Page 1

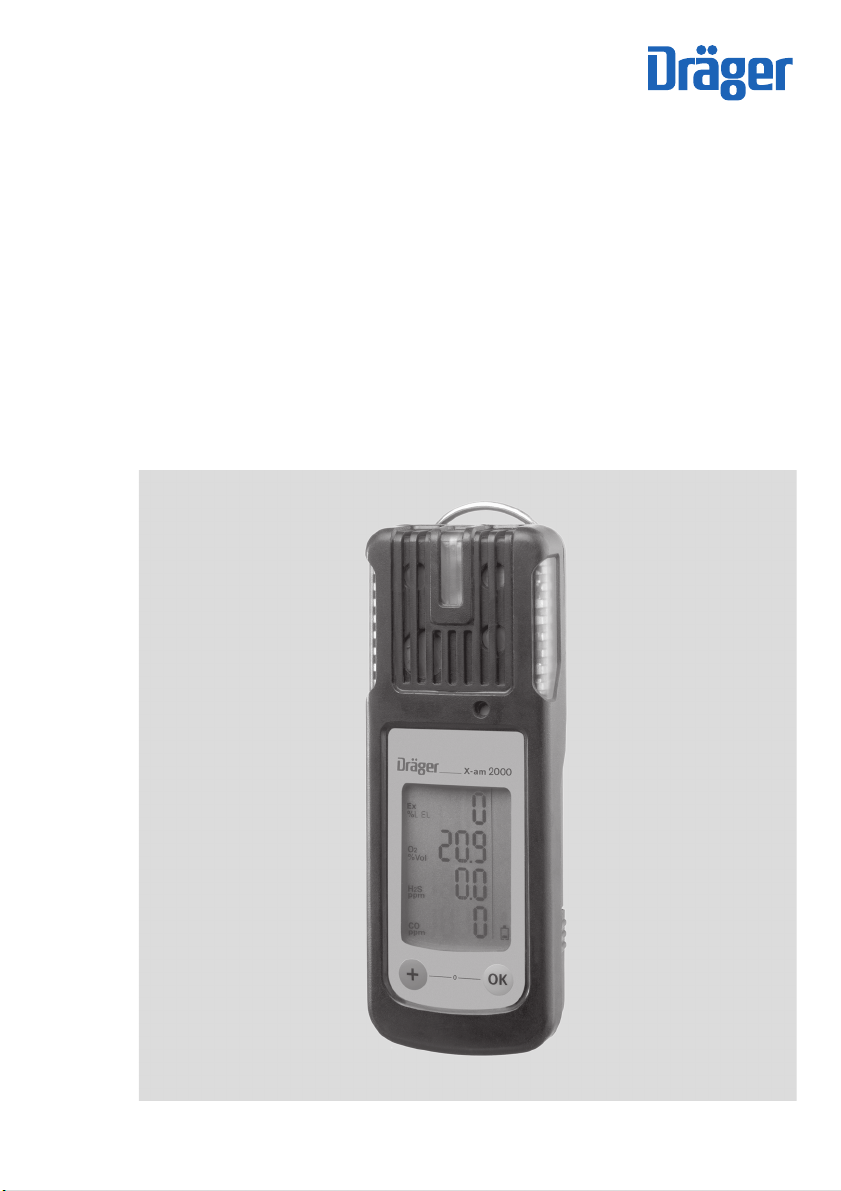

Dräger X-am® 1700, 2000

approved as type LQG 00xx

Multi-Gas Monitor

Technical Manual

ST-7452-2005.eps

Page 2

Content

Content

For Your Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Safety symbols used in these Technical Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Intended Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Tests and Approvals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Marking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Intended Operating Area and Operating Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . 7

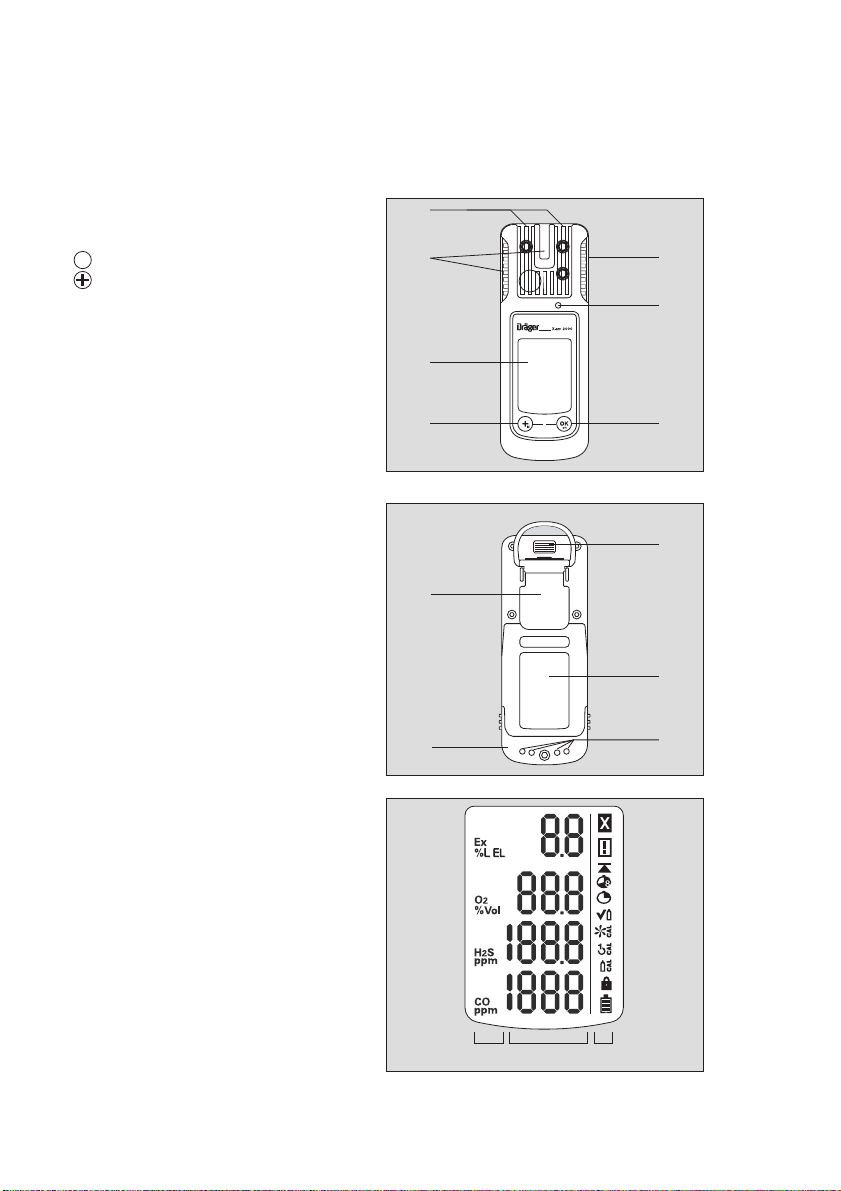

What is What . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Front panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Rear panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Special Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Standard Gas Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Standard Device Configuration on Delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Activating the Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Switching on the device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Switching off the device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Before entering the workplace . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

During operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Calling the Info Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Calling the Quick Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Possible functions of the quick menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Calling the Calibration Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Calibration menu functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Identifying Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Concentration pre-alarm A1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Concentration main alarm A2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

STEL / TWA exposure alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Battery pre-alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Battery main alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Device alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

End of operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Pump Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

With Dräger X-am 125 pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

With hand pump adapter and rubber ball pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Observe the following during pump operation mode . . . . . . . . . . . . . . . . . . . . . . . . 20

Configuring the Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Read Data Base and Display Graphically . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2

Page 3

Content

Faults, Cause and Remedy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Warning messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Fault messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Maintenance intervals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Carrying Out the Function Test with Gas (Bump Test) . . . . . . . . . . . . . . . . . . . . . . . 29

Manual implementation without the documentation of result in the device

memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Menu implementation with the documen-tation of results in the device memory . 30

Automatic implementation with the Bump Test Station . . . . . . . . . . . . . . . . . . . . 33

Calibrating / Adjusting the Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Carrying out the fresh air calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Carry out the 1-button calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Calibrating/adjusting the sensitivity for a single measuring channel . . . . . . . . . . 40

Replacing the Batteries / Rechargeable Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Charging the Rechargeable Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Charging with the multiple charging station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Charging with charging module and plug-in power pack or vehicle charging

adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Replacing the Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Disposing of the Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Sensor Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Order List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Spare parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Declaration of Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

3

Page 4

For Your Safety

For Your Safety

Strictly follow the Instructions for Use

Any use of the device requires full understanding and strict observation of the Instructions for

Use supplied with the device.

The device is only to be used for the purposes specified here.

Maintenance

The maintenance intervals and measures stated in this Technical Handbook as well as the

specifications in the Instructions for Use of the used DrägerSensors

Repair of the instrument may only be carried out by trained service personnel.

Accessories

Do not use accessory parts other than those listed in the order list.

Safe coupling with electrical devices

Devices which are not mentioned in the Instruction for Use or in this Technical Handbook can

only be coupled electronically after consultation with the manufacturers or an expert.

Use in areas subject to explosion hazards

Devices or components for use in explosion-hazard areas which have been tested and approved according to national, European or international Explosion Protection Regulations may be

used only under the conditions explicitly specified in the approval and with consideration of

the relevant legal regulations. The equipment or components may not be modified in any

manner. The use of faulty or incomplete parts is forbidden. The appropriate regulations must

be observed at all times when carrying out repairs on these devices or components.

Safety symbols used in these Technical Manual

These Technical Manual contain a number of warnings for risks and hazards which might

occur when using the device. These warnings contain signal words to alert you to the degree

of hazard you may encounter. These signal words and corresponding hazards are as follows:

1)

must be observed.

DANGER

Indicates an immediate hazardous situation which, if not avoided, could result in death or

serious injury.

WARNING

Indicates a potential hazardous situation which, if not avoided, could result in death or

serious injury.

1) The Instructions for Use of the DrägerSensors are supplied with the device on CD.

4

Page 5

Intended Use

CAUTION

Indicates a potential hazardous situation which, if not avoided, could result in injury or

damage to property.

Can also be used to warn against any wanton actions.

NOTICE

Additional information on the use of the device.

Intended Use

Portable gas measuring device for the continuous monitoring of the concentration of several

gases in the ambient air in the working area and in explosion-hazard areas.

X-am 1700:

independent measurement of four gases.

X-am 1700: 2 years service life from activation of the device (refer to page 11).

X-am 2000 depending on the device type:

independent measurement of one gas up to four gases.

5

Page 6

Tests and Approvals

D Type: LQG 0000

Dräger Safety

23560 Lübeck

Germany

DEMKO 06 ATEX 140055X

Um=4.6V Im=1.3A IECEx ULD 06.0001X

Ex ia s Zone 0 I/IIC TC T4/T3 ANZEx 06.3037X

Only as to intrinsic safety for use in haz loc.

Intrinsically safe / Securite Intrinseque Ex ia

Class I&II, Div. 1, Gr.A,B,C,D,E,F,G TC T4/T3

CSA: Class I, Div. 1, Gr.A,B,C,D TC T4/T3

TC & Ambient Temperature: see Battery Pack!

Read manual for safety precautions.

Do not change or charge batteries in haz loc.

I M2 / II 2G

BVS 06 ATEX G 006X PFG 06 G 001

Ex ia d I/IIC T4/T3

-20°C Ta +50/+40°C

Warning:

C 0158

LR97594

9N54

C22.2 No. 152

РОСС ГБ05.DE. B03849

ExdiaIMbX

Ex d ia IIC T4(T3) Gb X

ГБ05

Tests and Approvals

Marking

Power pack 83 18 703;

approved as type ABT 0000

Temperature class T4

o

–20

C ≤ Ta ≤ +50 oC

use with alkaline batteries

Energizer No. E91

Energizer No. EN91 (industrial)

Varta Type 4106 (power one)

Temperature class T3

o

–20

C ≤ Ta ≤ +40 oC

use with NiMH batteries

GP 180AAHC (1800 mAh)

Power pack 83 18 704;

approved as HBT 0000

Temperature class T4

o

–20

C ≤ Ta ≤ +50 oC

Serial no.

1)

WARNING

Read the safety measures in the Instructions for Use.

Do not replace or charge batteries in potentially explosive areas. Danger of explosion!

1) Year of construction is coded by the third capital letter of the serial number: T = 2003, U = 2004, W = 2005,

X = 2006, Y = 2007, Z = 2008, A = 2009, B = 2010, C = 2011, etc.

Example: Serial number ARUH-0054: the third letter is U, so the year of construction is 2004.

6

Page 7

Tests and Approvals

Intended Operating Area and Operating Conditions

Hazardous areas classified by zones

The device is intended to be used in hazardous areas or mines susceptible to firedamp classified zone 1 or zone 2, within a temperature range of –20

(depending on battery pack and batteries), where gases of explosion groups IIA, IIB or IIC

and temperature class T3 or T4 (depending on battery pack and batteries) may be present.

If used in mines, the device is only to be used in areas known to have a low risk of mechanical

impact.

Hazardous areas classified by divisions

The device is intended to be used in hazardous areas or mines susceptible to firedamp classified Class I&II, Div. 1 or Div. 2, within a temperature range of –20

–20oC to +50oC (depending on battery pack and batteries), where gases or dusts of groups

A, B, C, D or E, F, G and temperature class T3 or T4 (depending on battery pack and batteries) may be present.

o

C to +50 oC or –20 oC to +50oC

o

C to +50 oC or

Safety Instructions

WARNING

To reduce the danger of explosion, do not mix new batteries with old batteries and do not

mix batteries made by different manufacturers.

WARNING

Always disconnect the device from the power pack before carrying out any maintenance

operations.

WARNING

Substitution of components may impair intrinsic safety.

CAUTION

Not tested in an oxygen-enriched atmosphere (>21 % O2).

Only the combustible gas detection portion of this instrument has been assessed for performance.

WARNING

High off-scale readings may indicate an explosive concentration.

WARNING

Before each day's usage sensitivity must be tested on a known concentration of the gas to

be detected equivalent to 25 to 50% of full scale concentration. Accuracy must be within

0 to +20% of the actual value. Accuracy may be corrected by calibration.

7

Page 8

What is What

00223854_01.eps

0

1

2

6

5

4

3

2

OK

00323854_01.eps

2

1

4

3

5

00423854_01_en.eps

123

What is What

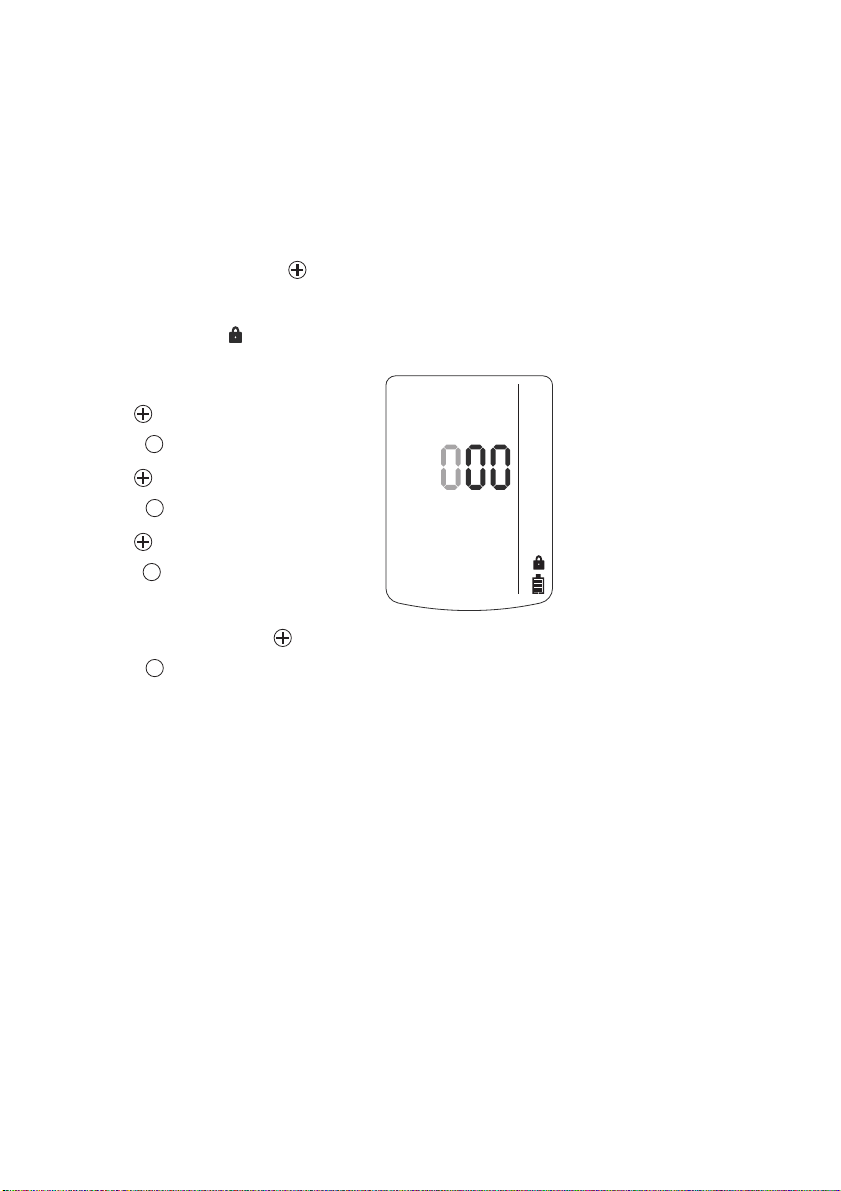

Front panel

1 Gas entry

2 Alarm LED

3 Buzzer

4 key

5 key

6 Display

Rear panel

1 IR interface

2 Fastening clip

3 Type plate

4 Charging contacts

5 Power pack

Display

1 Measured gas display

2 Measured value display

3 Special symbols

8

Page 9

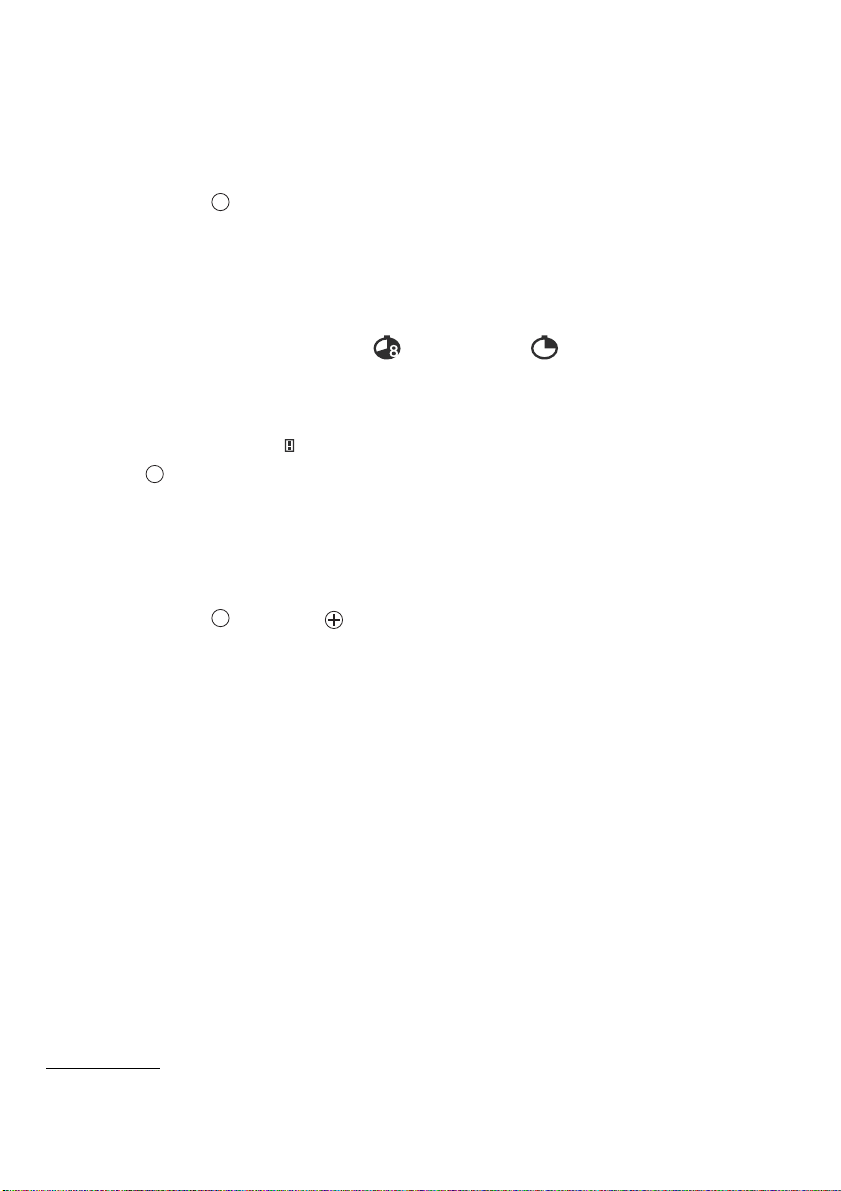

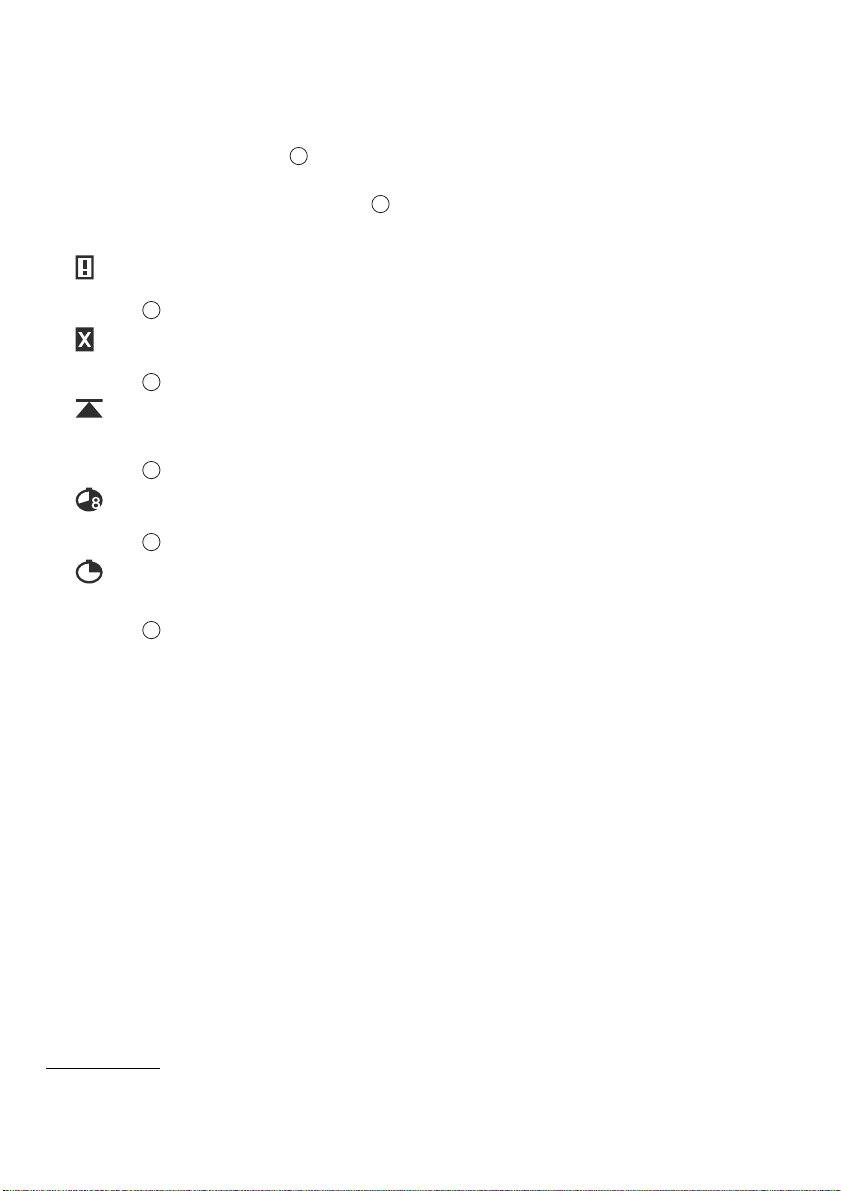

Special Symbols

Fault message, refer to page 14

Warning message, refer to page 14

The peak value display for all measuring gases, refer to page 14

What is What

The exposure evaluation display (TWA) for measuring gas H

refer to page 14

S and CO,

2

The exposure evaluation display (STEL) is switched on for measuring rangasge H

and CO, refer to page 14

The device is set to function test with gas (bump test),

refer to page 29

The device is set to the fresh air calibration function,

refer to page 36

The device is set to the 1-button calibration function,

refer to page 38

The device is set to the single-gas calibration function,

refer to page 40

The function for password entry is active, refer to page 16

Battery / rechargeable battery 100 % full

Battery / rechargeable battery 2/3 full

Battery / rechargeable battery 1/3 full

Battery / rechargeable battery empty

S

2

9

Page 10

Configuration

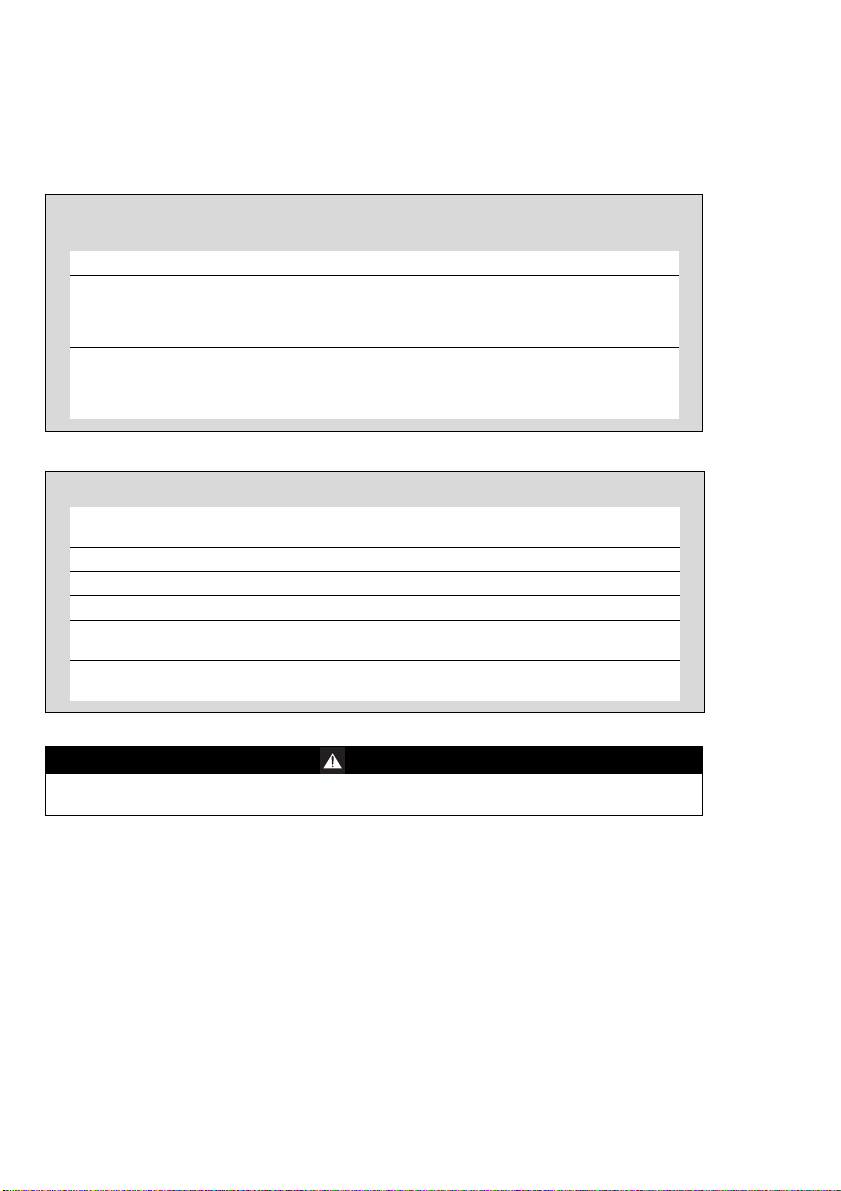

Configuration

Standard Gas Configuration

DrägerSensor CatEx

125 PR

[%LEL]

Measuring range

Alarm A1

- setpoint

- can be acknowledged

- self-latching

Alarm A2

- setpoint

- can be acknowledged

- self-latching

2)

2)

0 to 100 0 to 25 0 to 2000 0 to 100

20

yes

no

2)

40

no

yes

Standard Device Configuration on Delivery

XXS O

[Vol.-%]

1)

19

no

yes

23

no

yes

2

XXS CO

XXS H2S LC

[ppm]

30

yes

no

60

no

yes

X-am 1700 / X-am 2000

[ppm]

10

yes

no

20

no

yes

Function test with gas (bump test) in

Quick Menu

2)

Fresh air calibration in Quick Menu

Life sign

Switch off

LEL factor

2)

2)

2)

2)

4.4 (4.4 vol. % corresponds to 100 %LEL)

Quick bump test

off

on

allowed

(CH4)

Averaging time

2)

15 minutes for STEL

8 hours for TWA

Changing the standard configuration: See “Configuring the Device” on page 21.

WARNING

After a basic initialization has been carried out with the PC software Dräger CC Vision, individual alarm settings may have been changed.

___________________

1)

In the case of O2 A1 is the lower alarm setpoint: an alarm is issued if the value is too low.

2)

Different settings can be selected to meet customer requirements on delivery. The current setting can

be checked and changed with the software "CC Vision".

A version of Dräger CC-Vision which can be used for Dräger X-am 1700/2000 is supplied with the

device on CD.

10

Page 11

Activating the Device

02223854_01_de.eps

OK

Before using the device for the first time,

insert the supplied batteries or a charged

NiMH power pack T4 (order no. 83 18 704),

refer to Replacing the Batteries, page 42.

Charge the rechargeable batteries if necessary, page 43.

The Dräger X-am 2000 is ready for operation.

Only in the case of Dräger X-am 1700:

The following activation sequence also has

to be carried out:

● Press and hold the key for approx. 3

seconds until the countdown »3.2.1«

shown in the display has elapsed.

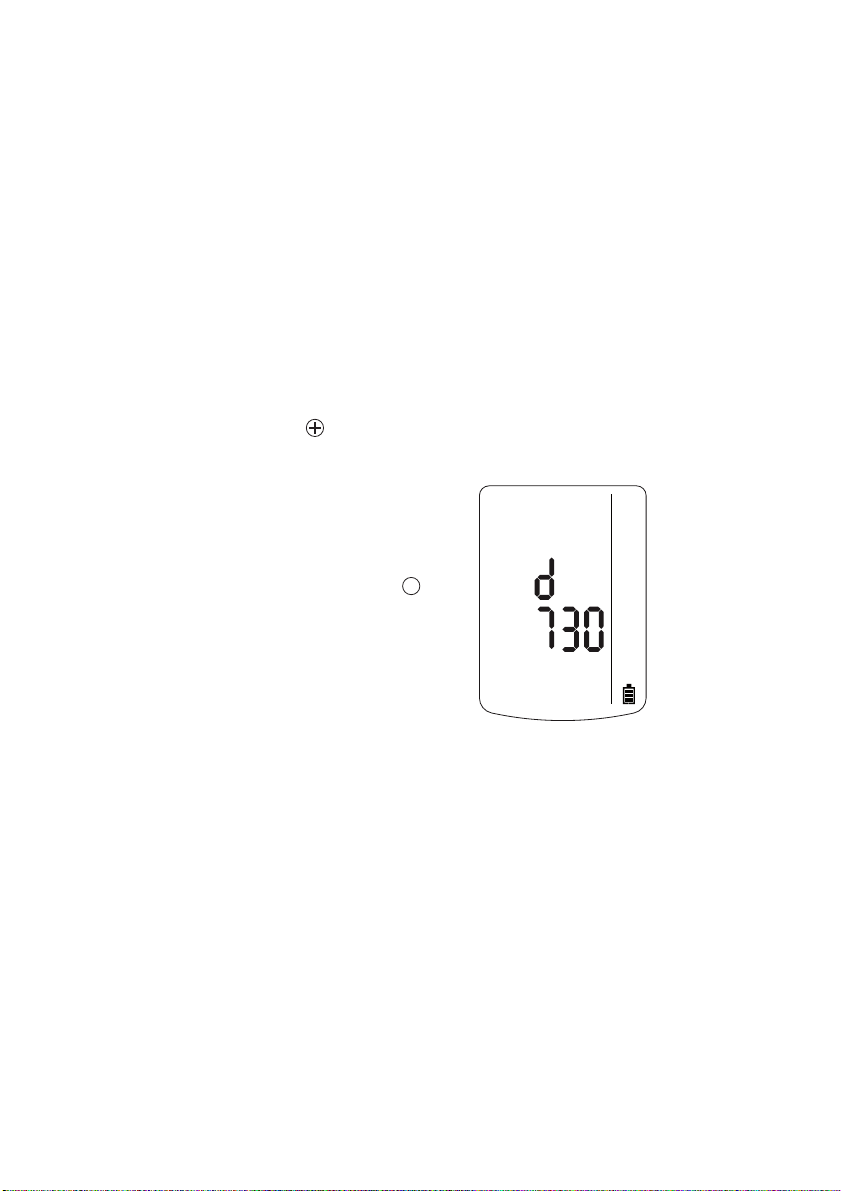

— The remaining operating time is dis-

played, e.g. » d 730 « (remaining operating time 730 days).

— After that, the device is automatically

switched off again. You can switch it on

again at any time by pressing the key.

Activating the Device

11

Page 12

Operation

OK

OK

Operation

Switching on the device

● Press and hold the key for approx. 3 seconds until the countdown »3.2.1« shown

in the display has elapsed.

— All the display segments, including the visual, audible and vibration alarms, are activated

for a short time.

— The software version is displayed.

— The device performs a self test.

— The remaining operating time is displayed, e.g. »d730« (remaining operating time

730 days). This applies to Dräger X-am 1700 and if the service life is activated in Dräger

X-am 2000.

— All alarm setpoints A1 and A2 as well as » « (TWA)

and CO are displayed in succession.

— The time until the calibration interval expires is displayed in days, e.g. » CAL 73 «.

— The sensor which is next due for calibration/adjustment is displayed with the days remai-

ning until the next calibration/adjustment e.g. » Ex %UEG CAL 20 «.

— During the warm-up time of the sensors, the respective display of the measured value flas-

hes and the special symbol » « (for warning) is displayed. No alarms are issued during

the running-in period of the sensors.

● Press the key to cancel the display of the activation sequence.

Switching off the device

● Press and hold the key and the key at the same time until the countdown

»3.2.1« shown in the display has elapsed.

— Before the device is switched off, the visual, audible and vibration alarms are activated for

a short time.

OK

1)

and » « (STEL)*) for H2S

1) Nur wenn in Gerätekonfiguration aktiviert. Auslieferungszustand: nicht aktiviert.

12

Page 13

Operation

Before entering the workplace

CAUTION

Check and, if necessary, adjust the calibration before carrying out safety-relevant measurements. A function test with gas (bump test) must be carried out in accordance with local

regulations.

● Switch on the device. The current measured values are shown in the display.

● Observe any warning » « or fault » « messages.

The device can be operated normally. If the warning message does not go out automatically during operation, the device must be maintained after the end of use.

The device is not ready to measure and requires maintenance.

If one of these special symbols is displayed, appropriate measures, refer to page 23 to

page 25, must be taken.

● Check that the gas inlet opening on the device is not covered.

WARNING

The presence of catalyst poisons in the measured gas (e.g., volatile silicone, sulfur, heavy

metal compounds or halogenated hydrocarbons) can damage the DrägerSensor CatEx

125 PR. If the sensor cannot be calibrated to the target concentration anymore, the sensor

must be replaced. The display of the CatEx 125 PR sensor may be incorrect in an oxygenpoor atmosphere. Electrical operating safety (Ex protection) is not guaranteed in an oxygenenriched atmosphere. Danger of explosion!

During operation

During operation, the measured values for every measured gas are displayed.

If a measuring range is exceeded or a negative drift occurs, the following displays are shown

instead of the measured value display:

» « (too high concentration) or » « (negative drift).

— If the concentrations of combustible materials are too high, this may result in a lack

of oxygen.

— If the O

In the event of an alarm, the corresponding displays, including the visual, audible and vibration alarms are activated – refer to “Identifying Alarms” on page 18.

When the measuring range on the CatEx channel is significantly exceeded (very high concentration of flammable substances), a latching alarm is triggered. This CatEx latching alarm is

acknowledged either automatically by a functioning (i.e. free of warnings and malfunctions)

oxygen channel or by manually switching the unit off and on again in fresh air.

concentrations are under 8 vol. %, a fault with » « is displayed for the

2

Ex channel instead of the measured value, if the measurement is below the pre-alarm

threshold.

WARNING

After exposition to concentrations above 100 %LEL, the indication displayed at the CatEx

channel may be incorrect. Before any further use of the device within the concentration

range from 0 to 100 %LEL, check and, if necessary, adjust the zero point and the sensitivity.

After the measuring range of the TOX measuring channels has been exceeded temporarily

(up to one hour), checking the measuring channels is not necessary.

When using a CatEx sensor in the Dräger X-am 2000, the zero point and sensitivity must be

adjusted after any extreme impact loading.

13

Page 14

Operation

OK

OK

OK

OK

OK

Calling the Info Mode

● In measuring mode, press the key for approx. 3 seconds.

1)

Any information and fault codes, the peak values as well as the TWA

values are displayed in succession (press the key for the next display). If any warning or

fault messages exist, the corresponding note or error codes are displayed (page 23 to

page 27).

Warning messages are displayed. Numerical codes of the warning messages: see

page 23.

and STEL*) exposure

⇓ -key

Fault messages are displayed. Numerical codes of the fault messages: see

page 25.

⇓ -key

The peak values = the maximum measured values in the case of e.g. CO, H

or the minimum measured values in the case of O

displayed

OK

⇓ key

The average values of the exposures based on a shift of e.g. 8 hours (TWA) of all

the active sensors for the exposure evaluation are displayed

OK

⇓ key

The short-term values (STEL) = average values of the concentrations over the

average value duration of all the active sensors for the exposure evaluation are

displayed

within the storage interval are

2

S, ...

2

⇓ key

The device is in measuring mode again

— If no key is pressed for 10 seconds, the device returns automatically to measuring mode.

1) Only when activated in the device configuration. Delivery status: not activated.

14

Page 15

Operation

Calling the Quick Menu

— If functions were activated for the quick menu with the PC software "CC Vision"

(no functions are activated in the quick menu on delivery):

● In measuring mode, press the key three times.

If no functions have been activated in the quick menu, the device remains in measuring

mode.

— You can select the activated functions of the quick menu by pressing the key.

● Press the key to call the selected function.

Possible functions of the quick menu

● Press the key to cancel the active function and to switch to measuring mode.

— If no key is pressed for 60 seconds, the device returns automatically to measuring mode.

OK

Function test with gas (bump test), refer to page 29

Fresh air calibration, refer to page 36

15

Page 16

Operation

OK

OK

OK

Calling the Calibration Menu

— The calibration menu can only be ac-

cessed by entering a password.

Password on delivery: » 001 «

— The default password on delivery can be

changed using the PC software "CC Vision".

● In measuring mode, press the key for

at least 5 seconds.

— The function for entering the password is

selected.

— The special symbol » « (for the "enter

password" function) is displayed.

— The display shows » 000 « with the first

digit flashing.

● Use the key to set the flashing digit.

● Press the key, the second digit starts

flashing.

● Use the key to set the flashing digit.

● Press the key, the third digit starts

flashing.

● Use the key to set the flashing digit.

● Press the key to confirm the password

once it has been set completely.

— The calibration menu functions can now

be selected by pressing the key.

● Press the key to call the selected

function.

OK

02323854_01.eps

16

Page 17

Operation

Calibration menu functions

Fresh air calibration, refer to page 36

1-button calibration, refer to page 38

Single gas calibration, refer to page 40

● Press the key to cancel the active function.

— If no key is pressed for 10 minutes, the device returns automatically to measuring mode.

17

Page 18

Identifying Alarms

OK

OK

OK

Identifying Alarms

An alarm is displayed visually, audibly and through vibration in a specific pattern.

Concentration pre-alarm A1

The alarm is indicated by an intermittent alarm message:

Display »A1« and measured value alternating: not for O

— The pre-alarm A1 is not self-latching and stops when the concentration has dropped below

the alarm setpoint A1.

— In the case of A1 a single tone is audible and the alarm LED flashes.

Acknowledging a pre-alarm:

● Press the key. Only the audible alarm and the vibration alarm are switched off.

Concentration main alarm A2

The alarm is indicated by an intermittent alarm message:

Display »A2« and measured value alternating:

In the case of A2 a double tone is audible and the alarm LED flashes twice.

: »A1« and measurement value alternating = oxygen deficiency

For O

2

» A2 « and measurement value alternating = oxygen surplus

DANGER

Leave the area immediately. Danger to life! A main alarm is self-latching

and cannot be acknowledged or cancelled.

After leaving the area, if the concentration is less than the alarm setpoint A2:

● Press the key. The alarm messages are switched off.

● A latching alarm on the CatEx channel (due to the measuring range being significantly ex-

ceeded) cannot be acknowledged by the key. The CatEx latching alarm is acknowledged either automatically by a functioning (i.e. free of warnings and malfunctions) oxygen

channel or by manually switching the unit off and on again in fresh air.

!

2

STEL / TWA exposure alarm

The alarm is indicated by an intermittent alarm message:

Display »A2« and »« or »« and measured value alternating:

CAUTION

Leave the area immediately. After this alarm, the deployment of personnel

is subject to the relevant national regulations.

— The STEL and TWA alarm cannot be acknowledged or cancelled.

● Switch off the device. The values for the exposure evaluation are deleted after the device

is switched on again.

18

Page 19

Identifying Alarms

OK

Battery pre-alarm

The alarm is indicated by an intermittent alarm message:

Flashing special symbol »« on the right side of the display:

Acknowledging the pre-alarm:

● Press the key. Only the audible alarm and the vibration alarm are switched off.

— The battery still lasts approx. 20 minutes after the first battery pre-alarm.

OK

Battery main alarm

The alarm is indicated by an intermittent alarm message:

Flashing special symbol »« on the right side of the display:

The battery main alarm cannot be acknowledged or cancelled:

— The device is automatically switched off again after 10 seconds.

— Before the device is switched off, the visual, audible and vibration alarms are activated for

a short time.

Device alarm

Intermittent alarm message:

Special symbol » « on the right side of the display:

— The device or one or several sensor channels are not ready for operation.

— For remedies, refer to page 23 to page 25.

● If necessary, commission the Dräger Safety Service Center to eliminate the error.

End of operation

Only in the case of X-am 1700.

A warning period starts before the end of the operating time.

— After switching on the device, the special symbol » « (for warning) is displayed.

Acknowledging the end of operation warning:

● Press the key. The device will continue to operate until the operating time has elapsed.

— When the operating time has elapsed, the text »d0« flashes. The device cannot be swit-

ched on anymore.

19

Page 20

Pump Operation

Pump Operation

With Dräger X-am 125 pump

Accessories:

Dräger X-am 125 pump, sampling hose and probes, see Order List, see “Accessories” on

page 53

Commissioning and performing the measurement:

● see the Instructions for Use of the Dräger X-am 125.

With hand pump adapter and rubber ball pump

Accessories:

Hand pump adapter, rubber ball pump, sampling hose and probes, see Order List, see

“Accessories” on page 53.

Commissioning and performing the measurement:

● see the Instructions for Use of the used accessories.

Observe the following during pump operation mode

● The required waiting time when flushing the extension hose or probes.

Prior to every measurement, flush the Dräger sampling hose or the Dräger probes with the

air sample to be measured.

— It is absolutely necessary to flush the extension hose for a period of time to eliminate or

minimize the effects which may interfere with measurements when using a sampling hose

or a probe, e.g. memory effects, dead volume.

— The flushing time depends on various factors e.g. type and concentration of the gas or va-

por to be measured, material, length, diameter and age of the sampling hose or the probe.

Generally, when using a sampling hose (new, dry, clean), a typical flushing time of approx.

3 seconds is required per meter. This flushing time applies in addition to the sensor response time (see the Instructions for Use of the used gas measuring device).

Example:

— In the case of a 10 m long sampling hose, the flushing time is approx. 30 seconds and the

sensor response time is in addition approx. 60 seconds. Hence, the total time required to

read the gas measuring device is approx. 90 seconds.

— The flow rate alarm is delayed depending on the length of the hose by 10 to 30 seconds.

20

Page 21

Configuring the Device

p

Configuring the Device

To individually configure a device with standard configuration, the device must be connected

with a PC.

0

IR

USB 1.1

Dräger

CC-Vision

USB DIRA with USB cable

(order no. 83 17 409)

0

USB 1.1

Dräger

CC-Vision

Calibration cradle (order no. 83 18 752)

with inserted

USB DIRA with USB cable (order no. 83 17 409)

0

USB 1.1 / COM

Dräger

CC-Vision

E-Cal module Dräger X-am 125

(order no. 83 18 754)

The installed PC software "CC Vision" is used for configuration.

● Observe the documentation and online help of the software.

— A version of Dräger CC Vision which can be used for X-am 1700/2000 is supplied with the

device on CD.

s

01423854_01_en.e

21

Page 22

Read Data Base and Display Graphically

IR

Calibration cradle (order no. 83 18 752)

with inserted

USB DIRA with USB cable (order no. 83 17 409)

USB DIRA with USB cable

(order no. 83 17 409)

E-Cal module Dräger X-am 125

(order no. 83 18 754)

USB 1.1

USB 1.1

USB 1.1 / COM

01823854_01_en.eps

Dräger

GasVision

Dräger

GasVision

Dräger

GasVision

0

0

0

Read Data Base and Display Graphically

To read the data base of the device and display it graphically, the device must be connected

with a PC.

The installed PC software "GasVision" is used for reading and displaying the data base.

● Observe the documentation and online help of the software.

22

Page 23

Faults, Cause and Remedy

Faults, Cause and Remedy

Fault Cause Remedy

Not possible to switch on the

device

Not possible to switch off the

device

Display »–––« Measuring range calibrated

To display the numerical codes of the warning and fault messages in the info mode, see

page 14.

Warning messages

Special symbol » « and

displayed numerical code:

151 Service life of device about to

152 Customer's service life coun-

Discharge the power pack Charge the power pack,

Discharge the alkaline batteries

The device is not set to

measuring mode

The device is configured to

"Disable prohibited"

incorrectly

Electronics or sensors defective

Cause Remedy

elapse

ter about to elapse

page 43.

Insert new alkaline batteries,

page 42.

Select measuring mode.

Configure the device to

"Disable allowed" with "CC

Vision".

Recalibrate the measuring

range, page 35.

Must be repaired by DrägerService.

Procure follow-on device.

Reset the service life counter

using "CC Vision".

153 Data base 90% full Read the data base soon and

154 Data base full Read the data base and clear

155 Interval for the function test

159 Calibration not possible.

251 DrägerSensor CatEx 125 PR

252 DrägerSensor CatEx 125 PR

with gas (bump test) elapsed

The menu function cannot be

carried out because of a message which is preventing the

function (e.g. sensors in

warm-up phase).

in warm-up phase

in warm-up phase

clear memory afterwards.

memory.

Carry out the function test,

page 29.

Determine the message code

via the info menu and switch it

off, if necessary.

Wait until warm-up time is

complete.

Wait until warm-up time is

complete.

23

Page 24

Faults, Cause and Remedy

Special symbol » « and

displayed numerical code:

253 Ex concentration has drifted

Cause Remedy

into the negative range

Carry out the fresh air calibration, page 36.

254 The temperature is too high Operate the device within the

allowed temperature range.

255 The temperature is too low Operate the device within the

256 The calibration interval for

257 Alarm setpoint A2 setting is

351 DrägerSensor XXS O

352 DrägerSensor XXS O

353 O

DrägerSensor CatEx 125 PR

has elapsed

greater than 60 %LEL

warm-up phase

warm-up phase

concentration drifted into

2

the negative range

2

2

354 The temperature is too high Operate the device within the

allowed temperature range.

Carry out the span calibration

for DrägerSensor CatEx

125 PR, page 40.

Set alarm setpoint to less than

60 % LEL.

in the

Wait until warm-up time is

complete.

in the

Wait until warm-up time is

complete.

Fresh air calibration required,

page 36.

allowed temperature range.

355 The temperature is too low Operate the device within the

allowed temperature range.

356 The calibration interval for

DrägerSensor XXS O

elapsed

2

Carry out the span calibration

has

for DrägerSensor XXS O2,

page 40.

451 DrägerSensor XXS H

warm-up phase

452 DrägerSensor XXS H

453 H

warm-up phase

S concentration has drifted

2

into the negative range

S in the

2

S in the

2

Wait until warm-up time is

complete.

Wait until warm-up time is

complete.

Carry out the fresh air calibration, page 36.

454 The temperature is too high Operate the device within the

allowed temperature range.

455 The temperature is too low Operate the device within the

allowed temperature range.

456 The calibration interval for

551 DrägerSensor XXS CO in the

DrägerSensor XXS H

elapsed

warm-up phase

2

Carry out the span calibration

S has

for DrägerSensor XXS H2S,

page 40.

Wait until warm-up time is

complete.

24

Page 25

Faults, Cause and Remedy

Special symbol » « and

displayed numerical code:

552 DrägerSensor XXS CO in the

553 CO concentration has drifted

554 The temperature is too high Operate the device within the

555 The temperature is too low Operate the device within the

556 The calibration interval for

Cause Remedy

warm-up phase

into the negative range

DrägerSensor XXS CO has

elapsed

Wait until warm-up time is

complete.

Carry out the fresh air calibration, page 36.

allowed temperature range.

allowed temperature range.

Carry out the span calibration

for DrägerSensor XXS CO,

page 40.

Fault messages

Special symbol »«

and displayed numerical

code:

101 The service life of the device

102 The customer's service life

103 The device is defective The device must be repaired by

104 Check sum error program

105 Update error The device must be repaired by

106 Check sum error data Reconfigure the device with "CC

107 Failed visual inspection or

108 The data base is defective Execute the menu function

109 The menu function cannot be

201 The zero point calibration of

Cause Remedy

has elapsed

counter has elapsed

code

alarm element test

carried out because of an

error.

the DrägerSensor CatEx

125 PR is not valid

Return the device to Dräger

Safety to be disposed.

Reset the service life counter

using "CC Vision".

DrägerService.

The device must be repaired by

DrägerService.

DrägerService.

Vision", otherwise return device

to DrägerService.

Repeat visual inspection and

alarm element test with X-dock.

again; otherwise the device must

be repaired by DrägerService.

Determine the error code via the

info menu and switch it off, if

necessary.

Carry out the fresh air calibration, page 36.

25

Page 26

Faults, Cause and Remedy

Special symbol »«

and displayed numerical

Cause Remedy

code:

202 The span calibration of the

DrägerSensor CatEx 125 PR

Carry out the span calibration,

page 38 or page 40.

is not valid

203 The measurement value of the

DrägerSensor CatEx 125 PR

Carry out the fresh air calibration, page 36.

is in the negative range

204 The DrägerSensor CatEx

205 Error during the function test

125 PR is not inserted

with gas (bump test) of the

DrägerSensor CatEx 125 PR

206 Function not possible:

O

deficiency

2

Check the DrägerSensor CatEx

125 PR, page 46.

Repeat the function test, calibrate or replace the

DrägerSensor CatEx 125 PR, if

necessary, page 46.

Use DrägerSensor CatEx

125 PR in atmospheres with

more than 10.0 % O2 by vol..

207 Failed filter test. Repeat filter test with X-dock.

208 Failed rise time test. Repeat rise time test with X-dock.

301 The zero point calibration of

DrägerSensor XXS O

valid

2

302 The span calibration of the

DrägerSensor XXS O

valid

303 O

304 The DrägerSensor XXS O

concentration drifted into

2

the negative range

not inserted

2

Carry out the fresh air calibra-

is not

tion, page 36.

Carry out the span calibration.

is not

page 40 or carry out the fresh air

calibration, page 36.

Fresh air calibration required,

page 36.

is

Check the DrägerSensor XXS

2

O2, page 46.

305 Error during the function test

with gas (bump test) of the

DrägerSensor XXS O

2

Repeat the function test, calibrate or replace the DrägerSensor XXS O

if necessary, page 46.

2

307 Failed filter test. Repeat filter test with X-dock.

308 Failed rise time test. Repeat rise time test with X-dock.

401 The zero point calibration of

DrägerSensor XXS H

valid

S is not

2

402 The span calibration of the

DrägerSensor XXS H

valid

S is not

2

Carry out the fresh air calibration, page 36.

Carry out the span calibration,

page 40.

26

Page 27

Faults, Cause and Remedy

Special symbol »«

and displayed numerical

Cause Remedy

code:

403 Measured value of the Dräger-

Sensor XXS H2S is in the

Carry out the fresh air calibration, page 36.

negative range

404 DrägerSensor XXS H

405 Error during the function test

inserted

with gas (bump test) of the

DrägerSensor XXS H

S is not

2

S

2

Check DrägerSensor XXS H2S,

page 46.

Repeat the function test, calibrate or replace the

DrägerSensor XXS H2S, if

necessary, page 46.

407 Failed filter test. Repeat filter test with X-dock.

408 Failed rise time test. Repeat rise time test with X-dock.

501 The zero point calibration of

the DrägerSensor XXS CO is

Carry out the fresh air calibration, page 36.

not valid

502 The span calibration of the

DrägerSensor XXS CO is not

Carry out the span calibration,

page 40.

valid

503 The measured value of the

DrägerSensor XXS CO is in

Carry out the fresh air calibration, page 36.

the negative range

504 The DrägerSensor XXS CO is

505 Error during the function test

not inserted

with gas (bump test) of the

DrägerSensor XXS CO

Check the DrägerSensor XXS

CO, page 46.

Repeat the function test, calibrate or replace the DrägerSensor XXS CO, if necessary,

page 46.

507 Failed filter test. Repeat filter test with X-dock.

508 Failed rise time test. Repeat rise time test with X-dock.

27

Page 28

Maintenance

Maintenance

Maintenance intervals

The device should be inspected and maintained by suitably qualified persons every six

months (consult: EN 60079-29-2 – Gas measuring device - Selection, installation, use and

maintenance of apparatus for the measurement of combustible gases or oxygen, EN 45544-4

– Electrical apparatus used for the direct detection and direct concentration measurement of

toxic gases and vapours - Part 4: Guide for selection, installation, use and maintenance and

national regulations). We recommend that you calibrate all channels after 6 months.

● Depending on device configuration:

Replace the alkaline batteries or charge the battery – refer to page 42 to page 43 – after

each use, at the latest after the battery alarm has been triggered or after 2 weeks.

● Device calibration – page 35.

— In regular intervals, according to the used sensors and the operating conditions. For sen-

sor-specific calibration data, refer to the Instructions for Use of the used sensors

— Before you carry out safety-related relevant measurements, the zero point and sensitivity

of the devices should be tested in accordance with national regulations.

● Inspection by suitably qualified persons – every year.

— The inspection intervals must be established in each individual case and shortened if ne-

cessary, depending on technical safety considerations, engineering conditions and the

technical requirements of the equipment.

— We recommend that a service agreement be concluded with Dräger Safety and that re-

pairs also be carried out by them.

● Replace the sensors, page 46 – if necessary, when it is not possible to calibrate the sensors anymore.

1)

.

1) The Instructions for Use of the used sensors are supplied with the device on CD.

28

Page 29

Carrying Out the Function Test

0.5 L/min

0

with Gas (Bump Test)

Manual implementation without the documentation of result in the device memory

● Prepare a test gas cylinder, the volume

flow must be 0.5 L/min and the gas concentration must be higher than the alarm

setpoint concentration to be tested.

Example test gas cylinder 68 11 130 =

mixed gas with 50 ppm CO, 15 ppm H

2.5 vol. % CH4, 18 vol. % O

● Connect the test gas cylinder with the calibration cradle (83 18 752).

● Vent the test gas into a fume cupboard or

into the open air (with a hose connected

to the second connector of the calibration

cradle).

2

CAUTION

Do not inhale the test gas. Risk to health!

Observe the hazard warnings of the relevant Safety Data Sheets.

● Switch on the device and insert it into the

calibration cradle – press downwards until it engages.

● Open the test gas cylinder valve to let test

gas flow over the sensors.

● Wait until the device displays the test gas

concentration with sufficient tolerance –

Ex: 40 %LEL ... 74 %LEL

O2: 17.4 vol.-% ... 18.6 vol.-%

H2S: 12 ppm ... 18 ppm

CO: 40 ppm ... 60 ppm

If the alarm setpoints are exceeded, the

device displays the gas concentration in

alternation with »A1« or »A2« depen-

ding on the test gas concentration.

● Close the test gas cylinder valve and remove the device from the calibration cradle.

— If the concentration has now fallen under

the A1 alarm setpoint:

● Acknowledge the alarm.

● If the displays are outside of the

above-mentioned ranges:

● Calibrating the device, refer to page 35.

1)

1)

1)

S,

2

1)

Maintenance

____________

1) Upon application of the Dräger mixed gas (order no. 68 11 130), the displays should be in this range.

Different concentrations can be adjusted using the enclosed software Dräger CC Vision.

29

Page 30

Maintenance

Menu implementation with the documen-tation of results in the device

memory

The "Quick bump test" or the "Extended

bump test" is selected using the Dräger CC

Vision PC software. The "Quick bump test"

checks whether the gas concentration has

exceeded the Alarm 1 threshold (with oxygen, the check is whether the concentration

has fallen below the Alarm 1 threshold). The

"Extended bump test" checks whether the

gas concentration has exceeded the Alarm 1

threshold (with oxygen, the check is whether

the concentration has fallen below the Alarm

1 threshold) and whether the gas concentration has reached the preset bump test concentration.

Setting on delivery: Quick bump test.

● Prepare a test gas cylinder, the volume

flow must be 0.5 L/min and the gas concentration must be higher than the alarm

setpoint concentration to be tested.

Example test gas cylinder 68 11 130 =

mixed gas with 50 ppm CO, 15 ppm H

2.5 vol. % CH4, 18 vol. % O

● Connect the test gas cylinder with the calibration cradle (83 18 752).

● Vent the test gas into a fume cupboard or

into the open air (with a hose connected

to the second connector of the calibration

cradle).

2

S,

2

●

CAUTION

Do not inhale the test gas. Risk to health!

Observe the hazard warnings of the relevant Safety Data Sheets.

0.5 L/min

● Switch on the device and insert it into the

calibration cradle – press downwards until it engages.

● Call the quick menu and select the function test with gas (bump test), page 15.

30

0

00523854_01_en.eps

Page 31

— The current gas concentration values and

OK

_

_

p

02623854_01_en.eps

the special symbol » « (for bump test)

flash.

● Press the key to start the function test

with gas.

● Open the test gas cylinder valve to let test

gas flow over the sensor.

— If gas concentration exceeds the alarm

thresholds A 1 or A 2 the corresponding

alarm will occur.

Exit the function test with gas:

For the manual bump test:

After the set bump test concentration is

reached:

● Press the key.

— The display containing the current gas

concentration changes with the display

»OK«.

— The bump test that was carried out is do-

cumented with the result and date in the

device memory.

● Close the test gas cylinder valve and remove the device from the calibration cradle.

— If the concentration values have now fal-

len under the A1 alarm setpoints, the de-

OK

vice returns to the measuring mode.

— If during the function test no alarm occurs

within 1 minute and the gassing test was

not confirmed by pressing OK, the alarm

mode is activated to indicate failure.

— The fault message » « appears and

» « is displayed instead of the

measured value on the faulty measuring

channel.

● In this case, repeat the function test with

gas or calibrate the device, page 35.

Maintenance

02423854_01_en.eps

s

en.e

01

02523854

31

Page 32

Maintenance

_

_

p

_

_

p

For the automatic bump test:

After the set bump test concentration is

reached:

— The display containing the current gas

concentration changes with the display

»OK«.

— The bump test that was carried out is do-

cumented with the result and date in the

device memory.

● Close the test gas cylinder valve and remove the device from the calibration cradle.

— If the concentration values have now fal-

len under the A1 alarm setpoints, the device returns to the measuring mode.

— If during the function test no alarm occurs

within 1 minute, the alarm mode is activated to indicate failure.

— The fault message » « appears and

» « is displayed instead of the

measured value on the faulty measuring

channel.

● In this case, repeat the function test with

gas or calibrate the device, page 35.

The function test with gas can also be carried

out automatically.

The "Bump Test Station" is required for this

function, refer to page 33.

s02623854

en.e

01

02523854

s

en.e

01

32

Page 33

Maintenance

_

_

p

Automatic implementation with the Bump Test Station

Prerequisite:

The device must first be configured for the automatic function test with gas (bump test) using

the PC software "CC Vision".

— Activate the device for the automatic function test.

— Composition of test gas (mixed gas) – standard on delivery: 50 ppm CO, 15 ppm H

vol. % CH

— Define which measuring channels should participate in the automatic function test. By de-

fault, all measuring channels participate in the function test.

, 18 vol. % O

4

2

● Prepare the Bump Test Station according to the instructions.

● Switch on the device and insert it into the receptacle of the Bump Test Station until it locks

into place.

S, 2.5

2

0

— The function test with gas is started auto-

matically. The special symbol » « (for

bump test) flashes.

— If the gas concentration exceeds the

alarm setpoint A 1 or A 2, the relevant

alarm is triggered, which is automatically

acknowledged after approx. 10 seconds.

Next:

— The display of the current gas concentra-

tion changes with the display »OK«.

The bump test that was carried out is documented with the result and date in the

device memory.

33

03823854_01.eps

s

en.e

01

02523854

Page 34

Maintenance

_

_

p

● Remove the device from the Bump Test

Station.

— If the concentration values have now fal-

len under the A1 alarm setpoints, the device returns to the measuring mode.

— If during the function test no alarm occurs

and the current measured values do not

reach the set target concentration, the error alarm is activated to indicate failure.

— The fault message » « appears and

» « is displayed instead of the

measured value on the faulty measuring

channel.

● In this case, repeat the function test with

gas or calibrate the device, page 35.

s

en.e

01

The function test with gas can also be carried

out manually, refer to page 29 and page 30.

02623854

34

Page 35

Maintenance

Calibrating / Adjusting the Device

Calibration may not be possible due to device and channel errors.

Allow the sensors to warm up before the calibration / adjustment!

Warm-up time: refer to the Instructions for Use of the installed DrägerSensors (on CD).

Calibration interval:

— Observe the relevant specifications in the Instructions for Use of the installed DrägerSen-

sors.

— For critical applications, observe the recommendations in EN 60079-29-2

EN 45544-42) and national regulations. We recommend that you calibrate all channels after 6 months.

CAUTION

Do not inhale the test gas. Risk to health!

Observe the hazard warnings of the relevant Safety Data Sheets.

— Improve the zero point accuracy – carry out the fresh air calibration, page 36.

— Set the sensitivity of all sensors to the value of the test gas – carry out the 1-button cali-

bration, page 38.

— Set the sensor sensitivity to a value of the test gas – calibrate/adjust the sensitivity,

page 40.

1)

or

1) EN 60079-29-2 – Gas measuring device - Selection, installation, use and maintenance of apparatus

for the measurement of combustible gases or oxygen.

2) EN 45544-4 – Electrical devices for the direct detection and direct concentration measurement of toxic

gases and vapours – Part 4: Guidelines for selection, installation, use and maintenance.

35

Page 36

Maintenance

OK

Carrying out the fresh air calibration

To improve the zero point accuracy, you can

carry out a fresh air calibration.

— Calibrate the device to fresh air, free of

measured gases or other interfering gases.

— All the sensors are included in the fresh

air calibration. Sensors which have not

warmed up or which are faulty prevent a

calibration.

In the case of sensors which are in the

warm-up phase, the message » 159 « is

displayed with the special symbol » «

(for warning message).

In the case of a sensor or device error,

the message » 109 « is displayed with

the special symbol » « (for fault message).

The message is cleared after 5 seconds

and the function is available again in the

menu.

— During the fresh air calibration, the zero

point of all the sensors (with the exception of the DrägerSensor XXS O

0.

In the case of the DrägerSensor XXS O2,

the display is set to 20.9 vol. %.

● Switch on the device.

Depending on device configuration:

● Call the quick menu and select the "fresh

air calibration" function, page 15.

or

● Call the calibration menu and select the

"fresh air calibration" function, page 16.

— The current gas concentration values

flash.

When the measured values are stable:

● Press the key to perform the fresh air

calibration.

) is set to

2

03123854_01_en.eps

36

Page 37

— The display containing the current gas

_

_

p

OK

_

_

p

concentration changes with the display

»OK«.

● Press the key to confirm the calibration or wait for 5 seconds.

If a fault has occurred during the fresh air

calibration.

— The fault message » « appears and

» « is displayed for the respective sensor instead of the measured value

● In this case, repeat the fresh air calibration.

● If necessary, replace the sensor,

page 46.

Maintenance

s

en.e

01

03223854

s

en.e

01

03323854

37

Page 38

Maintenance

02723854_01.eps

0,5 L/min

0

02823854_01_en.eps

OK

Carry out the 1-button calibration

— All the sensors which can be calibrated

are included in the 1-button calibration.

The sensors which have not warmed up

or which are faulty are not included.

— In the case of the 1-button calibration, the

sensitivity of all sensors is set to the value

of the test gas.

When using the test gas cylinder

68 11 130 = mixed gas with 50 ppm CO,

15 ppm H

O2.

— If a mixed gas with another composi-

tion is used, the specified concentration values in the device must be

changed

to the target values of the used mixed

gas using the PC software "Dräger CC

S, 2.5 vol. % CH4, 18 vol. %

2

Vision".

● Connect the test gas cylinder with the calibration cradle.

● Vent the test gas leaving the adapter into

a fume cupboard or into the open air (with

a hose connected to the second connector of the calibration cradle).

CAUTION

Do not inhale the test gas. Risk to health!

Observe the hazard warnings of the relevant Safety Data Sheets.

● Switch on the device and insert it into the

calibration cradle until it locks into place.

● Call the calibration menu, enter the

password and select the "1-button calibration" function, page 16.

● Press the key to start the 1-button calibration.

● Open the test gas cylinder valve to let test

gas flow over the sensor.

— The currently displayed measured values

start to flash.

The flashing stops after a static measured value has been reached.

— The calibration is now carried out auto-

matically.

— The displayed measured values change

to the values according to the gas supplied.

38

Page 39

When the calibration is completed and

_

_

p

OK

the displayed measured values are stable:

— The display containing the current gas

concentration changes with the display

»OK«.

● Press the key or wait for 5 minutes to

quit the calibration.

— The device changes to the measuring

mode

● Close the test gas cylinder valve and remove the device from the calibration

cradle.

If a fault has occurred during the 1-button

calibration.

— The fault message » « appears and

» « is displayed for the respective sensor instead of the measured value

● In this case, repeat the 1-button calibration or carry out a single gas calibration

(Span cal), refer to page 40.

● If necessary, replace the sensor,

page 46.

Maintenance

s

en.e

01

02923854

03023854_01_en.eps

39

Page 40

Maintenance

03523854_01_en.eps

OK

OK

Calibrating/adjusting the sensitivity for a single measuring channel

— The span calibration can be carried out

specifically for individual sensors.

— In the case of the span calibration, the

sensitivity of the selected sensor is set to

the value of the used test gas.

— Use a standard test gas.

Allowed test gas concentration:

Ex: 40 to 100 %LEL

10 to 25 vol. %

O

2

CO: 20 to 999 ppm

S: 5 to 99 ppm

H

2

● Connect the test gas cylinder with the calibration cradle.

● Vent the test gas leaving the adapter into

a fume cupboard or into the open air (with

a hose connected to the second connector of the calibration cradle).

CAUTION

Do not inhale the test gas. Risk to health!

Observe the hazard warnings of the relevant Safety Data Sheets.

0.5 L/min

0

● Switch on the device and insert it into the

calibration cradle.

● Press the [ + ] key and keep it depressed

for 5 seconds to call the calibration menu,

enter the password and select the "span

calibration" function, page 16.

● Press the key to start the span calibration.

— The display flashes the gas of the first

measuring channel, e.g. » Ex - %LEL «.

● Press the key to carry out the calibration of this measuring channel.

or

● Use the key to select another measuring channel (O

CO - ppm).

- vol. %, H2S - ppm or

2

40

02723854_01_en.eps

Page 41

● Press the key to carry out the calibra-

OK

_

_

p

OK

OK

_

_

p

tion of the selected measuring channel.

— The calibration gas concentration is dis-

played.

● Press the [OK] key to confirm the cali-

bration gas concentration or use the [+]

key to change the calibration gas concentration and complete the process by pressing the [OK] key.

— The measurement value flashes.

● Open the test gas cylinder valve to let test

gas flow over the sensor.

— The displayed, flashing measurement va-

lue changes to the value according to the

supplied test gas.

When the displayed value has stabilized

(after at least 120 seconds):

● Press the key.

— The display containing the current gas

concentration changes with the display

»OK«.

● Press the key to quit the calibration of

this measuring channel.

Maintenance

— The next measuring channel is offered for

calibration.

— After the last measuring channel has

been calibrated/adjusted, the device switches to measuring mode.

● Close the test gas cylinder valve and remove the device from the calibration cradle.

s

en.e

01

03623854

If a fault has occurred during the span calibration.

— The fault message » « appears and

» « is displayed for the respective sensor instead of the measured value

● In this case, repeat the calibration.

● If necessary, replace the sensor,

page 46.

Note on adjusting the Ex channel to

nonane as the measured gas:

— When calibrating the Ex channel, pro-

pane can be used as a substitute for the

calibration gas.

— When using propane to adjust the Ex

channel to nonane, the display must be

set to 2x the test gas concentration used.

41

s

en.e

01

03723854

Page 42

Maintenance

1

2

3

–

+

–

+

OK

Replacing the Batteries / Rechargeable Batteries

WARNING

Do not replace the batteries / rechargeable batteries in hazardous areas. Danger of explosion!

Batteries / rechargeable batteries are part of the Ex approval. Only the following types may

be used:

Alkaline batteries – T4 – (not rechargeable!)

Energizer No. E91, Energizer No. EN91 (Industrial), Varta Type 4106 (power one),

Varta Type 4006 (Industrial)

NiMHy rechargeable batteries – T3 – (rechargeable)

GP 180AAHC (1800) max. 40

Switching off the device:

● Keep the key and the key de-

pressed at the same time.

1 Loosen the screw (2.0 mm hexagon sok-

ket) on the power pack and remove the

power pack.

2 Replace the alkaline batteries with new

ones or rechargeable NiMHy batteries

with charged ones – ensure correct po-

larity.

3 Completely replace the power pack T4

(with sealed rechargeable batteries, order no. 83 18 704).

● Insert the power pack into the device and

tighten screw, the device is switched on

automatically.

After replacing the power pack T4, it is

recommended that a complete charging is

carried out.

o

C ambient temperature.

WARNING

Do not throw used batteries into fire or try

to open them by force. Danger of explosion!

Dispose of the batteries in accordance with

local regulations.

After batteries have been replaced:

— The settings and data are stored when

the battery is replaced.

The sensors warm up again.

42

Page 43

Maintenance

00723854_01.eps

0

2

1

0

2

1

0

2

1

1

Charging the Rechargeable Batteries

WARNING

Do not charge underground or in explosion-hazard areas! Danger of explosion!

The chargers are not designed in accordance with the regulations for firedamp and explosion protection.

Even if the device is not used, we recommend that you store the device in the charger (Charging module X-am 1/2/5000, order no. 83 18 639)!

To maintain the lifetime of the batteries, charging is temperature controlled and only performed in a temperature range of 5 to 35

When this temperature range is left, the charging is automatically interrupted and automatically continued after the temperature range has been reached again.

The charging time is typically 4 hours.

A new NiMH power pack reaches its full capacity after three full charging/discharging cycles.

Charging with the multiple charging station

— A maximum of 20 devices can be charged at the same time on the power pack (order no.

83 18 805) of the multiple charging station.

● When attaching the charging modules, disconnect the power pack from the mains supply!

Attaching charging modules

1 Turn the slots of the interlock into a horizontal position by using a screwdriver or coin.

2 Insert the projecting tongue of the charging module (at the same time, current entry) until

it engages.

1 Close the interlock with a quarter turn (slot is positioned vertically).

o

C.

● Attach additional charging modules in the same way.

— Always connect or disconnect the charging modules individually and not in groups in order

to prevent the charging station from becoming damaged. During transportation, the power

pack and the charging modules should also always be handled individually and without inserted devices.

43

Page 44

Maintenance

0

13 2

● Position the device on an even and level

surface.

● Connecting the power pack to the mains.

1 The green "Mains" LED lights.

● Insert the device into the charging module.

2 Display LED on the charger:

Charge

Fault

Full

If a fault occurs:

Remove the device from the charging

module and insert it again.

If the fault still occurs, have the charging

module repaired.

It takes approx. 4 hours to fully charge an

empty rechargeable battery.

A short circuit of the charging contacts in the

charging modules, e.g. by metallic objects

that have fallen in, does not result in damage

to the charging station. It should, however,

be avoided due to possible heating hazards

and incorrect displays on the charging

module.

In the event of a short circuit or if the power

pack is overloaded:

3 The red "Overload" LED lights, and an

audible alarm sounds.

— After the fault has been corrected, the

alarm is switched off automatically and

the charging process is restarted.

— In the event of a power failure, the devi-

ces already charged will be protected

from discharging.

44

Page 45

Maintenance

Charging with charging module and plug-in power pack or vehicle charging adapter

— When using the power pack (order no. 83 16 994), up to 5 devices can be charged at the

same time, with power pack (order no. 83 15 635) up to 2 devices.

— The power pack contained in the rechargeable battery and charging kit (order no.

83 18 785) is suitable for charging a device.

— When using the vehicle charging adapter (order no. 83 17 754), it is recommended that

you supply every charging module separately.

2

1

0

83 16 994 (100 ... 240 V)

or

83 15 635 (100 ... 240 V)

The charging process is carried out analogue to the charging with the multiple charging station.

83 17 754

00923854_02_en.eps

45

Page 46

Replacing the Sensors

01123854_01.eps

0

OK

01923854_01.eps

0

2

1

3

4

Replacing the Sensors

● Switch off the device: keep the key

and the key depressed at the same

time.

● Loosen the screw (2.0 mm hexagon sokket) on the power pack and remove the

power pack.

● Loosen the 4 screws (1.5 mm hexagon

socket) on the rear panel of the device.

● Remove the upper half of the housing.

Position of the sensors:

1 DrägerSensor CatEx 125 PR –

68 12 950

2 DrägerSensor XXS O

(blue marking)

3 DrägerSensor XXS H

(yellow marking)

4 DrägerSensor XXS CO – 68 10 882 (gray

marking)

The position of the sensors must not be

swapped! If the position is swapped, it can

result in damage to the sensors.

– 68 10 881

2

S LC – 68 11 525

2

CAUTION

● Remove the sensor to be replaced from

the sensor receptacle – in the case of the

DrägerSensor CatEx 125 PR, disconnect

the flat cable connection before.

● Insert the new sensor into the sensor receptacle.

● Insert the flat cable connection of the

DrägerSensor CatEx 125 PR into the

plug-in connector on the board.

● Check that the sensors are positioned

correctly and make adjustments if necessary.

● Attach the upper half of the housing and

● Insert the power pack into the device and

● Switch on the device –

tighten the 4 screws on the rear panel.

tighten the screw.

Allow the sensors to warm up completely

(max. 15 minutes).

46

Page 47

Replacing the Sensors

Next:

● Carry out the fresh air calibration, page 36.

and then:

● Calibrate the sensitivity:

either

carry out the 1-button calibration, page 38

or

calibrate/adjust the sensitivity, page 40.

Electrochemical sensors

— Do not expose to fire,

— Do not force open. Danger! Acid-Burn Risk!

— Like batteries, only dispose of as special waste,

in accordance with local waste disposal regulations. Further information can be obtained from

the relevant local authority and from appropriate waste disposal companies.

The DrägerSensor CatEx 125 PR should be disposed of as electronic waste.

47

Page 48

Care

Care

The device does not need any special maintenance.

● Dirt and deposits can be removed from the device by washing it with cold water. A sponge

can be used for wiping if necessary.

NOTICE

Abrasive cleaning implements (brushes etc.), cleaning agents and cleaning solvents can

destroy the dust and water filters.

● Carefully dab dry the device using a cloth.

48

Page 49

Disposing of the Device

Disposing of the Device

EU-wide regulations for the disposal of electric and electronic appliances which have

been defined in the EU Directive 2002/96/EC and in national laws are effective from

August 2005 and apply to this device.

Common household appliances can be disposed of using special collecting and recycling

facilities. However, as this device has not been registered for household usage, it must not be

disposed of through these means. The device can be returned to your national Dräger Sales

Organization for disposal. Please do not hesitate to contact the above if you have any further

questions on this issue.

49

Page 50

Tech ni cal Data

Technical Data

X-am 1700 / 2000

Ambient conditions:

during operation and storage

Device data

Protection class IP 67 for devices with sensors

Intensity of alarm Typically 90 dB (A) in 30 cm distance

Operation time

– Alkaline battery Typically 12 hours under normal conditions

– NiMHy rechargeable

batteries

Dimensions approx. 130 mm x 48 mm x 44 mm (H x W x D)

Weight approx. 220 g to 250 g

–20 to 50 °C

(–20 to 40 °C for NiMH single cells type 180AAHC)

700 to 1300 hPa

10 to 90% (short-term up to 95%) relative humidity

Typically 12 hours under normal conditions

CE markings Electromagnetic compatibility (Directive 2004/108/EC)

Approvals: see “Tests and Approvals” on page 6

Explosion protection (Directive 94/9/EC)

Sensor Data

Extract! See the Instructions for Use of the used sensors for details.

Ex O

Measuring principle Catalytic com-

Measured value response

time t

0...90

Measured value response

time t

0...50

1) For falling concentrations, the settling time for nonane is 50 seconds.

for methane

for propane

for methane

for nonane

bustion

≤20 seconds

≤35 seconds

≤7 seconds

≤50 seconds

1)

2

Electro-

chemical

≤10 seconds ≤15 seconds ≤25 seconds

≤6 seconds ≤6 seconds ≤6 seconds

H2SLC CO

Electro-

chemical

Electro-

chemical

50

Page 51

Tech nical Dat a

Measuring range

for methane

Zero error

Ex O

0 to 100 %LEL

0 to 100 vol. %

1)

2

0 to

25 vol. %

––– ––– 2 ppm 6 ppm

H2SLC CO

0 to 100 ppm

H

S

2

0 to 2000 ppm

CO

2)

(EN 45544)

Device drift ––– ––– ≤1 % of the

measured

value/month

≤1 % of the

measured

value/month