Page 1

XR2000 BEAM

User’s Manual Rel 1.4

D.T.S. Illuminazione srl - ITALY

http://www.dts-lighting.it

GB

Made in Italy

Page 2

2

Le informazioni contenute in questo documento sono state attentamente redatte e controllate. Tuttavia

non è assunta alcuna responsabilità per eventuali inesattezze. Tutti i diritti sono riservati e questo

documento non può essere copiato, fotocopiato, riprodotto per intero o in parte senza previo consenso

scritto della D.T.S .

DTS si riserva il diritto di apportare senza preavviso cambiamenti e modifiche estetiche , funzionali o di

design a ciascun proprio prodotto. D.T.S non assume alcuna responsabilità sull’uso o sull’applicazione dei

prodotti o dei circuiti descritti.

The information contained in this publication has been carefully prepared and checked. However, no

responsibility will be taken for any errors. All rights are reserved and this document cannot be copied,

photocopied or reproduced, in part or completely, without prior written consent from D.T.S.

D.T.S. reserves the right to make any aesthetic, functional or design modifications to any of its products

without prior notice. D.T.S. assumes no responsibility for the use or application of the products or circuits

described herein.

XR2000 BEAM

ARC 1200

Les informations contenues dans le présent manuel ont été rédigées et contrôlées avec le plus grand

soin. Nous déclinons toutefois toute responsabilité en cas d'éventuelles inexactitudes. Tous droits

réservés. Ce document ne peut être copié, photocopié ou reproduit, dans sa totalité ou partiellement,

sans le consentement préalable de .

D.T.S.

de design, sans préavis, à chacun de ses produits. décline toute responsabilité sur l'utilisation ou

Todos los derechos han sido reservados y este documento no puede ser copiado, fotocopiado

D.T.S.

estético, funcional o de diseño a cada producto suyo. no se asume responsabilidad de

se réserve le droit d'apporter toutes modifications et améliorations esthétiques, fonctionnelles ou

D.T.S.

sur l'application des produits ou des circuits décrits.

Las informaciones contenidas en este documento han sido cuidadosamenteredactadas y

controladas. Con todo, no se asume ninguna responsabilidad por eventuales inexactitudes.

o reproducido, total o parcialmente, sin previa autorizaciónescrita de

se reserva el derecho a aportar sin previo aviso cambios y modificaciones de carácter

D.T.S.

ningún tipo sobre la utilización o sobre la aplicació

n de los productos o de los circuitos descritos.

D.T.S

D.T.S.

Page 3

3

INDEX:

1- SYMBOLS 4

2- GENERAL WARNING 4

3- GENERAL WARRANTY CONDITION 4

4- TECHNICAL FEATURES 5

5- ACCESSORIES 7

6- IMPORTANT SAFETY INFORMATION 8

6.1 Fire prevention

6.2 Prevention of electric shock

6.3 Protection against ultraviolet radiation

6.4 Safety

6.5 Level of protection against the penetration of solid and liquid objects

7- MOUNTING THE LAMP 9

7.1 Lamp alignment

8- VOLTAGE AND FREQUENCY 10

9- INSTALLATION 10

9.1 Safety cable

9.2 Protection against liquids

9.3 Movement

9.4 Risk of fire

9.5 Forced ventilation

9.6 Ambient temperature

10- MAINS CONNECTION 11

10.1 Protection

11- DMX SIGNAL CONNECTION 12

11.1 DMX Addresses

11.2 Selecting the DMX address

12- FIRMWARE UPDATING 13

13- DISPLAY FUNCTIONS 14

14- ERROR MESSAGES 17

15- HIDDEN MENU 18

16- PAN & TILT SPEED 19

17- FANS SPEED 19

18- OPENING THE PROJECTOR HOUSING 20

19- REPLACING GOBOS 20

20- PERIODIC CLEANING 21

20.1 Lenses and reflectors

20.2 Fans and air passages

21- PERIODIC CONTROLS

22- DMX PROTOCOL 22

23- 8 MOTORS CONTROL CARD 34

24- PAN & TILT CARD 35

25- CABLES RESEND CARD

26- DISPLAY CARD

27- LAMP ON-OFF CONTROL CARD

28- ROTATING GOBO WHEEL 36

29- COLOUR WHEEL 1 37

30- MORE GOBOS PROVIDED IN THE PACK AS STANDARD ACCESSORIES 38

XR2000 BEAM

ARC 1200

Page 4

1- SYMBOLS

Graphic symbols used on this manual

THIS SYMBOL INDICATES A HOT SURFACE

THIS SYMBOL INDICATES ELECTRIC SHOCK RISK

4

XR2000 BEAM

ARC 1200

!

F

UV

2M

2- GENERAL WARNING

THIS SYMBOL INDICATES GENERAL RISK

THIS SYMBOL MEANS “DO NOT PLACE THE UNIT ON

INFLAMMABLE SURFACES”

THIS SYMBOL MEANS “RADIATION FROM THIS LAMP

CAN CAUSE DAMAGE TO EYES AND SKIN”

THIS SYMBOL INDICATES THE MINIMUM DISTANCE TO

BE KEPT BETWEEN THE DEVICE AND THE LIT OBJECT

Read the instruction contained in this user manual carefully, as they give important information

regarding safety during installation , use and maintenance.

The device is not for domestic use and must be installed by a qualified electrician or experienced

person.

Always disconnect the device from the mains before replacing the lamp.

The lamp must be replaced if it has been damaged or deformed by prolonged use or overheating.

The device must always be equipped with an efficient ground connection.

3- GENERAL WARRANTY CONDITIONS

The unit is guaranteed for 24 months from the date of purchase against manufacturing material defects.

Page 5

5

XR2000 BEAM

ARC 1200

4- TECHNICAL FEATURES

XR2000 BEAM is a new compact moving head with an extremely high light power, projecting a parallel

and very concentrated beam.

With its new lens unit, XR2000 BEAM generates a luminosity of an incredible 150,000 Lux at 5 metres,

using only a 700 W lamp, giving an exceptional balance between performance and power consumption.

XR2000 BEAM is designed for a wide range of professional applications, like concerts, shows, tours and

big events.XR2000 BEAM ensures in fact great flexibility in use, because in a single projector it

incorporates a range of functions normally available only on different units (long-throw projectors with

high-power lamps, PAR 64 ACL, moving heads).XR2000 BEAM offers:

* Exceptional light power (150,000 Lux at 5 metres);

* The capacity to project a highly condensed and intense beam of light even over great distances, thanks

to the high efficiency of the new lens;

* Variety of colours (linear CMY synthesis + wheel with 7 colours);

* Customizable gobo wheel;

* Insertable linear frost filter (soft edge);

* Fast and uniform Pan and Tilt movements.

The XR2000 BEAM is also the ideal light for a vast range of applications in which quiet operation is a

priority, thanks to its silent ventilation system and silent pan/tilt operation.

The 16 bit Pan/Tilt mechanism features an exclusive Super Speed function, and a locking system with

recessed buttons. Access to every feature of the internal menu is simple and direct, thanks to the new

user interface featuring a LCD backlit graphic display (128 x 64).

XR2000 BEAM

(Cod. 03.MB001.EB.L)

• Electronic ballast 90-245V 50/60 Hz • Black finish

Lamp

Lamp: Philips MSR Gold 700/2 Fastfit

Automatic switching ON of lamp in case of accidental switching OFF.

Lamp ON/OFF via DMX; Reset via DMX.

Optical group

Dichroic glass reflector

Dimmer / shutter / strobo

Linear dimmer

Shutter

Strobe from 0,85 flash/sec to 10 flash/sec

Colours

CMY colour synthesis system + colour wheel (7 colours + open) with linear selection for perfect 2-colour

beams

Colour change with blackout sync; rainbow effect

150.000 Lux at 5 m (5,5°beam angle)

Gobos

1 customizable rotating gobo wheel (7 gobos); extractable gobo holders

Gobo change with synchronized blackout

Gobo scrolling; Gobo shake

Frost

Frost filter (soft edge)

Page 6

6

XR2000 BEAM

ARC 1200

4- TECHNICAL FEATURES

Pan / Tilt

Pan 540°(3,9 sec.); Tilt 270°(2,6 sec.); 16-bit resolution

Super Speed function; extremely smooth and precise movements even at the highest speeds

Pan / Tilt locking system with recessed buttons

Automatic Pan/Tilt repositioning in case of knocks

DMX channels

21(default) or 16 DMX channels

Internal operating system updatable via DMX

Interface

LCD backlit graphic display (128x64)

Connections

4 XLR connectors (3-pole In and Out; 5-pole In and Out) by Neutrik

POWERCONN connector by Neutrik

Power supply

Electronic ballast: 90 - 260 V (50/60 Hz)

Power consumption: 820 W

Power saving mode (the lamp dims to 50% six seconds after shutter closure)

Standard accessories

2 x “C” GQuick clamps with “fastlock” connection

Thermal

Operating ambient temperature: -10° / 40°

Weight

37 Kg

Page 7

4- TECHNICAL FEATURES

Dimensions

7

XR2000 BEAM

ARC 1200

Packaging Dimensions (LxWxH)

610 x 540 x 720 mm

Weight: 42 Kg

Unit Dimensions (LxWxH)

510x510x775mm

Weight: 37 Kg

5- ACCESSORIES

As standard

•1 x MSR Gold 700/2 Fastfit lamp

•1 x POWERCONN male cable connector (cod. 0520P014)

•1 x XLR 5 Pins male cable connector (cod. 0508B028)

•1 x XLR 5 Pins female cable connector (cod. 0508B027)

•5 x Metal Gobos

•2 x “C” Clamp GQUICK with “Fast Lock” connection 1/4 turn (max. load. 80Kg) (cod. 0521A014)

• User’s manual

Optional (on request)

• Double Professional Flight case; compartment for lamps and accessories, swivel wheels, cover with

hinges with-stay, dishes on cover for piling, 8 handles (2 each side) (cod. 0521C038)

• Raincover for XR2000 base (top) (cod. 03.MA009)

• Raincover for XR2000 base (bottom) (cod. 03.MA010)

• Embedding flange for XR2000 (visible display) (cod. 03.MA008)

• Embedding flange for XR2000 (no visible display) (cod. 03.MA007)

• Wireless DMX receiver card (cod. 03.LA.012)

• “C”Clamp G60 black (max. load 50Kg) (cod. 0521A004)

• “C”Clamp G60 chrome (max. load. 50Kg) (cod. 0521A004.20)

• “C”Clamp GQUICK with “Fast Lock”connection 1/4 turn (max. load. 80Kg) (cod. 0521A014)

• “C”Clamp G100 black / professional (max. load. 200Kg) (cod. 0521A015)

• Omega clamp with “Fast Lock”connection 1⁄4 turn

• Safety wire (3mm x 60 cm), ring spring catch, max. capacity load 60Kg (cod. 0521A010)

Page 8

6- IMPORTANT SAFETY INFORMATION

6.1 Fire prevention:

8

XR2000 BEAM

ARC 1200

XR2000 BEAM uses a PHILIPS /2

The use of any other alternative lamp is not recommended and will null and void the fixture's warranty.

-Never locate the fixture on any flammable surface.

-Minimum distance from flammable materials: 1.5 MT.

-Minimum distance from the closest illuminable surface: 2 MT.

-Replace any blown or damaged fuses only with those of identical value. Refer to the wiring diagram if

there is any doubt.

-Connect the projector to mains power via a thermal magnetic circuit breaker.

6.2 Prevention of electric shock:

-High voltage is present inside the unit. Unplug the unit prior to performing any function which involves

touching the inside of the moving head, including lamp replacement.

-The level of technology inherent in the requires the assistance of specialised personnel

for all servicing. Please refer to an authorised DTS service centre.

-A good earth connection is essential for proper functioning of the projector.

-Never connect the unit without proper earth connection.

-The fixture should be located in places with a good air ventilation.

6.3 Protection against ultraviolet radiation:

MSR Gold 700 Fastfit lamp

F

2M

XR2000 BEAM

UV

-Never turn on the lamp if any of the lenses, filters or ABS covering are damaged. Their respective

shielding functions will only operate efficiently if they are in perfect working order.

-Never look directly the lamp when it is on.

6.4 Safety:

-The projector should always be installed with bolts, clamps and other tools that are capable of

supporting the weight of the unit.

-Always use a second safety cable to sustain the weight of the unit in case of the failure of the main

fixing point.

-The external surface of the unit, at various points, may exceed 70°C. Never handle the unit until at

least 10 minutes have elapsed since the lamp was turned off.

-Always replace the lamp if any physical damage is evident.

-Never install the fixture in an enclosed area lacking sufficient air flow. The ambient temperature should

not exceed 40°C.

-A hot lamp may explode, so always wait for at least 10 minutes prior to attempting to replace the lamp.

-Always wear suitable hand protection when handling the lamp.

6.5 Level of protection against the penetration of solid and liquid objects:

!

!

-The projector is classified as an ordinary appliance and its protection level against the penetration of

solid and liquid objects is IP 20.

For outdoor use, D.T.S. reccomend the use of the dedicated raincovers:

Raincover for XR2000 base (top) (cod. 03.MA009)

•

Raincover for XR2000 base (bottom) (cod. 03.MA010)

•

Page 9

9

XR2000 BEAM

ARC 1200

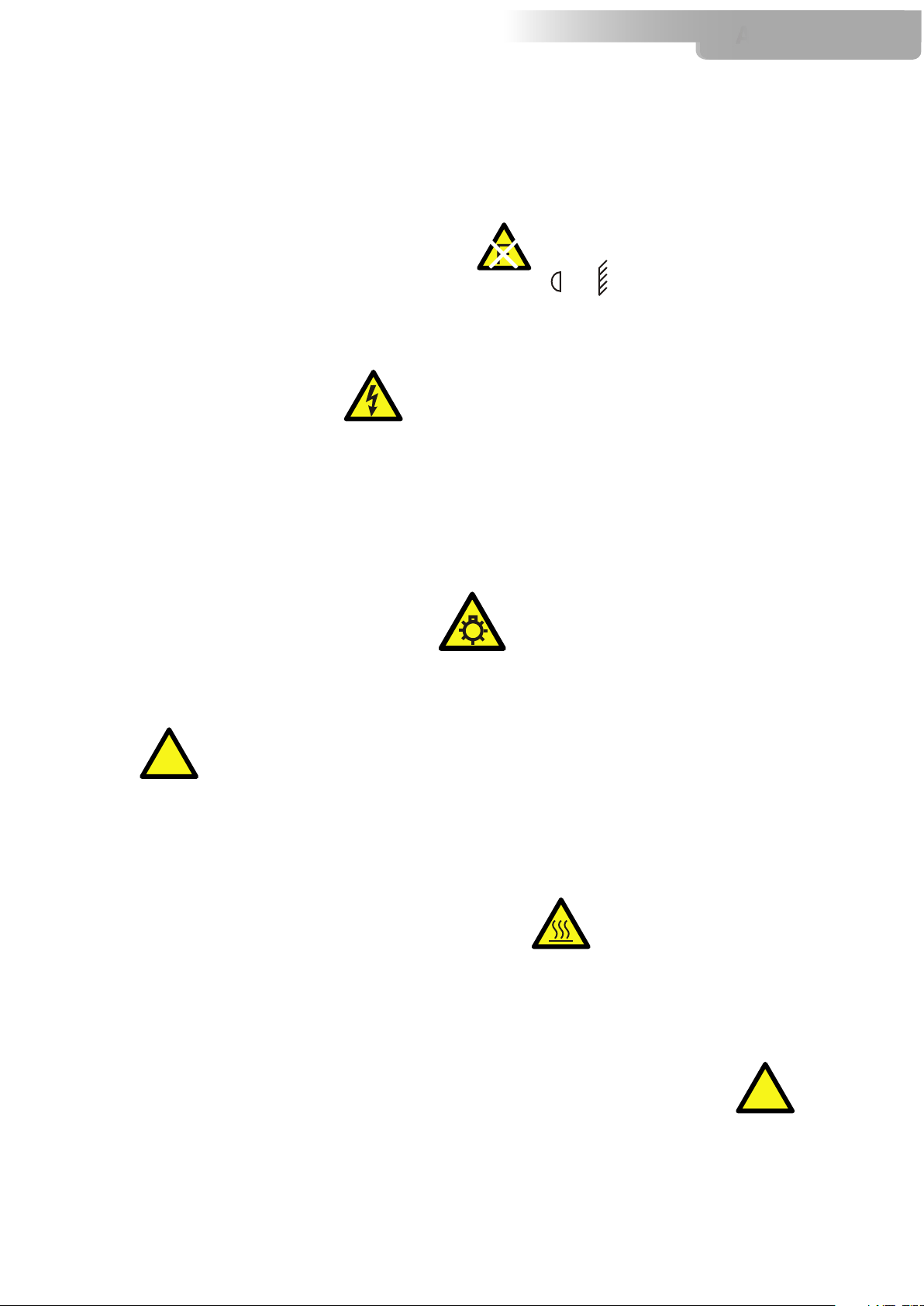

7- MOUNTING THE LAMPS

Warning: Switch off the unit before replacing the lamp.

Philips MSR Gold 700/2 Fastfit

Power 700W

Luminous flux 50,000 lm

Colour temperature 7.500°K

Lampbase PGJX50

Rated life 750 hours

1) Using a screwdriver, loose the 3 screws A, B, C, (photo 1) and remove the metal cover .

Photo 2Photo 1 Photo 4Photo 3

2) Insert the lamp (photo2).

3) Rotate the lamp 1/4 turn clockwise (photo 3 and 4).

The lamp used on XR2000 BEAM is made in quartz glass and should be handled with care. Always

follow the instructions supplied in the lamp's packaging. Never touch the glass directly but use the tissue

provided in the lamp's packaging. The lamp socket is not symmetrical.

DO NOT USE UNDUE FORCE ON THE GLASS. In case of difficulty, read again the instructions and repeat

the procedure.

4) Replace the metal cover and tighten the screws A,B,C, which were previously removed.

WARNING: Never look directly at the lamp when it’s lit.

Discharge lamps emits UV rays; radiation from this lamp can cause damage to eyes and skin.

PGJX50

UV

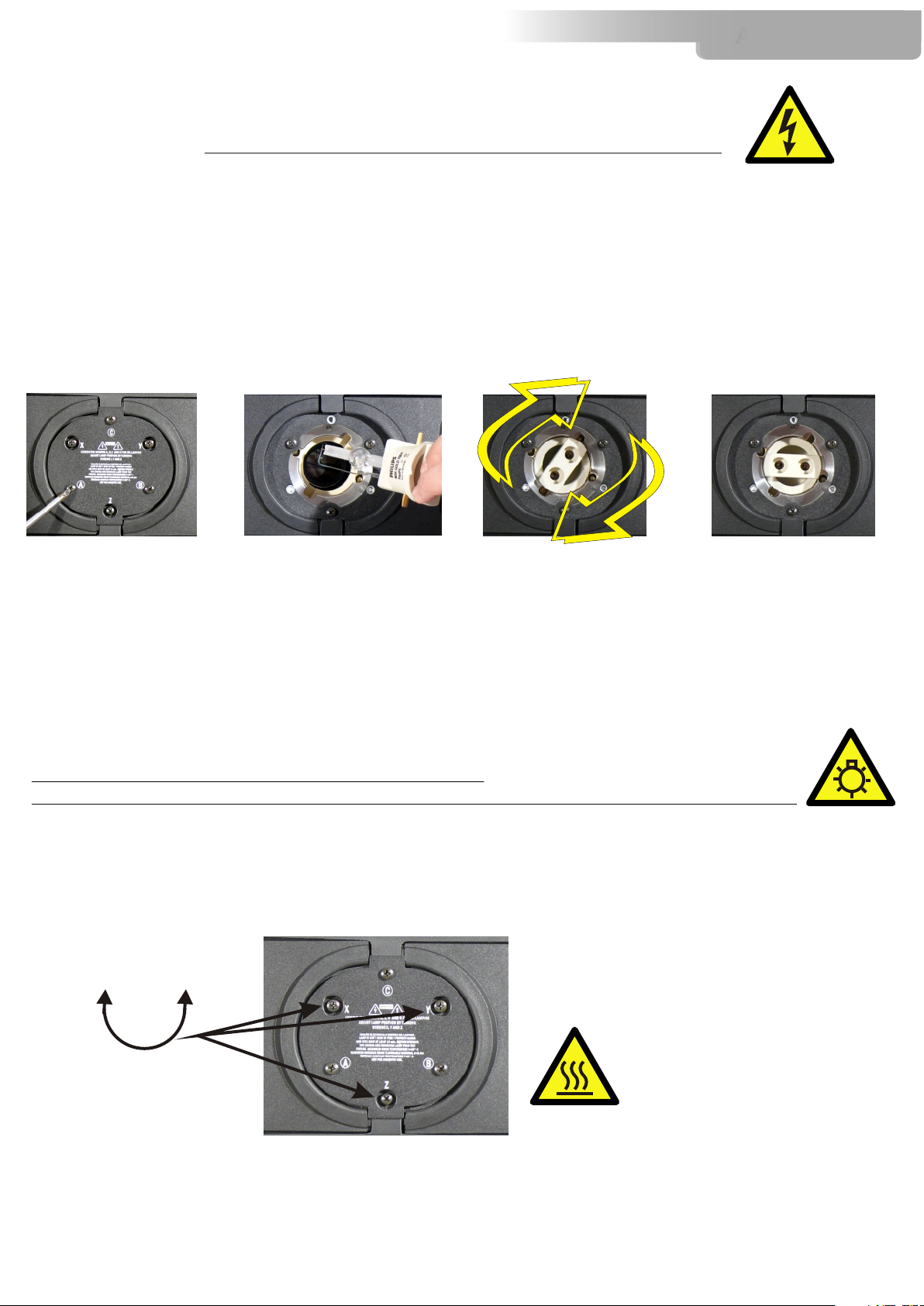

7.1 Lamp alignment

Attention: we recommend to align the lamp in the optical system to avoid overheating of the dichroic

filters and other components inside the unit. The lamp alignment is also essential to obtain the

maximum unifirmity and luminous performance by the projection.

Lamp

Alignment

Photo 5

1) Mount the fixture in an orientation so that it may be squarely projected onto a smooth white surface

no less than 3 meters away. 2) Using a console or the menu system, focus an open (white) beam onto

the surface and observe the beam. 3) Using a phillips-head screw driver, rotate the

Z (photo 5)

When the lamp is correctly optimized,

zones wich are brighter than others.

until you achieve a uniform flat field.

you will have an evenly projected light beam, with no shadows or

3 adjusters X, Y and

Page 10

10

XR2000 BEAM

ARC 1200

8- VOLTAGE AND FREQUENCY

The XR2000 BEAM with electronic ballast can operate at 90-260 VOLT 50 or 60 Hz.

9- INSTALLATION

XR2000 BEAM may be either floor or ceiling mounted.

For floor mounting installations, the XR2000 BEAM is supplied with four rubber mounting feet on the

base.

For ceiling mounted installations, we reccomend the use of appropriate clamps to fix the unit to the

mounting surface.

The supporting structure from which the unit is hung should be capable of bearing the weight of the

unit, as should any clamps used to hung it. The structure should also be sufficiently rigid so as not to

move or shake whilst the XR2000 BEAM is moving.

Eight 1/4 turn Fast Locks connections placed in the base of the units allow to fix the XR2000 BEAM in

any position, by using the two Fast Lock ‘C’ clamps provided in the box.

.

9.1- Safety cable

We recommend the use of a safety cable or chain connected to the XR2000 BEAM and to the suspension

truss in order to avoid the fixture accidentally falling should the main fixing point fail. Make sure that the

iron cable or chain can bear the weight of the entire unit.

You may attach the safety chain to the two holes (A) located on the base of the fixture, as shown in the

picture below.

A

9.2- Protection against liquids

The projector contains electric and electronic components which should under no circumstances come

into contact with oil, water or any other liquid. The proper unit functioning would be compromised

should this occur.

Page 11

11

XR2000 BEAM

ARC 1200

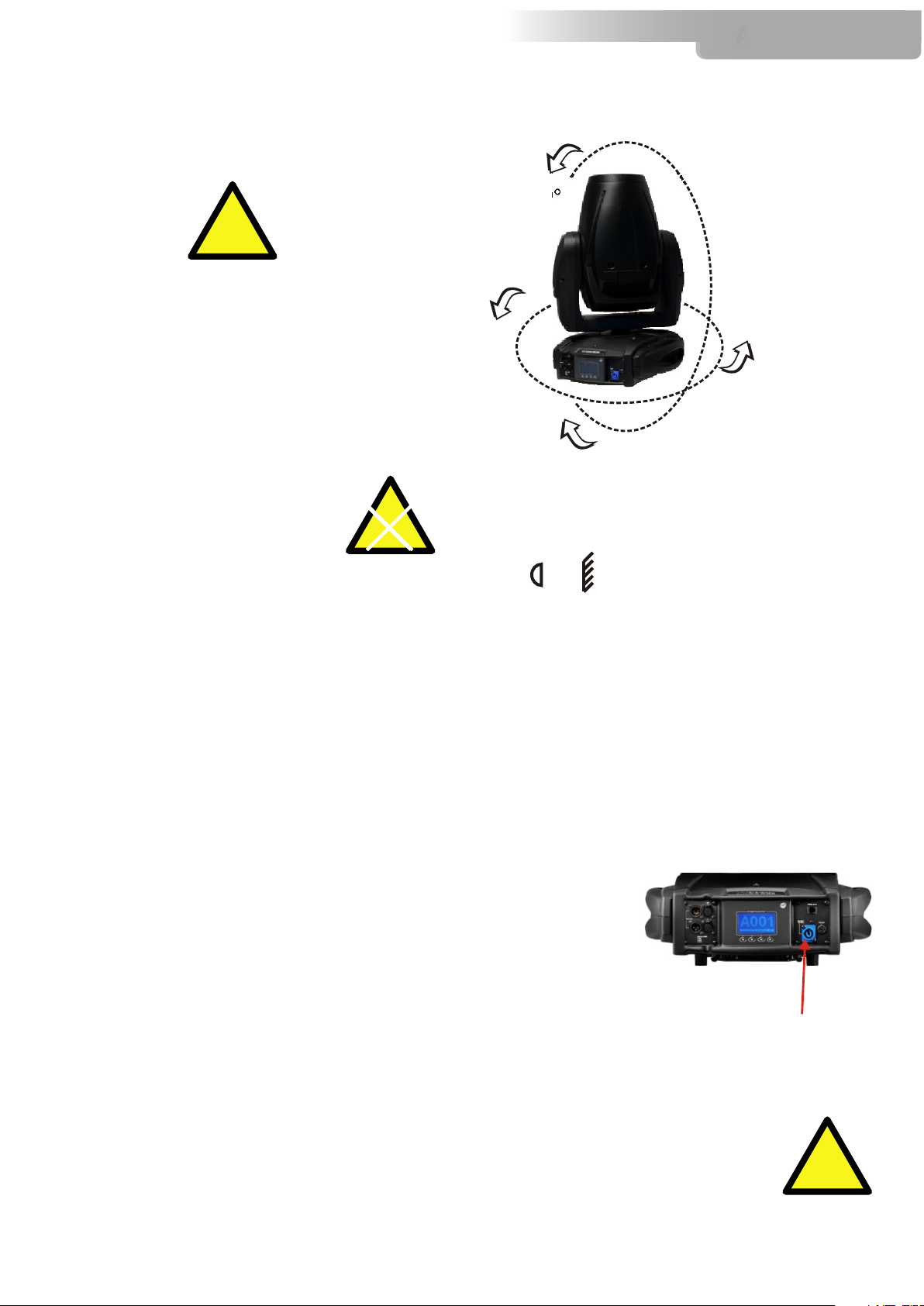

9.3- Movement

The projector has a maximum movement of 540° for Pan and 270° for Tilt. DO NOT place any

obstructions in the path of the projector's movement.

270°

!

WARNING

Do not place any object in the path

of the projector’s movement

9.4- Risk of fire

Each fixture produces heat and must be installed in a well-ventilated place. The minimum recommended

distance from flammable material is 1 MT.

540°

F

Minimum distance from the object being illuminated is 2 MT.

9.5- Forced ventilation

You will note, on inspection, that the unit features various air inlets and cooling fans located on both the

base and head of the fixture. These should, under no circumstances, be blocked or obstructed whilst the

projector is in operation.

Doing so could cause the fixture to seriously overheat thereby compromising its proper operation.

9.6- Ambient temperature

The projector should never be installed in places that lack a constant air flow. The ambient temperature

should NOT exceed 40°C.

10- MAINS CONNECTION

XR2000 BEAM with electronic ballast operate at 90-260 VOLT 50-60 Hz.

Prior to connecting the unit to your mains supply,

ensure that the model in your possession correctly matches

the mains supply available. For connection purposes,

ensure that your plug is capable of supporting 8 amps at 230V,

Or16 amps at 100-120 V

Strict adherence to regulatory norms is strongly recommended.

2M

Electronic ballast

90-260V 50 / 60Hz

10.1- Protection

The use of a thermal magnetic circuit breaker is recommended for each XR2000 BEAM.

A good earth connection is essential for the correct operation of the projector.

!

Page 12

12

XR2000 BEAM

ARC 1200

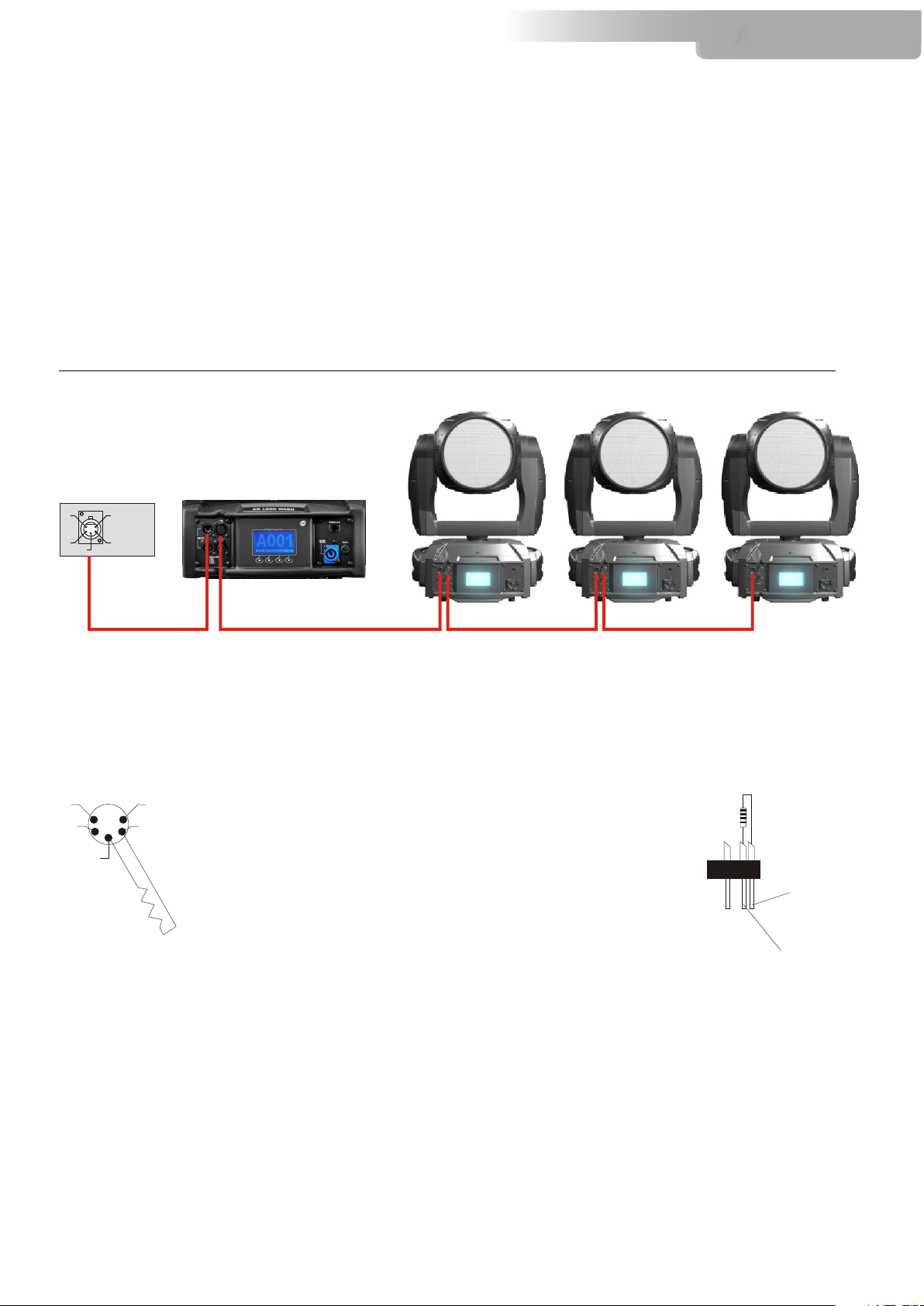

11- DMX SIGNAL CONNECTION

The unit operates using the digital DMX 512 (1990) signal. Connection between the mixer and the

projector or between projectors must be carried out using a two pair screened ø 0.5 mm cable and a XLR

5 or 3 pins connector. Ensure that the conductors do not touch each other. Do not connect the cable

ground to the XLR chassy

The plug housing must be isolated. Connect the mixer signal to the DMX IN projector plug and connect it

to the next projector by connecting the DMX OUT plug on the first projector to the DMX IN plug of the

second one.

This way, all the projectors are cascade connected.

NB. If the display showing the DMX address flashes, then one of the following errors has occurred:

- DMX signal not present

- DMX address not valid

- DMX reception problem

CONTROLLER

S TA ND AR D

D M X 5 1 2

5

1

1=GND

2=DATA3=DATA+

4 2

3

For Installations where long distance DMX cable connections are needed, we suggest to use a DMX

terminator.

The DMX terminator is a male XLR 3-5 pins connector with a 120 ohm resistor

Between pin 2 and 3.

The DMX terminator must be plugged into the last unit (DMX out panel connector) of the DMX line.

5

4

120 ohm

1

2

3

OUT

PLACE A 120 OHM RESISTOR BETWEEN PIN 2

AND 3 OF A MALE XRL CONNECTOR AND PLUG IT

INTO THE DMX OUT PANEL CONNECTOR OF THE

LAST UNIT CONNECTED TO THE DMX LINE

PIN 3

PIN 2

Page 13

13

XR2000 BEAM

ARC 1200

11.1-DMX Addresses

XR2000 BEAM can be controlled with 21 (default) or 16 DMX channels.

If you want to use the unit in 21 channels, set the following addresses on the mixer:

Projector 1 A001

Projector 2 A022 If you want to select the next projector, just add “21”

Projector 3 A043

….. A….

projector 6 A106

11.2-Selecting the DMX address

1) Press the UP-DOWN key until you reach the required DMX channel. The numbers on the display will

start to flash (but the new DMX address hasn't yet been set).

2) Press ENTER to confirm your selection. The numbers on the display will stop flashing and the

projector is now setted to the new DMX address.

TRICKS:

if you keep pushed the UP or DOWN keys, the channels are calculated more quickly and you get a

faster selection.

12 FIRMWARE UPDATING

Warning:

This procedure require a base knolewge of computer applications and Windows

Hyperterminal program.

To update the software version of the you need:

D.T.S. RED BOX interface (D.T.S. Code: 03.LA.008).

USB-DMX Drivers for the D.T.S. RED BOX interface .

(The drivers and the installation procedure are available in our web site www.dts-lighting.it)

‘Updating the software version’

Please follow the procedure below to perform the update:

1. Install the D.T.S. RED BOX USB-DMX driver on the PC you will use to update the unit software.

2. Connect the D.T.S. RED BOX interface to the PC by using a USB cable.

3. Connect the D.T.S. RED BOX interface to the fixture by using a DMX cable.

4. Download the new software version into the unit by using Windows Hyperterminal program.

Please refer to an authorised DTS service centre.

XR2000 BEAM

!

It will be possible to download the software from the reserved area of D.T.S. web site:

www.dts-lighting.it.

Page 14

14

XR2000 BEAM

ARC 1200

13- DISPLAY FUNCTIONS

DISPLAY

DMX OUT

DMX IN

DMX IN

DMX OUT

MENU

ENTER

UP

DOWN

FUSE 16A T 5X20

MAINS

Electronic ballast

90-260V 50 / 60Hz

DISPLAY FUNCTIONS

The XR2000 BEAM display panel shows all the available functions . Using these functions, it is

possible to change some of the parameters and add some functions. Changing the DTS setting

can vary the functions of the unit so that it does not respond to the DMX 512 used to control it.

Carefully follow the instructions below before carrying out any variations or selections.

NOTE: the symbol shows which key has to be pushed to obtain the desired function.

Menu

PAN DIRECTION

This menu allows to set the Pan

movement.

Normal or Reversed

Menu

TILT DIRECTION

This menu allows to set the Pan

movement.

Normal or Reversed

Menu

PAN TILT SPEED

Pan Tilt Speed control (1-4)

Pan Direction

Up-Down

Tilt Direction

Up-Down

Pan Tilt Speed

Up-Down

Up-DownENTER

PAN DIRECTION

Pan movement Normal or Reversed

ENTER

Default = Normal

NORMAL

MENU ENTER DOWN UP

Up-DownENTER

TILT DIRECTION

Tilt movement Normal or Reversed

ENTER

Default = Normal

NORMAL

MENU ENTER DOWN UP

Up-DownENTER

PAN TILT SPEED

Pan Tilt Speed control

ENTER

Default = 4

4

MENU ENTER DOWN UP

Page 15

13- DISPLAY FUNCTIONS

15

XR2000 BEAM

ARC 1200

Up-Down

Display

Menu

DISPLAY FLIP / STAND BY / CONTRAST

Display Flip:

Reverses display's reading depending on the

mounting position

(On the ground or suspended).

Display Standby:

To turn off the display (after 5 seconds)

Or leave it always on.

Display Contrast:

Display contrast regulation (1-16)

Up-DownENTER

DISPLAY

FLIP

FLIP

Display Flip

ON THE GROUND (Default)

SUSPENDED

ENTER

ON THE GROUND

MENU ENTER DOWN UP

DISPLAY

STANDBY

FLIP

OFF

MENU ENTER DOWN UP

DISPLAY

CONTRAST

FLIP

Display Standby

OFF = Display Standby disabled

(Default)

ON = Display goes OFF after 5

seconds

Display Contrast

1-16 (Default = 8)

ENTER

ENTER

8

MENU ENTER DOWN UP

Up-Down

Up-Down

DMX Mode

Lamp

Menu

DMX MODE

To select DMX mode :

21 channels or 16 channels

Menu

LAMP

Lamp always ON, always OFF,

lamp ON-OFF selectable via DMX

And lamp life time reset

ADJUST

To adjust the lamp with no mixer

connected.

It’s possible to set the parameters for

PAN-TILT and ZOOM

Up-DownENTER

DMX MODE

DMX mode

ENTER

21 channels (Default)

16 channels

21 channels

MENU ENTER DOWN UP

Up-DownENTER

MENU

LAMP

BY DMX

FLIP

DOWN

ENTER

UP

LAMP

ADJUST

FLIP

BY DMX = ON / OFF via DMX (default)

ALWAYS ON = Forced ON

ALWAYS OFF = Forced OFF

RESET COUNTER = Lamp life time

reset

LAMP ADJUST =

To adjust the lamp

with no mixer connected.

It’s possible to set the parameters for

PAN-TILT and ZOOM

ENTER

ENTER

MENU

ENTER

DOWN

UP

Page 16

13- DISPLAY FUNCTIONS

16

XR2000 BEAM

ARC 1200

Menu

RESET

Reset via DMX ENABLED / DISABLED

and unit reset

Menu

FAN SPEED

Fan Speed control

Menu

GOBO ROTATION

Gobo rotation control the Rotating speed of gobo

Reset

Up-Down

Fan Speed

Up-Down

Gobo Rotation

Up-Down

Up-DownENTER

RESET

BY DMX

ENABLED

MENU ENTER DOWN UP

Up-DownENTER

FAN SPEED

ENABLED = Reset via DMX enabled

(Default)

DISABLED = Reset via DMX disabled

NOW = Unit motors reset

Fan speed control

ENTER

ENTER

1-5 (Default = 5)

5

MENU ENTER DOWN UP

Up-DownENTER

GOBO ROTATION

During gobo scrolling

ON

OFF = (Default)

ENTER

OFF

MENU ENTER DOWN UP

Menu

CMY BLACKOUT

CMY filters blades inserted at 100% if the dimmer

remain closed for more than 5 seconds.

By activating this function, it will be possible to

reduce substantially any visible light reflection

coming out from the front lens when dimmer is

closed.

Menu

SYSTEM INFO

Lamp life time, lamp strikes, unit life time, 8

motors card software version, Pan&Tilt card

software version and unit model

Menu

RESERVED

Pan lock-Tilt lock

Pan free-Tilt free

System Reboot

(Code = 100)

CMY Blackout

Up-Down

System info

Up-Down

Reserved

Up-Down

Up-DownENTER

CMY BLACKOUT

ON = Blackout enabled (Default)

ENTER

OFF = Blackout disabled

ON

MENU ENTER DOWN UP

Up-DownENTER

Up-DownENTER

SYSTEM INFO

LAMP LIFE:0000H STRIKE:001

UNIT LIFE: 0010H

8M R.20

PT R.19

MODEL: XR2000 BEAM

MENU ENTER DOWN UP

RESERVED

ENTER CODE

000

MENU ENTER DOWN UP

PAN LOCK

NO

SYSTEM INFO

Lamp life time, lamp strikes, unit life

time, 8 motors card software

version, Pan&Tilt card software

version and unit model

Pan Lock = Lock the Pan to the

desired value

Tilt Lock = Lock the Tilt to the

desired value

Pan Free = Remove power to Pan

motor

Tilt Free = Remove power to Tilt

motor

System Reboot = Unit Reboot

without needing of turning OFF the

unit

ENTER

ENTER

MENU ENTER DOWN UP

Page 17

13- DISPLAY FUNCTIONS

17

XR2000 BEAM

ARC 1200

Up-Down

Up-Down

Default

Motors Test

Menu

DEFAULT

To restore main settings

Menu

TEST MODE

Full test and single function test.

Up-DownENTER

DEFAULT

RESTORE MAIN SETTINGS

MENU ENTER DOWN UP

Default

To restore main settings

ENTER

DEFAULT

RESTORE MAIN SETTINGS

SURE?

PRESS ENTER TO CONFORM

PRESS MENU TO CANCEL

MENU ENTER DOWN UP

Up-DownENTER

MOTORS TEST

ALL

MENU ENTER DOWN UP

Motors Test

ALL ,PAN, TILT, DIMMER, SHUTTER,

COLOUR WHEEL, CYAN, MAGENTA,

YELLOW and FROST.

ENTER

14- ERROR MESSAGES

ERROR

COLOUR WHEEL

MENU ENTER DOWN UP

COLOUR WHEEL

POSITION ERROR

ERROR

PAN

MENU ENTER DOWN UP

MENU ENTER DOWN UP

CYAN POSITION

ERROR

MENU ENTER DOWN UP

ERROR

CYAN

ERROR

TILT

ERROR

MAGENTA

MENU ENTER DOWN UP

MAGENTA POSITION

ERROR

ERROR

INTERNAL BUS

MENU ENTER DOWN UP

ERROR

YELLOW

MENU ENTER DOWN UP

YELLOW POSITION

ERROR

ERROR

DMX ADDRESS

MENU ENTER DOWN UP

PAN REPOSITIONING

ENCODER ERROR

TILT REPOSITIONING

ENCODER ERROR

COMMUNICATION

PROBLEM BETWEEN 8

MOTORS CARD AND

PAN&TILT CARD

DMX ADDRESS

ERROR

Page 18

18

XR2000 BEAM

ARC 1200

15- HIDDEN MENU

For technical personnel only.

To operate this menu:

-Connect the projector to the DMX controller (DMX SIGNAL MUST BE CORRECTLY RECEIVED)

- Reset the XR2000 BEAM (reset from the MENU, not from the DMX controller!).

- While reset is running, press the MENU and ENTER keys at the same time.

CALIBRATION

MOTORS ALIGNMENT

PAN

134

MENU ENTER DOWN UP

ELECTRONIC

CALIBRATION OF THE

MOTORS

MIN LAMP POW.

1=65% 100=100%

10

MENU ENTER DOWN UP

LAMP POWER WHEN

DIMMER CLOSED

DEFAULT CAL

SET ALL MOTORS AT 128

MENU ENTER DOWN UP

RESET EEPROM.

RESET ALL SETTINGS

TO 128 VALUE

EXIT TO MAIN

MENU ENTER DOWN UP

EXIT FROM HIDDEN

MENU

FANS SPEED

ONLY AT MIN LAMP POWER

3

MENU ENTER DOWN UP

FAN SPEED WHEN

DIMMER CLOSED

Calibration mode

CALIBRATION

MOTORS ALIGNMENT

PAN

134

MENU ENTER DOWN UP

PAN ALIGNMENT

To align Pan position

CALIBRATION

MOTORS ALIGNMENT

COLOUR WHEEL

151

MENU ENTER DOWN UP

COLOUR WHEEL ALIGNMENT

To align Colour wheel

CALIBRATION

MOTORS ALIGNMENT

TILT

167

MENU ENTER DOWN UP

TILT ALIGNMENT

To align Tilt position

CALIBRATION

MOTORS ALIGNMENT

SHUTTER

145

MENU ENTER DOWN UP

SHUTTER ALIGNMENT

To align Shutter blades

CALIBRATION

MOTORS ALIGNMENT

GOBO

151

MENU ENTER DOWN UP

GOBO WHEEL ALIGNMENT

To align Gobo wheel

CALIBRATION

MOTORS ALIGNMENT

FROST

85

MENU ENTER DOWN UP

FROST ALIGNMENT

To align Frost

CALIBRATION

MOTORS ALIGNMENT

GOBO INDEX

141

MENU ENTER DOWN UP

GOBO WHEEL INDEX ALIGNMENT

To align Gobo wheel Index

CALIBRATION

MOTORS ALIGNMENT

CYAN ZERO

162

MENU ENTER DOWN UP

CYAN ZERO ALIGNMENT

Cyan zero position setting

Page 19

Calibration mode

19

XR2000 BEAM

ARC 1200

CALIBRATION

MOTORS ALIGNMENT

CYAN PATH

134

MENU ENTER DOWN UP

CYAN PATH ALIGNMENT

Cyan excursion setting

CALIBRATION

MOTORS ALIGNMENT

YELLOW PATH

121

MENU ENTER DOWN UP

YELLOW PATH ALIGNMENT

Yellow excursion setting

CALIBRATION

MOTORS ALIGNMENT

MAGENTA ZERO

167

MENU ENTER DOWN UP

MAGENTA ZERO ALIGNMENT

Magenta zero position setting

CALIBRATION

MOTORS ALIGNMENT

MAGENTA PATH

151

MENU ENTER DOWN UP

MAGENTA PATH ALIGNMENT

Magenta excursion setting

CALIBRATION

MOTORS ALIGNMENT

YELLOW ZERO

141

MENU ENTER DOWN UP

YELLOW ZERO ALIGNMENT

Yellow zero position setting

16- PAN & TILT SPEED (default: 4)

You can set the PAN and TILT motors at high speed on your XR2000 BEAM.

Press menu until you see PAN TILT SPEED.

Press ENTER and select a speed with UP-DOWN (there are 4 speeds). Confirm by pressing ENTER.

17- FAN SPEED ( default: 5)

Fan speed regulation makes it possible to reduce fan noise. However, the ambient temperature must be

less than 35° C.

Page 20

20

XR2000 BEAM

ARC 1200

18- OPENING THE PROJECTOR HOUSING

It is possible to inspect the inside of the projector by removing the cover as indicated below.

ATTENTION

REMOVE MAINS POWER PRIOR TO ACCESSING THE PROJECTOR’S INTERNAL COMPONENTS.

1) Using a screwdriver, loose the 3 screws A, B, C, (photo 1) and remove the metal cover .

2) Loosen the 2 screws which fix the head covers (photo 2) .

3) Once unscrewed, simply lift the covers to access the internal components (photo 3).

Photo 1

Photo 2

Photo 3

19- REPLACING GOBOS

XR2000 BEAM uses a mechanical system which allows the fixture's gobos to be removed without the use

of special tools. Replacement gobos should be made of either heat resistant glass or metal.

An ever-increasing range of gobos is available from your DTS sales network.

Gobo dimensions are as follows:

ø external (ED) = 27.9 mm

ø of image with defined edge (ID) = 24 mm

thickness = from 0.2 to 4 mm (see catalogue)

Max thickness

4 mm

ID

ED

Coated side

When an object is held up the coated side of the glass gobo there

is no space between the object and its reflection.

Uncoated side

When an object is held up the uncoated side of the glass gobo

there is a space between the object and its reflection.

Load with coated surface toward the light source.

Coated side

Uncoated side

Page 21

21

Replacing gobos on the rotating gobo wheel

When replacing gobos, ensure that the projector is switched off.

1) Open the projector housing as described on page 20.

2) Remove the gobo holder to allow easier access to the gobo (photo 1).

3) Release the gobo retaining spring and carefully remove the gobo (photo 2).

4) Reverse the procedure to install a replacement gobo.

XR2000 BEAM

ARC 1200

Photo 1

Photo 2

20- PERIODIC CLEANING

20.1- Lenses and reflectors

Even a fine layer of dust can reduce the luminous output substantially. Regularly clean all lenses

and the reflector using a soft cotton cloth, dampened with a specialist lens cleaning solution.

20.2- Fans and air passages

The fans and air passages must be cleaned approximately every 6 weeks. This periodic cleaning

will depend of course, on the conditions in which the projector is operating. Suitable instruments

for performing this type of maintenance are a brush and a common vacuum cleaner or an air

compressor. If necessary, clean the fans and air passages more frequently.

21- PERIODIC CONTROLS

!

Attention

Disconnect mains power prior to removing the projector housing.

Lamp

The lamp should be replaced if there is any visible damage or deformation due to heat. This will

help to avoid the danger of the lamp exploding.

XR2000 BEAM lamp lifespan is about 750 hours, then it is necessary to replace it.

UV

Mechanical parts

Periodically check all mechanical parts,gears, guides, belts, etc.for wear and tear, replacing them if

necessary. Periodically check the lubrication of all components, particularly the parts subject to

high temperatures. If necessary, lubricate with suitable lubricant, available from your D.T.S.

distributor. Check the tension of the belts and adjust it if necessary.

Electrical components

Check all electrical components for correct earthing and proper connection of all connectors,

refastening if necessary.

Fuse replacement

Locate the fuse, which protects the lamp and electronics, in the base of the XR2000 BEAM

Using a multimeter, test the condition of the fuse, replacing it with one of equivalent type if

necessary.

Page 22

22- DMX PROTOCOL

21 CHANNELS MODE (DEFAULT)

1 PAN msb 540°

2 PAN lsb

3 TILT msb 270°

4 TILT lsb

5 SPEED MOVEMENT

6 DIMMER

7 SHUTTER

8 COLOUR

9 COLOUR mode

10 CYAN

11 MAGENTA

12 YELLOW

13 SPEED CMY

14 MACRO CMY

15 GOBO

16 GOBO MODE

17 GOBO ROTATION/INDEX

18 GOBO INDEX FINE

19 GOBO SHAKE

20 FROST

21 RESET - LAMP

22

XR2000 BEAM

ARC 1200

DMX CHANNEL

DMX CHANNEL

DMX CHANNEL

DMX CHANNEL

DMX CHANNEL

DMX range

Value

000 - 010

011-025

026-127

128-247

248-255

1

2

3

4

5

Mid point

DMX value

Parameter: PAN msb

Parameter: PAN lsb

Parameter: TILT msb

Parameter: TILT lsb

Parameter: SPEED MOVEMENT

Move

range

(degrees)

Mode Option Function

Standard

Fast movement

Vector mode from fast to slow

Variable time reaction to

DMX signal ( fast to slow)

Silent Mode

Page 23

DMX CHANNEL 6

DMX range

Value

Mid point

DMX value

0-7

8-255

DMX CHANNEL

DMX range

Value

000-019

020-039

040-059

060-079

080-089

090-099

100-109

Mid point

DMX value

110-119

120-129

130-139

140-149

150-159

160-169

170-179

180-189

190-199

200-209

210-219

220-227

228-233

234-255

Parameter: DIMMER

Move

range

(degrees)

7

Parameter: SHUTTER

Move

range

(degrees)

23

XR2000 BEAM

ARC 1200

Mode Option Function

Black-out

Proportional dimmer

Mode Option Function

Black - out

Open

Black-out

Random Strobe

Strobe speed 1 min. (0,85 Hz)

Strobe speed 2 (1,4 Hz)

Strobe speed 3 (2 HZ)

Strobe speed 4 (3,75 Hz)

Strobe speed 5 (5 Hz)

Strobe speed 6 max. (6,75 Hz)

Pulse open speed 1 min.

Pulse open speed 2

Pulse open speed 3

Pulse open speed 4 max.

Pulse closed speed 1 min.

Pulse closed speed 2

Pulse closed speed 3

Pulse closed speed 4 max.

Colour and Gobo in black-out

Pan and Tilt in black-out

Open

DMX CHANNEL 8

DMX range

Value

000-031

032-063

064-095

096-127

128-159

160-191

192-223

224-255

Mid point

DMX value

Parameter: COLOUR

IF CHANNEL 9 = FULL COLOUR (DMX range value 0 - 63)

Move

range

(degrees)

Mode Option Function

Colour 1

Colour 2

Colour 3

Colour 4

Colour 5

Colour 6

Colour 7

Colour 8

Page 24

24

XR2000 BEAM

ARC 1200

DMX CHANNEL 8

DMX range

Value

000 - 27

028 - 055

056 - 083

084 - 111

112- 139

140 - 167

168 - 195

196 - 223

224 - 255

Mid point

DMX value

IF CHANNEL 9 = PROPORTIONAL COLOUR (Dmx range value 128 - 191)

000 - 010

011-255

Parameter: COLOUR

IF CHANNEL 9 = FULL COLOUR (Dmx range value 64 -127)

Move

range

(degrees)

Mode Option Function

Colour 1

Colour 1-2

Colour 2-3

Colour 3-4

Colour 4-5

Colour 5-6

Colour 6-7

Colour 7-8

Colour 8-1

No Colour

Proportional colour

000- 009

010-127

128-137

138-255

DMX CHANNEL 9

DMX CHANNEL 9

DMX CHANNEL 9

DMX range

DMX range

Value

Value

000 - 063

064 - 127

128 - 191

192 - 255

DMX CHANNEL 10

DMX range

Value

000 - 255

Mid point

Mid point

DMX value

DMX value

Mid point

DMX value

IF CHANNEL 9 = RAINBOW (Dmx range value 192 - 255)

Parameter:

Parameter:

Parameter:

Parameter: CYAN

COLOUR MODE

Move

Move

range

range

(degrees)

(degrees)

Move

range

(degrees)

No Colour

Right Rot.Speed from Max to Min

Stop

Left Rot.speed from Min to Max

Mode Option Function

Mode Option Function

Full colour

Full colour

Half colour

Half colour

Proportional colour

Rainbow

Rainbow

Mode Option Function

Proportionall colour

DMX CHANNEL 11

DMX range

Value

000 - 255

Mid point

DMX value

Parameter: MAGENTA

Move

range

(degrees)

Mode Option Function

Proportional colour

Page 25

DMX CHANNEL 11

DMX CHANNEL 11

DMX CHANNEL 12

DMX range

DMX range

DMX range

Value

Value

Value

000 - 255

DMX CHANNEL 13

DMX range

Value

000 - 007

008 - 255

DMX CHANNEL 14

DMX range

Value

000 - 009

010 - 014

015 - 019

020 - 024

025 - 029

030 - 034

035 - 039

040 - 044

045 - 049

050 - 054

055 - 059

Mid point

Mid point

Mid point

DMX value

DMX value

DMX value

Mid point

DMX value

Mid point

DMX value

Parameter: YELLOW

Parameter:

Move

Move

Move

range

range

range

(degrees)

(degrees)

(degrees)

Parameter: SPEED CMY

Move

range

(degrees)

Parameter: MACRO CMY

Move

range

(degrees)

060 - 064

065 - 069

070 - 074

075 - 079

080 - 084

085 - 089

090 - 094

095 - 099

100-104

105-109

110-114

115-121

122-128

129-135

136-142

143-149

150-156

157-163

164-170

171-177

25

Mode Option Function

Mode Option Function

Mode Function

XR2000 BEAM

ARC 1200

Proportional colour

Mode Option Function

No function

Variabile speed from max to min

Mode Option Function

No function

Macro 1

Macro 2

Macro 3

Macro 4

Macro 5

Macro6

Macro 7

Macro 8

Macro 9

Macro 10

Macro11

Macro 12

Macro 13

Macro 14

Macro 15

Macro 16

Macro17

Macro 18

Macro 19

Macro 20

Macro 21

Macro rainbow wait = 0

Macro rainbow wait = 2

Macro rainbow wait = 3

Macro rainbow wait = 4

Macro rainbow wait = 5

Macro rainbow wait = 6

Macro rainbow wait = 7

Macro rainbow wait = 8

Macro rainbow wait = 9

Page 26

DMX CHANNEL 14

DMX range

Value

178-185

186-192

193-199

200-206

207-213

114-220

221-227

228-234

235-241

242-248

249-255

DMX CHANNEL

Mid point

DMX value

15

Parameter: MACRO CMY

Move

range

(degrees)

Parameter: GOBO

Mode Option Function

26

Macro rainbow wait = 10

Full colours rainbow = 0

Full colours rainbow = 2

Full colours rainbow = 3

Full colours rainbow = 4

Full colours rainbow = 5

Full colours rainbow = 6

Full colours rainbow = 7

Full colours rainbow = 8

Full colours rainbow = 9

Full colours rainbow = 10

XR2000 BEAM

ARC 1200

DMX range

Value

0-25

26-51

52-77

78-103

104-129

130-155

156-181

182-207

208-213

214-219

220-225

226-231

232-237

238-243

244-249

250-255

Mid point

DMX value

Move

range

(degrees)

Mode Option Function

Open

Gobo 1

Gobo 2

Gobo 3

Gobo 4

Gobo 5

Gobo 6

Gobo 7

Rotation speed 1 min.

Rotation speed 2

Rotation speed 3

Rotation speed 4

Rotation speed 5

Rotation speed 6

Rotation speed 7

Rotation speed 8 Max

DMX CHANNEL

DMX range

Value

0-127

128-255

16

Mid point

DMX value

Parameter: GOBO MODE

Move

range

(degrees)

Mode Option Function

Gobo Rotation Mode

Gobo Index Mode

Page 27

DMX CHANNEL 17

DMX range

Value

Mid point

DMX value

27

Parameter: GOBO ROTATION/GOBO INDEX COARSE

Move

range

(degrees)

Mode Option Function

XR2000 BEAM

ARC 1200

IF CHANNEL 16 = Gobo Rotation Mode (Dmx range value 0 - 127)

0-9

10-127

128-137

138-255

0-255

DMX CHANNEL

DMX range

Value

0-255

DMX CHANNEL

DMX range

Value

0-9

10-22

23-35

36-48

49-61

62-74

75-87

88-100

101-113

114-126

127-138

139-151

152-164

165-177

178-190

191-203

204-216

217-229

230-242

243-255

IF CHANNEL 16 = Gobo Index Mode (Dmx range value 128 - 255)

18

Mid point

DMX value

19

Mid point

DMX value

Parameter: GOBO INDEX FINE

Move

range

(degrees)

Parameter: GOBO 1 SHAKE

Move

range

(degrees)

Mode Option Function

Mode Option Function

Stop

SX Rot. Prop. Speed Max to Min

Stop

DX Rot. Prop. Speed Min to Max

Gobo index Coarse

Gobo Index Fine

Stop

Gobo Shake R-L Speed 1 Min.

Gobo Shake R-L Speed 2

Gobo Shake R-L Speed 3

Gobo Shake R-L Speed 4

Gobo Shake R-L Speed 5

Gobo Shake R-L Speed 6

Gobo Shake R-L Speed 7

Gobo Shake R-L Speed 8

Gobo Shake R-L Speed 9 Max

Stop

Gobo Shake L-R Speed 1 Min

Gobo Shake L-R Speed 2

Gobo Shake L-R Speed 3

Gobo Shake L-R Speed 4

Gobo Shake L-R Speed 5

Gobo Shake L-R Speed 6

Gobo Shake L-R Speed 7

Gobo Shake L-R Speed 8

Gobo Shake L-R Speed 9 Max

Page 28

DMX CHANNEL 20

DMX range

Value

000-009

010-255

Mid point

DMX value

Parameter: FROST

Move

range

(degrees)

28

Mode Option Function

XR2000 BEAM

ARC 1200

No function

Linear frost position

DMX CHANNEL 21

DMX range

Value

0-9

10-60

61-129

130-179

180-200

201-239

240-255

Mid point

DMX value

Parameter: RESET / LAMP

Move

range

Mode

(degrees)

Option

Function

No Effect

Lamp OFF (activ.after 3 seconds)

No Effect

Lamp ON (activ.after 3 seconds)

No Effect

Internal motor reset

Total Reset

Page 29

23 DMX PROTOCOL

16 CHANNELS MODE

1 PAN msb 540°

2 PAN lsb

3 TILT msb 270°

4 TILT lsb

5 SPEED MOVEMENT

6 DIMMER

7 SHUTTER

8 COLOUR

9 CYAN

10 MAGENTA

11 YELLOW

12 GOBO

13 GOBO ROTATION/INDEX

14 GOBO SHAKE

15 FROST

16 RESET - LAMP

29

XR2000 BEAM

ARC 1200

DMX CHANNEL

DMX CHANNEL

DMX CHANNEL

DMX CHANNEL

DMX CHANNEL

DMX range

Value

0-10

11-25

26-127

128-247

248-255

1

2

3

4

5

Mid point

DMX value

Parameter: PAN msb

Parameter: PAN lsb

Parameter: TILT msb

Parameter: TILT lsb

Parameter: SPEED MOVEMENT

Move

range

(degrees)

Mode Option Function

Standard

Fast movement

Vector mode from fast to slow

Variable time reaction to

DMX signal ( fast to slow)

Silent Mode

Page 30

DMX CHANNEL 6

DMX range

Value

Mid point

DMX value

0-7

8-255

DMX CHANNEL

DMX range

Value

0-19

20-39

40-59

60-79

80-89

90-99

100-109

Mid point

DMX value

110-119

120-129

130-139

140-149

150-159

160-169

170-179

180-189

190-199

200-209

210-219

220-227

228-233

234-255

Parameter: DIMMER

Move

range

(degrees)

7

Parameter: SHUTTER

Move

range

(degrees)

30

XR2000 BEAM

ARC 1200

Mode Option Function

Black-out

Proportional dimmer

Mode Option Function

Black - out

Open

Black-out

Random Strobe

Strobe speed 1 min. (0,85 Hz)

Strobe speed 2 (1,4 Hz)

Strobe speed 3 (2 HZ)

Strobe speed 4 (3,75 Hz)

Strobe speed 5 (5 Hz)

Strobe speed 6 max. (6,75 Hz)

Pulse open speed 1 min.

Pulse open speed 2

Pulse open speed 3

Pulse open speed 4 max.

Pulse closed speed 1 min.

Pulse closed speed 2

Pulse closed speed 3

Pulse closed speed 4 max.

Colour and Gobo in black-out

Pan and Tilt in black

Open

-out

DMX CHANNEL 8

DMX range

Value

000-011

012-023

024-035

036-047

048-059

060-071

072-083

084-095

Mid point

DMX value

Parameter: COLOUR

Move

range

(degrees)

Mode Option Function

Colour 1

Colour 1-2

Colour 2

Colour 2-3

Colour 3

Colour 3-4

Colour 4

Colour 4-5

Page 31

31

XR2000 BEAM

ARC 1200

DMX CHANNEL 8

DMX range

Value

096 - 107

108 - 119

120 - 131

132 - 143

144 - 155

156 - 167

168 - 179

180 - 197

198 - 200

201 - 203

204 - 206

207 - 209

210 - 212

213 - 215

216 - 218

219 - 221

222 - 224

225 - 228

229 - 231

232 - 234

235 - 237

238 - 240

241 - 243

244 - 246

247 - 249

250 - 252

253 - 255

Mid point

DMX value

Parameter: COLOUR

Move

range

(degrees)

Mode Option Function

Colour 5

Colour 5-6

Colour 6

Colour 6-7

Colour 7

Colour 7-8

Colour 8

Colour 8-1

Right rotation speed 9 Max

Right rotation speed 8

Right rotation speed 7

Right rotation speed 6

Right rotation speed 5

Right rotation speed 4

Right rotation speed 3

Right rotation speed 2

Right rotation speed 1Min

Stop

Left rotation speed 1 Min

Left rotation speed 2

Left rotation speed 3

Left rotation speed 4

Left rotation speed 5

Left rotation speed 6

Left rotation speed 7

Left rotation speed 8

Left rotation speed 9 Max

DMX CHANNEL 9

DMX range

Value

0-255

DMX CHANNEL 10

DMX range

Value

0-255

Mid point

DMX value

Mid point

DMX value

Parameter: CYAN

Move

range

(degrees)

Parameter: MAGENTA

Move

range

(degrees)

Mode Option Function

Mode Option Function

Proportional colour

Proportional colour

Page 32

DMX CHANNEL 11

DMX CHANNEL 11

DMX CHANNEL 11

DMX range

DMX range

DMX range

Value

Value

Value

000 - 255

DMX CHANNEL

DMX range

Value

-

025

000

026

-

051

052-077

078-103

104-129

130-155

156-181

Mid point

Mid point

Mid point

DMX value

DMX value

DMX value

12

Mid point

DMX value

182-207

208-213

214-219

220-225

226-231

232-237

238-243

244-249

250-255

Parameter: YELLOW

Move

Move

Move

range

range

range

(degrees)

(degrees)

(degrees)

Parameter: GOBO

Move

range

(degrees)

32

Mode Option Function

Mode Option Function

Mode Option Function

XR2000 BEAM

ARC 1200

Proportional colour

Mode Option Function

Open

Gobo 1

Gobo 2

Gobo 3

Gobo 4

Gobo 5

Gobo 6

Gobo 7

Rotation speed 1 min.

Rotation speed 2

Rotation speed 3

Rotation speed 4

Rotation speed 5

Rotation speed 6

Rotation speed 7

Rotation speed 8 Max

DMX CHANNEL

DMX range

Value

000 - 127

128 - 180

118811 -- 220022

203 - 255

DMX CHANNEL

DMX range

Value

0-9

10-22

23-35

36-48

49-61

62-74

13

Mid point

DMX value

14

Mid point

DMX value

Parameter: GOBO ROTATION/INDEX

Move

range

(degrees)

Parameter: GOBO SHAKE

Move

range

(degrees)

Mode Option Function

Proportional index 0° - 360°

Left rotation

Stop

Right rotation

Mode Option Function

Stop

Gobo Shake R-L Speed 1 Min.

Gobo Shake R-L Speed 2

Gobo Shake R-L Speed 3

Gobo Shake R-L Speed 4

Gobo Shake R-L Speed 5

Page 33

DMX CHANNEL

14

DMX range Mid point

Value DMX value

075-087

088-100

101-113

114-126

127-138

139-151

152-164

165-177

178-190

191-203

204-216

217-229

230-242

243-255

Parameter: GOBO SHAKE

Move

range Mode Option Function

(degrees)

33

Gobo Shake R-L Speed 6

Gobo Shake R-L Speed 7

Gobo Shake R-L Speed 8

Gobo Shake R-L Speed 9 Max

Stop

Gobo Shake L-R Speed 1 Min

Gobo Shake L-R Speed 2

Gobo Shake L-R Speed 3

Gobo Shake L-R Speed 4

Gobo Shake L-R Speed 5

Gobo Shake L-R Speed 6

Gobo Shake L-R Speed 7

Gobo Shake L-R Speed 8

Gobo Shake L-R Speed 9 Max

XR2000 BEAM

ARC 1200

DMX CHANNEL 15

DMX range Mid point

Value DMX value

000-009

010-255

DMX CHANNEL 16

DMX range Mid point

Value DMX value

0-9

10-60

61-129

130-179

180-200

201-239

240-255

Parameter: FROST

Move

range

(degrees)

Parameter: RESET / LAMP

Mode Option Function

Move

range

Mode

(degrees)

Option

No function

Linear frost position

Function

No Effect

Lamp OFF (activ.after 3 seconds)

No Effect

Lamp ON (activ.after 3 seconds)

No Effect

Internal motor reset

Total Reset

Page 34

23- 8 MOTORS CONTROL CARD

8 MOTORS CONTROL CARD

J7 Magnetic Sensors

Connector

Line 1 Brown:

Line 2 Orange:

GND

ORANGE

BROWN

VCC

34

XR2000 BEAM

ARC 1200

Gobo

(BLACK)

RotGobo

(DARK GREEN)

J1 Internal DATA

Communication

Connector

From J8 Pan & Tilt

card

30 VDC

Strobe

(YELLOW)

Frost

(PINK)

+

Color

(GREY)

-

Magenta

(LIGHT BLUE)

Cyan

(GOLD)

Fans

Yellow

(BLUE)

Fans

Page 35

24-PAN & TILT CARD

ENCODER PAN

(RED)

ENCODER TILT

(ORANGE)

PAN

(WHITE)

35

TILT

(BROWN)

GND

(BLACK)

30 VDC

(RED)

XR2000 BEAM

ARC 1200

FAN

(WHITE)

TO J2

LAMP

ON-OFF

CARD

DATA 2

DATA 1

(VIOLET)

(LIGHT GREEN)

(BROWN)

MOTOR TILT

TO J1

DISPLAY CARD

(WHITE)

25-CABLES RESEND CARD

(ORANGE)

ENCODER TILT

27-LAMP ON-OFF CONTROL CARD

TO J1

8 MOTORS CARD

(GREEN)

26-DISPLAY CARD

J4

DMX INPUT

(WHITE)

FROM J16

PAN&TILT

CARD

J2

J3

TO J9

ELECTRONIC

BALLAST

Page 36

28- ROTATING GOBO WHEEL

3

2

4

36

5

6

XR2000 BEAM

ARC 1200

1

7

GOBO 1 METAL

0516G033.01

GOBO 4 METAL GOBO 5 METAL GOBO 6 METAL

GOBO 2 METAL

0516G033.02

GOBO 3 METAL

0516G033.03

GOBO 7 METAL

0516G033.04

0516G033.05 0516G033.06

0516G033.15.M.58

Page 37

29- COLOUR WHEEL

2

37

XR2000 BEAM

ARC 1200

1

1

7

3

4

5

6

COL1

0507K004.D10

CONV.FILTER CTO

TC3256

0507C046.D10

WOOD SW 460

COL6COL5

COL3COL2

0507C051.D10

ORANGE LW590

COL7

COL4

0507C042.D10

GREEN WB5055

0507C047.D10

RED LW 640

0507C041.D10

DARK BLUE SW490

0507C053.D10

AMBER LW 550

Page 38

38

XR2000 BEAM

ARC 1200

30- MORE GOBOS PROVIDED IN THE PACK AS STANDARD ACCESSORIES

GOBO 8 METAL

0516G033.08 0516G033.09 0516G033.10

GOBO 11 METAL

GOBO 9 METAL GOBO 10 METAL

GOBO 12 METAL

0516G033.11 0516G033.12

Page 39

NOTES

39

XR2000 BEAM

ARC 1200

Page 40

The information contained in this publication has been carefully prepared and checked.

However, no responsibility will be taken for any errors. All rights are reserved and this document

cannot be copied, photocopied or reproduced, in part or completely, without prior written consent

from D.T.S.. D.T.S. reserves the right to make any aesthetic, functional or design modifications to

any of its products without prior notice. D.T.S. assumes no responsibility for the use or

application of the products or circuits described herein.

MADE IN ITALY

*0517I107*

0517I107

D.T.S. Illuminazione s.r.l - Via Fagnano Selve 10-12-14 47843 - Misano Adriatico (RN) Italy

Tel. +39 0541 611131 Fax +39 0541 611111 info@dts-lighting.it www.dts-lighting.it

Loading...

Loading...