Page 1

Owner’s manual

DUCATISPORTTOURING

ST4s

ST4s ABS

E

1

Page 2

E

2

Page 3

Hearty welcome among Ducati fans! Please accept our

best compliments for choosing a Ducati motorcycle. We

think you will ride your Ducati motorcycle for long

journeys as well as short daily trips. Ducati Motor Holding

S.p.A. wishes you smooth and enjoyable riding.

We are steadily doing our best to improve our “Technical

Assistance” service. For this reason, we recommend you

to strictly follow the indications given in this manual,

especially for motorcycle running-in. In this way, your

Ducati motorbike will surely give you unforgettable

emotions. For any servicing or suggestions you might

need, please contact our authorized service centers.

Enjoy your ride!

Note

Ducati Motor Holding S.p.A. declines any liability

whatsoever for any mistakes incurred in drawing up this

manual. The information contained herein is valid at the

time of going to print. Ducati Motor Holding S.p.A.

reserves the right to make any changes required by the

future development of the above-mentioned products.

E

For your safety, as well as to preserve the warranty,

reliability and worth of your motorcycle, use original

Ducati spare parts only.

Warning

This manual forms an integral part of the

motorcycle and - if the motorcycle is resold - must

always be handed over to the new owner.

3

Page 4

TABLE OF CONTENTS

General 6

Warranty 6

E

Symbols 6

Useful information for safe riding 7

Carrying the maximum load allowed 8

Identification data 10

Controls 11

Position of motorcycle controls 11

Instrument panel 12

LCD unit functions 14

LCD - parameter setting/display 16

The immobilizer system 24

Keys 25

Code card 26

Procedure to disable imobilizer engine block through

throttle twistgrip 27

Duplicate keys 28

Key-operated ignition switch and steering lock 29

Left switch 30

Clutch lever 32

Cold start lever 33

Right switch 34

4

Throttle twistgrip 35

Front brake lever 35

Rear brake pedal 36

Gear change pedal 36

Setting the gear change and rear brake pedals 37

Main components and devices 39

Location 39

Tank filler plug 40

Seat catch and helmet hooks 41

Side stand 42

Lifting handgrip 43

Power outlet 43

Centre stand 44

Rear view mirrors 45

Front fork adjusters 46

Rear shock absorber adjusters 48

Changing motorcycle track alignment 50

Directions for use 52

Running-in recommendations 52

Pre-ride checks 54

ABS system 55

Starting the engine 56

Moving off 59

Braking 59

ABS system 59

Stopping the motorcycle 61

Parking 61

Refueling 62

Tool kit and accessories 63

Page 5

Main maintenance operations 64

Removing the fairing 64

Side panniers 69

Lifting the fuel tank 70

Cleaning and changing air filters 71

Checking the coolant level 72

Checking brake and clutch fluid level 73

Checking brake pads for wear 74

Lubricating cables and joints 75

Throttle cable adjustment 76

Charging the battery 77

Chain tensioning 78

Chain lubrication 79

Replacing bulbs 80

Beam setting 85

Tyres 86

Checking engine oil level 88

Cleaning and replacing the spark plugs 89

Cleaning the motorcycle 90

Storing the bike away 91

Important notes 91

Technical data 92

Overall dimensions 92

Weights 92

Top-ups 93

Engine 94

Timing system 94

Performance data 95

Spark plugs 95

Frame 95

Wheels 95

Tyres 95

Brakes 96

Transmission 97

Suspensions 98

Exhaust system 98

Available colours 98

Electric system 99

For United States of America version Only 105

Routine maintenance record 114

E

5

Page 6

GENERAL

Warranty

In your own interest, and in order to guarantee product

E

reliability, you are strongly advised to refer to our

authorized Dealers and workshops for any servicing

requiring particular technical expertise. Our highly skilled

staff have access to the implements required to perform

any servicing job at best, and use Ducati original spare

parts only as the best guarantee for full

interchangeability, smooth running and long life.

All Ducati motorcycles come with a “Warranty Card”.

However, warranty does not apply to the motorcycles

used in competitions or competitive trials. No motorcycle

part may be tampered with, altered, or replaced with

parts other than original Ducati spare parts during the

warranty period, or the warranty right will be

automatically invalidated.

6

Symbols

Ducati Motor Holding S.p.A. advises you to read this

booklet carefully so as to become familiar with your

motorcycle. In case of any doubts, please call a Ducati

dealer or authorized workshop. The information

contained herein will prove useful on your trips - and

Ducati Motor Holding S.p.A. wishes you smooth,

enjoyable riding - and will help you keep the performance

of your motorcycle unchanged for a long time.

This manual contains some special remarks:

Warning

Failure to comply with these instructions may put

you at risk and lead to severe injury or death.

Important

Possibility of damaging the motorcycle and/or its

components.

Note

Additional information concerning the job being

carried out.

The terms right and left are referred to the motorcycle

viewed from the riding position.

Page 7

Useful information for safe riding

Warning

Read this section before riding your motorcycle.

Accidents are frequently due to inexperience. Always

make sure you have your licence with you when riding;

you need a valid licence to be entitled to ride your

motorcycle.

Do not lend your motorcycle to inexperienced riders or

who do not hold a valid licence.

Both rider and pillion passenger must always wear a

safety helmet.

Wear proper clothing, with no loose items or accessories

that may become tangled in the controls or limit your

zone of vision.

Never start or run the engine indoors. Exhaust gases are

poisonous and may lead to loss of consciousness or even

death within a short time.

Both rider and pillion passenger should keep their feet on

the footpegs when the motorcycle is in motion.

Always hold the handlebars firmly with both hands so

you will be ready for sudden changes of direction or in

the road surface. The pillion passenger should always

hold on to the suitable rear handgrip with both hands.

Ride within the law and observe national and local rules.

Always respect speed limits where these are posted.

However, always adjust your speed to the visibility, road

and traffic conditions you are riding in.

Always signal your intention to turn or pull to the next

lane in good time using the suitable turn indicators.

Be sure you are clearly visible and do not ride within the

blind spot of vehicles ahead.

Be very careful when tackling road junctions, or when

riding in the areas near exits from private grounds, car

parks or on slip roads to access motorways.

Always turn off the engine when refueling.

Be extremely careful not to spill fuel on the engine or on

the exhaust pipe when refueling.

Do not smoke when refueling.

While refueling, you may inhale noxious fuel vapors.

Should any fuel drops be spilled on your skin or clothing,

immediately wash with soap and water and change your

clothing.

Always remove the key when you leave your motorcycle

unattended.

The engine, exhaust pipes, and mufflers stay hot for a

long time.

Warning

The exhaust system might be hot, even after

engine is switched off; pay particular attention not to

touch exhaust system with any body part and do not park

the vehicle next to inflammable material (wood, leaves

etc.).

Park your motorcycle where no one is likely to hit it and

use the side/center stand.

Never park on uneven or soft ground or your motorcycle

may fall over.

E

7

Page 8

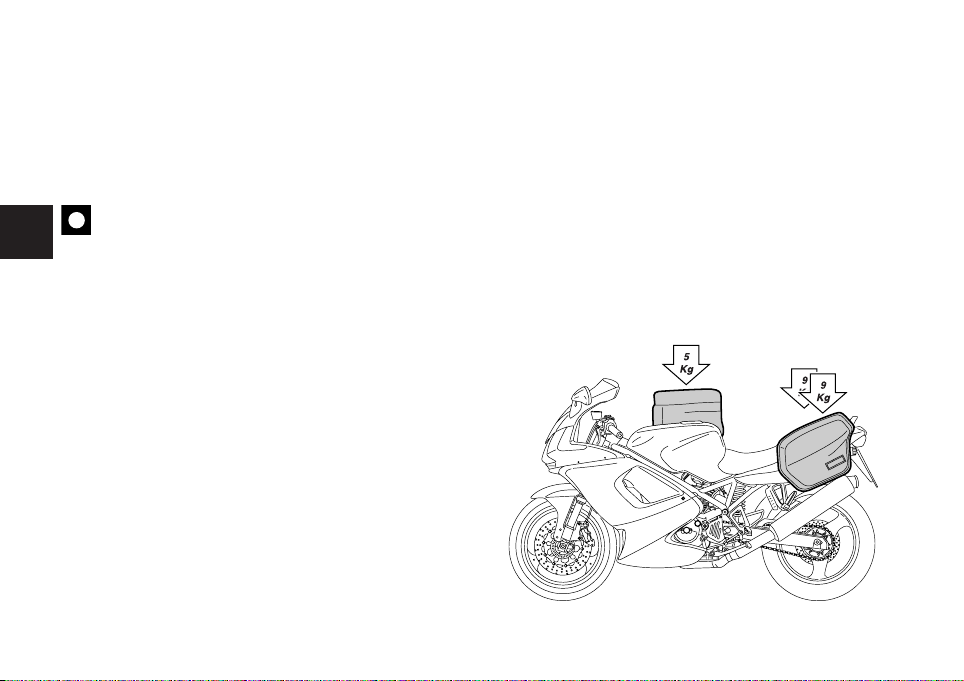

Carrying the maximum load allowed

Your motorcycle is designed for long-distance riding,

carrying the maximum load allowed in full safety and

comfort.

Even weight distribution is critical to preserving these

safety features and avoiding trouble when performing

sudden manoeuvres or riding on bumpy roads.

Important

E

When the side panniers are fitted, it is

recommended to never exceed 120 Km/h.

Further reduce speed if tyres are worn down and when

riding on poor road surface or with poor visibility.

8

Information about carrying capacity

The total weight of the motorcycle in running order

including rider, pillion passenger, luggage and additional

accessories should not exceed 420 Kg.

The weight of luggage alone should never exceed 23 Kg

divided as follows (fig. 1):

max 9 kg for each side pannier;

max 5 kg for tank bag.

fig. 1

Page 9

Try to arrange your luggage or heavy accessories in the

lowest possible position and close to motorcycle centre.

Be sure to secure the luggage to the supports provided

on the motorcycle as firmly as possible. Improperly

secured luggage may affect stability.

Never fix bulky or heavy objects to the handlebar or to

the front mud guard as this would affect stability and

cause danger.

Do not insert any objects you may need to carry into the

gaps of the frame as these may foul moving parts.

If you install the side panniers (available from Ducati

Spare Parts Department):

sort luggage and accessories so to distribute weight

evenly and then arrange them in the panniers so that

they are well balanced; lock both side panniers using the

suitable key lock.

Make sure the tyres are inflated to the proper pressure

indicated at page 86 and that they are in good condition.

E

9

Page 10

Identification data

All Ducati motorcycles have two identification numbers,

for frame (fig. 2) and engine (fig. 3).

Frame number

Engine number

E

Note

These numbers identify the motorcycle model and

should always be indicated when ordering spare parts.

10

fig. 2

fig. 3

Page 11

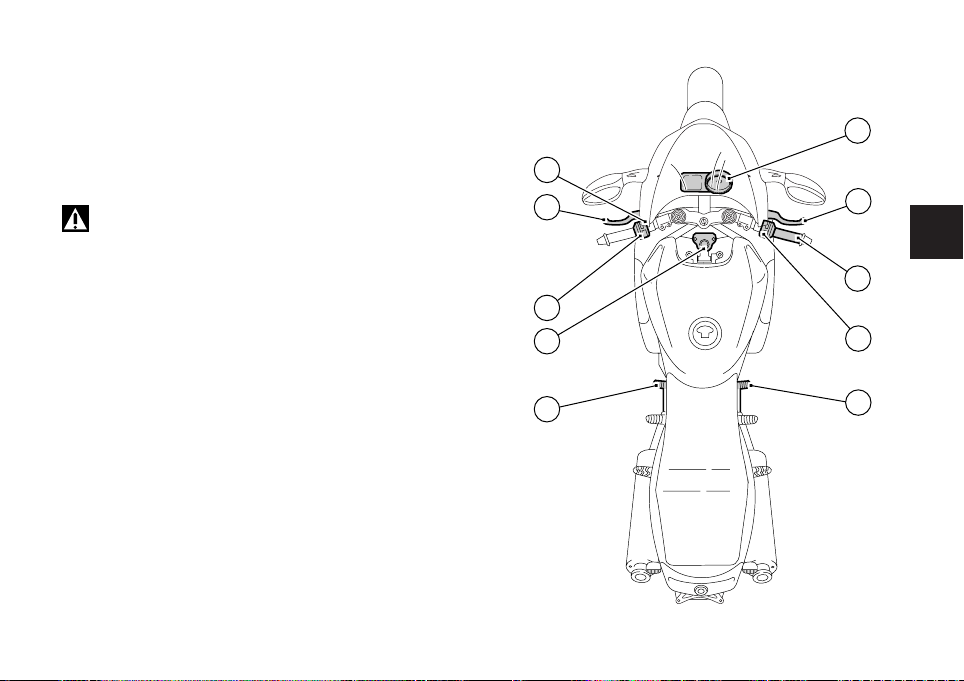

CONTROLS

4

5

3

2

9

10

6

7

8

1

Warning

This section details the position and function of all

the controls you need to drive your motorcycle. Be sure

to read this information carefully before you use the

controls.

Position of motorcycle controls (fig. 4)

1) Instrument panel.

2) Key-operated ignition switch and steering lock.

3) Left switch.

4) Clutch lever.

5) Cold start lever.

6) Right switch.

7) Throttle twistgrip.

8) Front brake lever.

9) Gear change pedal.

10) Rear brake pedal.

E

fig. 4

11

Page 12

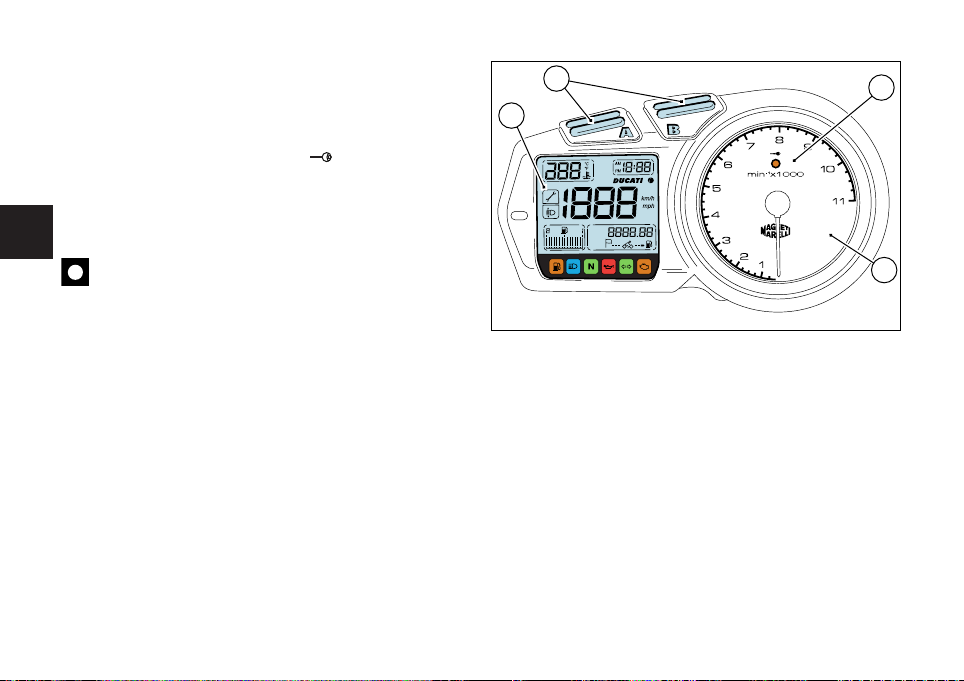

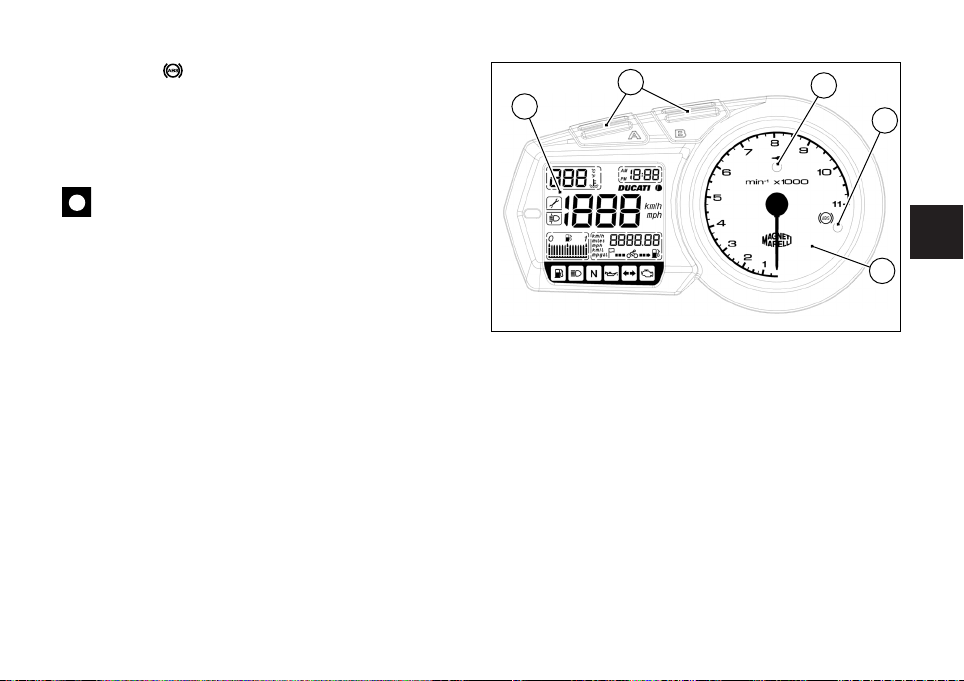

Instrument panel (fig. 5.1-5.2)

1) LCD, (see page 14).

2) Control buttons A and B.

Buttons used to display and set instrument panel

parameters.

3) Immobilizer IMMO indicator (amber).

The indicator stays on in case of wrong key code or key

code not recognised; it flashes in case an immobilizer

system warning was reset with the procedure to override

the immobilizer with the throttle twistgrip (see page 27).

E

Important

The instrument panel allows to making diagnosis on

the electronic injection/ignition system.

These menus are for the trained personnel only; do not

use them for any reason. Should you accidentally enter

this function, turn the key to OFF and contact an

authorised Ducati Service Center for the necessary

inspections.

4) Revolution counter (rpm).

Shows the engine rotation speed/minute.

12

2

3

1

km/h

miles

mph

km/L

mpgal

4

fig. 5.1

Page 13

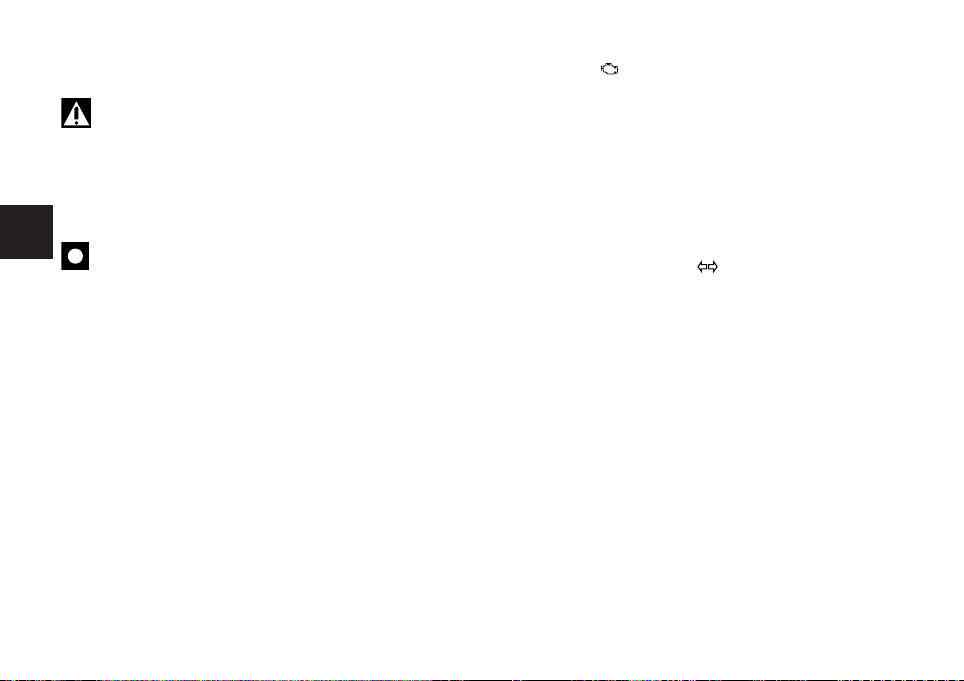

5) ABS light (orange) (ST4s ABS)

Turns on for a few seconds when the key is turned to ON

(CHECK) and then goes out; ABS on.

Turns on and flashes when the ABS system has been

turned off using the button incorporated in the LH switch

(see page 31).

Important

When the ABS light stays on, it means the ABS is

not working. This will not affect the operation of the

regular braking system. However, contact a Dealer or

Authorized Workshop. A possible cause is insufficient

battery voltage and it is a good rule to charge the battery.

Another possible cause is a fault in the system.

2

1

3

5

E

4

fig. 5.2

13

Page 14

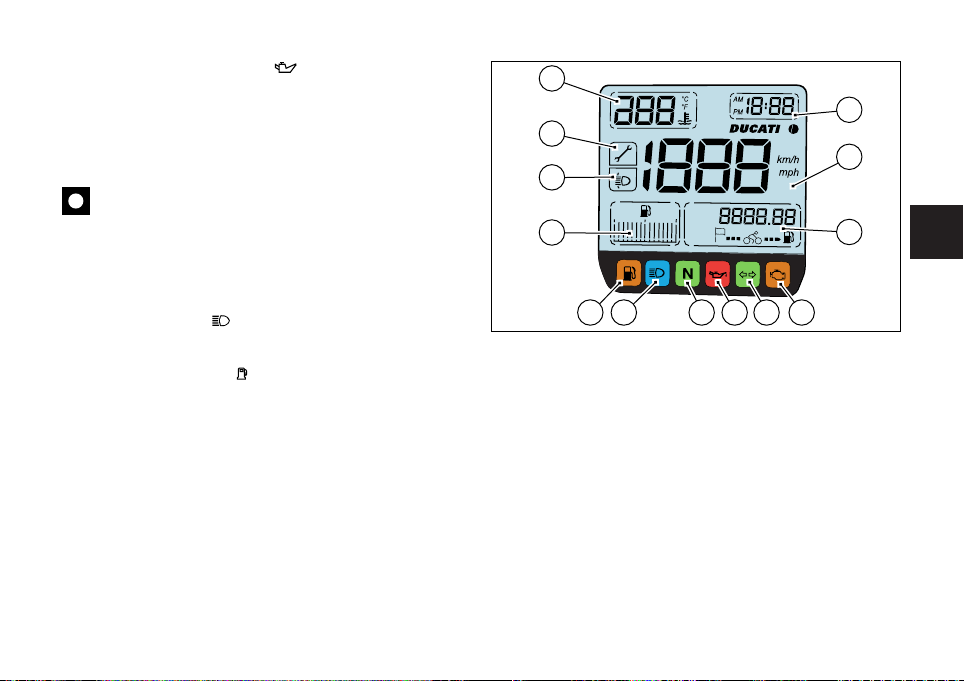

LCD unit functions

Warning

Stop the motorcycle before using the instrument

panel controls. Never operate the instrument panel

controls while riding.

1) Water temperature warning light.

This function indicates engine water temperature.

E

Important

Never use the vehicle when the temperature

reaches max. value or the engine might damage.

2) Clock.

3) Tachometer.

This function indicates vehicle speed.

4) Auxiliary display.

This function indicates odometer, trip meter, average

speed, instant fuel consumption, average fuel

consumption, fuel used, range and residual fuel quantity,

in this sequence.

14

5) EOBD light (amber).

When on, this light is used by the control unit to signal

the presence of errors and sometimes the consequent

engine disabling.

It is also used as a reference light during the immobilizer

overriding procedure with the throttle twistgrip.

If there are no errors, the light should turn on when the

ignition switch is turned ON and should go off after a few

seconds (usually 1.8 - 2 seconds).

6) Indicators repeater light (green).

Comes on and flashes when a turn indicator is on.

Page 15

7) Engine oil pressure light (red).

k

m

/h

m

ile

s

m

p

h

k

m

/L

m

p

g

a

l

0

1

5

4

3

2

67810

11

12

13

1

9

Comes on when engine oil pressure is too low. It briefly

comes on when the ignition is switched to ON and

normally goes out a few seconds after engine starts.

It may shortly come on when the engine is very hot,

however, it should go out as the engine revs up.

Important

If this light (7) stays on, stop the engine or it may

suffer severe damage.

8) Neutral light N (green).

Comes on when in neutral position.

9) High beam light (blue).

Comes on when high beam is on.

10) Fuel warning light (yellow).

Comes on when there are about 6.5 liters of fuel left in

the tank.

11) Fuel Display.

This function indicates the quantity of fuel in the fuel

tank. When the last bar stays on (flashing), the low fuel

light (10) comes on.

12) Beam vertical adjustment indicator.

The pilot light comes on to signal that the user has

entered the beam vertical setting mode.

E

fig. 6

13) Service warning.

The light comes on to signal that the vehicle has covered

the distance corresponding to a Scheduled Maintenance

interval. The light keeps flashing until the vehicle has

travelled 50 km after hitting the service interval. Then it

stays on permanently. The system shall be reset by the

DUCATI Authorised Service Center that has serviced the

vehicle.

15

Page 16

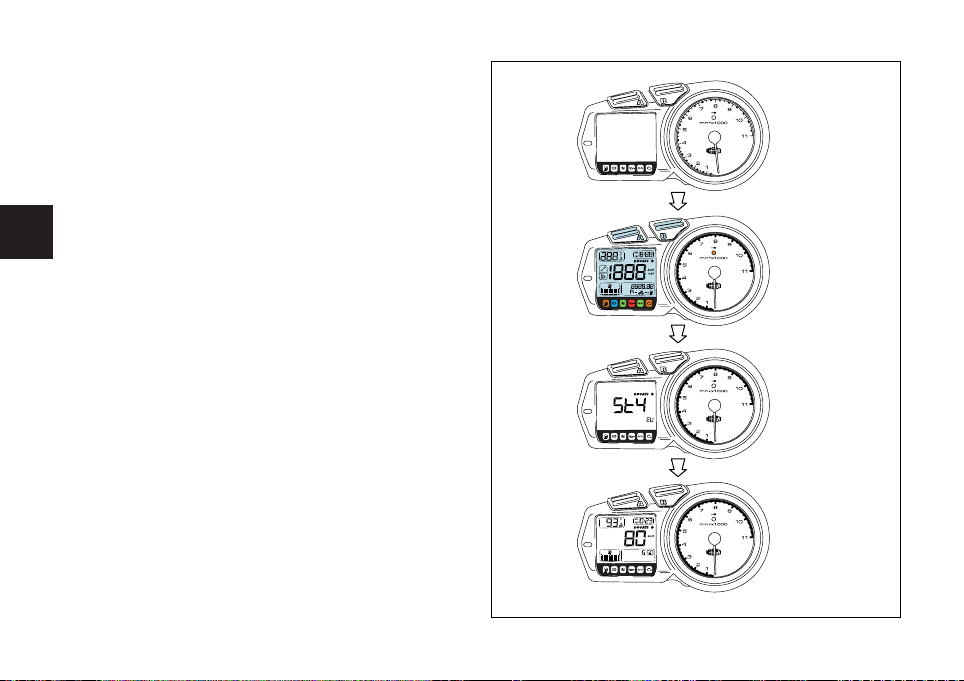

LCD - Parameter setting/display

0

1

km/h

miles

mph

km/L

mpgal

km/h

OFF

CHECK 1

CHECK 2

ON

0

1

When turning the key from OFF to ON (Key-ON) the

instrument panel carries out a Check of the whole

instruments: indexes, displays and pilot lights (see fig. 7).

E

16

fig. 7

Page 17

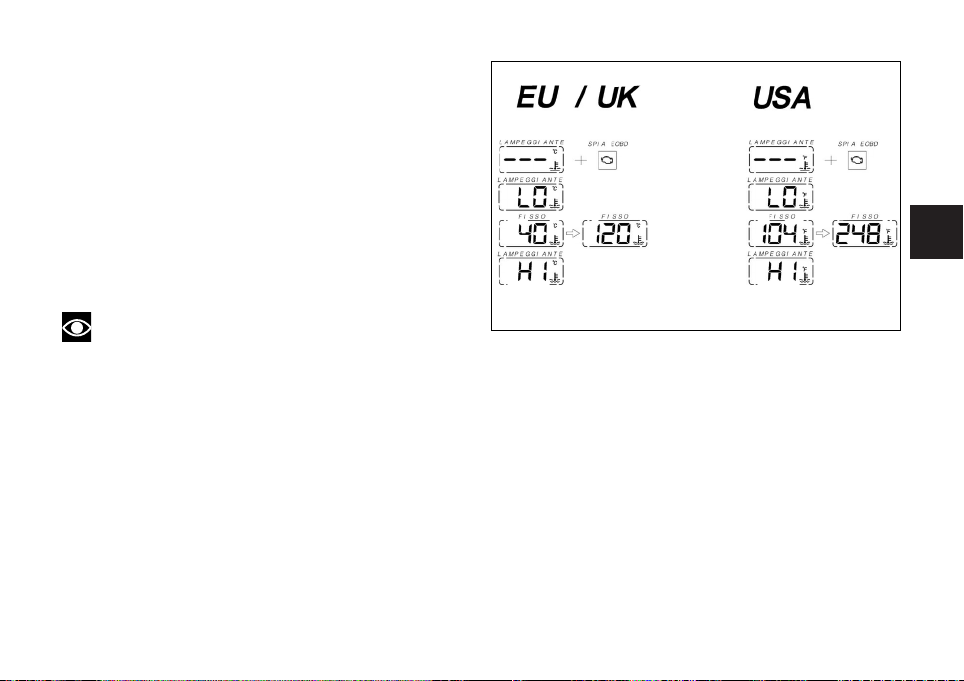

Water temperature indicator (fig. 8)

It indicates engine cooling water temperature.

If temperature drops under 40°C/104°F, “LO” will start

flashing on the display.

If water temperature ranges between 40 °C/104 °F and

120 °C/248 °F, temperature value is displayed in fixed

mode.

If water temperature ranges between +121 °C/250 °F

and +124 °C/255 °F, “HI” will start flashing on the

display.

If water temperature is +125°C /257 °F, a flashing dotted

line “---“ will be displayed and EOBD light will turn on (5,

fig. 6).

Note

If water temperature sensor is disconnected, a

dotted line “---“ will be displayed and the EOBD light will

turn on (5, fig. 6).

E

fig. 8

17

Page 18

Clock setting function

km

miles

km

km/h

km/L

mpgal

km/L

L

gal

km

miles

L

miles

mph

mpgal

gal

ODOMETER

TRIP METER

AVERAGE SPEED

INSTANT FUEL CONSUMPTION

AVERAGE CONSUMPTION

FUEL USED

RANGE

DIGITAL FUEL LEVEL INDICATION

Hold down button (A, see page 12) for 2 seconds, the

wording AM begins to flash. If button (B) is pressed

again, PM begins to flash; press button (B) to go back to

previous step. Press button (A) to confirm and start

setting hours that shall begin to flash.

Use button (B) to change hour value. If button (B) is

pressed for more than 5 seconds, fast scroll is activated.

Press button (A) to confirm and start setting minutes.

Use button (B) to set minutes. Press button (A) to

E

confirm and exit clock setting mode and go back to

normal operation.

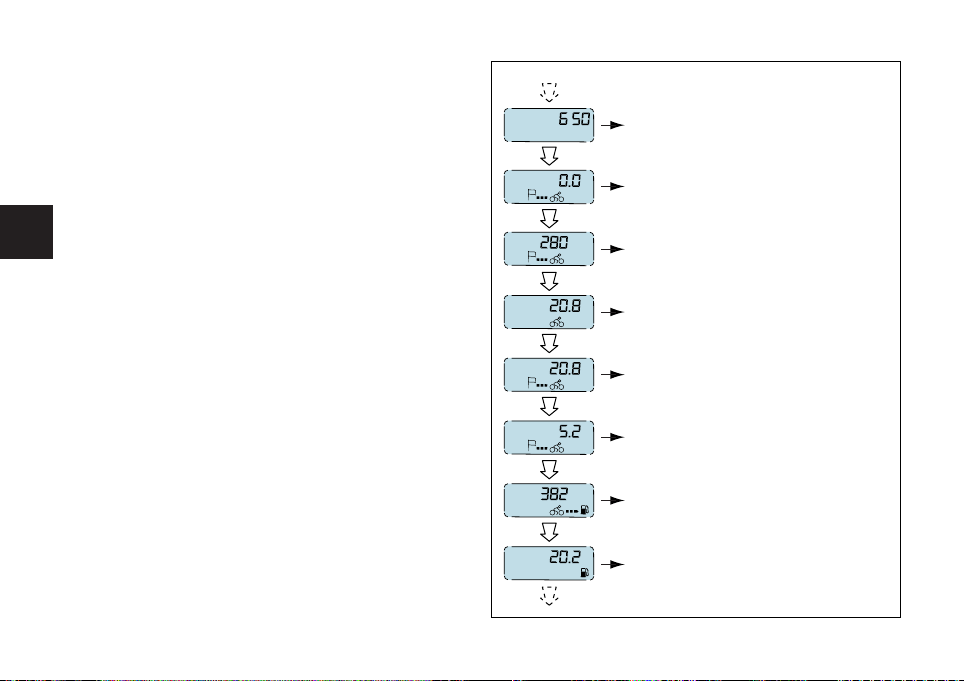

Auxiliary display functions (fig. 9)

Press button (B) with the key on ON to scroll down the

following functions, in sequence:

- Odometer

- TRIP meter

- Average speed

- Instant fuel consumption

- Average consumption

- Fuel used

- Range

- Digital fuel level indication

18

fig. 9

Page 19

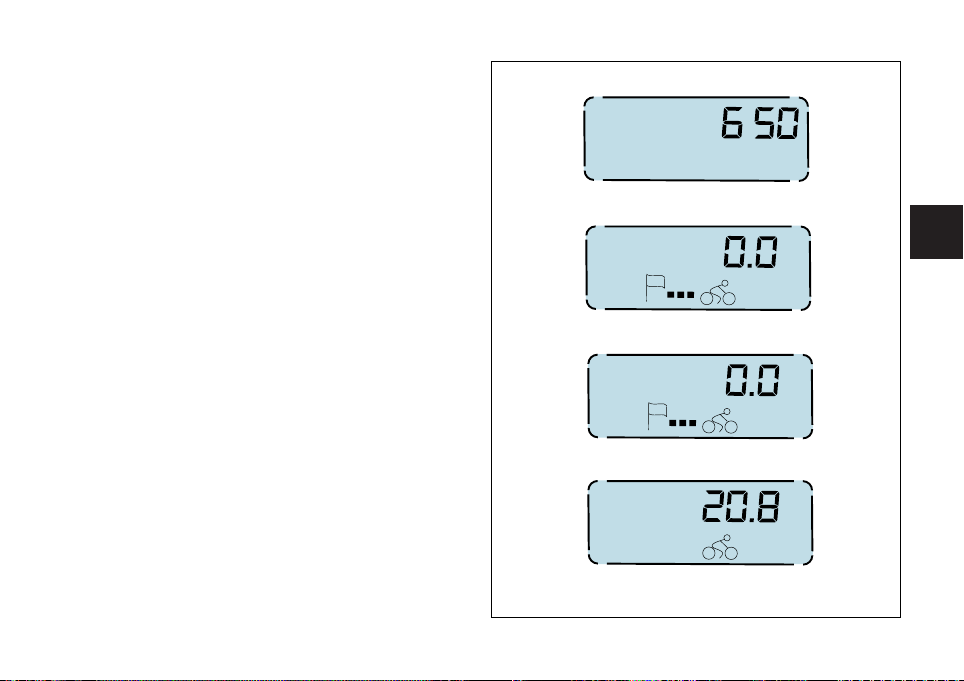

"Odometer" indication (fig. 10)

km

miles

km

miles

km

miles

km/L

mpgal

Indicates total distance covered by the vehicle.

"TRIP meter" indication

This function indicates the distance covered since the

meter was last reset. It is possible to reset this indication

by entering the relevant function and holding down

button (A, see page 12), for at least 2 seconds. When a

value of 9999.9 km (or miles) is reached, the display will

automatically reset.

"Average speed" indication

This function indicates vehicle average road speed.

Average speed calculation is based on the distance

travelled since the "TRIP meter" was last reset.

"Instant fuel consumption" indication

This function indicates the instant consumption of the

vehicle when in motion. When the vehicle is stopped

with engine running, a string of dashes is displayed

"- - . -". With vehicle stopped and engine off "0.0" is

displayed.

E

fig. 10

19

Page 20

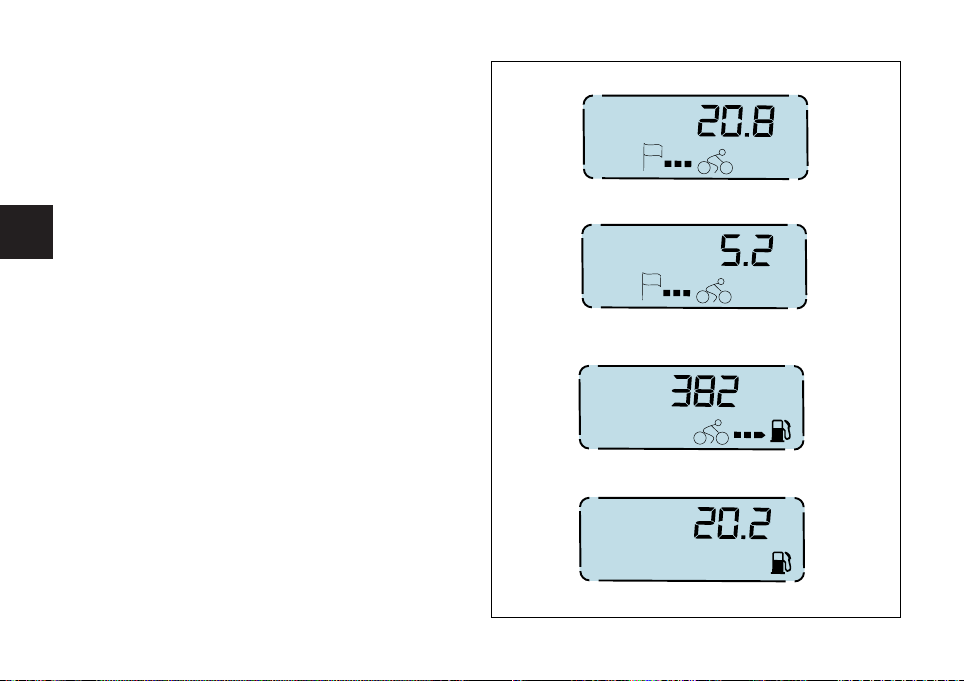

"Average consumption" indication (fig. 11)

km/L

mpgal

L

gal

km

miles

L

gal

This function indicates the vehicle average consumption

when in motion. The calculation is based on the distance

travelled since the "TRIP meter" was last reset. When the

vehicle is stopped, either with the engine off or running,

the last value stored is displayed until indication is

refreshed.

"Fuel used" indication

This function indicates the fuel used by the vehicle to

E

travel the distance. The calculation is based on the

distance travelled since the "TRIP meter" was last reset.

When indication exceeds 9999.9 liters (2201.9 Imp. gal. -

2641.9 US gal.), the display shows a string of dashes

"- - . -".

20

fig. 11

Page 21

"Range" indication

This function indicates how far the vehicle can travel

using the fuel left in the tank. When this display function

is not selected, the display automatically switches to

"Range" indication as soon as the LOW FUEL LIGHT (10,

fig. 6) comes on and the display shows a string of dashes

"- - . -" and the indication for 10 seconds. Range indication

is then turned on automatically every 60 seconds while

the low fuel light stays on.

When the vehicle is stopped, either with the engine off

or running, the last value stored is displayed until

indication is refreshed.

Note

The value is refreshed every10 seconds, the

tolerance is 0.5 km.

"Digital fuel level" indication

This function indicates how much fuel is left in the fuel

tank.

When the LOW FUEL LIGHT (10, fig. 6) comes on, the

display shows a string of dashes "- - . -" and the fuel

pump symbol begins to flash.

E

21

Page 22

BBBA

AAAA

AB B B

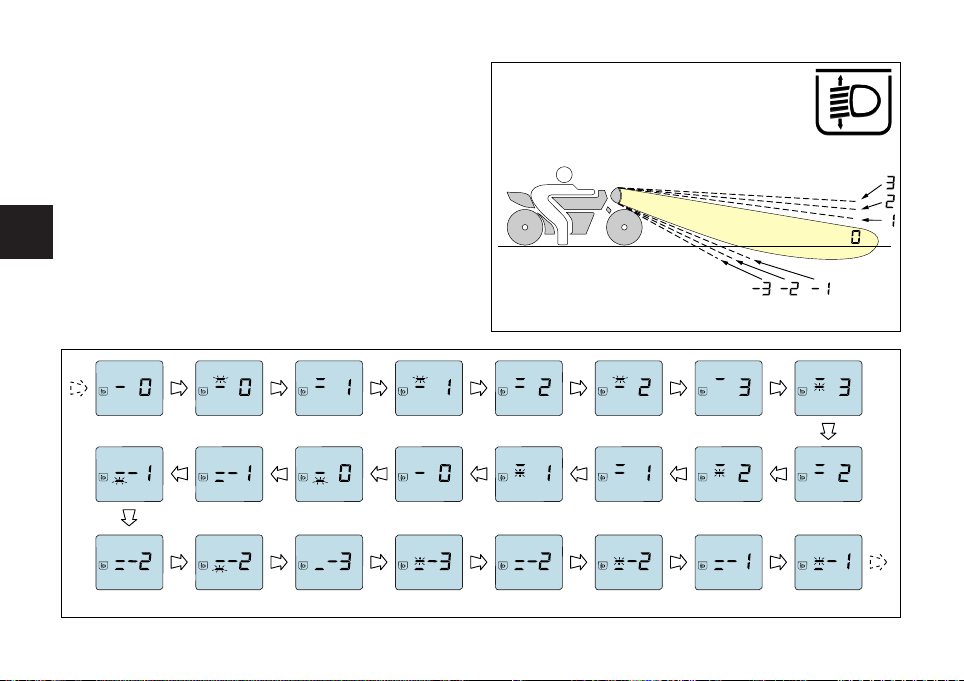

Beam vertical adjustment (fig. 12.1-12.2)

This function allows headlight beam height setting.

To enter this function, hold down button (B, see fig. 5.1)

and turn the key to ON; the display shows a value (fig.

12.2) corresponding to beam position and the pilot light

on the display, indicating beam vertical setting mode (12,

fig. 6) comes on.

Use buttons (A) and (B), respectively, to lower or raise

the beam. Range available is from position "3" (max.

beam height) to position "-3" (min. beam height).

E

Turn the key to OFF to exit the function. While exiting

setting mode, the selected beam position is stored.

fig. 12.1

22

fig. 12.2

Page 23

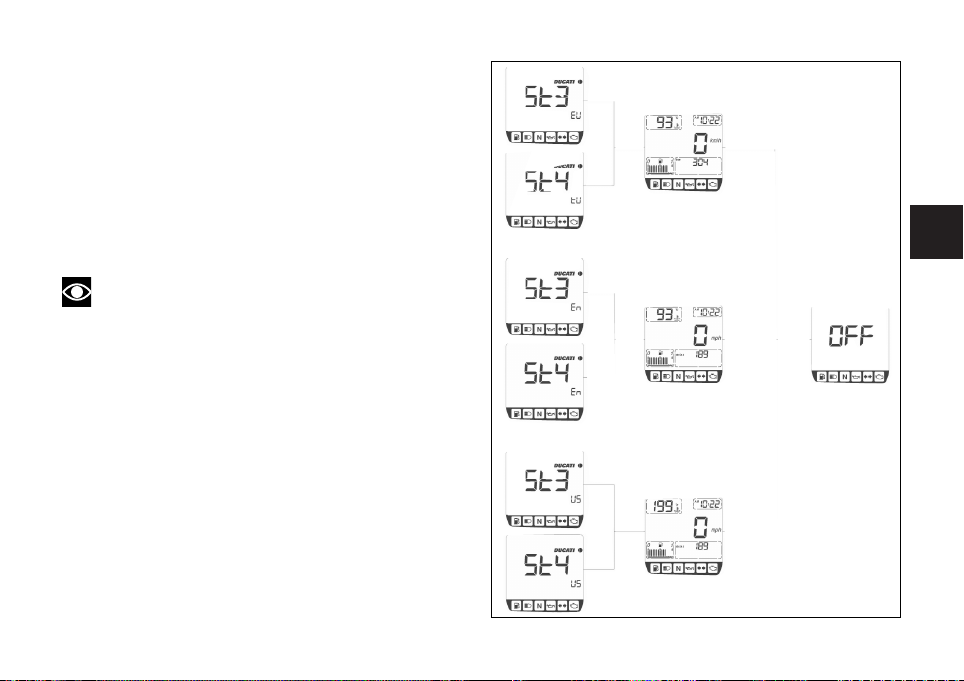

Special selection function: vehicle model and unit of

measurement (fig. 13)

The control unit automatically informs the instrument

panel about the vehicle model and unit of measurement

to be displayed; hold down buttons (A) and (B) and turn

ignition switch from OFF to ON to force the system and

change these parameters. The display shows vehicle

model and version in flashing mode. Press button (B) to

display in sequence all possible settings. To save the

setting chosen hold down button (A) for at least 5

seconds, until OFF is displayed, then turn the key to OFF.

Note

When this function is activated, vehicle ignition is

inhibited.

E

fig. 13

23

Page 24

Backlighting function

Instrument panel backlighting is active only if the parking

light or the low/high beam is on.

In this case the instrument panel automatically turns on

or off the backlighting, thanks to some sensors

measuring light condition and ambient temperature.

Note

While starting the engine, the system switches off

the headlight and turns it back on again after engine has

started, or anyway when the button (3, fig. 21) is

released.

Pilot lights brightness function

This function is active only if the parking light or the

low/high beam is on.

E

Pilot lights brightness is automatically adjusted by the

instrument panel according to the outer light measured.

Auto-off headlight function

This function allows you to reduce current consumption

from the battery, by automatically managing headlight

switching-off.

The device is enabled in two instances:

- If the key is turned from OFF to ON and no attempt is

made to start the engine. After 60 seconds, the headlight

is switched off and will be turned on only upon the

following Key-ON.

- After having used the bike, with headlight on, if the

engine is stopped via the ENGINE KILL switch (2, fig. 21),

after 60 seconds from engine stop, the headlight is

turned off and will be turned on upon the following

engine start-up.

24

The immobilizer system

For improved anti-theft protection, the motorcycle is

equipped with an IMMOBILIZER, an electronic system

that inhibits engine operation whenever the ignition

switch is turned off.

Accommodated in the handgrip of each ignition key is an

electronic device that modulates an output signal. This

signal is generated by a special antenna incorporated in

the switch when the ignition is turned on and changes

every time. The modulated signal acts as a “password”

and tells the CPU that an "authorised" ignition key is

being used to start up the engine. When the CPU

recognises the signal, it enables engine start-up.

Page 25

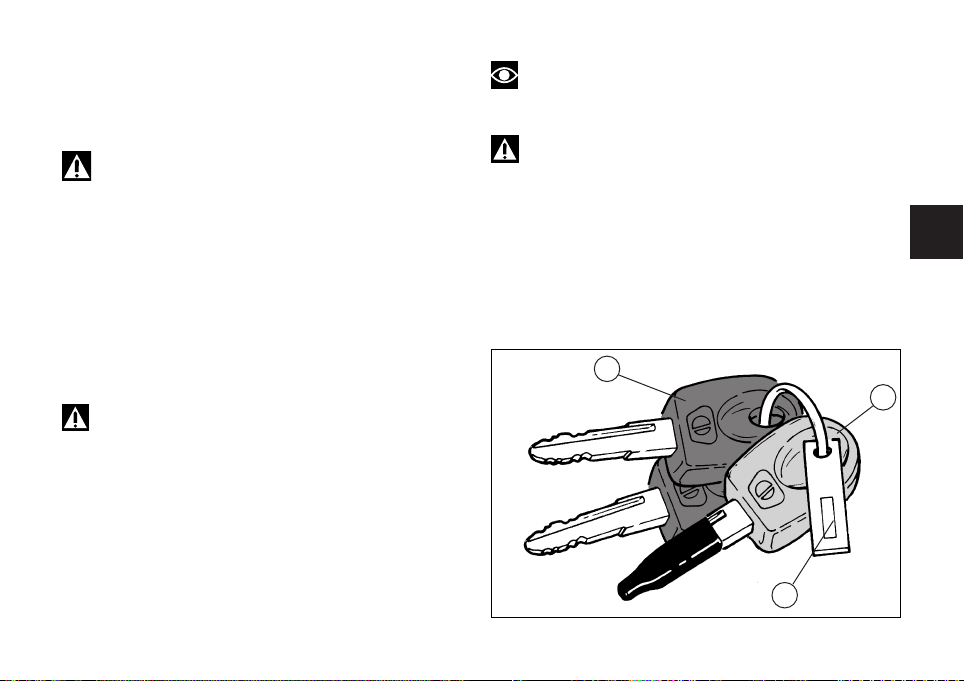

Keys (fig. 14)

1

B

A

The Owner receives a set of keys comprising:

- 1 RED key (A)

- 2 BLACK keys (B)

Warning

Red key has a rubber cover for preserving it in

perfect conditions and avoiding contact with other keys.

Never remove this protection unless really needed.

The black keys are regular ignition keys and are used to:

- start up the engine

- open the lock of the fuel tank filler plug

- open the seat lock.

The red key performs the same functions as the black

keys, and is also used to wipe off and re-program other

black keys, if needed.

Warning

Any important shock might damage the electronic

components fitted into the key.

Note

The three keys have a small plate (1) attached that

reports their identification number.

Warning

Keep the keys in different places. Store the plate (1)

and the red key in a safe place.

It is also recommended to use always the same black

key to start the bike.

E

fig. 14

25

Page 26

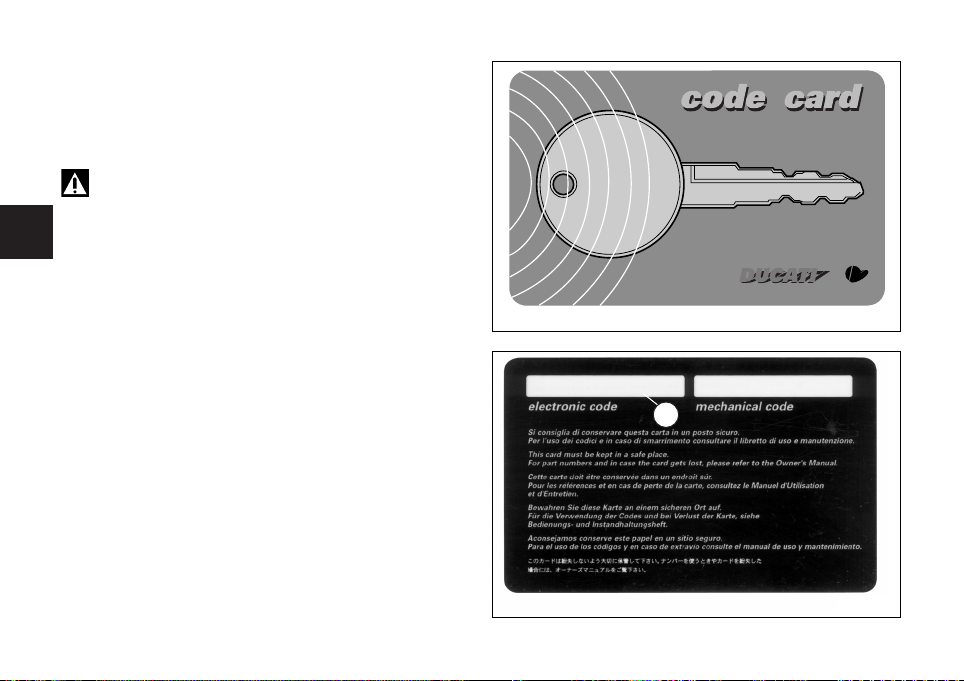

Code card

A CODE CARD (fig. 15) is supplied together with the

keys, it indicates the electronic code (A, fig. 16) to be

used in case of emergency start-up and the engine will

not start up after the key-ON.

Warning

Keep the CODE CARD in a safe place. However, it

is advisable to keep the electronic code printed on the

CODE CARD handy when you ride your motorcycle, in

E

case it is necessary to remove engine block through the

procedure that uses the throttle twistgrip (see page 35).

In case of faulty immobilizer system, this procedure gives

the chance to disable "engine block" function -signalled by

the orange EOBD warning light (5, fig. 6).

26

fig. 15

A

fig. 16

Page 27

Procedure to disable immobilizer engine block

through throttle twistgrip

1) Turn the key to ON and fully open throttle. Keep it

open. The EOBD warning light turns off after 8 seconds.

2) Release the throttle as soon as the EOBD warning

light turns off.

3) EOBD pilot light will flash. Count a number of flashes

corresponding to the first figure of the code printed on

the CODE CARD, open full throttle and keep the position

for 2 seconds, then release. In this way the input of one

figure is acknowledged, EOBD pilot light comes on and

stays on for 4 seconds. Carry out the same procedure for

the following figures of the code. Failure to do so will

cause the EOBD pilot light to flash 20 times, then it will

stay on. This means that the procedure has been

aborted. It will be necessary to turn the key to OFF and

restart from point 1.

4) Repeat operations described in point 3 up to the last

figure of the code.

5) Release the throttle twistgrip, if the code is correct the

following two conditions may occur:

A) the EOBD warning light shall flash signalling that

engine block has been disabled. The warning light turns

off after 4 seconds or if engine revolutions go over the

limit value of 1000 rpm.

B) the IMMO light (3, fig. 5.1-5.2) flashes until engine

rpm get above 1000 rpm, or until engine is re-started.

6) If the code is NOT correct, the EOBD warning light and

the IMMO light stay on and it is then possible to repeat

the procedure, starting from point 2, as many times as

necessary (infinite).

Note

Should the throttle twistgrip be released before the

set time, the warning light turns on again. It is then

necessary to bring the key to OFF and restart the

procedure from point 1.

27

E

Page 28

Operation

When the ignition key is turned to OFF, the immobilizer

inhibits engine operation.

When the ignition key is turned back to ON to start the

engine (Key-ON), the following happens:

1) if the CPU recognised the code, the IMMO light on the

instrument panel will flash briefly. This means that the

immobilizer system has recognised the key code and

enabled engine ignition. When you press the start

button, the engine will start up.

E

2) If the IMMO light stays on, it means that the code has

not been recognised. When this is the case, turn the

ignition key back to OFF and then to ON again. If the

engine still does not start, try with another black key.

If the other key does not work out either, contact the

DUCATI Service network.

3) Should the IMMO pilot light still be flashing, it means

that an immobilizer system fault was reset (e.g. with the

overriding procedure through throttle grip).

Important

Use only one key during the procedure. Failure to

do so might prevent the system from recognizing the

code of the key in use.

28

Duplicate keys

If you need any additional key, contact the DUCATI

Service network with all the keys you have left and your

CODE CARD.

DUCATI Service will program new keys and re-program

your original keys, up to 8 keys in total.

You may be asked to identify yourself as the legitimate

owner of the motorcycle. Be sure you have any

documents you might need to this end ready.

The codes of any keys not submitted will be wiped off

from the memory to make those keys unserviceable in

case they have been lost.

Note

If you sell your motorcycle, do not forget to give all

keys and the CODE CARD to the new owner.

Page 29

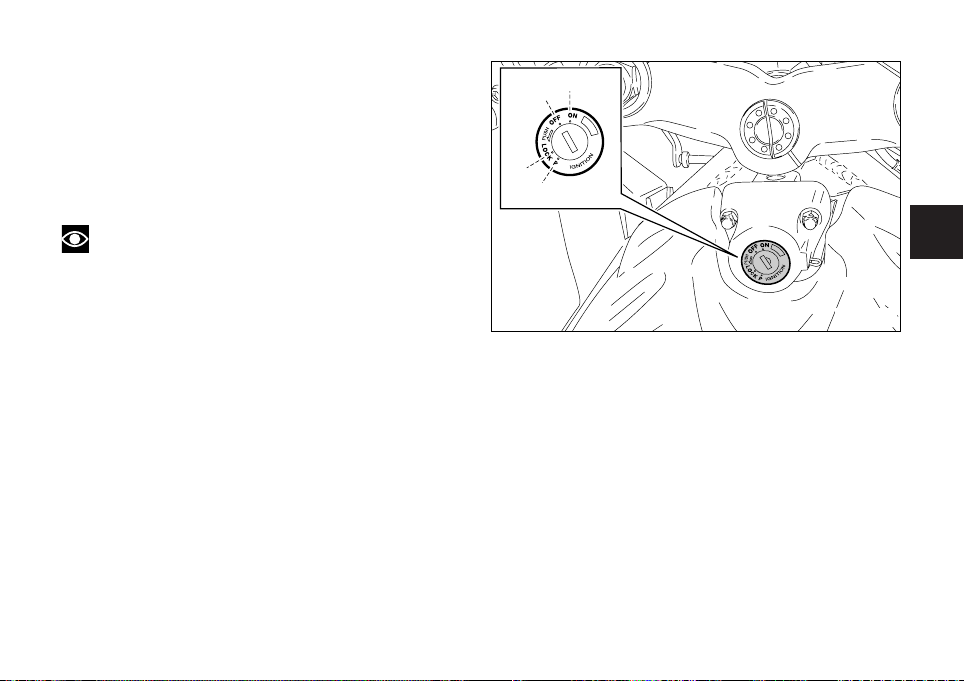

Key-operated ignition switch and steering lock

(fig. 17)

It is located in front of the fuel tank and has four

positions:

A) ON: lights and engine on;

B) OFF: lights and engine off;

C) LOCK: steering locked;

D) P: parking light and steering lock.

A

B

C

D

Note

To move the key to the last two positions, press it

down before turning it. Switching to (B), (C) and (D), you

will be able to take the key out.

E

fig. 17

29

Page 30

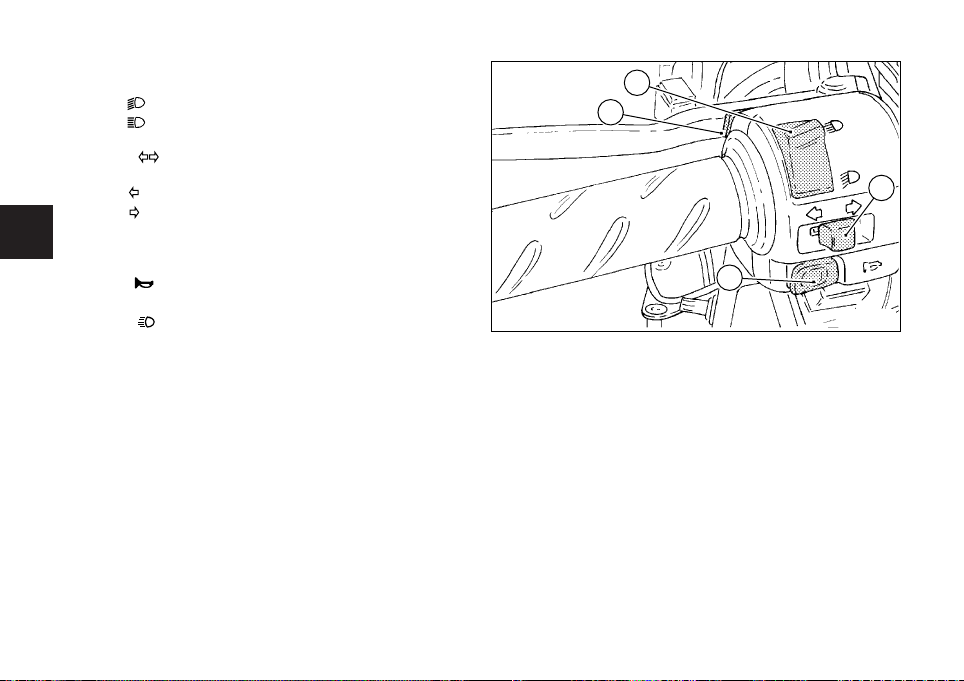

Left switch (fig. 18.1-18.2)

3

2

1

4

1) Dip switch, light dip switch, two positions:

position = low beam on;

position = high beam on.

2) Switch = 3-position turn indicator:

centre position = OFF;

position = left turn;

position = right turn.

To cancel turn indicators, push in once switch returns to

E

central position.

3) Button = warning horn.

4) Button = passing.

fig. 18.1

30

Page 31

3

2

1

4

5

ST4s ABS

5) Button = ABS off.

To turn off the ABS, hold down the button for over 3

seconds until the orange ABS light on the instrument

panel starts to flash.

Release the ABS button.

Note

When the button is held down for over 5 seconds

or is released before the ABS light comes on, the ABS

stays on.

E

Warning

Perform this operation when the vehicle is stopped

(key turned to ON).

Note

The orange light will keep flashing as a reminder

that the ABS system is off.

Note

The ABS is reset automatically when the key is

turned to OFF. The next time the key is turned to ON,

the ABS will be on.

ST4s ABS

fig. 18.2

31

Page 32

Clutch lever (fig. 19)

Lever (1) disengages the clutch. It features a dial adjuster

(2) for lever distance from the twistgrip on handlebar.

To set lever distance from twistgrip, push lever (1) fully

forward and turn the dial adjuster (2) to one of its four

positions. Remember that position no. 1 gives maximum

distance between lever and twistgrip, whereas lever and

twistgrip are closest when adjuster is set to position no.

4.

When you pull in the lever (1), you will disengage the

E

engine from the gearbox and therefore from the driving

wheel. Using the clutch properly is essential to smooth

riding, especially when moving off.

Warning

Set clutch lever when motorcycle is stopped.

4

3

1

2

2

Important

Using the clutch properly will avoid damage to

transmission parts and spare the engine.

Note

It is possible to start the engine with side stand

down and the gearbox in neutral. When starting the bike

with a gear engaged, pull the clutch lever (in this case the

side stand must be up).

32

1

fig. 19

Page 33

Cold start lever (fig. 20.1-20.2)

B

A

B

A

Use this device to start the engine from cold. It will

increase the engine idling speed after starting.

Lever positions:

A) closed

B) fully open.

The lever can be opened and closed gradually to adjust

speed until engine is fully warm.

Important

Never use the cold start device when the engine is

warm or leave it open when riding.

E

fig. 20.1

fig. 20.2ST4s ABS

33

Page 34

Right switch (fig. 21)

1) Switch, light switch, three positions:

right position = light off;

centre position = front and rear parking lights,

number plate and instrument panel lights on;

left position = headlight, front and rear parking lights,

number plate and instrument panel lights on.

2) Switch for ENGINE STOP, two positions:

position (RUN) = run.

E

position (OFF) = stop.

Warning

This switch is mainly intended for use in

emergency cases when you need to stop the engine

quickly. After stopping the engine, return the switch to

the position to enable starting.

Important

Stopping the engine using switch (2) when riding

with lights on and leaving the ignition key in the ON

position, may run the battery flat as the lights will remain

on.

3) Button = engine start

34

2

4

1

3

fig. 21

Page 35

Throttle twistgrip (fig. 22)

The twistgrip on the right handlebar opens the throttles.

When released, it will spring back to the initial position

(idling speed).

Front brake lever (fig. 22)

Pull in the lever (1) towards the twistgrip to operate the

front brake. The system is hydraulically operated and you

just need to pull the lever gently.

The control lever features a dial adjuster (2) for lever

distance from the twistgrip on handlebar.

To adjust, keep lever (1) completely extended, turn knob

(2) and set it to one of the four available positions.

Consider that:

position no. 1 corresponds to the maximum distance

between lever and twistgrip, while position no. 4

corresponds to the minimum distance.

Warning

Front brake lever adjustment is to be carried out

when the bike is stopped.

Warning

Please read the instructions on pages 59 and 60

before using these controls.

4

3

1

2

2

E

1

fig. 22

35

Page 36

1

1

2

3

4

5

6

N

Rear brake pedal (fig. 23)

Push down on the pedal (1) to apply the rear brake. The

system is hydraulically operated.

E

Gear change pedal (fig. 24)

The gear change pedal is at rest when in the central

position N, is moved up and down to change gears and

then returns to the central position.

down = push down on the pedal to engage 1

to shift down. The N light will go out.

up = lift the pedal to engage the 2ndgear and then the

3rd, 4th, 5thand 6thgear.

Each time you move the pedal you will engage the next

gear.

st

gear and

fig. 23

36

fig. 24

Page 37

Setting the gear change and rear brake pedals

(fig. 25 and 26)

The gear change and rear brake pedals can be adjusted

to suit the preferred riding position of each rider.

To set the gear change pedal,

lock linkage (1) and loosen the check nuts (2) and (3).

Note

Nut (2) has a left-hand thread.

Fit an open-end wrench to hexagonal element of linkage

(1) and rotate until setting pedal in the desired position.

Tighten both check nuts onto linkage.

E

fig. 25

37

Page 38

To set the rear brake pedal,

5

4

7

6

loosen check nut (4).

Turn pedal travel adjusting screw (5) until pedal is in the

desired position.

Tighten check nut (4).

Work pedal by hand to make sure it has 1.5 - 2 mm free

play before brake begins to bite.

If not so, set the length of cylinder linkage as follows.

Loosen the check nut (6) on cylinder linkage.

Tighten linkage into fork (7) to increase play, or unscrew

E

linkage to reduce it.

Tighten check nut (6) and check pedal free play again.

fig. 26

38

Page 39

MAIN COMPONENTS AND DEVICES

87

6

8

3 5

10

7 1

1

2

7

4

9

2

6

Location (fig. 27)

1) Tank filler plug.

2) Seat catch and helmet hook.

3) Side stand.

4) Lifting handgrip.

5) Centre stand.

6) Rear view mirrors.

7) Front fork adjusters.

8) Rear shock absorber adjusters.

9) Power outlet.

10) Catalyzer.

E

fig. 27

39

Page 40

Tank filler plug (fig. 28)

1

1/4

0

OPEN

Opening

Lift the protection lid (1) and fit the ignition key into the

lock. Turn the key clockwise 1/4 turn to unlock. Lift the

plug.

Closing

Refit the plug with the key in it and push it down into its

seat.

E

Turn the key anticlockwise to its initial position and take it

out. Close the lock protection lid (1).

Note

The plug can only be closed with the key in.

Warning

Always make sure you have properly refitted (see

page 62) and closed the plug after each refueling.

40

fig. 28

Page 41

0

0

1

1

O

P

E

N

C

L

O

S

E

4

1

2

3

Seat catch and helmet hooks

Opening (fig. 29)

Fit the ignition key into the lock (4) and turn the key

clockwise about 1/4 turn until the rear end of the seat

lifts up. Pull the seat backwards to slide it off its front

holders (1).

On the rear end of the compartment underneath the

seat, there is the helmet fastening cable (2) (see page

63). Insert the cable into the helmet and insert the ends

of the cable into one of the two hooks (3). Leave the

helmet hanging outside (fig. 30) and refit the seat.

E

Warning

This system is intended to lock your helmet safely

when you park your motorcycle. Never leave the helmet

hanging from the hook when riding or it may get in the

way and make you lose control of the motorcycle.

Closing

Make sure that all parts are arranged and secured

properly inside the compartment under the seat. Slide

the front ends of the seat bottom underneath the frame

U-bolt and push down on the rear end of the seat until

you hear the catch click. Make sure the seat is firmly

secured to the frame and take the key out of the lock.

fig. 29

fig. 30

41

Page 42

Anti-theft padlock (fig. 31)

The anti-theft padlock (1) is stored under the seat.

Remove strap (2) to take padlock out.

Use the padlock in addition to the steering lock when

parking your motorcycle in unsafe areas.

Warning

Using padlocks or other locks designed to prevent

motorcycle motion, such as brake disc locks, rear

sprocket locks, and so on is dangerous and may impair

E

motorcycle operation and affect the safety of rider and

passenger.

2

42

Side stand (fig. 32)

Important

Put the motorcycle on the side stand only when

you expect to stop for a short time.

Before lowering the side stand, make sure that the

bearing surface is hard and flat.

Do not park on soft or pebbled ground or on asphalt melt

by the sun heat and similar or the motorcycle may fall

over.

When parking in downhill road tracts, always park the

motorcycle with its rear wheel facing downhill.

To pull down the side stand, hold the motorcycle

handlebars with both hands and push down on the thrust

arm (1) with your foot until it is fully extended. Tilt the

motorcycle until the side stand is resting on the ground.

Warning

Do not sit on the motorcycle when it is supported

on the side stand.

To move the side stand to its rest position (horizontal

position), tilt the motorcycle to the right and, at the same

time, lift the thrust arm (1) with your foot.

1

fig. 31

Page 43

Note

Check for proper operation of the stand mechanism

(two springs, one into the other) and the safety sensor

(2) at regular intervals.

Note

It is possible to start the engine with side stand

down and the gearbox in neutral. When starting the bike

with a gear engaged, pull the clutch lever (in this case

the side stand must be up).

Lifting handgrip

A handgrip (1, fig. 33) that pivots on the left pillion

passenger footpeg is provided to help you place the

motorcycle on the centre stand or keep it upright when

manoeuvring to park it.

Fold out the handgrip. After use, just release it and it will

fold back to its rest position.

Power outlet

A specific power outlet (2, fig. 33) has been fitted to feed

dedicated accessories. Outlet is protected by a 20A fuse.

2

E

fig. 32

1

fig. 33

43

Page 44

Centre stand

2

3

Always use the centre stand (1, fig. 34) to support the

motorcycle steadily when parked. It is designed to

support the motorcycle even when carrying the

maximum load allowed.

Warning

Before putting the motorcycle on the centre stand,

make sure the bearing surface is hard and flat.

E

Hold the left handlebar with your left hand and the lifting

handgrip (2, fig. 35) with your right hand. Push down on

the thrust arm (3) of the centre stand until it touches the

ground. At the same time, hold the handgrip and pull the

motorcycle upward and backward.

To take the bike off the centre stand, simply hold the

handlebars and push the motorcycle forward, until the

rear wheel touches the ground. The stand will spring

back to rest position automatically.

Warning

Before moving off, always make sure the centre

stand is fully up.

Check for proper operation of the stand mechanism (two

springs, one into the other) at regular intervals.

1

3

fig. 34

fig. 35

44

Page 45

Rear view mirrors (fig. 36)

A

B

The rear view mirrors of your motorcycle are made up of

two parts held together by a special inner spring. This

spring counters mirror rotation so the mirror will not

smash the headlamp fairing if hit accidentally. The spring

then moves the mirror back to its original position.

Important

If either of the mirror parts comes off, have the

mirror repaired or replaced by a Ducati Dealer or

Authorized Workshop.

Warning

Never ride with a missing rear view mirror: the

inability to see the traffic behind you may lead to severe

accidents.

The mirrors have bifocal lenses that offer a wider range

of vision, with no blind spots:

A) inner area = normal view

B) outer area = magnified view.

Warning

What you see in the mirror is actually closer to you

than it appears in the mirror view, even more so when

looking at the magnifying outer area (B).

E

fig. 36

45

Page 46

2

A

1

1

Front fork adjusters

The front fork has rebound and compression damping

adjusters.

This adjustment is done using the outer adjusters:

1) (fig. 37) to adjust rebound damping;

2) (fig. 37) to adjust inner springs preload;

3) (fig. 38.1-38.2) to adjust compression damping.

Turn the adjuster (1) on fork leg top with a flat

E

screwdriver to adjust rebound damping.

To reach the adjuster (3, fig. 38.1-38.2), insert a

screwdriver into the passing hole on the wheel shaft at

fork leg axis.

As you turn the adjusting screws (1 and 3), you will hear

them click. Each click identifies a setting. Turn the screw

all the way in to set the hardest damping (position 0).

This will be your starting point. Now turn the screw

anticlockwise and listen for the clicks that identify setting

positions no. “1”, “2” and so on.

fig. 37

46

Page 47

3

STANDARD factory setting is as follows:

3

compression: 12 clicks;

rebound: 11 clicks.

The setting range is 14 clicks (both for rebound and

compression). The 14th click gives the softest damping.

To change the preload of the spring inside each fork leg

turn the hex. adjuster (2) with a 22-mm hexagon wrench.

Height A (fig. 37) determines preload and may vary from

25 to 10 mm.

Factory setting is 16 mm.

Important

Adjust both fork legs to same settings.

E

fig. 38.1

ST4s ABS

fig. 38.2

47

Page 48

Rear shock absorber adjusters

1

2

3

The rear shock absorber has outer adjusters that enable

you to adjust your motorcycle to the load.

The adjuster (1, fig. 39) located on the rear right hand

side - at the control unit - sets rebound damping.

The adjuster (2, fig. 40) on the shock absorber expansion

reservoir controls compression damping.

Turning the adjusters (1 and 2) clockwise gives harder

damping H, turning anticlockwise gives softer damping

S.

E

STANDARD setting. Turn the adjusters all the way in

(clockwise) then:

- undo the adjuster (1) 14 clicks;

- undo the adjuster (2) 14 clicks.

The knob (3, fig. 40) located on the rear right hand side

under the passenger footpeg controls outer spring

preload.

To change spring preload, turn the knob (3) by hand

clockwise or anticlockwise to increase or decrease spring

preload as required.

STANDARD spring length:

149.5 mm.

fig. 39

fig. 40

48

Page 49

Warning

The shock absorber is filled with gas under

pressure and may cause severe damage if taken apart by

unskilled persons.

Important

When carrying a passenger and luggage, set the

rear shock absorber spring to proper preload to improve

motorcycle handling and keep safe clearance from the

ground. You may find that rebound damping needs

adjusting as well.

E

49

Page 50

Changing motorcycle track alignment (fig. 41-42-

H

1

3

2

2

1

3

43)

Motorcycle track alignment is the result of tests carried

out under different riding conditions by our technical

staff.

Modifying factory setting is a very delicate operation,

which may lead to serious damages if carried out by

unskilled people.

Before changing standard setting, measure the reference

value (H, fig. 41).

E

The rider can modify track alignment according to his/her

needs by changing working position of the shock

absorber. Loosen lock nuts (3) to change ball joints (1)

center distance.

Note

Please note that the lower nut (3) has a left-hand

thread.

Set linkage (2) with an open-end wrench.

When finished, tighten the nuts (3) to 25 Nm.

Warning

Length of linkage (2), included between the two

joint center lines (1), should not exceed 272 mm.

fig. 41

50

fig. 42

Page 51

UNIBALL articulated head (A) maximum extension is 5

B

A

threadings, i.e. 7.5 mm (B).

E

fig. 43

51

Page 52

DIRECTIONS FOR USE

another and above all not to adversely affect the life of

basic engine parts, it is advisable to avoid harsh

accelerations and not to run the engine at high rpm for

too long, especially uphill.

Furthermore, the drive chain should be inspected

frequently. Lubricate as required.

Running-in recommendations

E

Max. rotation speed (fig. 44)

Rotation speed for running-in period and during standard

use (rpm)

1) up to 1000 km;

2) from 1000 to 2500 km;

3) after 2500 km.

Up to 1000 km

During the first 1000 km, keep an eye on the rev counter.

It should never exceed 6000 rpm.

During the first hours of riding, it is advisable to run the

engine at varying load and rpm, though still within

recommended limit.

To this end, roads with plenty of bends and even slightly

hilly areas are ideal for a most efficient running-in of

engine, brakes and suspensions.

For the first 100 km, use the brakes gently. Do not brake

violently or keep brake applied for too long. This will

enable a correct break-in of friction material on brake

pads against brake discs.

For all mechanical parts of the motorcycle to adapt to one

52

From 1000 to 2500 km

At this point, you can squeeze some more power out of

your engine. However never exceed 7500 rpm.

Page 53

Important

km/h

miles

mph

km/L

mpgal

0

1

1

2.500 ÷ +Km

1.000

÷

2.500 Km

0

÷

1.000 Km

During the whole running-in period, the

maintenance and service rules recommended in the

Warranty Card should be observed carefully. Have the

service inspections performed as recommended in the

Warranty Card.

Failure to comply with these rules will release Ducati

Motor Holding S.p.A. from any liability whatsoever for

resulting engine damage or shorter engine life.

After 2500 km

After running-in, never exceed 10000 rpm under standard

conditions of use.

Strict observance of running-in recommendations will

ensure longer engine life and reduce the likelihood of

overhauls and tune-ups.

E

fig. 44

53

Page 54

Pre-ride checks

Warning

Failure to carry out these checks before riding, may

lead to motorcycle damage and injury to rider and

passenger.

Before riding, perform a thorough check-up on your bike

as follows:

Fuel level in the tank

E

Check fuel level in the tank.

Fill tank if needed (page 62).

Engine oil level

Check oil level in the sump through the sight glass. Top

up if needed (page 88).

Brake and clutch fluid

Check fluid level in the relevant reservoirs.

Coolant level

Check coolant level in the expansion reservoir. Top up if

necessary (page 72).

Tyre condition

Check tyre pressure and condition (page 86).

Controls

Work the brake, clutch, throttle and gear change controls

(levers, pedals and twistgrips) and check for proper

operation.

Lights and indicators

Make sure lights, indicators and horn work properly.

Replace any burnt-out bulbs (page 80).

54

Key-operated locks

Check that fuel filler plug and seat catch locks are closed

firmly.

Stand

Make sure side stand (pages 42 and 43) and centre stand

(page 44) operate smoothly and are in the correct

position.

ABS light

Set the key to ON and make sure the light comes on for

a few seconds. When the light turns off, it means that

the ABS is on.

Warning

In case of malfunctioning, do not start the

motorcycle and call a Ducati Dealer or Authorized

Workshop.

Page 55

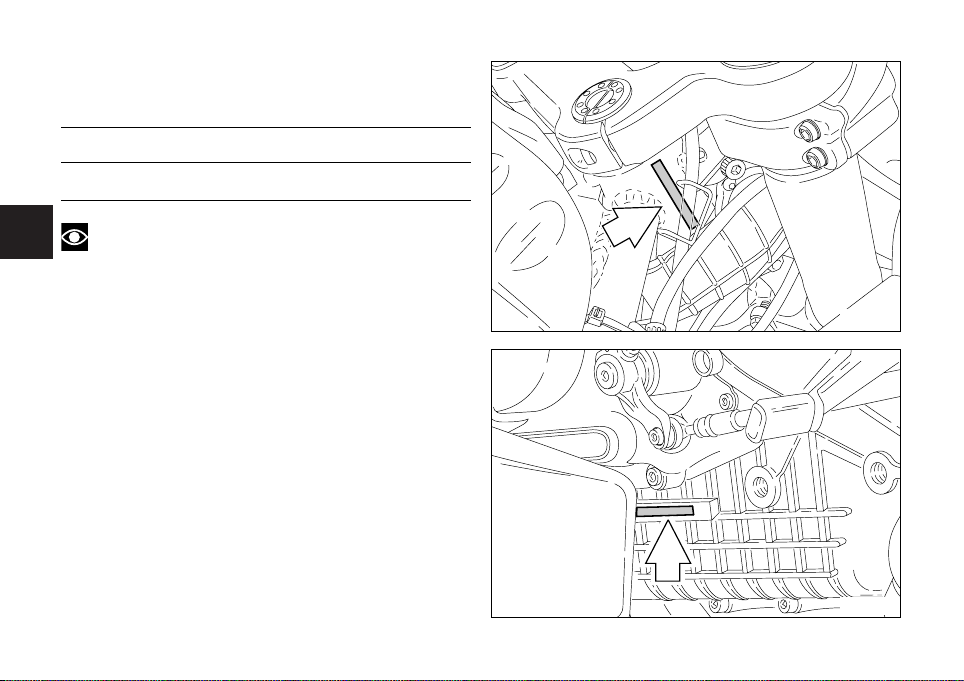

ABS system (ST4s ABS)

2

Ensure that front (1) and rear phonic wheel (2) are clean.

Warning

Clogged reading slots would compromise system

proper operation.

It is recommended to disable ABS system in case of

muddy road surface because under this condition the

system might be subject to sudden failure.

1

E

fig. 45

fig. 46

55

Page 56

Starting the engine

ON

Note

Follow the “High ambient temperature” procedure

to start the engine when it is warm.

Warning

Before starting the engine, become familiar with

the controls you will need to use when riding.

E

Regular ambient temperature

(10 °C/50 °F to 35 °C/ 95 °F):

1) Move the ignition key to ON (fig. 47). Make sure both

the green light N and the red light on the instrument

panel come on.

Important

The oil pressure light should go out a few seconds

after the engine has started (page 15).

Warning

The side stand must be fully up (in a horizontal

position) as its safety sensor prevents engine start when

down.

Note

It is possible to start the engine with side stand

down and the gearbox in neutral. When starting the bike

with a gear engaged, pull the clutch lever (in this case the

side stand must be up).

56

fig. 47

Page 57

2) Move the cold start lever to the B position (fig. 48).

1

2

3) Check that the stop switch (1, fig. 49) is positioned to

(RUN), then press the starter button (2).

Let the engine start without using the throttle control.

A

Important

Never operate the electric start button more than 5

seconds at a time. If needed, allow 10 seconds before

attempting to restart the engine.

4) Move the cold start lever to the vertical position (A) to

let engine idle at about 1400-1500 rpm.

Important

Do not rev up the engine when it is cold. Allow

some time for oil to reach all points that need lubricating.

5) As the engine warms up, move the cold start lever

gradually towards the vertical position (A, fig. 48). Once

fully warm, the engine should hold idling rpm with the

cold start shut down.

B

E

fig. 48

fig. 49

57

Page 58

High ambient temperature (over 35 °C/95 °F):

Follow the same procedure, however, do not use the

cold start device.

Cold ambient temperature (below 10 °C/50 °F):

Follow the procedure for “Regular ambient

temperature”, however allow 5 minutes for the engine

to warm up (see step 5).

E

58

Page 59

Moving off

1) Disengage the clutch squeezing the control lever.

2) Push down on gear change lever sharply with the tip

of your foot to engage the first gear.

3) Speed up engine, by turning the throttle twistgrip and

slightly releasing the clutch lever at the same time. The

motorcycle will start moving off.

4) Let go of clutch lever and speed up.

5) To shift up, close the throttle to slow down engine,

disengage the clutch, lift the gear change lever and let go

of clutch lever.

To shift down, release the twistgrip, pull the clutch

control lever, shortly speed up to help gears synchronize,

shift down and release the clutch.

The controls should be used correctly and timely: when

riding uphill do not hesitate to shift down as soon as the

motorcycle tends to slow down, so you will avoid

stressing the engine and the motorcycle abnormally.

Important

Avoid harsh accelerations, as this may lead to

misfiring and transmission snatching. The clutch lever

should not be pulled longer than necessary after gear is

engaged, or friction parts may overheat and wear out.

Braking

Slow down in time, shift down to engine-brake first and

then brake applying both brakes. Pull the clutch lever

before stopping the motorcycle, to avoid sudden engine

stop.

ABS system (ST4s ABS)

Using the brakes correctly under adverse conditions is

the hardest – and yet the most critical - skill to master for

a rider. Statistically, the risk of a fall or an accident is

highest during braking. A locked front wheel leads to loss

of traction and stability, resulting in loss of control.

The Anti-Lock Brake System (ABS) has been developed

to enable riders to use the vehicle’s braking force to the

fullest possible amount in emergency braking or under

poor pavement or adverse weather conditions.

ABS uses hydraulics and electronics to limit pressure in

the brake circuit when a special sensor mounted to the

wheel signals the electronic control unit that the wheel is

about to lock up. This avoids wheel lockup and preserves

traction.

E

59

Page 60

Pressure is raised back up immediately and the control

unit keeps controlling the brake until the risk of a lockup

disappears.

Normally, the rider will perceive ABS operation as a

harder feel or a pulsation of the brake lever and pedal.

The front and rear brakes use separate control systems,

meaning that they operate independently. Likewise, the

ABS is not an integrated braking system and does not

control both the front and rear brake at the same time.

The ABS may be turned off by pressing the button

E

incorporated in the LH switch (see page 31).

60

Warning

When the ABS is off, the vehicle provides the

standard braking force offered by the regular braking

system. As a result, using one brake at a time will reduce

braking efficiency.

Never use brake controls harshly or violently or you may

lock the wheels and lose control of the motorcycle.

When riding in the rain or on slippery surfaces, braking

will become less effective. Always use the brakes very

gently and carefully when riding under these conditions.

Any sudden manoeuvres may lead to loss of control.

When tackling long, high-gradient downhill road tracts,

shift down gears to use engine braking. Apply one brake

at a time and use brakes sparingly. Keeping the brakes

applied all the time would cause the friction material to

overheat and reduce braking power dangerously.

Underinflated tyres reduce braking efficiency, handling

accuracy and stability in a bend.

Page 61

Stopping the motorcycle

If you let go of the throttle twistgrip, the motorcycle will

slow down gradually and smoothly. Then, shift down

releasing the clutch, and finally change from first to

neutral. Apply brakes and you will bring the motorcycle

to a complete stop. To switch the engine off, simply turn

the key to OFF (fig. 50).

Important

Never leave the key in the ON position when

engine is stopped, or this will damage the electric

components.

Parking

Stop the motorcycle, then put it on the centre stand to

park it (see page 44).

Turn the handlebar fully left and turn the key to the

LOCK position (fig. 51).

To avoid theft, use the supplied padlock (see page 42).

If you park in a garage or other facilities, make sure that

there is proper ventilation and that the motorcycle is not

near a source of heat.

You may leave the parking lights on by turning the key to

position P.

E

fig. 50

fig. 51

61

Page 62

Important

Do not leave the key turned to P for long periods or

the battery will run down.

Never leave the ignition key in the switch when you are

leaving your bike unattended.

Warning

The exhaust system might be hot, even after

engine is switched off; pay particular attention not to

touch exhaust system with any body part and do not park

E

the vehicle next to inflammable material (wood, leaves

etc.).

Refueling

Never overfill the tank when refueling. Fuel should never

be touching the rim of filler recess (fig. 52).

Warning

Use low-lead fuel having at least 95 fuel octane

rating. Be sure there is no fuel trapped in the filler recess.

62

Max level

fig. 52

Page 63

Tool kit and accessories (fig. 53)

DUCATI

3

2

6

4

5

1

0

0

1

1

O

P

E

N

C

L

O

S

E

8

The compartment under the seat holds:

an Owner’s manual

a helmet fastening cable

a tool bag for normal maintenance and checks.

To reach this compartment, the seat must be removed by

opening the catch (8) (page 41).

Tool bag holds (fig. 54)

1) Box wrench for spark plugs.

2) Double-bit screwdriver.

3) Allen wrenches.

4) Helmet fastening cable.

5) Extension.

6) Box wrench.

E

fig. 53

fig. 54

63

Page 64

1

MAIN MAINTENANCE OPERATIONS

Removing the fairing

Some servicing operations need the motorcycle fairing to

be removed.

E

Warning

Firmly secure all removed parts when refitting

them, otherwise some of them might suddenly come off

when riding and you may lose control of your motorcycle.

Important

At reassembly always use nylon washers when

tightening fastening screws, not to damage painted parts

and Plexiglas windscreen of headlight fairing. Some

fastening screws are of the self-tapping type; do not

overtighten, otherwise threading might damage and

screws would not be tightened properly next time.

Lower body panels

Unscrew the four screws (1) that hold each lower body

panel to the upper body panels (fig. 55).

64

fig. 55

Page 65

4

2

2

3

5

3

7

3

6

7

Undo one of the two lower screws (2, fig. 56) securing

one fairing to the other.

Keep the washer (5, fig. 56) and the wellnut (6, fig. 56) of

the plate (4, fig. 56). Keep the plate connected to a lower

fairing.

Undo the two screws (3, fig. 56) securing the lower

fairings to the air scoop.

Remove the breather hose (7, fig. 56) from the left lower

fairing.

Remove both lower fairings.

E

fig. 56

65

Page 66

6

6

7

6

Instrument panel covers

4

4

5

Undo the two screws (1) securing the rear control panel

(2) to the headlight fairing.

Pull out the rear control panel (2) from the front control

panel (3).

Undo the screws (4) and remove the windscreen (5) to

remove the front control panel (3).

Undo the screws (6), disconnect the wiring from the

E

instrument panel and remove the front control panel (3)

complete with instrument panel.

fig. 58

66

fig. 57

fig. 59

Page 67

1

Headlight fairing

2

Remove the instrument panel covers.

Detach the rear view mirrors from the headlight fairing by

unscrewing the four inner screws (1, fig. 60).

Disconnect the cables (2, fig. 61) of the turn indicators.

E

fig. 60

fig. 61

67

Page 68

3 3

3

3

3

Unscrew the 8 fastening screws (3, fig. 62-63) that hold

the headlamp fairing to the side body panels.

Remove the fairing sliding it off the headlamp.

Important

When refitting, it is necessary to loosen the screws

of both rear-view mirror mounts and then fit the headlight

fairing. Make sure direction indicator cables are not

squeezed and fit rear-view mirrors with the relevant

gasket, secure them with screws (1, fig. 60).

E

Set the headlight fairing so that its top edge is horizontal.

Tighten screws (3, fig. 62-63) starting from the front ones

then tighten mirror mount screws previously loosened.

fig. 62

68

fig. 63

Page 69

Removing the upper and lower body panels together

1

4

2

3

Unscrew the eight fastening screws (3, fig. 62-63) that

hold headlamp fairing to the body panels.

Unscrew the front fastening screw (1, fig. 65) that holds

each body panel to the front baffle.

Unscrew the rear fastening screw (2, fig. 65) holding

each body panel to the frame.

Unscrew the two lower fastening screws (3, fig. 65)

holding the body panels to the central air conveyor.

Unscrew one of the two screws (4, fig. 65) joining the

body panels together. Remove the body panels, be

careful not to damage the headlight fairing.

E

fig. 65

Side panniers

The motorcycle comes ready to fit the side panniers.

Side panniers kit in the same colour as the motorcycle is

available from Ducati Spare Parts Department.

Kit includes all parts needed to install the panniers as

well as the relevant instructions.

fig. 64

69

Page 70

Lifting the fuel tank

1

2

3

Unscrew the 2 screws (1, fig. 66) that hold the cover to

the tank support. Remove the cover sliding it off the

ignition switch.

Pull and lift the clip (2, fig. 67) off the tank support.

Lift the tank and unhook the support rod (3, fig. 68). Rest

the tank onto the rod as shown in the figure.

When you are finished, reverse the above procedure to

refit all the parts you have removed.

E

Warning

Make sure the fuel in the tank is less than 5 litres

(the fuel warning light on the instrument panel should be

on) or fuel may leak out through the filler plug breather.

70

fig. 66

fig. 67

fig. 68

Page 71

Cleaning and changing air filters

2

1

Replace air filter at the required intervals shown in the

routine maintenance chart (see Warranty Card). The air

box is accessible after lifting the fuel tank.

Undo the clips (1, fig. 69) of the cover on both sides of

the air box, then remove cover (2).

Remove the filter (3, fig. 70) and fit a new one.

Important

A dirty filter will reduce air intake, increase fuel

consumption, reduce engine power, and foul the spark

plugs. Do not use the motorcycle without filter or

suspended matters could get into the engine and cause

damage.

Install the filter properly into its seat in the air box as

shown in figure 70 and refit all the parts you have

removed.

Important

If you are using the motorcycle on dusty or very

wet roads, replace filter more frequently than

recommended intervals (see Warranty Card).

E

fig. 69

3

fig. 70

71

Page 72

Checking the coolant level

Check the coolant level in the expansion tank, on the RH

side of the motorcycle.

The coolant level must be between the MAX and MIN

marks (fig. 71).

Top up if the level is too low.

Remove the r.h. side guard of the instrument panel.

Unscrew the filler (1, fig. 72) and add a mixture

consisting of water and antifreeze SHELL Advance

Coolant or Glycoshell (35-40% of the volume) up to MAX

E

mark.

Refit the filler (1) and reassemble all removed parts.

This mixture improves operating conditions (coolant will

start freezing at –20 °C/- 4 °F).

Coolant circuit capacity: 3.5 cu dm (liters).

Warning

Place the motorcycle on a flat surface and make

sure the engine is cold before proceeding.

72

OPEN

fig. 71

CLOSE

1

fig. 72

Page 73

Checking brake and clutch fluid level

Fluid level should never fall below the MIN mark on

each reservoir (fig. 73). If level drops below the limit, air

might get into the circuit and affect the operation of the

system involved.

Brake and clutch fluid must be topped up and changed at

the intervals specified in the routine maintenance chart

(see Warranty Card) by a Ducati Dealer or Authorized

Workshop.

Important

It is recommended all brake and clutch lines be

changed every four years.

Clutch system

If the control lever has exceeding play and the

transmission snatches or jams as you try to engage a

gear, it means that there is air in the circuit. Contact your

Ducati Dealer or an Authorized Workshop to have the

system inspected and air drained out.

Warning

Clutch fluid level will increase as clutch plate friction

material wears down. Do not exceed specified level

(3 mm above minimum level).

Brake system

If you find exceeding play on brake lever or pedal and

brake pads are still in good condition, contact your Ducati

Dealer or an Authorized Workshop to have the system

inspected and any air drained out of the circuit.

Warning

Brake and clutch fluid will damage paintwork and

plastic parts if accidentally spilled.

E

fig. 73

73

Page 74

MIN

1 mm

Checking brake pads for wear

Front brake (fig. 74)

To facilitate inspection without removing the pads from

the calipers, brake pads have a wear mark. If the grooves

in the friction material are still visible, the pad is still in

good condition.

Rear brake (fig. 74)

The friction material on each pad should be at least

E

1 mm thick.

Important

Have the brake pads replaced at a Ducati Dealer or

Authorized Workshop.

74

fig. 74

Page 75

Lubricating cables and joints

1

3

2

The condition of the outer sheaths of the throttle and

cold start cables should be checked at regular intervals.

The sheaths should show no signs of squeezing or

cracking. Work the controls to make sure the cable slides

smoothly inside the sheath: if you feel any friction or hard

spots, have the cable replaced by a Ducati Dealer or

Authorized Workshop. To prevent these failures, smear

the ends of the Bowden cables with SHELL Advance

Grease or Retinax LX2 at regular intervals.

For the throttle cable, it is best to remove the cover (1,

fig. 75) by unscrewing the two fastening screws (2) and

then grease the cable end and the pulley.

Warning

When refitting the cover, be sure to slide the cable

properly onto the suitable pulley and inside the guide in

the cover (3).

Refit the cover and tighten the screws (2).

To ensure smooth operation of the stand joints, clean off

any dirt and apply SHELL Alvania R3 at all points exposed

to friction.

E

fig. 75

75

Page 76

1,5

÷

2 mm

1

Throttle cable adjustment

The throttle twistgrip must have a free play of 1.5 - 2 mm

measured at the edge of the twistgrip, at all positions of

the handlebars. If it needs adjusting, use the suitable

adjuster (1, fig. 76) provided on the throttle control.

E

76

fig. 76

Page 77

Charging the battery (fig. 77)

Before charging the battery, it is best to remove it from

the motorcycle.

Remove the r.h. side fairing (see page 69), undo the

screw (1) and remove the upper bracket.

Always disconnect the black negative terminal (-) first,

and then the red positive terminal (+).

Warning

Batteries develop explosive gases: keep it away

from heat sources.

Charge the battery in a ventilated room.

Connect the battery charger leads to the battery

terminals (red to positive terminal +, black to negative

terminal -).

Important

Make sure the charger is off when you connect the

battery to it, or you might get sparks at the battery

terminals that could ignite the gases inside the cells.

Always connect the red positive (+) terminal first.

Reinstall the battery on its mount and secure the upper

bracket with the screw (1). Apply some grease on the

fastening screws to improve conductive capacity and

connect the terminals.

Warning

Keep the battery out of the reach of children.

Charge the battery at 1 A for 5-10 hours.

-

1

E

+

fig. 77

77

Page 78

Chain tensioning

32÷34 mm

Turn the rear wheel slowly until you find the position

where chain is tightest.

Put motorcycle on the centre stand and push the chain

up pressing with a finger at mid-length of swingarm. The

lower stretch of chain must have a slack (fig. 78) of

32 mm.

Chain tension is adjusted as follows:

Slacken the nut (1, fig. 78) of the wheel shaft, tighten

(turn clockwise) or slacken the screw (2) on either side of

E

the swingarm equally to increase or reduce chain

tension. If you are slackening the chain, you will have to

push the wheel forward.

Important

Improper chain tension will lead to early wear of

transmission parts.

fig. 78

Make sure you have adjusted to the same setting marks

on both sides of the swingarm.

This will ensure perfect wheel alignment.

Grease the thread of the wheel shaft nut (1) with SHELL

Retinax HDX2 grease and torque nut to 83 Nm.

Grease the threads of adjusting screws (2) with SHELL

Alvania R3 grease and torque them to 8 Nm.

78

1

2

fig. 79

Page 79

Chain lubrication

The chain fitted on your motorcycle has O-rings that keep

dirt out of and lubricant inside the sliding parts. The seals

might be irreparably damaged if the chain is cleaned

using any solvent other than those specific for O-ring

chains or washed using steam or water jets. After

cleaning, blow the chain dry or dry it using absorbent

material and apply SHELL Advance Chain or Advance

Teflon Chain on each link.

Important

Using non-specific lubricants may lead to severe

damage to chain, front and rear sprocket.

E

79

Page 80

3

Replacing bulbs

Before replacing a burnt-out bulb, make sure that the

new one complies with voltage and wattage as specified

on the“Electric System” for that lighting device (page

99).

Removing the headlight bulbs (fig. 80-81-82-83-84)

Remove the instrument panel covers (see page 66) and

release the clamps (1) of the light cover (2) to reach the

headlight bulbs.

E

L.h. Hi-beam light-bulb (fig. 81):

pull out the bulb cable (3) and disconnect the bulb from

the cable.

Note

Be careful to hold the new bulb at the base only.

Never touch the transparent body with your fingers or it

will blacken resulting in reduced bulb brilliancy.

80

1

2

fig. 80

fig. 81

Page 81

R.h. Hi-beam light-bulb (fig. 82-83):

5

4

6

Disconnect the connector (4).

Release the clip (5) keeping the bulb cable (6).

Refit following the removal procedure in the reverse