Page 1

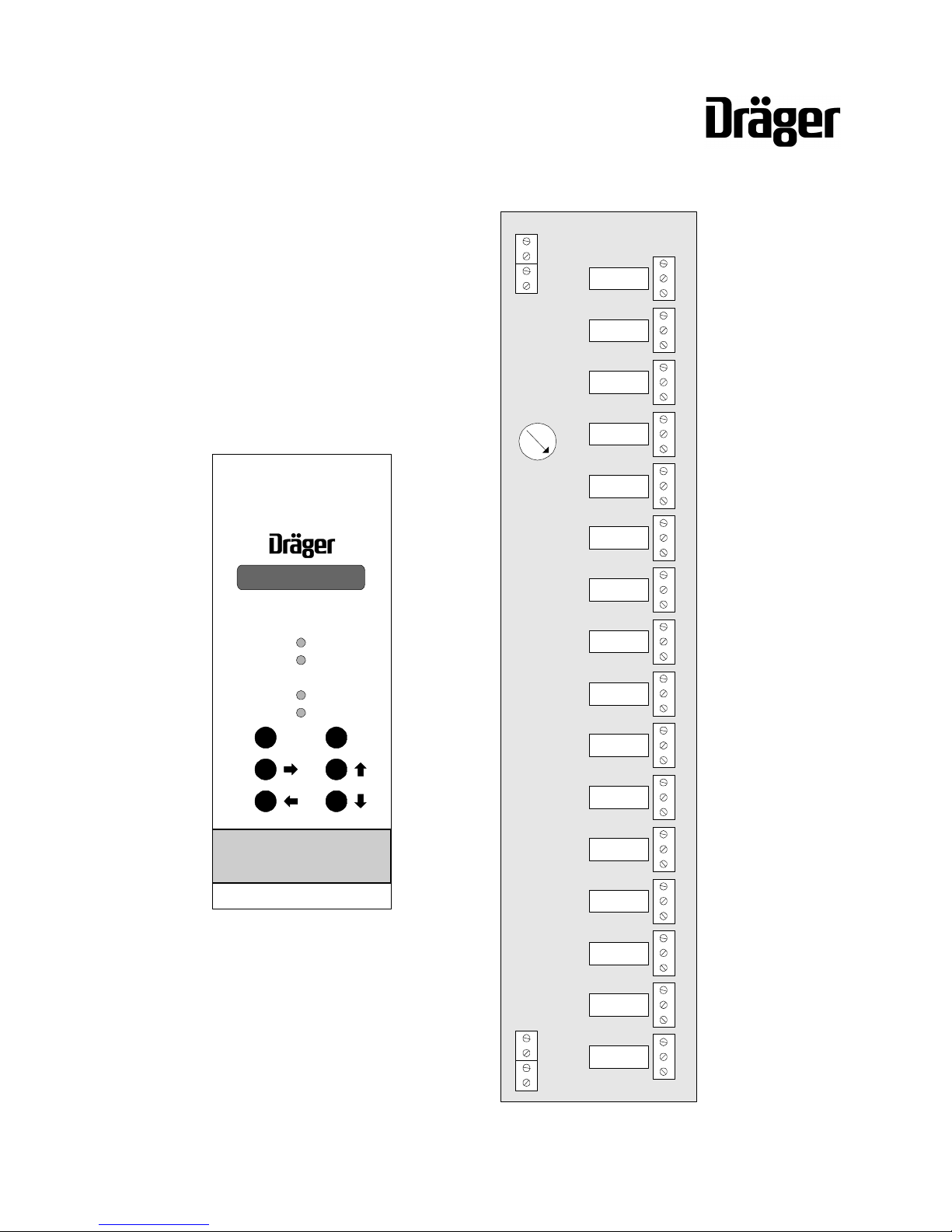

RELAY MODULE

RELAY DISPLAY CARD

(ATEX VERSION)

REGARD

GAS DETECTION SYSTEM

RELAY DISPLAY

Alarm

Tripped

Power

Inhibit

R

SHIFT

012:ALRM

INSTRUCTIONS FOR USE

Page 2

Page 3

REGARD Relay Module & Relay Display Card (ATEX version)

Issue 1 – July 2003

3

CONTENTS

Page

FOR YOUR SAFETY............................................................................................................... 4

Safe operation ................................................................................................................ 4

CE marking and ATEX marking...................................................................................... 5

Special conditions for safe use....................................................................................... 5

OPERATION............................................................................................................................ 6

Intended use................................................................................................................... 6

Description..................................................................................................................... 6

Operational fault relay .......................................................................................... 6

Electromagnetic compatibility......................................................................................... 6

Display card front panel controls and indicators.............................................................. 7

Display ................................................................................................................. 7

LEDs.................................................................................................................... 7

Controls................................................................................................................ 8

Relay module indicators................................................................................................. 8

Acknowledging alarms.................................................................................................... 8

Relays configured “Single” and “LNAK1” ............................................................... 9

Operational faults..........................................................................................................10

Operational fault codes........................................................................................10

WARNING - FAULT C indication on the relay display card..................................11

WARNING - FLTMB indication on the relay display card .....................................11

Loss of communication between relay display card and relay module(s)..............11

INSTALLATION ......................................................................................................................12

Install relay display card................................................................................................12

Install relay modules......................................................................................................12

Set module numbers ...........................................................................................15

Connect equipment to relay terminals..................................................................16

Connect DC supply to modules............................................................................16

Optional connections.....................................................................................................17

Remote reset.......................................................................................................17

Operational fault relay .........................................................................................17

Switch-on and initial checks...........................................................................................18

CONFIGURATION..................................................................................................................19

Command mode............................................................................................................19

Function of front panel controls in command mode..............................................19

Table of commands .............................................................................................20

Configure channel cards and master card......................................................................21

Configure relay display card..........................................................................................21

Configuration sequence.......................................................................................22

Optional configuration settings.............................................................................27

MAINTENANCE......................................................................................................................28

Recommended maintenance intervals...........................................................................28

Commands for system maintenance..............................................................................29

TECHNICAL DATA .................................................................................................................33

Relay display card.........................................................................................................33

Relay module................................................................................................................33

Part numbers.................................................................................................................33

EC-Type Examination certificate...................................................................................34

Page 4

REGARD Relay Module & Relay Display Card (ATEX version)

Issue 1 – July 2003

4

FOR YOUR SAFETY

Follow the instructions

Follow the instructions for installation, operation and maintenance.

Use in areas subject to explosion hazards

The relay module and relay display card are not designed for use in a flammable

atmosphere without suitable protection.

Liability for proper function or damage

Liability for proper function of this apparatus is irrevocably transferred to the owner or

operator to the extent that the apparatus has been commissioned, serviced or

repaired by personnel not employed or authorised by Draeger Service, or when this

apparatus was used in a manner not conforming to its intended use.

Draeger Limited can not be held responsible for any damage caused by noncompliance with the above recommendations. The warranty and liability provisions of

the terms and conditions of sale and delivery of Draeger Limited are likewise not

modified by recommendations given above.

Maintenance

This apparatus must be inspected and serviced by experts at regular intervals and a

record maintained of such inspections and servicing. Repairs and general overhaul of

this apparatus should only be carried out by competent personnel.

We recommend that either a training course or service contract is obtained from the

Draeger Service department and that all repairs are also carried out by them.

Safe operation

For safe operation:

• Set relays on relay modules normally energised. In the event of power loss,

communications failure or configuration data loss, the relays will de-energise.

• Connect an alarm device or other indicator to the operational fault relay on the

relay display card.

Page 5

REGARD Relay Module & Relay Display Card (ATEX version)

Issue 1 – July 2003

5

CE marking and ATEX marking

Regard cards and modules are CE marked to indicate conformity with the essential

requirements of the “ATEX” Directive 94/9/EC:

0518

The number after the CE mark is the number of the Notified Body involved the

production control phase.

The card also carries the following marking in accordance with the directive:

This marking means that the card is suitable for use in non-hazardous areas, in nonmining Category 2 applications for the detection of flammable gases.

THIS MARKING DOES NOT MEAN THAT THE CARD IS “EXPLOSION PROOF”.

Regard cards cannot be used in areas subject to explosion hazards

(“hazardous areas”) without suitable additional protection.

The certification code corresponds with the ATEX EC-type-examination certificate:

DMT 02 ATEX G 002 X

The year of construction of the card/module can be derived from the card's/module's

serial number.

Special conditions for safe use

• When relay display card(s) and relay module(s) are used, the fault relay of the

master card shall be configured as master fault.

• After configuration of the relay display card, check that the Regard channels used

are present within the system.

• The power supply of the relay modules shall be supervised by external means in

such a way that there is a signal if the supply voltage falls below the minimum

value.

• If safety-related alarms or fault signals are configured with relay display cards and

relay modules, two relays on separate relay modules shall be used in a redundant

arrangement. The relays shall have the same configuration and be wired in such

a way that the external device is activated if one of the two relays switches.

• Relays that are intended for safety-related purposes shall be configured as

latching and non-acknowledgeable during the alarm condition.

II (2) G

Page 6

REGARD Relay Module & Relay Display Card (ATEX version)

Issue 1 – July 2003

6

OPERATION

Intended use

The REGARD relay modules and relay display card provide:

• Additional common and voted alarm relays for a system comprising any

combination of channel cards.

• A1, A2, A3 and/or Fault relays for each channel of a Regard HART card or eightchannel display card.

NOTE Neither A3 alarms nor use with the Regard 'HART' card are included in the

scope of the EC-type examination certificate DMT 02 ATEX G 002 X.

• Additional alarm relays for single-channel Regard cards.

The relay modules and relay display card are intended for permanent installation in a

non-hazardous environment, such as a control room or marshalling cabinet.

Description

The relay display card fits into the Regard rack and controls up to 16 relay modules.

Each relay module has 16 relays. The relay modules are connected to the relay

display card by a single twisted-pair cable. Relay modules can be located up to 1km

from the relay display card, allowing shorter cable runs between the actuating relays

and the controlled devices.

Up to eight relay display cards can be fitted in a Regard system – i.e. connected to

the same RS-485 bus. This restriction is removed if remote configuration of the relay

display cards is not required.

The relay display card “listens” to the messages on the RS-485 bus between the

Regard master card and channel cards. The relay display card requires a Regard

master card for operation. The master card must be configured to communicate

with all channel cards that are programmed on the relay display card .

NOTE – the relay display card gives no indication that a particular channel is not

communicating with the master card. Communication faults are indicated on either

the master card or the relevant channel card.

Operational fault relay

The relay display card has one relay, that indicates a critical operational fault of the

relay display card or relay module(s). This relay is always normally energised,

latching and non-acknowledgeable.

Electromagnetic compatibility

The Regard relay module and relay display card have been tested for compliance

with the EMC Directive. Take the following steps to ensure compliance:

• Installation must follow the instructions given in this manual.

• Installation must also follow the Draeger document “Guidelines for the construction

and installation of Regard systems to comply with the EMC Directive” which is

available separately.

• Observe instructions to use screened cable, where given

Instructions or precautions that are essential for electromagnetic compatibility are

identified by “EMC!” in the margin.

Page 7

REGARD Relay Module & Relay Display Card (ATEX version)

Issue 1 – July 2003

7

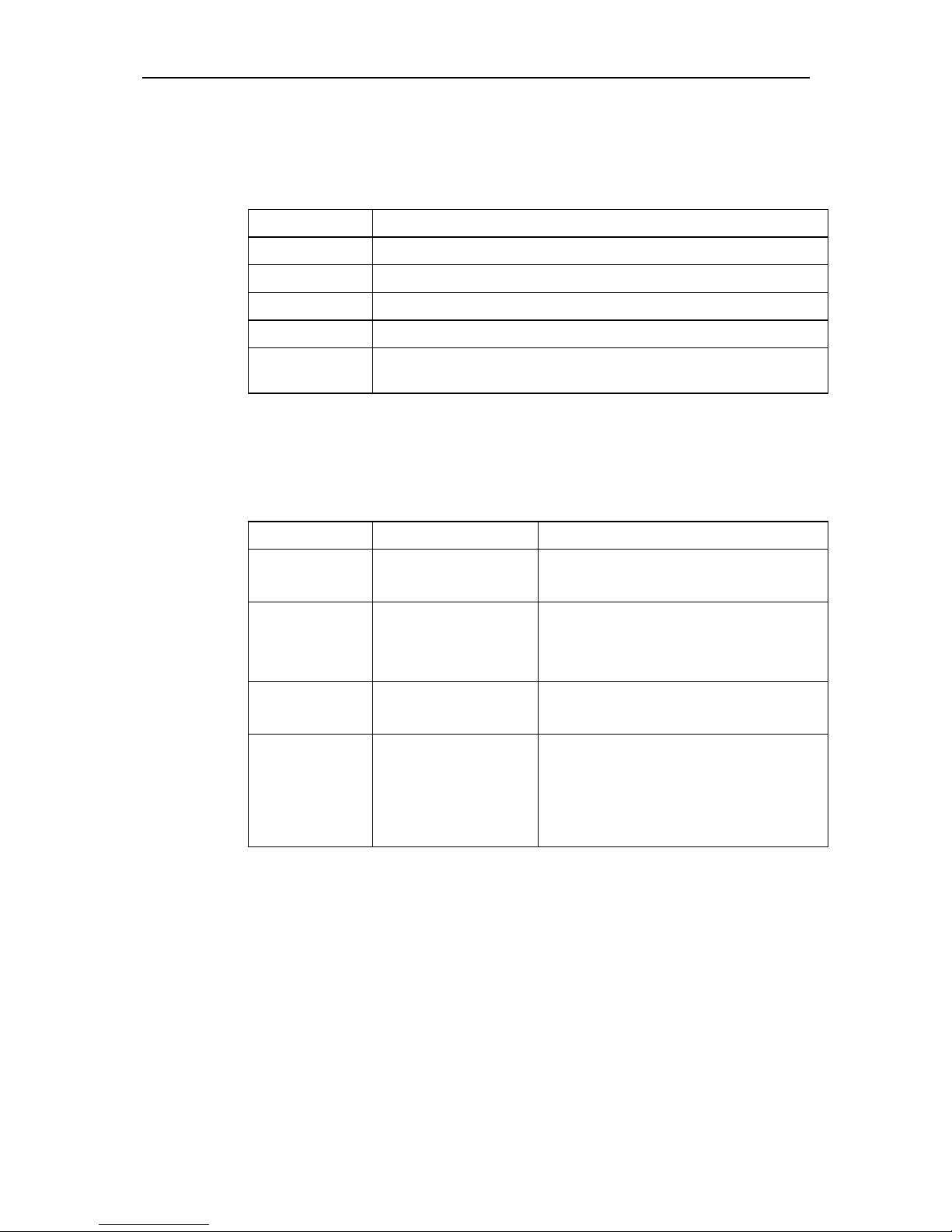

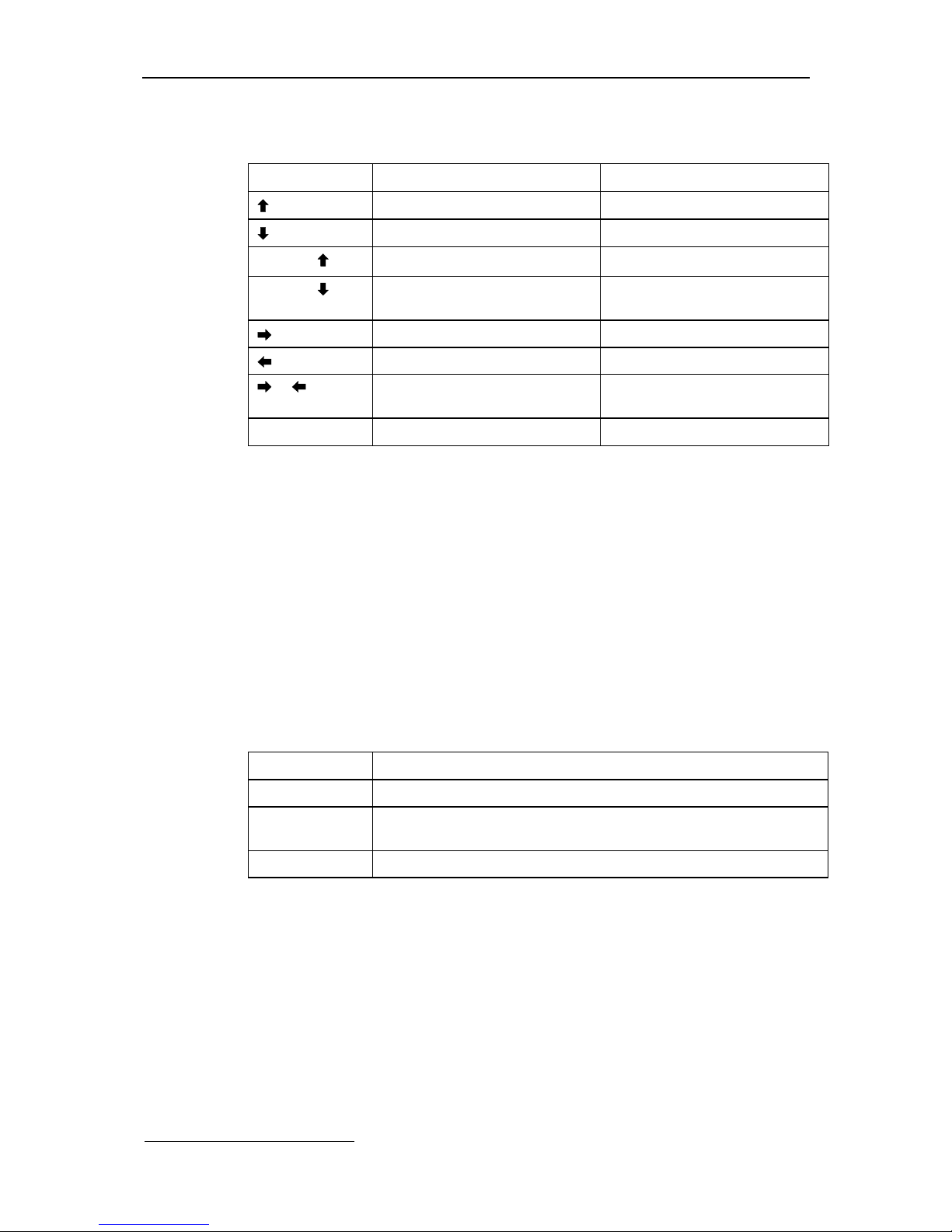

Display card front panel controls and indicators

Display

Display normally shows the state of each alarm relay in sequence. When a relay is in

its alarm state, only relays in alarm are displayed.

Display Meaning

001:CLR

Relay 001 in non-alarm state

002:ALRM

Relay 002 in alarm state

016:NOP

Operation of relay 016 not set (no operation)

256:DBLD

Relay 256 disabled

FAULT…

FLTM…

Operational fault

Relays are numbered from 001 to 256. Relays on relay module 1 are numbers 001 to

016, relays on relay module 2 are numbers 017 to 032, and so on.

LEDs

The LEDs show the status of the alarm relay currently featured in the display.

LED State Meaning

Alarm

On

Off

Relay in alarm state

Relay not in alarm state

Tripped

On

Flashing

Off

Alarm tripped & acknowledged

Alarm tripped, not acknowledged

No alarm

Power

On

Flashing

DC power on

Operational fault

Inhibit

On

Blinking on (normally

off, on every 5 secs)

Blinking off (normally

on, off every 5 secs.)

Relays inhibited

Relay(s) disabled

Relays inhibited + relays disabled

Page 8

REGARD Relay Module & Relay Display Card (ATEX version)

Issue 1 – July 2003

8

Controls

Function of front panel controls during normal operation:

Push button Result Note

Display relay latch mode

E.g. 001:LACK

Display relay energise mode

E.g. 023:ENER

SHIFT +

Display relay operating mode

E.g. 002:SA1

SHIFT +

Channel number of relay

configured SINGLE

E.g. 002:CH13

Display status of next relay —

Display status of previous relay —

+

Hold / release display of relay

status

Key presses alternately hold and

release display

R

Acknowledge / reset alarm —

Relay module indicators

• Power LED indicates that DC supply to module is connected.

• Relay LED next to each relay is lit when relay coil is energised.

Acknowledging alarms

The action required to acknowledge an alarm depends on it mode.

Momentarily connecting the remote reset terminals of the relay display card will also

acknowledge an alarm.

Note that, since one display card can control up to 256 relays, it is possible for all 256

relays to be acknowledged by a single reset operation. In particular, if any relays are

set to ACK1 or LACK1 then those relays will be untripped even in the presence of an

alarm condition (see the warning below).

Mode Action required to acknowledge alarm:

Common Press Reset on relay display card or master card

Single Automatically acknowledged by channel alarm (except when set

LNAK1)

Voted Press Reset on relay display card or master card

WARNING – when a relay latch mode is set to ACK1 or LACK1, a tripped relay

can be cleared even though an alarm condition may still be present. These

latch modes are generally employed as a convenience to silence audible alarms

while the cause of the alarm is being addressed.

1

See explanation of relay configuration options on page 25

Page 9

REGARD Relay Module & Relay Display Card (ATEX version)

Issue 1 – July 2003

9

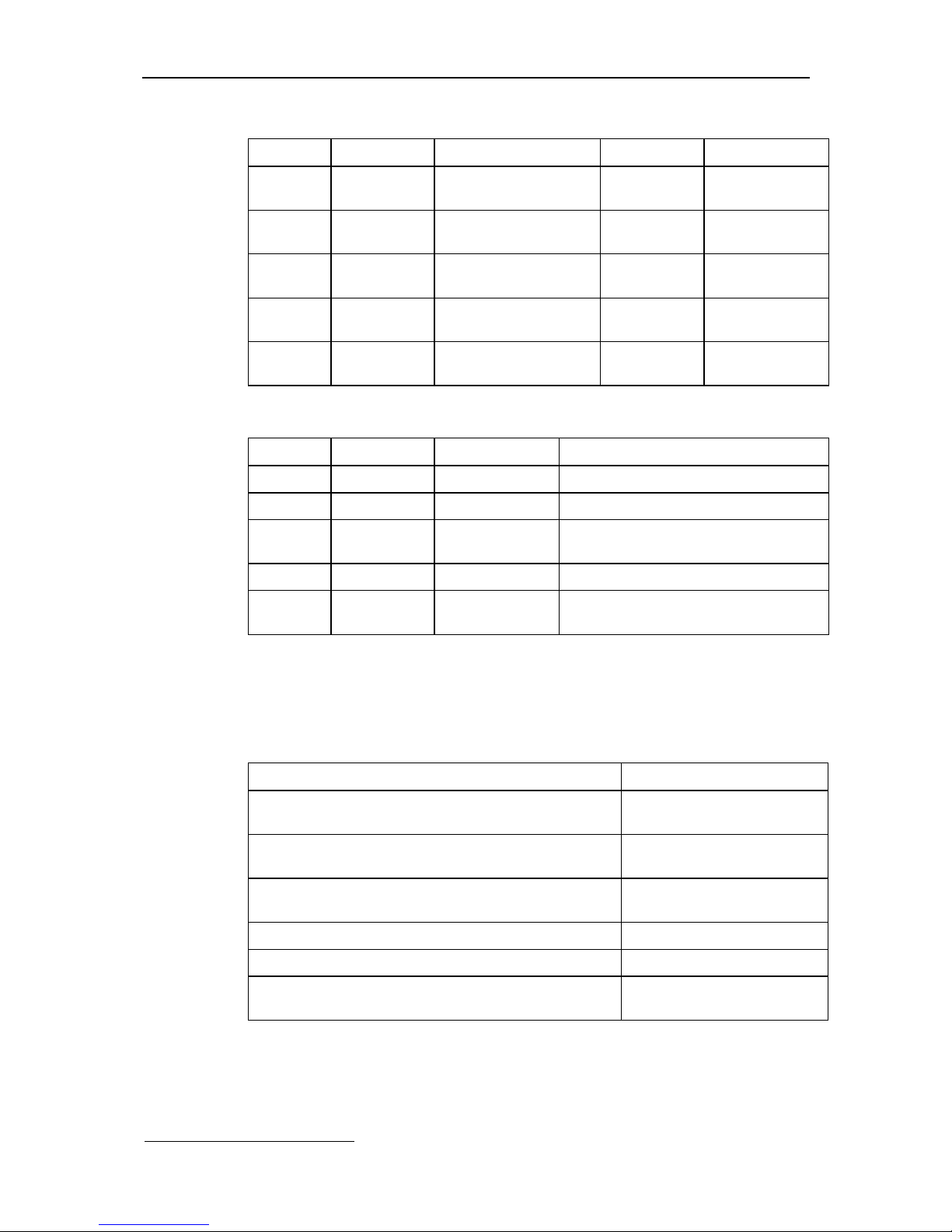

Alarm is acknowledged while alarm condition is still present

Setting Alarm trips Reset pressed Alarm clears Reset pressed

DNAK

1

Relay trips Alarm acknowledged

Relay stays tripped

Relay clears No effect

LNAK

1

Relay trips Alarm acknowledged

Relay stays tripped

No effect Relay clears

NAK

1

Relay trips Alarm acknowledged

Relay stays tripped

Relay clears No effect

LACK

1

Relay trips Alarm acknowledged

Relay clears

No effect No effect

ACK

1

Relay trips Alarm acknowledged

Relay clears

No effect No effect

Alarm is not acknowledged

Setting Alarm trips Alarm clears Reset pressed

DNAK

1

Relay trips No effect Alarm acknowledged; relay clears

LNAK

1

Relay trips No effect Alarm acknowledged; relay clears

NAK

1

Relay trips Relay clears Alarm acknowledged; relay stays

cleared

LACK

1

Relay trips No effect Alarm acknowledged; relay clears

ACK

1

Relay trips Relay clears Alarm acknowledged; relay stays

cleared

Relays configured “Single” and “LNAK1”

Relays configured Single and LNAK1 must be acknowledged at the relay display card

or master card, by pressing Reset or through remote reset input, if the channel card

gas alarm is acknowledged at the channel card before the gas alarm clears.

Event Relay (alarm) state

Gas alarm trips on channel card Relay in alarm state.

Tripped LED flashes

Channel card acknowledged Relay in alarm state.

Tripped LED on

Gas level falls below trip point Relay in alarm state

Tripped LED Off

Channel card acknowledged No change

Subsequent channel card acknowledgement No change

Reset pressed on relay display card or master card Relay in non alarm state.

Tripped LED off

1

See explanation of relay configuration options on page 25

Page 10

REGARD Relay Module & Relay Display Card (ATEX version)

Issue 1 – July 2003

10

Operational faults

An operation fault is a failure in the operation of either the relay display card or the

relay module. Operational faults are either:

• critical – card may stop working, or

• advisory – card will continue to work safely, but its functions may be limited

When an operational fault occurs:

• Power LED flashes once a second

• If fault is critical, operational fault relay de-energises

• Display shows fault code alternately with normal display

Press Reset to clear the fault. If fault will not clear, or recurs, call Draeger Service.

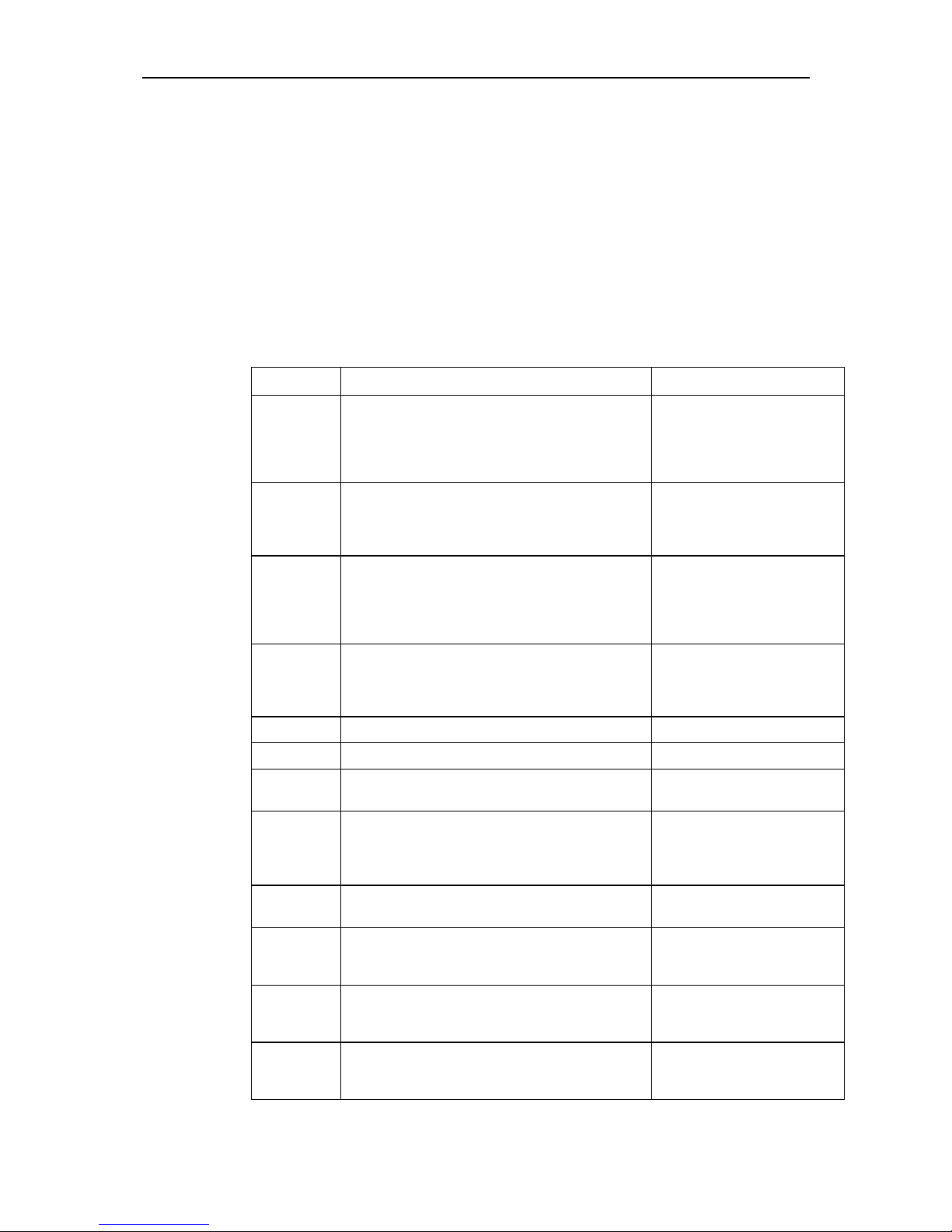

Operational fault codes

Fault code Meaning Remedy

FAULT BR

FAULT Bñ

FAULT Bò

FAULT Bï

FAULT Bð

Push button key fault. Advisory.

One of the front panel push button keys appears to

be continuously pressed.

Check push button keys.

FAULT C

Communications failure – Regard. Critical.

Relay display card is not receiving data from the

Regard master card. Alarms will not activate

relays. (See below for a fuller explanation.)

Check the integrity of the RS485 connections between the

relay display card, master card

and all channel cards.

FAULT CM

Communications failure – module. Critical.

One or more relay modules are not acknowledging

messages from the display card. (Modules may be

receiving data, but this cannot be confirmed.)

Relays may not operate.

Check module number.

Check RS-485 connection to

relay modules.

FAULT DR

FAULT DC

Relay or Card Data error. Critical.

Configuration settings have been corrupted.

Default configuration settings will be used.

Relays may not operate.

Check configuration settings.

FAULT HV

Supply voltage too high. Critical.

Reduce supply voltage.

FAULT LV

Supply voltage too low. Critical.

Increase supply voltage.

FAULT Mx

Microcontroller failure. Critical.

Card/module has stopped working.

Hold down Reset to reset the

card.

FLTMC nn

Module Communications failure. Advisory.

Module number nn is not receiving data from the

relay display card. All relays on module will

automatically de-energise.

Check module Nos. Check RS485 connection to relay

modules.

FLTMB nn

Relay module DC supply brownout. Critical.

Fault in DC supply to relay module number nn.

Check power supply to relay

module.

FLTMW nn

Relay module watchdog reset. Advisory.

An unknown error has caused relay module

number nn to reset.

Check relay module

installation.

FAULT RR

Remote reset fault. Advisory.

Remote reset terminals appear to be continuously

shorted. The remote reset input will be ignored.

Check remote reset.

FAULT Wi

FAULT We

Watchdog reset. Advisory.

Unknown error caused card to reset. Card will

continue to operate normally.

Check relay display card

installation.

Page 11

REGARD Relay Module & Relay Display Card (ATEX version)

Issue 1 – July 2003

11

In the situation where multiple faults occur consecutively, the first fault to occur will be

displayed. When that is cleared subsequent faults may be displayed if they are

unaffected by the clearing of prior faults.

In the situation where multiple faults occur simultaneously, only one will be indicated

on the display. The fault states are monitored continuously in the following order:

FAULT DR, DC, C, CM, HV, LV, BR, Bñ, Bò, Bï, Bð, FLTMC, FLTMB and FLTMW.

Any of these may be overridden by the hardware exception faults Mx, Wi and We

WARNING - FAULT C indication on the relay display card

The relay display card (RDC) is designed to listen to communications between

the master card and channel cards. A FAULT C indication will be indicated on

the RDC if:

§ there is no valid communication between the master card and at least one

channel card,

§ the communication link to the RDC is broken,

§ the checksum setting is not consistent throughout the system.

On a system with more than one channel the RDC will appear to be working

normally providing that at least one channel is communicating correctly with

its master card. Channels not communicating correctly will not generate

alarms, however, these channels will exhibit communication faults either on

the channel card itself or on the master card.

WARNING - FLTMB indication on the relay display card

The relay module initiates a brown-out indication on the RDC at voltages much

lower than the minimum specification. It is possible for the relay module to

malfunction due to a low supply voltage without this fault appearing on the

RDC.

Loss of communication between relay display card and relay module(s)

If the RS-485 connection between the relay display card and a relay module is

broken, or the communications between the two is otherwise interrupted, all

relays on the relay module will de-energise.

• There is a delay of 5 seconds, after the connection is broken, before the relays deenergise. If the connection is re-made within 5 seconds, the relays do not deenergise.

• When the connection is re-made, the relays will stay de-energised for 10 seconds.

Page 12

REGARD Relay Module & Relay Display Card (ATEX version)

Issue 1 – July 2003

12

INSTALLATION

Handle circuit boards with care during installation. Do not touch the circuit boards or

components.

Use of the relay modules and relay display card requires a Regard master card. All

Regard channel cards (e.g. 4-20, Ex, HART, 8-channel) must be connected to the

same RS-485 bus as the relay display card and the master card.

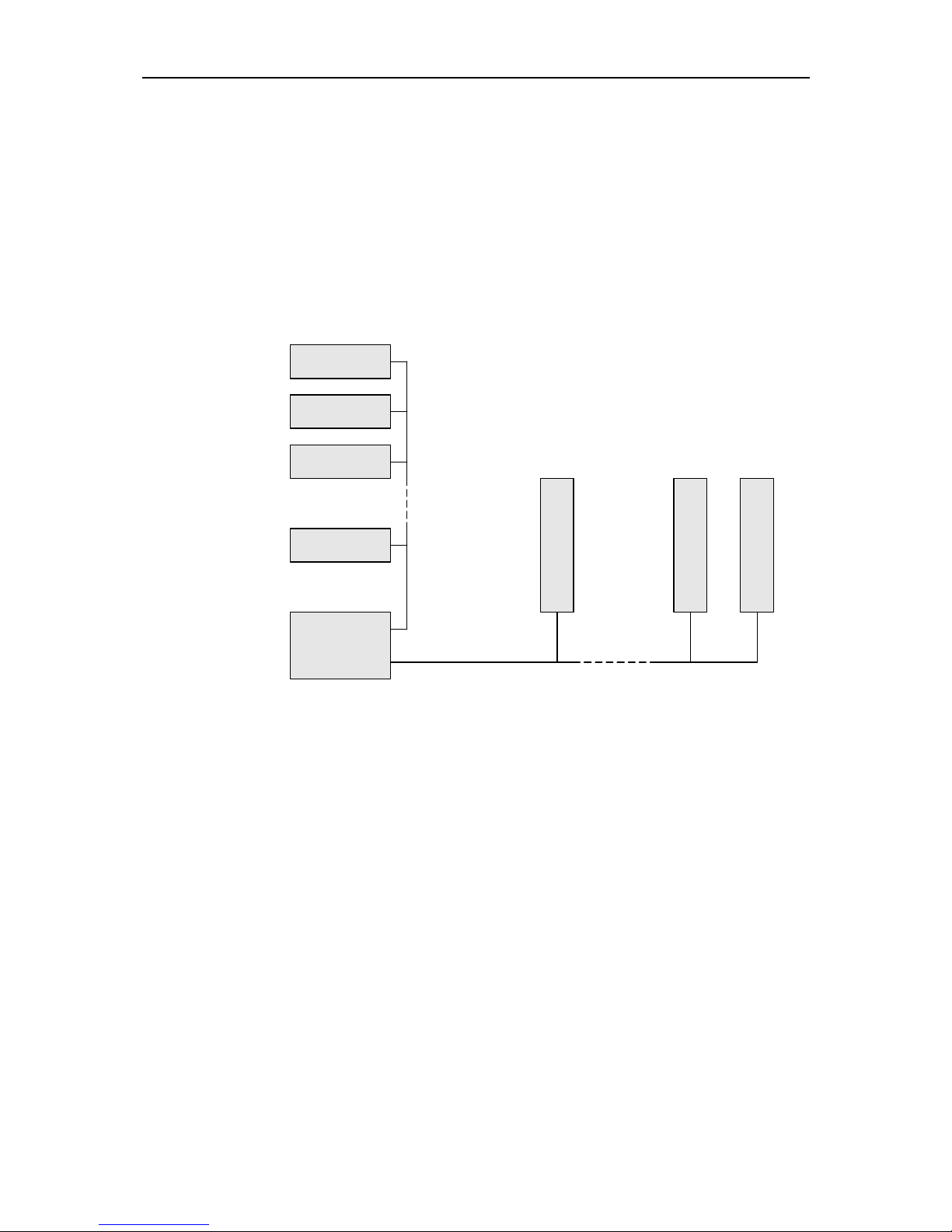

The diagram below shows how the relay display card and relay modules connect to a

Regard system. Note that there is a separate RS-485 bus from the relay display card

to the relay modules. (Diagram for illustration only.)

RELAY

DISPLAY

CARD

RELAY MODULE

RELAY MODULE

RELAY MODULE

MASTER

CARD

CHANNEL 1

CHANNEL 2

CHANNEL 99

MAIN RS-485 BUS

RS-485 BUS TO RELAY MODULES

Install relay display card

Fit the relay display card in slot in Regard rack.

EMC! Tighten the screws on the front panel fully.

Install relay modules

EMC! Install the relay module in a metal enclosure or other enclosure which gives protection

against radio-frequency interference.

• Fit relay modules to 35mm symmetric or 32mm asymmetric DIN rail.

• Maximum cable length of the RS-485 bus must not exceed 1000m

• Voltage difference between 0V at the relay display card and all relay module must

not exceed 5V. Use an RS-485 isolator if the voltage difference is greater that 5V.

Page 13

REGARD Relay Module & Relay Display Card (ATEX version)

Issue 1 – July 2003

13

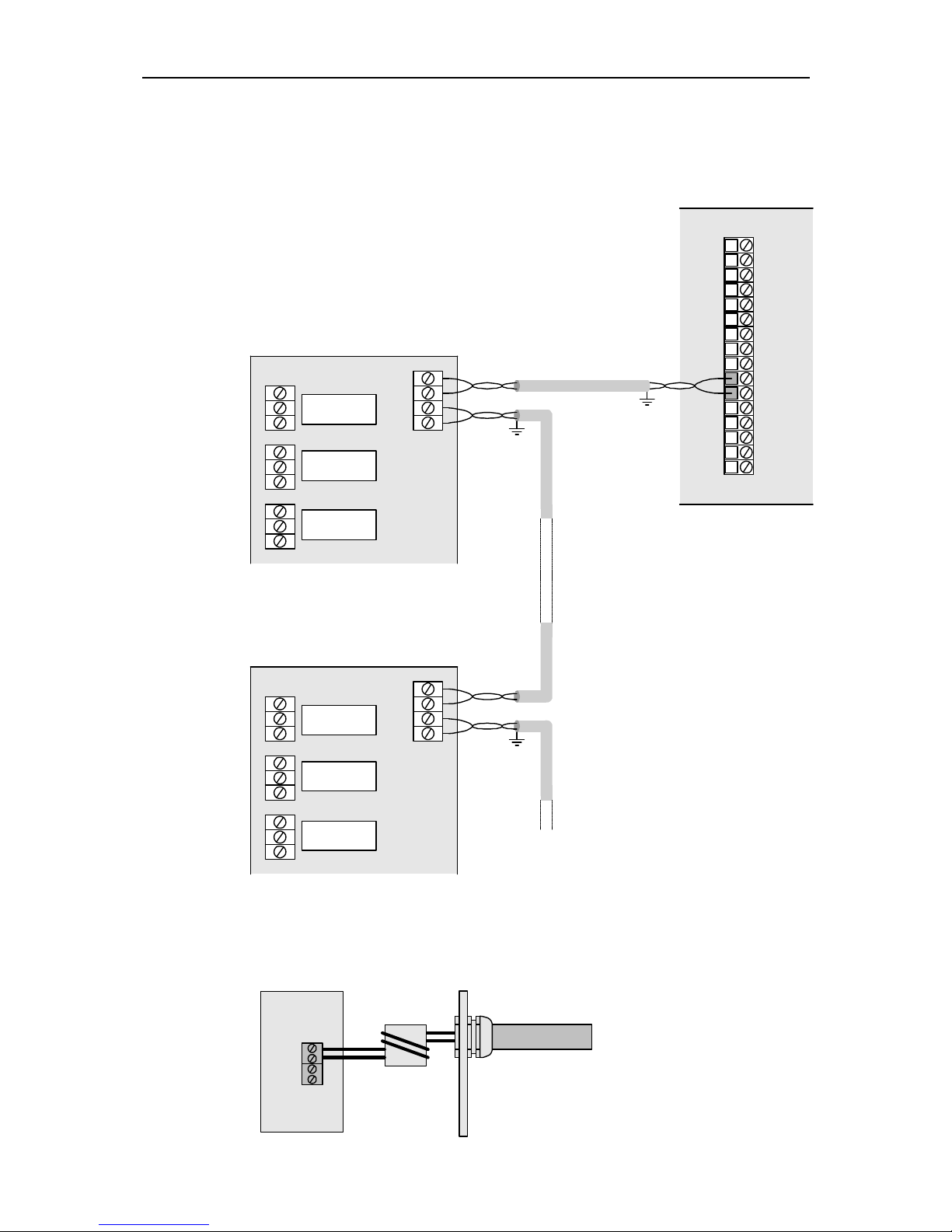

• Connect “A” on relay module to “A” on relay display card (terminal 11 on Regard

rack)

• Connect “B” on relay module to “B” on relay display card (terminal 10 on Regard

rack)

1

2

3

5

4

6

7

8

9

10

11

12

13

14

15

16

B

A

REGARD RACK

BABABABA

RELAY MODULE

RELAY MODULE

EMC! Use screened twisted pair cable. If the RS-485 cable between the relay module and

relay display card is outside the enclosure, pass the cable through a ferrite tube at the

entry point to the enclosure.

A

B

Page 14

REGARD Relay Module & Relay Display Card (ATEX version)

Issue 1 – July 2003

14

Allowed connection arrangements

“Bus”

RELAY

DISPLAY

CARD

RELAY MODULE

RELAY MODULE

MAXIMUM CABLE LENGTH: 1000m

RELAY MODULE

“Bus” with “stubs”

• Maximum allowed length of a stub is 5m

<1000m

RELAY

DISPLAY

CARD

RELAY MODULE

RELAY MODULE

RELAY MODULE

RELAY MODULE

<5m

<5m

<1000m

RELAY

DISPLAY

CARD

RELAY MODULE

RELAY MODULE

RELAY MODULE

RELAY MODULE RELAY MODULERELAY MODULE

Page 15

REGARD Relay Module & Relay Display Card (ATEX version)

Issue 1 – July 2003

15

Disallowed connection arrangements

“Star” – NOT ALLOWED

RELAY

DISPLAY

CARD

RELAY MODULE

RELAY MODULE

RELAY MODULE

RELAY MODULE

“Tree” – NOT ALLOWED

RELAY

DISPLAY

CARD

RELAY MODULE

RELAY MODULE

RELAY MODULE

RELAY MODULE

RELAY MODULE

Set module numbers

Set the ID number of each module using the rotary switch (SW1) on the module.

SW1

Each module connected to a relay display card must have a unique ID number.

• First module must be 0

• ID numbers must be contiguous– do not leave any gaps in the sequence.

Examples:

• 3 relay modules, numbers 0, 1, 2.

• 16 relay modules: numbers 0, 1, 2, 3, 4, 5, 6, 7, 8, 9, A, B, C, D, E, F.

• Relay modules are identified by the relay display card as “ID number + 1”, e.g. the

module with ID number 0 will be module 1 on the relay display card.

• The order of the relay modules on the RS-485 bus does not affect the operation of

the relay modules. Using a logical numbering sequence for the modules makes

programming the relay display card easier.

Page 16

REGARD Relay Module & Relay Display Card (ATEX version)

Issue 1 – July 2003

16

Connect equipment to relay terminals

Normally-open and normally-closed contacts are labelled on the relay module.

Labels show function of relay when de-energised:

NC NOC

EMC! Use screened cable for connections to relays

Connect DC supply to modules

Connect 24V DC supply to terminals marked 24V and 0V. Observe the polarity of the

terminals. Second pair of terminals can be used to connect supply to another relay

module.

• Do not connect more than 4 modules in series.

• Do not switch on 24V supply to relay modules until installation is complete.

24V

0V

Page 17

REGARD Relay Module & Relay Display Card (ATEX version)

Issue 1 – July 2003

17

Optional connections

Remote reset

If required, connect normally-open contact to remote reset terminals on relay display

card to allow remote reset of alarm relays. Connect using screw terminals on Regard

rack.

EMC! Use screened cable.

REGARD RACK

1

2

3

5

4

6

7

8

9

10

11

12

13

14

15

16

Operational fault relay

Use operational fault relay on relay display card to provide warning signal of failure

of relay display card. Connect using screw terminals on Regard rack.

EMC! Use screened cable.

REGARD RACK

1

2

3

5

4

6

7

8

9

10

11

12

13

14

15

16

RELAY SHOWN

ENERGIZED

(NORMAL STATE)

Page 18

REGARD Relay Module & Relay Display Card (ATEX version)

Issue 1 – July 2003

18

Switch-on and initial checks

Switch on DC supply to the relay display card and the relay module(s).

Check that the Power LED on the relay display card and relay modules are lit.

If power to the relay modules is connected more than 5 seconds before the relay

display card, the relay display card will indicate a communications fault warning.

Press R push button to cancel the warning.

Relay display card may indicate a fault condition until it is correctly configured.

Page 19

REGARD Relay Module & Relay Display Card (ATEX version)

Issue 1 – July 2003

19

CONFIGURATION

Command mode

Configuration and maintenance of the display card is performed using front panel

controls and display, by setting the card into command mode.

Command mode is entered by pressing and holding the Reset button for about 5

seconds.

In command mode:

• Display of relays status is replaced by display of command mode options and

configuration settings;

• The Inhibit LED lights and the Fault relay trips to indicate that operation of all

relays on relay modules is prevented (“inhibited”).

Configuration and maintenance commands are operated by selecting the command

number using the and push buttons.

Entering command mode automatically inhibits all alarm relays on the module(s)

connected to the relay display card.

Function of front panel controls in command mode

Push buttons

Push button Function

R

Confirm entry or selection

Select next command or option

Increase displayed value

Select previous command or option

Decrease displayed value

Select next relay

Select previous relay

SHIFT +

Jump +16 relays

SHIFT +

Jump –16 relays

Display

LED State Meaning

Alarm

Off

On

Relay not in alarm state

Relay in alarm state

Tripped

Off

On

No alarm

Alarm condition true

Power

On

Flashing

DC power on

Operational fault

Inhibit

On

Blinking

Relays inhibited

Relays inhibited + relays disabled

Page 20

REGARD Relay Module & Relay Display Card (ATEX version)

Issue 1 – July 2003

20

Table of commands

Cmd Command Function Command mode level Default

No. name Read Maint. Config. setting

00–0 CMD QUIT Quit command mode

• • •

00–1 PASSWORD Enter password

• • •

00–3 CHG P.WD Change password

• •

04–4 RLY ENER Set relay normally energised or

energise on alarm

o

•

NORM

†

11–1 VOTING Set relay voting configuration o

•

11–4 RLY MODE Set relay mode: common, voted, single

or no operation

o

•

NOP

†

11–7 LATCHING

Set relay latching, non-latching,

delay-latching, acknowledgeable,

non-acknowledgeable

o

•

LACK

14–0 LED TEST Test display & LEDs

• • •

14–1 RMT TEST Test remote reset

• • •

14–2 OPR TEST Test operational fault relay

• •

14–4 RLY TEST Test relay operation

• •

14–8 MOD TEST Test communications with modules

• • •

52–0 MODULES Set number of relay modules o o

•

1

52–1 CARD NUM Set relay display card number o o

•

1

52–6 CHECKSUM Set communications checksum

•

CRC

60–1 DISPLAY Turn display on or off

•

ON

60–4 DISABLE Disable relay

• •

NO

• Command can be accessed and setting changed

o Command can be accessed but setting cannot be changed

†

Relays with mode NOP will always be de-energised.

There is no SAVE command on the relay display card (00-2). Settings are saved automatically.

The relay display card does not automatically exit command mode if no buttons are pressed for 10

minutes. There is no LOCK command (60-0) to lock the card in command mode.

Page 21

REGARD Relay Module & Relay Display Card (ATEX version)

Issue 1 – July 2003

21

Configure channel cards and master card

Before configuring relay display card ensure that the other components of the Regard

system are correctly configured:

• Set operation of Regard master card and channel cards (4-20, Ex, HART, 8channel, etc.)

• Regard Master card must be configured to communicate with all channel cards

that will control alarms on relay module(s).

Configure relay display card

Use the blank sheets at the end of this manual to plan and record the configuration of

the relay modules.

Example

Card No. 1

Module No. 1

Relay No. Mode (11-4) Voting (11-1) Latching (11-7) Energise (04-4)

1 CA1 — ACK ENER

2 CA2 — ACK ENER

3 CA3 — ACK ENER

4 CF — LNAK NORM

5 SA1 CH1 — ACK ENER

6 SA2 CH1 — ACK ENER

7 SA3 CH1 — ACK ENER

8 SA1 CH2 — ACK ENER

9 SA2 CH2 — ACK ENER

10 SA3 CH2 — ACK ENER

11 SA1 CH3 — ACK ENER

12 SA2 CH3 — ACK ENER

13 SA3 CH3 — ACK ENER

14 SF CH1 — LNAK NORM

15 SF CH2 — LNAK NORM

16 SF CH3 — LNAK NORM

Card No. 1

Module No. 2

Relay No. Mode (11-4) Voting (11-1) Latching (11-7) Energise (04-4)

17 VA1 01 02 03 LACK ENER

18 VA2 01 02 03 LACK ENER

19 VA3 01 02 03 LACK ENER

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Page 22

REGARD Relay Module & Relay Display Card (ATEX version)

Issue 1 – July 2003

22

Configuration sequence

Enter configuration-level password

Factory-set configuration password is CCCC.

00–1 PASSWORD

PRESS DISPLAY

• Select 00–1

00-1

• Enter command

R PASSWORD

then

Ready for password entry

????

• Select first letter of password

C???

• Confirm first letter

R CC??

• Enter 2nd 3rd and 4th letters of password

R

CCCC

• Enter

Access at configuration level confirmed

R CONFIG

then

Command ends

00-1

Set number of relay modules

Set the number of relay modules connected to the relay display card.

52-0 MODULES

PRESS DISPLAY

• Select 52-0

52-0

• Enter command

R MODULES

then

Current setting:

1

• Select number of modules, e.g. 3

3

• Exit command

R 52-0

Page 23

REGARD Relay Module & Relay Display Card (ATEX version)

Issue 1 – July 2003

23

Set function of relays

11–4 RLY MODE

PRESS DISPLAY

• Select 11-4

11-4:001

• Enter

R RLY MODE

then

Current setting:

001:NOP

Relay number

Function

• Select function e.g. CA1

001:CA1

If SA1, SA2, SA3 or SF function selected, extra

step required (see below)

• Select next/previous relay and repeat

010:CA1

• Enter

R 11-4:010

For “Single” function:

• Select function SA1, SA2, SA3 or SF

001:SA1

• Enter

R 001:CH1

Channel number

• Select channel number

001:CH2

• Select next/previous relay and repeat

002:CA1

WARNING – it is possible to select channel numbers which are not present in the system and

the display card will not indicate that this setting is invalid.

Code Meaning Relay operation

CA1 Common A1

Alarm when A1 alarm on any channel.

CA2 Common A2

Alarm when A2 alarm on any channel.

CA3 Common A3

Alarm when A3 alarm on any channel.

CF Common Fault

Alarm when Fault alarm on any channel.

SA1 Single A1

A1 alarm for one channel.

SA2 Single A2

A2 alarm for one channel.

SA3 Single A3

A3 alarm for one channel.

SF Single Fault

Fault alarm for one channel.

VA1 Voted A1

Alarm when n out of m A1alarm on selected channels.

VA2 Voted A2

Alarm when n out of m A2alarm on selected channels.

VA3 Voted A3

Alarm when n out of m A3alarm on selected channels.

VF Voted Fault

Alarm when n out of m Fault alarm on selected channels.

NOP No operation None (relay always de-energised)

Page 24

REGARD Relay Module & Relay Display Card (ATEX version)

Issue 1 – July 2003

24

Set voting configuration

For relays configured voting (i.e. VA1, VA2, VA3 or VF), use command 11–1 to set

voting information for each relay.

Example 2 out of 3 voting for channels 4, 6 and 9.

11-1 VOTING

PRESS DISPLAY

• Select 11-1

11-1:001

• Enter

R VOTING

then

Current setting:

n OF 1

Number of channels in voting group (m)

• Select value of m (e.g. 3)

n OF 3

• Enter

R 1 OF 3

No of alarms required to trip (n)

• Select value of n (e.g. 2)

2 OF 3

• Enter

R 1 CH1

First channel in voting group

Channel number

• Select first channel in voting group (e.g. 4)

1 CH4

• Enter

R 2 CH5

Second channel in voting group

Channel number

• Select second channel in voting group (e.g. 6)

2 CH6

• Enter

R 3 CH7

• Select last channel in voting group

3 CH9

• Exit command

R 11-1:001

WARNING – it is possible to select channel numbers which are not present in the system and

the display card will not indicate that this setting is invalid.

Page 25

REGARD Relay Module & Relay Display Card (ATEX version)

Issue 1 – July 2003

25

Set relay latch/acknowledge operation

Determines the operation of a relay when the alarm condition clears or when the relay

alarm is acknowledged.

WARNING – when a relay latch mode is set to ACK or LACK, a tripped relay can

be cleared even though an alarm condition may still be present. These latch

modes are generally employed as a convenience to silence audible alarms

while the problem is being addressed.

Mode Function

ACK Non Latching and Acknowledgeable

Relay returns to non-alarm state when the relay alarm condition has cleared

or the relay alarm has been acknowledged.

NAK Non Latching and Non Acknowledgeable

Relay returns to its non-alarm state when the relay alarm condition has

cleared. Acknowledging the relay alarm whilst the alarm condition is still

true will not reset the relay.

LACK Latching and Acknowledgeable

Relay returns to its non alarm state when the relay alarm is acknowledged.

The relay will not automatically go back to its non-alarm state when the

alarm condition stops.

LNAK Latching and Non Acknowledgeable

Returns to its non alarm state when the alarm condition stops and then the

alarm is acknowledged. Acknowledging the relay alarm whilst the alarm

condition is still true will not reset the relay. The relay will not automatically

go back to its non-alarm state when the alarm condition stops.

DNAK

Delay Latching and Non-Acknowledgeable

Relay returns to its non alarm state when the alarm condition stops and the

alarm has been acknowledged. Acknowledging the relay alarm whilst the

alarm condition is still true will not reset the relay. The relay will

automatically go back to its non-alarm state when the alarm condition stops

if the relay has already been acknowledged.

11-7 LATCHING

PRESS DISPLAY

• Select 11-7

11-7:001

• Enter

R LATCHING

then

Current setting:

001:LACK

• Select new setting (e.g. ACK)

001:ACK

• Select next/previous relay until setting for all

relays configured

002:DNAK

• Exit command

R 11-7:002

Page 26

REGARD Relay Module & Relay Display Card (ATEX version)

Issue 1 – July 2003

26

Set relays energise on alarm or normally energised

04–4 RLY ENER

PRESS DISPLAY

• Select 04-4

04-4:001

• Enter

R RLY ENER

then

Current setting:

001:NORM

• Select NORM or ENER, e.g. ENER*

001:ENER

• Select next/previous relay and repeat

005:ENER

• Exit command

R 04-4:005

* NORM = Normally energised ENER = Energise on alarm

Set communications checksum

The relay display card must use the same communications checksum for RS-485

communications as the rest of the Regard system. Use CRC whenever possible.

52-6 CHECKSUM

PRESS DISPLAY

• Select 52-6

52-6

• Enter command

R CHECKSUM

then

Current setting:

CRC

• Select mode, e.g. CSUM

CSUM

• Exit command

R 52-6

Quit command mode

00-0 QUIT

PRESS DISPLAY

• Select 00–0

00-0

• Enter

R QUIT:NO

• Select YES

QUIT:YES

• Enter

Card exits command mode

R 001:CLR

Page 27

REGARD Relay Module & Relay Display Card (ATEX version)

Issue 1 – July 2003

27

Optional configuration settings

Set relay display card number

To allow remote configuration, each relay display card must be assigned a unique

card number.

Note: This setting allows differentiation of relay display cards on the same RS-485

bus by remote configuration software. It does not affect the operation of the relay

display card or relay modules in any way.

52-1 CARD NUM

PRESS DISPLAY

• Select 52-1

52-1

• Enter

R CARD NUM

then

Current setting:

CARD:1

• Select card number, e.g. 2

CARD:2

• Exit command

R 52-1

Turn display off

To save power, the display can be turned off. Display is then blank unless a relay is in

alarm or a button is pressed.

60–1 DISPLAY

PRESS DISPLAY

• Select 60-1

60-1

• Enter

R DISPLAY

then

Current setting:

ON

• Select ON or OFF, e.g. OFF

OFF

• Exit command

R 60-1

Page 28

REGARD Relay Module & Relay Display Card (ATEX version)

Issue 1 – July 2003

28

MAINTENANCE

Recommended maintenance intervals

EN 50073 and respective national regulations should be observed.

Daily:

• Visual check to determine readiness for operation

At regular intervals:

• Inspection by trained personnel.

The inspection intervals in each individual case are subject to technical safety

considerations, engineering processes and the technical requirements for the

equipment. A maximum interval of three months is recommended.

• Check connections to relays and between modules and relay display card

• Check operation of relays (command 14-4)

Page 29

REGARD Relay Module & Relay Display Card (ATEX version)

Issue 1 – July 2003

29

Commands for system maintenance

Change password

• Factory-set maintenance password is MMMM.

• Factory-set configuration password is CCCC.

• To change Configuration-level password, use command 00–3 after entering

existing Configuration-level password

• To change Maintenance-level password, use command 00–3 after entering

existing Maintenance-level password.

• Password must be 4 characters.

Example: change configuration password to ABCD.

00–3 CHG P.WD

PRESS DISPLAY

• Select 00–3

00-3

• Enter

R CHG P.WD

then

Existing password

CCCC

• Select first letter of new password

ACCC

• Enter

R AACC

• Select second letter

ABCC

• Enter

R ABBC

• Select third letter

ABCC

• Enter

R ABCC

• Select the fourth letter

ABCD

• Enter (NEW indicates new password)

R CFG:NEW

then

Command exits

00-3

Page 30

REGARD Relay Module & Relay Display Card (ATEX version)

Issue 1 – July 2003

30

Test LEDs and display

14-0 LED TEST

PRESS DISPLAY

• Select 14-0

14-0

• Press R to test

R LED TEST

LEDs and display flash

• Press R to stop

R 14-0

Test remote reset

14–1 RMT TEST

PRESS DISPLAY

• Select 14-1

14-1

• Enter

R RMT TEST

then

Remote reset terminals closed-circuit

CLOSED

or

Remote reset terminals open-circuit

OPEN

or

Remote reset terminals closed-circuited for more

than 20 seconds

FAULTY

• Press R to stop

R 14-1

Test operational fault relay

14–2 OPR TEST

PRESS DISPLAY

• Select 14-2

14-2

• Enter

R OPR TEST

then

Relay in non alarm state

OFF

or

Relay in alarm state

ON

• Change relay state

OFF

• Exit command

R 14-2

Page 31

REGARD Relay Module & Relay Display Card (ATEX version)

Issue 1 – July 2003

31

Test relay module relay

14–4 RLY TEST

PRESS DISPLAY

• Select 14-4

14-4:001

• Enter

R RLY TEST

then

If relay not energised

001:OFF

or

If relay energised

001:ON

• Change relay state

001:ON

• Select next/previous relay

002:OFF

• Exit command

R 14-4:002

Test communications with relay modules

14–8 MOD TEST

PRESS DISPLAY

• Select 14-8

14-8

• Enter

R MOD TEST

then

Checking communication with relay module 1

MOD1 ??

then

Communications okay

MOD1 OK

or

No communications with module

MOD1 NO

• Select next/previous module

MOD2 OK

• Exit command

R 14-8

Page 32

REGARD Relay Module & Relay Display Card (ATEX version)

Issue 1 – July 2003

32

Disable relay(s)

Each relay on the relay modules can be prevented from changing state when an

alarm occurs.

If a relay that is in its alarm state is disabled, the relay will change to its non-alarm

state upon exit from command mode.

The “Inhibit” LED blinks when one or more relays are disabled.

For disabled relays:

• “Tripped” LED continues to indicate that alarm condition is true

• “Alarm” LED does not operate.

Warning: a disabled relay will not indicate a gas alarm or fault alarm.

60-4 DISABLE

PRESS DISPLAY

• Select 60-4

60-4:001

• Enter

R DISABLE

then

Current setting:

001:NO

• Select YES (disabled) or NO (not disabled)

001:YES

• Select next/previous relay

003:YES

• Exit command

R 60-4:003

Page 33

REGARD Relay Module & Relay Display Card (ATEX version)

Issue 1 – July 2003

33

TECHNICAL DATA

Relay display card

Supply voltage 18 to 35V DC

Environmental operating range

• Temperature

–20° to +55°C

• Humidity

0 to 90%RH, non-condensing

• Vibration

To BS 2011 Part 2.1Fc

Storage temperature range –25° to +70°C

Current consumption

• Typical

50mA

• Maximum

150mA

Operation fault relay

• Type

Single pole double throw (1 Form C)

• Switching capacity

5A, 250VAC; 5A 30VDC

• Max. switching power

1,250VA, 150W

• Max. switching voltage

250VAC, 100VDC

• Min. switching voltage & current

12V, 100mA

Format Single Eurocard, 10 HP front panel

Dimensions 187 x 129 x 50mm

Fuse 800mA quick blow (F), 20 x 5mm

Relay module

Supply voltage 18 to 35V DC

Environmental operating range

• Temperature

–20° to +55°C

• Humidity

0 to 90%RH, non-condensing

• Vibration

To BS 2011 Part2.1Fc

Storage temperature range –25° to +70°C

Current consumption

• Typical

50mA

• Maximum

350mA

Relays

• Type

Single pole double throw (1 Form C)

• Switching capacity

5A, 250VAC; 5A 30VDC

• Max. switching power

1,250VA, 150W

• Max. switching voltage

250VAC, 100VDC

• Min. switching voltage & current

12V, 100mA

Wire cross-section

• Relays

2.5 mm

2

• DC inputs & RS-485

1.5 mm

2

Format DIN rail mounting module

Dimensions 360 x 90 x 60mm

Fuse 1A quick blow (F) 20 x 5mm

Note that for both the display card and the input module, type-examination covers:

• operating temperatures: 0 to +55°C

• storage temperatures: –25° to +55°C

Part numbers

Description Part Number

Regard relay display card (ATEX version) 4206719

Regard relay module (ATEX version) 4206720

Page 34

REGARD Relay Module & Relay Display Card (ATEX version)

Issue 1 – July 2003

34

EC-Type Examination certificate

Page 35

Relay module configuration sheet

Card No.

Module No. 1

Relay No. Mode (11-4) Voting (11-1) Latching (11-7) Energise (04-4)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

Card No.

Module No. 2

Relay No. Mode (11-4) Voting (11-1) Latching (11-7) Energise (04-4)

17

18

19

20

21

22

23

24

25

26

26

28

29

30

31

32

Page 36

Relay module configuration sheet (contd.)

Card No.

Module No. 3

Relay No. Mode (11-4) Voting (11-1) Latching (11-7) Energise (04-4)

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

Card No.

Module No. 4

Relay No. Mode (11-4) Voting (11-1) Latching (11-7) Energise (04-4)

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

Page 37

Relay module configuration sheet (contd.)

Card No.

Module No. 5

Relay No. Mode (11-4) Voting (11-1) Latching (11-7) Energise (04-4)

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

Card No.

Module No. 6

Relay No. Mode (11-4) Voting (11-1) Latching (11-7) Energise (04-4)

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

Page 38

Relay module configuration sheet (contd.)

Card No.

Module No.

Relay No. Mode (11-4) Voting (11-1) Latching (11-7) Energise (04-4)

Card No.

Module No.

Relay No. Mode (11-4) Voting (11-1) Latching (11-7) Energise (04-4)

Page 39

Page 40

Draeger Safety UK Ltd

Kitty Brewster Industrial Estate

Blyth

Northumberland

NE24 4RG

England

Tel. +44 1670 352891

Fax +44 1670 356266

Dräger Safety AG & Co. KGaA

Revalstraße 1

D-23560 Lübeck

Germany

Tel. +49 4 51 882 - 2794

Fax +49 4 51 882 - 4991

Draeger Industrie S.A.

3c, route de la Fédération

F-67025 Strasbourg Cedex

France

Tel. +33 388 40 7676

Fax +33 388 40 7667

http://www.draeger.com/gds

Draeger Safety, Inc.

10450 Stancliff

Suite 220

Houston, TX 77099

U.S.A.

Tel. +1 281 498 1082

Fax +1 281 498 5190

Draeger South East Asia Pte, Ltd.

67, Ayer Rajah Crescent #06-03

SGP-0513 Singapore

Singapore

Tel. +65 6872 92 88

Fax +65 6773 20 33

Beijing Fortune Draeger Safety

Equipment Co. Ltd

22 Yu An Rd, B Area

Tianzhu Airport Industrial Zone

Houshayu

Shunyi District

Beijing 101300

PR China

Tel. +86 10 8049 8000

Fax. +86 10 8049 8005

Manual P/N 4206728

Issue 1 – July 2003

Subject to alteration

For use with relay display card software version D1.0 and V3.0

Loading...

Loading...