REGARD-1

Single-channel controller

Installation, operation and maintenance

Issue 6 – December 2006

Issue 6 – December 2006

2

Contents

FOR YOUR SAFETY ................................................................................................. 3

INTENDED USE......................................................................................................... 4

CE marking and ATEX approval.............................................................................. 5

Other tests and approvals ....................................................................................... 5

Special conditions for safe use............................................................................... 5

DESCRIPTION ........................................................................................................... 6

Main board .............................................................................................................. 7

Display board ........................................................................................................ 10

Pellistor board ....................................................................................................... 11

Options board........................................................................................................ 11

INSTALLATION ....................................................................................................... 13

Installation environment ........................................................................................ 13

Mounting points..................................................................................................... 13

AC supply.............................................................................................................. 14

Connecting transmitters and measuring heads..................................................... 15

Relay outputs ........................................................................................................ 18

A1 and A2 24V “digital” outputs............................................................................. 18

Remote reset input................................................................................................ 20

CONFIGURATION AND CALIBRATION................................................................. 21

Set measuring range............................................................................................. 21

Calibrating a 4-20 unit ........................................................................................... 23

Calibrating an SE Ex unit ...................................................................................... 25

Configuring alarms ................................................................................................ 28

MAINTENANCE ....................................................................................................... 35

Fault finding........................................................................................................... 35

SPECIFICATIONS ................................................................................................... 36

Part numbers......................................................................................................... 37

EC type-examination certificate............................................................................. 38

EC Declaration of Conformity................................................................................ 43

Issue 6 – December 2006

3

FOR YOUR SAFETY

Follow the instructions

Follow the instructions for installation, operation and maintenance.

Maintenance

The equipment must be inspected and serviced regularly by trained personnel. Keep

a record of inspections and servicing.

Repairs of this apparatus should only be carried out by competent personnel.

We recommend that either a training course or service contract is obtained from

Draeger and that all repairs are carried out by them.

Refer to EN 50073 and/or local regulations.

Refer to the operating manual of the transmitter or measuring head information on

operation and maintenance of the transmitter or measuring head.

Not for use in areas where explosion hazards are possible

This equipment is not approved or certified for installation in potentially explosive

atmospheres.

Liability for proper function or damage

Liability for proper function of the equipment is irrevocably transferred to the owner or

operator to the extent that the equipment is serviced or repaired by personnel not

employed or authorised by DraegerService, or if the equipment is used in a manner

not conforming to its intended use.

Draeger Safety UK Limited can not be held responsible for any damage caused by

non-compliance with the above recommendations. The warranty and liability

provisions of the terms and conditions of sale and delivery of Draeger Safety UK

Limited are likewise not modified by the recommendations given above.

Draeger Safety UK Ltd

Issue 6 – December 2006

4

INTENDED USE

Regard–1 single-channel controller for 4-20mA transmitters

x For stationary, continuous monitoring of flammable or toxic gases and

vapours, oxygen deficiency or enrichment

x Display of measured gas value

x Indication of alarms and control of countermeasures

x Indication of time-weighted average value, time-weighted average alarm

output and data logger (requires optional RS-232/TWA alarm board)

Regard–1 single-channel controller for SE Ex measuring heads

x For stationary, continuous monitoring of flammable gases and vapours

x Display of measured gas value

x Indication of alarms and control of countermeasures

x Indication of time-weighted average value, time-weighted average alarm

output and data logger (requires optional RS-232/TWA alarm board)

The SE Ex unit will not work with the Dräger SE Ex LC measuring head.

Both units are suitable for use in residential, commercial and light industry

environments.

The Regard-1 controller is certified according to the directive 94/9/EC (ATEX

Directive) to be operated with performance approved 4-20mA transmitters (EC-type

examination certificate BVS 03 ATEX G 011X), or with Dräger SE Ex pellistor

measuring heads.

Issue 6 – December 2006

5

CE marking and ATEX approval

Regard-1 is CE marked to indicate conformity to the following directives:

x “ATEX directive” 94/9/EC

x “EMC directive” 89/336/EEC

x “Low-voltage directive” 73/23/EEC

The controller also carries the following ATEX marking:

THIS MARKING DOES NOT MEAN THAT THE UNIT IS “EXPLOSION PROOF”.

Regard-1 cannot be used in areas subject to explosion hazards (“hazardous

areas”) without suitable protection.

Other tests and approvals

In addition to the measuring function for flammable gases in the range 0 to 100

%LEL and for oxygen (inertisation) in the range 0 to 25 %(V/V), Regard-1 has been

tested according to DIN EN 45544-1 combined with DIN EN 45544-2 for toxic gases,

and according to DIN EN 50104 for oxygen enrichment and oxygen deficiency, by

EXAM BBG Prüf- und Zertifizier GmbH, Dinnendahlstrasse 9, 44809 Bochum,

Germany.

The "Bericht über die Eignungsuntersuchung" has been issued under PFG-No.

41301303.

In Germany only:

Read and consider chapter 5 of the "Bericht über die Eignungsuntersuchung", which

follows. (Text included in German edition manual only.)

Special conditions for safe use

according to EC-type examination certificate

BVS 03 ATEX G 011 X

Vibration can cause malfunction of alarm and fault contacts. Do not expose to

vibrations with frequencies above 55 Hz or amplitudes above 0.15 mm.

For safety relevant decisions only use the status of the relays. Do not use the display

reading or LED indications. For calibration and adjustment of alarm set points use a

voltmeter between test points TP1 and TP2 to determine the gas reading and the

alarm thresholds.

Regard-1 4-20: if used with a transmitter whose output current can be below 20mA

for concentrations above full scale, set the alarm relays latching.

Regard-1 SE

Ex: set at least one alarm relay – the one with the highest alarm level –

to be latching.

II (2) G

Issue 6 – December 2006

6

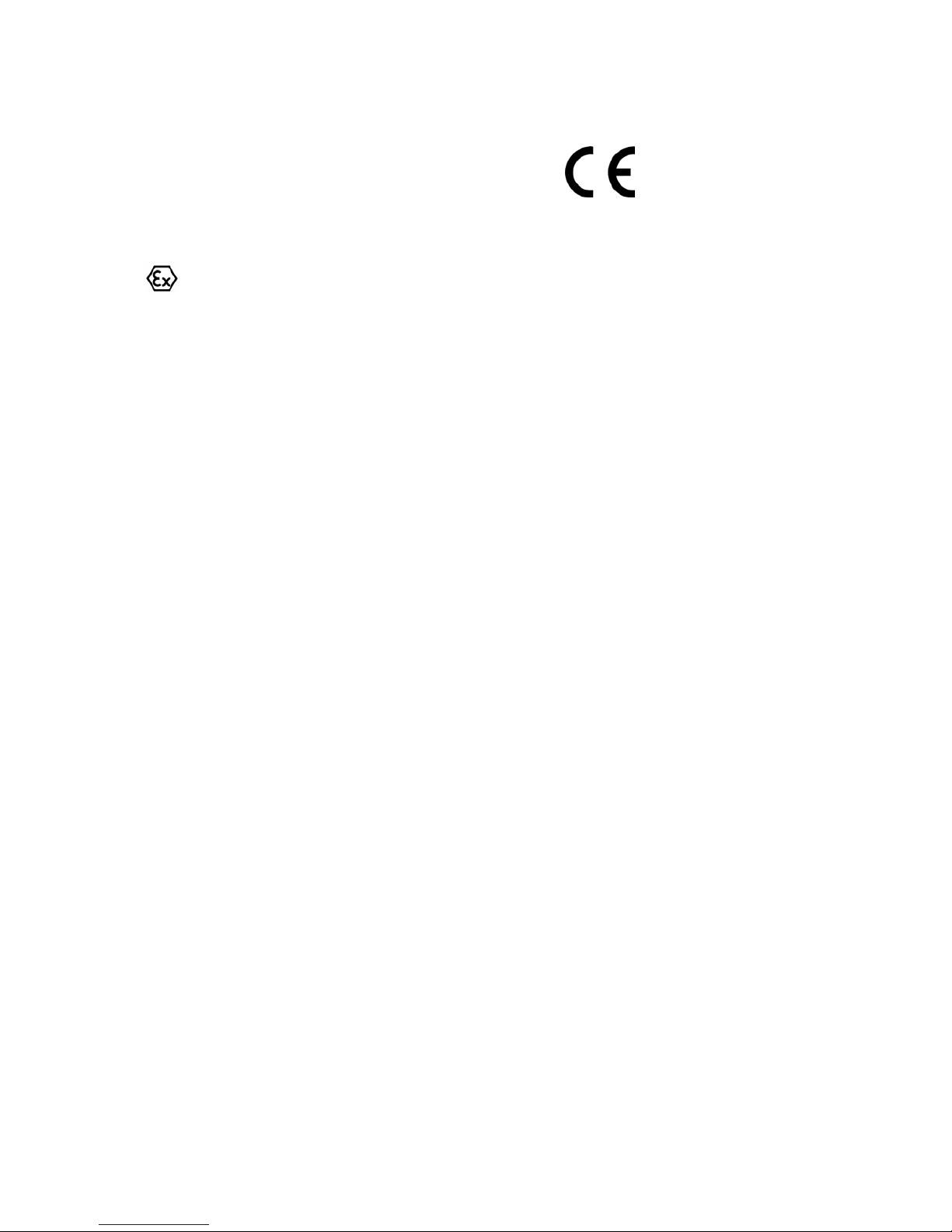

DESCRIPTION

The unit is available in two versions: 4-20mA or SE Ex, with or without gas level

display.

An additional “Options board” is available that provides an isolated 4-20mA output,

TWA alarm relay and data logger with RS-232.

Two 1.2AH lead-acid batteries can be fitted inside the unit’s enclosure to provide

continued operation for several hours if AC power is interrupted.

Lead-acid batteries

Display board

Pellistor board

Options board

Main board

Cable entry area

Issue 6 – December 2006

7

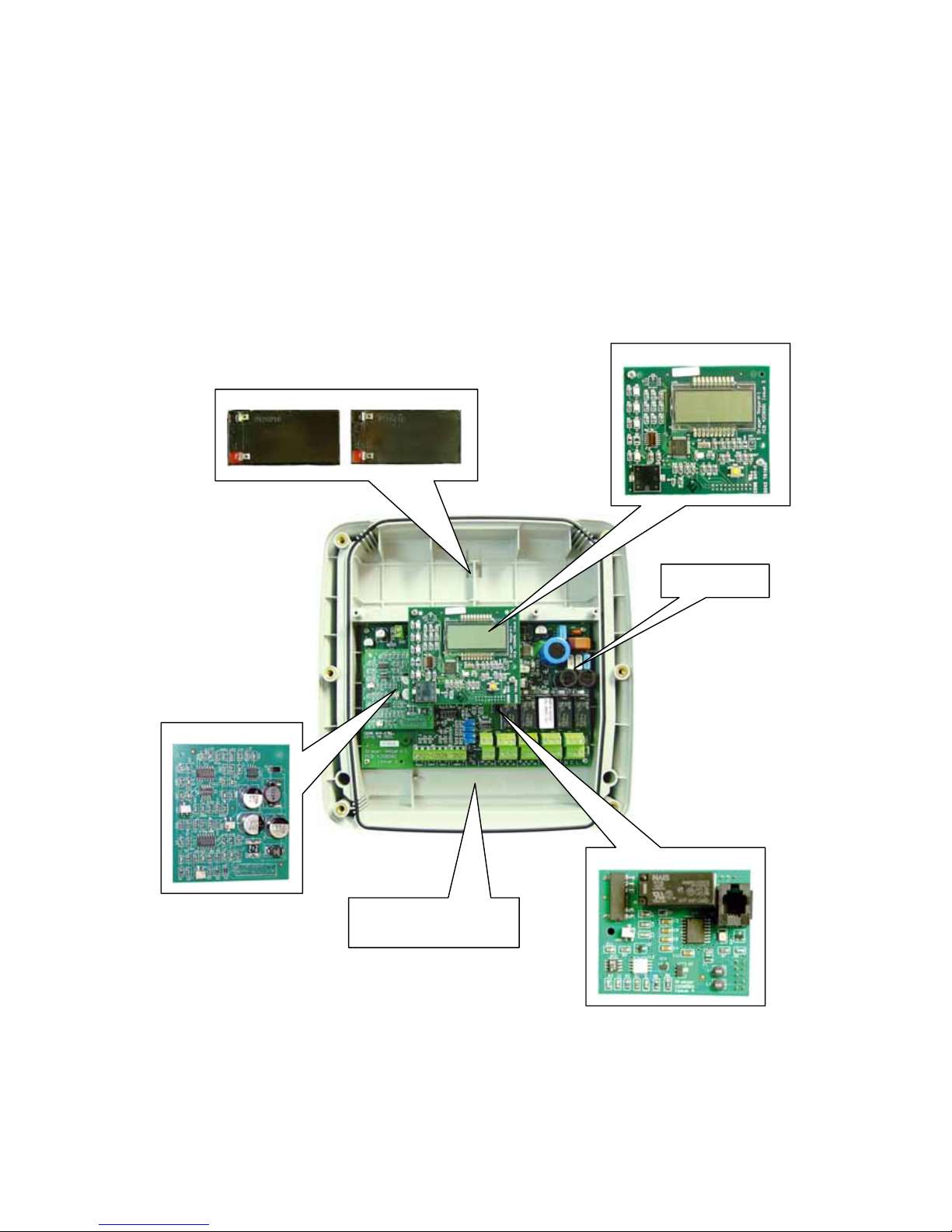

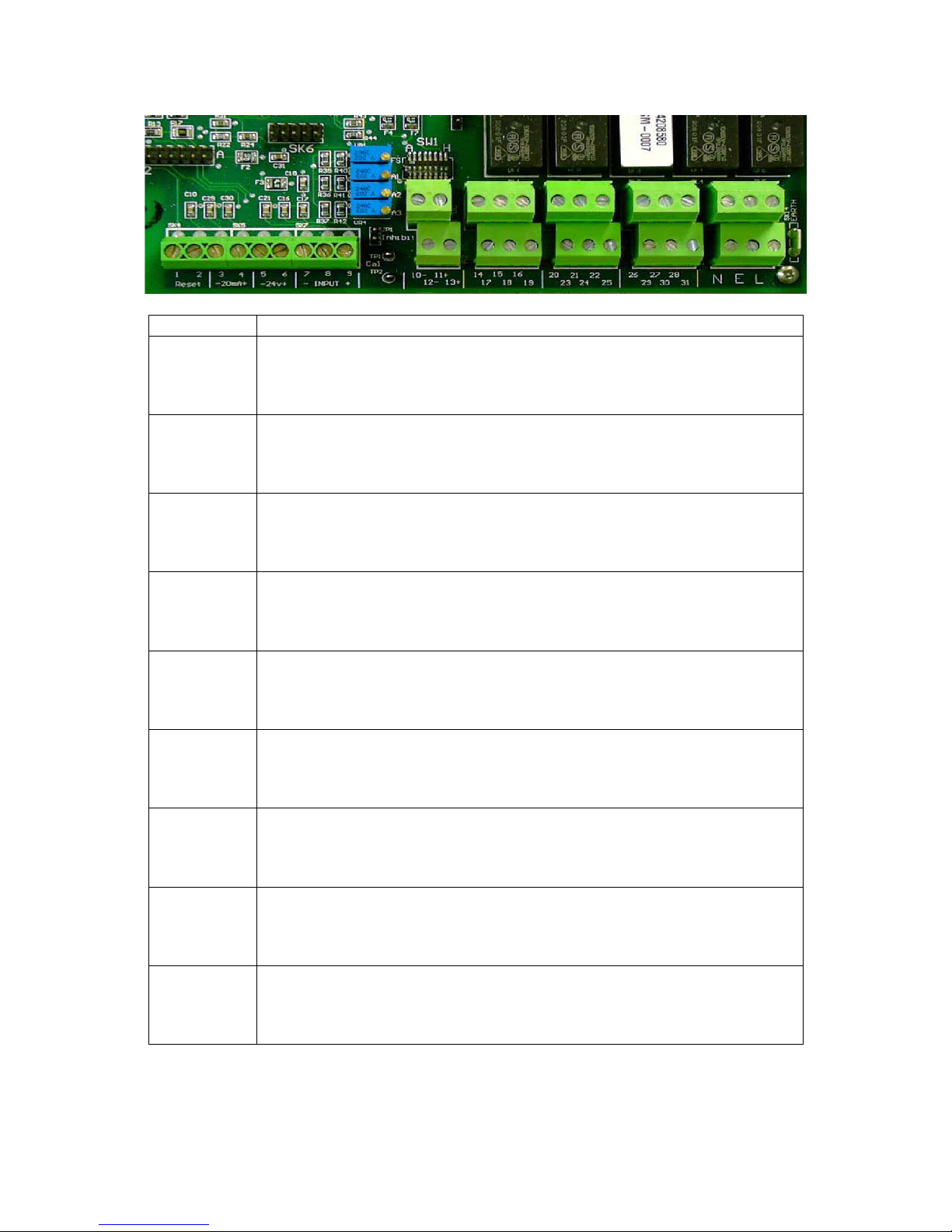

Main board

1. Terminals for batteries or external DC input.

2. Connector for display board.

3. Potentiometers for A1 – A3 alarms and display adjustment.

4. Terminals for field devices.

5. Connector for Options board.

1 2

3

4

5

5

Issue 6 – December 2006

8

Field devices terminals

No Function

1 2

Reset

External reset input

3 4

- 20mA +

4-20mA output (requires Options board)

5 6

- 24V +

24 VDC unswitched output (100mA max.)

7 8 9

- Input +

4-20mA transmitter or SE Ex sensor input

10- 11+

12- 13+

A1 24V switched output (100mA max.)

A2 24V switched output (100mA max.)

14 15 16

17 18 19

A1 relay output

A2 relay output

20 21 22

23 24 25

TWA relay output (requires Options board)

A3 relay output

26 27 28

29 30 31

Fault relay output

Inhibit relay output

N E L

98 – 253 VAC fused output (500mA max.) (back row terminals)

98 – 253 VAC input (front row terminals)

Issue 6 – December 2006

9

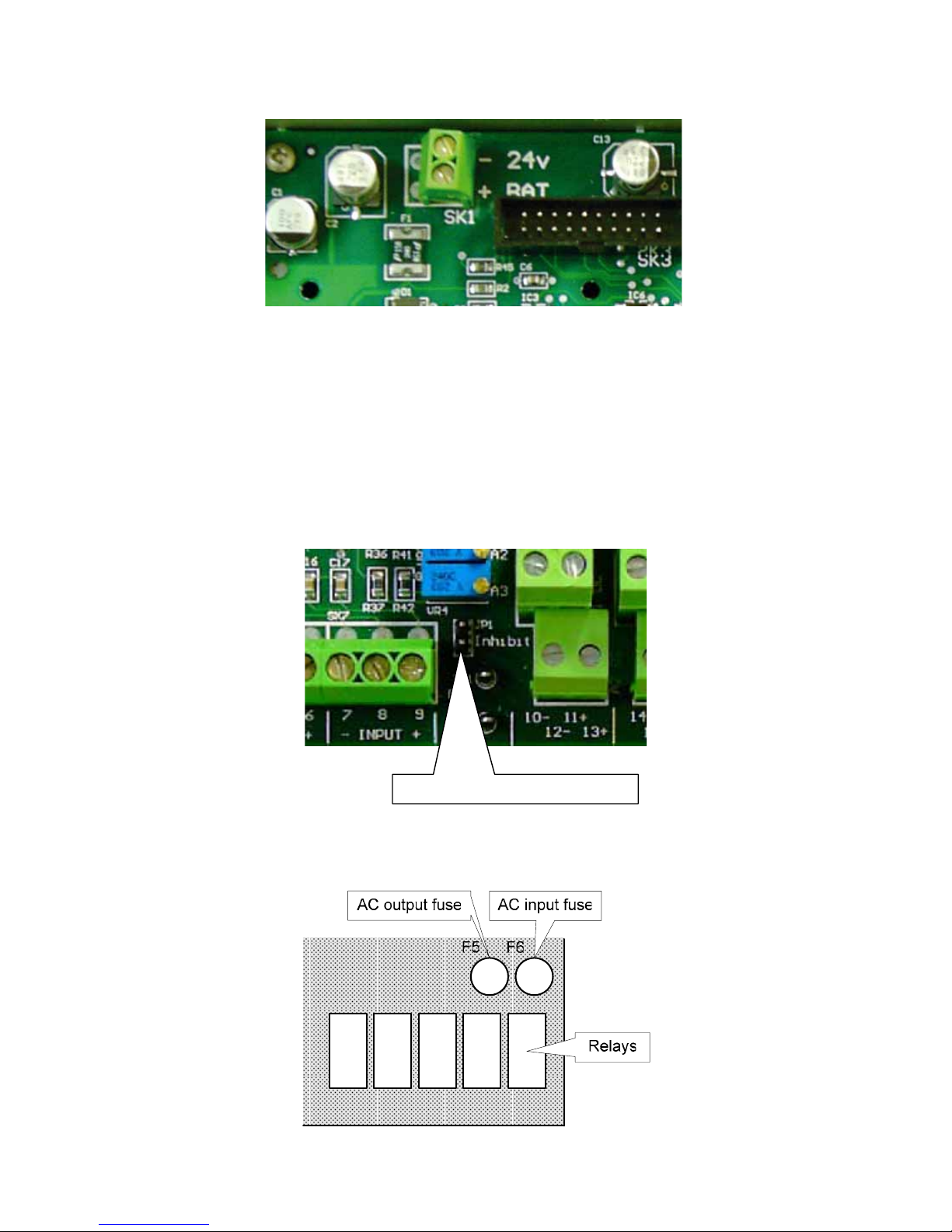

24 V battery terminals

For continued operation of the controller when the AC supply fails connect two 12V

1.2AH lead-acid batteries in series to the battery terminals. If unsealed batteries are

fitted, that could generate hydrogen when charged, drill a vent hole in the top of the

enclosure.

The 24V battery terminals can also be used for an external 24VDC input. Do not

connect AC and external DC supplies at the same time.

Maintenance inhibit jumper

When the inhibit jumper is fitted all relays will go to their normal, non-alarm, state.

Fuses

Maintenance inhibit jumpe

r

Issue 6 – December 2006

10

0.50

- 0.5

-Ur-

-Or-

Display board

The display shows the gas level, or indicates that the gas level exceeds the

measuring range (over-range) or is below the measuring range (under-range).

Examples

Normal gas level display.

Negative display reading. A negative display reading

may be caused by inaccurate calibration or by drift or

temperature effect of the sensor.

Under-range: reading below measuring range

Over-range: reading above measuring range. The

over-range indication is latching and can only be

cleared when the reading is again within the

measuring range. Press Reset to clear the overrange indication.

There are two versions of the display board:

x V1 displays gas level, under-range and over-range, and calculates a TWA gas

level over eight hours; this board contains firmware release 1.00 or 1.01.

x V2 displays gas level, under-range and over-range and calculates the TWA

gas level over an user-adjustable period, and logs the gas level to memory;

this board contains firmware release 2.00 or 2.01.

The firmware version is shown on the display for a few seconds after the unit is

turned on, and is also marked on the display board.

A buzzer on the display board provides a local audible alarm.

Display of measuring range, gas and unit

The front cover of the controller has a window in which to display the measured gas,

range and unit. Insert a label showing the required information in the slot inside of the

front cover. Pre-printed and blank labels are at the end of this manual.

Issue 6 – December 2006

11

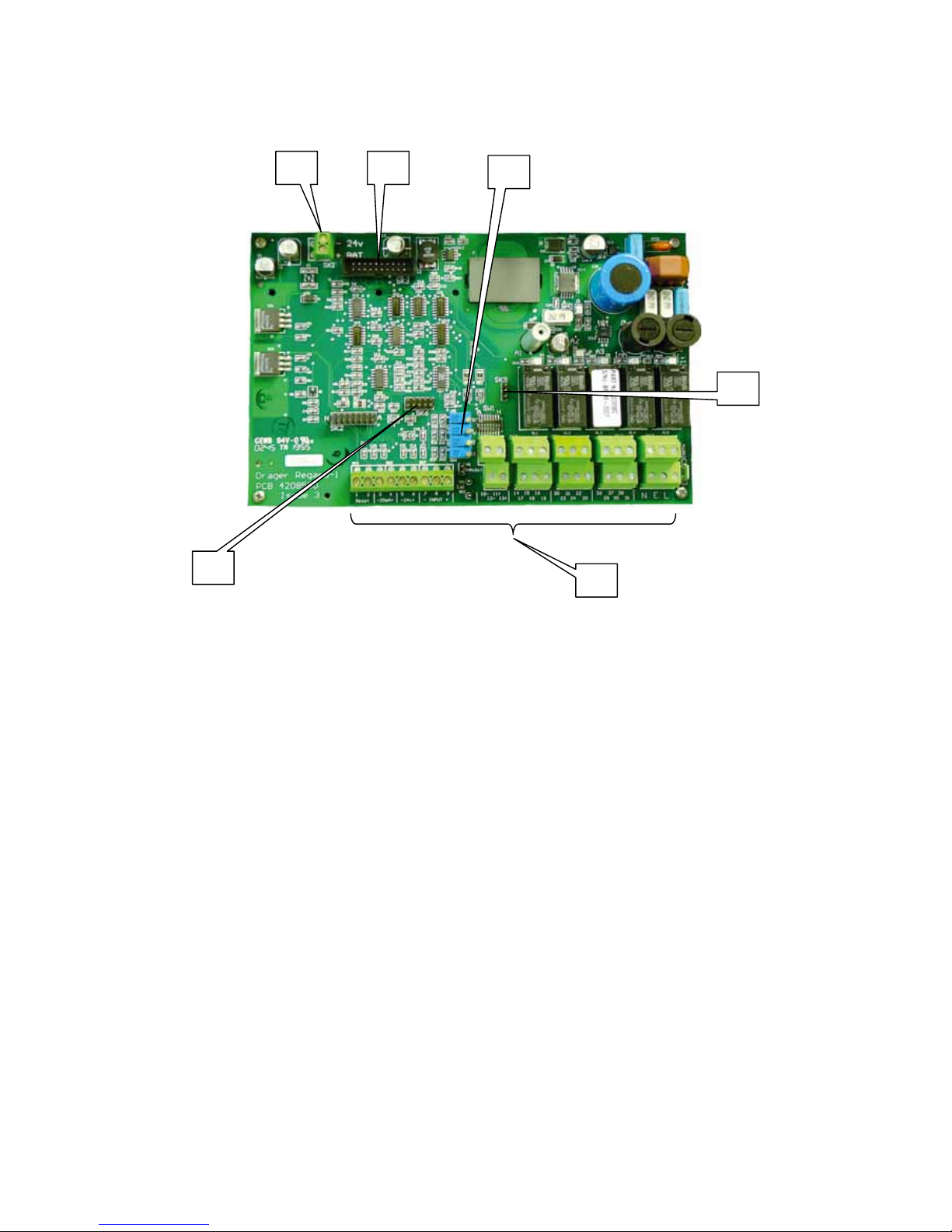

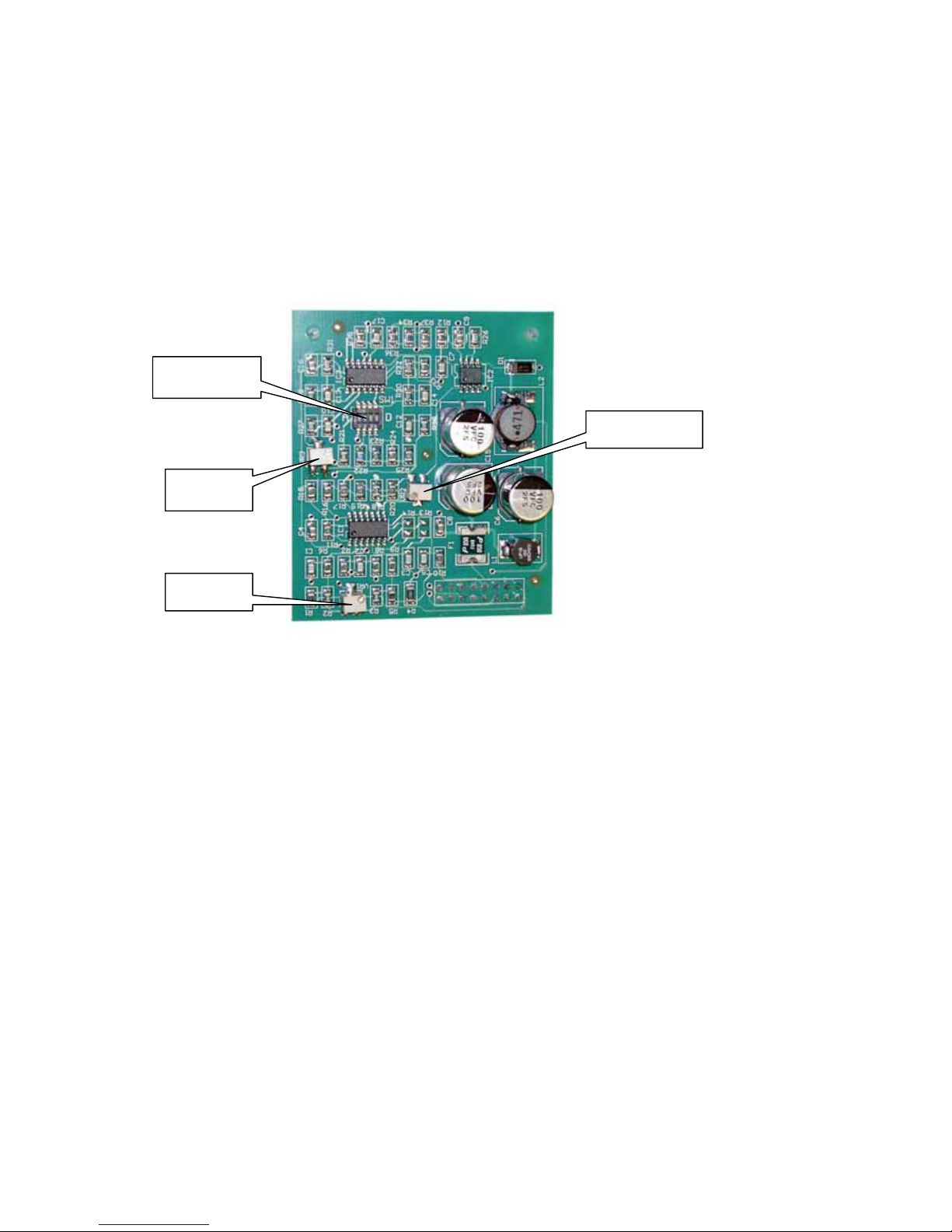

Pellistor board

The pellistor board supplies a constant current to the sensor and amplifies the signal

from the sensor.

To fit the pellistor board to a Regard-1 4-20:

x Remove all the links from SK2 on the main board

x Fit the pellistor board onto SK2

The pellistor board has a 4-pole switch and three potentiometers:

x SW1

Sets sensor current range and amplifier range

x VR1

Sets zero point

x VR2

Sets sensor current

x VR3

Sets gain (span)

Options board

The option board provides

x TWA alarm relay (requires display board V2 to operate)

x 4-20mA output proportional to gas level

x datalogger output

Fit the options board onto SK6 and SK9 on the main board.

SW1

VR3

VR1

VR2

Issue 6 – December 2006

12

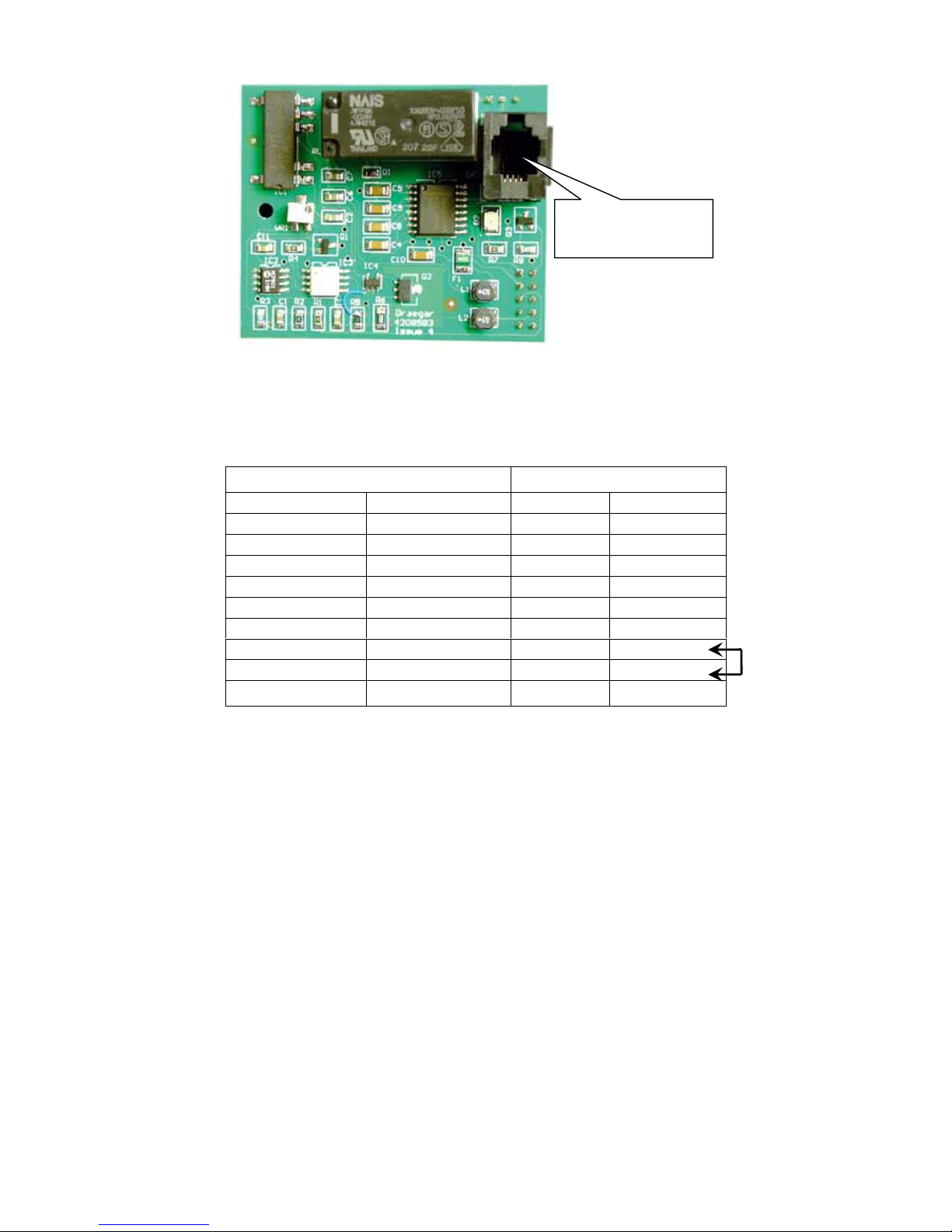

When the Options board is fitted, the 4-20mA output is on terminals 3 and 4 of the

main board and the TWA relay output is on terminals 20 to 22.

The RS-232 datalogger output is on an RJ11-style 4-position/4-conductor socket.

Data are sent by the controller as ASCII characters

Data rate: 2400 Baud

Data bits: 8

Stop bits: 1

Parity: none

Protocol: Xon / Xoff

The gas level is and TWA are printed every 1s. For example:

Gas 20.1 TWA 0.1

To reset the TWA value to zero, hold the unit’s Reset pushbutton pressed for 10s, or

hold the remote reset input closed for 10s, until the display shows tA-0.

RJ11 socket RS 232 Sub D – 9 Pole

Pin Function Pins Function

1 Rx 3 Tx

2 0 V 5 GND

3 Tx 2 Rx

4 0 V 5 GND

1 nc

6 nc

7 RTS

8 CTS

9 nc

RS-232 data

logger output

Issue 6 – December 2006

13

INSTALLATION

Installation environment

When selecting the installation place, consider the following::

x Locate the unit where the display and indicators are easily seen, and controls

are accessible

x The equipment is not “explosion proof” and must not be installed in a

hazardous area without additional Ex-protection.

x Avoid locations where excessive vibration is possible

x Avoid locations where aggressive or corrosive gases, contaminants or

pollutants harmful to electronic equipment, are present

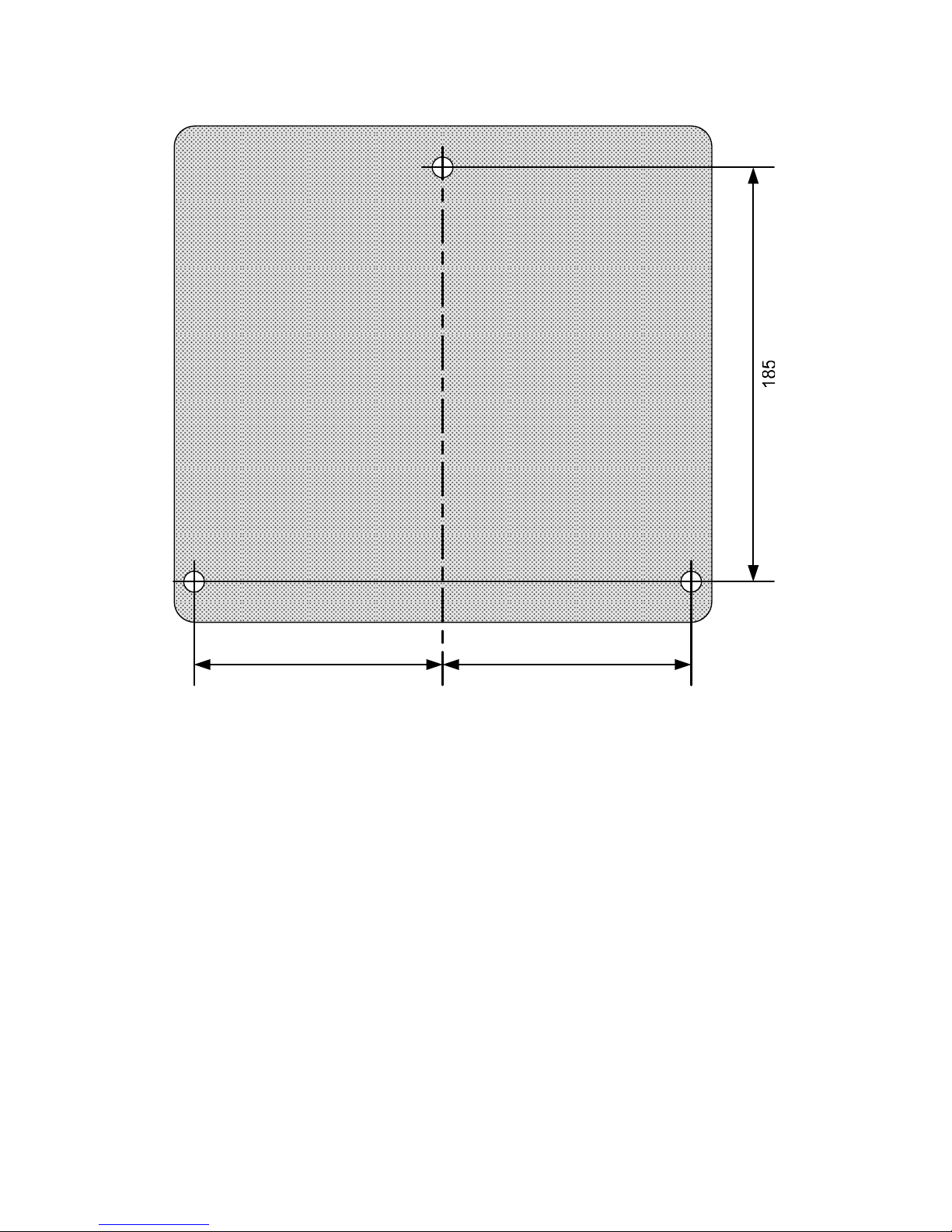

Mounting points

Mounting points of the enclosure base are shown here:

Mounting point

Mounting

hole

Mounting

hole

Mounting

hole

Mounting

hole

Front view Back view

Issue 6 – December 2006

14

Mounting points dimensions (not to scale):

114 114

Use a hole cutter to make the cable entries. Do not attempt to “knock out” the

cable entries.

AC supply

Connect a permanent AC supply to the unit.

If the AC supply to the unit is from an AC socket, the maximum allowed length of

cable between the socket and the unit is 3m.

Issue 6 – December 2006

15

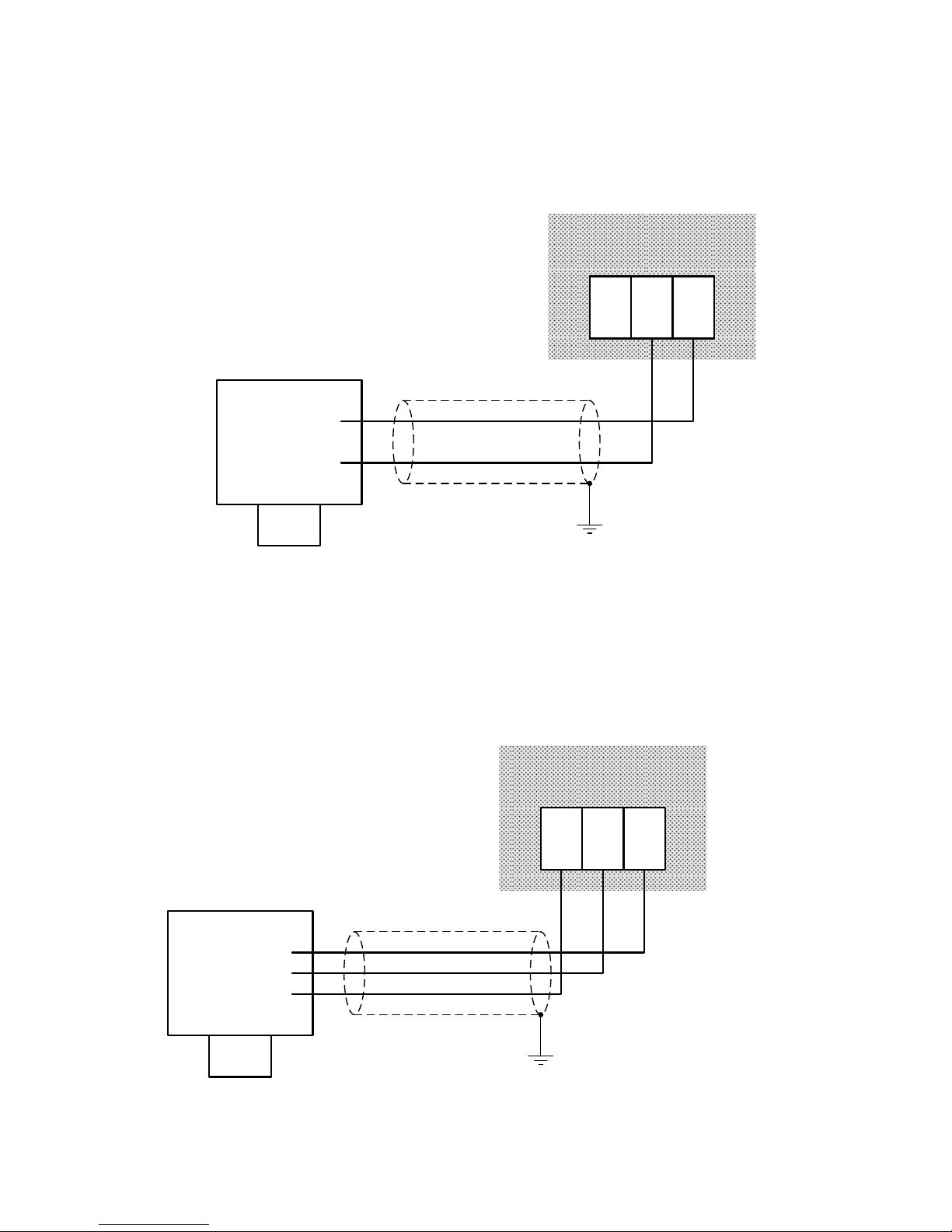

Connecting transmitters and measuring heads

Two-wire 4-20mA transmitter

Use cable with braided copper screen.

7 8 9

4-20mA signal

+ 24V

4-20mA transmitter

Regard-1 main board

Three-wire 4-20mA transmitter

Only for a transmitter with 4-20mA source output. Regard-1 will not work with a threewire transmitter that has a 4-20mA sink output.

Use cable with braided copper screen.

7 8 9

0V

4-20mA signal

+ 24V

4-20mA transmitter

Regard-1 main board

Issue 6 – December 2006

16

Maximum cable resistance for three-wire transmitters

When using 3-wire transmitters, to ensure that a short circuit between the 4-20mA

output and the zero volt wire at the transmitter causes a fault indication at the

controller, the cable resistance must not exceed the value given by the following

formula:

txr

cable

I

800

R

where:

Rcable is the resistance per core from Regard-1 to the transmitter,

Itxr is the transmitter operating current (in mA)

This formula assumes that the three cores of the connecting cable each have the

same resistance.

Example Polytron IR operating current at 24V is approx. 200mA. So limit of cable

resistance is

core per ohms 4

200

800

Two-wire 4-20mA transmitter with safety barrier

The following diagram shows the general arrangement. Refer to specific instructions

for safety barrier and transmitter for connections between transmitter and barrier, and

for instruction for earthing of barrier, where necessary.

Use cable with braided copper screen.

Issue 6 – December 2006

17

Polytron SE Ex (Pellistor) measuring head

Use cable with braided copper screen.

Do not connect the sensor/measuring head when the controller is powered:

this will damage the sensor.

Maximum cable resistance

The maximum allowed cable resistance is 6 ohms per core with the Dräger SE Ex

sensor. This limits the cable length according to the cross-sectional area of the cable:

Cable x-section Maximum length

1.0 mm2 250 m

1.5 mm2 400 m

2.5 mm2 700 m

4.0 mm2 1000 m

Issue 6 – December 2006

18

Relay outputs

Relay contacts when relays are in their normal state (ie, no alarm):

A1 relay

A2 relay

TWA relay

A3 relay

Fault relay

Inhibit relay

The fault relay is energised in its normal state (ie, when there is no fault)

Unscreened cable can be used for relay outputs.

A1 and A2 24V “digital” outputs

The digital outputs can be used to drive alarm devices directly. Use cable with

braided copper screen.

Example: flashing beacon activated by A1 alarm and klaxon activated by A2 alarm:

Issue 6 – December 2006

19

Output voltage and current

The voltage at each output decreases as the current drawn from the output

increases.

Output

voltage

Current

available

22 V 30 mA

18 V 100 mA

Issue 6 – December 2006

20

Remote reset input

To acknowledge and reset alarms remotely from the controller, connect a normallyopen switch to the remote reset terminals. Close the contacts momentarily to

acknowledge / reset alarm(s).

Use cable with braided copper screen.

Issue 6 – December 2006

21

CONFIGURATION AND CALIBRATION

Set measuring range

Use switch SW1 on the display board to set the display measuring range.

The number of decimal places is fixed according to the measuring range.

For display board with r1.00 or r2.00 firmware*, set the range using this table:

SW1

Measuring

range

DPs

A B C D E

0 - 1 2 OFF OFF OFF OFF OFF

0 - 3 2 ON OFF OFF OFF OFF

0 - 5 2 OFF ON OFF OFF OFF

0 - 10 2 ON ON OFF OFF OFF

0 - 25 1 OFF OFF ON OFF OFF

0 - 30 1 ON OFF ON OFF OFF

0 - 50 1 OFF ON ON OFF OFF

0 - 100 1 ON ON ON OFF OFF

0 - 200 0 OFF OFF OFF ON OFF

0 - 250 0 ON OFF OFF ON OFF

0 - 300 0 OFF ON OFF ON OFF

0 - 500 0 ON ON OFF ON OFF

0 - 1000 0 OFF OFF ON ON OFF

0 - 2000 0 ON OFF ON ON OFF

0 - 2500 0 OFF ON ON ON OFF

0 - 3000 0 ON ON ON ON OFF

0 - 5000 0 OFF OFF OFF OFF ON

0 - 9999 0 ON OFF OFF OFF ON

DPs = decimal places

SW1

Issue 6 – December 2006

22

* The firmware version is shown on the display for a few seconds after the unit is

turned on.

For display board with r1.01 or r2.01 firmware, set the range using this table:

SW1

Measuring

range

DPs

A B C D E

0 - 1 2 OFF OFF OFF OFF OFF

0 - 3 2 ON OFF OFF OFF OFF

0 - 5 2 OFF ON OFF OFF OFF

0 - 8 2 ON ON OFF OFF OFF

0 - 10 2 OFF OFF ON OFF OFF

0 - 20 1 ON OFF ON OFF OFF

0 - 25 1 OFF ON ON OFF OFF

0 - 30 1 ON ON ON OFF OFF

0 - 50 1 OFF OFF OFF ON OFF

0 - 100 1 ON OFF OFF ON OFF

0 - 200 0 OFF ON OFF ON OFF

0 - 250 0 ON ON OFF ON OFF

0 - 300 0 OFF OFF ON ON OFF

0 - 500 0 ON OFF ON ON OFF

0 - 1000 0 OFF ON ON ON OFF

0 - 2000 0 ON ON ON ON OFF

0 - 2500 0 OFF OFF OFF OFF ON

0 - 3000 0 ON OFF OFF OFF ON

0 - 5000 0 OFF ON OFF OFF ON

0 - 9999 0 ON ON OFF OFF ON

DPs = decimal places

For all firmware versions SW1-F sets the TWA function:

SW1-F TWA

ON ON

OFF OFF

Insert a card in the window above the display to show the measured gas and range.

Pre-printed and blank labels are at the end of this manual.

Issue 6 – December 2006

23

Calibrating a 4-20 unit

(Also refer to the transmitter’s operating manual for calibration instructions.)

Zero calibration

There is no zero adjustment for the 4-20 unit. The controller will indicate zero for a

transmitter signal of 4mA ± 0.3mA. If necessary, calibrate the transmitter to give

4.0mA at zero gas.

Span calibration

Span calibration can be performed either by applying calibration gas to the

transmitter/sensor, or by controlling the output of the transmitter directly (eg, by

means of the transmitter’s front panel controls) to simulate a gas signal.

x Connect a voltmeter across TP1 and TP2 on the main board:

If applying calibration gas to the transmitter:

x Apply calibration gas to the transmitter. Use a gas concentration that is between

40% and 90% of measuring range.

x Adjust potentiometer FS on the main board until the voltage across TP1 and TP2

corresponds to the gas concentration. If the controller has a display, confirm that

the reading is correct.

Gas concentration

(as % of measuring range)

Voltage across

TP1 & TP2 (V)

40 2.08

50 2.40

60 2.72

70 3.04

80 3.36

90 3.68

Issue 6 – December 2006

24

Location of FS (span adjust) potentiometer:

If controlling the transmitter output:

x Adjust the output of the transmitter to 20mA if possible; otherwise to a value

between 12mA and 20mA.

x Adjust potentiometer FS on the main board until the voltage across TP1 and TP2

corresponds to the transmitter output. If the controller has a display, confirm that

the reading is correct.

Transmitter output (mA) Voltage across

TP1 & TP2 (V)

Display reading

(0 – 100 range*)

12 2.4 50

13 2.6 56

14 2.8 63

15 3.0 69

16 3.2 75

17 3.4 81

18 3.6 88

19 3.8 94

20 4.0 100

* Scale for different measuring range

FS: span adjust

Issue 6 – December 2006

25

Calibrating an SE Ex unit

Use the controls on the pellistor board to set sensor current, calibrate zero and

calibrate span:

(Also refer to the measuring head’s operating manual for calibration instructions.)

Set the sensor current

1. Set the sensor drive current range with SW1-A on the pellistor board.

For all Dräger sensors, set SW1-A to OFF.

SW1

Drive current

range

A B C D

95 – 195 mA ON – – –

190 – 350 mA OFF – – –

The position of switches B, C and D does not matter yet.

2. Adjust the sensor current to the required value

x Turn off the unit by disconnecting the AC or DC supply and batteries, if fitted

x Connect an ammeter between terminal 9 and the sensor

x Re-connect the AC or DC supply

x Adjust VR2 on the pellistor board to set the current (270.0 mA for Dräger Ex

sensors). Allow two minutes for the current to settle after adjusting VR2. Readjust VR2 if necessary

x Disconnect power, remove the ammeter and reconnect the sensor

x Turn on power and allow sensor to settle or at least five minutes before

continuing with zero and calibration

SW1

VR3

VR1

VR2

Issue 6 – December 2006

26

Do not connect the sensor/measuring head when the controller is powered:

this will damage the sensor.

Calibrate zero

x Connect a voltmeter across TP1 and TP2 on the main board:

x Apply known clean air – free of flammable gas – or verify that no flammable

gas is present at the sensor.

x Turn VR1 on the pellistor board until the voltage across TP1 and TP2 is

800mV ± 20 mV. To increase the reading, turn VR1 anti-clockwise

.

x If the controller has a display, verify that it reads zero.

Calibrate span

1. Set sensitivity range

Set the amplifier gain range using switches SW1-B, -C and -D.

Range SW1

No. Sensitivity A B C D

1

10 – 60 mV

x

ON OFF OFF

2

60 – 110 mV

x

OFF ON OFF

3

110 – 160 mV

x

OFF OFF ON

4

160 – 220 mV

x

OFF OFF OFF

x Do not change the position of switch SW1-A.

For new Dräger Ex sensors, range 3 (110 – 160 mV) should work for most gases. If,

during calibration, the gas reading does not reach the required value use a lowernumbered sensitivity range. If the display reading is too high use a higher-numbered

sensitivity range.

Issue 6 – December 2006

27

2. Apply calibration gas

Use a calibration gas with concentration between 40% and 60% of the measuring

range.

x Apply gas using calibration adaptor at 0.5 l/min flow rate.

x Allow display reading to settle (about 2 to 3 minutes)

x Adjust VR3 on the pellistor board until the voltage across TP1 and TP2

corresponds to the concentration of the calibration gas.

Gas concentration

(as % of measuring range)

Voltage across

TP1 & TP2 (V)

40 2.08

45 2.24

50 2.40

55 2.56

60 2.72

x If the unit has a display, verify that the display reading corresponds to the gas

concentration.

Issue 6 – December 2006

28

Configuring alarms

There are three gas alarms. Each alarm can be set to be

x rising or falling

x latching or non-latching

Note

Regard-1 4-20: if used with a transmitter whose output current can be below 20mA

for concentrations above full scale, set the alarm relays latching.

Regard-1 SE

Ex: set at least one alarm relay – the one with the highest alarm level –

to be latching.

The A2 alarm can also be set to be acknowledgeable. You can use the A2 relay to

control an audible alarm that you want to be able to silence even when the gas alarm

is still tripped.

Use switch SW1 on the main board set the operation of the alarms/relays:

A1 alarm

SW1

Mode of operation

A B

Rising

Falling

ON

OFF

Non-latching

Latching

ON

OFF

SW1 on main

board

Issue 6 – December 2006

29

A2 alarm

SW1

Mode of operation

C D H

Rising

Falling

ON

OFF

Non-latching

Latching

ON

OFF

Not acknowledgeable

Acknowledgeable

ON

OFF

A3 alarm

SW1

Mode of operation

E F

Rising

Falling

ON

OFF

Non-latching

Latching

ON

OFF

Fault alarm

SW1

Mode of operation

G

Non-latching

Latching

ON

OFF

x The A1, A2 and A3 relays energise on alarm.

x The Fault relay de-energises on alarm (ie, is normally energised).

Issue 6 – December 2006

30

Setting alarm thresholds on 4-20 units

Use the potentiometers marked A1, A2 and A3 on the main board to set the alarm

thresholds:

For safety relevant decisions only use status of Alarm/Fault LEDs and relays.

Do not use display reading. For calibration and adjustment of alarm set points

use DVM between test points TP1 and TP2 only.

To set the alarm levels you must simulate a gas signal. You can do this

x using a potentiometer that can be varied from 1200 to 6000 ohms

x by directly controlling the output of the transmitter

x using a 4-20mA loop calibrator

Using a potentiometer:

x Connect the potentiometer between terminals 8 and 9.

Test potentiometer

1200 to 6000 ohms

Test points

TP1 + TP2

A1 pot.

A2 pot.

A3 pot.

Issue 6 – December 2006

31

Using a 4-20mA source loop calibrator

x Connect the loop calibrator between terminals 7 and 8.

The method to set the alarm thresholds is the same for each.

To set A1 alarm

1. Turn A1 potentiometer fully clockwise

2. Adjust test pot until voltage across TP1 and TP2 is at the required threshold

3. Turn A1 pot anticlockwise until the A1 alarm trips

For the A2 and A3 alarms, repeat the above procedure with the A2 and A3

potentiometers.

x If an alarm is not required, turn its potentiometer fully clockwise.

x The fault alarm threshold is fixed at 3.2mA.

Use this table to determine the alarm threshold. Read off the voltage across TP1 and

TP2 corresponding to the required alarm threshold.

Alarm threshold

(% of 0 – 100 range)

Voltage across

TP1 & TP2 (V)

5% 0.96

10% 1.12

15% 1.28

20% 1.44

25% 1.60

30% 1.76

35% 1.92

40% 2.08

45% 2.24

50% 2.40

55% 2.56

60% 2.72

65% 2.88

70% 3.04

75% 3.20

80% 3.36

85% 3.52

90% 3.68

95% 3.84

Issue 6 – December 2006

32

For oxygen deficiency and enrichment alarms, use this table to determine alarm

thresholds for a 0 – 25% range:

Alarm threshold Transmitter signal

(mA)

Voltage across

TP1 & TP2 (V)

17% 14.9 2.98

18% 15.5 3.10

19% 16.2 3.24

20% 16.8 3.36

21% (Normal reading)

22% 18.1 3.62

23% 18.7 3.74

24% 19.4 3.88

Issue 6 – December 2006

33

Setting alarm thresholds on SE Ex units

Use the potentiometers marked A1, A2 and A3 on the main board to set the alarm

thresholds:

Use VR1 on the pellistor board

to simulate a sensor signal.

Measure the voltage across test points TP1 and TP2 to determine the alarm

threshold. If the unit has a display you can use the display reading to give additional

confirmation that the alarm set points are correct.

Alarm threshold

(% of 0 – 100

range)

Voltage across

TP1 & TP2 (V)

10% 1.12

15% 1.28

20% 1.44

25% 1.60

30% 1.76

VR1

A1

A2

A3

Issue 6 – December 2006

34

35% 1.92

40% 2.08

45% 2.24

50% 2.40

55% 2.56

60% 2.72

Alarms below 10% and above 60% of measuring range are not recommended for

flammable gas detection.

To set A1 alarm

1. Turn A1 potentiometer fully clockwise

2. Adjust VR1 until the voltage across TP1 and TP2 is at the required

threshold (turn VR1 anticlockwise to increase the voltage across TP1

and TP2)

3. Turn A1 potentiometer anticlockwise until the A1 alarm trips

To set A2 alarm

1. Turn A2 potentiometer fully clockwise

2. Adjust VR1 until voltage across TP1 and TP2 is at the required

threshold

3. Turn A2 potentiometer anticlockwise until the A2 alarm trips

To set A3 alarm

1. Turn A3 potentiometer fully clockwise

2. Adjust VR1 until voltage across TP1 and TP2 is at the required

threshold

3. Turn A3 potentiometer anticlockwise until the A3 alarm trips

If an alarm is not required turn that alarm’s potentiometer fully clockwise.

After setting the alarm thresholds, adjust VR1 so that the voltage across TP1 and

TP2 is 800 mV ± 20 mV.

Regard-1 SE Ex has a fixed fault alarm threshold at about –5% of the measuring

range.

Issue 6 – December 2006

35

MAINTENANCE

Check the unit for operation regularly. Service the controller every 12 months.

The transmitter or measuring head may require periodic recalibration. Refer to the

instruction manual for the transmitter or measuring head for guidance.

If batteries are fitted to the control unit then these batteries should be maintained in

accordance with the instructions of the battery manufacturer.

Observe EN 50073 and respective national regulations.

Fault finding

Fault Remedy

1 Control unit non operational Check input fuse (F6). Replace if necessary.

Check third party electrical supply.

2 Display blank Check cable connection between main circuit

board and display board.

Adjust contrast potentiometer on display

board.

3 Self test routine fails Replace display board

4 Under-range displayed Check transmitter connections.

Check and measure loop current.

4-20 units:

Ensure links fitted to positions A, B, C,

D and E of SK2 on main board

5 24 Vdc output too low Check loading is < 100mA

6 A1 or A2 24 Vdc output too

low

Check loading is < 100mA

Reduce load

7 AC output failed Check loading does not exceed 500mA

Replace fuse.

8 Incorrect measuring range Check setting of SW1 on display board

10 No TWA information Set SW1-F on the display board to ON

11 Water ingress Check sealing ring is in place

12 Display repeats power-on test

during normal operation

(1)

Replace display board

Note 1: Display board program execution is monitored by a watchdog. A watchdog

reset during normal operation will cause the display to repeat its power-on

self test.

Issue 6 – December 2006

36

SPECIFICATIONS

Regard-1 4-20 Regard-1 SE Ex

Dimensions

270 mm u 270 mm u 90 mm

Mass (without

batteries)

Approx. 2.5 kg

Housing material ABS – VO

Ingress protection IP 65

Cable entries 6 No. M20

AC supply voltage 98 to 253 VAC, 50-60 Hz

DC supply voltage 18 to 30 VDC

Power consumption 50 W (without transmitter) 70 W (including sensor)

Mains fuses 500mA (T) HRC.

Battery charge

voltage

- maximum current

27.6 r 0.6 VDC

500 mA

DC output

24 r 1 VDC, 100 mA max.

Battery type (x2) 12 V, 1.2 AH

A1 and A2 outputs

22 VDC at 30 mA

18 VDC at 100 mA

Alarm relays

(A1, A2, A3)

single-pole changeover

max. 250 VAC, 3 A

max. 30 VDC, 2 A

energise on alarm

Fault relay

single-pole changeover

max. 250 VAC, 3 A

max. 30 VDC, 2 A

normally energised (de-energise on fault)

Inhibit relay

single-pole changeover

max. 250 VAC, 3 A

max. 30 VDC, 2 A

energise on alarm

Visual outputs

- with display board

fitted

“AC power on” LED

“DC power on” LED

A1, A2 and A3 alarm LEDs, Fault LED, Inhibit LED

LCD gas level indicator

Transmitter/sensor

input

2- or 3-wire 4-20mA,

24 VDC / 400 mA

3-wire Pellistor

constant current supply

200…350 mA

Storage conditions

–10°C to 60°C

0 to 100% rH, non-condensing

Operating conditions

0°C to 55°C

0 to 100% rH, non-condensing

Warm up time 30 s

Response time

2 s

Approvals and CE Electromagnetic Compatibility (EMC) Directive

Issue 6 – December 2006

37

marking Low-voltage directive

ATEX directive

Data logger RS-232

output

Format: ASCII

Data rate: 2400 Baud

Data bits: 8

Stop bits: 1

Parity: none

Flow control: Xon / Xoff

Part numbers

Description Part number

Regard-1 4-20 4208585

Regard-1 SE Ex 4208600

Accessories and spare parts

Pellistor board 4208582

Options board 4208583

Lead-acid batteries (2 off) 4208586

Display board V1 4208581

Display board V2 4208636

Calibration screwdriver 4208595

PC connection lead 4208596

“Light pipes” 4208589

Issue 6 – December 2006

38

EC type-examination certificate

Issue 6 – December 2006

39

Issue 6 – December 2006

40

Issue 6 – December 2006

41

Issue 6 – December 2006

42

x Display board V2.0 is not included in the scope of this type-examination.

x The options board is not included in the scope of this type-examination.

Issue 6 – December 2006

43

EC Declaration of Conformity

DECLARATION OF CONFORMITY

We

Draeger Safety UK Ltd

Kitty Brewster Industrial Estate

Blyth, Northumberland

NE24 4RG

England

declare that

REGARD–1

in accordance with Directive 94/9/EC (Equipment and protective systems intended

for use in potentially explosive atmospheres), is in conformance with the EC-Type

Examination Certificate

BVS 03 ATEX G 011 X

for equipment group and category

II (2) G

issued by

EXAM BBG Prüf- und Zertifizier GmbH

Dinnendahlstrasse 9

44809 Bochum

Germany

Notified body number 0158.

Harmonized standards:

EN 61779-1:2000 + A11:2004

EN 61779-4:2000

EN 61779-5:2000

EN 50104:2002 + A1:2004

EN 50271:2001

(Signed) D Longstaff

____________________

Technical Manager

June 2005

Issue 6 – December 2006

44

Issue 6 – December 2006

45

Front panel labels

Gas A1:

Range A2:

Unit A3:

Gas Methane (CH4) A1: %LEL

Range 0 – 100 A2: %LEL

Unit %LEL A3: %LEL

Gas A1:

Range A2:

Unit A3:

Gas Oxygen (O2) A1: %vol rising / falling

Range 0 – 5 / 25 / 100 A2: %vol rising / falling

Unit %vol A3: %vol rising / falling

Gas Ammonia (NH3) A1: ppm

Range 0 – 100 / 300 / 1000 A2: ppm

Unit ppm A3: ppm

Gas Carbon monoxide (CO) A1: ppm

Range 0 – 100 / 300 / 1000 A2: ppm

Unit ppm A3: ppm

Gas Hydrogen sulphide (H2S) A1: ppm

Range 0 – 20 / 50 / 100 A2: ppm

Unit ppm A3: ppm

Issue 6 – December 2006

46

Issue 6 – December 2006

47

Issue 6 – December 2006

48

Draeger Safety UK Ltd

Kitty Brewster Industrial Estate

Blyth

Northumberland

NE24 4RG

United Kingdom

Tel +44 1670 352891

Fax +44 1670 544475

Manual part number 4208591

This manual supersedes and replaces the following manuals:

4208603 issue 1

4208591 issue 5

For use with display board firmware r1.00 and r1.01.

Loading...

Loading...