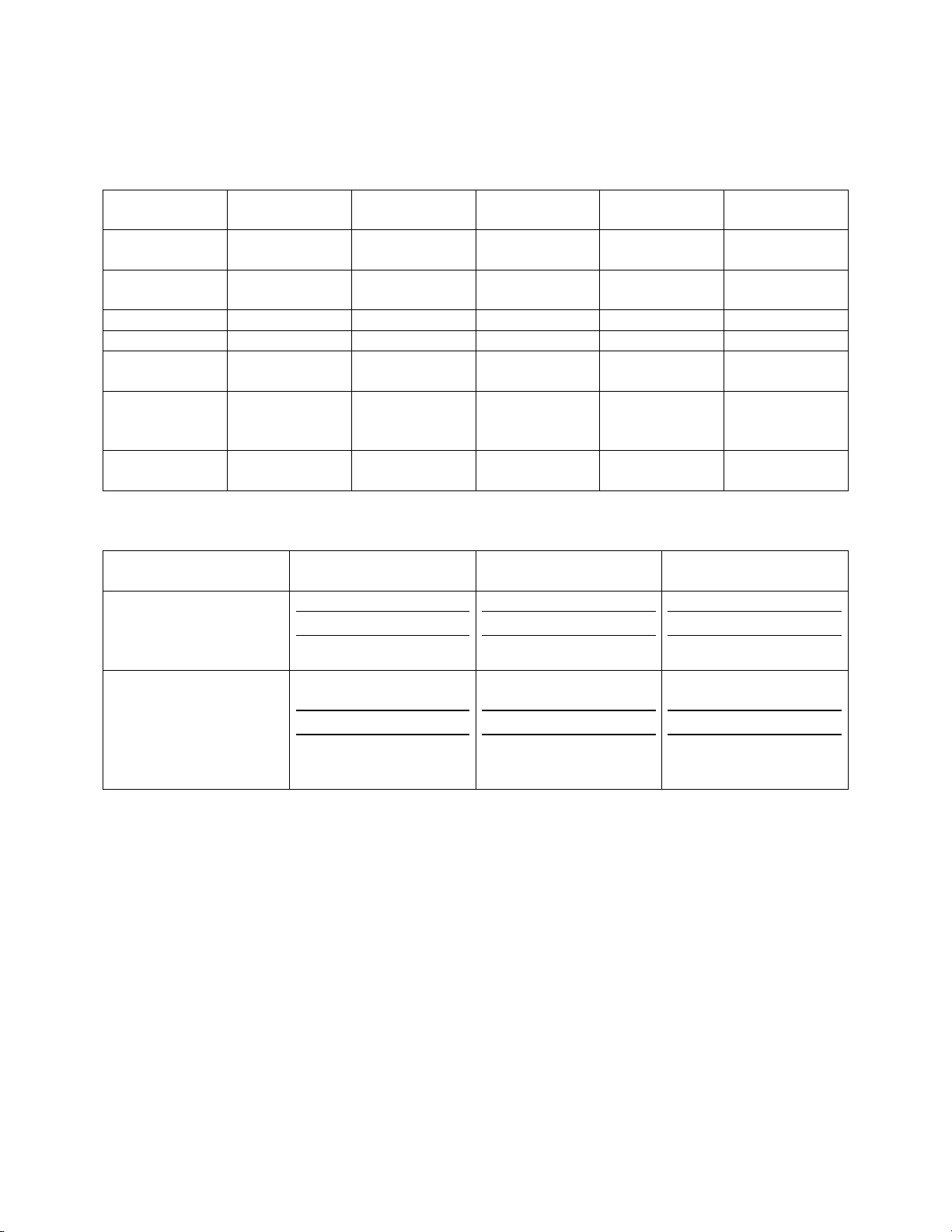

TABLE 1-1. Technical Specifications

TABLE 1-2. Operational Characteristics

Section II Inspection, Testing, and Maintenance

2-1. Inspection

2-2. Inspection Classification

2-3. Initial Inspection

2-4. Frequent Inspection

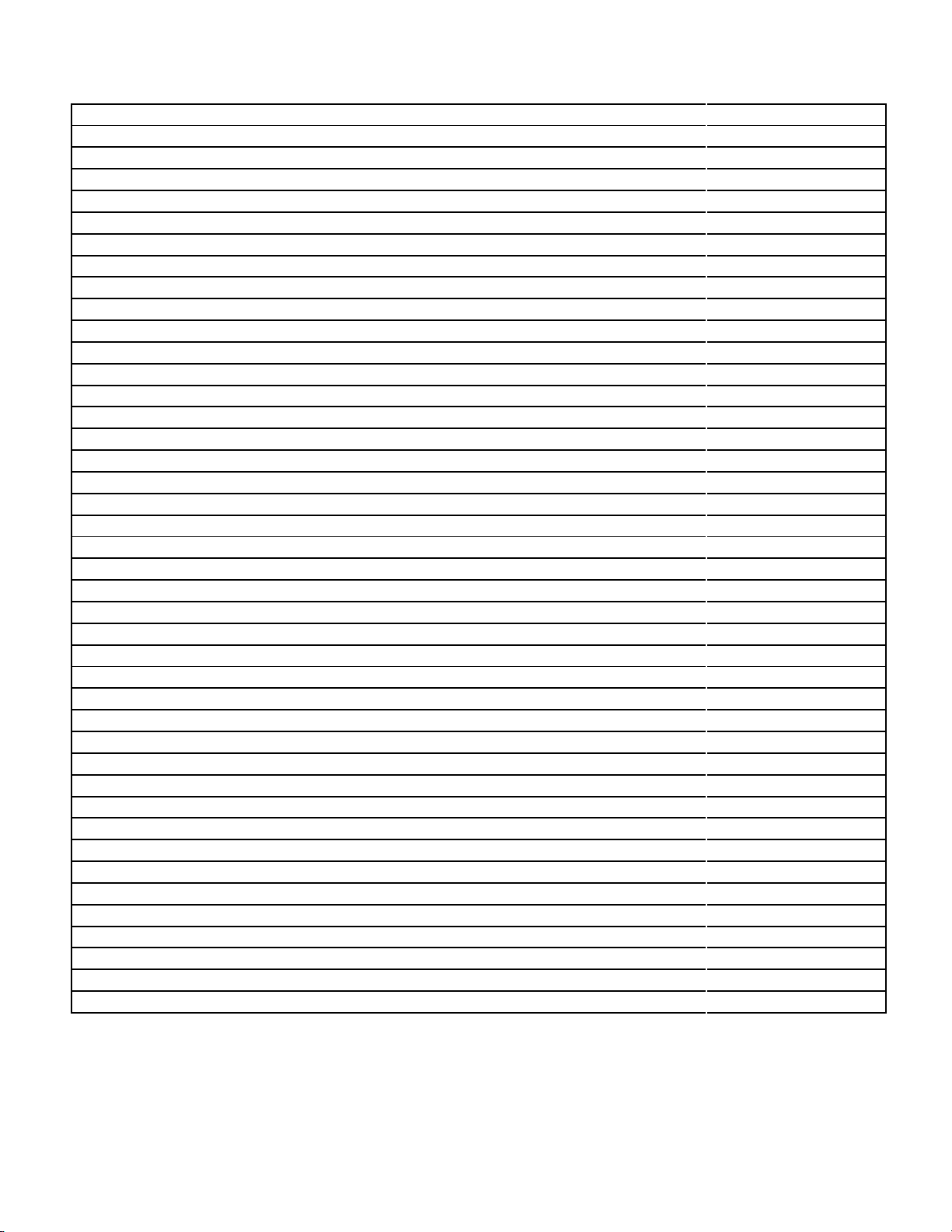

FIGURE 2-1. Inspector's Report

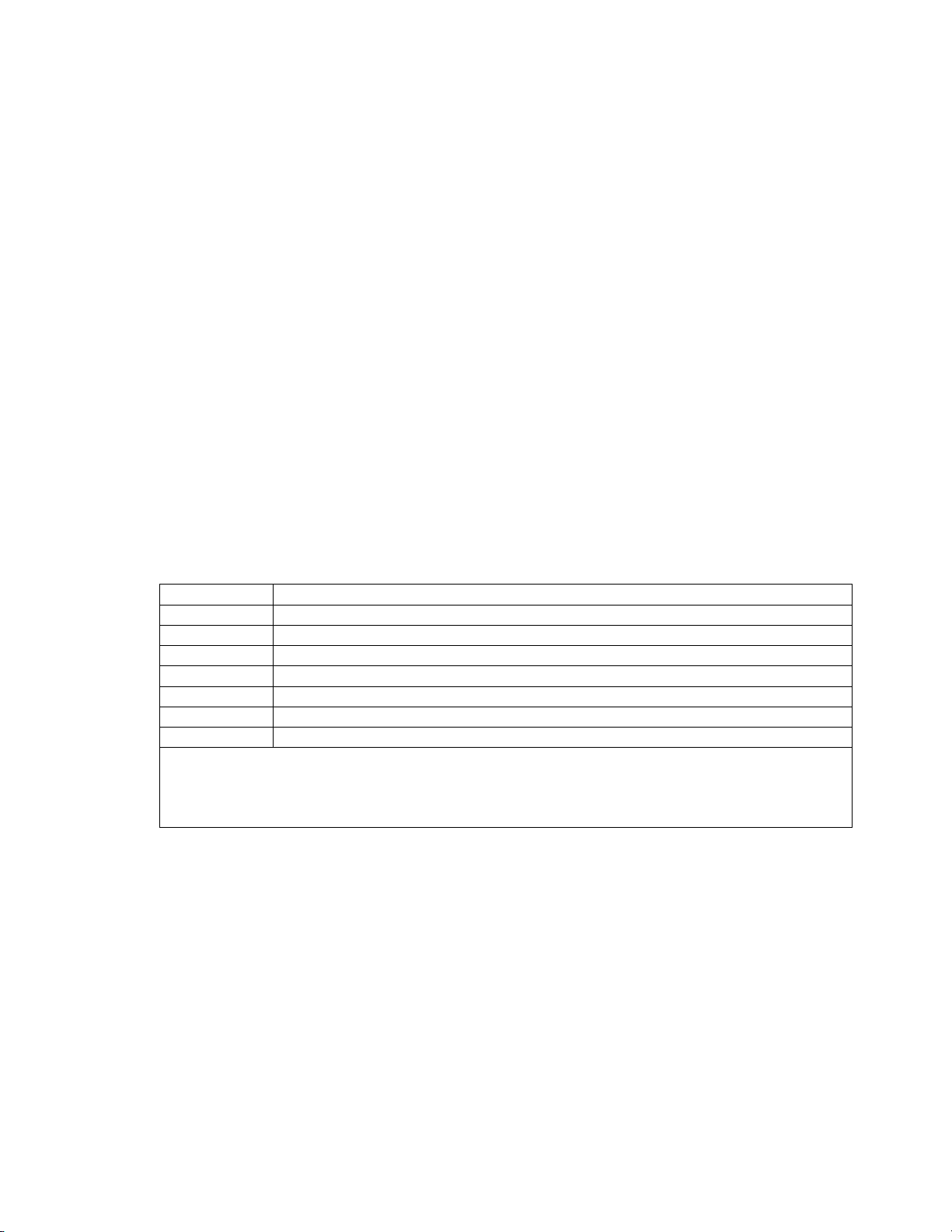

TABLE 2-1. Minimum Inspection Schedule

2-5. Periodic Inspection

2-6. Special Inspection Requirements

FIGURE 2-2. Lifting Nut Inspection

2-7. Load T est

2-8. Maintenance

2-9. Lubrication

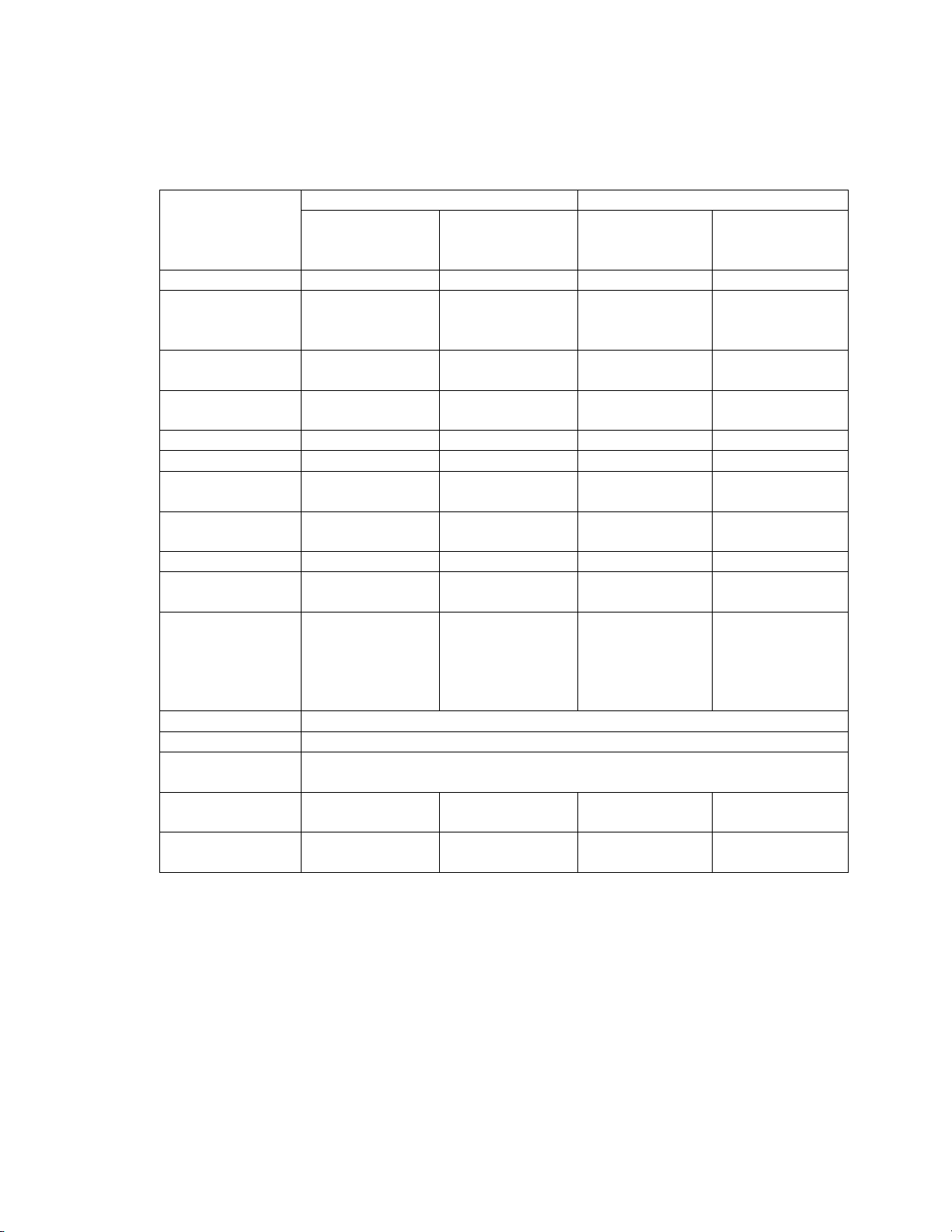

FIGURE 2-3. Throttle Adjustment

Section III Operation

3-1. Operational Requirement

3-2. Operating Procedures and Precautions

Section IV Illustrated Parts List

4-1. General

List of Illustrations

FIGURE 4-1. Exploded Illustration of 528AMJ and 536AMJ Jacks

FIGURE 4-2. Exploded Illustration of Gage Area

Parts Breakdown for 528AMJ and 536AMJ Jacks

FIGURE 4-3. Exploded Illustration of 528CMJ and 536CMJ Jacks

FIGURE 4-4. Exploded Illustration of Gage Area

Parts Breakdown for 528CMJ and 536CMJ Jacks

FIGURE 4-5. Exploded Illustration of 126AMJ, 132AMJ, and 144AMJ Jacks

FIGURE 4-6. Exploded Illustration of Gage Area

Parts Breakdown for 126AMJ, 132AMJ, and 144AMJ Jacks

FIGURE 4-7. Exploded Illustration of 126CMJ, 132CMJ, and 144CMJ Jacks

FIGURE 4-8. Exploded Illustration of Gage Area

Parts Breakdown of 126CMJ, 132CMJ, and 144CMJ Jacks

FIGURE 4-9. Exploded Illustration of X6000 Air Motor

Parts Breakdown of X6000 Air Motor

FIGURE 4-10. Exploded Illustration of X4153 Air Motor

Parts Breakdown of X4153 Air Motor

Table of Contents

1

1

1

1

2

22222

3345566

6

6

7

777

888

10

11

12-15

16

17

18-21

22

23

23-27

28

29

29-33

353637

38

Subject to the condition stated herein, Du Norton Air Motor Jack Co. will repair or replace, without charge, any parts proved to our satisfaction to have been defective in material

1. Units or any parts that become inoperative because of improper maintenance, eccentric loading, overloading, chemical or abrasive action, excessive heat, or other abuse.

3. Equipment and accessories not of DNAMJ Co.'s manufacture are warranted only to the extent of the original manufacturer's warranty and subject to the same conditions as

4. Except as stated herein, DNAMJ Co. makes no other warranties, expressed or implied, including warranties of merchantability and tness for a particular purpose.

or workmanship. Claims must be made within one year aer the date of shipment.

2. Equipment which has been altered or modied by anyone without DNAMJ Co.'s authorization.

stated above regarding improper maintenance, abuse, overloading, etc.

Du Norton Air Motor Jack Warranty Policy

e warranty is null and void for:

Introduction

1-1. General

a. This manual provides instructions for

operating, inspection, testing, and

maintenance, as well as an illustrated

parts list for the following Duff Norton

Air Motor Jacks:

528AMJ 528CMJ

536AMJ 536CMJ

126AMJ 126CMJ

132AMJ 132CMJ

144AMJ 144CMJ

b. This publication is written in accordance

with standards set forth in the current

ANSI B30.1. To ensure reliable and

long, satisfactory use of the air motor

jacks, the instructions contained in this

publication should be closely followed.

Safety precautions to protect against

accidental injury or property damage

should be observed at all times while

using the jacks. All personnel

concerned with the installation,

operation, inspection, and maintenance

of the jacks are urged to read the

American National Standard (ANSI

B30.1). That standard contains

important rules (some mandatory and

some of an advisory nature) designed to

prevent or minimize injury or otherwise

protect life, limp, and property. You

should especially be aware of the

mandatory rules pertaining to inspection

Section I

requirements and advisability of

maintaining written, dated, and signed

inspection reports and records.

NOTE

The air motor jacks are recommended for

general industrial use.

1-2. Construction

The Duff Norton Air Motor Jack

consists of a cast shell, a lifting mechanism

made up of gears, bearings, shafts, & pinions,

and a lifting screw. These jacks are driven by an

air motor and require a source of compressed air

for operation. Carrying handles, wheels, and

trundle handle for transporting and positioning

the jacks are provided.

1-3. Technical Specifications and

Operational Characteristics

a. The user should be aware of the

capabilities of air motor jack s, e sp e c ially load

capacity.

WARNING

Overloading can be hazardous to the jack,

operating personnel, and the load in the event

of jack failure.

b. See Table 1-1 for technical

specifications of the jacks.

c. See Table 1-2 for operational

characteristics for the jacks.

1

TABLE 1-1. TECHNICAL SPECIFICATIONS

528AMJ

528CMJ

Sustaining

Capacity, Tons

Lifting

Capacity, Tons

Height, Inches 28 36 26 32 44

Raise, Inches 17 25 13 ¾ 18 30

Base Diameter,

Inches

Head

Diameter,

Inches

Weight,

Pounds

Jack Load (Tons) Average Rate* of Rise

528AMJ

528CMJ

536AMJ

536CMJ

126AMJ

126CMJ

132AMJ

132CMJ

144AMJ

144CMJ

*Values are for jacks supplied with air of 100 psi dynamic air pressure at the air valve entrance

2-1. Inspection

The inspection classifications herein are

minimum requirements and should be

augmented when experience from operating

conditions indicate. See Table 2-1 for minimum

inspection schedule.

2-2. Inspection Classification

The jack inspection classific a tio n

consists of initial inspection prior to use and two

50 50 100 100 100

50 50 100 100 100

14 15 13 13 18

5 5 6 1/8 6 1/8 6 1/8

394 425 448 480 530

TABLE 1-2. OPERATIONAL CHARACTERISTICS

536AMJ

536CMJ

0

25

50

0

50

100

Section II

Inspection, Testing, and Maintenance

126AMJ

126CMJ

(in./min.)

11.2

7.1

2.6

6.0

3.2

2.2

general classifications designated as Frequent

Inspection and Periodic Inspection based upon

the intervals at which inspection should be

performed. The intervals in turn are dependent

upon the nature of the critical components of the

jack and the degree of their exposure to wear,

deterioration or malfunction.

2-3. Initial Inspection

132AMJ

132CMJ

Cu. Ft. of Free* Air

Required Per Minute

144AMJ

144CMJ

190

170

120

200

180

155

2

Any new or repaired jack shall be

carefully inspected prior to in itia l u se . An

inspection shall be made by or under the

direction of a person familiar with air motor jack

operations and industrial safety standards.

a. Check for proper service of grease and

oil (refer to paragraph 2-9).

b. Make a detailed external inspection for

proper assembly. Check for any loose

or missing parts, such as cotter pins,

springs, or washers. Remove from

service any jack incorrectly assembled

or with missing parts.

c. Operate the jack through at least one

lifting and lowering cycle while

observing lifting-mechanism operation.

Remove from service any jack which

shows evidence of erratic operation.

FIGURE 2-1. INSPECTOR’S REPORT

Item Remarks (List Deficiencies and Recommended Action

Inspector’s Date Approved Date

Signature Inspected By

d. Perform load test in accordance with

paragraph 2-7.

2-4. Frequent Inspection

Visual examination by the operator or

other qualified designated personnel with

records not required.

a. Normal service—one month

b. Severe service—before each use or

daily, whichever is less frequent.

3

Scored or

damaged control

Lubrication (refer

Scored or

Loose bolts or

Damaged or

Air Screen X X

rod

to para 2-9)

Cracked or

damaged housing

Damaged threads X X

Leaking oil X X

damaged standard

Improper

functioning

Damaged top X X

rivets

improperly

assembled

accessory

equipment

Motor blades As per Paragraph 2-6.a

Lifting Nut As per Paragraph 2-6.b

Periodic

Inspection

Same as Frequent

Inspection

Disassemble and

check for wear

Any unsafe condition disclosed by the

inspection shall be corrected before operation

of the jack is resumed. Repairs should be

performed only by designated qualified

personnel.

TABLE 2-1. MINIMUM INSPECTION SCHEDULE

Normal Service Severe Service

Minimum

Inspection

Schedule

*By Operator or designated personnel without records

**By appointed person making records of apparent external conditions to provide the basis

for continuing evaluation

***Or daily, whichever is longer

****If external conditions indicate internal difficulty

CAUTION

Visual

Monthly*

X X

X X

X X

X X

X X

X X

X X

X X

X**** X

Record

Yearly**

c. The following items shall be visually

inspected and observed during operation

for any deficiencies which might appear

between frequent inspections. The

deficiencies listed shall be carefully

examined and determination made

Visual

Before

Use***

Record

Yearly

4

whether or not they constitute a hazard.

If such a determination is made, the jack

shall be removed from service until the

deficiency is corrected.

(1) Check for scored or damaged control

rod.

(2) Check for scored or damaged standard

and keys.

(3) Check for any abnormal conditions,

loose cotter pins, cap screws, and nuts.

(4) Inspect all visible components for

condition and security of all parts.

(5) Check for adequate lubrication. (Refer

to paragraph 2-9).

(6) Check for foreign substance which may

damage or interfere with proper

operation of the jack.

NOTE

A jack that has been idle for one year or

more shall be inspected in accordance with

Frequent Inspection (Table 2-1).

2-5. Periodic Inspection

Visual inspections by designated

qualified personnel, making records of apparent

external conditions, provide the basis for a

continuing evaluation.

a. Normal service—one year

b. Severe service—before each use or

daily, whichever is less frequent, unless external

conditions indicate that disassembly should be

done to permit detailed inspection.

c. Perform inspection in the same manner

as Frequent Inspections, except that records are

kept. A dated and signed inspection record shall

be kept on all Periodic Inspections. See Figure

2-1 for a typical “Inspector’s Record.”

NOTE

It is recommended that the Periodic

Inspection be performed by and Authorized

Warranty Service Center or appropriate trained

authorized individuals.

a. During Periodic Inspection, if extern a l

appearance indicates possible internal difficulty,

the jack shall be disassembled for cleaning and

examination for internal wear or damage.

See Table 2-1 for Minimum Inspection

Schedule.

2-6. Special Inspection Requirements

a. Air motor blades:

Motor blades should be inspected for

wear after each 100 jack lifting cycles. When

blades are worn to a thickness of 25/32 inch or

less, they should be replaced.

b. Lifting Nut:

The jack’s lifting nut should be

inspected for wear after every 100 jack lifting

cycles. In applications where the jack is

exposed to dirt, dust, metal chips, or other

contaminants, the inspection frequency should

be increased.

WARNING

Failure to properly inspect and maintain the

lifting nut could result in a dropped load and

serious worker injury.

To inspect the lifting nut refer to Figures

4-1 through 4-8 and Figure 2-2, and proceed as

follows:

(1) Fully extend the upright unloaded jack.

(2) Loosen the two screws and remove the

gage from the jack.

(3) Clean grease from the hole which had

been covered by the gage.

(4) Insert the slender end of the gage into

the hole.

(5) If the thin tip of the gage can be made to

enter the space between the top flank of the

lifting nut thread and the bottom flank of the

lifting screw thread, the lifting n u t is worn out.

(Refer to Figure 2-2).

(6) Remove jack with worn out lifting nut

from service and ensure that it is properly

repaired before returning to service.

5

Figure 2-2. LIFTING NUT INSPECTION

2-7. Load Test

Any new, altered, or repaired jack shall

be tested for its ability to sustain its rated load

prior to regular use. The jack shall be operated

to 100 percent of its capacity. See Table 1-1 for

applicable load capacity.

2-8. Maintenance

The maintenance of the jack shall

include lubrication, cleaning, and replacement of

defective parts during disassembly and

assembly.

2-9. Lubrication

a. Air motor:

Remove the filler plugs and fill with

Mobil DTE Oil Light (Duff p/n X6002) or

equivalent oil after every eight hours of use. Air

line filter lubrication should be used for this

jack. Rotor ball bearings should be coated with

grease each time the motor is disassembled.

6

b. Weekly lubrication for the jack:

(1) Standard, keys, and shut-off rod. Use a

light oil.

(2) Control valve parts. Use a light oil.

c. Monthly lubrication of the jack:

(1) Lubricate lifting screw through hole in

standard. Use Mobil DTE Oil Light (Duff p/n

X6002).

(2) Clean and lubricate handle latch and

throttle control parts. Use M o b il D TE Oil Light

(Duff p/n X6002).

d. After repair or overhaul:

Drain, flush, and refill internal jack

mechanism with Mobilgrease XHP 461 or

equivalent.

e. Clean and grease wheels regularly.

f. Screw lubrication under heavy load use.

When operating the jack under heavy

loading, pump Mobilgrease XHP 461 grease into

the standard every few jack lifting cycles.

(3) Remove grease level plug and check

grease level. Fill with Mobilgrease XHP 461 or

equivalent.

FIGURE 2-3. THROTTLE ADJUSTMEN T F O R 528A MJ/CMJ, 536AMJ/CMJ, 126AMJ/CMJ,

132AMJ/CMJ, AND 144AMJ/CMJ

Jack is properly adjusted when parts are in position

shown in drawing at left. The head is no less than 3/16

from the top of the shell. The control lever end “F” is

against the end of the stop groove. Pin “D” is against

the end of the throttle lever. Screw “ B ” is in th e h o le

“E” in the control rod.

To make adjustments, loosen lock nuts “A” and “C” and

screw “B.” Then screw control rod in or out of end until

point “F” and pin “D” are in the position shown, with

the head no less than 3/16 from shell. Retighten screw

“B” in hole “E” and lock the nuts “A” and “C.”

SECTION III

OPERATION

3-1. Operational Requirement

a. Operators shall be instructed in the

proper use of the jack.

b. The operator shall familiarize himself

with the jack, its capabilities, and its o p e ra tion .

He/she should also know and understand the

mandatory requirements of American National

Standard (ANSI B30.1).

c. The throttle lever is located o n th e

control valve above the air motor.

(1) To raise a load, pull the throttle le v er to

UP.

(2) To lower a load, push the throttle lever

to DOWN.

(3) To cease movement of a load, place the

throttle lever in the horizontal po s ition .

(4) The throttle lever will automatically

move to the horizontal position when the jack

has extended or lowered to its limit.

3-2. Operating Procedures and

Precautions

The following precautions shall be

followed in operation of the jack:

a. Visually inspect the jack before each

shift or each use, whichever is less frequent.

7

b. Clean any jack exposed to rain, sand, or

grit—then oil before use.

c. Determine if the load is within the load

rating of the jack. Refer to Table 1-1 for load

rating of the jack.

d. Support the jack at the base in such a

manner that it cannot shift under the load.

e. Use shims or constraints to prevent

slippage of base or load.

f. Avoid off-center loading of the jack.

Assure that it is centered, plumbed, and properly

blocked.

g. Do NOT use an extender.

h. Follow the load with cribbing or

blocking.

i. Take measure to prevent personnel from

working or passing under the load until the load

is secured against accidental lowering by

cribbing, blocking, or other means.

j. Ensure that all personnel are clear of the

load before lowering.

k. Ensure that all operators are instructed

as to signals and other procedures for multiple

jacks or other special lifts.

SECTION IV

ILLUSTRATED PARTS LIST

4-1. General

This section contains exploded view

illustrations. The number adjacent to each part

is the index number. Keyed to this index

number on the parts listing is the part name, part

number, and quantity required. When ordering

parts for a particular jack, please specify part

name, part number, quantity desired, and full

jack description, and serial number, if known.

l. Ensure that the lifting nut is ins p e cte d

for wear as per paragraph 2-6.b.

LIST OF ILLUSTRATIONS

Figure

No.

4-1 528AMJ/536AMJ 9

4-2 Gage Area for

4-3 528CMJ/536CMJ 15

4-4 Gage Area for

4-5 126AMJ/132AMJ/144AMJ 21

4-6 Gage Area for

4-7 126CMJ/132CMJ/144CMJ 27

4-8 Gage Area for

4-9 X6000 Air Motor 33

4-10 X4153 Air Motor 35

Jack/Air Motor No. Page

528AMJ/536AMJ

528CMJ/536CMJ

126AMJ/132AMJ/144AMJ

126CMJ/132CMJ/144CMJ

No.

10

16

22

28

8

9

Loading...

Loading...