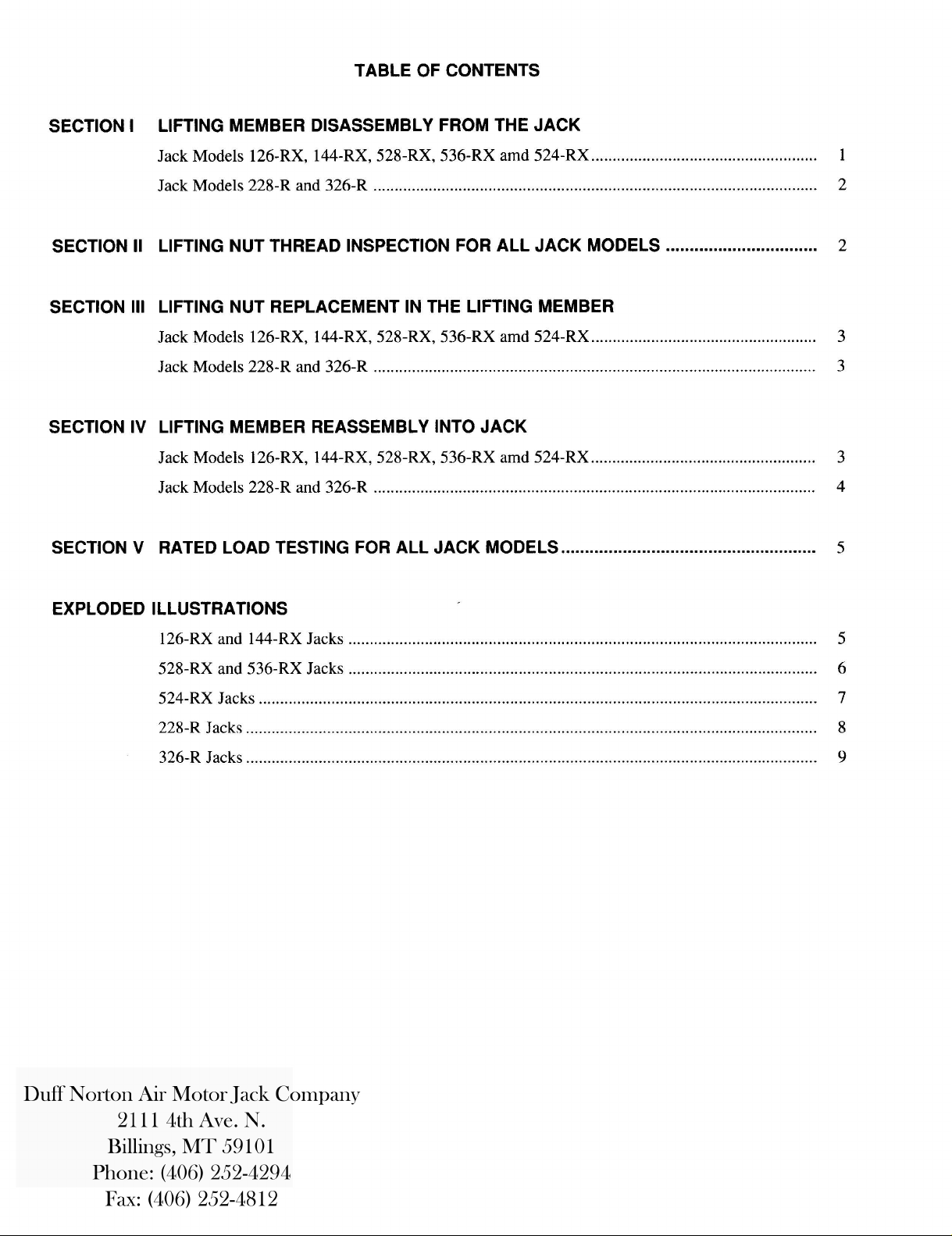

Duff-Norton 126-RX, 144-RX, 528-RX, 524-RX, 536-RX Instructions Manual

...

1

INSTRUCTIONS FOR INSPECTING LIFTING NUTS FOR THREAD WEAR IN DUFF NORTON

AIR MOTOR JACK MODELS 126RX, 144RX, 528RX, 536RX, 524RX, 228R, AND 326R

At the heart of every Duff Norton air motor jack is the

power thread mechanism—comprised of an externally

threaded lifting screw and an internally threaded

lifting nut. As the threads of the lifting nut make

sliding contact with the lifting screw, they begin to

wear. If the jack is operated long enough the thread

will wear to the point where it no longer has the

thickness required to support the jack load. When this

happens, the lifting nut will shear at the lifting screw

thread outside diameter, and the jack member will

collapse—bringing the load it was supporting crashing

down on the cribbing or blocking which should be

used in any jacking operation.

For this reason it is important to inspect the lifting nut

in your Duff Norton air motor jacks for wear at regular

intervals—after every 100 full extend and retract

cycles under full rated load when the jack is operated

with recommended lubrication in a clean environment.

Of course, the inspection interval should be modified

up or down based on the stroke, load, lubrication and

environment conditions existing during actual use.

The Duff Norton “Operating, Inspection and

Maintenance Instructions” manual covers inspection

of lifting nut threads for wear in great detail. The

procedure it describes is suitable for use mainly by

trained mechanics in authorized jack repair centers.

Duff Norton Air Motor Jack Co. has developed an

inspection procedure which is more readily used by

authorized jack repair centers. The procedure requires

that the lifting member be removed from the jack.

The lifting nut threads are then checked by measuring

them with a specially designed gage made from flat

sheet metal. The gage has teeth that enter the thread

spaces and indicate whether the threads are worn

beyond the allowable limit. A set of four gages (part #

X4829) for the various air motor jack models is

available.

Instructions for using the new gages for inspecting air

motor jack lifting nuts for thread wear are presented

below. These instructions involve only the inspection

of lifting nuts for thread wear. It is important that

other aspects of air jack operation, inspection and

maintenance as presented in the maintenance manual

be understood and followed for the continued safe

operation of jacks.

Duff Norton Air Motor Jack Co. has also developed a

video to show the inspection procedure.

Extra gage sets, gage use instructions, maintenance

manuals and the how-to video are available from Duff

Norton Air Motor Jack Co. at:

Duff Norton Air Motor Jack Co.

2111 4th Ave. N.

Billings, MT 59101

Phone: 406-252-4294

Fax: 406-252-4812

To disassemble the lifting member from the jack, to

inspect the lifting nut for power thread wear, to

replace worn out lifting nuts in lifting members, to

reassemble the lifting member into the jack and to test

the reassembled jack, refer to the exploded illustration

appropriate to the jack model and proceed per the

instructions below.

I. LIFTING MEMBER DISASSEMBLY FROM THE JACK

A. JACK MODELS 126RX, 144RX, 528RX,

536RX, AND 524RX

1. Disconnect the air supply from the

jack and position the jack upright.

2. Remove the bolts (Item 87 for 126RX,

144RX, & 524RX; Item 89 for 528RX &

536RX), the lockwashers (Item 88 for

126RX, 144RX, & 524RX; Item 90 for

528RX & 536RX), and the handle bracket

assembly (Items 81-86 & 89 for 126RX,

144RX, & 524RX; Items 83-88 & 91 for

528RX & 536RX) from the jack.

3. Remove the screws (Item 90 for 126RX

& 144RX; Item 92 for 528RX & 536RX;

Item 97 for 524RX), the lockwashers (Item

91 for 126RX & 144RX; Item 93 for 528RX

& 536RX; Item 98 for 524RX), and the

throttle lever guard (Item 92 for 126RX &

144RX; Item 94 for 528RX & 536RX; Item

99 for 524RX) from the jack.

4. Loosen the check nut (Item 98 for 126RX

& 144RX; Item 100 for 528RX & 536RX;

Item 91 for 524RX) on the control rod (Item

99 for 126RX & 144RX; Item 101 for

528RX & 536RX; Item 90 for 524RX).

5. Remove the check nut (Item 76 for

126RX & 144RX; Item 78 for 528RX,

536RX & 524RX)

Loading...

Loading...