Page 1

SLICE User’s Manual

May, Aug, Dec 2010

Version 1.0b

Page 2

SLICE User’s Manual support@dtsweb.com

Table of Contents

Contacting Technical Support ................................................................................... 4

1.

1.1. DTS Technical Support ...................................................................................... 4

1.2. DTS Web Site .................................................................................................. 4

1.3. DTS Offices ..................................................................................................... 4

2. SLICE Overview...................................................................................................... 6

2.1. SLICE MICRO and SLICE NANO........................................................................... 6

2.2. SLICE Modular Concept ..................................................................................... 6

2.3. SLICE Basic Hardware Components..................................................................... 8

2.3.1. Base SLICE............................................................................................... 8

2.3.2. Bridge SLICE ............................................................................................ 9

2.3.3. IEPE SLICE ............................................................................................... 9

2.3.4. Digital SLICE .......................................................................................... 10

2.3.5. ACCEL SLICE .......................................................................................... 10

2.3.6. ARS SLICE.............................................................................................. 10

2.3.7. Battery SLICE ......................................................................................... 11

2.3.8. Stack Extender ....................................................................................... 11

2.3.9. End-of-Chain (EOC) Terminal .................................................................... 11

2.3.10. SLICE System Interface............................................................................ 12

2.3.11. SLICE Distributor..................................................................................... 13

2.3.12. SLICE USB Interface ................................................................................ 13

2.3.13. SLICE Ethernet Interface .......................................................................... 14

2.3.14. SLICE MICRO and NANO Connectors .......................................................... 15

2.4. Batteries ....................................................................................................... 15

2.4.1. 9.6 V Rechargeable NiMH Batteries ............................................................ 15

2.4.2. 11.1 V Rechargeable Lithium-Polymer Batteries ........................................... 16

2.5. SLICE Software .............................................................................................. 16

3. Mounting and Connecting SLICE Hardware ............................................................... 16

3.1. General Connection Guidelines ......................................................................... 16

3.2. Guidelines for High Shock and Vibration Testing.................................................. 17

3.3. SLICE Connectors and Cables........................................................................... 17

3.3.1. SLICE Connectors.................................................................................... 17

3.3.2. SLICE Cables .......................................................................................... 18

3.4. Power Requirements ....................................................................................... 19

3.5. Using the End-of-Chain (EOC) Terminal ............................................................. 20

3.6. Using the SLICE System Interface..................................................................... 21

3.7. Using the SLICE USB Interface ......................................................................... 22

3.8. Using the SLICE Ethernet Interface ................................................................... 23

3.9. Using the SLICE Distributor.............................................................................. 24

4. Sensor ID and Supported Sensor Types................................................................... 25

4.1. Sensor ID...................................................................................................... 25

4.2. Supported Sensor Types.................................................................................. 26

5. Software ............................................................................................................. 26

5.1. Basic Requirements ........................................................................................ 26

5.2. Data Collection Concepts ................................................................................. 27

5.2.1. Standalone Operation .............................................................................. 27

5.2.2. Data Collection Modes .............................................................................. 27

Version 1.0 - May 2010 2 ©DTS, Inc. - All Rights Reserved

Page 3

SLICE User’s Manual support@dtsweb.com

5.2.2.1. Circular Buffer Mode........................................................................... 27

5.2.2.2. Recorder Mode .................................................................................. 27

5.3. SLICEWare .................................................................................................... 27

5.3.1. Software Installation................................................................................ 28

5.3.2. Menu Descriptions ................................................................................... 29

6. Powering Up SLICE ............................................................................................... 43

6.1. Status (STS) LED ........................................................................................... 43

6.2. Power (PWR) LED ........................................................................................... 44

Appendix A: SLICE Buyer’s Guide ............................................................................... 45

Appendix B: Base and Bridge SLICE Specifications ........................................................ 54

Appendix C: End-of-Chain (EOC) Terminal ................................................................... 60

Appendix D: SLICE System Interface .......................................................................... 61

Appendix E: SLICE Distributor.................................................................................... 64

Appendix F: SLICE USB Interface ............................................................................... 68

Appendix G: SLICE Ethernet Interface......................................................................... 70

Appendix H: SLICE Grounding Recommendations.......................................................... 72

Appendix I: Bridge SLICE Sensor Connection Guide....................................................... 78

Appendix J: Software Reference ................................................................................. 84

Version 1.0 - May 2010 3 ©DTS, Inc. - All Rights Reserved

Page 4

SLICE User’s Manual support@dtsweb.com

1. Contacting Technical Support

DTS is a world leader in ultra-small, low power, high shock rated, high sample rate data

acquisition and sensing systems.

DTS is based in Seal Beach, California, USA, just south of Los Angeles. DTS has offices in 6

times zones for fast, expert technical support.

1.1. DTS Technical Support

For the fastest technical support, please contact your local DTS technical support

engineer or e-mail support@dtsweb.com

1.2. DTS Web Site

For the most up to date specifications, user’s manuals and other information, please

go to www.dtsweb.com

1.3. DTS Offices

.

.

United States

Eastern Standard Time (EST) (GMT-5)

Please call DTS North American Technical Center

+1 248 427-0045

7:00 AM - 5:00 PM, Monday through Friday

After hours, please e-mail support@dtsweb.com

Pacific Standard Time (PST) (GMT-8)

Please call DTS Corporate Headquarters

+1 562 493-0158

7:00 AM - 5:00 PM, Monday through Friday

After hours, please e-mail support@dtsweb.com

Japan

(GMT+9)

Please contact DTS Japan Technical Center

Rihito Shoji

9:00 AM - 5:00 PM (Japan), Monday through Friday

After hours, please e-mail support.japan@dtsweb.com

Version 1.0 - May 2010 4 ©DTS, Inc. - All Rights Reserved

Page 5

SLICE User’s Manual support@dtsweb.com

Europe

(GMT+1)

Please contact Dave Martin, European Regional Manager

+49 17 11 286 033 (German and English language support)

8:00 AM - 5:00 PM (Germany), Monday through Friday

After hours, please e-mail support@dtsweb.com

Asia/Pacific

(GMT+11)

Please call Steve Mitchell, Asia Pacific Regional Manager

+61 438 507 449

8:00 AM - 5:00 PM (Australia), Monday through Friday

After hours, please e-mail support@dtsweb.com

China

(GMT+8)

Please call Xi Tianlu, Asia Pacific Regional Manager

+86 21-6386-7559

8:00 AM - 5:00 PM (China), Monday through Friday

After hours, please e-mail support@dtsweb.com

India

(GMT+5.30)

Please call Dave Martin, Regional Manager

+49 17 11 286 033

8:00 AM - 5:00 PM (Europe), Monday through Friday

After hours, please e-mail support@dtsweb.com

Version 1.0 - May 2010 5 ©DTS, Inc. - All Rights Reserved

Page 6

SLICE User’s Manual support@dtsweb.com

2. SLICE Overview

For a quick overview of SLICE, please see the SLICE Buyer’s Guide in Appendix A.

SLICE is an ultra small, low power, high shock rated data acquisition system. SLICE is a

standalone system with microprocessor, memory, sensor excitation and signal conditioning

with options for built-in battery and internal sensors. Systems from 3 to hundreds of

channels can be built-up in 3 channel increments.

2.1. SLICE MICRO and SLICE NANO

SLICE comes in two sizes:

! SLICE MICRO (42 x 42 mm)

! SLICE NANO (26 x 31 mm)

They have the exact same function and circuit boards inside. SLICE MICRO has builtin connectors; SLICE NANO has wires with connectors.

31 mm

26 mm

SLICE NANO SLICE MICRO

42 mm

42 mm

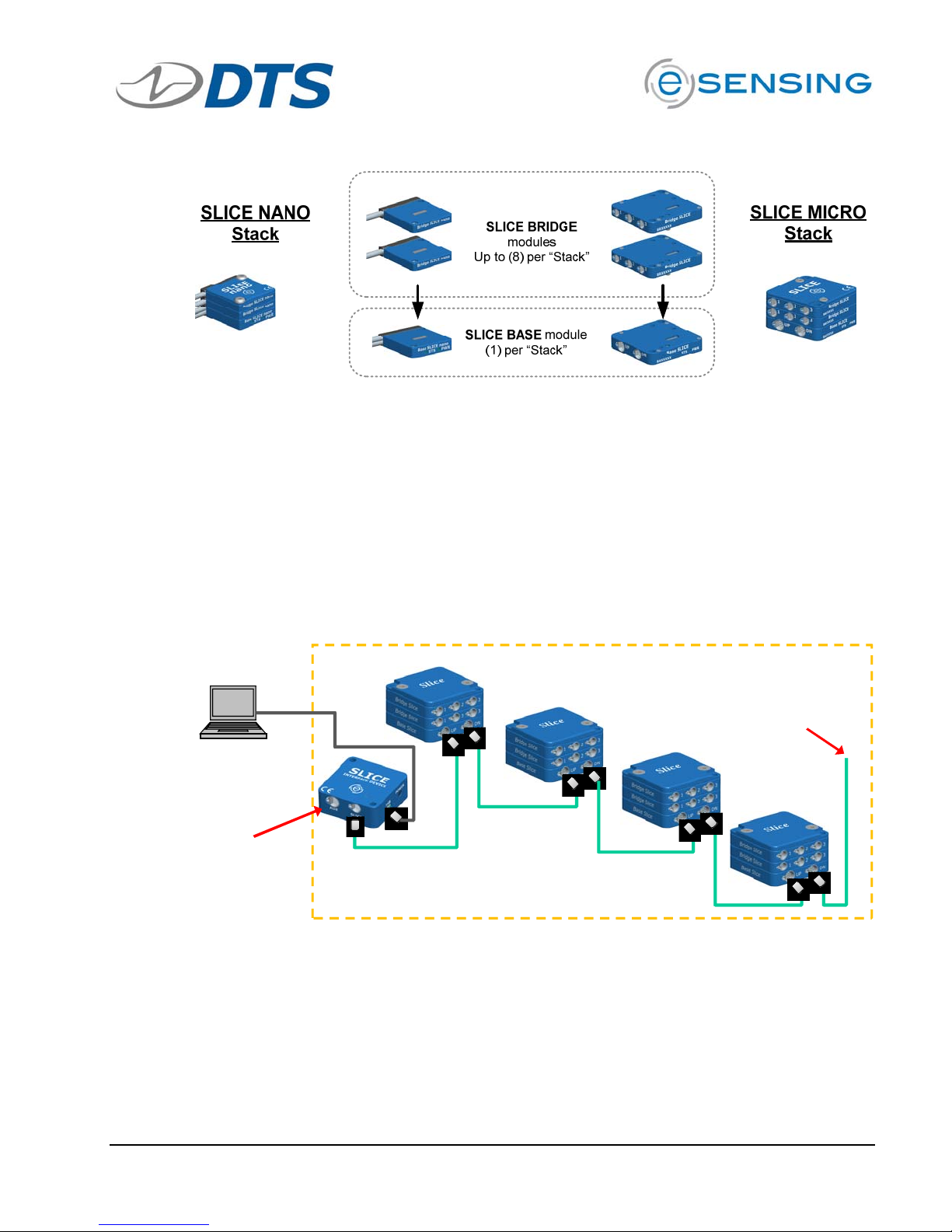

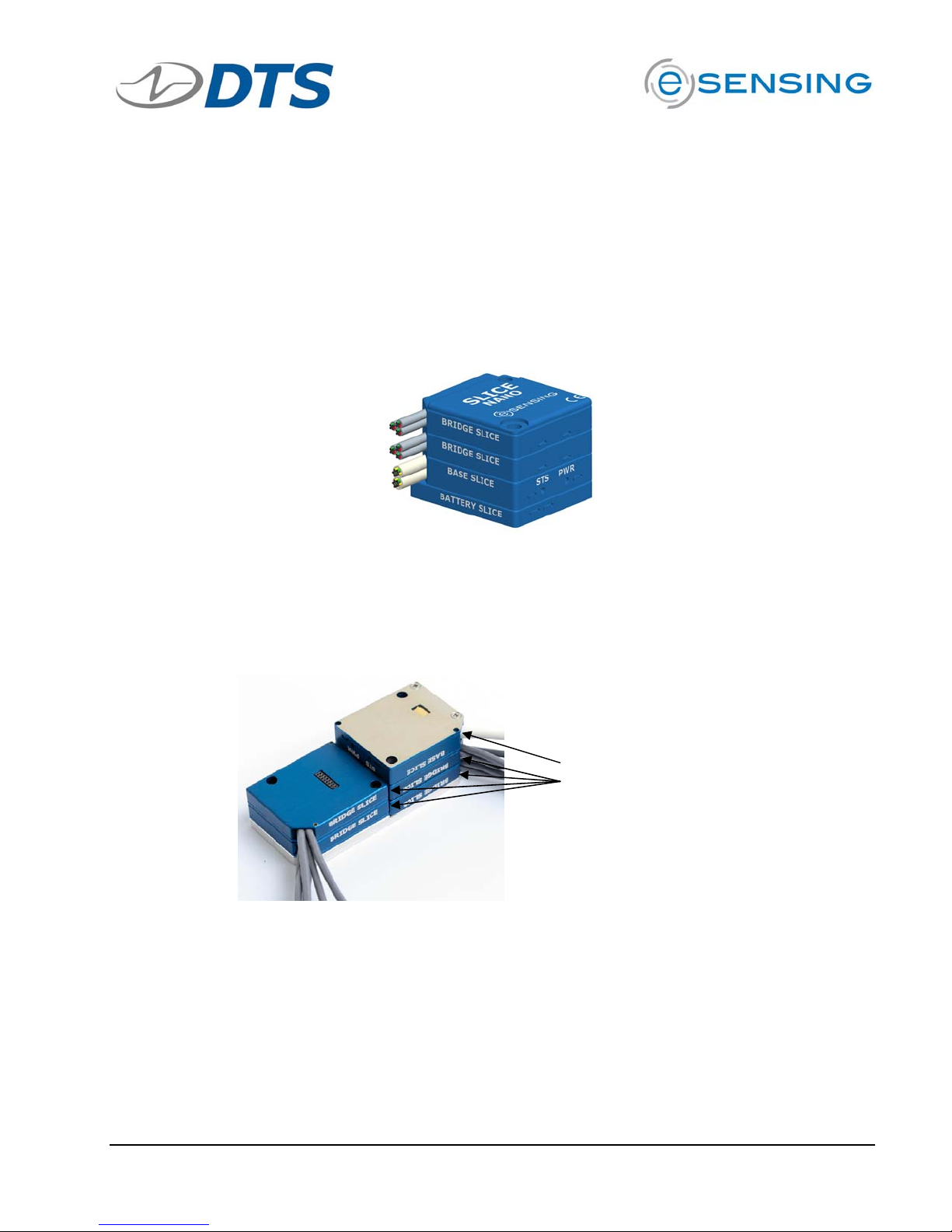

2.2. SLICE Modular Concept

Modular system – Plug multiple SLICEs onto Base SLICE to make a Stack

! Each SLICE “Stack” can accommodate 8 Sensor Input SLICES. Each Bridge

SLICE has 3 analog input channels. You may want multiple “Stacks” if more

channels are needed or placement in different locations makes sense for your

application.

! Each SLICE “Stack” consists of 1 Base SLICE and up to 8 additional Sensor

Input SLICEs.

Version 1.0 - May 2010 6 ©DTS, Inc. - All Rights Reserved

Page 7

SLICE User’s Manual support@dtsweb.com

Example SLICE set-up with multiple stacks:

! SLICE stacks are mounted to the device under test and chained together.

! The End-of-Chain Terminal can be connected to a trigger, battery, or other

devices.

! The beginning of the chain is connected to the SLICE Interface Device, SLICE

Ethernet Interface, SLICE USB Interface or directly to the PC. PC can be

disconnected after arming for standalone operation.

! Up to 4 SLICE stacks can be in any one chain.

! SLICE Distributor (not shown) allows for up to 4 SLICE chains for hundreds of

channel in one set-up.

Many options:

• Battery

• Trigger input

• Monitor statu s

• Up to 4 Stacks

PC provides

USB control

SLICE

Interface

Device

Device Under Test

Example: Crash dummy, aircraft wing, vehicle chassis,

industrial machinery, bridge structure, etc.

Version 1.0 - May 2010 7 ©DTS, Inc. - All Rights Reserved

Page 8

SLICE User’s Manual support@dtsweb.com

2.3. SLICE Basic Hardware Components

Below are the basic components of a SLICE system. You will have some subset of

these depending on your application or what was ordered.

The table below provides an overview of the types of SLICE modules available. Some

modules are only available in the MICRO or NANO version.

SLICE Module Description MICRO NANO Available

Base SLICE One needed for each SLICE

Stack

Bridge SLICE 3 channels of piezo-resistive

and voltage sensor inputs.

IEPE SLICE 3 channels of piezo-electric

sensor inputs

Digital SLICE 8 channels of isolated digital

inputs

Accel SLICE Bridge SLICE with integrated

3-axis accelerometer

ARS SLICE Bridge SLICE with integrated

3-axis Angular Rate Sensor

Stack Battery 2 cell LiPo battery connected

to bottom of Base SLICE

Yes Yes Now

Yes Yes Now

th

Yes No 4

Yes Yes 4

qtr 2010

th

qtr 2010

Yes No Now

Yes No Now

No Yes Now

2.3.1. Base SLICE

See Appendix B for detailed specifications.

You must have at least one Base SLICE for any SLICE system. The Base SLICE

is at the bottom of the SLICE stack and has these components:

! Microprocessor

! 6 GB flash data memory (standard)

! USB hub

! Power conditioning

! Control signals

A Base SLICE MICRO is shown below.

Connector to

Bridge SLICE or

other input

SLICE Bus

SLICEs

Up towards PC

SLICE Bus

Down to next

Base SLICE

Version 1.0 - May 2010 8 ©DTS, Inc. - All Rights Reserved

Page 9

SLICE User’s Manual support@dtsweb.com

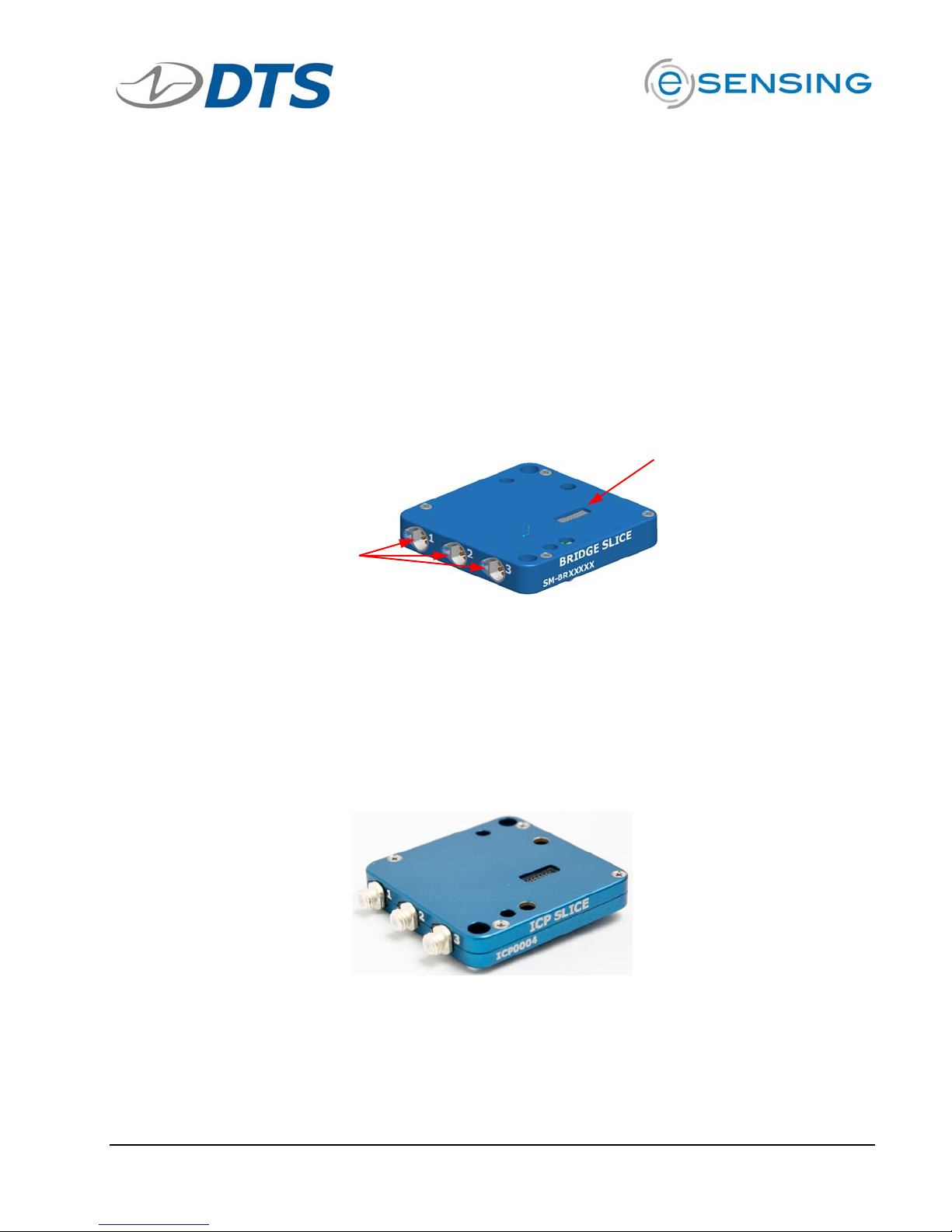

2.3.2. Bridge SLICE

See Appendix B for detailed specifications.

Up to 8 Bridge SLICEs can be stacked on top of the Base SLICE. Each Bridge

SLICE has these components:

! 3 channels of analog input

! Sensor excitation

! 16 bit, 100 kHz ADC, one per channel

! Software adjustable gain, anti-alias filters, offset, and shunt check

! TEDS sensor ID

A Bridge SLICE MICRO is shown below.

Connector to

next Bridge

SLICE

Sensor input

channels

2.3.3. IEPE SLICE

Available in fourth quarter 2010 in SLICE MICRO size only.

Features:

! 3 input channels

! Power: 26 VDC

! Current source: 2-4 mA

Version 1.0 - May 2010 9 ©DTS, Inc. - All Rights Reserved

Page 10

SLICE User’s Manual support@dtsweb.com

2.3.4. Digital SLICE

Available in fourth quarter 2010.

Preliminary specifications:

! Supply will have isolated +5 V

! 8 isolated inputs

! Input modes supported:

o CCNO - Contact closure normally open

o CCNC - Contact closure normally closed

o VIHL - Voltage Input High-Low

o VILH - Voltage Input Low-High; 3 input channels

2.3.5. ACCEL SLICE

The ACCEL SLICE has Bridge SLICE electronics with the addition of a built-in 3axis accelerometer. The following specifications apply:

! MSI Model 3038 accelerometers are used (see www.meas-spec.com

)

! Options from 50 to 2000 g

! DC response

Accel and ARS

SLICEs can be

positioned in any

order in a SLICE

MICRO stack

ARS SLICE

ACCEL SLICE

2.3.6. ARS SLICE

The ARS SLICE has Bridge SLICE electronics with the addition of a built-in 3-axis

angular rate sensor. The following specifications apply:

! DTS ARS are used (see

http://dtsweb.com/products/esensing_angular.php

)

! Options from 300 to 50000 deg/sec

! DC response

Version 1.0 - May 2010 10 ©DTS, Inc. - All Rights Reserved

Page 11

SLICE User’s Manual support@dtsweb.com

2.3.7. Battery SLICE

The Battery SLICE is connected to the bottom of the Base SLICE. It is only

available in the SLICE NANO version. The Battery SLICE is only a back-up

battery in case main power is lost. Specifications:

! 2 cell LiPo design, with charging directly from Base SLICE

! ~10 second run time

! Only 3.5 mm thick

2.3.8. Stack Extender

The Stack Extender is only available for the SLICE NANO package. The Stack

Extender allows the user to create a flatter, longer package.

Stack Extender

! Example: 12 channel system

! 1 Base SLICE

! 4 Bridge SLICEs

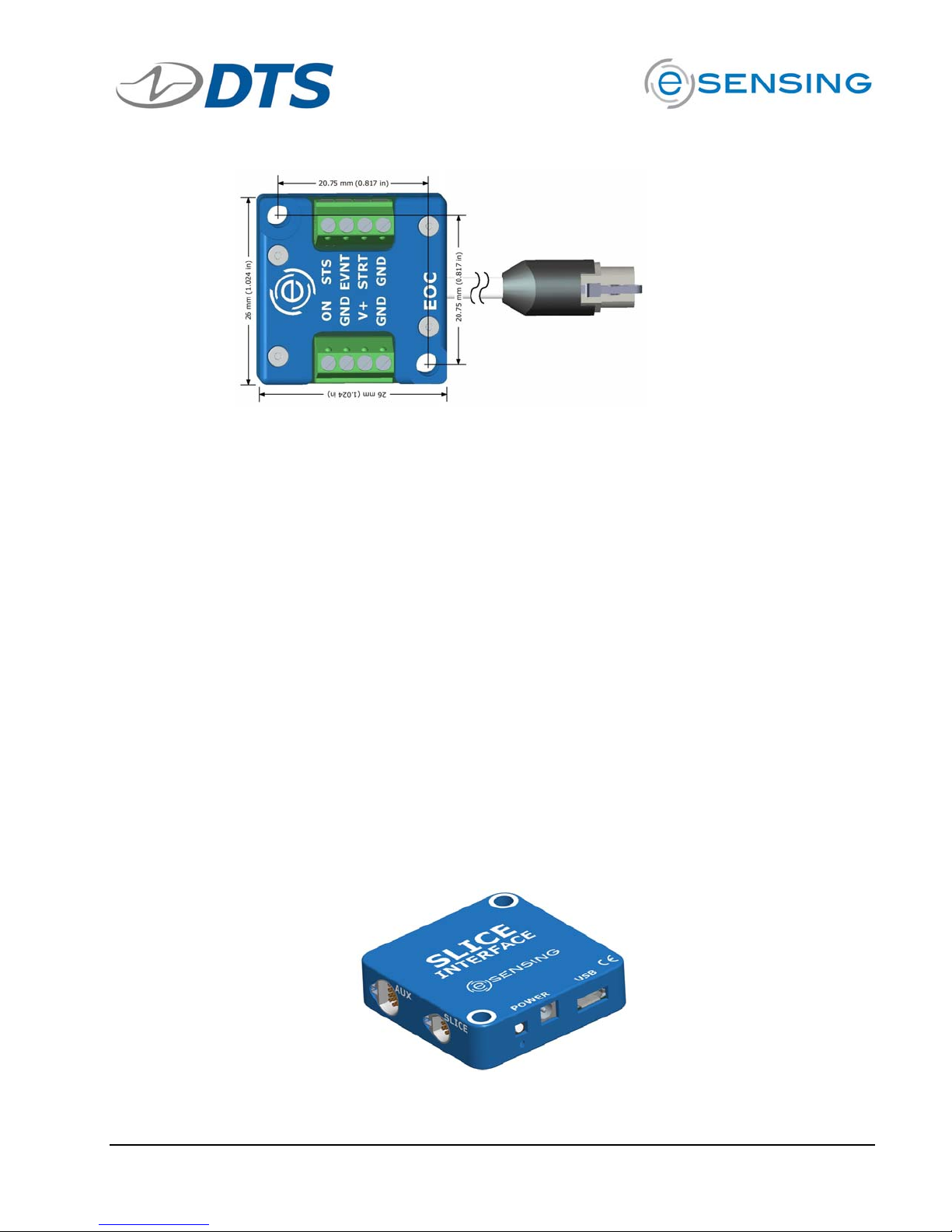

2.3.9. End-of-Chain (EOC) Terminal

See Appendix C for detailed specifications.

The EOC Terminal provides the easiest method to attach a battery, trigger signal

and status lamp to the SLICE system. It is ruggedized for high shock use.

Maximum channels:

1 chain x 2 stacks x 8 Bridge SLICEs x 3 chan/Bridge = 48 channels

Version 1.0 - May 2010 11 ©DTS, Inc. - All Rights Reserved

Page 12

SLICE User’s Manual support@dtsweb.com

To DN port on Base

SLICE MICRO or NANO

Connections:

! 2 SLICE stack chain

! 9 to 15 VDC input power

! ON signal

! Status output, start record input and event input signals

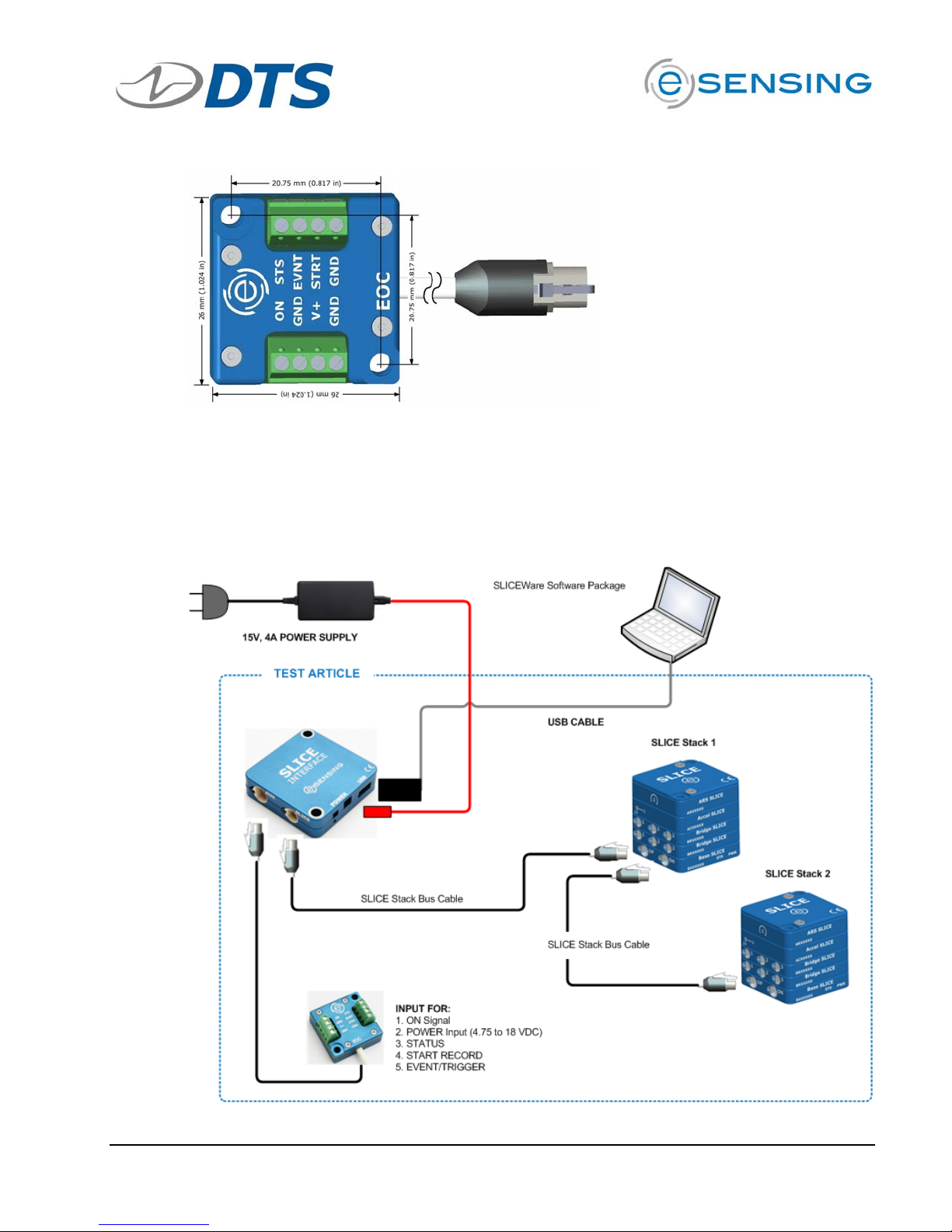

2.3.10. SLICE System Interface

See Appendix D for detailed specifications.

The SLICE System Interface allows the connection of one SLICE chain. It is

ruggedized for high shock use.

Maximum channels:

1 chain x 4 stacks x 8 Bridge SLICEs x 3 chan/Bridge = 96 channels

Connections:

! 1 SLICE stack chain

! USB communications

! 9 to 20 VDC input power

! ON/OFF switch

! AUX input (battery, trigger, etc.)

Version 1.0 - May 2010 12 ©DTS, Inc. - All Rights Reserved

Page 13

SLICE User’s Manual support@dtsweb.com

2.3.11. SLICE Distributor

See Appendix E for detailed specifications.

The SLICE Distributor allows the connection of up to four SLICE chains. It is

ruggedized for high shock use.

Maximum channels:

4 chains x 4 stacks x 8 Bridge SLICEs x 3 chan/Bridge = 384 channels

Connections:

! 4 SLICE stack chains

! Ethernet communications

! 9 to 20 VDC input power

! ON/OFF switch

! AUX input (battery, trigger, etc.)

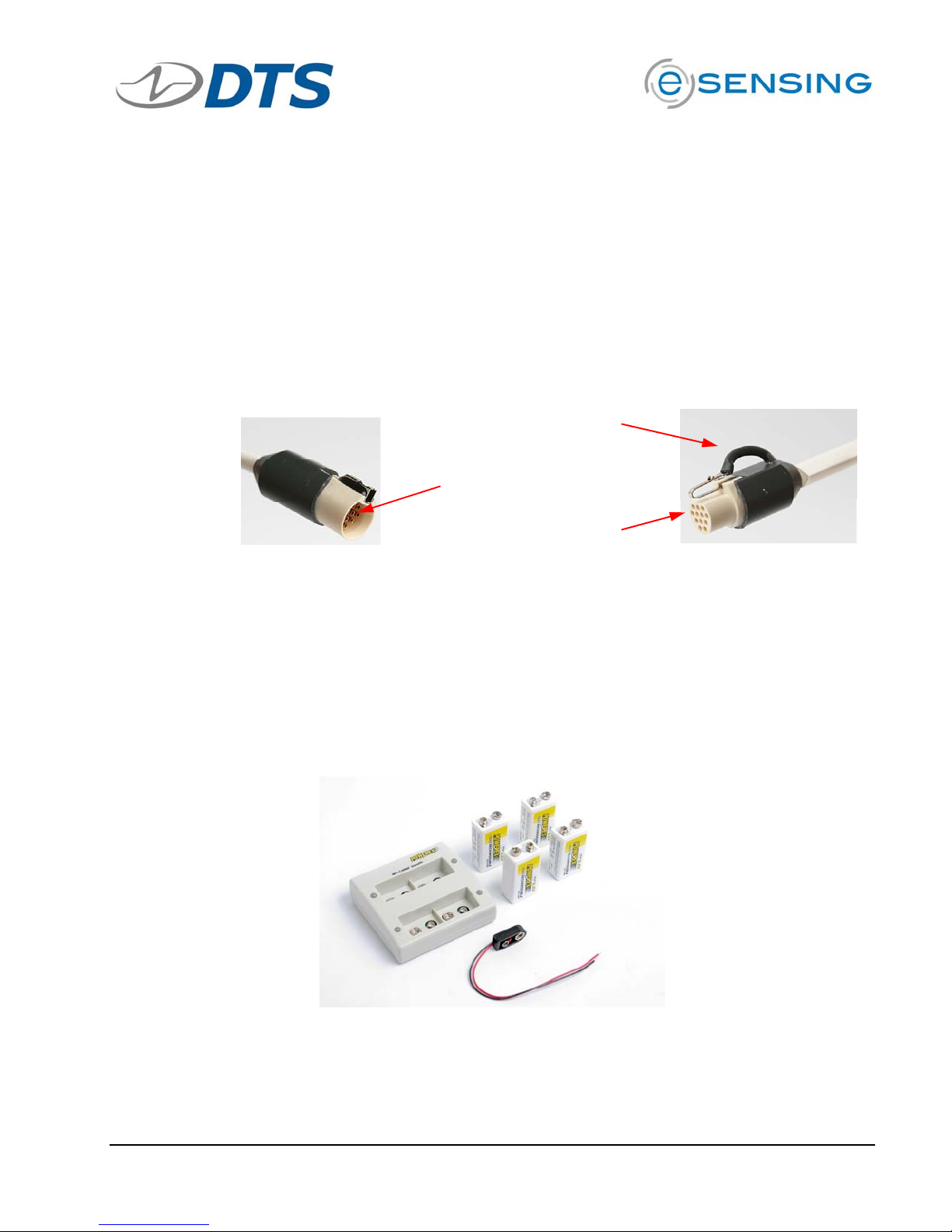

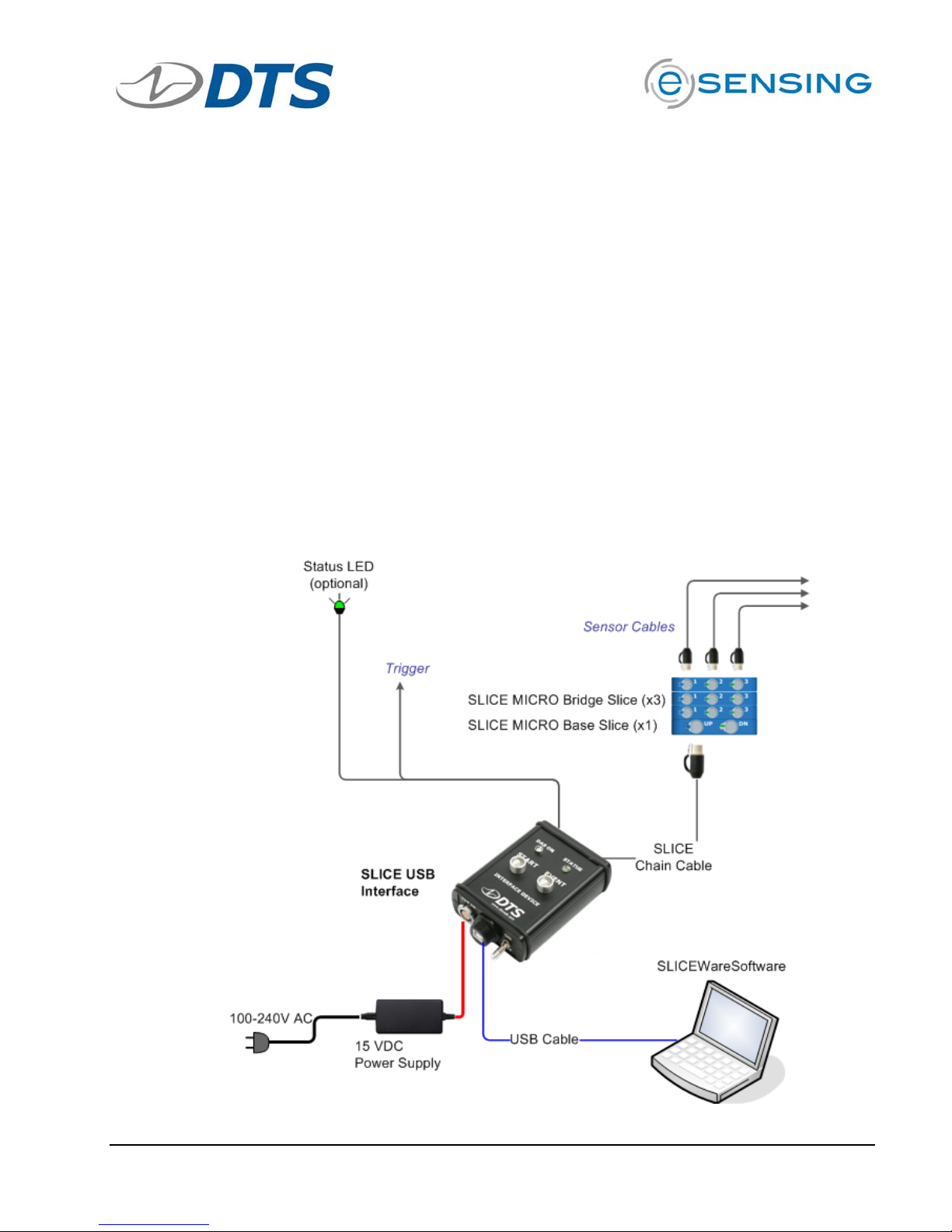

2.3.12. SLICE USB Interface

See Appendix F for detailed specifications.

The SLICE USB Interface allows the connection of one SLICE chain. It is meant

for bench-top use and is not ruggedized.

Maximum channels:

1 chain x 4 stacks x 8 Bridge SLICEs x 3 chan/Bridge = 96 channels

Connections:

! 1 SLICE stack chain

! USB communications

! 9 to 15 VDC input power

! ON/OFF switch

! Manual Start/Event

! AUX input (battery, trigger, etc.)

Version 1.0 - May 2010 13 ©DTS, Inc. - All Rights Reserved

Page 14

SLICE User’s Manual support@dtsweb.com

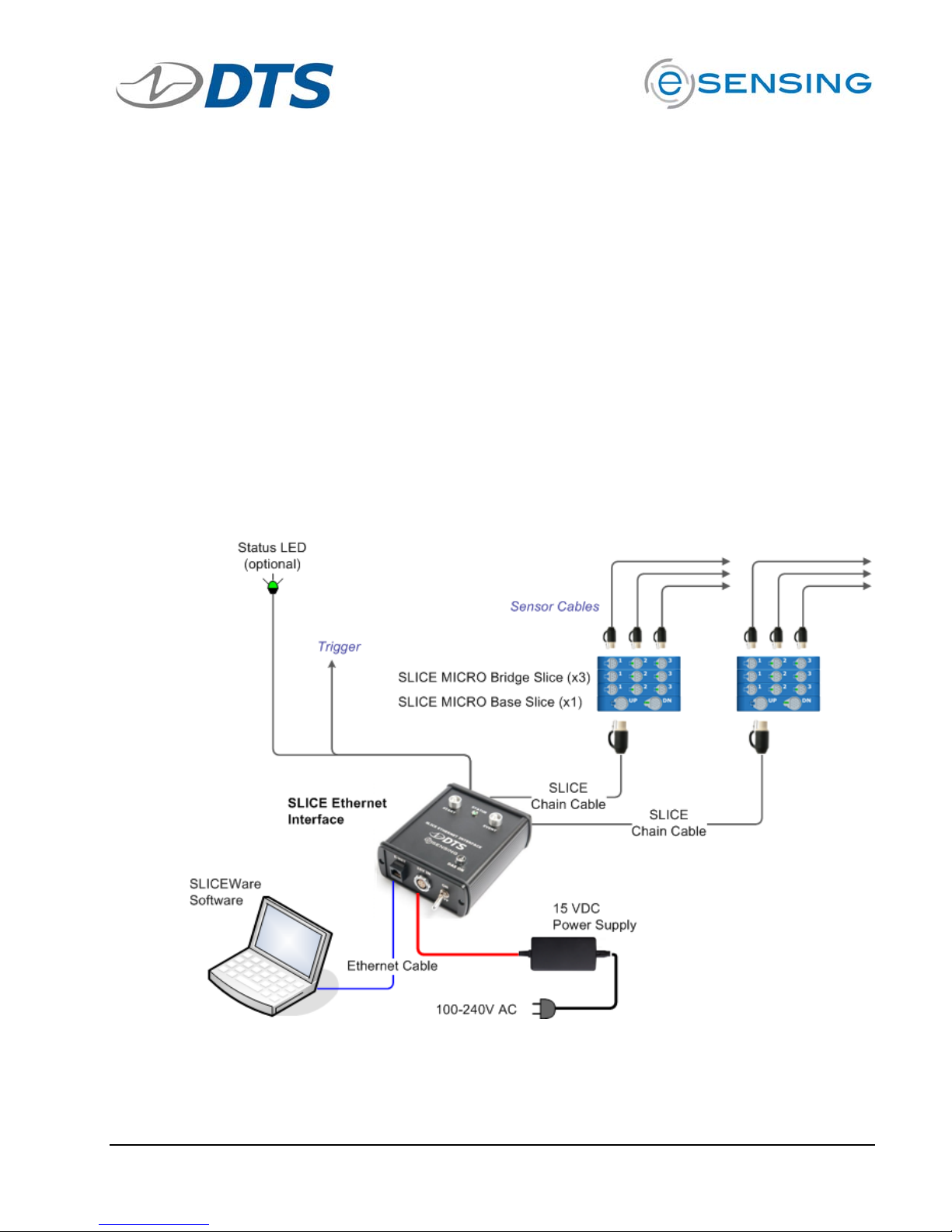

2.3.13. SLICE Ethernet Interface

See Appendix G for detailed specifications.

The SLICE Ethernet Interface allows the connection of two SLICE chains. It is

meant for bench-top use and is not ruggedized.

Maximum channels:

2 chains x 4 stacks x 8 Bridge SLICEs x 3 chan/Bridge = 192 channels

Connections:

! 2 SLICE stack chains

! Ethernet communications

! 9 to 15 VDC input power

! ON/OFF switch

! Manual Start/Event

! AUX input (battery, trigger, etc.)

Version 1.0 - May 2010 14 ©DTS, Inc. - All Rights Reserved

Page 15

SLICE User’s Manual support@dtsweb.com

2.3.14. SLICE MICRO and NANO Connectors

See Section 3 for more connector information.

SLICE systems use lightweight, rugged plastic connectors with reliable, gold

plated contacts. These are a MIL-STD-type pin and socket configuration where

the socket is exposed, instead of the pin, which is mechanically more robust.

For some bench-top units, LEMO-style as well as industry standard USB,

Ethernet and SubD connectors are used.

A typical SLICE rugged plastic connector is shown below.

Finger actuated

retention latch

Exposed sockets

Recessed pins

2.4. Batteries

DTS offers some commercial-off-the-shelf batteries for operation of SLICE systems.

Batteries must be disconnected from the SLICE system before connecting to a charger.

2.4.1. 9.6 V Rechargeable NiMH Batteries

! Allows up to 40 min runtime with a 6 channel SLICE System.

! Package of 4 batteries ensures you’ll always have back-ups ready to use.

Version 1.0 - May 2010 15 ©DTS, Inc. - All Rights Reserved

Page 16

SLICE User’s Manual support@dtsweb.com

2.4.2. 11.1 V Rechargeable Lithium-Polymer Batteries

! Available in 3 capacities: 2200, 4400, and 6600 mAh

2.5. SLICE Software

See Section 4.0 for detailed software information.

The SLICEWare software application allows for easy:

! Test set-up

! Sensor database management

! Real-time sensor check-out

! Test execution

! Data download and viewing

! Data export

A SLICE API (Application Programmers Interface) and LABView driver (fourth quarter

2010) are also available.

Please contact technical support (support@dtsweb.com

) for the latest update to your

software version.

3. Mounting and Connecting SLICE Hardware

This section gives details on how to connect your SLICE hardware. Choose the connection

method you have from the options below for the quickest information.

3.1. General Connection Guidelines

Great care should always be taken when connecting any power, switch, sensor or any

other device to the SLICE system.

! DO NOT exceed the rated voltage input range for the device. Whenever

possible use the power supply or battery pack supplied with your SLICE system.

Version 1.0 - May 2010 16 ©DTS, Inc. - All Rights Reserved

Page 17

SLICE User’s Manual support@dtsweb.com

! DO NOT connect directly to vehicle power or other noisy power sources.

! ALWAYS disconnect the battery from the SLICE system before connecting to a

battery charger.

! ALWAYS use SLICE NANO with a heat sink as the SLICE NANO case is very thin

aluminum with very little heat sinking ability. Never use SLICE NANO mounted

to a thermally non-conductive surface like wood or plastic.

! Refer to proper grounding procedures described in Appendix H.

! Check that all cables show no signs of physical damage.

! Be sure all sensors have their cable shields ungrounded at the sensor end and

grounded at the SLICE input connector.

3.2. Guidelines for High Shock and Vibration Testing

SLICE MICRO and SLICE NANO components can generally be used in test environments with maximum acceleration levels as high as 500 g. In some cases, SLICE

NANO can be used up to 5,000 g if proper care is used.

Proper mounting of the SLICE system, cables, and accessories is critical to successful

testing.

! DO NOT mount SLICE components in an area where they may be directly

impacted by an object.

! Use damping material whenever possible to help protect the SLICE system

from excessive shock or vibration, but remember that SLICE NANO requires a

heat sink.

! Be sure that connectors and wiring are properly secured.

3.3. SLICE Connectors and Cables

3.3.1. SLICE Connectors

SLICE is an ultra small data acquisition system. One challenge with a small

system is electrical connections. Although connectors such as Bendix, Amphenol,

and LEMO are common for instrumentation, all of these are much too large to be

practical for SLICE.

The SLICE system uses circular plastic connectors manufactured by Omnetics

Corporation (www.omnetics.com

contacts and are used in many military, aerospace and other high shock applications. Connectors are available direct from Omnetics or can be purchased from

DTS.

Below are the connector types used by SLICE.

). These connectors use high-quality, machined

Version 1.0 - May 2010 17 ©DTS, Inc. - All Rights Reserved

Page 18

SLICE User’s Manual support@dtsweb.com

3.3.2. SLICE Cables

DTS provides a number of different SLICE cable options depending on the

connection needs. SLICE stack to stack connection cables are shown below.

SLICE MICRO Base units can be connected together via a daisy-chain cable.

SLICE NANO Base units can be connected to each other directly or via a daisychain extension cable.

Version 1.0 - May 2010 18 ©DTS, Inc. - All Rights Reserved

Page 19

SLICE User’s Manual support@dtsweb.com

3.4. Power Requirements

The SLICE system runs on DC power.

To calculate the rough power needs for a particular system, use the information

below:

POWER!REQUIREMENTS!

10!V!POWER! INPUT /5!V!SENSOR!EX CITATION! IDLE! RECORDING!

BASE!SLICE! 40!mA! 110!mA!

BRIDGE!SLICE! ! 2!mA! 55! mA!

SENSOR!LOAD!(350!ohm/5!V!SENS OR!EXCITATION!)! 0!mA! 50!mA!

SINGLE!STACK!POWER!C ONSUMPTI ON !AT!5!!V!SENS OR!

EXCITATI ON!!

BASE!(QTY)! 1!

BRIDGE!(QTY)! 2!

SENSOR!LOAD!(%!of! 350! ohm)! 100!

IDLE!CURRENT! ! 44!mA!

IDLE!POWER!! 330! mW!

TOTAL!

RECORD!CURRENT! ! 320!mA!

RECORD!POWER! ! 2400!mW!

Version 1.0 - May 2010 19 ©DTS, Inc. - All Rights Reserved

Page 20

SLICE User’s Manual support@dtsweb.com

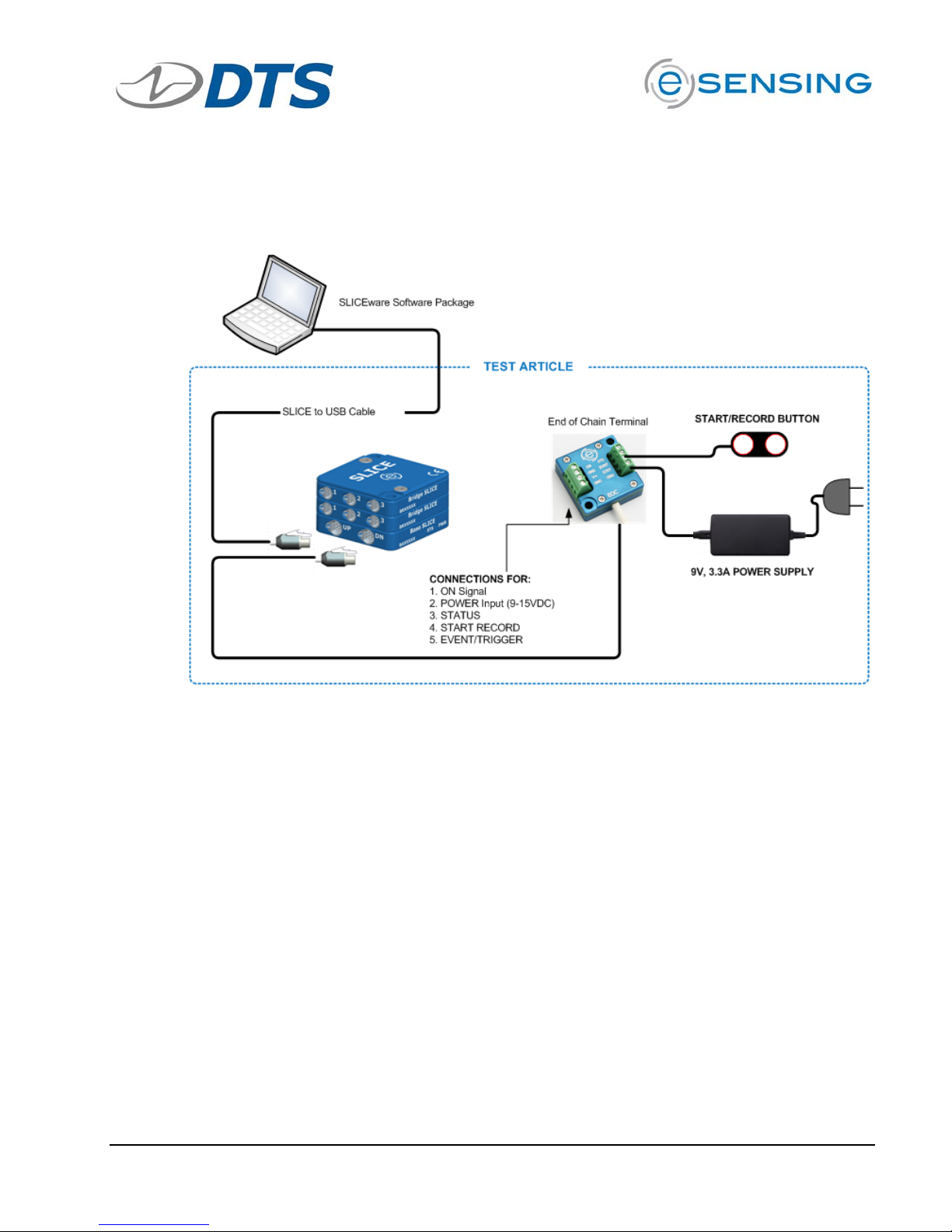

3.5. Using the End-of-Chain (EOC) Terminal

A diagram showing connections using the EOC Terminal is shown below.

Notes:

! Although this shows a SLICE MICRO system, connections with a SLICE NANO

are similar.

! The EOC Terminal is a shock rated item.

! Voltage input can be provided via the included power supply, a battery or any

voltage source between 9 and 15 VDC. Warning: Do not exceed the 15 VDC

input voltage range as damage may result.

! The ON terminal must be connected to the GND on the EOC Terminal for the

SLICE unit to turn on.

! If you connect an LED between the STS and GND terminals, you will get a

Status light when the system is armed.

Version 1.0 - May 2010 20 ©DTS, Inc. - All Rights Reserved

Page 21

SLICE User’s Manual support@dtsweb.com

To DN port on the last

Base SLICE MICRO or

NANO in a SLICE chain

See Appendix C for detailed information on the SLICE End-of-Chain Terminal.

3.6. Using the SLICE System Interface

The SLICE System Interface is similar to the EOC Terminal except it is used between

the first/only SLICE Stack and the PC. See the example diagram below.

Version 1.0 - May 2010 21 ©DTS, Inc. - All Rights Reserved

Page 22

SLICE User’s Manual support@dtsweb.com

Notes:

! Although this shows a SLICE MICRO, connections with a SLICE NANO are

similar.

! The SLICE System Interface is a shock rated item.

! The AUX Terminal can be used for easy connection to a battery, start record,

trigger, and status signal.

! Voltage input through the SLICE System Interface can be provided via the

included power supply a battery, or any voltage source between 9 and 20 VDC.

Warning: Do not exceed the 20 VDC input voltage range as damage may result.

! The SLICE System Interface has a recessed ON switch. Alternately the ON

signal can be connected to the GND on the EOC Terminal.

! If you connect an LED between the STS and GND terminals on the EOC

Terminal you will get a Status light when the system is armed.

3.7. Using the SLICE USB Interface

The SLICE USB Interface is similar to the SLICE System Interface. The main

difference is that the SLICE USB Interface is designed for bench-top, non-rugged use.

See the example diagram below.

Version 1.0 - May 2010 22 ©DTS, Inc. - All Rights Reserved

Page 23

SLICE User’s Manual support@dtsweb.com

Notes:

! Although this shows a SLICE MICRO, connections with a SLICE NANO are

similar.

! The SLICE USB Interface is NOT a shock rated item.

! Voltage input can be with the included power supply a battery, or any voltage

source between 9 and 15 VDC. Warning: Do not exceed the 15 VDC input

voltage range as damage may result.

! The AUX connector is a standard D-sub HD15. This can be used to hardwire a

Start Record or Event switch or monitor the Status line.

3.8. Using the SLICE Ethernet Interface

The SLICE Ethernet Interface is similar to the SLICE USB Interface. The main

difference is that the SLICE Ethernet Interface has an Ethernet connection to the PC

instead of a USB connection. This allows for a longer communications cable between

the PC and the SLICE system. The SLICE Ethernet Interface can also connect 2 SLICE

chains for large system configurations. See the example diagram below.

Notes:

! Although this shows a SLICE MICRO, connections with a SLICE NANO are

similar.

Version 1.0 - May 2010 23 ©DTS, Inc. - All Rights Reserved

Page 24

SLICE User’s Manual support@dtsweb.com

! The SLICE Ethernet Interface is NOT a shock rated item.

! Voltage input can be with the included power supply a battery, or any voltage

source between 9 and 15 VDC. Warning: Do not exceed the 15 VDC input

voltage range as damage may result.

! The AUX connector is a standard D-sub HD15. This can be used to hardwire a

Start Record or Event switch or monitor the Status line.

3.9. Using the SLICE Distributor

The SLICE Distributor allows for the connection of up to 4 SLICE chains and converts

the communications signals from USB to Ethernet. This allows for a longer communications cable between the PC and the SLICE system. The most common application

for the SLICE Distributor is for an embedded system with a high channel count as

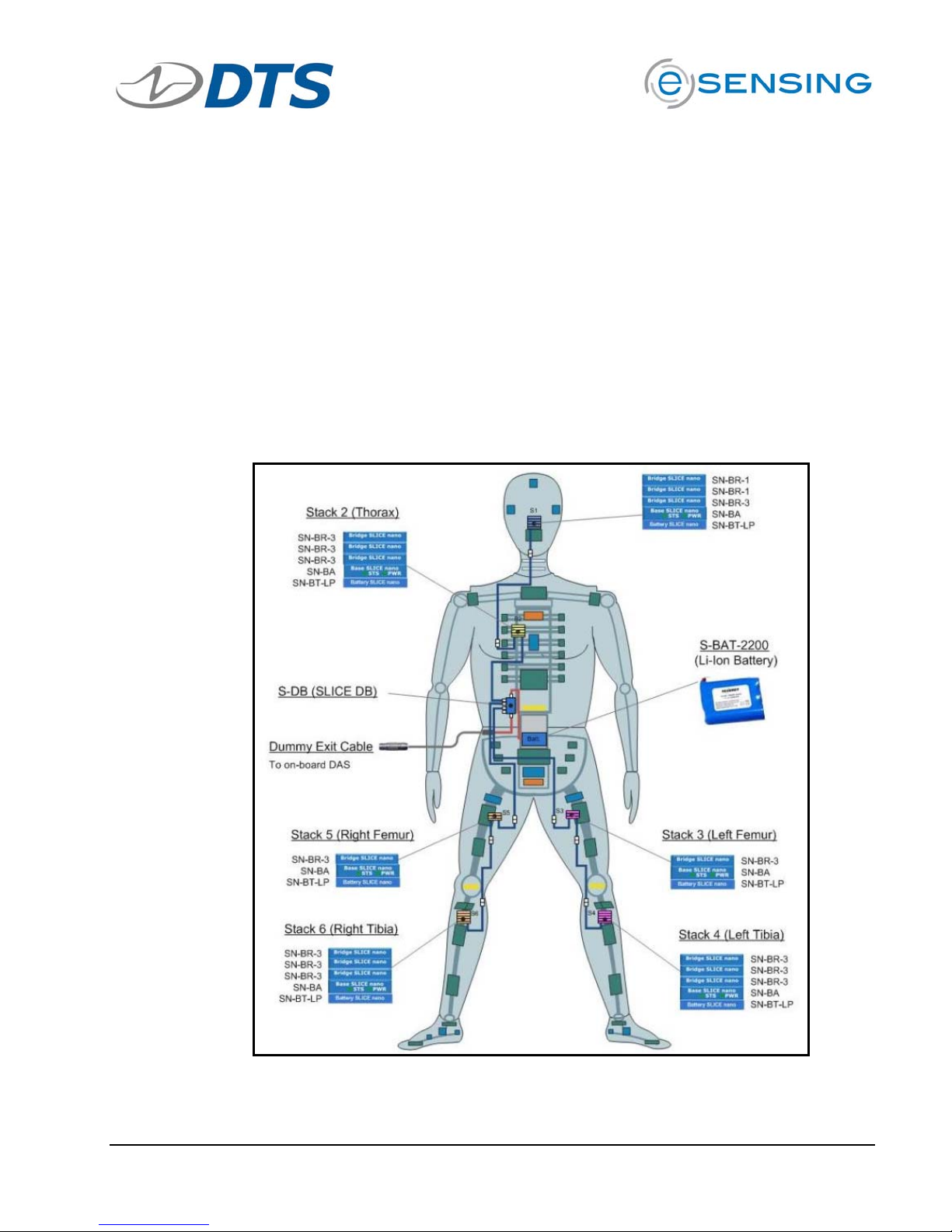

shown for the in-dummy (manikin) configuration below.

SLICE Application Diagram: 42-channel integrated

Version 1.0 - May 2010 24 ©DTS, Inc. - All Rights Reserved

SLICE NANO for H3-50% Dummy

Page 25

SLICE User’s Manual support@dtsweb.com

4. Sensor ID and Supported Sensor Types

This section covers basic information regarding SLICE compatible sensors and sensor ID.

More detailed information regarding sensor connections can be found in Appendix I.

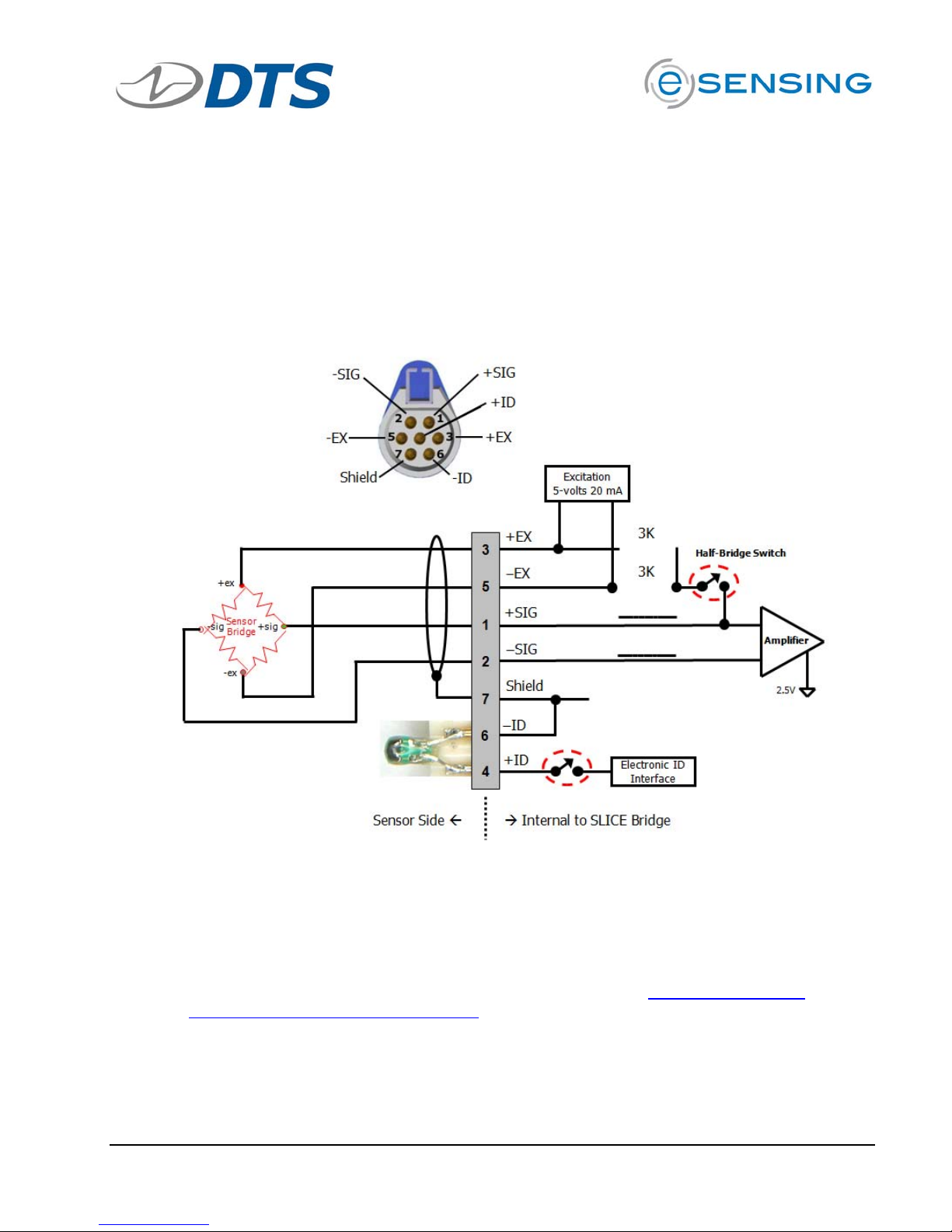

The diagram below shows a common 4-wire bridge sensor connection to a Bridge SLICE

input channel.

4.1. Sensor ID

Sensor ID is also referred to as electronic ID (EID). The function of EID is for the

SLICE hardware to automatically read and determine what sensor is attached to each

sensor input channel.

SLICE uses EID chips from Maxim IC, model DS2401 (see http://www.maxim-

ic.com/quick_view2.cfm/qv_pk/2903). To make soldering of the EID more easy, DTS

provides EID microcards, which have a chip scale packaged DS2401 soldered to a

circuit board with wires attached (see below).

Version 1.0 - May 2010 25 ©DTS, Inc. - All Rights Reserved

Page 26

SLICE User’s Manual support@dtsweb.com

EID “microcard” soldered to pins 4 and 6

Omnetics 7-pin Sensor Connector

4.2. Supported Sensor Types

The Bridge SLICE supplies 5 VDC excitation up to 20 mA and supports many types of

accelerometers, load cells, pressure sensors and other sensor types. The following

general sensor types are supported:

! Full (4-wire) or half bridge (2- or 3-wire) resistive and piezo-resistive types

! Voltage input: Input range 0.1 to 4.9 V; larger range with voltage expander

circuit

! Conditioned sensors with 5 V excitation and 2.5 V centered signal output

The IEPE SLICE MICRO (fourth quarter 2010) will support common piezo-electric

sensor types.

If you have questions regarding what sensors are supported please contact

support@dtsweb.com

and provide the sensor manufacturer and model number if

available.

5. Software

This section covers software installation and use.

See Appendix J for additional software reference information regarding files formats and

firmware updates.

5.1. Basic Requirements

®

SLICEWare is a Windows

! Windows XP, Windows Vista, or Windows 7 32-bit. 64-bit support is coming

soon

! 1 GHz or faster processor

! 2 GByte RAM minimum. More RAM is important for longer/higher sample rate

data acquisition.

! 100 MByte disk space for Software plus storage for test data

! 1024 x 768 minimum screen resolution

based program. Minimum PC specifications are:

Version 1.0 - May 2010 26 ©DTS, Inc. - All Rights Reserved

Page 27

SLICE User’s Manual support@dtsweb.com

5.2. Data Collection Concepts

This section discusses the basics of data collection with SLICE.

5.2.1. Standalone Operation

SLICE is a standalone data logger. This means that once it is armed, the PC can

be disconnected if desired. After receiving a Start Record or Trigger signal, the

SLICE autonomously collects data, storing it to flash memory with no user

interaction. After the test, the user can reconnect the PC to download the data.

There is also a real-time mode in the SLICEWare software application that

allows the user to check channel inputs on an oscillograph-looking screen.

5.2.2. Data Collection Modes

SLICE supports two data collection modes, Circular Buffer and Recorder.

5.2.2.1. Circular Buffer Mode

In circular buffer mode, the user can program SLICE to record pre-trigger

data. For example, the test set-up can specify to record x seconds pretrigger and x seconds post trigger. Time Zero (T=0) is marked when the

trigger signal is received.

5.2.2.2. Recorder Mode

5.3. SLICEWare

This section discusses the basics of data collection with SLICE using the SLICEWare

application.

The SLICEWare software application allows for easy:

! Test set-up

! Sensor database management

! Real-time sensor check-out

! Test execution

! Data download and viewing

! Data export

Recorder mode starts when a Start Record signal is received and continues

for the time specified in the test set-up. If a trigger signal is received

sometime after the Start Record, this marks the T=0 point.

Version 1.0 - May 2010 27 ©DTS, Inc. - All Rights Reserved

Page 28

SLICE User’s Manual support@dtsweb.com

5.3.1. Software Installation

Locate the installation files on the CD or flash drive provided.

Double-click the “set-up.exe” file to begin installation.

Click

installation folder and confirming installation.

Version 1.0 - May 2010 28 ©DTS, Inc. - All Rights Reserved

for each of the screens: set-up wizard, driver installation,

Page 29

SLICE User’s Manual support@dtsweb.com

You must allow the driver to be installed. You may see these screens:

For Windows

®

Vista, click to “Install this driver software anyway.”

For Windows

®

XP, click “Continue Anyway.”

Note: Windows

®

will ask you to reinstall the hardware driver each time you

connect the SLICE stack to a different USB port.

To start SLICEWare, either double-click the

icon or go to:

5.3.2. Menu Descriptions

Click Prepare tab …

This tab identifies the relationship between available sensors and the

attached SLICE units. Sensor information can be added, removed, viewed,

edited or assigned to channels on connected data acquisition hardware.

Version 1.0 - May 2010 29 ©DTS, Inc. - All Rights Reserved

Page 30

SLICE User’s Manual support@dtsweb.com

The image below highlights the different screen areas. The red boxes and type

are used in this manual only (not visible in actual software).

RIBBON CONTROL

SENSOR LIST

SENSOR DETAIL

STATUS BAR

CONNECTED SENSORS

Click anywhere on a line in the Sensor List to show the Sensor Details for that

sensor.

SENSOR LIST

Version 1.0 - May 2010 30 ©DTS, Inc. - All Rights Reserved

SENSOR DETAIL

Page 31

SLICE User’s Manual support@dtsweb.com

Prepare Tab Groupings

Current Sensor

Sensor ID Manual Sensor Assignment

Current Sensor

! Add: Will add a blank Sensor Details field to all for creating a new sensor

entry.

! Delete: Deletes the sensor that is highlighted in the sensor list.

! Undo Edit: Reverts all edits made in the sensor details fields.

! Read ID: Reads the EID from the channel selected in the Connected

Sensor list. The returned ID value will be populated in the Sensor ID field

for the sensor that is highlighted in the sensor list.

! Measure Bridge: Measures a sensors bridge resistance from the channel

selected in the Connected Sensor list. The returned bridge resistance will

be populated in the Bridge resistance (ohms) field for the sensor that is

highlighted in the sensor list.

! Save: Saves edits made in the Sensor Detail area.

Manual Sensor Assignment

! For sensors connectors without an EID.

! You cannot un-assign or overwrite an auto-assigned channel.

! Assign: After highlighting a sensor in the Sensor List and highlighting an

un-assigned channel in the Connected Sensors area, use this to assign the

sensor.

! Un-assign: Remove the highlighted channel in the Connected Sensors area.

! Apply: Commits the sensor set-up information to SLICE.

! Note: A sensor that is manually applied should not have a value in the

Sensor ID field and the SLICE should not have an EID installed on the

connector. If the Sensor ID field is populated or an EID exists on the

channel, the sensor will need to be re-applied after switching away from

and then back to the Prepare tab.

Version 1.0 - May 2010 31 ©DTS, Inc. - All Rights Reserved

Page 32

SLICE User’s Manual support@dtsweb.com

Sensor ID

! Refresh: The sensor IDs are read when the software is started or when a

SLICE is rebooted. If sensor connections are switched, choosing refresh

will read the connected IDs on the current channels.

Sensor Details

General Calibration History

Attributes Options

General

! Serial Number: Used to identify the sensor. Can be any unique identifier.

The sensor list is sorted by default with the serial number.

! Comment: User field can be any text entry.

! Manufacturer: Not enabled as of 200910.

! Model: Not enabled as of 200910.

! Sensor ID: Enter or “READ ID” to populate.

Attributes

! Full Scale: The maximum expected value the sensor will be subjected to.

! Units: The Engineering Units of the sensor.

! Sensitivity:

o When Proportional to Excitation is checked: This value is the

calibrated sensitivity in mV/V/EU.

o When Proportional to Excitation is un-checked: This value is the

calibrated sensitivity in mV/EU.

! Initial EU: Typically left at 0.00. This entry may be used to insert an

engineering value to the starting point of the recorded sensor.

! Excitation: Leave at 5.0. Adjustment is not enabled as of 200910.

Version 1.0 - May 2010 32 ©DTS, Inc. - All Rights Reserved

Page 33

SLICE User’s Manual support@dtsweb.com

Calibration History

! This field is automatically updated whenever a new sensitivity is applied to

the sensor attributes. You cannot enter directly into this field.

Options

! Invert: When checked, the data will be inverted.

! Shunt Check and Bridge Resistance: When Shunt Check is checked, the

sensor will have the bridge resistance measured during diagnostics and

compared to the value entered in Bridge resistance.

! SW Filter: Choose the frequency of a software filter to be applied to the

data when viewing. This only affects the viewed data as all data stored will

be as collected with the hardware anti-alias filter.

! Zero Method (post download software zeroing):

o Use Pre-Cal Zero: The Zero Measured Output (ZMO) of the sensor

during calibration will be used to set the EU zero of the downloaded

data.

o Average Over Time: Used in conjunction with ZeroStart and

ZeroEnd, the average EU value during the Start and End window

will be used to Zero the collected data. The Zero Start/End window

must be set to data that will be collected. If using a negative time,

then the Acquire tab must include this window.

o None: The actual recorded input will not be adjusted or

compensated for zero level. This setting can be used to show the

actual mV offset. An example may be to record a logic level signal

and see the actual on/off state.

o Remove Offset (hardware): When checked, this will remove the

ZMO during diagnostics. This will “electrically” zero the input.

o ZeroStart/End: See Zero Method!Average Over Time.

o Offset Check: Used in conjunction with Limit Low/High during

diagnostics. When checked, the ZMO is measured and compared

the Low/High limits as a pass/fail criteria during diagnostics.

Step-by-Step Procedure to Add a New Sensor

1. On the PREPARE tab,

click the “Add” button in

the “Current Sensor”

button group

Version 1.0 - May 2010 33 ©DTS, Inc. - All Rights Reserved

Page 34

SLICE User’s Manual support@dtsweb.com

2. Edit the Sensor Details

Field

3. Select “Save” in the

“Current Sensor” button

group

Connect SLICE …

Connect the USB and power up the SLICE system…

Version 1.0 - May 2010 34 ©DTS, Inc. - All Rights Reserved

Page 35

SLICE User’s Manual support@dtsweb.com

SLICE hardware appears on right hand side …

Click Diagnostics tab …

This tab ensures that the connected hardware is operating normally.

Hardware diagnostics include checks for battery level, excitation voltage,

noise and expected offset.

Version 1.0 - May 2010 35 ©DTS, Inc. - All Rights Reserved

Page 36

SLICE User’s Manual support@dtsweb.com

SLICEWare configures any connected channels …

Detailed calibration results for all channels …

Version 1.0 - May 2010 36 ©DTS, Inc. - All Rights Reserved

Page 37

SLICE User’s Manual support@dtsweb.com

Click Real-time tab …

This tab shows data input to the attached SLICE hardware in real-time. It is

a useful tool for establishing confidence in the current hardware configuration prior to data collection.

1 g roll tests …

Version 1.0 - May 2010 37 ©DTS, Inc. - All Rights Reserved

Page 38

SLICE User’s Manual support@dtsweb.com

Real-time with X, Y and Z …

Click Acquire tab …

This tab configures and controls the data acquisition process. The user

enters the test name, description, sample rate, acquisition mode (circular

buffer or recorder mode), pre- and post-trigger times and then prepares the

system for data acquisition with the arm command. After the test is

completed, the user can use the download command to view the data.

Version 1.0 - May 2010 38 ©DTS, Inc. - All Rights Reserved

Page 39

SLICE User’s Manual support@dtsweb.com

Enter sampling rates and pre-post test times etc …

System ARMed …

Version 1.0 - May 2010 39 ©DTS, Inc. - All Rights Reserved

Page 40

SLICE User’s Manual support@dtsweb.com

System triggered and acquiring data …

Downloading data …

Version 1.0 - May 2010 40 ©DTS, Inc. - All Rights Reserved

Page 41

SLICE User’s Manual support@dtsweb.com

Click Review tab …

This tab displays collected data. Previously downloaded tests can be viewed

and examined on a per-channel basis.

Dynamic “zoom” selection …

Version 1.0 - May 2010 41 ©DTS, Inc. - All Rights Reserved

Page 42

SLICE User’s Manual support@dtsweb.com

Click Data tab …

This tab provides export options for collected data. Export options include

CSV, ISO and DIAdem formats.

Export options for CSV, ISO and DIAdem formats …

Version 1.0 - May 2010 42 ©DTS, Inc. - All Rights Reserved

Page 43

SLICE User’s Manual support@dtsweb.com

6. Powering Up SLICE

This section covers what to expect when powering up a SLICE system and running a test.

The LEDs on the Base SLICE indicate the status of the system.

6.1. Status (STS) LED

Action Result

Power up

Communicating with PC

Recording Data (Recorder Mode) -or- Armed (Circular Buffer)

Armed in Recorder Mode

Unit received Event

Idle

The status LED is red, green or blue. At system power up, the LED cycles from red to

green to blue followed immediately by the power LED boot-up sequence.

The status LED indicates communication and arm status.

! When the unit is not armed, the status LED will blink green when handling a

command from the PC.

! For Recorder Mode

o When the unit is first armed, the LED will go solid blue to indicate that it

is waiting for the START RECORD signal but not taking data.

o When it receives the START RECORD signal, the LED will turn green to

indicate that it is actively recording data.

o The LED will turn off when data collection has completed.

o If an EVENT signal is received while the unit is recording data, the LED

will turn red and then turn off when data collection has completed.

! For Circular Buffer Mode

o When the unit is armed, the LED will go solid green to indicate that it is

collecting data and waiting for the EVENT signal.

o When an EVENT signal is received the LED will turn red and then turn off

when data collection has completed.

Version 1.0 - May 2010 43 ©DTS, Inc. - All Rights Reserved

Page 44

SLICE User’s Manual support@dtsweb.com

6.2. Power (PWR) LED

Action

Power up

Connected to USB power Only

Connected to external power – power is OK

Connected to external power – power is low

Result

(not armed)

The power LED is red, green or blue.

! At power up, the LED cycles from red to green to blue immediately after the

status LED has completed its boot-up sequence.

! When USB is connected, the LED will turn blue.

! With OK external power, the LED will turn green.

! With low external power, the LED will turn red.

! These transitions do not happen if the unit is armed.

Version 1.0 - May 2010 44 ©DTS, Inc. - All Rights Reserved

Page 45

!

REV:!3!MAY!2010!

SLICE&MICRO&

3!channel!SLICES!to!create!system!STACK!

Connectors!built!into!case!enclosure!

42!x!42!mm!footprint!

Rugged!enclosure!perfect!for!high!stress!environment!

SLICEs!!available!with!embedded!sensors!

Identical!electronics!as!SLICE!NANO!

!

SLICE&NANO&

3!channel!SLICEs!to!create!system!STACK!

Connectors!via!factory!installed!cable!

26!x!31!mm!footprint!

Recommended!for!embedded!applications!

BASE&SLICE&(1&REQUIRED&PER&STACK)&

Microprocessor!

8!G!on‐board!FLASH!memory;!6G!for!data!storage!

Status!controls!

Connection!to!PC!and!additional!stacks!

Available!in!MICRO!and!NANO!

BRIDGE&SLICE&&(3&channels)&

For!use!with!your!sensors:!

! ‐!Strain!gage!

! ‐!Wheatstone!bridge!

! ‐!Voltage!based!

! ‐!MEMS!piezo‐resistive!

Available!in!MICRO!and!NANO!

ACCEL&SLICE&(3&channels)&

Internal!3‐axis!accelerometer!

Ranges!from!50!to!2000!g!

Available!in!MICRO!ONLY!

ARS&SLICE&(3&channels)&

Internal!3‐axis!angular!rate!sensor!

Ranges!from!300!to!50k!deg/sec!

Available!in!MICRO!ONLY!

MIX&AND&MATCH&&

SELECT&ANY&COMBINATION&UP&TO&24&CHANNELS&PER&STACK&

1.&&&CHOOSE&SLICE™&MICRO&OR&SLICE™&&NANO& 2.&DEFINE&SENSOR&NEEDS&

APPENDIX(A(‐(SLICE&B!"#$%&'(!)*#&

Page 46

!

REV:!3!MAY!2010!

Each!SLICE!STACK!consists!of!1!BASE!SLICE!and!up!to!8!individual!3!channel!

SENSOR!INPUT!SLICEs;!maximum!of!24!channels!per!STACK;!up!to!384!chan‐

nels!per!system!

SLICE!STACKS!ca n!be!daisy‐chained!for!larger!channel!systems!or!for!place‐

ment!at!different!locations!

BASE!SLICE!NANO!Module!

1!per!STACK!

BRIDGE!SLICE!NANO!Module!

‐Up!to!8!per!STACK!

‐Maximum!24!ch!per!STACK!

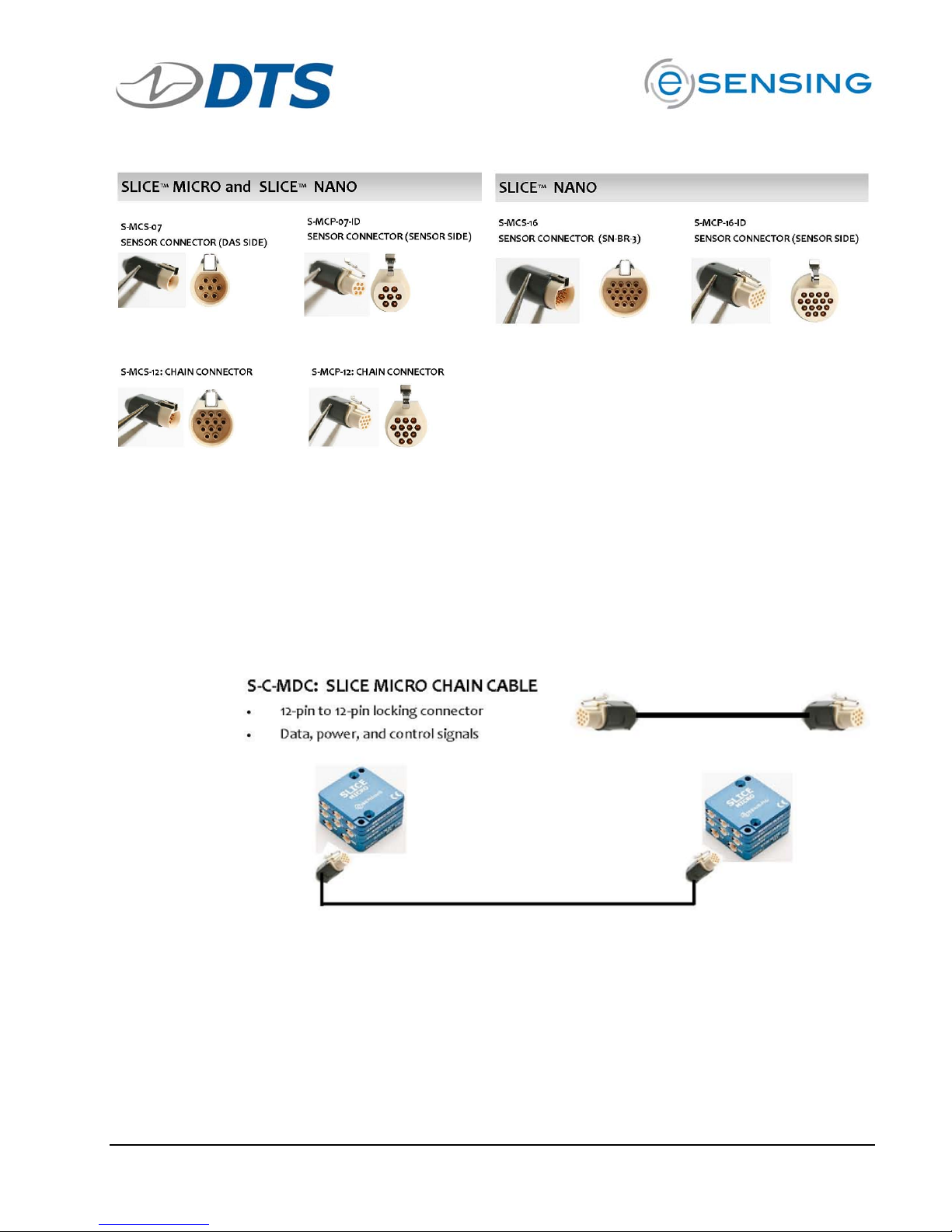

S‐C‐MDC:&&SLICE&MICRO&CHAIN&CABLE&&

12‐pin!to!12‐pin!locking!connector!

Data,!power,!and!control!signals!

S‐C‐NDC:&&SLICE&NANO&CHAIN&CABLE&&

12‐pin!to!12‐socket!locking!connector!

Data,!power,!and!control!signals!

For!connections!longer!than!8!inches!

Connections!longer!than!8!inches!Connections!less!than!8!inches!

SLICE&B!"#$%&'(!)*#&

3.&DETERMINE&NUMBER&OF&CHANNELS&NEEDED& 4.&CONNECT&MULTIPLE&S LICE™&&STACKS&

BRIDGE!SLICE!MICRO!Module!

‐Up!to!8!per!STACK!

‐Maximum!24!ch!per!STACK!

BASE!SLICE!MICRO!Module!

1!per!STACK!

Page 47

REV:!3!MAY!2010!

5.!!SLICE&CONNECTION&OPTIONS&!

S‐EOC:&&SLICE&END&OF&CHAIN&&

USB!Communication!

7!to!15!VDC!power!input!

Supports!up!to!!4!STACKS!in!daisy‐chained!

configuration!

S‐SSI:&&SLICE&SYSTEM&INTERFACE&

USB!Communication!

9!to!20!VDC!power!input!

Supports!up!to!4!STACKS!in!daisy‐chained!

configuration!

Recommended!for!multi‐stack!configura‐

tions!

!

S‐DB:&&SLICE&DISTRIBUTOR&

Ethernet!communication!

9!to!20!VDC!power!input!

Supports!up!to!!16!STACKS!!in!4!daisy‐

chained!configuration!

Recommended!for!large!configurations!

!

6.!!BATTERY&OPTIONS&!

RECHARGEABLE&9.6&V&NiMH&BATTERIES&

Allows!up!to!40!min!runtime!with!6!channel!!

SLICE!System!

Package'of'4'batteries'ensures'you’ll'always'

have!back‐ups!ready!to!use!

RECHARGEABLE&11.1&VDC&LiPo&BATTERIES&

Available!in!3!capacities:!

! ‐!!2200!mAh!!!

! ‐!4400!mAh!

! ‐!6600!mAh!

POWER&REQUIREMENTS& ! !

10!V!POWER!INPUT/5!V!SENSOR!EXCITATION! IDLE! RECORDING!

BASE!SLICE! 40!mA! 110!mA!

BRIDGE!SLICE!! 2!mA! 55!mA!

SENSOR!LOAD!(350!ohm/5!V!SENSOR!EXCITATION!) ! 0! mA! 50!mA!

SINGLE&STACK&POWER&CONSUMPTION&AT&5&&V&SENSOR&

EXCITATION&&

TOTAL& !

BASE!(QTY)! 1! !

BRIDGE!(QTY)! 2! !

SENSOR!LOAD!(%!of!350!ohm)! 100! !

IDLE!CURRENT!! 44!mA! !

IDLE!POWER!! 330!mW! !

RECORD!CURRENT!! 320!mA! !

RECORD!POWER!! 2400!mW! !

SLICE&B!"#$%&'(!)*#&

SLICE&NANO&STACK&BATTERY&

Charges!whenever!input!power!is!connected!to!!NANO!BASE!

~15!min!from!complete!discharge!to!full!charge!(10.5!VDC,!100!mA,!

at!input!connector!on!!NANO!BASE!

Page 48

REV:!3!MAY!2010!

CABLE&KIT&OPTIONS:&&BASE&CABLE&KIT&

9&V,&3.3&A&POWER&SUPPLY&&

START/RECORD&BUTTON&

S‐EOC:&END‐OF‐CHAIN&TERMINAL&&

S‐C‐MSC:&USB&CABLE&

CONNECTIONS&FOR:&

‐!ON!SIGNAL!

‐!7‐15!VDC!POWER!INPUT!

‐!STATUS!

‐!START!RECORD!

‐!EVENT/TRIGGER!

TEST&ARTICLE&

SLICEWare&SOFTWARE&

SM‐K‐BASE&and&SN‐K‐BASE&CABLE&KIT&includes:"

Qty!1.!!End‐of‐Chain!Terminal!

Qty!1.!!Power!supply!and!cable!

Qty!1.!!USB!cable!

Qty!1.!!Event/trigger!cable!

SLICE&B!"#$%&'(!)*#&

Page 49

REV:!3!MAY!2010!

CABLE&KIT&OPTIONS:&&SSI&CABLE&KIT&

SSI&AUX&TERMINAL&

CONNECTIONS&FOR:&

‐!ON!SIGNAL!

‐!9‐20!VDC!POWER!INPUT!

‐!STATUS!

‐!START!RECORD!

‐!EVENT/TRIGGER!

TEST&ARTICLE&

SLICEWare&SOFTWARE&

15&V,&4&A&POWER&SUPPLY&

USB&CABLE&

S‐C‐MDC&CABLE&

SM‐K‐SSI&and&SN‐K‐SSI&CABLE&KIT&includes:"

Qty!1.!!System!Interface!

Qty!1.!!SSI!Aux!Terminal!

Qty!1.!!Power!!supply!and!cable!

Qty!1.!!USB!cable!

Qty!1.!!Event/trigger!cable!

SLICE&B!"#$%&'(!)*#&

Page 50

REV:!3!MAY!2010!

POWER& ‐!7‐15!VDC!input!voltage!to!entire!stack!

via!BASE!

! ‐!100!mA!maximum!current!draw!

! ‐!Reverse!current!protection!

! ‐!Remote!power!control!input!for!turn‐

ing!unit!on/off!

COMMUNICATION& ‐!USB!from!BASE!(Stack)!to!PC!and!

module!to!module!

! ‐!DTS!software!using!Windows!XP,!Vista!

TRIGGER& ‐!Contact!closure!

DATA&STORAGE& ‐!6!Gbyte!non‐volatile!flash!

! ‐!120K!samples/sec/channel!maximum!

! ‐!Recorder!or!circular!buffer!mode!

ENVIRONMENT& ‐!0°!to!50°!C!operating!temp!

! ‐!Rated!to!500g,!4!msec!half‐sine!

SYSTEM& ‐!One!BASE!supports!a!maximum!cur‐

rent!draw!of!1!A!total!per!stack!

! ‐!Sensor!excitation!shuts!down!when!

not!recording!

! ‐!Exceeds!SAEJ211!response!

THREE&DIFFERENTIAL,&

PROGRAMMABLE&SEN‐

SOR&CHANNELS&

‐!2.5!or!5.0!V!excitation!via!one!20!mA!cur‐

rent!limited!source!per!channel!*voltage!set!

at!factory!

! ‐!±2.4!V!input!range!(2.5!V!center)!

! ‐!DC!to!40!kHz!bandwidth!

! ‐!1.0!to!1280!gain!

& ‐!Auto!offset!range!=!100%!of!effective!input!

! ‐!16‐bit!SAR,!one!ADC!per!channel!

& ‐!Software!adjustable,!5‐pole!Butterworth,!

low‐pass,!anti‐alias!filter!(1!Hz—40!kHz)!

& ‐!1/2!bridge!and!shunt!emulation!support!

! ‐!120K!samples/sec/channel!maximum!

! ‐!120!mA!maximum!current!draw!(depends!

significantly!on!sensor!load!

THREE&INTERNAL&&SEN‐

SORS&(MICRO&ONLY)&

‐!3‐axis!accelerometers!

! ‐!Available!range;!50,!100,!200,!2000!g!!

! ‐!65!mA!maximum!current!draw!

THREE&INTERNAL&SEN‐ ‐!3‐axis!!angular!rate!sensors!

! ‐!Available!ranges;!300,!1500,!8k,!50k!deg/sec!!

! ‐!75!mA!maximum!current!draw!

BACKUP&BATTERY& ‐!Charges!whenever!sufficient!input!

! ‐!~15!minutes!from!complete!discharge!to!

full!charge!(10.5!VDC,!100!mA,!at!input!

connector!on!BASE)!

!

‐!Discharge!rates:!

! ~16!seconds!at!1!A!

! ~!2!minutes!at!400!mA!

BASE&SLICE&MICRO&

BASE&SLICE&NANO&

BRIDGE&SLICE&MICRO&

BRIDGE&SLICE&NANO&

ACCEL&SLICE&

ARS&SLICE&

STACK&BATTERY&&

SLICE&TECHNICAL&SPECIFICATIONS&

Page 51

REV:!3!MAY!2010!

SLICE&TECHNICAL&SPECIFICATIONS&

S‐MCP‐07‐ID&

SENSOR&CONNECTOR&(SENSOR&SIDE)&

S‐MCP‐12:&CHAIN&CONNECTOR&

S‐MCP‐16‐ID&

SENSOR&CONNECTOR&(SENSOR&SIDE)&

S‐MCS‐07&

SENSOR&CONNECTOR&(DAS&SIDE)&

S‐MCS‐12:&CHAIN&CONNECTOR&&

S‐MCS‐16&

SENSOR&CONNECTOR&&(SN‐BR‐3)&

SLICE™&MICRO&and&&SLICE™&&NANO&

SLICE™&&NANO&

Page 52

!

REV:!3!MAY!2010!

SLICE&MICRO&DIMENSIONAL&SPECIFICATIONS&

Page 53

REV:!3!MAY!2010!

SLICE&NANO&DIMENSIONAL&SPECIFICATIONS&

Page 54

APPENDIX B - Base and Bridge SLICE support@dtsweb.com

April 2010 ©Diversified Technical Systems, Inc. - All Rights Reserved

SLICE MICRO Base

SLICE

NANO Base

Power:

- 7-15 VDC input voltage to entire stack

via Base

- 100 mA maximum current draw

- Reverse current protection

- Remote power control input for

turning unit on/off

Communication:

- USB from Base (Stack) to PC and

module to module

- DTS software using Windows

®

XP,

Vista

Trigger:

- Contact closure

Data Storage:

- 6 Gbyte non-volatile flash

- 120k samples/sec/channel maximum

- Recorder or circular buffer mode

Environment:

- 0 to 50°C operating temperature

- Rated to 500 g, 4 msec half-sine

System:

- One Base supports a maximum

current draw of 1 A total per stack

- Sensor excitation shuts down when

not recording

- Exceeds SAEJ211 response

SLICE

MICRO Bridge

SLICE NANO Bridge

Three differential, programmable sensor

channels:

- 2.5 or 5.0 V excitation via one

20 mA current-limited source per

channel (voltage set at factory)

- ±2.4 V input range (2.5 V center)

- DC to 40 kHz bandwidth

- 1.0 to 1280 gain

- Auto offset range = 100% of

effective input

- 16-bit SAR, one ADC per channel

- Software-adjustable, 5-pole Butter worth, low-pass, anti-alias filter

(1 Hz – 40 kHz)

- ½ bridge and shunt emulation support

- 120 mA maximum current draw

(depends significantly on sensor load)

SLICE MICRO Accel

- 3 internal accelerometers

- Options from 50 to 2000 g

- 65 mA maximum current draw

SLICE

MICRO ARS

- 3 internal angular rate sensors

- Options from 300 deg/sec to

50000 deg/sec

- 75 mA maximum current draw

SLICE

NANO Stack Battery

- Charges whenever input power is

connected to the Base

- ~15 minutes from complete discharge

to full charge (10.5 VDC, 100 mA, at

input connector on Base)

- Discharge rates:

~16 seconds at 1 A

~2 minutes at 400 mA

Specifications may be revised without notice. Drawings not to scale.

Page 55

SLICE NANO Base Pin Assignments support@dtsweb.com

July 2009 ©Diversified Technical Systems, Inc. - All Rights Reserved

DOWN connector**

(looking into the connector)

Mating connector: DTS P/N S-MCP-12

Pin Function

1

On (contact closure input to ground)

2

Start (contact closure input to ground)

3

Event (contact closure input to ground)

4

Status output (5 V via 10K with respect

to ground)

5

7–15 VDC

6

7–15 VDC

7

Ground

8

Ground

9

USB_PWR

10

USB_DP

11

USB_DM

12

Ground

UP* connector**

(looking into the connector)

Mating connector: DTS P/N S-MCS-12

Pin Function

1

On (contact closure input to ground)

2

Start (contact closure input to ground)

3

Event (contact closure input to ground)

4

Status output (5 V via 10K with respect

to ground)

5

7–15 VDC

6

7–15 VDC

7

Ground

8

Ground

9

USB_PWR

10

USB_DP

11

USB_DM

12

Ground

** Both cables are 10 cm in length * to PC

1

3

4

7

8

10

12

11

3

1

7

4

10

8

11 12

Page 56

SLICE NANO Bridge Pin Assignments support@dtsweb.com

July 2009 ©Diversified Technical Systems, Inc. - All Rights Reserved

Channels 1, 2 and 3*

(looking into the connector)

Mating connector: DTS P/N S-MCP-07

Pin Function

1 + Sig

2 - Sig

3 + Ex

4 + ID

5** - Ex

6** - ID

7** Shield

* Three connectors; cables 6, 10

and 14 cm in length

** Pins 5, 6 and 7 are common

Pin Function

1

+ Sig (Ch 1)

2

+ ID (Ch 1)

3

- Sig (Ch 2)

4

+ Sig (Ch 2)

5

- Sig (Ch 1)

6

+ Ex (Ch 1)

7

- Ex (Ch 1)

8

+ Ex (Ch 2)

*** One connector; cable 10 cm in length

Pin Function

9

+ ID (Ch 2)

10

+ Sig (Ch 3)

11

+ Ex (Ch 3)

12

- Ex (Ch 3)

13

- Ex (Ch 2)

14

- Sig (Ch 3)

15

+ ID (Ch 3)

16

- ID (Ch 1, 2, 3)/Shield

1

2

3

5

6

7

Channels 1-3***

(looking into the connector)

Mating connector: DTS P/N S-MCP-16

1

4

5

9

10

13

14

16

Page 57

SLICE NANO Mechanical Specifications support@dtsweb.com

June 2009 ©Diversified Technical Systems, Inc. - All Rights Reserved

Ø3.2 mm (0.125 in) mounting thru holes x2

Accepts M2.5 (loose fit); 4-40 (free fit); M3 (tight fit)

Weight

Lid ~2.6 grams

Bridge (1 conn) ~12.6 grams

Bridge (3 conn) ~13.8 grams

Base ~14.2 grams

Battery ~7 grams

Mounting Screw Length (min)

BH or SHC

Total Stack Height

mm (inch)

M2.5*/M3** 4-40**

13.5 (0.531) 18 mm 3/4"

17.5 (0.689) 22 mm 7/8"

19 (0.748) 25 mm 1"

23 (0.906) 30 mm 1-1/8"

24.5 (0.965) 30 mm 1-1/8"

28.5 (1.122) 35 mm 1-1/4"

30 (1.181) 35 mm 1-3/8"

34 (1.339) 40 mm 1-1/2"

35.5 (1.398) 40 mm 1-3/4"

39.5 (1.555) 45 mm 1-3/4"

41 (1.614) 45 mm 1-3/4"

45 (1.772) 50 mm 2"

46.5 (1.831) 60 mm 2"

50.5 (1.988) 60 mm 2-1/2"

52 (2.047) 60 mm 2-1/2"

56 (2.205) 60 mm 2-1/2"

57.5 (2.264) 70 mm 2-1/2"

61.5 (2.421) 70 mm 3"

63 (2.480) 70 mm 3"

67 (2.638) 70 mm 3"

Specifications may be revised without notice. Torque specs: * 3.9 in-lb (0.44 Nm); ** 5.2 in-lb (0.59 Nm)

D

C

C

B

B

A

90° cable

clearance

Cables

A = 26 mm (1.024 in)

B = 20.75 mm (0.817 in)

C = 2.62 mm (0.103 in)

D = 31 mm

(

1.220 in

)

1.5 mm

(0.059 in)

6.5 mm

(0.256 in)

5.5 mm

(0.217 in)

4.0 mm

(0.157 in)

Page 58

SLICE MICRO Pin Assignments support@dtsweb.com

July 2009 ©Diversified Technical Systems, Inc. - All Rights Reserved

DOWN and UP* connectors for SLICE

MICRO Base

(looking into the connector)

Mating connector: DTS P/N S-MCP-12

Pin Function

1

On (contact closure input to ground)

2

Start (contact closure input to ground)

3

Event (contact closure input to ground)

4

Status output (5 V via 10K with respect

to ground)

5

7–15 VDC

6

7–15 VDC

7

Ground

8

Ground

9

USB_PWR

10

USB_DP

11

USB_DM

12

Ground

Channels 1, 2 and 3 for SLICE

MICRO Bridge

(looking into the connector)

Mating connector: DTS P/N S-MCP-07

Pin Function

1 + Sig

2 - Sig

3 + Ex

4 + ID

5* - Ex

6* - ID

7* Shield

* Pins 5, 6 and 7 are common

* to PC

1

3

4

7

8

10

12

11

1

2 3

5

6 7

Page 59

SLICE MICRO Mechanical Specifications support@dtsweb.com

April 2010 ©Diversified Technical Systems, Inc. - All Rights Reserved

Weight

Height

mm (inch)

Lid ~9 grams 2 (0.079)

Accel ~33 grams 9 (0.354)

ARS ~33 grams 9 (0.354)

Bridge ~25 grams 7 (0.276)

Base ~28 grams 8 (0.314)

Assembly Screw

Length (FH)

Mounting Screw Length (min)

(BH or SHC)

Total Stack Height

mm (inch)

M3* M4** 6-32***/8-32**

17 (0.67) 16 mm 22 mm 7/8"

24 (0.95) 20 mm 30 mm 1-1/4"

26 (1.02) 25 mm 35 mm 1-1/4"

31 (1.22) 30 mm 35 mm 1-1/2"

33 (1.30) 30 mm 40 mm 1-1/2"

35 (1.38) 35 mm 40 mm 1-5/8"

38 (1.50) 35 mm 45 mm 1-3/4"

40 (1.57) 40 mm 45 mm 1-3/4"

42 (1.65) 40 mm 50 mm 2"

45 (1.77) 45 mm 50 mm 2"

47 (1.85) 45 mm 55 mm 2-1/4"

49 (1.93) 45 mm 55 mm 2-1/4"

52 (2.05) 50 mm 60 mm 2-1/4"

54 (2.13) 50 mm 60 mm 2-1/2"

56 (2.21) 55 mm 70 mm 2-1/2"

59 (2.32) 55 mm 70 mm 2-1/2"

61 (2.40) 60 mm 70 mm 3"

63 (2.48) 60 mm 70 mm 3"

66 (2.60) 65 mm 70 mm 3"

68 (2.68) 65 mm 80 mm 3"

70 (2.76) 70 mm 80 mm 3"

73 (2.87) 70 mm 80 mm 3"

75 (2.95) 75 mm 80 mm 3-1/2”

77 (3.03) 75 mm 90 mm 3-1/2”

80 (3.15) 80 mm 90 mm 3-1/2”

82 (3.23) 80 mm 90 mm 3-1/2”

84 (3.31) 80 mm 90 mm 3-1/2”

Specifications may be revised without notice. Torque specs: * 5.2 in-lb (0.59 Nm); ** 19.8 in-lb (2.24 Nm); *** 9.6 in-lb (1.1 Nm)

A

B

C

Ø4.3 mm (0.169 in) mounting thru holes x2

Accepts 6-32 (loose fit); M4 (free fit); 8-32 (tight fit)

A = 42 mm (1.654 in)

B = 34.2 mm (1.346 in)

C = 3.9 mm (0.154 in)

C

A B

Page 60

APPENDIX C – SLICE End-of-Chain Terminal support@dtsweb.com

©Diversified Technical Systems, Inc. - All Rights Reserved

SLICE End-of-Chain Terminal

Function Connections

ON Turns on SLICE Contact closure = ON to GND (continuous)

If ON signal is removed and the system is not armed,

the system will turn off

If ON signal is removed and the system is armed, the

system will remain on and collect data (sufficient

input power permitting)

V+ Power input +V = input voltage (red)

-V = GND (black)

STS Status output 5 V logic-level output = STS to GND

Conditioned status output; LED direct drive (>

20 mA)

LED is on only when SLICE is collecting data

EVNT Event input Contact closure = EVNT to GND (momentary)

An EVNT signal can initiate data collection (circular

buffer mode) or mark an event within the data

collection window (recorder mode)

STRT Start record

input

Contact closure = STRT to GND (momentary)

A STRT signal initiates data collection (recorder mode)

Weight: 12 grams (without cabling)

20-30 AWG terminals.

All GND terminations are common.

Reverse polarity and overvoltage protection.

26 mm (1.024 in)

20.75 mm (0.817 in)

26 mm (1.024 in)

20.75 mm (0.817 in)

to DN port on

SLICE

MICRO or

SLICE

NANO Base

Page 61

APPENDIX D - SLICE System Interface support@dtsweb.com

August 2009 ©Diversified Technical Systems, Inc. - All Rights Reserved

Torque specs: * 19.8 in-lb (2.24 Nm); ** 9.6 in-lb (1.1 Nm)

Specifications may be revised without notice.

42 mm (1.654 in)

38,1 mm (1.5 in)

3,9 mm

(0.154 in)

! 4,2 mm diam (0.165 in)

x2 mounting thru holes

Use M4* or 6-32** screws

34,2 mm

(1.346 in)

42 mm (1.654 in)

38,1 mm (1.5 in)

34,2 mm

(1.346 in)

3,9 mm

(0.154 in)

11 mm

(0.433 in)

to UP port on SLICE MICRO®

or SLICE NANO

®

; supports

<

4 A via VDC power or

500 mA via USB power

USB 2.0

momentary ON/OFF

push button switch

Status LED Action

No input power

Power input detected; system OFF

Power input detected; system ON

Collecting data

3.5 mm/1.0 mm DC power jack;

10-15 VDC, 4 A max input

see pin assignments for

AUX functions

Page 62

SLICE Interface Pin Assignments support@dtsweb.com

December 2010 ©Diversified Technical Systems, Inc. - All Rights Reserved

Pin Function

1

ON; contact closure input to ground

2

START; contact closure input to ground

3

EVENT; contact closure input to ground

4

STATUS LED output; 4-5 V, 10 mA max,

relative to ground

5

CHARGE output; 10-18 VDC, 2 A out

6

Ground

7

No connection

8

Ground

Pin Function

9

START input; 1.5-14 VDC, relative to ground

10

+EPWR input; 10-18 VDC, 4 A*

11

Ground

12

Ground

13

EVENT input; 1.5-14 VDC, relative to ground

14

+EPWR input; 10-18 VDC, 4 A*

15

+BAT input; 10-18 VDC, 4 A

16

+BAT input; 10-18 VDC, 4 A

* !13 V required for charging SLICE chain/stack battery

AUX connector

(looking into the connector)

Mating connector: DTS P/N 13000-30160

1

4

5

9

10

13

14

16

Page 63

SLICE Interface Pin Assignments (cont.) support@dtsweb.com

December 2010 ©Diversified Technical Systems, Inc. - All Rights Reserved

SLICE connector

(looking into the connector)

Mating connector: DTS P/N 13000-30170

Pin Function

1

On (contact closure input to ground)

2

Start (contact closure input to ground)

3

Event (contact closure input to ground)

4

Status output (5 V via 10K with respect

to ground)

5

7–15 VDC

6

7–15 VDC

7

Ground

8

Ground

9

USB_PWR

10

USB_DP

11

USB_DM

12

Ground

1

3

4

7

8

10

12

11

Page 64

APPENDIX E - SLICE Distributor support@dtsweb.com

August 2009 ©Diversified Technical Systems, Inc. - All Rights Reserved

Status LED Action

No input power

Power input detected; system OFF

Power input detected; system ON

Armed in recorder mode;

not collecting data

Collecting data

Torque specs: * 19.8 in-lb (2.24 Nm); ** 9.6 in-lb (1.1 Nm)

Specifications may be revised without notice.

53,98 mm (2.125 in)

49,4 mm (1.945 in)

4,99 mm

(0.197 in)

! 4,27 mm diam

(0.168 in) x2

mounting thru holes

Use M4* or

6-32** screws

35,94 mm

(1.415 in)

13,46 mm

(

0.530 in)

53

,

98 mm

(

2.125 in

)

48

,

98 mm

(

1.929 in

)

43

,

99 mm

(

1.732 in

)

4,19 mm

(

0.165 in)

24,89 mm

(0.98 in)

momentary ON/OFF

push button switch

see pin assignments

for AUX connector

functions

see pin assignments for

SYS connector functions

Optional 802.11 b/g wireless

support (10-32 antenna port)

SLICE system connectors; to

UP port on SLICE MICRO

®

or

SLICE NANO

®

(supports

<

10 A per connector)

Page 65

SLICE Distributor Pin Assignments support@dtsweb.com

December 2009 ©Diversified Technical Systems, Inc. - All Rights Reserved

Pin Function

1

/PWR_ON

2

- Event

3

+ Event

4

RECORD_STATUS

5

CHARGE (2 A max)

6

Ground

7

Ground

8

+ID

Pin Function

9

START_RECORD

10

+ BAT

11

Ground

12

No connection

13

CHARGE_STATUS

14

+ BAT

15

EN_BAT_PWR

16

Start (contact closure input to ground)

9-20 VDC in; 10 A max

AUX connector

(looking into the connector)

Mating connector: DTS P/N S-MCP-16-SDA

1

4

5

9

10

13

14

16

Page 66

SLICE Distributor Pin Assignments (cont.) support@dtsweb.com

December 2009 ©Diversified Technical Systems, Inc. - All Rights Reserved

Pin Function

1

/PWR_ON

2

- Event

3

+ Event

4

RECORD_STATUS

5

ON_STATUS

6

Ground

7

Ground

8

No connection

Pin Function

9

START_RECORD

10

+ V1

11

Ground

12

Tx+

13

Rx+

14

+ V1

15

Tx-

16

Rx-

SYS connector

(looking into the connector)

Mating connector: DTS P/N S-MCP-16-SDX

1

4

5

9

10

13

14

16

Page 67

SLICE Distributor Pin Assignments (cont.) support@dtsweb.com

December 2009 ©Diversified Technical Systems, Inc. - All Rights Reserved

SLICE system connectors (1, 2, 3 and 4)

(looking into the connector)

Mating connector: DTS P/N S-MCP-12

Pin Function

1

On (contact closure input to ground)

2

Start (contact closure input to ground)

3

Event (contact closure input to ground)

4

Status output (5 V via 10K with respect

to ground)

5

7–15 VDC

6

7–15 VDC

7

Ground

8

Ground

9

USB_PWR

10

USB_DP

11

USB_DM

12

Ground

1

3

4

7

8

10

12

11

Page 68

APPENDIX F

SLICE USB Interface (UI)

The SLICE USB Interface connects 1 SLICE system to a PC via USB.

* *

* You must pull out on the switch before moving—do not force.

Correct input power applied

SLICE system is on

SLICE system is

recording data

support@dtsweb.com March 2010

+1 562 493 0158 ©Diversified Technical Systems, Inc. - All Rights Reserved

Page 69

SLICE USB Interface (UI)

2 3 4

5 6

11

SLICE AUX

(ECG.2B.312.CLL) DB15F (high density)

12

8

7

10

1

2

9

15

10

3

4 5

11

6

(panel view) (panel view)

Pin Function Pin Function

1 /ON 1 /START, CC to ground

2 /START 2 +Status out

3 /EVENT 3 /EVENT, CC to ground

4 STATUS 6 Ground

5 12.6 VDC out 7 -Status out

6 12.6 VDC out 8 Ground

7 Ground

8 Ground

9 USB power

10 USB_DP

11 USB_DM 15V IN

12 Ground (ECG.2B.304.CLL)

1

This is a standard USB (“B”) interface. A commercial, off-the-shelf

USB cable is acceptable.

support@dtsweb.com March 2010

+1 562 493 0158 ©Diversified Technical Systems, Inc. - All Rights Reserved

1

(panel view)

Pin Function

1 +Power (15 VDC)

2 -Power/Ground

3, 4 Ground

Page 70

APPENDIX G

SLICE Ethernet Interface (EI)

The SLICE Ethernet Interface connects 1 or 2 SLICE systems to a PC via Ethernet.

* *

System boot-up

* You must pull out on the switch before moving—do not force.

Input power is over voltage

Correct input power applied

System on

All SLICE systems

are recording data

support@dtsweb.com March 2010

+1 562 493 0158 ©Diversified Technical Systems, Inc. - All Rights Reserved

Page 71

SLICE Ethernet Interface (EI)

2 3 4

5 6

11

SLICE 1 / SLICE 2 AUX

(ECG.2B.312.CLL) DB15F (high density)

12

8

7

10

1

2

9

15

10

3

4 5

11

6

(panel view) (panel view)

Pin Function Pin Function

1 /ON 1 /START, CC to ground

2 /START 2 +Status out

3 /EVENT 3 /EVENT, CC to ground

4 STATUS 6 Ground

5 6.5-15 VDC out 7 -Status out

6 6.5-15 VDC out 8 Ground

7 Ground

8 Ground

9 USB power

10 USB_DP

11 USB_DM 15V IN

12 Ground (ECG.2B.304.CLL)

1

This is a standard Ethernet (RJ45)

interface. A commercial, off-theshelf patch cable is acceptable.

support@dtsweb.com March 2010

+1 562 493 0158 ©Diversified Technical Systems, Inc. - All Rights Reserved

1

(panel view)

Pin Function

1 +Power (9-15 VDC range)

2 -Power/Ground

3, 4 Ground

Page 72

APPENDIX H

SL ICE Grounding

Rec

ommendations

Page 73

SL ICE Grounding and Shielding Overvie

w

Electromagnetic Interference (EMI), Radio Frequency Interference (RFI) and

Electrostatic Discharge (ESD) can seriously degrade the performance of

electronic equipment if not addressed. DTS SLICE systems contain protection

f

or

EMI/RFI/ESD, h

owever, many dynamic testing environments

(pyrotechnics, blast) are particularly noisy and require the utmost attention

to grounding and shielding practices. The following recomm endations are

intended to maximize protection and keep systems functioning properly in

the harshest environments

.

Ground all DAS equipment, power supplies and sensor mounting fixtures

whenever possible. This is an extremely important s tep toward ensuring the

best performance from your SLICE system.

•Always connect a cable from a good Earth ground to the test article, test fixture or

instrumented vehicle. Not only does this help divert potentially disruptive electrical

energy, it is also good safety practice. For remote testing applications, a metal ground

rod driven 3 ft into the soil can be an effective Earthing device.

•Ground

all SLICE enclosures to the test article o

r v

ehicle

• Install ground cables between all SLICE Stacks and the test article or vehicle.

• Install ground cables between electrically isolated test article/sensor mounting surfaces

and the SLICE Stacks.

© 2009-2010 DTS Principles of Dynamic Data Acquisition

Page 74

SL ICE Grounding and Shielding Overvie

w

Shield sensor cables

• Use shielded sensor cables. The shield provides a path for EMI /RFI energy to flow to the