Page 1

13000-30030-MAN (Rev. 3) © Diversified Technical Systems, Inc. - All Rights Reserved

SLICE Distributor

User’s Manual

February 2018

Page 2

SLICE Distributor User’s Manual February 2018

support.dtsweb.com ii 13000-30030-MAN (Rev. 3)

Table of Contents

DTS Support ....................................................................................................................... 3

Introducing the SLICE Distributor .................................................................................... 4

SLICE Distributor Connector Panel .................................................................................. 4

LED Indicator ................................................................................................ ................... 5

On/Off Pushbutton Switch ................................................................................................ 5

SYS and AUX Connectors ............................................................................................... 5

Communication Features ............................................................................................. 6

SLICE System Connectors .............................................................................................. 6

Basic Care and Handling ................................................................................................... 7

Shock Rating .................................................................................................................... 7

Mounting Considerations ............................................................................................. 7

Thermal Considerations ................................................................................................ ... 7

Power Management ............................................................................................................ 8

Maximum Power Consumption ........................................................................................ 8

Maximum Input Power ..................................................................................................... 8

Maximum Output Power .................................................................................................. 8

Charging/Powering Attached Equipment ......................................................................... 8

Power Requirements of SLICE Equipment .................................................................. 9

Grounding ........................................................................................................................... 9

Troubleshooting Basics .................................................................................................... 9

Appendix A: Connector Information .............................................................................. 11

Appendix B: Mechanical Specifications ........................................................................ 13

Appendix C: Hardware Configuration Specifications .................................................. 14

Changing the IP Address ............................................................................................... 15

Page 3

SLICE Distributor User’s Manual February 2018

support.dtsweb.com 3 13000-30030-MAN (Rev. 3)

DTS Support

SLICE systems are designed to be reliable and simple to operate. Should you need

assistance, DTS has support engineers worldwide with extensive product knowledge and

crash test experience to help via telephone, e-mail or on-site visits.

The best way to contact a DTS support engineer is to submit a request through the DTS Help

Center web portal (support.dtsweb.com). You must be registered

(support.dtsweb.com/registration) to submit a request (https://support.dtsweb.com/hc/en-

us/requests/new). Registration also enables access to additional self-help resources and

non-public support information.

This manual supports the following products:

13000-30030: SLICE Distributor

Page 4

SLICE Distributor User’s Manual February 2018

support.dtsweb.com 4 13000-30030-MAN (Rev. 3)

Introducing the SLICE Distributor

The SLICE Distributor serves as a single interface supporting power, Ethernet

communications and status signals for an extended SLICE system. It supports in excess of

200 channels via 4 SLICE MICRO/NANO chains (4 stacks per chain), and is designed to

integrate in-dummy and withstand high shock environments.

• Rated for 500 g dynamic testing environments.

• Supports >200 SLICE MICRO/NANO DAS channels via 4 SLICE system connectors.

• Supports an input range of 9-18 VDC (15 VDC nominal), 10 A maximum.

• Supports main and battery back-up power inputs.

• Supports Ethernet communications.

• Over- and undervoltage protection, overcurrent protection, power input polarity

protection.

• LED indicator provides status information.

• Integral mounting holes.

• Ideal for embedded and in-dummy high channel-count applications.

SLICE Distributor Connector Panel

The ON switch, LED indicator and all connectors are accessible from the front panel.

Instructions on how to properly connect cables can be found in the section on

Troubleshooting Basics. Connector information and pin assignments can be found in

Appendix A. Mechanical specifications are included in Appendix B. Appendix C provides

information on the network parameters of your equipment.

SLICE Distributor Connector Panel

SLICE MICRO/NANO DAS connectors (1-4)

- Functionally identical

- Supports power, start, event, status and

USB communications

Status LED

Pushbutton

Switch

SYS connector

- Main power input

- Ethernet communications

- Status and control signals

AUX connector

- Status and control signals

- Back-up power input

Page 5

SLICE Distributor User’s Manual February 2018

support.dtsweb.com 5 13000-30030-MAN (Rev. 3)

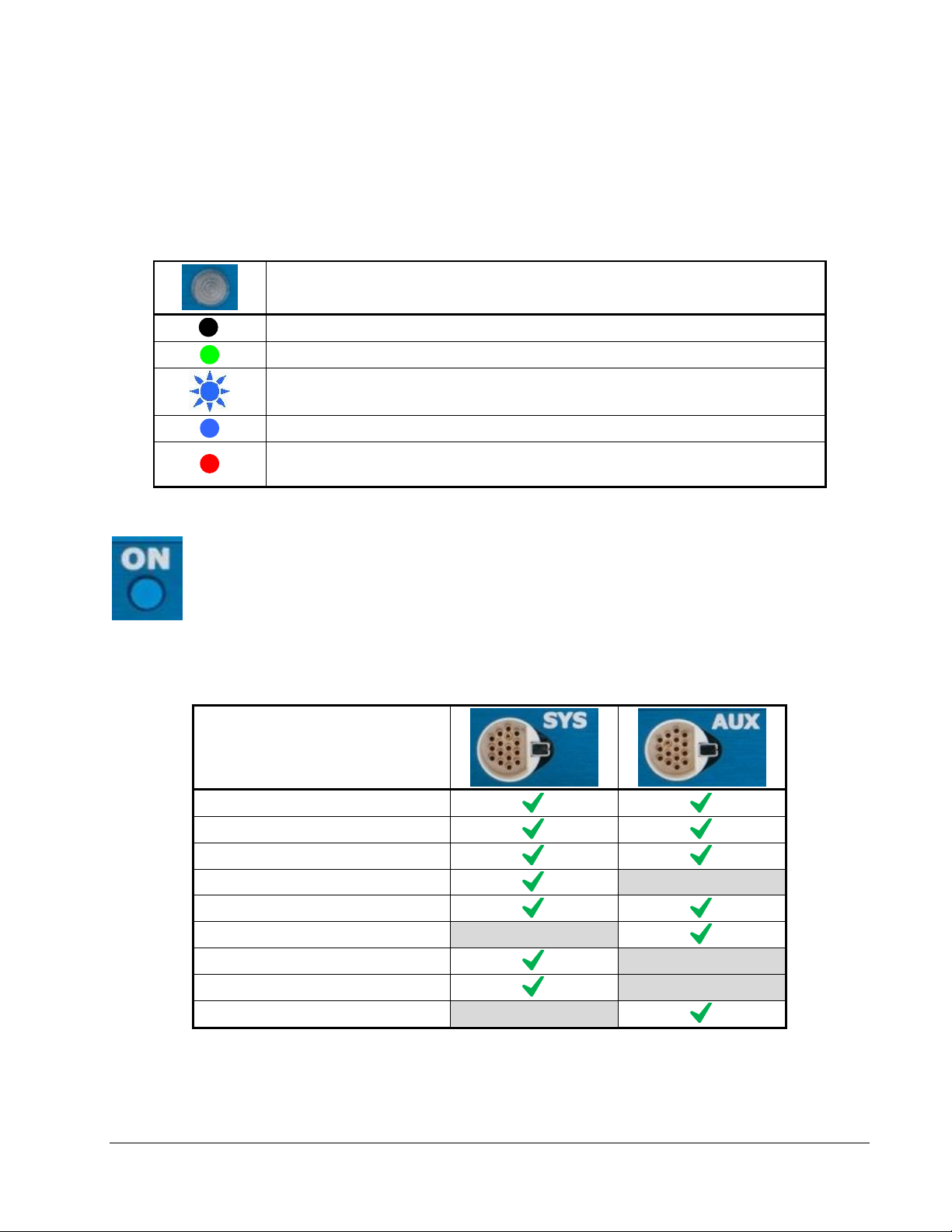

LED Indicator

There is 1 LED that provides status information. This LED is an indicator of SLICE Distributor

status only; it does not indicate the status of any attached equipment.

A thorough understanding of the LED states will facilitate an efficient approach to

troubleshooting and a quick resolution to any problems.

SLICE Distributor Status

Unit off; no input power detected

Unit off; input power detected (input range OK); output power is active

Unit initializing

Unit on (input range OK); all outputs active

Input power is overvoltage –or– overcurrent condition is present

(If unit is on, cycle power to reset)

On/Off Pushbutton Switch

A momentary pushbutton switch is used for on/off control. When the unit is on

(LED is blue), all internal system electronics and output power are energized and

the unit is fully functional. (This is the normal operating mode.) When the unit is

off, the LED is either green (input power detected) or off (no input power).

SYS and AUX Connectors

The functions available via the SYS and AUX connectors are summarized below.

Function

Power on

Event

Recording status

On status

Start record (5 V)

Start record (contact closure)

Ethernet communications

Main power input

Back-up power input

Whenever sufficient input power is connected to the SYS connector, all attached SLICE DAS

containing an internal battery will charge.

Page 6

SLICE Distributor User’s Manual February 2018

support.dtsweb.com 6 13000-30030-MAN (Rev. 3)

Communication Features

The SLICE Distributor supports the industry-standard Ethernet 10/100BaseT/Tx

communication method. Communication is enabled after the power-up sequence has

completed. (See Appendix C for information on the network parameters of your equipment.)

SLICE System Connectors

These 4 connectors are identical and support power, start, event, status

and USB communication signals for the DAS. One SLICE connector

supports up to 3 SLICE stacks, with a maximum of 8 SLICE Bridges per

stack, in any combination of SLICE MICRO or NANO. SLICE MICRO

Accel and ARS units can be used in place of a Bridge and the SLICE

NANO Battery can be used with any SLICE NANO stack.

= + +

= 54 ch

(maximum)

(Original Base MICRO and/or NANO; SLICE NANO Battery optional)

= + +

= 72 ch

(maximum)

(MICRO and/or NANO Base+; SLICE NANO Battery optional)

Maximum current for all 4 SLICE System connectors combined is 10 A with a maximum of

4 A per connector. Carefully calculate your expected maximum power consumption to

ensure compliance with power limits. (Please see page 9 for information on power

requirements.)

Page 7

SLICE Distributor User’s Manual February 2018

support.dtsweb.com 7 13000-30030-MAN (Rev. 3)

Basic Care and Handling

The SLICE Distributor is designed to operate reliably in dynamic testing environments.

Though resistant to many environmental conditions, care should be taken not to subject the

unit to harsh chemicals, submerge it in water, or drop it onto any hard surface.

WARNING:

Electronic equipment dropped from desk height onto a solid

floor may experience as much as 10,000 g. Under these

conditions, damage to the unit is likely.

If you plan to store the unit, place it in a location with ambient temperatures below 30°C, low

relative humidity, and free from dust and direct sunlight. When not in use or if shipping is

required, we suggest that you always place the unit in the padded carrying case originally

provided with your system. When transporting the unit, treat it as you might a laptop

computer.

The SLICE Distributor is not user-serviceable and should be returned to the factory for

service or repair.

Shock Rating

The SLICE Distributor is rated for 500 g, 4 ms half-sine duration, in all axes.

Mounting Considerations

The unit should be securely bolted to the test article or dynamic testing device to provide the

best shock protection. Mounting methods and hardware selection should be carefully

calculated to withstand expected shock loading and facilitate proper grounding. Check bolt

tightness periodically to ensure that the unit is securely fastened to the baseplate or testing

platform. (See Appendix B for the unit’s mechanical specifications.)

Thermal Considerations

It is unlikely that the unit will overheat if common-sense measures are taken. In normal use,

the SLICE Distributor is bolted to a structure with enough thermal mass to serve as a heat

sink, keeping the temperature well within acceptable limits. However, when used

continuously at the maximum output level, the unit may get very warm to the touch. Since

the system draws the most power when armed, running the calibrations and arming as late

as possible will minimize self-heating, particularly in embedded applications. Should you

have any questions about using the SLICE Distributor in your environment, please contact

DTS.

Page 8

SLICE Distributor User’s Manual February 2018

support.dtsweb.com 8 13000-30030-MAN (Rev. 3)

Power Management

The SLICE Distributor should be powered from a high-quality power source with output

voltage and current ratings appropriate for the installation. It does not contain an internal

power source, but has separate connectors to support main power and back-up power inputs.

The SLICE Distributor contains power conditioning circuitry with a wide input range and wellregulated outputs. It will boost input voltages at the low end of the specified range in order

to maintain a consistent output voltage. This conversion, however, will come at the expense

of the supplied input current. A simple voltage measurement at the cable end that connects

directly to the SLICE Distributor will verify whether the unit is receiving sufficient input voltage.

Maximum Power Consumption

The maximum power consumption is 180 W.

Maximum Input Power

The maximum input power is 15 VDC nominal (9-18 VDC range) at 10 A.

Maximum Output Power

The combined maximum output power available via the 4 SLICE system connectors is 120 W

(12 V at 10 A). The maximum output power available per SLICE system connector is 12 V

at 4 A. The maximum output current available via the AUX connector is 2.5 A (input VDC = output VDC).

Charging/Powering Attached Equipment

When sufficient main input power is connected to the SLICE Distributor, it will simultaneously

power and charge any attached SLICE DAS containing an internal battery.1 The length of

time required to charge attached equipment depends primarily on the discharge state of the

batteries. The SLICE Distributor does not need to be on for attached equipment to charge.

WARNING:

Interconnecting SLICE equipment while signals/power are active/hot is not

supported.

The SLICE Distributor uses a common 12-conductor SLICE system chain

connector that supports power, communication and control signals. If a port or

cable is hot, it is possible that the locking clip or incorrect connector orientation

might randomly short pins and damage the equipment. Application of power

and other signals should occur after all cables have been connected to the

SLICE Distributor. DTS strongly suggests following this procedure at all times

to avoid potential damage to your equipment.

1

The SLICE Distributor does not contain a battery charging circuit and cannot be used to charge any external

device/battery that does not contain its own battery charging circuitry.

Page 9

SLICE Distributor User’s Manual February 2018

support.dtsweb.com 9 13000-30030-MAN (Rev. 3)

Power Requirements of SLICE Equipment

SLICE DAS use extensive power management to minimize power consumption. The lowest

power demand condition is during charging when power is off. Current demand is at its

maximum when the systems are fully armed and powering full sensor loads.

Power Consumption

(per item)

Power Off

(charging battery)

Power On

(armed + max load)

SLICE NANO/MICRO

- Base/Base+

- Bridge

- Battery (NANO only)

- Accel (MICRO only)

- ARS (MICRO only)

- IEPE (MICRO only)

---

---

100 mA

---

---

---

100 mA/70 mA

110 mA/75 mA*

100 mA

65 mA

75 mA

70 mA/85 mA*

* Base+

For additional information, please see the SLICE Hardware User’s Manual.

Grounding

The SLICE Distributor has integrated mounting holes that will provide a simple method of

grounding the entire data acquisition system when bolted to a properly-grounded test fixture.

DTS recommends checking continuity between the SLICE Distributor and the test fixture to

confirm resistance readings of <1 ohm.

Troubleshooting Basics

Begin troubleshooting by checking the operational state of the SLICE Distributor alone. DTS

suggests always using the connection sequence below to avoid possible damage from hot

swapping the cables.

1. With the unit off (and no DAS connected), connect the SLICE Distributor’s power

source to the SYS connector.

– If the status LED is green, then voltage input levels are within specifications and

main output power is active. Proceed to step 2.

– If the status LED is off, this can mean that the input voltage is too low or input

polarity is reversed. You will need to correct this before proceeding.

– If the status LED is red, this can mean:

a) Input voltage is too high. You will need to correct this before proceeding.

b) Overcurrent condition is present. This likely means the SLICE Distributor is

not working properly. Contact DTS Support for assistance.

2. When the status LED is green, turn on the SLICE Distributor.

3. When the status LED is solid blue, the SLICE Distributor is on and fully functional (all

internal system electronics and output power are energized). This is the normal

operating mode.

Page 10

SLICE Distributor User’s Manual February 2018

support.dtsweb.com 10 13000-30030-MAN (Rev. 3)

If the SLICE Distributor is operating normally, the next step is to add the DAS. DTS suggests

always using the connection sequence below to avoid possible damage from hot swapping

the cables.

1. With the unit off and power not connected, connect the SLICE DAS to the SLICE

system connectors.

2. Connect the SLICE Distributor’s power source to the SYS connector.

3. When the status LED is green, turn on the SLICE Distributor.

– When the status LED is solid blue (normal operating mode), then inspect the LED

indicators on the SLICE DAS for system health.

– If the status LED is red, this can mean input voltage is too high or overcurrent

condition is present. You will need to correct this before proceeding.

4. Connect the Ethernet comm cable from the SYS connector to your PC.

If at any time the status LED indicator shows an error or fault condition, you will need to

correct this before proceeding. (The LED is an indicator of SLICE Distributor status only; it

does not indicate the status of any attached equipment.) A fault signal generated by the

SLICE Distributor or SLICE DAS is forwarded externally via the AUX and SYS connectors

and will prevent you from arming your system. When the DAS is recording data, the status

signal from the AUX and SYS connectors will be high; the status signal will be low for all

other states where the DAS is on and connected to the SLICE Distributor.

Page 11

SLICE Distributor User’s Manual February 2018

support.dtsweb.com 11 13000-30030-MAN (Rev. 3)

Appendix A: Connector Information

AUX connector SYS connector

(pin 12 plugged) (pin 8 plugged)

(looking into the connector) (looking into the connector)

Pin

Function

Pin

Function

1

/PWR_ON (contact closure to ground)

1 /PWR_ON (contact closure to ground)

2

-Event, isolated, bi-directional,

contact closure to pin 3

2 -Event, isolated, bi-directional,

contact closure to pin 3

3

+Event, isolated, bi-directional,

contact closure to pin 2

3 +Event, isolated, bi-directional,

contact closure to pin 2

4

Recording status (high = recording)

4 Recording status (high = recording)

5

Reserved

5 ON status

6

-VDC input from ext battery/Ground

6 Ground

7

-VDC input from ext battery/Ground

7 Ground

8

Reserved

8 No connection

9

Start record input (apply 5 V with

respect to ground)

9 Start record input (apply 5 V with

respect to ground)

10

+VDC input from external battery

10

9-18 VDC in

11

Ground

11

Ground

12

No connection

12

Ethernet Tx+

13

Reserved

13

Ethernet Rx+

14

+VDC input from external battery

14

9-18 VDC in

15

Reserved

15

Ethernet Tx-

16

Start record input, contact closure to

ground

16

Ethernet Rx-

1 4 5

9

10

13

14

16

1 4 5

9

10

13

14

16

Page 12

SLICE Distributor User’s Manual February 2018

support.dtsweb.com 12 13000-30030-MAN (Rev. 3)

SLICE system connectors (1-4)

(looking into the connector)

Pin

Function

1

/ON, bi-directional, contact closure input to ground

2

/START, bi-directional, contact closure input to ground

3

/EVENT, bi-directional, contact closure input to ground

4

Status output (3 V = recording)

5

12 VDC out

6

12 VDC out

7

Ground

8

Ground

9

USB_PWR

10

USB_DP

11

USB_DM

12

Ground

1

3 4 7 8 10

12

11

Page 13

SLICE Distributor User’s Manual February 2018

support.dtsweb.com 13 13000-30030-MAN (Rev. 3)

Appendix B: Mechanical Specifications

Weight: ~135 g

Use M4* or 6-32** screws

Torque specs: * 19.8 in-lb (2.24 Nm); ** 9.6 in-lb (1.1 Nm) Units in inches (mm)

Accessories/support equipment:

13000-3010x: Cable, SLICE Distributor to SYSTEM port (DMD)

13000-30110: Cable, SLICE Distributor to DDX cable (SDX) (1 m)

13000-30440: SLICE Distributor AUX Connector Assy

13000-30441: SLICE Distributor AUX Cable Assy (5 m; pigtail term)

13000-30450: SLICE Distributor SYS Connector Assy

13000-30451: SLICE Distributor SYS Cable Assy (5 m; pigtail term)

13000-30660: Cable, SLICE Distributor, Ethernet comm (SYS to RJ45) (20 m)

13000-31140: SLICE NiMH Battery Interface; 12 V (10 AAA cells)

13000-31150: SLICE Back-up Battery Pack; 12 V (1 x 10 AAA cells)

13000-40050: SLICE Distributor Cable Kit

(x = multiple lengths available)

Page 14

SLICE Distributor User’s Manual February 2018

support.dtsweb.com 14 13000-30030-MAN (Rev. 3)

Appendix C: Hardware Configuration Specifications

SLICE Distributors are typically delivered with a default IP address as follows:

IP address

192.168.0.x where:

x = 1-9 for S/Ns SD00001-SD00009;

x = 10-99 for S/Ns SD00010-SD00099;

x = 100 for S/Ns SD00100, SD00200, SD00300;

x = 101 for S/Ns SD00101, SD00201, SD00301;

x = 2-99 for S/Ns SD00102-SD00399

Netmask

255.255.252.0

The calibration data for your equipment identifies the IP address as shipped from the factory.

If the calibration data is not available, try using the default address described in the table

above.

If you need information on the specifics of your equipment, please submit a request through

the DTS Help Center web portal (support.dtsweb.com) and include the serial number(s) of

the equipment and parameters you are asking about.

Page 15

SLICE Distributor User’s Manual February 2018

support.dtsweb.com 15 13000-30030-MAN (Rev. 3)

Changing the IP Address

Using a web browser, enter the unit’s current IP address. (Use compatibility mode with

Internet Explorer.)

Enter the desired IP address and/or netmask into the available fields and click “Apply”.

If the IP address is valid, the page will show success. Reboot the device for the settings to

be applied.

If you receive an error, submit a request through the DTS Help Center and attach the system

log file.

Page 16

SLICE Distributor User’s Manual February 2018

support.dtsweb.com 16 13000-30030-MAN (Rev. 3)

Revision History

Date

By

Description

15 Feb 2018

EK

Corrected number of stacks (was 4; now 3) referenced in second paragraph and

illustrations on page 6. Updated network info to refer to Appendix C. (Rev 3)

27 Feb 2017

EK

Added Appendix C and page 8 footnote. Updated accessories. (Rev 2)

22 Oct 2015

EK

Corrected number of stacks (was 3; now 4) referenced in second paragraph, page 6.

(Rev 1)

30 Oct 2014

EK

Initial release. (Rev 0)

Loading...

Loading...