Page 1

Regard 3900 Series

i

Sixteen Channel Controller

Instructions for Use

WARNING

Strictly follow the Instructions for Use. The user must fully

understand and strictly observe the instructions. Use the

!

product only for the purposes specied in the Intended

Use section of this document.

Dräger. Technology for Life

®

Page 2

This page intentionally left blank

Page 3

Contents

Contents

1 For your safety ................................................................................................................................................................4

1.1 General safety statements ................................................................................................................................................4

1.2 Definitions of alert icons ....................................................................................................................................................4

2 Description ......................................................................................................................................................................5

2.1 Product overview ..............................................................................................................................................................5

2.2 Intended use .....................................................................................................................................................................5

2.3 Limitations on use .............................................................................................................................................................5

2.4 Approvals ..........................................................................................................................................................................5

3 User information .............................................................................................................................................................7

3.1 Display screen ..................................................................................................................................................................7

3.2 Alarm, fault and active LEDs .............................................................................................................................................8

3.3 Power and inhibit LEDs .....................................................................................................................................................8

3.4 Internal sounder ................................................................................................................................................................8

3.5 External warning devices ..................................................................................................................................................9

3.6 Control buttons (and remote reset) ...................................................................................................................................9

3.7 LED and display screen test .............................................................................................................................................9

4 Technical information ...................................................................................................................................................10

4.1 General ...........................................................................................................................................................................10

4.2 Display board ..................................................................................................................................................................10

4.3 Input module ...................................................................................................................................................................11

4.4 Relay module ..................................................................................................................................................................11

4.5 Output module ................................................................................................................................................................12

5 Installation and set up ..................................................................................................................................................13

5.1 General instructions ........................................................................................................................................................13

5.2 Positioning and mounting the controller ..........................................................................................................................13

5.3 Cable entries ...................................................................................................................................................................14

5.4 Cable screen earthing plate ............................................................................................................................................14

5.5 Power supplies ................................................................................................................................................................15

5.6 Installing control modules ...............................................................................................................................................16

5.7 Connecting remote sensor transmitters ..........................................................................................................................20

5.8 Connecting other remote devices ...................................................................................................................................23

6 Conguringandcalibratingthecontroller .................................................................................................................25

7 Troubleshooting

7.1 Polytron remote sensor transmitter faults .......................................................................................................................27

8 Maintenance ..................................................................................................................................................................27

9 Disposal of electrical and electronic equipment .......................................................................................................27

10 Technical data ...............................................................................................................................................................28

10.1 Transfer function .............................................................................................................................................................29

11 Order list ........................................................................................................................................................................30

............................................................................................................................................................26

Annexe

A ConguringandcalibratingaRegard3920controller ..............................................................................................31

A.1 General ...........................................................................................................................................................................31

A.2 Main menu ......................................................................................................................................................................31

A.3 Information menu ............................................................................................................................................................32

A.4 Calibration menu .............................................................................................................................................................33

A.5 Settings menu .................................................................................................................................................................34

3Regard 3900 Series

Page 4

For your safety

1 For your safety

1.1 General safety statements

● Before using this product, carefully read the Instructions for Use.

● Do not dispose of the Instructions for Use. Ensure that they are retained and appropriately used by the product user.

● Only fully trained and competent users are permitted to use this product.

● Comply with all local and national rules and regulations associated with this product.

● Only trained and competent personnel are permitted to inspect, repair and service the product as detailed in these Instructions

for Use (see Section 8 on Page 27). Further maintenance work that is not detailed in these Instructions for Use must only be

carried out by Dräger or personnel qualied by Dräger. Dräger recommends a Dräger service contract for all maintenance

activities.

● Properly trained service personnel must inspect and service this product as detailed in the maintenance section of this

document.

● Use only genuine Dräger spare parts and accessories, or the proper functioning of the product may be impaired.

● Do not use a faulty or incomplete product, and do not modify the product.

● Notify Dräger in the event of any component fault or failure.

1.2 Denitionsofalerticons

Alert icons are used in this document to provide and highlight text that requires a greater awareness by the user. A denition of

the meaning of each icon is as follows:

WARNING

!

Indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

CAUTION

!

Indicates a potentially hazardous situation which, if not avoided, could result in physical injury or damage to the product

or environment. It may also be used to alert against unsafe practices.

NOTICE

Indicates additional information on how to use the product.

i

i

4

Regard 3900 Series

Page 5

Description

2 Description

2.1 Product overview

The Dräger Regard 3900 series is a range of controllers that are used to continuously monitor up to sixteen 4–20 mA remote

sensor transmitters in order to warn of potentially dangerous or harmful conditions.

The series includes the Regard 3900, 3910 and 3920. The Regard 3900 and 3920 are sealed control panels, and the Regard

3910 is a modular system intended to be installed in a rack-based system. Other differences are explained in this document

where necessary.

The controller monitors the current signals from the remote sensor transmitters on input channels and provides warnings when

alarm or fault conditions occur. Each of the input channels can provide alarms for up to three gas levels (A1, A2 and A3) and two

fault conditions (F1 and F2). The gas-level alarms are congured to provide an indication of potentially dangerous or harmful gas

levels at the transmitter, and can be set to activate as the monitored gas levels are rising or falling. The faults (F1 and F2) operate

when the transmitter sends the relevant fault signal (F2 is only used when the transmitter provides a second fault signal).

The combination of internal control modules (input modules, relay modules and output modules) and the controller conguration

settings can be altered to meet the gas detection and warning requirements. Additionally the warning devices used with the

controller can be selected and congured as required by the user. The Regard 3900 series controllers are congured using a

Microsoft Windows

2.2 Intended use

Regard 3900 series controllers are used with 4–20 mA transmitters to provide stationary, continuous monitoring of ammable

or toxic gases and vapours, and oxygen deciency or enrichment. The controller is primarily intended for use as a part of a gas

detection system, but can be used with any remote sensor transmitter which uses a 4–20 mA source output (transmitters that

use a 4–20 mA sink output cannot be used). This document describes the Regard 3900 series used as a controller for a gas

detection system.

®

based software program. The Regard 3920 also has a built-in conguration system.

The controller is intended for use in residential, commercial and industrial environments to provide:

● Display of measured gas level.

● Visual and audible alarms at the controller and external warning devices.

2.3 Limitations on use

WARNING

The controller is not designed or approved for use in areas where combustible or explosive gases, vapours or dust mixtures

!

are likely to occur. Do not use the Regard 3900 series controller in areas subject to explosion hazards (“hazardous

areas”) without suitable protection. Contact Dräger for further information.

The controller cannot be used with three-wire transmitters that have a 4–20 mA sink output.

2.4 Approvals

The Regard 3900 series controller is certied according to the directive 94/9/EC (ATEX directive) to be operated with performance

approved 4–20 mA transmitters (EC-type examination certicate TRL 06 ATEX 21099X).

Output modules are not included in the scope of the Regard 3900 ATEX EC-type examination. Output modules shall not be used

for countermeasures against risk of explosion.

SpecialconditionsforsafeuseaccordingtoEC-typeexaminationcerticateTRL06ATEX21099X

1. Only remote sensor transmitters with valid and appropriate ATEX certication for safety and measurement performance shall

be connected to this control equipment. These connections may be via ATEX certied safety interface barriers.

2. Any cable used for interconnection of remote sensor transmitters should be selected to ensure that its resistance does not

have any adverse effects on the operation of the control unit.

Requirements of EN 60079-29-1

If a Regard 3900 series controller is used for ammable gas detection to protect against risk of explosion, at least one gas alarm

relay should be set latching. (See EN 60079-29-1:2007 Explosive atmospheres – Gas detectors – Performance requirements of

detectors for ammable gases.)

CEMarkingandATEXapproval

The Regard 3900 is CE marked to indicate conformity to the following directives:

● ATEX directive 94/9/EC

● EMC directive 2004/108/EC

● Low-voltage directive 2006/95/EC

5Regard 3900 Series

Page 6

Description

NOTICE

Using a power supply unit (PSU) not supplied or installed by Dräger may require reassessment of the compliance of the

i

i

controller with the EMC directive and/or the low-voltage directive.

ATEXMarking

The controller also has the following ATEX marking:

II (2) G

WARNING

This marking does not mean that the unit is “explosion proof”. The Regard 3900 series cannot be used in areas subject

!

to explosion hazards (“hazardous areas”) without suitable protection.

6

Regard 3900 Series

Page 7

3 User information

Regard 3920

User information

Regard 3900

Regard 3910

3825

3.1 Display screen

The display screen is a multi-line, 20-character, backlit, LCD screen that provides information about the gases that the controller

is monitoring. During the normal gas-level display, the screen shows four lines of text.

Channel

identity

▼

0 1 : 0 % L E L M e t h a n

0 2 : 0 . 0 1 p p m C h l o r i

0 3 : 0 . 1 p p m H 2 S

0 4 : 1 2 3 4 p p b G a s n a m

● Very low gas levels of ± 2% of the measuring range are displayed as zero (this is referred to as the zero clamp).

● The display screen contrast is adjustable. Contact a trained maintenance technician or Dräger if adjustment is required.

3.1.1 Display screen scrolling

The display screen shows the information from up to four channels at a time, and if there are more than four channels installed,

the display screen scrolls to show all channels sequentially.

● Press Hold / II / ▲ for <1 second to freeze the display screen (stop scrolling).

● Press Hold / II / ▲ again for <1 second to unfreeze the display screen (restart scrolling).

Gas level Measurement

▼

units

▼ ▼

Gas name

or measuring range

3.1.2 Gas name or measuring range

The display screen can toggle between the gas name and the measuring range. The default is the gas name.

● Press Hold / II / ▲ for >1 second to show the full-scale deection (FSD) (the example below shows measuring range of 0–2000).

0 2 : 1 2 3 5 p p m ( 2 0 0 0 )

3.1.3 Over-range

Over-range is displayed if the gas level increases above the measuring range (the transmitter signal is above 20 mA). The overrange indication is latching (i.e. it remains on-screen even if the gas level returns into the measuring range).

● Press Acknowledge / OK (or operate the remote reset if available) to clear an over-range indication. If it is pressed when the

gas level is above the measuring range, the indication clears when gas level falls into the measuring range.

0 2 : O v e r - r a n g e

7Regard 3900 Series

Page 8

User information

3.1.4 Under-range

Under-range is displayed when the gas level is below the measuring range (the transmitter signal is below 3.8 mA – but not a

recognized maintenance or fault signal).

0 2 : U n d e r - r a n g e

3.1.5 Maintenance

Maintenance is displayed when transmitter maintenance is due (the transmitter signal is a recognized maintenance signal).

0 2 : M a i n t e n a n c e

3.2 Alarm, fault and active LEDs

WARNING

The alarm levels and the activation modes are congured to meet the requirements of the user. The actions and

!

countermeasures to be taken when any alarm or fault LED activates must be dened by the person responsible for the

gas detection system.

Although there are up to three gas-level alarms (A1 to A3) and two fault alarms (F1 and F2), there are no LEDs on the controller

for alarm A3 or fault F2. Remote warning devices can be congured to provide indications for alarm A3 and fault F2 when

required.

LED Condition

Alarm A1 Flashing

Alarm A2 Flashing

Fault F1 Flashing

Active /

Steady

Off

Steady

Off

Steady

Off

Steady

Blinking (off every 30 sec)

Off

A1 alarm tripped

A1 alarm acknowledged but alarm condition present

No alarm condition

A2 alarm tripped

A2 alarm acknowledged but alarm condition present

No alarm condition

F1 alarm tripped

F1 alarm acknowledged but fault present

Channel healthy

Channel active

Alarms inhibited

Channel inactive

(see also Inhibit / LED in Section 3.3)

3.3 PowerandinhibitLEDs

The power supply to the controller can be from an AC or DC power source or both. When both are used, the DC power source

(usually a battery system) is used as a backup supply in case of AC power supply failure.

Power AC /

It is optional to connect this LED when the controller uses both AC and DC power sources. When the LED is connected, it is

illuminated when the controller is supplied from the (primary) AC supply, and is off when the controller is supplied from the

(backup) DC supply.

Power DC /

Illuminates when there is a 24 Vdc supply to the internal control modules. (Irrespective of the power supply to the controller, the

internal control modules require a 24 Vdc supply.)

Inhibit/ LED

Illuminates to indicate that the alarms are inhibited, and therefore the normal gas-level monitoring and warning functions of

the controller are inactive. When the LED is illuminated, the Active /

30 seconds. Any remote warning device congured to activate when the alarms are inhibited would also activate.

LED

LED

LEDs blink off and the internal sounder beeps every

The alarms are inhibited when an internal inhibit switch is set to the maintenance position: usually for maintenance or repair of

the controller.

3.4 Internal sounder

The internal sounder emits an audible warning tone when A1, A2, A3, or F1 activates (not when F2 activates). The sounder also

beeps every 30 seconds when alarms are inhibited.

● Press Acknowledge / OK (or operate the remote reset if available) to silence the sounder.

8

Regard 3900 Series

Page 9

User information

3.5 External warning devices

External warning devices used with the Regard 3900 series controllers are activated by relays inside the controller, and are

congured to meet the user’s gas detection requirements. The relays can be congured to operate in a number of ways:

● Latching relays remain activated (in the alarm state) when an alarm condition has occurred but is no longer present.

● Non-latching relays deactivate (return to the non-alarm state) when an alarm condition is no longer present.

● Acknowledgeable relays can be manually deactivated (returned to the non-alarm state) when the alarm condition is still

present. This is used to switch off or silence external warning devices when the alarm condition is still present.

● Non-acknowledgeable cannot be deactivated when the alarm condition is present.

● Alarms inhibited relays activate when an internal inhibit switch is set to the maintenance position (see Inhibit / LED in

Section 3.3 on Page 4).

Latching or non-latching

Setting Meaning

Latching The relay requires manual action to reset after alarm activation.

Non-latching The relay automatically returns to the non-alarm state when the

Acknowledgeableornon-acknowledgeable

Press Acknowledge / OK or operate the remote reset:

• If the alarm condition is clear or if the relay is acknowledgeable,

the relay returns to the non-alarm state immediately.

• If the alarm condition is present, the relay returns to the non-

alarm state when the alarm condition clears.

alarm condition clears.

Setting Meaning

Acknowledgeable The relay can be reset manually when the alarm condition is

Non-acknowledgeable Relay cannot be reset manually. The relay automatically returns to

present.

Press Acknowledge / OK or operate the remote reset – the relay

returns to the non-alarm state.

the non-alarm state when the alarm condition clears.

3.6 Controlbuttons(andremotereset)

Acknowledge / OK

Acknowledges activated alarms, faults and display screen messages. When pressed, depending on the associated transmitter

signal and the controller settings:

● Alarm and fault LEDs on the controller extinguish or change to steady.

● The internal sounder is silenced.

● Display screen messages clear (for example: over-range).

● External warning devices remain activated or deactivate depending on the conguration.

Remote reset

A remote reset is a switch that performs the same functions as the Acknowledge / OK button, remotely from the controller.

Hold/II/▲

Controls the scrolling function and toggles between the gas name and the measuring range on the display screen.

● Press Hold / II / ▲ for <1 second to freeze and unfreeze scrolling (when more than four channels are used).

● Press Hold / II / ▲ for >1 second to toggle between the gas name and the measuring range.

Regard 3920 only

The ▲ / ▼ / OK buttons on Regard 3920 are also used to navigate and select settings within the built-in conguration menus

(see Annexe A on Page 30).

3.7 LED and display screen test

Pressing and holding two control buttons simultaneously tests the LEDs, display screen and internal sounder of the controller.

While the buttons are held, all LEDs illuminate (the Power AC /

segments ll and the sounder emits the alarm tone.

● Regard 3900: press Acknowledge and Hold

● Regard 3910: press OK and II

● Regard 3920: press OK and ▲

Use this function as a condence check of controller visual and audible outputs when required.

LED only illuminates if connected), all display screen

9Regard 3900 Series

Page 10

Technical information

4 Technical information

WARNING

!

This section and all subsequent sections contain technical and set-up information for trained maintenance technicians.

The procedures should not be attempted by untrained personnel as it could make the controller or gas detection system

unsafe for use.

4.1 General

The controller has a display board and up to six control modules. The control modules are a combination of input modules,

relay modules and output modules, which is exible within the limitations of the controller. Internally, all control modules and the

display board are connected together using a ribbon cable.

The controller can be supplied from an AC or DC source or both, and irrespective of the power supply to the controller the internal

control modules receive a 24 Vdc supply. The following internal LEDs operate during use:

● A green LED on each of the control modules illuminates to indicate that the internal DC voltage is supplied.

● Two red LEDs on the right-hand side of the display board and each of the control modules icker during normal operation.

● A red LED next to each relay on an input module or relay module illuminates when the relay is energized.

4.2 Displayboard

The display board is tted inside the controller, and houses the display screen and the LEDs that are visible on the front panel.

The display screen and LEDs provide information and warnings in response to the conditions measured at the remote sensor

transmitters. Also on the display board are the inhibit switch and the contrast control.

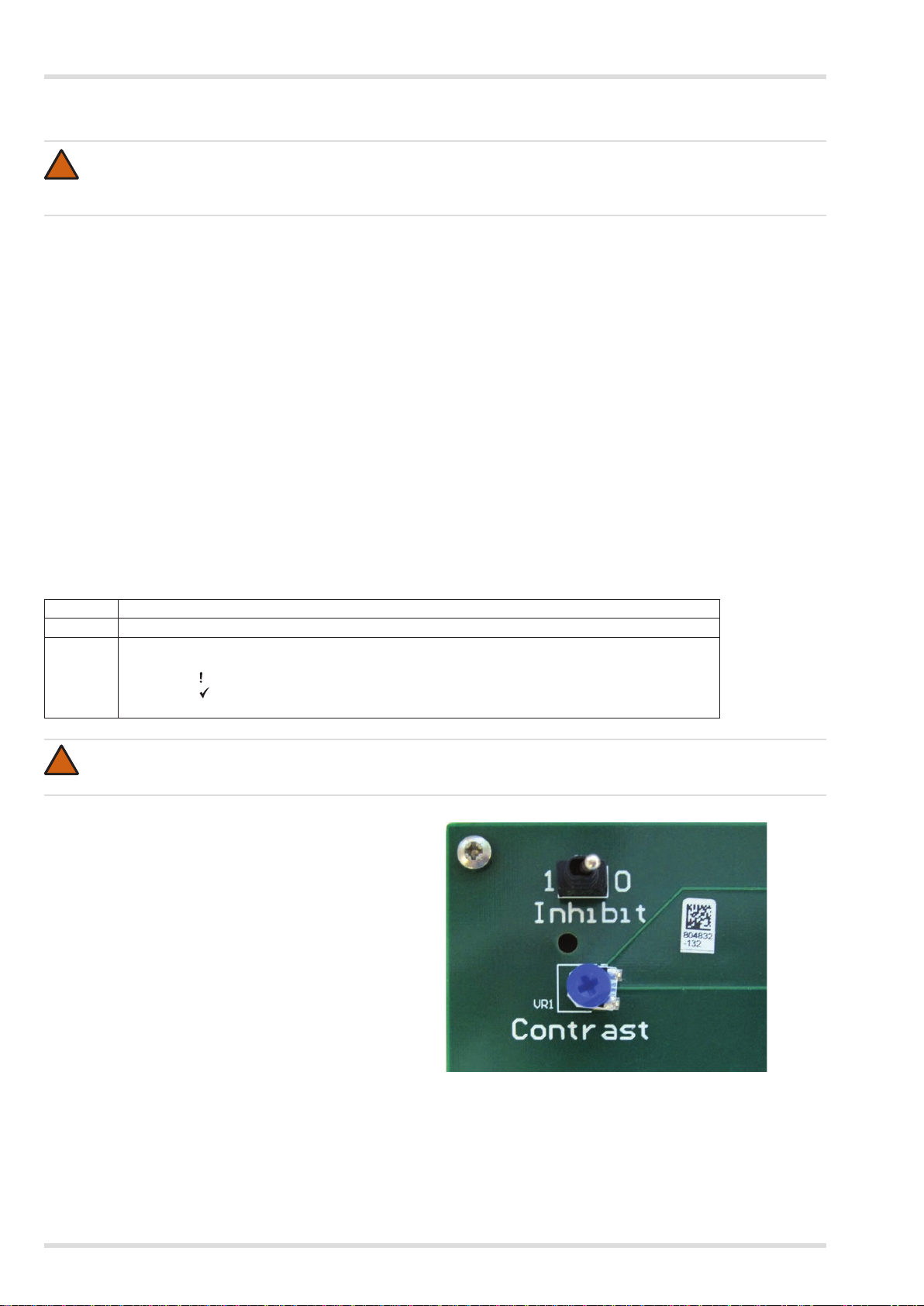

4.2.1 Inhibitswitch

The inhibit switch is used during maintenance or repair of the controller to hold the controller relays in their current state, and

thereby prevent activation of the gas-level warnings. The inhibit switch operates as follows:

Position Effect

0 All relays operate normally

1 Relays congured as “alarms inhibited” energize (associated remote warning devices activate).

!

4.2.2 Contrast control

The display screen contrast can be adjusted using the contrast

control. When required, use a suitable screwdriver to turn

the control to adjust the contrast. Note that LCD screens are

affected by temperature and adjustment may be required to

suit very cold or very hot environments.

All other relays are held in their current state.

The Inhibit /

The Active / LEDs blink off and the internal sounder beeps every 30 seconds.

Output module signals freeze at their current level.

WARNING

Setting the inhibit switch to position 1 holds the controller relays in their current state and prevents activation of gas-level

warnings. Always return the switch to position 0 after the maintenance or repair task.

LED illuminates.

10

3801

Regard 3900 Series

Page 11

Technical information

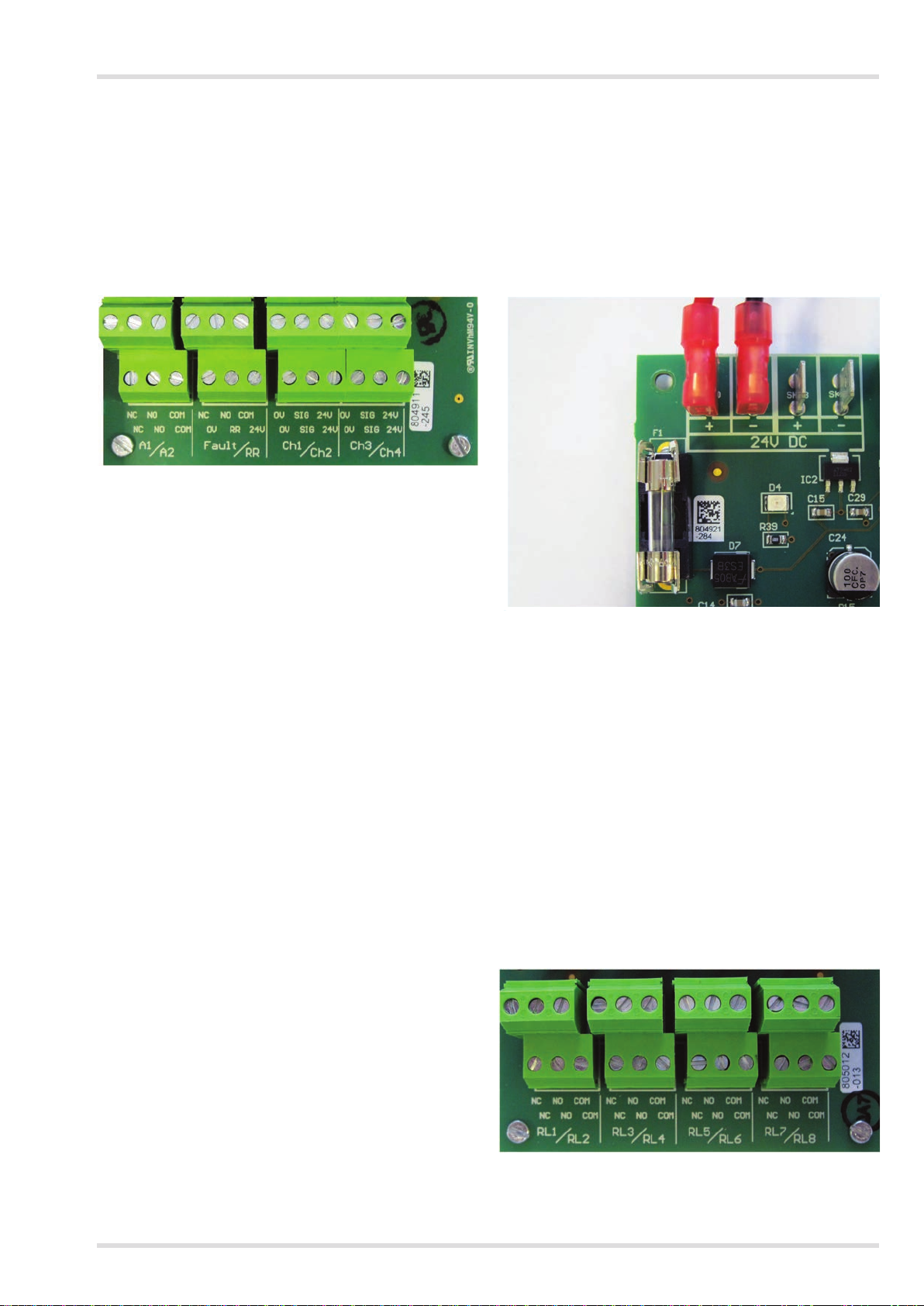

4.3 Input module

An input module has four channels that can each monitor the current signal from a remote sensor transmitter. Each of the

channels can provide alarms for up to three gas levels (A1, A2 and A3) and two fault conditions (F1 and F2). The gas-level

alarms are congured to provide an indication of potentially dangerous or harmful gas levels at the transmitter, and can be set to

activate as the monitored gas levels are rising or falling. The faults (F1 and F2) operate when the transmitter sends the relevant

fault signal (F2 is only used when the transmitter provides a second fault signal).

Each input module has three relays that operate when an F1 (fault 1), A1 (alarm 1) and A2 (alarm 2) signal is received from any of

the channels monitored by the board. The relays are volt-free single-pole changeover type that can be used to activate external

warning devices. The fuse on the input module protects the module against a short circuit on the input channels (Ch1 to Ch4).

3802

3803

The input module terminals are:

● Ch1 to Ch4 are channels for two-wire or three-wire 4–20 mA remote sensor transmitters.

● A1, A2 and Fault (F1) are terminals for the input module relays.

● RR are the remote reset terminals that are used to connect a normally-open switch, remote from the controller, to perform the

same function as the Acknowledge / OK button.

During installation, each input module is congured with a different module number (1–4) in order to set the channel numbers

(1–16) within the controller system (see Section 5.6.2 on Page 17).

Each input module requires a 24 Vdc supply using cables that are supplied with the module (see Section 5.6.3 on Page 18).

4.3.1 Input module relay settings

Input module relays settings are preset or can be set during conguration as follows:

● All input module relays are non-acknowledgeable.

● A1 and A2 relays energize on alarm.

● F1 relay is always (preset) normally energized.

● Each relay can be set latching or non-latching during conguration.

4.4 Relay module

A relay module is used to activate external warning devices

(alarms, ventilators or other safety equipment) when alarm or

fault conditions are sensed at the Regard 3900 series controller.

The module has eight volt-free single-pole changeover relays

of which one is a non-congurable system-fault relay (RL1)

and seven are congurable relays (RL2 to RL8).

RL1 to RL8 are the terminals for the relay module relays.

During installation, each relay module is congured with

a different module number (1 or 2) in order to set the relay

numbers (1–16) within the controller system (see Section 5.6.2

on Page 17).

3804

11Regard 3900 Series

Page 12

Technical information

4.4.1 Relay module relay settings

RL1 is used to indicate that a system-fault has occurred. For example: RL1 will de-energize if the ribbon cable is disconnected

from the relay module, or if an F1 fault signal is received from any remote sensor transmitter in the system. RL1 is preset to:

● Function: common F1

● Normally energized

● Latching

● Non-acknowledgeable

The other seven relays can be set during conguration to:

● Function: see table below

● Normally energized or energize on alarm

● Latching or non-latching

● Acknowledgeable or non-acknowledgeable

Function Relay changes state when

Common A1 A1 trips on any channel

Common A2 A2 trips on any channel

Common A3 A3 trips on any channel

Common F1 F1 trips on any channel

Common F2 F2 trips on any channel

Common A1, A2 or A3 A1 or A2 or A3 trips on any channel

Single A1 A1 trips on one specied channel

Single A2 A2 trips on one specied channel

Single A3 A3 trips on one specied channel

Single F1 F1 trips on one specied channel

Single F2 F2 trips on one specied channel

Voting A1 A1 trips on a specied number of channels in a group

Voting A2 A2 trips on a specied number of channels in a group

Voting A3 A3 trips on a specied number of channels in a group

Voting F1 F1 trips on a specied number of channels in a group

Voting F2 F2 trips on a specied number of channels in a group

Alarms inhibited

The inhibit switch on the display board is moved to position 1

No function Relay does not change state

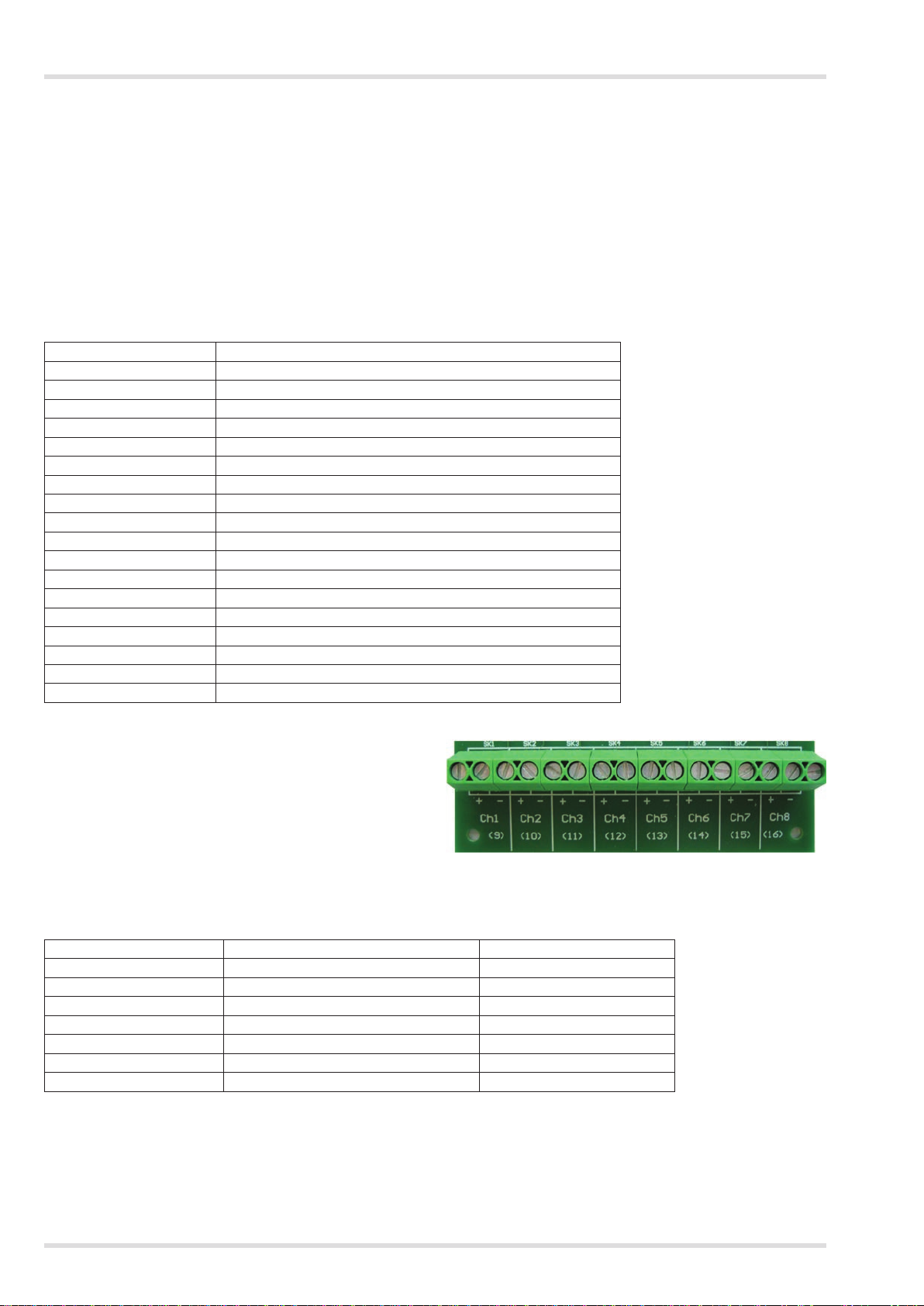

4.5 Output module

An output module is used to send the current signals that are

received from the remote sensor transmitters to an external

monitoring device or system. The module has eight output

channels (Ch 1–8) that match the signals from the controller

input channels (either Ch 1–8 or Ch 9–16) (see Section 5.6.2

on Page 17).

+ Signal

- 0 V

The signal outputs and 0 V duplicate the input channel signals but are electrically isolated from the input channels. The signal

outputs are current source that will only work when connected to a passive load.

Input channel signal (mA) Display screen reading (0–100 range) Output channel signal (mA)

Below 3.8 Under-range or maintenance Matches input signal

1

3.8 to 4.2 0 4.0 (zero clamp

)

4.3 2 4.3

12 50 12

20 100 20

Above 20 Over-range Matches input signal

Input channel inactive Not applicable 0

Note 1: The zero clamp provides a 4 mA output signal for very low gas levels of ± 2% of the measuring range.

Alarmsinhibit

If the inhibit switch is set to position 1 the output signals freeze at their current level. When the inhibit switch is returned position 0

the output signals return to the normal level.

3805

Output module fault

If the output module has a fault, the output signal on all channels is 1 mA (± 0.3 mA).

12

Regard 3900 Series

Page 13

403 mm (15.9 in.)

305 mm (12.0 in.)

Installation and set up

5 Installation and set up

5.1 General instructions

The following general instructions should be observed for all installation, repair or maintenance tasks on the controller. Refer also

to the remote sensor transmitter operating manual for information about the transmitters and sensors.

WARNING

!

Disconnect or switch off all AC and DC supplies to the controller before attempting installation, repair or maintenance

tasks on the controller. Failure to disconnect the power supply may result in personal injury and/or may damage the

controller, remote sensor transmitter, or wiring.

1. Disconnect or switch off all AC and DC supplies to the controller.

2. Remove the two cover screws (5 mm hexagonal key) and open the front cover.

3. Carry out the necessary installation, repair or maintenance task.

4. Check the sealing ring and close the front cover.

5. Ret and secure the two cover screws.

5.2 Positioning and mounting the controller

WARNING

!

The Regard 3900 series controllers are not “explosion proof” and must not be installed in a hazardous area without

additional Ex-protection.

Observe the following instructions regarding the installation environment:

● Locate the controller where it is accessible, and the display screen and indicators are easily seen.

● Avoid locations where excessive vibration (frequency above 55 Hz or amplitude above 0.15 mm (0.006 in.)) is possible.

● Avoid locations where aggressive or corrosive gases, contaminants or pollutants harmful to electronic equipment are present.

● Temperature conditions: 0 to 55 °C (32 to 131 °F).

● Relative humidity: Regard 3900/3920 – 0 to 100%, non-condensing; Regard 3910 – 0 to 95%, non-condensing.

5.2.1 Regard 3900 and 3920

A A

B

C

B

120 mm (4.7 in.)

210 mm (8.3 in.)

250 mm (9.8 in.)

B B

A

C

A

Mounting template – Dimensions not to scale

A M6 x 10 mm (0.4 in.) threaded hole

B Mounting hole

C Hanger

240 mm (9.4 in.)

300 mm (11.8 in.)

3807

13Regard 3900 Series

Page 14

Installation and set up

CAUTION

!

If the controller is mounted using the mounting holes (B), remove all control modules to prevent damage when drilling the

holes in the panel.

Observe normal precautions if drilling into walls or other structures to avoid damage to existing wiring, gas pipes, water

pipes, etc.

The panel requires a space of at least 50 mm (2 in.) on the left-hand side to allow the front cover to open. Dräger recommend a

space of at least 50 mm (2 in.) around the entire panel.

Mount the panel using the following as required:

● Use the M6 threaded holes (A) or the hangers (C) to maintain the ingress protection rating (IP 65) of the panel.

● Drill through the mounting holes (B) using a 5 mm (3/16 in.) drill bit. Drilling the mounting holes reduces the ingress protection.

● A mounting bracket that maintains the ingress protection rating of the panel is available from Dräger. The bracket is supplied

with the screws and washers required to t the bracket to the threaded holes (A) on the rear of the panel (see Section 11 on

Page 29 for the part number).

5.2.2 Regard 3910

Separate Assembly Instructions are supplied with the Regard 3910 controller.

5.3 Cableentries

CAUTION

Do not attempt to knock out cable entries as it may crack the control panel casing. Take care when cutting the cable

!

entries to avoid damaging internal components and wiring, and remove control modules to prevent damage when drilling

if necessary.

1. Select the cable hole on the top or bottom of the panel casing which is adjacent to the cable termination inside the panel.

2. Use an M20 hole cutter to cut out the pre-marked cable hole.

3. Insert the cable and t an M20 cable gland to seal the cable hole and prevent moisture ingress.

5.4 Cablescreenearthingplate

An earthing plate is available from Dräger to earth cable screen inside the panel of the Regard 3900 and 3920. When used,

connect the plate to an external low-impedance earth using braided cable with a large cross-section. Note that the earthing plate

is not required for the controller to meet the EMC directive.

14

Regard 3900 Series

Page 15

Installation and set up

5.5 Power supplies

The external power supply to the controller can be from an AC or DC power source or both. When both are used the DC power

source is used as a backup supply and can be a 24 Vdc supply or a 24 V battery. The specication and tolerances for AC and

DC power sources is shown in the technical data (Section 10 on Page 28).

5.5.1 AC Supply

NOTICE

i

i

If the internal 24 Vdc power supply unit (PSU) is not provided by Dräger, ensure that it meets the EMC (electromagnetic

compatibility) directive and the LVD (low-voltage directive) requirements. The PSU must also meet the following EMC

standards – immunity: EN 61000-6-2; emissions: EN 61000-6-3 or EN 61000-6-4.

If the AC supply to the controller is from an AC socket, the maximum length of cable between the socket and the controller

is three metres (9.8 feet).

For an AC power supply, use a 24 Vdc PSU connected as shown below. The PSU should be selected depending on the number

of input channels used. Dräger recommend the following:

● 4 channels – 2 A PSU.

● 8 channels – 5 A PSU.

● 12 or 16 channels – 10 A PSU.

AC on

+24 Vdc to

input modules

0 V

+24 V

L

N

E

External

230 Vac

in

Sk2

Display board

5.5.2 DC Supply

To supply the controller from an external DC supply:

● Use a regulated interference-free 24 Vdc supply.

● If the supply could be subject to high levels of conducted RF interference, use a lter to remove the interference.

● If HART (highway addressable remote transducer) diagnostics can be used for the remote sensor transmitters, the supply

must conform to the HART requirements (refer to the remote sensor transmitter operating manual).

AC on

230 Vac 24 Vdc PSU

+24 Vdc to

input modules

0 V

+24 V

3808

External

24 Vdc

in

Sk2

Display board

Fused

terminals

3810

15Regard 3900 Series

Page 16

Installation and set up

5.5.3 AC and DC Supplies

When used together, AC is the primary supply and DC is the backup supply. Diodes and/or relays may be required to switch

between the primary and the backup supplies.

Power AC /

When the controller is supplied with both AC and DC, it is optional to connect the 24 Vdc output from the PSU to the AC on

terminal on Sk2 on the display board. When connected, the Power AC / LED is illuminated when controller is supplied from

the (primary) AC supply, and is off when the controller is supplied from the (backup) DC supply. Note that a diode is required to

prevent current ow from the backup supply falsely indicating a functioning AC supply.

LED

AC on

Optional

0 V

+24 V

L

N

E

External

230 Vac

in

Sk2

Display board

0 V

24 Vdc to

input modules

+24 V

0 V

+24 V

External

24 Vdc or

battery

3811

5.6 Installing control modules

WARNING

Output modules are not included in the scope of the Regard 3900 ATEX EC-type examination. When an output module

!

is tted, the controller cannot be used for control of countermeasures against risk of explosion.

The controller can have up to six control modules using the combinations detailed in Section 5.6.1. When tting control modules

observe the following:

● Use the short pedestal screws for the lower level; use the long pedestal screws for the middle level; and use the long pedestal

screws and the plastic spacers for the upper level. (All of the screws have M3 threads.)

● Do not connect control modules outside the control panel of Regard 3900 and 3920 controllers.

● Refer also to the separate Assembly Instructions supplied for tting control modules to a Regard 3910 controller.

Example showing two input modules and one output module

16

3812

Regard 3900 Series

Page 17

Module Nr.

Installation and set up

5.6.1 Controlmodulecombinations

The combination of control modules must meet the following conditions:

● A maximum of six control modules (input, relay and output modules combined)

● A maximum of four input modules.

● A maximum of two relay modules.

● A maximum of four input modules and relay modules combined.

● A maximum of four output modules.

The table below shows the combinations. Using the highlighted row in the table as an example, the controller could have: three

input modules (up to 12 input channels); a single relay module (up to 8 relays); two, one or no output modules (16, 8 or 0 output

channels).

Input

module

4 0 2

3 1 2

3 0 3

2 2 2

2 1 3

2 0 4

1 2 3

1 1 4

1 0 4

5.6.2 Numberingcontrolmodules

!

Input modules

Place a link on the relevant “Module Nr” terminals on the input module to determine the channel numbers in the Regard 3900

system. When numbering the input module observe the following:

● Each input module within the controller must have a different module number (1 to 4).

● If there is only one module tted, set it as number 1.

● Number modules in sequence or difculty will occur when trying to congure the system.

Relay

module

WARNING

Renumbering an input or relay module (by moving the link on the module) after conguring the controller could prevent

alarms from activating as required. If an input or relay module is renumbered, recongure the controller to ensure that

alarms activate as required.

Maximum

number

of output

modules

1

2

3

4

3813

Link

position

1 1 – 4

2 5 – 8

3 9 – 12

4 13 – 16

Channels

17Regard 3900 Series

Page 18

Installation and set up

Relay modules

Place a link on the relevant “Relays” terminals on the relay module to determine the relay numbers in the Regard 3900 system.

When numbering the relay module observe the following:

● If there is only one relay module tted, place the link on position 1–8.

● If a second relay module is tted, place the link on position 9–16.

1 - 8

2

3

Relays

9 -16

3814

Link

position

1-8

Relay on

module

RL1

RL2

RL3

RL4

RL5

RL6

RL7

RL8

Number

in

system

1

2

3

4

5

6

7

8

Link

position

9-16

Relay on

module

RL1

RL2

RL3

RL4

RL5

RL6

RL7

RL8

Number

in

system

9

10

11

12

13

14

15

16

Output modules

Place a link on the relevant “Channels” terminals on the output module to determine the channel outputs: 1–8 or 9–16. Two or

more output modules can be set to the same channels if required.

1 - 8

2

3

9 -16

Channels

5.6.3 Controlmoduleanddisplayboardwiring

Input module 24 Vdc supply

Connect all input modules to the internal DC supply using the cables supplied with the module. Connect the rst input module

using the long (PSU to module) cables, and connect subsequent input modules in parallel using the short (module to module)

cables as shown.

3815

18

3809

Regard 3900 Series

Page 19

Installation and set up

Ribboncable

Connect the ribbon cable to the display board and to all control modules, using the standard ribbon cable supplied by Dräger.

The display board, relay modules and output modules do not require a separate DC supply.

Note: For Regard 3910 non-standard cable lengths can be supplied by Dräger. The maximum permitted length of the ribbon

cable is 2 metres (6.6 feet).

3816

19Regard 3900 Series

Page 20

Installation and set up

5.7 Connecting remote sensor transmitters

The wiring diagrams in this section show the general wiring layout for remote sensor transmitters. Refer to the remote sensor

transmitter operating manual for the specic details about the remote connections, including terminal marking, colour coding,

lettering, etc.

Observe the following for all transmitter types:

● The cable cross-section for transmitter wiring is a maximum 2.5 mm2 (0.004 in.2) and a minimum 0.5 mm2 (0.0008 in.2).

● Use screened cable if required by the transmitter.

5.7.1 Two-wire 4–20 mA transmitters

Input module

Ch1 Ch2 Ch3 Ch4

0 V SIG 24 V 0 V SIG 24 V 0 V SIG 24 V 0 V SIG 24 V

20

+24 V

4–20 mA signal

Channel 1

+24 V

4–20 mA signal

Channel 2

+24 V

4–20 mA signal

Channel 3

+24 V

4–20 mA signal

Channel 4

3817

Regard 3900 Series

Page 21

Installation and set up

5.7.2 Two-wire4–20mAtransmitterswithsafetybarrier

● Refer also to the instructions for the safety barrier and transmitter for connections between transmitter and barrier, and for

the barrier earth connection.

Hazardous area

Transmitter

+24 V

Signal

Non-hazardous area

Safety barrier

0 V

+24 V

Ex i

0 V

Signal

Input module

RR Ch1

0 V RR 24 V 0 V SIG 24 V

3819

21Regard 3900 Series

Page 22

Installation and set up

5.7.3 Three-wire 4–20 mA transmitters

● Only connect transmitters that have a 4–20 mA source output. Regard 3900 cannot be used with a three-wire transmitter that

has a 4–20 mA sink output (if necessary use a sink-to-source converter).

● The module can supply up to 400 mA to a three-wire transmitter.

● Use a cable where the three cores each have the same resistance.

● To ensure that a short circuit between the 4–20 mA signal output and the 0 V wire at the transmitter causes a fault indication

at the controller, each cable core must not exceed the resistance given by the formula:

R

cable = 250 x Ifault

Itxr

Rcable is the maximum resistance per core from the controller to the transmitter (in Ω).

I

fault is the fault trip level (in mA).

I

txr is the transmitter operating current (in mA).

Example using a transmitter with an operating current of 100 mA and a fault trip level of 3.2 mA.

Rcable = 250 x 3.2 = 8 Ω per core

100

Input module

Ch1 Ch2 Ch3 Ch4

0 V SIG 24 V

0 V SIG 24 V

0 V SIG 24 V

0 V SIG 24 V

22

0 V

4–20 mA signal

Channel 1

+24 V

0 V

4–20 mA signal

Channel 2

+24 V

0 V

4–20 mA signal

Channel 3

+24 V

0 V

4–20 mA signal

Channel 4

Regard 3900 Series

+24 V

3820

Page 23

Installation and set up

5.8 Connecting other remote devices

● The cable cross-section for remote devices is a maximum 2.5 mm2 (0.004 in.2) and a minimum 0.5 mm2 (0.0008 in.2).

5.8.1 Remote reset

A remote reset is a switch that performs the same functions as the Acknowledge / OK button remotely from the controller (see

Section 3.6 on Page 9). When a remote reset is required:

● Connect a normally-open switch to the remote reset (RR) terminals of an input module.

● If more than one input module is installed, it is sufcient to connect the remote reset switch to only one input module.

Input module

RR

0 V RR 24 V

3821

5.8.2 Relay terminals (input and relay modules)

The relay terminals on input modules (A1, A2 and Fault (F1)) and relay modules (RL1 to RL8) can be used to provide a switching

function for remote warning devices such as alarms, ventilators or other safety equipment. When connecting remote devices

observe the following:

● The voltage and current ratings of the relay contacts are shown in the technical data (see Section 10 on Page 28).

● Use screened or unscreened cable for relay outputs.

● When an internal supply is required to drive the external device, use an output from the power supply unit (PSU).

● The gures below show the relay contacts when relays are in the non-alarm or non-fault state.

NC NO COM

NC NO COM

Input or relay module

Energize on alarm

Input or relay module

Normally energized

3822

23Regard 3900 Series

Page 24

Output module

+ –

Ch1 Ch2 Ch3 Ch4

(9) (10) (11) (12)

Channel 1

+

–

+ –

+ – + –

Channel 2

+

Channel 3

+

Channel 4

+

External device

–

–

–

Installation and set up

5.8.3 Output module terminals

The output module terminals (Ch1 to Ch8) are used to output the corresponding remote sensor transmitter signal to an external

monitoring device or system.

● Each channel output is a current source that will only work when connected to a passive load.

3823

24

Regard 3900 Series

Page 25

Conguring and calibrating the controller

6 Conguringandcalibratingthecontroller

The conguration and calibration tools for Regard 3900 series controllers are used to view and change the conguration of the

controller, including the combination of internal control modules and the settings for the gas detection and warning devices. The

tools also allow zero point and span calibration.

Congure and calibrate the controller for all channels during initial installation and then when required during maintenance or

repair of the controller or gas detection system.

After completing any conguration or calibration, ensure that all alarms and warning devices operate as intended.

Congurationandcalibrationtools

For Regard 3900 and 3910, use the Dräger Regard 3900 Conguration Software. The software is a Microsoft Windows based

program that requires an interface unit (RS-232) and a compatible PC. The software and interface unit are available from Dräger.

See the Instructions for Use supplied with the software for full instructions.

For Regard 3920, use the built-in conguration system (see Annexe A on Page 30). Regard 3920 can also be congured using

the Dräger Regard 3900 Conguration Software if required.

25Regard 3900 Series

Page 26

Troubleshooting

7 Troubleshooting

Symptom Fault Remedy

Display screen blank and all LEDs off No supply to controller Check and repair the external supply

Faulty power supply unit Replace power supply unit

Internal wiring fault Check and repair internal power

Display screen blank No supply to display board Check and reconnect ribbon cable to

Display screen shows: NO INPUTS Ribbon cable fault Repair or replace ribbon cable

Display screen shows:

4–20 BOARD ERROR or

RELAY BOARD ERROR or

OUTPUT BOARD ERROR

LED and display screen test fails Faulty display board Replace display board

Power DC /

display screen on

Display screen shows: Under-range Faulty transmitter connection Check and repair the transmitter wiring

Display screen shows: Over-range Short-circuit remote sensor transmitter

Fault (F) LED illuminated for a single

channel

Fault (F) LED illuminated for a group of

four channels.

Input module tted, but no LEDs

illuminated or data on the display

screen for the module

Controller gas level different to the

level displayed at the remote sensor

transmitter

Fault (F) LED illuminated (steady) or

ashing when channel inactive

Water ingress Faulty seal Check and repair the cover sealing

LED not illuminated, but

Faulty input, relay or output module Replace the faulty module

Controller supply fault Check and repair the external or

Faulty display board Replace display board

Incorrect loop current Recalibrate

Faulty transmitter Replace the transmitter

wiring

Remote sensor transmitter fault Check and repair the transmitter

Transmitter wiring fault Check and repair the transmitter wiring

Incorrect loop current Recalibrate

Faulty transmitter Replace the transmitter

Faulty input module Replace input module

Transmitter wiring fault Check and repair the transmitter wiring

Ribbon cable fault Check and repair/replace ribbon cable

Faulty input module Replace input module

Ribbon cable fault Check and repair/replace ribbon cable

Internal wiring fault Check and repair internal power

Faulty input module Replace input module

Faulty display board Replace display board

Transmitter calibration fault Recalibrate

Input channel calibration fault Recalibrate

Input channel range incorrectly set Set the input channel range the same

Conguration error

and wiring

distribution wiring

display board and all modules

Replace display board

internal 24 Vdc supply

Check and repair the transmitter wiring

distribution wiring

as the transmitter range

Set the inhibit switch to position 1, then

return it to position 0

ring, cable entries and the front cover

information label

Output module faults

No signal from all outputs; green LED

not illuminated

No signal from all or some outputs;

green LED illuminated

Output is constant at 1 ± 0.3 mA. No signal from input modules Check and connect/repair the ribbon

Output constant but gas-level on

display screen changing

Output signal too low or will not reach

20 mA

26

No supply to module Check and connect/repair ribbon cable

Faulty output module Replace output module

Incorrect channels selected on output

module

Faulty output module Replace output module

Alarms inhibited

Load resistance too high Reduce load resistance

to module

Move link to the correct terminals on

the output module

cable

Return inhibit switch to position 0

Regard 3900 Series

Page 27

Troubleshooting

Symptom Fault Remedy

DrägerRegard3900CongurationSoftwarefaults

Unable to transfer conguration to or

from the controller

Calibration failure message on screen Remote sensor transmitter fault Check and repair the transmitter wiring

No supply to controller Check and repair the external supply

and wiring

Interface unit (RS-232) fault Check and repair/replace the interface

unit

and recalibrate

7.1 Polytron remote sensor transmitter faults

Polytron warning signal

The Polytron transmitter warning signal (3 mA for 1s every 10s) will trip the Fault (F1) relay on the input module if the trip level is

set above 2.9 mA. If the fault relay is non-latching, the relay will change state momentarily every 10s in time with warning signal.

Because the duration of the 3 mA signal is short, it may not trip the relay every time. If this occurs, refer to the remote sensor

transmitter operating manual.

Polytron maintenance signal

The maintenance signal on older Polytron transmitters (3~5 mA at 1 Hz) will trip the Fault (F1) relay on the input module if the

trip level is set above 2.9 mA. If the fault relay is non-latching, the fault relay will toggle. If this occurs, refer to the remote sensor

transmitter operating manual.

8 Maintenance

Observe EN 60079-29-2 and any relevant national regulations in the country of use.

There are no specic maintenance tasks for the Regard 3900 controller. Carry out any maintenance or calibration tasks in line

with the instructions and frequency described in the remote sensor transmitter operating manual.

NOTICE

During maintenance the inhibit switch on the display board can be used to hold the controller relays in their current state,

i

i

and thereby prevent activation of the gas-level warnings. See Section 4.2.1 on Page 10 for the inhibit switch operating

instructions.

9 Disposal of electrical and electronic equipment

EU-wide regulations for the disposal of electrical and electronic equipment, which have been dened

in the EU Directive 2002/96/EC and in national laws, are effective from August 2005 and apply to this

device. Common household appliances can be disposed of using special collecting and recycling facilities.

However, as this device has not been registered for household usage it must not be disposed of through

these means. The device can be returned to your national Dräger Safety Sales Organization for disposal.

Please do not hesitate to contact Dräger if you have any further questions about this issue.

27Regard 3900 Series

Page 28

Technical data

10 Technical data

Control panel versions (Regard 3900 and 3920)

Dimensions 415 × 305 ×

Weight Approximately 5 kg (11 lb)

Material ABS – VO

Ingress protection IP65

Cable entries M20 (qty 30)

All versions

Cable cross-section

AC input voltage (to PSU)

AC current consumption Typical Maximum

DC input voltage 18 to 30 Vdc

DC current consumption @ 24 V Input module: 60 mA excluding transmitters

Visual and audible outputs Visible: LEDs and display screen

Storage temperature -25 to 70 °C (-13 to 158 °F)

Operating temperature 0 to 55 °C (32 to 131 °F)

Relative humidity (RH) – operating

and storage

Start-up time

Response time <2 seconds

Accuracy Within 1% of measured value

Module xings M3

Maximum 2.5 mm2 (0.004 in.2)

Minimum 0.5 mm2 (0.0008 in.2)

Typical: 98 to 253 Vac, 50 to 60 Hz

2 A PSU < 0.5 A 0.5 A

5 A PSU 0.5 A 1 A

10 A PSU 1 A 2 A

Relay module: 200 mA

Output module: 300 mA

Display screen: 170 mA

Interface unit (RS-232): 50 mA

Audible: Sounder

Regard 3900/3920: 0 to 100%, non-condensing

Regard 3910: 0 to 95%, non-condensing

<40 seconds

175 mm (16.3 x 12 x 6.9 in.)

Relays (all modules)

Type Volt-free single-pole changeover

Contact material Silver alloy

Nominal switching capacity

Maximum switching power 1250 VA; 150 W

Switching voltage Maximum: 250 Vac; 100 Vdc

Switching current Maximum: 5 A

Output module

Output range

Isolation 50 V

Resolution 0.1 mA

Accuracy Within 1% of input signal (less zero clamp)

Maximum load

Storage temperature -25 to 70 °C (-13 to 158 °F)

5 A 250 Vac; 5 A 30 Vdc

Minimum: 10 V

Minimum: 100 mA

0.1 to 21.7 mA

500 Ω

28

Regard 3900 Series

Page 29

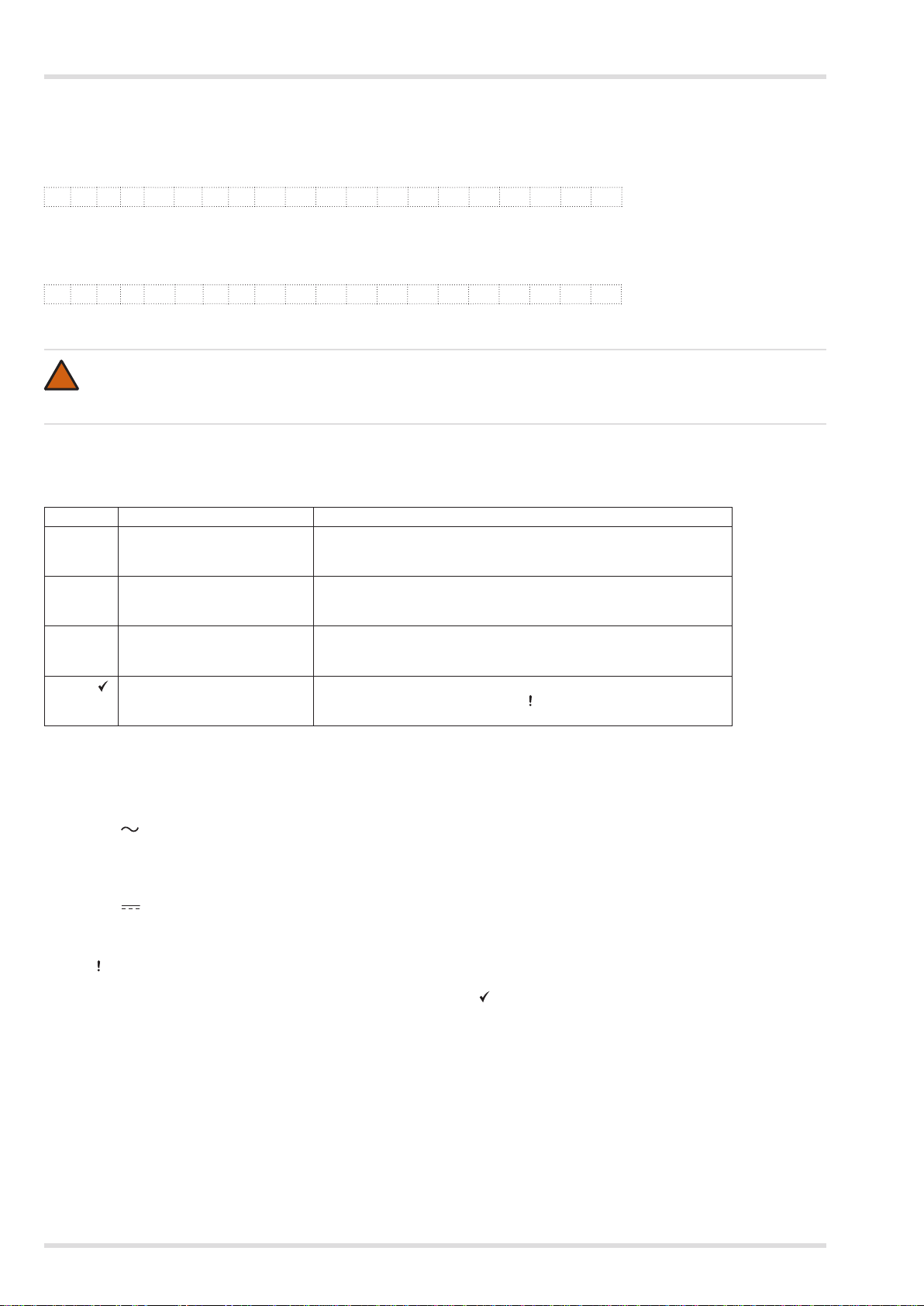

10.1 Transfer function

100

Gas concentration (% LEL)

Input signal Display reading

> 20.0 mA Over-range

4.3 to 20 mA Linear gas reading according to selected range

3.7 to 4.3 mA 0

< 3.7 mA Under-range or maintenance, depending on fault trip level

Gas concentration reading for 0–100 % LEL

80

60

Technical data

40

20

0

4 6 8 10 12 14 16 18 20

Input signal (mA)

3904

29Regard 3900 Series

Page 30

Order list

11 Order list

NOTICE

Regard 3800 series components are not compatible with the Regard 3900 series. Always refer to the relevant Regard

i

i

series order list when ordering parts and accessories.

Description Quantity Order code

Regard 3900 (control panel with display board) 1 4208780

Regard 3910 (bezel assembly with display board) 1 4208830

Regard 3920 (control panel with display board) 1 4208850

Display board (Regard 3900 and 3910) 1 4208781

Display board (Regard 3920) 1 4208856

Input module 1 4208782

Relay module 1 4208784

Output module 1 4208797

Dräger Regard 3900 Conguration Software 1 4208804

Interface unit (RS-232) 1 4208785

Ribbon cable 1 4208750

Power cable long (PSU to module) 1 (pair) 4208792

Power cable short (module to module) 1 (pair) 4208791

Earthing plate 1 4208777

Mounting bracket 1 4208796

Instructions for Use (English) 1 4208800

Instructions for Use (German) 1 4208801

Instructions for Use (French) 1 4208802

Instructions for Use (Spanish) 1 4208803

30

Regard 3900 Series

Page 31

Conguring and calibrating a Regard 3920 controller

A ConguringandcalibratingaRegard3920controller

A.1 General

The built-in conguration system in the Regard 3920 allows the user to view and change the controller conguration, including

the combination of internal control modules and the settings for the gas detection and warning devices. The system also allows

zero point and span calibration.

Entry into the conguration system is password protected and there are two entry levels. The calibration level is used when only

calibration is required, and the settings level is used when altering controller settings and calibration are required. The initial entry

passwords are shown below, and changing passwords is described in the settings menu (see Section A.5 on Page 19).

Calibration: _ _ _ 1

Settings: _ _ _ 2

To enter and use the conguration system:

1. Press ▼ for >1 second and then press OK to open the Enter password screen.

2. Enter the password and then press OK to open the main menu.

01: 20.9 %vol Oxygen

02: 14 ppm H2

03: 0 %LEL CH4

04: 4 ppb H2S

3. Use the ▲ / ▼ / OK buttons to navigate and select settings as shown in table below.

Key Function

OK Accept menu items and characters

▲ Navigate up/back in the menus and character lists

▼ Navigate down/ forward in the menus and character lists

When using the conguration system, note the following:

● Before conguring the controller, ensure that all input, relay and output modules are correctly numbered (see Section 5.6.2

on Page 11).

● Alarms are automatically inhibited when a conguration menu is open.

● Changes made during conguration are saved automatically.

● The display screen automatically returns to the gas-level display if a key is not pressed for 10 minutes.

►

Enter password

_ _ _ 2

↑ Exit

- Language

+ Information

►

+ Calibration

+ Settings

A.2 Main menu

Main menu

Exit

Language

Information

Calibration

Settings

Exit – Returns to the normal gas-level display.

Language – Selects the on-screen language (the settings menu is always in English).

Information

Calibration– Enters the calibration menu (see Section A.4 on Page 32).

Settings – Enters the settings menu (see Section A.5 on Page 33).

– Enters the information menu (see Section A.3 on Page 31).

31Regard 3900 Series

Page 32

Conguring and calibrating a Regard 3920 controller

A.3 Information menu

Information

Test LEDs

Tags

Modules

Test LEDs – Activates the LED and display screen test (see Section 3.7 on Page 9). Press OK to start and stop the test.

Tags – Displays all channel tags (read only).

Modules – Displays all module types and versions (read only).

32

Regard 3900 Series

Page 33

A.4 Calibrationmenu

Calibration

Module 1

Channel 1

Channel 2

Channel 3

Channel 4

Module 2

Conguring and calibrating a Regard 3920 controller

Tag

Zerocalibration

Spancalibration

Gas concentration

Signal mA

Channel 5

.

.

.

Channel 8

Module 3

Module 4

Use the calibration menu to calibrate the controller for all channels during initial installation and then when required during

maintenance or repair of the controller or gas detection system. Refer also to the remote sensor transmitter operating manual

for transmitter calibration instructions.

In the chart above, the Module 1 menu is expanded to show the zero and span calibration menus for Channel 1. Depending

on the number of modules congured as input modules, Channels 5 to 16 would be available on Modules 2, 3 and 4. The chart

shows Module 2 congured as an input module.

Tag – Displays the channel tag (read only).

Zerocalibration–Before calibrating the channel, it is mandatory to calibrate the transmitter to ensure that the transmitter output

signal is 4 mA for a zero gas reading.

1. Select Zerocalibration for the relevant channel.

2. Select Calibratechannel.

○ When the success message appears, exit the menu to save the calibration.

○ If a failure message appears, refer to the troubleshooting information (see Section 7 on Page 26).

Spancalibration–Calibrate the span by either applying calibration gas to the remote sensor transmitter, or by controlling the

transmitter output using the transmitter controls to simulate a gas signal.

Applyingacalibrationgas

1. Use a calibration adaptor to apply calibration gas to the transmitter. Use a concentration between 40% and 90% of the

measuring range, at the ow rate in the transmitter operating manual.

2. Allow the controller display screen reading to settle for 2 to 3 minutes.

3. Navigate to the relevant channel calibration menu.

4. Select Spancalibration and then Gas concentration.

5. Enter the concentration of the calibration gas, and then select Calibratechannel.

○ When the success message appears, exit the menu to save the calibration.

○ If a failure message appears, refer to the troubleshooting information (see Section 7 on Page 26).

Controlling the transmitter output

1. Set the signal output of the transmitter between 10 mA and 20 mA.

2. Navigate to the relevant channel calibration menu.

3. Select Spancalibration and then Signal mA.

4. Enter the transmitter signal, and then select Calibratechannel.

○ When the success message appears, exit the menu to save the calibration.

○ If a failure message appears, refer to the troubleshooting information (see Section 7 on Page 26).

33Regard 3900 Series

Page 34

Conguring and calibrating a Regard 3920 controller

A.5 Settings menu

Settings

Module 1: mA

A1 relay

A2 relay

Fault relay

Channel 1

Channel 2

Channel 3

Channel 4

Module 2:

Module 3: Rly

Module 4: –

Passwords

Date & time

NOTICE

The settings menu and the channel and relay sub-menus always use English language text.

i

i

Use the settings menu and the channel and relay sub-menus to congure the combination of internal control modules and the

settings for the gas detection and warning devices.

Module – Shows the module type (mA = input module Rly = relay module

or none. Module 3 and 4 can be an input module, relay module or none.

–

Relay 1

Relay 2

Relay 3

Relay 8

.

.

.

– = none). Module 1 and 2 can be an input module

A1 relay – Sets the A1 (alarm 1) relay latching or non-latching.

A2 relay – Sets the A2 (alarm 2) relay latching or non-latching.

If a Regard 3900 series controller is used for ammable gas detection to protect against risk of explosion, at least one gas alarm

relay should be set latching. (See EN 60079-29-1:2007 Explosive atmospheres – Gas detectors – Performance requirements of

detectors for ammable gases.)

Fault relay – Sets the F1 (fault 1) relay latching or non-latching.

Channel

Relay – Selects the relay settings (see Section A.5.2 on Page 35).

Passwords – Resets the entry passwords.

Date & time – Sets the controller date and time. The date format is YYYY/MM/DD. The time format is HH:MM:SS (setting the

time resets seconds to zero).

34

– Selects the input (4–20) channel settings (see Section A.5.1 on Page 34).

Regard 3900 Series

Page 35

A.5.1 Channel menu

Channel 1

Active

Tag

Gas name

Gas unit

Range

A1 alarm

A2 alarm

A3 alarm

F1 trip level

F2 trip level

Conguring and calibrating a Regard 3920 controller

Use the channels menu to view or congure the input (4–20) module channels.

The input channels present depend on the combination of internal control modules. For a controller using four input modules

(sixteen input channels), the channel layout would be:

Module 1 – Channels 1–4 Module 3 – Channels 9–12

Module 2 – Channels 5–8 Module 4 – Channels 13–16

Active – Activates (Yes) or deactivates (No) the channel.

WARNING

!

Deactivating an input module channel after it has been allocated to an alarm could prevent the alarm from activating as

required. Do not deactivate an input module channel after it has been allocated to a single or voting alarm.

Tag – Enter a unique channel identication name/number if required (maximum of sixteen characters).

Gas name – Enter the gas name (maximum of six characters).

Gas Unit – Enter the gas units (maximum of four characters).

Range – Choose from the list to select the measuring range (no custom ranges are allowed). When a measuring range is

selected, the A1 and A2 trip levels are automatically set to 20 % and 40 % of the range. The table below shows the measuring

range, resolution (step increment) and decimal places for the A1, A2 and A3 alarm trip levels.

Range Resolution Decimal places Range Resolution Decimal places

0 – 1 0.01 2 0 – 25 0.1 1

0 – 2 0.01 2 0 – 30 0.1 1

0 – 3 0.01 2 0 – 50 0.1 1

0 – 4 0.01 2 0 – 75 0.1 1

0 – 5 0.01 2 0 – 100 1 0

0 – 6 0.01 2 0 – 200 1 0

0 – 7 0.01 2 0 – 250 1 0

0 – 8 0.01 2 0 – 300 1 0

0 – 9 0.01 2 0 – 500 1 0

0 – 10 0.1 1 0 – 1000 5 0

0 – 11 0.1 1 0 – 2000 5 0

0 – 12 0.1 1 0 – 3000 10 0

0 – 15 0.1 1 0 – 5000 10 0

0 – 20 0.1 1 0 – 9999 25 0

A1 / A2 / A3 alarm – Enter an alarm T rip level

the A3 alarm). Also select Rising or Falling to set the alarm to activate for rising or falling gas levels.

F1 / F2 trip level

– Enter a fault alarm trip level between 1 mA and 3.8 mA (setting F2 to zero switches off the F2 alarm).

between 4 % and 100 % of the measuring range (setting A3 to zero switches of f

35Regard 3900 Series

Page 36

Conguring and calibrating a Regard 3920 controller

A.5.2 Relay menu

Relay 2

Function

Channel(s)

Alarm type

Energize mode

Latch

Acknowledge

Use the relay menu to view or congure the relay module relays.

Relays 1 and Relay 9 are preset, non-congurable, system-fault relays, which cannot be congured. Relays 2–8 and 10–16 are

congurable. The relays present depend on the combination of internal control modules. For a controller using two relay modules

(sixteen relays), the relay layout would be:

Module 3 – Relay 1–8

Module 4 – Relay 9–16

Function – Set the relay as:

Channel(s) – Only required for single or voting alarms.

Single – Select the channel from the channel list.

Voting – Enter [number of channels required to satisfy vote] out of [number of channels in voting group]. Then select

the channels from the channel list.

NOTICE

Inactive channels are shown with a dotted tick box.

i

i

If the selected channels do not match the number of channels required or the voting group, an on-screen message

informs the user.

Create a common alarm for a group of N channels by conguring the relay as voting 1 out of N, and specifying the

relevant channels in the voting group.

The following settings are only required for common, single and voting alarms.

Alarm type – Select the alarm or fault required (A1, A2, A3, F1 or F2).

Energize mode – Select energize on alarm or normally energized.

Latch – Select latching or non-latching.

Acknowledge – Select acknowledgeable or non-acknowledgeable.

Common,Single,Voting,Alarmsinhibited or No function.

36

Regard 3900 Series

Page 37

This page intentionally left blank

37Regard 3900 Series

Page 38

Draeger Safety UK Limited

Ullswater Close

Riverside Business Park

Blyth

Northumberland NE24 4RG

Tel +44 1670 352891

Fax +44 1670 544475

www.draeger.com

4208800

© Dräger Safety UK Limited

Edition 04 – April 2013

Subject to alteration

US Distributor: Draeger Safety, Inc.

101 Technology Drive

Pittsburgh, PA15275-1057

USA

Tel +1 412 787 8383

Fax +1 412 787 2207

www.draeger.com

Loading...

Loading...