Ducane (HVAC) SH13 User Manual

INSTALLATION AND

MAINTENANCE INSTRUCTIONS

(2,4)SH13 Series

Self-Contained Heat Pump

WARNING

Improper installation, adjustment, alteration, service, or maintenance can cause injury or

property damage. Refer to this manual. For assistance or additional information, consult a

qualified installer or service agency.

WARNING

Installation and servicing of air conditioning

equipment can be hazardous due to internal

refrigerant pressure and live electrical components. Only trained and qualified service

personnel should install or service this equipment. Installation and service performed by

unqualified persons can result in property

damage, personal injury, or death.

WARNING

If this unit is to be installed in a mobile or manufactured home application, the ductwork must

be sized to achieve static pressures within the

manufacturer’s guidelines. All other installation

guidelines must also be followed. Failure to do

so may result in equipment damage, personal

injury, and improper performance of the unit.

*48369K005*

WARNING

Sharp metal edges can cause injury. When

installing the unit, use care to avoid sharp

edges.

TABLE OF CONTENTS

INSTALLATION ...................................... 2

OPERATION .......................................... 7

MAINTENANCE................................... 10

WIRING DIAGRAM .............................. 11

WARRANTY ........................................ 12

Manufactured By

A.A.C.

A Lennox International Inc. Company

421 Monroe Street

Bellevue, OH 44811

CAUTION

The installation of this appliance must conform to the requirements of the National Fire Protection Association;

the National Electrical Code, ANSI/NFPA No. 70 (latest edition) in the United States; the Canadian Electrical

Code Part 1, CSA 22.1 (latest edition) in Canada; and any state or provincial laws or local ordinances. Local

authorities having jurisdiction should be consulted before installation is made. Such applicable regulations or

requirements take precedence over the general instructions in this manual.

# 48369K005 Page 1

Save these instructions for future reference

INSTALLATION

Location

These instructions explain the recommended method of

installation of the SH heat pump unit and associated

electrical wiring.

This unit is designed and approved for use as a selfcontained air-to-air outdoor heat pump system.

The units are factory equipped with a transformer and

blower control for applications without auxiliary heat.

Electric heat accessory kits (PHK) can be ordered for field

installation of additional heat where required.

These instructions, and any instructions packaged with

mating components and/or accessories, should be carefully read prior to beginning installation. Note particularly

any CAUTIONS or WARNINGS in these instructions and

all labels on the units.

These instructions are intended as a general guide only, for

use by qualified personnel and do not supersede any national

or local codes in any way. Compliance with all local, state,

provincial, or national codes pertaining to this type of

equipment should be determined prior to installation.

IMPORTANT: This product has been designed and manufactured to meet ENERGY STAR criteria for energy efficiency.

However, proper refrigerant charge and proper air flow are

critical to achieve rated capacity and efficiency. Installation

of this product should follow the manufacturer’s refrigerant

charging and air flow instructions. Failure to confirm

proper charge and airflow may reduce energy efficiency and shorten equipment life.

The unit is designed to be located outdoors with sufficient

clearance for free entrance to the air inlet and discharge air

openings. The location must also allow for adequate

service access.

The unit must be installed on a solid foundation that will not

settle or shift. Adequate structural support must be provided. Maintain minimum clearances as shown in Figure 1

and Table 1 and install the unit in level position. Isolate the

base from the building structure to avoid possible transmission of sound or vibration into the conditioned space.

The unit foundation should be raised to a minimum of

3" above finish grade. In areas which have prolonged

periods of temperature below freezing and snowfall, the

unit should be elevated above the average snow line. Extra

precaution should be taken to allow free drainage of

condensate from defrost cycles to prevent ice accumulation. The unit should not be located near walkways to

prevent possible icing of surface from defrost condensate.

Avoid placing the unit near quiet areas such as

sleeping quarters or study rooms. Normal operating

sound levels may be objectionable if the unit is placed

near certain rooms.

Do not permit overhanging structures or shrubs to

obstruct condenser air discharge inlet or outlet.

For improved start-up performance, the indoor coil

should be washed with suitable detergent to remove

any residue from manufacturing processes.

Inspection of Shipment

Upon receipt of equipment, carefully inspect it for possible

shipping damage. If damage is found, it should be noted on

the carrier’s freight bill. Take special care to examine the

unit inside the carton if the carton is damaged. File a claim

with the transportation company.

If any damages are discovered and reported to the carrier

DO NOT INSTALL THE UNIT, as claim may be denied.

Check the unit rating plate to confirm specifications

are as ordered.

Limitations

The unit should be installed in accordance with all national

and local safety codes.

Limitations of the unit and appropriate accessories must

also be observed.

The unit must not be installed with any ductwork in the

outdoor air stream. The outdoor fan is not designed to

operate against any additional static pressure.

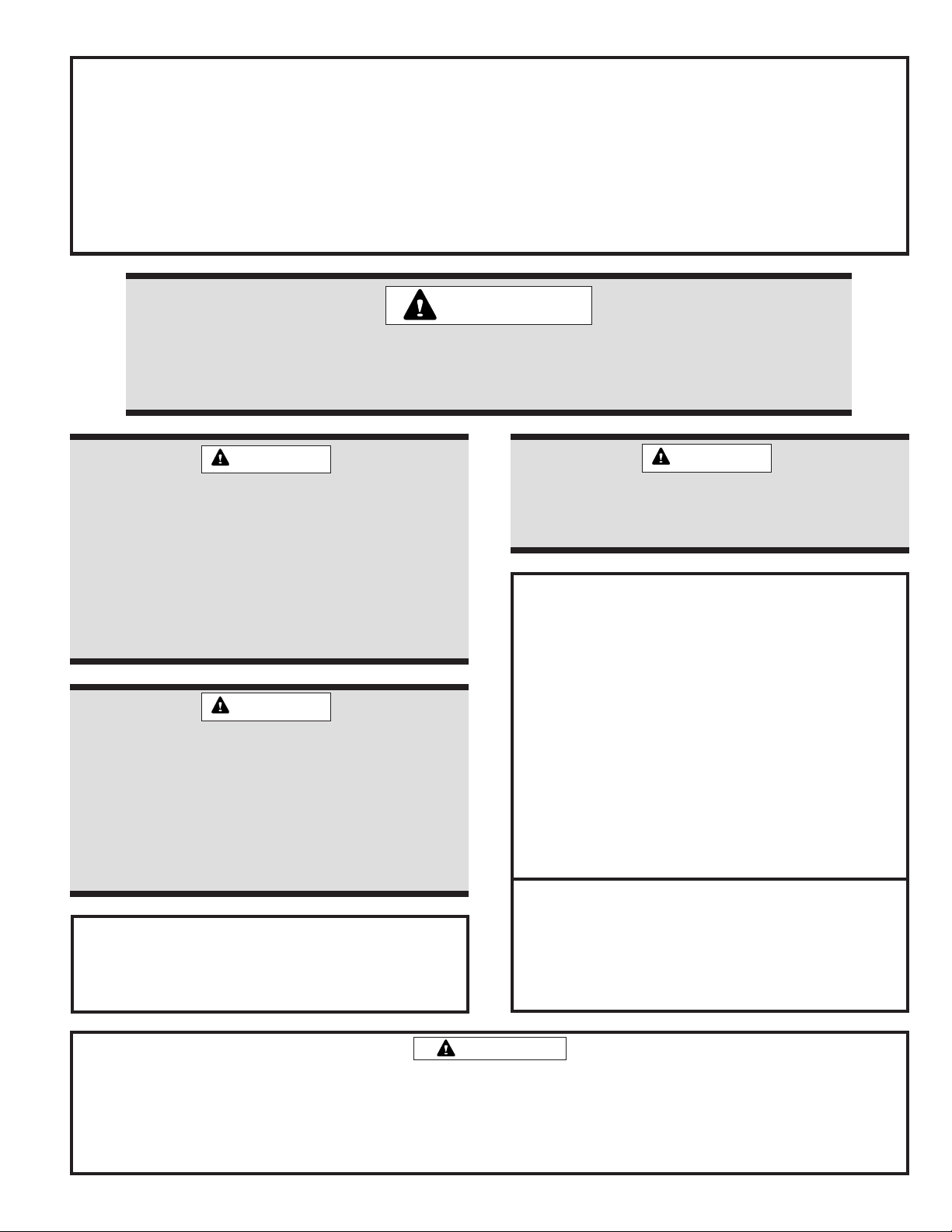

Exercise care when moving the unit. Do not remove any

packaging until the unit is near the place of installation. An

accessory lift kit can be purchased to aid in rigging (see

Figure 1). Spreaders whose length exceed the largest

dimension across the unit must be used across the top

of the unit. Recommended spreader length: 3 ton and smaller

package units – 44", 3.5 ton and larger units – 54".

Units may also be moved or lifted with a forklift while still

in the factory-supplied packaging. The lengths of the

forks of the forklift must be a minimum of 42".

CAUTION

Before lifting a unit, make sure that the weight

is distributed equally on the cables so that it

will lift evenly.

Page 2 # 48369K005

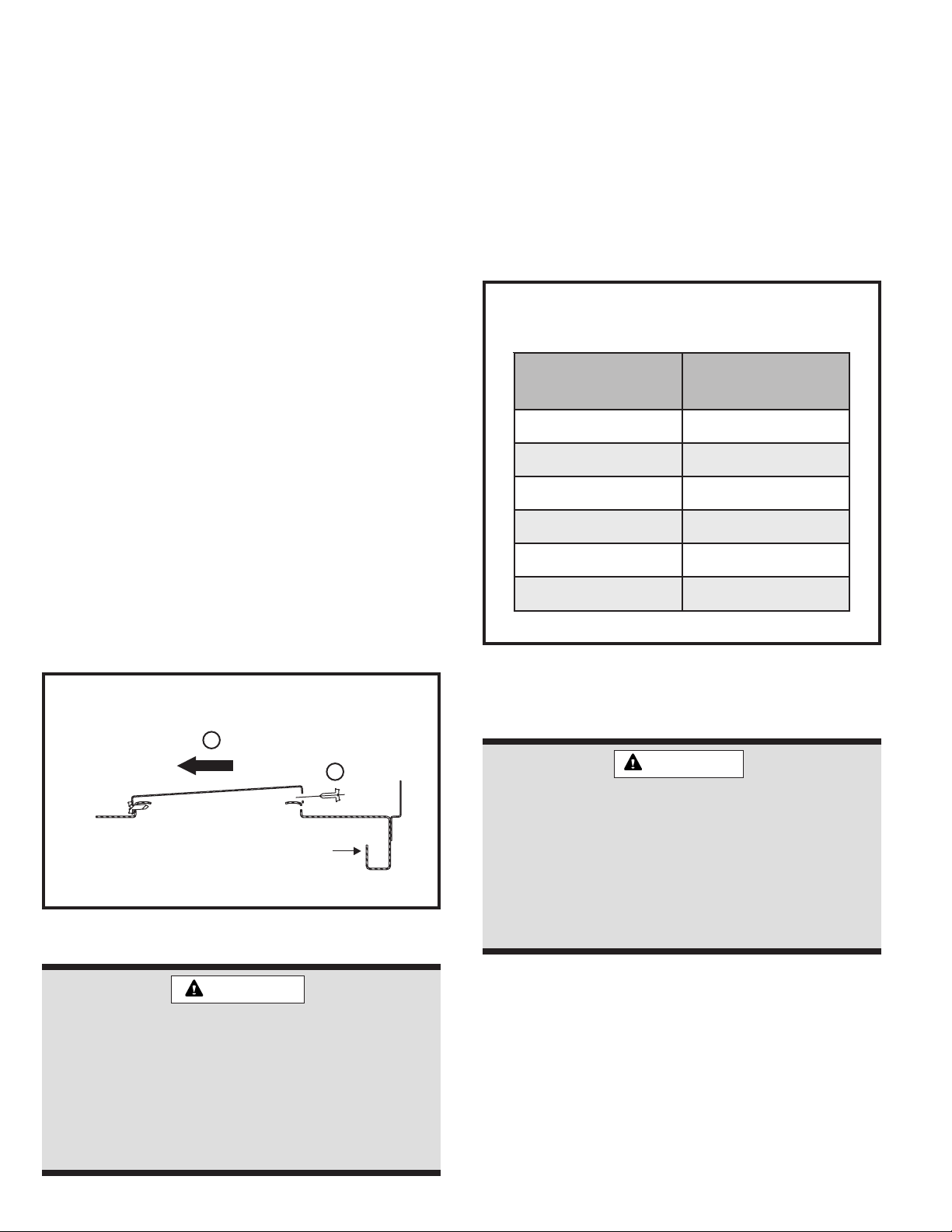

Unit

Drain Connection

Positive Liquid Seal Required

3.00" Min.

1.00" Min.

12.00"

Max.

Using Accessory Lift Kit

Minimum Clearance Requirements

Lifting Bracket

Spreaders

(Field Supplied)

Accessory

Sheet Metal

Screw

To avoid possible

damage to unit

panels from lifting

clevis, place

packing material

between clevis

and panels before

lifting unit.

Figure 1

Roof Curb Installation

If a roof curb is used, follow the manufacturer’s Installation

Instructions and be sure that all required clearances are

observed (see following Clearances section).

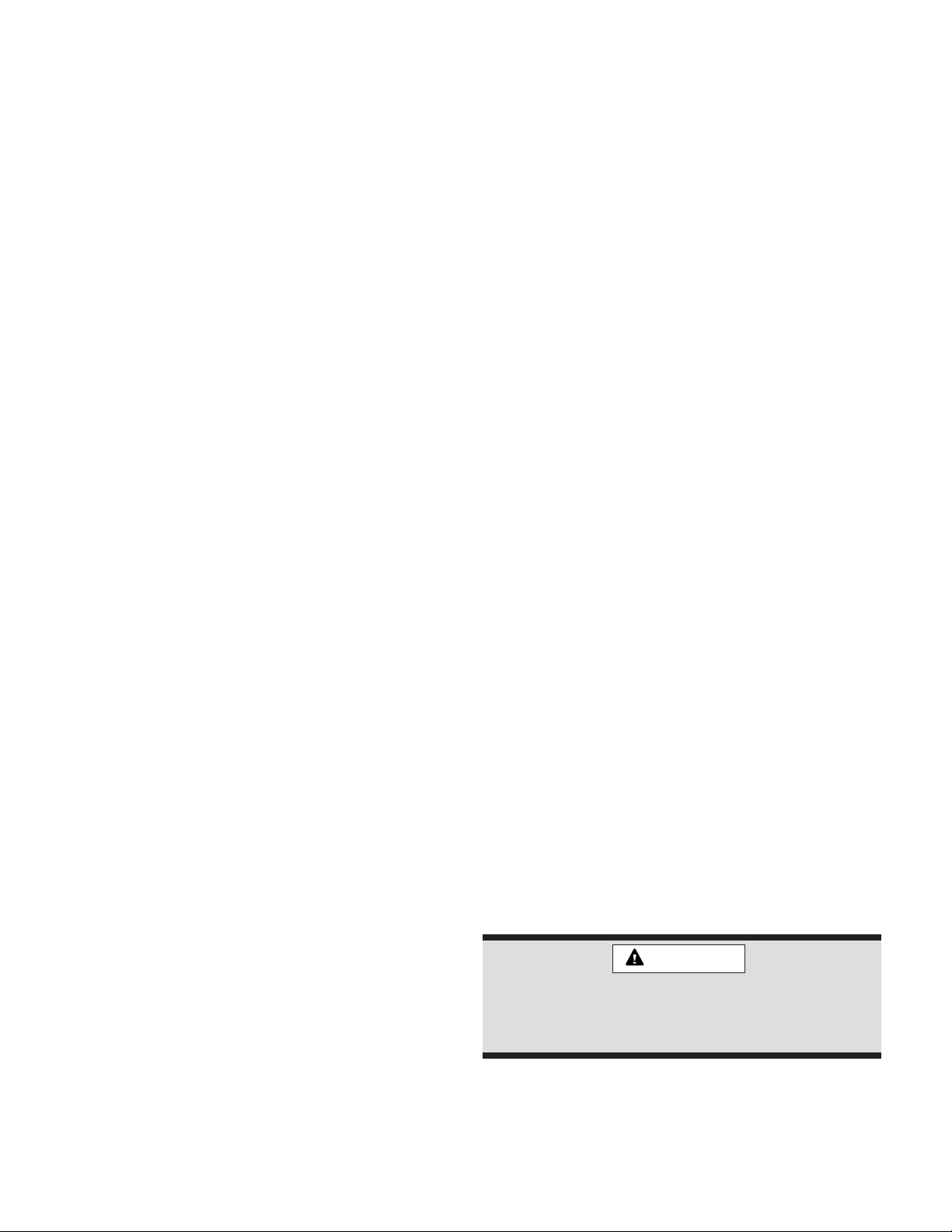

Roof Curb Assembly

oT

elbitsubmoC

lairetaM

tnorF"0"84"3

raeR "0 "42 "3

resnednoC

dnE

rewolB

dnE

poT"0"63"63

"0"42"3

"0 "03 "0

roF

ecivreS

roF

reporP

noitarepO

Table 1

Condensate Drain

The SH package unit is equipped with a 3/4" FPT coupling for condensate line connection. Plumbing must

conform to local codes. Use a sealing compound on male

pipe threads.

The condensate drain line must be properly trapped

and routed to a suitable drain. See Figure 3 for proper

drain arrangement. The drain line must pitch to an open

drain or pump to prevent clogging of the line. Seal around

the drain connection with suitable material to prevent air

leakage into the return air system.

Figure 2

Typical Condensate Drain Connection

Clearances

All units require certain clearances for proper operation and

service. Refer to Table 1 for the minimum clearances to

combustibles as well as minimum clearances necessary

for servicing and proper unit operation.

In the U.S., units may be installed on combustible floors

made from wood or class A, B, or C roof covering material.

In Canada, units may be installed on combustible floors.

Service Access

Access to all serviceable components is provided by four

removable panels: filter compartment, blower compartment, heater compartment, and top panel.

# 48369K005 Page 3

Figure 3

Ductwork

Filters

Ductwork should be designed and sized according to the

methods in Manual Q of the Air Conditioning Contractors of

America (ACCA).

A closed return duct system shall be used. This shall not

preclude use of economizers or outdoor fresh air intake. It

is recommended that supply and return duct connections

at the unit be made with flexible joints.

The supply and return air duct systems should be designed for the CFM and static requirements of the job.

They should not be sized by matching the dimensions

of the duct connections on the unit.

Outdoor ductwork must be insulated and waterproofed.

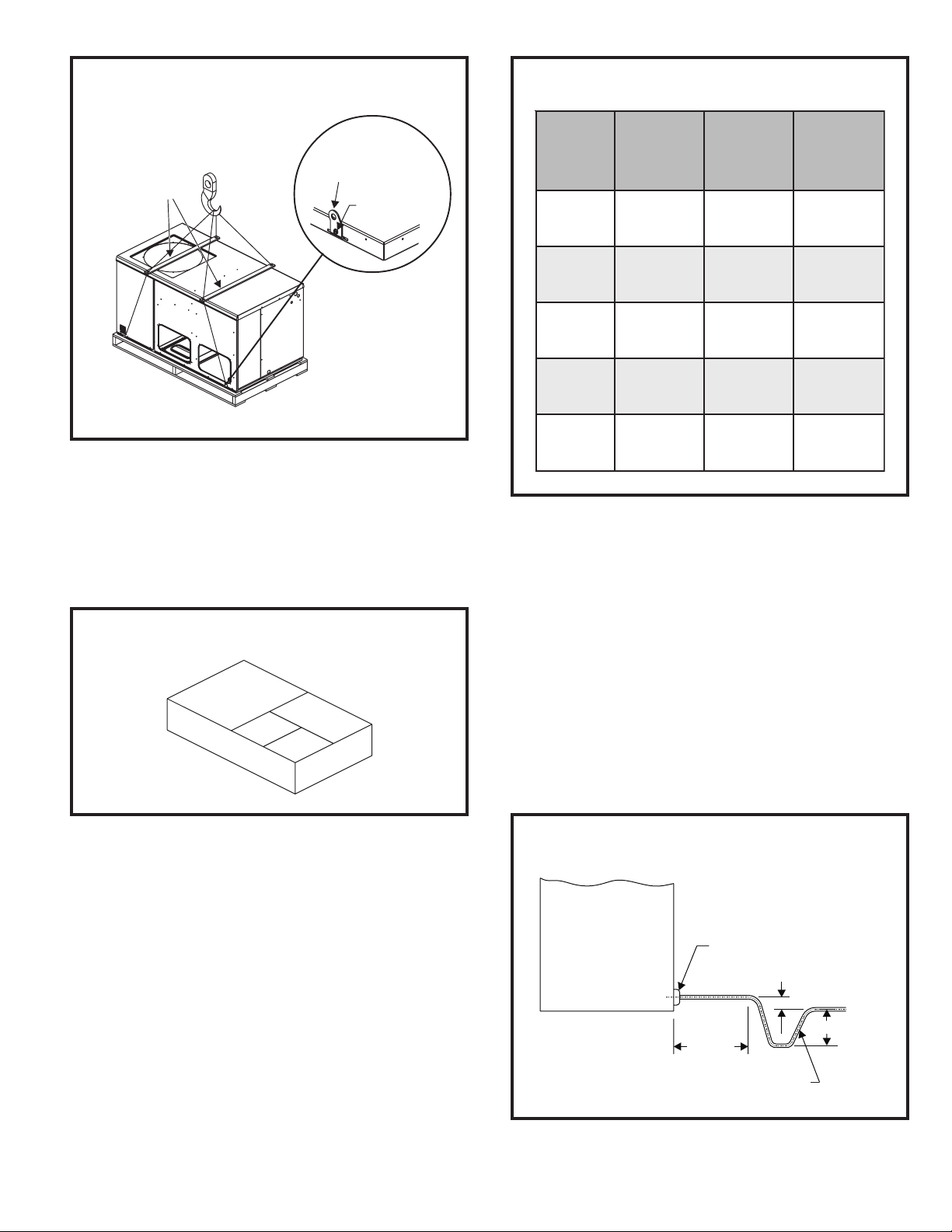

Equipment is shipped for side ductwork connection. The

unit can be converted to bottom ductwork connection by

removing the duct covers located over the bottom duct

openings and placing these covers over the side duct

openings (see Figure 4).

To remove the bottom duct cover over supply opening:

1. Remove screw on cover nearest side opening.

2. Lift end of cover slightly and push to slide back screw/

pin free from duct flange.

Air filters are to be used with this heating/cooling unit.

Filters are not factory supplied in the unit. However, a filter

frame accessory is available from the manufacturer that

allows filters to be installed within the unit. If the filter

frame accessory is not used, a filter must be installed in

the duct work by the installer. Filters must always be

installed ahead of the evaporator coil and must be kept

clean or replaced. Dirty filters will reduce the airflow of the

unit. Filters should be sized in accordance with Table 2.

Minimum Required Surface Area

for Disposable Filters

gnilooClanimoN

000,4276.2

000,03 33.3

000,6300.4

000,24 76.4

000,8433.5

000,06 76.6

aerAretliF

).tf.qs(

3. Slide duct cover out the side duct opening.

Removing Bottom Duct Covers

2

1

1. Remove screw and lift.

2. Slide cover to free back pin.

Base

Figure 4

CAUTION

When fastening ductwork to side duct flanges

on unit, insert screws through duct flanges

only; do not insert screws through casing. If

using bottom duct work, do not use screws to

secure ductwork to bottom duct opening

under drain pan side. Using screws to secure

bottom duct may damage drain pan.

Table 2

Electrical Wiring

WARNING

Line voltage is present at all components when

unit is not in operation on units with single pole

contactors. Disconnect all remote electric

power supplies before opening access panel.

Unit may have multiple power supplies. Failure

to disconnect all power supplies could result in

personal injury or death.

All wiring should be done in accordance with the

National Electrical Code, ANSI/NFPA No. 70 (latest

edition); Canadian Electrical Code Part 1, CSA C22.1

(latest edition); or local codes where they prevail. Use

wiring with a temperature limitation of 75°C minimum. Run

the 208 or 230 volt, 60 hertz electric power supply through

a fused disconnect switch to the connection box of the unit

and connect as shown in the wiring diagram located on the

inside of the control access panel.

Page 4 # 48369K005

Loading...

Loading...