Page 1

Dräger X-am® 5100

Visit: www.thesafetyequipmentstore.com or besafe@thesafetyequipmentstore.com for sales and service.

(MQG 0020)

Technical Manual

Page 2

Page 3

Contents

1 For Your Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.1 Follow the Instructions for Use . . . . . . . . . . . . . . . . 4

1.2 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.3 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.4 Safe coupling with electrical devices . . . . . . . . . . . . 4

1.5 Use in areas subject to explosion hazards . . . . . . . 4

1.6 Safety symbols used in this Technical Manual . . . . 4

2 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.1 Product overview . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.2 Intended Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.3 Intended operating area and operating conditions . 5

2.4 Tests and Approvals . . . . . . . . . . . . . . . . . . . . . . . . 6

3 Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.1 Preparations for use . . . . . . . . . . . . . . . . . . . . . . . . 7

3.2 Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.3 Performing the bump test . . . . . . . . . . . . . . . . . . . 11

3.4 During use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.5 Identifying Alarms . . . . . . . . . . . . . . . . . . . . . . . . . 12

4 Menu functions . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.1 Calling the Info Mode . . . . . . . . . . . . . . . . . . . . . . 13

4.2 Calling the Info-Off Mode . . . . . . . . . . . . . . . . . . . 13

4.3 Quick Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.4 Adjustment menu . . . . . . . . . . . . . . . . . . . . . . . . . 14

5 Calibrating the instrument . . . . . . . . . . . . . . . . . 15

5.1 Adjustment interval: . . . . . . . . . . . . . . . . . . . . . . . . 15

5.2 Performing a fresh air adjustment . . . . . . . . . . . . . 15

5.3 Performing a sensitivity adjustment . . . . . . . . . . . 16

6 Replacing the Sensors . . . . . . . . . . . . . . . . . . . . 18

7 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . 19

7.1 Warning messages . . . . . . . . . . . . . . . . . . . . . . . . 19

7.2 Fault messages . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

8 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

8.1 Maintenance intervals . . . . . . . . . . . . . . . . . . . . . . 21

8.2 Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

9 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

9.1 Disposal of electrical and electronic appliances . . 22

9.2 Electrochemical sensors . . . . . . . . . . . . . . . . . . . . 22

10 Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

11 Ordering list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

12 Declaration of Conformity . . . . . . . . . . . . . . . . . 25

Contents

Dräger X-am 5100 3

Page 4

For Your Safety

1 For Your Safety

1.1 Follow the Instructions for Use

Any use of the instrument requires full understanding and strict

observation of the Instructions for Use supplied with the

instrument. The instrument is only to be used for the purposes

specified here.

1.2 Maintenance

The maintenance intervals and measures specified in this

Technical Manual as well as the specifications in the

Instructions for Use/data sheets

sensors used must be carefully observed. Repairs to the

instrument may only be carried out by trained service

personnel.

1.3 Accessories

Only the accessories specified in the ordering list may be used.

1.4 Safe coupling with electrical devices

Devices which are not mentioned in the Instructions for Use or

in this Technical Manual can only be coupled electronically

after consultation with the manufacturers or an expert.

1.5 Use in areas subject to explosion hazards

Devices or components for use in explosion-hazard areas,

which have been tested and approved according to national,

European or international Explosion Protection Regulations,

may only be used under the conditions explicitly specified in

the approval and with consideration of the relevant legal

regulations. Devices and components must not be altered.

The use of faulty or incomplete parts is forbidden.

The applicable regulations must be observed at all times when

carrying out repairs on these devices or components.

1

for the DrägerSensor

® 2

1.6 Safety symbols used in this Technical Manual

This Technical Manual contains a number of warnings for risks

and hazards which might occur when using the instrument.

These warnings contain signal words to alert you to the degree

of hazard you may encounter. These signal words and

corresponding hazards are as follows:

WARNING

!

Death or serious physical injury may occur as

a result of a potential hazard situation if appropriate

precautionary measures are not taken.

CAUTION

!

Indicates a potentially hazardous situation which, if not

avoided, could result in injury or damage to property or

to the environment. Can also be used to warn against

any wanton actions.

NOTICE

i

i

Additional information on the use of the product.

1 Instructions for Use/data sheets for the utilized sensors and the PC software

CC-Vision for Dräger X-am 5100 can be downloaded on the product page

of the X-am 5100 at the following Internet address: www.draeger.com. See

also the enclosed Instructions for Use and data sheets for the sensors used.

2 DrägerSensor

4 Dräger X-am 5100

®

is a registered trademark of Dräger.

Page 5

Description

2 Description

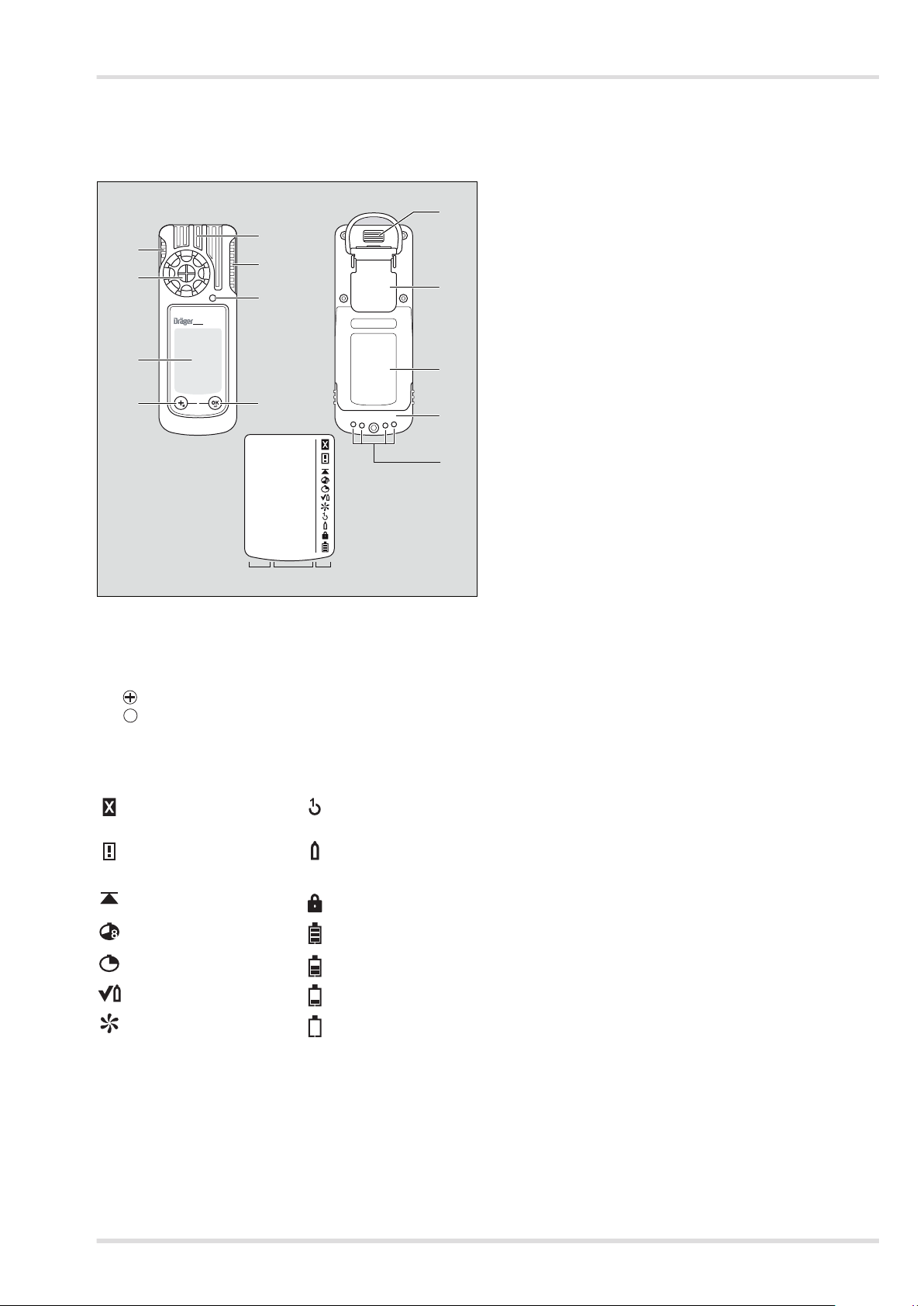

2.1 Product overview

1

2

X-am 5100

3

45

0

1

1

6

0.0

HCl ppm

7

8

9

10

11

2.2 Intended Use

Portable single gas detection instrument for the continuous

monitoring of the concentration of HCl, HF, H

in the ambient air within the working area and in explosionhazard areas.

or hydrazine

2O2

2.3 Intended operating area and operating conditions

2.3.1 Hazardous areas classified by zones

This instrument is intended for use in hazardous areas

classified as Zone 0, Zone 1 or Zone 2, or in mines in which

there is a danger of firedamp, in a temperature range of -20 °C

to +50 °C, and in areas where gases of explosion groups IIA,

IIB or IIC and temperature class T3 or T4 (depending on

batteries and rechargeable battery) may be present.

In mines, the instrument may only be used in areas with a low

risk of mechanical influence.

12 13 14

00133279.eps

1 Alarm LED 8 Fastening clip

2 Gas entry 9 Type plate

3 Display 10 Power pack

4 key 11 Charging contacts

OK

5 key 12 Measured gas display

6 Buzzer 13 Measured gas display

7 IR interface 14 Special symbols

Special symbols:

Fault message 1-button sensitivity

Warning message Standard sensitivity

Display peak value Password required

Show TWA Battery 100 % full

Show STEL Battery 2/3 full

Bump test mode Battery 1/3 full

Fresh air adjustment Battery empty

adjustment

adjustment

Dräger X-am 5100 5

Page 6

Description

2.4 Tests and Approvals

2.4.1 Marking

TC RU C-DE.ГБ06.В.00095

PO Ex ia l X

0 Ex ia IlC T4/T3 X

Dräger Safety Type: MQG 0020

23560 Lübeck, Germany

`

C

I M1/II 1G

Ex ia I/IIC T4/T3 Ma/Ga Um=4.6V Im=1.3A

BVS 10 ATEX E 080X IECEx BVS 10.0053X

Intrinsically safe Ex ia, CSA 11 1800517

CSA: Class I, Div. 1, Groups A,B,C,D TC T4/T3

-20°C Ta +50/+40°C: see Battery Pack!

For TC T4/T3: see Battery Pack!

Warning: Read manual for safety precautions.

Do not change or charge batteries in haz loc.

Serial No.

2.4.2 Permissible power packs

Power pack 83 22 237,

approved as Type ABT 0100

Temperature class T4

-20 °C ≤ Ta ≤ +50 °C

use with alkaline batteries

Duracell Procell MN1500

0158

Class I, Zone 0, A/Ex ia IIC T4/T3 /Ga

≤ ≤

1

on a separate label

2.4.3 Safety instructions

WARNING

!

Read the safety measures in the Instructions for Use.

Do not replace or charge batteries in potentially

explosive areas. Danger of explosion!

To reduce the danger of explosion, do not mix new

batteries with old batteries and do not mix batteries

made by different manufacturers.

Always disconnect the instrument from the power pack

before carrying out any maintenance operations.

Substitution of components may impair intrinsic safety.

High off-scale readings may indicate an explosive

concentration.

CAUTION

!

Not tested in oxygen enriched atmospheres (>21 % O2).

Only use power packs ABT 0100 (Order No,

83 22 237), HBT 0000 (Order No. 83 18 704) or

HBT 0100 (Order No. 83 22 244). See marking on

power pack for approved batteries and related

temperature class.

Temperature class T3

-20 °C Ta +40 °C

use with NiMH batteries

GP 180AAHC (1800 mAh)

use with alkaline batteries

Varta Powerone 4006

Varta Powerone 4106

Panasonic Powerline LR6

Power pack 83 18 704;

approved as HBT 0000

Temperature class T4

-20 °C ≤ Ta ≤ +50 °C

Power pack 83 22 244;

approved as HBT 0100

Temperature class T4

-20 °C ≤ Ta ≤ +50 °C

1 The year of manufacture is coded by the third capital letter of the serial number:

Y = 2007, Z = 2008, A = 2009, B = 2010, C = 2011, D = 2012, E = 2013, etc.

Example: Serial No. ARCH-0054: the third letter is C, so the year of

manufacture is 2011.

6 Dräger X-am 5100

Page 7

3 Use

Use

3.1 Preparations for use

Before using the instrument for the first time, the

enclosed batteries or a charged T4 NiMH power pack

(Order No. 83 18 704 / 83 22 244) must be inserted,

see "Replacing the batteries / rechargeable batteries" on

page 8.

The X-am-5100 is ready for operation.

3.1.1 Charging the rechargeable batteries

WARNING

!

Danger of explosion!

Do not charge underground or in explosion-hazard

areas!

The chargers are not designed in accordance with the

regulations for firedamp and explosion protection.

Charge power packs type HBT 0000 or HBT 0100 with

the appropriate Dräger charger. Charge single NiMH

cells for battery holder ABT 0100 in accordance with the

manufacturer's specifications. Ambient temperature

during the charging procedure: 0 to +40 °C.

NOTICE

i

i

Even if the instrument is not in use, Dräger

recommends that you store it in the charger

(chargermodule X-am 1/2/5000, Order No. 83 18 639).

To maintain the lifetime of the batteries, charging is only

performed within a temperature range of 5 to 35 °C.

Outside this temperature range, the charging is

automatically interrupted and resumes automatically after

the temperature is within the range again.

The charging time is typically 4 hours.

A new NiMH power pack reaches its full capacity after three

complete charging/discharging cycles.

Never store the instrument for extended periods without

being connected to a power source (maximum of 2 months)

because the internal buffer battery will drain.

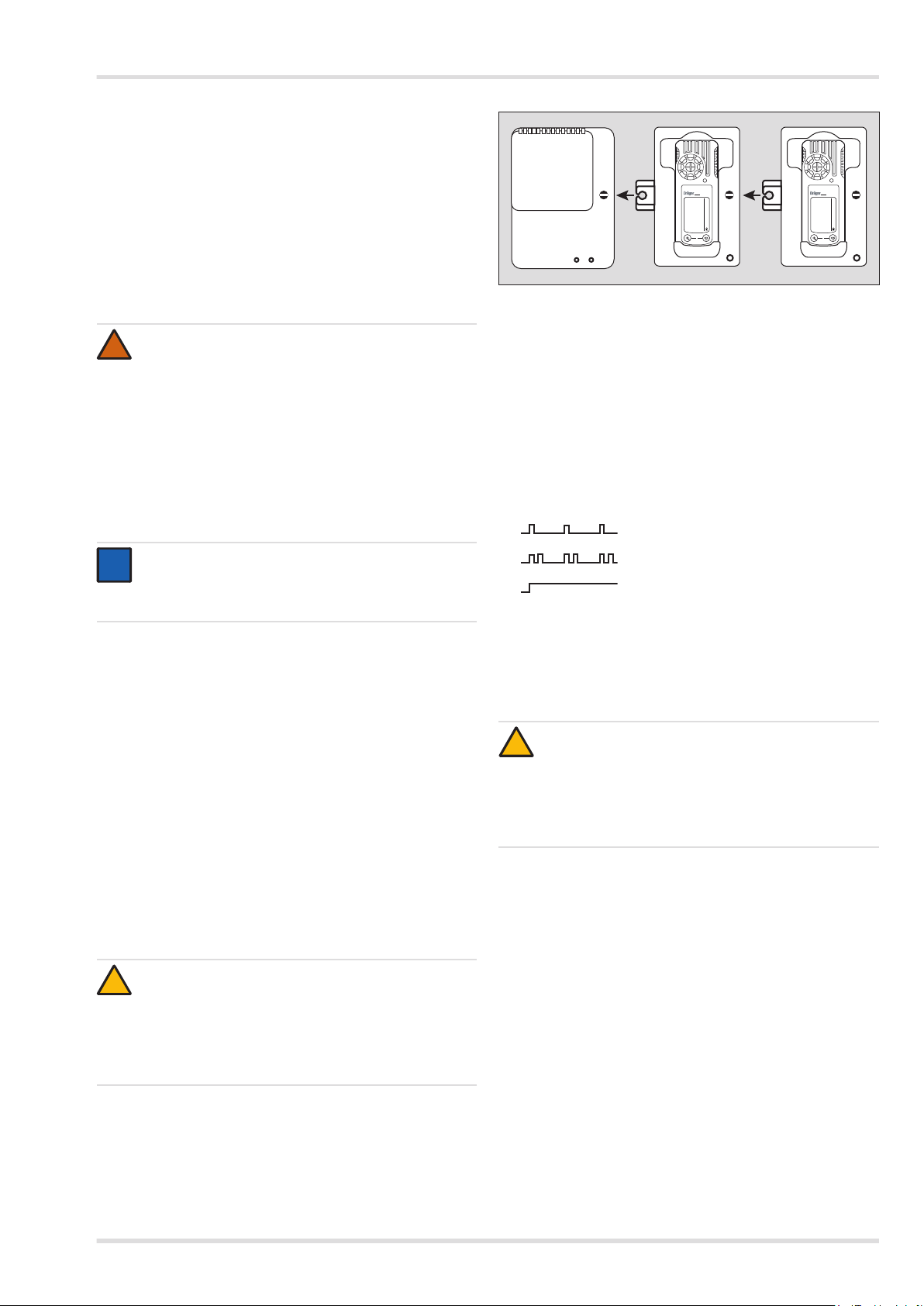

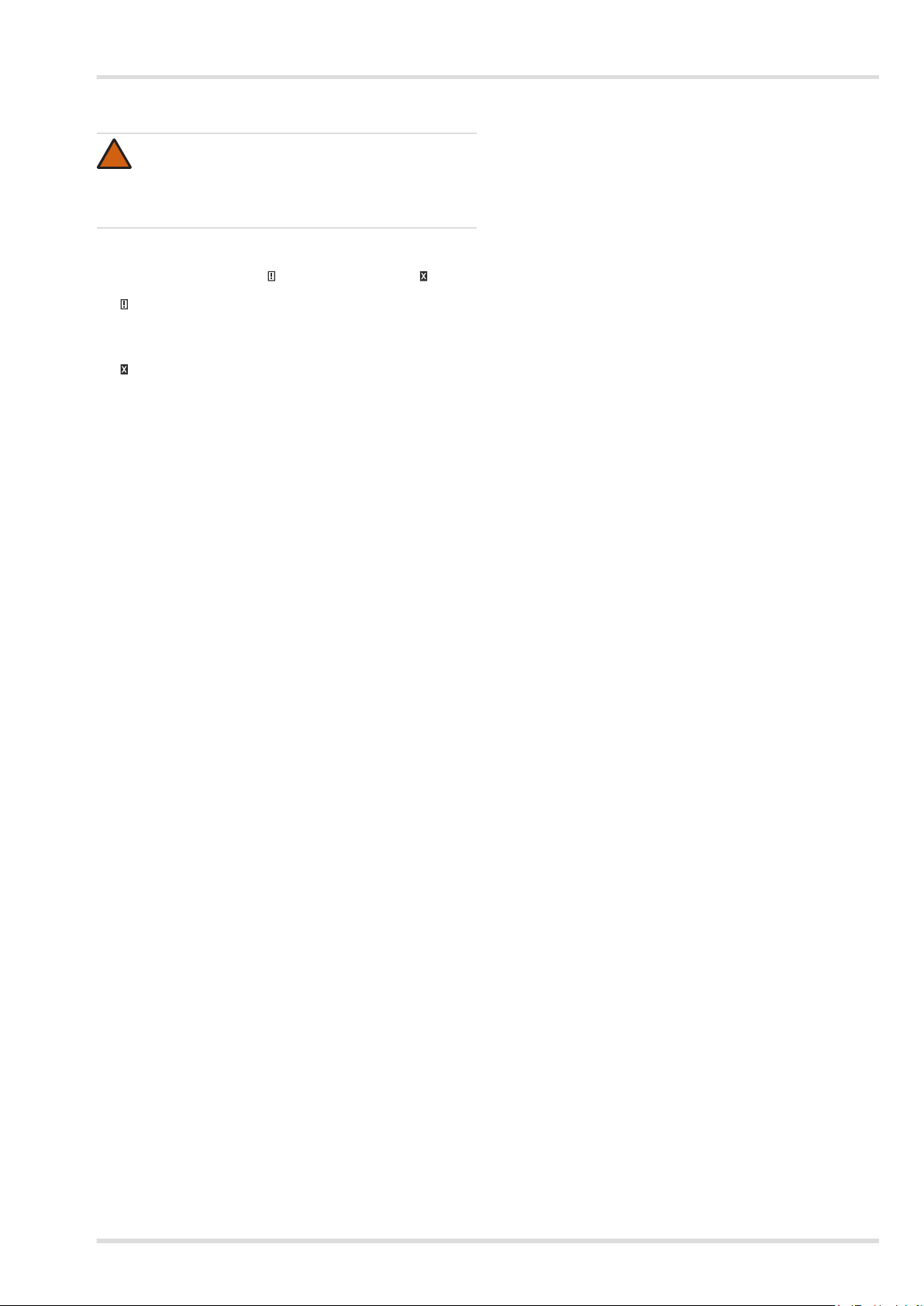

Charging with the multiple charging station

A maximum of 20 instruments can be charged at the same

time on the power pack (Order No. 83 18 805) of the

multiple charging station.

When attaching the charging modules, disconnect the

power pack from the mains supply!

CAUTION

!

Always connect or disconnect the charging modules

individually and not in groups in order to prevent the

charging station from becoming damaged. During

transportation, the power pack and the charging

modules should also always be handled individually

and without inserted instruments.

2

1

34 5 5

Position the instrument on an even and level surface.

X-am 5100

0.0 0.0

HCl ppm

0

2

1

HCl ppm

X-am 5100

0

1

00733280.eps

1. Turn the slots of the interlock into a horizontal position by

using a screwdriver or coin.

2. Insert the projecting tongue (2) of the charging module

(doubles as power feed) until it engages.

3. Close the lock (1) with a quarter turn (slot is positioned

vertically).

4. Attach additional charging modules in the same way.

5. Connect the power pack to the mains.

The green "Mains" LED (1) lights.

6. Insert the switched-off instrument into the charging module.

LED indicator (5) on the charger:

Charge

Fault

Full

If a fault occurs:

Remove the instrument from the charging module and

insert it again.

If the fault still occurs, have the charging module repaired.

It takes approx. 4 hours to fully charge an empty

rechargeable battery.

CAUTION

!

A short circuit of the charging contacts in the charging

modules, e.g., by metallic objects that have fallen in,

will not result in damage to the charging station.

It should, however, be avoided due to possible heating

hazards and incorrect displays on the charging

module.

In the event of a short circuit or if the power pack is

overloaded:

The red "Overload" LED (3) lights, and an audible alarm

sounds.

After the fault has been corrected, the alarm is switched

off automatically and the charging process is restarted.

In the event of a power failure, the instruments already

charged will be protected from discharging.

Dräger X-am 5100 7

Page 8

Use

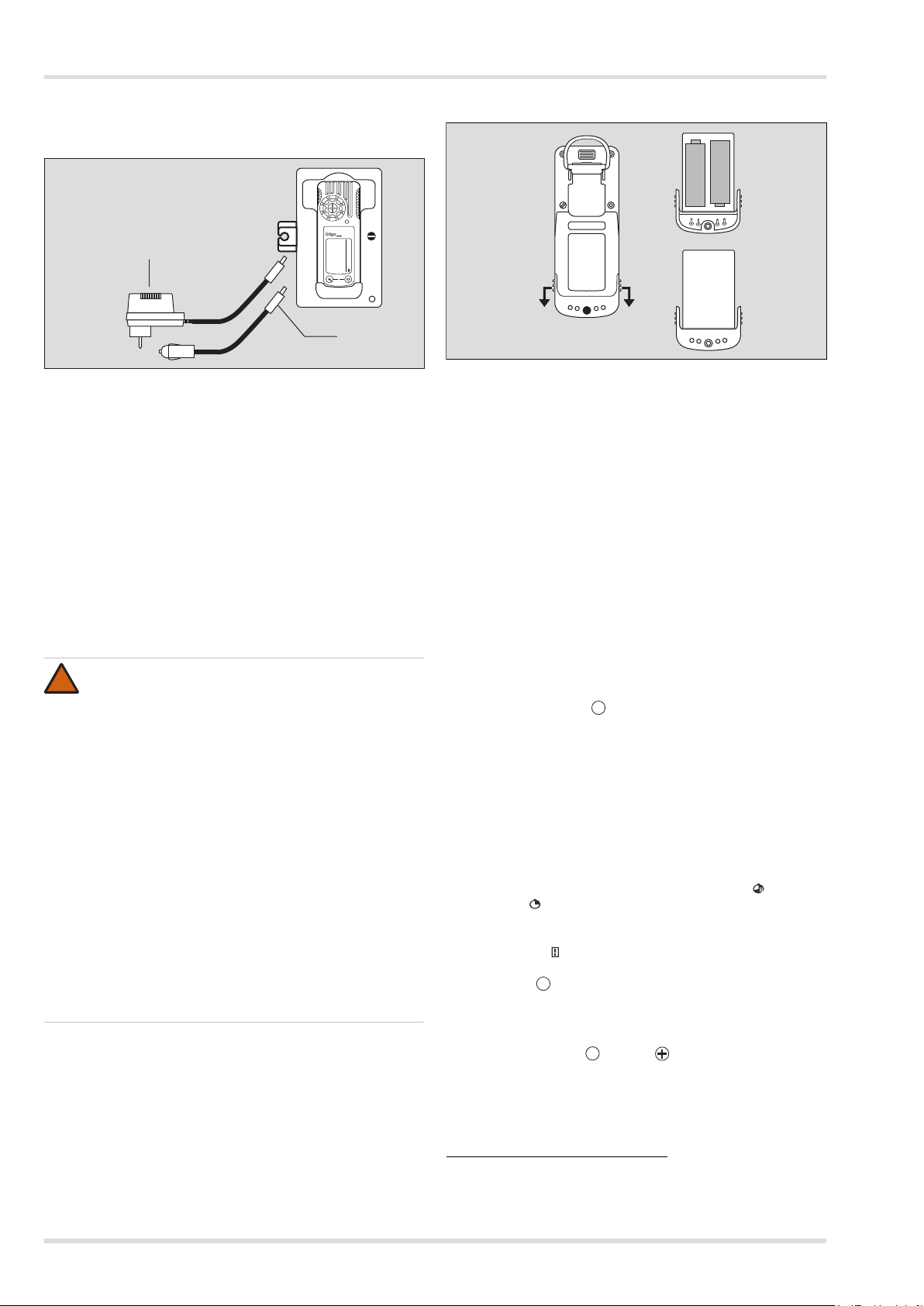

Charging with charger module and plug-in power pack or

vehicle charging adapter

–

+

2

+

–

83 16 994 (100 ... 240 V)

83 15 635 (100 ... 240 V)

HCl ppm

X-am 5100

0.0

0

45 30 057

00933280.eps

When the power pack is used (Order No. 83 16 994) up to

5 instruments, or with power pack (Order No. 83 15 635),

up to 2 instruments can be charged at the same time.

The power pack contained in the rechargeable battery and

charging set (Order No. 83 18 785) is suitable for charging

one instrument.

When the vehicle charging adapter is used (Order

No. 45 30 057) it is recommended that each charging

module is supplied separately.

The charging process is carried out analogue to charging

with the multiple charging station.

3.1.2 Replacing the batteries / rechargeable batteries

WARNING

!

Danger of explosion!

Do not replace the batteries / rechargeable batteries in

areas where there is a danger of explosion.

Do not throw used batteries into fire or try to open them

by force. Dispose of the batteries in accordance with

national regulations.

Batteries / rechargeable batteries are part of the Ex

approval.

Only the following types may be used:

Alkaline batteries – T4 – (not rechargeable)

Duracell Procell MN1500

Alkaline batteries – T3 – (not rechargeable)

Varta Powerone 4006

Varta Powerone 4106

Panasonic Powerline LR6

NiMH rechargeable batteries – T3 – (rechargeable)

GP 180AAHC (1800)

max. 40 °C ambient temperature.

3

1

00633280.eps

1. Switch off the instrument if necessary (see "Switching off

the instrument" on page 8).

2. Loosen the screw (2.0 mm hexagon socket) on the power

pack and remove the power pack.

3. Replace the alkaline batteries with new ones or the

rechargeable NiMHy batteries with charged ones – ensure

correct polarity.

4. Completely replace the T4 power pack (with sealed

rechargeable batteries, Order No. 83 18 704 / 83 22 244).

5. Insert the power pack into the instrument and tighten the

screw, the instrument switches on automatically.

After replacing the power pack T4, it is recommended that

a complete charging is carried out.

After the batteries have been replaced:

The settings and data are stored when the battery is

replaced. The sensors warm up again.

3.1.3 Switching on the instrument

1. Press and hold the key for approx. 3 seconds until the

countdown » 3 . 2 . 1 « shown in the display has elapsed.

All the display segments, including the visual, audible

and vibration alarms, are activated for a short time.

The software version is displayed.

The instrument performs a self test.

The next sensor to be calibrated is shown, together

with the days remaining until the next calibration, e.g.

» HCl ppm CAL 20 «.

The time until the bump test interval elapses is

displayed in days, e.g., » bt 123 «.

All alarm thresholds A1 and A2 as well as » « (TWA)

and » « (STEL)1, are displayed consecutively.

During the sensor warm-up period, the respective

display of the measured value flashes and the special

symbol » « (for warning) is displayed. No alarms are

issued during the sensor warm-up period.

2. Press the key to cancel the display of the activation

OK

sequence.

3.1.4 Switching off the instrument

1. Press and hold the key and key at the same time until

the countdown » 3 . 2 . 1 « shown in the display has

elapsed.

Before the instrument is switched off, the visual, audible

and vibration alarms are activated for a short time.

OK

OK

1

1 Only when activated in the instrument configuration. Delivery status: not

activated.

8 Dräger X-am 5100

Page 9

3.1.5 Before entering the workplace

WARNING

!

Before safety-related measurements, check the

calibration and recalibrate if necessary. A bump test

must be carried out in accordance with the national

regulations.

1. Switch on the instrument. The current measured values are

shown in the display.

Observe any warning » « or fault messages » «.

The instrument can be operated normally. If the warning

message does not disappear automatically during

operation, the instrument must be serviced after the end

of use.

The instrument is not ready to measure and requires

maintenance.

2. Check that the gas inlet opening on the instrument is

not covered.

Use

Dräger X-am 5100 9

Page 10

Use

3.2 Configuration

3.2.1 Standard gas configuration

Alarm A1

1

Alarm A2

1

DrägerSensor Measuring range

XS EC HF/HCI [ppm]

2

XS EC H2O2 [ppm]

XS EC N2H4 [ppm]

1 Different settings can be selected to meet customer requirements on delivery. The current setting can be checked and changed with the Dräger CC Vision

software. A version of the CC-Vision software that can be used for Dräger X-am 5100 is available for download from the product page for the X-am 5100 at the

following web address: www.draeger.com

2 Valid for HCl.

0 to 30 5 Yes No 10 No Yes

0 to 20 1 Yes No 2 No Yes

0 to 3 0.1 Yes No 0.2 No Ye s

3.2.2 Standard instrument configuration

1

threshold

1

3.2.3 Configuring the instrument

can be acknowledged

self-latching

threshold

can be acknowledged

To customise its configuration, the instrument must be

Dräger X-am 5100

Bump test mode Quick bump test

connected to a PC with the USB-DIRA adapter (Order

No. 83 17 409). Dräger CC-Vision PC software is used to

perform the configuration.

Fresh air adjustment On

Life signs (visual only) On

Disabling permitted / blocked for A2

Averaging time 15 minutes for STEL

8 hours for TWA

0

IR

X-am 5100

USB 1.1

self-latching

1 Different settings can be selected to meet customer requirements on

delivery. The current setting can be checked and changed with the

Dräger CC Vision software.

00433280.eps

Changing the standard configuration

The installed Dräger CC Vision PC software is used for

configuration.

Observe the documentation and online help of the software.

A version of the CC-Vision software that can be used for

Dräger X-am 5100 is available for download from the

product page for the X-am 5100 at the following web

address: www.draeger.com.

Reading the database and displaying it Graphically

The installed PC software Dräger GasVision is used for

reading and displaying the database.

Observe the documentation and online help of the software.

Changing the configuration: See “Troubleshooting” on

page 19.

WARNING

!

After a basic initialization has been carried out with

the Dräger CC Vision PC software, individual alarm

settings may have been changed.

10 Dräger X-am 5100

Page 11

Use

3.3 Performing the bump test

3.3.1 Manual testing without documentation of results in

1. Prepare a test gas source (e.g., cylinder, permeation oven);

2. Fit the calibration adapter

3. Connect the test gas

4. Vent the test gas into

5. Switch on the instrument.

6. Open the valve on the test gas source to let test gas flow

7. Recommendation: Wait until the instrument displays the

8. Close the valve on the test gas source.

If the concentration has now fallen under the A1 alarm

If the displays are outside of the above-mentioned ranges:

3.3.2

The "Quick bump test" or the "Extended bump test" is

Setting on delivery: Quick bump test.

the instrument memory

NOTICE

i

i

Sensor-specific features affecting the bump test are

described in the respective sensor data sheets.

the volume flow must be 0.5 L/min and the gas

concentration must be higher than the alarm threshold

concentration to be tested.

(68 06 291) to the sensor

cap.

source to the calibration

adapter.

a fume cupboard or into

0

x-am 5100

the open air (with a hose

connected to the second

connector of the calibration

adapter).

00533280.eps

WARNING

!

Never inhale the test gas. Danger to health!

Observe the hazard warnings in the relevant Safety

Data Sheets.

over the sensor.

test gas concentration with sufficient tolerance.

However, wait at least until alarm threshold A1 or A2 has

been exceeded.

If the alarm thresholds are exceeded, the instrument

displays the gas concentration in alternation with » A1 «

or » A2 « depending on the test gas concentration.

threshold:

Acknowledge the alarm.

Calibrate the instrument, see "Calibrating the instrument"

on page 15.

Bump test with documentation of results in the instrument memory.

selected using the Dräger CC Vision PC software. The

"Quick bump test" checks whether the gas concentration

has exceeded the Alarm 1 threshold (with oxygen, the

check is whether the concentration has fallen below the

Alarm 1 threshold). The "Extended bump test" checks

whether the gas concentration has exceeded the Alarm 1

threshold (with oxygen, the check is whether the

concentration has fallen below the Alarm 1 threshold) and

whether the gas concentration has reached the preset

bump test concentration.

1. Prepare a test gas source (e.g., cylinder, permeation oven);

the volume flow must be 0.5 L/min and the gas

concentration must be higher than the alarm threshold

concentration to be tested.

2. Fit the calibration adapter

(68 06 291) to the sensor

cap.

3. Connect the test gas

source to the calibration

adapter.

4. Vent the test gas into

a fume cupboard or into

0

x-am 5100

the open air (with a hose

connected to the second

connector of the calibration

adapter).

00533280.eps

WARNING

!

Never inhale the test gas. Danger to health!

Observe the hazard warnings in the relevant Safety

Data Sheets.

5. Switch on the instrument.

6. Call up the Quick Menu and select the bump test,

see "Quick Menu" on page 13.

The current gas

concentration values

and the special symbol

» « (for bump test)

flash.

7. Press the key to start

the bump test.

OK

HCl ppm

8. Open the valve on the test

gas source to let test gas

flow over the sensor.

If gas concentration

exceeds the alarm

thresholds A 1 the

10433280.eps

corresponding alarm will

occur.

If a gas alarm (Quick

bump test) is triggered or

the preset bump test

concentration (Extended

bump test) is reached

within the specified time:

The display containing the

OK

HCl ppm

current gas concentration

changes with the display

» OK «.

The bump test that was

carried out is documented

with the result and date in

10533280.eps

the instrument memory.

9. Close the valve on the test

gas source.

If the concentration has now fallen below the A1 alarm

threshold, the instrument returns to the measuring mode.

If the set bump test concentration is not reached after a

sensor-specific time interval, an instrument error is

generated.

Dräger X-am 5100 11

Page 12

Use

3.4 During use

CAUTION

!

To ensure correct measurement operation, the gas

inlet opening on the instrument must not be covered

or dirty.

The sensor cap must not be twisted.

During operation, the measured values for the measured

gas are displayed.

If a measuring range is exceeded or a negative drift occurs,

the following displays are shown instead of the measured

value display:

» «

» «

In the event of an alarm, the corresponding displays,

including the visual, audible and vibration alarms, are

activated, see "Identifying Alarms" on page 12.

i

i

(Too high concentration) or

(Negative drift).

NOTICE

Special states in which there is no measuring

operation (quick menu, calibration menu, warm-up of

sensors, password input) are indicated by a visual

signal (slow flashing of the alarm LED

).

In the case of A2, a double tone is audible and the alarm

LED flashes twice.

After leaving the area, if the concentration is less than the

alarm threshold A2:

Press the key. The alarm messages are switched off.

OK

3.5.3 STEL / TWA exposure alarm

WARNING

!

Leave the area immediately. After this alarm,

the deployment of personnel is subject to the relevant

national regulations.

The alarm is indicated by an intermittent alarm

message:

Display » A2 « and » « (STEL) or » « (TWA) and

measured value alternating:

The STEL and TWA alarm cannot be acknowledged

or cancelled.

Switch off the instrument. The values for the exposure

evaluation are deleted after the instrument is switched

on again.

3.5.4 Battery pre-alarm

The alarm is indicated by an intermittent alarm

message:

Flashing special symbol » « on the right

side of the display:

3.5 Identifying Alarms

An alarm is displayed visually, audibly and through vibration in

a specific pattern.

3.5.1 Concentration pre-alarm A1

The alarm is indicated by an intermittent alarm

message:

Display » A1 « and measured value alternating.

The pre-alarm A1 is not self-latching and stops when the

concentration has dropped below the alarm threshold A1.

In the case of A1 a single tone is audible and the alarm

LED flashes.

Acknowledging the pre-alarm:

Press the key. Only the audible alarm and the vibration

alarm are switched off.

3.5.2 Concentration main alarm A2

!

The alarm is indicated by an intermittent alarm

message:

Display » A2 and measured value alternating.

OK

WARNING

Danger to life! Leave the area immediately. A main

alarm is self-latching and cannot be acknowledged or

cancelled.

Acknowledging the pre-alarm:

Press the key. Only the audible alarm and the vibration

OK

alarm are switched off.

The battery lasts for at least another 20 minutes after the

first battery pre-alarm.

3.5.5 Battery main alarm

The alarm is indicated by an intermittent alarm

message:

Flashing special symbol » « on the right side

of the display:

The battery main alarm cannot be acknowledged or cancelled:

The instrument is automatically switched off again after

10 seconds.

Before the instrument is switched off, the visual, audible

and vibration alarms are activated for a short time.

3.5.6 Instrument alarm

The alarm is indicated by an intermittent alarm

message:

Special symbol » « displayed on the right

side of the display:

The instrument is not ready for operation.

For remedies, see "Troubleshooting" on page 19 to page 20.

Commission maintenance personnel or DrägerService to

rectify the error.

12 Dräger X-am 5100

Page 13

Menu functions

4 Menu functions

4.1 Calling the Info Mode

In measuring mode, press the key for approx. 3 seconds.

If any warning or fault messages are present, the

corresponding information or error codes are displayed

(see "Troubleshooting" on page 19 to page 20).

Press the key successively for the next display.

The peak values and the exposure values TWA

STEL

OK

1

are displayed.

Warning messages are displayed. Numerical codes

of warning messages: see "Warning messages" on

page 19.

OK

key

Fault messages are displayed. Numerical codes of

fault messages: see "Fault messages" on page 20.

OK

key

The peak values = the maximum measured values

are displayed.

OK

key

The average values of the exposures based on

a shift of, e.g., 8 hours (TWA) are displayed

OK

key

The short-term values (STEL) = average values of

the concentrations over the average value duration

are displayed

OK

key

The instrument is in measuring mode again

If no key is pressed for 10 seconds, the instrument reverts

automatically to measuring mode.

OK

1

and

4.3 Quick Menu

4.3.1 Quick menu functions

Bump test, see "Performing the bump test" on page 11.

Fresh air adjustment, see "Performing a fresh air

adjustment" on page 15.

Display and deletion of the peak values, see "Quick

menu "Displaying and deleting peak values"" on

page 13.

4.3.2 Calling the Quick Menu

The fresh air adjustment and the bump test are activated in the

quick menu on delivery. The function for displaying and

deleting peak values can additionally be activated with the

Dräger CC Vision PC software.

1. In measuring mode, press the key three times.

If functions in the quick menu have been activated using

the Dräger CC-Vision PC software, you can select these

functions using the key. If no functions have been

activated in the quick menu, the instrument remains in

measuring mode.

2. You can select the activated functions of the quick menu by

pressing the key.

Press the key to call the selected function.

Press the key to cancel the active function and to

switch to measuring mode.

If no key is pressed for 60 seconds, the instrument

reverts automatically to measuring mode.

4.3.3 Quick menu "Displaying and deleting peak values"

After the function has been

selected, the current peak

values are displayed;

the special peak values

symbol appears in the

display at the same time.

OK

12

HCl ppm

4.2 Calling the Info-Off Mode

When the instrument is in a deactivated state, press the

key.

The name of the gas, measuring unit and measuring

range limit value are displayed.

Pressing the key again exits the Info Off mode (or via

OK

timeout).

1. The peak values can be

deleted by pressing the

OK

key for 5 seconds.

The next display appears.

2. Press the key to end

OK

the function.

HCl ppm

1 Only when activated in the instrument configuration. Delivery status:

not activated.

Dräger X-am 5100 13

10133280.eps

0

10233280.eps

Page 14

Menu functions

4.4 Adjustment menu

4.4.1 Functions of the adjustment menu

Fresh air adjustment, see "Performing a fresh air

adjustment" on page 15

1-button sensitivity adjustment

Standard sensitivity adjustment

4.4.2 Calling the adjustment menu

The adjustment menu can only be accessed by entering

a password.

Password on delivery: » 001 «

The default password on delivery can be changed using

the PC software Dräger CCVision.

1. In measuring mode, press the key for at least 5 seconds.

The function for entering the password is selected.

The special symbol » « (for the "Enter password"

function) is displayed.

The display shows » 000 «, with the first digit flashing.

2. Use the key to set the

flashing digit.

3. Press the key, the

second digit starts flashing.

4. Use the key to set the

flashing digit.

5. Press the key, the third

digit starts flashing.

6. Use the key to set the

flashing digit.

7. Press the key to

confirm the password once

it has been set completely.

OK

000

OK

OK

10333280.eps

8. The adjustment menu

functions can now be selected by pressing the key.

Press the key to call the selected function.

Press the key to cancel the active function.

If no key is pressed for 10 minutes, the instrument

OK

reverts automatically to measuring mode.

14 Dräger X-am 5100

Page 15

Calibrating the instrument

5 Calibrating the instrument

WARNING

!

Always adjust the zero point first, before the sensitivity.

Otherwise the adjustment will be incorrect!

Adjustment may not be possible due to instrument and

channel errors.

Allow the sensor to warm up before the adjustment.

Warm-up time: see Instructions for Use/data sheet for the

installed DrägerSensor.

5.1 Adjustment interval:

Observe the relevant specifications in the Instructions for

Use/data sheet for the DrägerSensor installed.

For critical applications according to EN 60079-29-2

EN 45544-4

Improvement of zero point accuracy – perform a fresh air

2

and national regulations.

adjustment, see "Performing a fresh air adjustment" on

page 15.

5.2 Performing a fresh air adjustment

A fresh air adjustment can be performed to improve the zero

point accuracy.

Calibrate the instrument to fresh air, free of measured

gases or other interfering gases.

The zero point of the sensor is set to 0 during the fresh

air calibration.

Sensors that are faulty or not warmed-up will prevent the

adjustment.

In the case of sensors which are in the warm-up phase,

the message » 159 « is displayed with the special

symbol » « (for warning message).

In the case of a sensor or instrument error, the

message » 109 « is displayed with the special symbol

» « (for a fault message).

The message is cleared after 5 seconds and the

function is available again in the menu.

1. Switch on the instrument.

2. Depending on instrument configuration:

Call up the Quick Menu and select the fresh air

adjustment function » «, see "Quick Menu" on

page 13.

or

Call up the Adjustment menu and select the fresh air

adjustment function » «, see "Adjustment menu" on

page 14.

1

or

The measured values

flash.

When the measured

values have stabilized:

3. Press the key to

OK

carry out the fresh air

adjustment.

The display containing the

current gas concentration

changes with the display

» OK «.

4. Press the key to exit

OK

the calibration or wait for

approx. 5 seconds.

If a fault has occurred

during the fresh air adjustment:

The fault message » «

appears and » « is

displayed for the respective

sensor instead of the

measured value.

In this case, repeat the

fresh air adjustment.

If necessary, replace the

sensor, see "Replacing

the Sensors" on page 18.

HCl

ppm

0.0

OK

HCl ppm

HCl ppm

--

10733280.eps

10833280.eps

10933280.eps

1 EN 60079-29-2 – Guidelines for selection, installation, use and maintenance

of instruments for the detection and measurement of flammable gases and

oxygen.

2 EN 45544-4 – Electrical instruments for the direct detection and direct

concentration measurement of toxic gases and vapors – Part 4:

Guidelines for selection, installation, use and maintenance.

Dräger X-am 5100 15

Page 16

Calibrating the instrument

5.3 Performing a sensitivity adjustment

The sensitivity adjustment can optionally be performed by the

standard or by the 1-button method.

5.3.1 Standard sensitivity adjustment

CAUTION

!

Never inhale the test gas. Danger to health!

Observe the hazard warnings of the relevant Safety

Data Sheets.

NOTICE

i

i

To minimise adsorption effects, keep the length of the

hose as short as possible (maximum hose length: 1 m).

Dräger recommends using PTFE hoses.

During the sensitivity calibration, the sensitivity of the sensor is

set to the value of the test gas.

1. Fit the calibration adapter

(68 06 291) to the sensor

cap.

2. Connect the test gas

source to the calibration

adapter.

3. Vent the test gas into

a fume cupboard or into

0

the open air (with a hose

connected to the second

connector of the calibration

adapter).

4. Switch on the instrument.

5. Call up the adjustment menu, enter the password

and select the standard sensitivuty adjustment » «,

see Chapter 4.4.2 on page 14.

6. Press the key to start

the sensitivity calibration.

The name of the gas

OK

HCl

ppm

flashes.

7. Confirm with the key.

The calibration gas

OK

concentration is

displayed.

8. Press the key to

OK

confirm the calibration

gas concentration or use

the key to change

the calibration gas

concentration and

complete the process by pressing the key.

The set calibration gas concentration flashes.

9. Press the key to confirm the set value.

OK

10. Open the valve on the test gas source to let test gas flow

over the sensor.

The currently displayed measured values start to flash.

The displayed measured values change to the values

according to the gas supplied.

x-am 5100

00533280.eps

0.0

11033280.eps

OK

When the calibration is complete:

The display of the

current gas concentration

alternates with the » OK «

display.

12. Press the key or wait

for 5 seconds to quit the

calibration.

The instrument

OK

OK

HCl ppm

changes to the

measuring mode.

13. Close the valve on the test

gas source.

11133280.eps

If a fault has occurred during the sensitivity calibration:

The fault message » «

appears and » « is

displayed for the respective

sensor instead of the

measured value.

In this case, repeat the

sensitivity adjustment.

If necessary, change the

HCl ppm

--

sensor, see "Changing

sensors" on page 18.

11233280.eps

When the measured value is stabilized:

11. Press the key to carry out the calibration.

OK

16 Dräger X-am 5100

Page 17

Calibrating the instrument

5.3.2 1-button sensitivity adjustment

CAUTION

!

Never inhale the test gas. Danger to health!

Observe the hazard warnings of the relevant Safety

Data Sheets.

NOTICE

i

i

To minimise adsorption effects, keep the length of the

hose as short as possible (maximum hose length: 1 m).

Dräger recommends using PTFE hoses.

During the 1-button sensitivity adjustment, the sensitivity of the

sensor is set to the value of the test gas.

Using the Dräger CC Vision PC software, the preset

concentration values of the test gas cylinder used must be

changed in the instrument to the target values of the mixed

gas used.

1. Fit the calibration adapter

(68 06 291) to the sensor

cap.

2. Connect the test gas

source to the calibration

adapter.

3. Vent the test gas into

a fume cupboard or into

0

x-am 5100

the open air (with a hose

connected to the second

connector of the calibration

adapter).

00533280.eps

4. Switch on the instrument.

5. Call the calibration menu, enter the password and select

the 1-button sensitivity adjustment function » «,

see Chapter 4.4.2 on page 14.

6. Press the key to start

the sensitivity calibration.

7. Open the valve on the test

OK

HCl

ppm

0.0

gas source to let test gas

flow over the sensor.

The currently displayed

measured values start

to flash.

The flashing stops after

a static measured value

has been reached.

The adjustment is

now carried out

11333280.eps

automatically.

The displayed measured values change to the values

according to the gas supplied.

The automatic stability monitoring can be terminated by

pressing the key. A calibration then takes place

OK

immediately.

When the calibration is complete and the displayed

measured values have stabilized:

The display of the current

gas concentration

alternates with the » OK «

display.

8. Press the key or wait

for 5 seconds to quit the

calibration.

The instrument

OK

OK

HCl ppm

changes to the

measuring mode.

9. Close the valve on the test

gas source.

If a fault has occurred during the 1-button sensitivity

adjustment:

The fault message » «

appears and » « is

displayed for the respective

sensor instead of the

measured value.

In this case, repeat the

sensitivity adjustment.

If necessary, change the

HCl ppm

--

sensor, see "Changing

sensors" on page 18.

11433280.eps

11533280.eps

Dräger X-am 5100 17

Page 18

Replacing the Sensors

6 Replacing the Sensors

1. Connect the instrument to the PC with the USB-DIRA

adapter (Order No. 83 17 409).

0

X-am 5100

IR

USB 1.1

00433280.eps

2. Deactivate the slot using the CC-Vision PC software.

3. 4 screws on the lower shell should now be unfastened.

4. Carefully release the upper shell upwards from the

lower shell. Do not tilt the upper shell when doing this.

00133280.eps

NOTICE

i

i

When the upper shell is being released, it is possible

that the DrägerSensor will be pulled out of its mount at

the same time and remain in the upper shell.

5. Follow the remaining instructions in the CC Vision PC

software.

18 Dräger X-am 5100

Page 19

Troubleshooting

7 Troubleshooting

Fault Cause Remedy

Not possible to switch on

the instrument

Not possible to switch off

the instrument

Display » – – « Measuring range calibrated incorrectly Recalibrate the measuring range,

To display the numerical codes of the warning and fault messages in the info mode, see "Calling the Info Mode" on page 13.

7.1 Warning messages

Discharge the power pack Charge the power pack, see "Charging the

Discharge the alkaline batteries Insert new alkaline batteries, see "Replacing

The instrument is not set to measuring

mode

The instrument is configured to "Disable

prohibited"

Electronics or sensors defective Must be repaired by DrägerService.

rechargeable batteries" on page 7.

the batteries / rechargeable batteries" on

page 8.

Select measuring mode.

Configure the instrument to "Disable allowed"

with Dräger CC Vision.

see "Calibrating the instrument" on page 15.

Special symbol » « and

displayed numerical code:

152

153

154

155

159

351

352

353

354

355

356

Cause Remedy

Customer's service life counter about

to elapse

Database 90 % full Read the database soon and then clear

Database full Read the database and clear memory.

Interval for the bump test has elapsed Carry out the bump test, see "Performing the

Adjustment not possible. The menu

function cannot be carried out because

of a message which is preventing the

function (e.g., sensors in warm-up phase).

DrägerSensor XS EC1 in the warm-up

phase

DrägerSensor XS EC1 in the warm-up

phase

EC1 concentration has drifted into the

negative range

The temperature is too high Operate the instrument within the allowed

The temperature is too low Operate the instrument within the allowed

The calibration interval for DrägerSensor

XS EC1 has elapsed

Reset the service life counter using

Dräger CC Vision.

the memory.

bump test" on page 11.

Identify the message code via the info menu

and switch off, if necessary.

Wait until warm-up time is complete.

Wait until warm-up time is complete.

Perform a fresh air calibration,

see "Performing a fresh air adjustment" on

page 15.

temperature range.

temperature range.

Perform a sensitivity adjustment for

DrägerSensor XS EC1, see "Calibrating the

instrument" on page 15.

Dräger X-am 5100 19

Page 20

Troubleshooting

7.2 Fault messages

Special symbol » « and

displayed numerical code:

102 The customer's service life counter

103 The instrument is defective The instrument must be repaired by

104 Check sum error program code The instrument must be repaired by

105 The bump test interval has elapsed Carry out the bump test, see "Calibrating the

106 The calibration interval has elapsed

107 Bump test error Perform bump test, see "Performing the

108 The instrument is defective The instrument must be repaired by

109 The menu function cannot be carried out

301 No valid zero point adjustment of the

302 No valid sensitivity adjustment of the

303 The measured value of DrägerSensor XS

304 Dräger Sensor XS EC1 not inserted or

305 Error during bump test of Dräger Sensor

326 Error during accelerated warm-up of

Cause Remedy

has elapsed

(at least 1 calibration interval has elapsed)

because of an error.

Dräger Sensor XS EC1

Dräger Sensor XS EC1

EC 1 is in the negative range

defective

XS EC1

Dräger Sensor XS EC1

Reset the service life counter using Dräger

CC Vision.

DrägerService.

DrägerService.

instrument" on page 15.

Perform a sensitivity adjustment,

see "Calibrating the instrument" on page 15.

bump test" on page 11, or snsitivity

adjustment, see "Calibrating the instrument"

on page 15.

DrägerService.

Identify the error code via the info menu

and switch off, if necessary.

Perform a fresh air calibration,

see "Performing a fresh air adjustment" on

page 15.

Perform sensitivity adjustment or fresh air

adjustment, see "Calibrating the instrument"

on page 15.

Perform a fresh air calibration,

see "Performing a fresh air adjustment" on

page 15.

Check DrägerSensor XS EC1,

see "Replacing the Sensors" on page 18.

Repeat bump test. If necessary, adjust or

replace the Dräger Sensor XS EC1,

see "Replacing the Sensors" on page 18.

Remove the power pack and insert it again or

replace the sensor. Sensor must not be

exposed to gas during the first 5 minutes.

20 Dräger X-am 5100

Page 21

8 Maintenance

8.1 Maintenance intervals

The instrument should be inspected and maintained by

suitably qualified persons annually (consult: EN 45544-4 –

Electrical apparatus used for the direct detection and direct

concentration measurement of toxic gases and vapours - Part

4: Guide for selection, installation, use and maintenance and

national regulations).

Calibration intervals: see Instructions for Use for the respective

DrägerSensors.

Depending on instrument configuration:

Replace the alkaline batteries, see "Replacing the

batteries / rechargeable batteries" on page 8 or charge

the battery see "Charging the rechargeable batteries"

on page 7 – after each use, at the latest after the battery

alarm has been triggered or after 2 weeks.

Calibrate the instrument – see "Calibrating the instrument"

on page 15.

In regular intervals, according to the sensors used and

the operating conditions. For sensor-specific calibration

data, refer to the Instructions for Use/data sheets for the

Dräger sensors used

Before you carry out safety-related relevant

measurements, the zero point and sensitivity of the

instruments should be tested in accordance with

national regulations.

Inspection by suitably qualified persons – every year.

The inspection intervals must be established in each

individual case and shortened if necessary, depending

on safety related considerations, engineering conditions

and the technical requirements of the equipment.

Dräger recommend that a service agreement be

concluded with Dräger Service and that repairs also be

carried out by them.

Replace the sensors, see "Replacing the Sensors" on

page 18 – if necessary, when it is no longer possible to

adjust them.

1

.

Maintenance

8.2 Cleaning

CAUTION

!

Abrasive cleaning implements (brushes etc.), cleaning

agents and cleaning solvents can destroy the dust and

water filters.

The instrument does not need any special care.

If the instrument is very dirty, clean it with a cloth.

1 Instructions for Use/data sheets for the utilized sensors and the PC software

CC-Vision for Dräger X-am 5100 can be downloaded on the product page

of the X-am 5100 at the following Internet address: www.draeger.com. See

also the enclosed Instructions for Use and data sheets for the sensors used.

Dräger X-am 5100 21

Page 22

Disposal

9 Disposal

9.1 Disposal of electrical and electronic

appliances

This product must not be disposed of as municipal waste.

This is indicated by the adjacent icon.

You can return this product to Dräger free of charge. For

information please contact the national sales organisations

and Dräger.

Batteries and rechargeable batteries must not be disposed of

as municipal waste. This is indicated by the adjacent icon.

Collect and dispose of batteries and rechargeable batteries at

battery collection centres, in accordance with applicable

regulations.

9.2 Electrochemical sensors

WARNING

!

Acid burn risk!

Do not throw them into fires or use force to open them.

As for batteries, only dispose of as special waste in

accordance with local waste disposal regulations.

Further information can be obtained from the relevant

local authority and from appropriate waste disposal

companies.

22 Dräger X-am 5100

Page 23

10 Technical Data

Ambient conditions:

During operation and storage -20 to +50 °C

Instrument data

Protection class IP 54 for instruments with sensors

Alarm volume Typically 90 dB (A) in 30 cm distance

Operation time (with 24 hours' use per day, 1 minute alarm per day)

Alkaline battery

(Order No.

83 20 240 / 83 22 239)

NiMH rechargeable battery

(Order No. 83 18 704)

NiMH HC rechargeable battery

(Order No. 83 22 244)

Dimensions approx. 130 mm x 48 mm x 61 mm (H x W x D)

Weight approx. 220 g to 250 g

CE markings Electromagnetic compatibility (Directive 2004/108/EC)

Approvals: See “Description” on page 5.

Sensor data: See data sheets for the sensors used.

(-20 to +40 °C for NiMH Type 180AAHC single cells and T3 alkaline batteries)

700 to 1300 hPa

10 to 90 % (short-term up to 95 %) relative humidity

Typically 180 hours

Typically 150 hours

Typically 180 hours

Explosion protection (Directive 94/9/EC)

Technical Data

Dräger X-am 5100 23

Page 24

Ordering list

11 Ordering list

Name and Description

Order No.

Dräger X-am 5100 83 22 750

Power supply units:

NiMH power pack T4 83 18 704

NiMH power pack HC T4 83 22 244

Alkaline power pack T3/T4

(without alkaline batteries)

Alkaline batteries T4 (2 ea.)

1

83 22 237

83 20 240

for alkaline power pack

Alkaline batteries T3 (2 ea.)

83 22 239

for alkaline power pack

Rechargeable battery and charging set

83 18 785

(includes NiMH T4 power pack,

charging module for Dräger

X-am 1/2/5000 and plug-in power pack)

Chargers:

Charging module for Dräger X-am 1/2/5000 83 18 639

Power pack with connecting cord (worldwide)

83 15 805

for a maximum of 20 Dräger

X-am 1/2/5000 charging modules)

Plug-in power pack (worldwide)

83 16 994

for a maximum of 5 Dräger

X-am 1/2/5000 charging modules)

Plug-in power pack (worldwide)

83 15 635

for a maximum of 2 Dräger

X-am 1/2/5000 charging modules)

Vehicle connecting line 12 V/24 V

45 30 057

for Dräger X-am 1/2/5000 charging module

Vehicle installation set

83 18 779

for 1 Dräger X-am 1/2/5000 charging module

Additional strap for vehicle mounting bracket 83 18 788

1 The T3/T4 alkaline power pack (Order No. 83 18 703) is not a subject of the

BVS 08 ATEX G 002 X and PFG 08 G 001 certificates.

Name and Description

Order No.

Accessories for measured value

acquisition and configuration:

Dräger GasVision 83 14 034

Dräger CC Vision 64 08 515

PC communications set for 1 Dräger

83 18 761

X-am 1/2/5000 with USB port and

Dräger CC Vision

PC communications set for 2 Dräger

83 18 762

X-am 1/2/5000 with USB port,

Dräger CC Vision and bar code reader

USB DIRA with USB cable (USB infrared

83 17 409

adaptor for communication Dräger X-am

1/2/5000 – PC)

Calibration/adjustment accessories:

Test gas cylinder 10 ppm HCl 68 12 107

Test gas cylinder 10 ppm SO

2

68 10 645

On demand controller 83 16 556

Standard controller 68 10 397

Calibration adapter 68 06 291

Sensors:

DrägerSensor XS EC HF/HCl 68 09 140

DrägerSensor XS EC H2O

DrägerSensor XS EC N2H

2

4

68 09 170

68 09 190

24 Dräger X-am 5100

Page 25

12 Declaration of Conformity

Declaration of Conformity

Dräger X-am 5100 25

Page 26

Page 27

Page 28

Dräger Safety AG & Co. KGaA

Visit: www.thesafetyequipmentstore.com or besafe@thesafetyequipmentstore.com for sales and service.

Revalstraße 1

23560 Lübeck, Germany

Tel +49 451 882 0

Fax +49 451 882 20 80

www.draeger.com

90 33 280 - TH 4638.230

© Dräger Safety AG & Co. KGaA

Edition 04 - April 2014 (Edition 01 - July 2011)

Subject to alteration

Loading...

Loading...