Page 1

Installation and Operation Manual

ATLAS WOOD BURNING

COOKSTOVE

(DB04810 model)

ENGLISH

READ AND KEEP THIS MANUAL FOR REFERENCE

Printed in Canada

Security test made according

to regulations ULC S627 and

UL 1482 by an accredited

laboratory.

2018-07-04

45962A

Page 2

Page 3

THANK YOU FOR CHOOSING

THIS WOOD BURNING COOKSTOVE.

If this cookstove is

not installed properly,

combustible materials

near it may overheat

and catch fire.

To reduce the

risk of fire, follow

the installation

instructions in this

manual.

As one of North America’s

largest and most respected

wood stove and fireplace

manufacturers, Stove Builder

International takes pride in the

quality and performance of all

its products.

The following pages

provide general advice on

wood heating, detailed

instructions for safe and

effective installation, and

guidance on how to get the

best performance from this

cookstove.

It is highly recommended

that this cookstove be

installed and serviced by

professionals who are certified

in the United States by NFI

(National Fireplace Institute®)

or in Canada by WETT

(Wood Energy Technology

Transfer) or in Quebec

by APC (Association des

Professionnels du Chauffage).

Contact local building or fire

officials about restrictions

and installation inspection

requirements in your local

area.

A building permit might be

required for the installation

of this cookstove and

the chimney that it is

connected to. It is also highly

recommended to inform your

home insurance company.

Please read this entire manual

before installing and using this

cookstove.

ENGLISH

If the unit requires repairs during the warranty period, proof of purchase must be provided. The

purchase invoice must be kept. The date indicated on it establishes the warranty period. If it

can not be provided, the warranty period will be determined by the date of manufacture of the

product.

It is also highly recommended to register the warranty online at

https://www.drolet.ca/en/warranty/warranty-registration/

Registering the warranty will help to quickly find the information needed on the unit.

Installation and operation manual - Atlas woodburning cookstove

ONLINE WARRANTY REGISTRATION

Page 3

Page 4

TABLE OF CONTENTS

PART A - OPERATION AND MAINTENANCE .............................................................................. 7

1. Safety Information ................................................................................................................... 7

2. General information ................................................................................................................ 8

2.1 Specifications ............................................................................................................... 8

2.2 Cookstove Dimensions ................................................................................................. 9

3. Fuel ........................................................................................................................................ 10

3.1 Recommended Fuel ......................................................................................................10

4. Stove Operation .................................................................................................................... 10

4.1 Components Location ..................................................................................................10

4.2 Cooking .......................................................................................................................11

4.3 First Fires .....................................................................................................................11

ENGLISH

4.4 Lighting a Fire ..............................................................................................................11

4.5 Maintaining Wood Fires .................................................................................................12

4.6 Adjusting Primary and Secondary Air Inlet ......................................................................13

5. Cookstove Maintenance ....................................................................................................... 15

5.1 Cleaning and Painting the Cookstove.............................................................................15

5.2 Vermiculite Slabs and Baffle ..........................................................................................15

5.3 Combustion Chamber ...................................................................................................15

5.4 Grills and Trays ............................................................................................................15

5.5 Glass Maintenance .......................................................................................................15

6. Chimney Maintenance .......................................................................................................... 17

6.1 Why Sweep the Chimney? ............................................................................................17

6.2 Cleaning Frequency ......................................................................................................17

6.3 Chimney Sweeping .......................................................................................................17

PART B - INSTALLATION .............................................................................................................18

7. Safety Information ................................................................................................................. 18

7.1 Regulations Governing the Installation of the Cookstove .................................................18

8. Clearances to Combustible Materials .................................................................................. 18

8.1 Cookstove Positioning ..................................................................................................19

8.2 Location of the Certification Label .................................................................................19

8.3 Cookstove Clearances to Combustible Materials ............................................................19

8.4 Clearances Reduction to the Walls and the Ceiling ........................................................22

8.5 Clearances for Shield Installation ...................................................................................24

9. The Exhaust System ............................................................................................................. 25

9.1 General Information ......................................................................................................25

9.2 Suitable Chimneys ........................................................................................................25

9.3 Chimney Height ............................................................................................................26

Page 4

Installation and operation manual - Atlas woodburning cookstove

Page 5

10. Combustion Air Supply ......................................................................................................... 27

11. Chimney Connector Installation ........................................................................................... 27

11.1 Single Wall Chimney Connector Installation ....................................................................27

12. Troubleshooting .................................................................................................................... 30

13. Exploded View and Parts List .............................................................................................. 31

Atlas Cooking Stove Limited Lifetime Warranty ........................................................................34

ENGLISH

Dealer:

Installer:

Phone Number:

Serial Number:

Installation and operation manual - Atlas woodburning cookstove

Page 5

Page 6

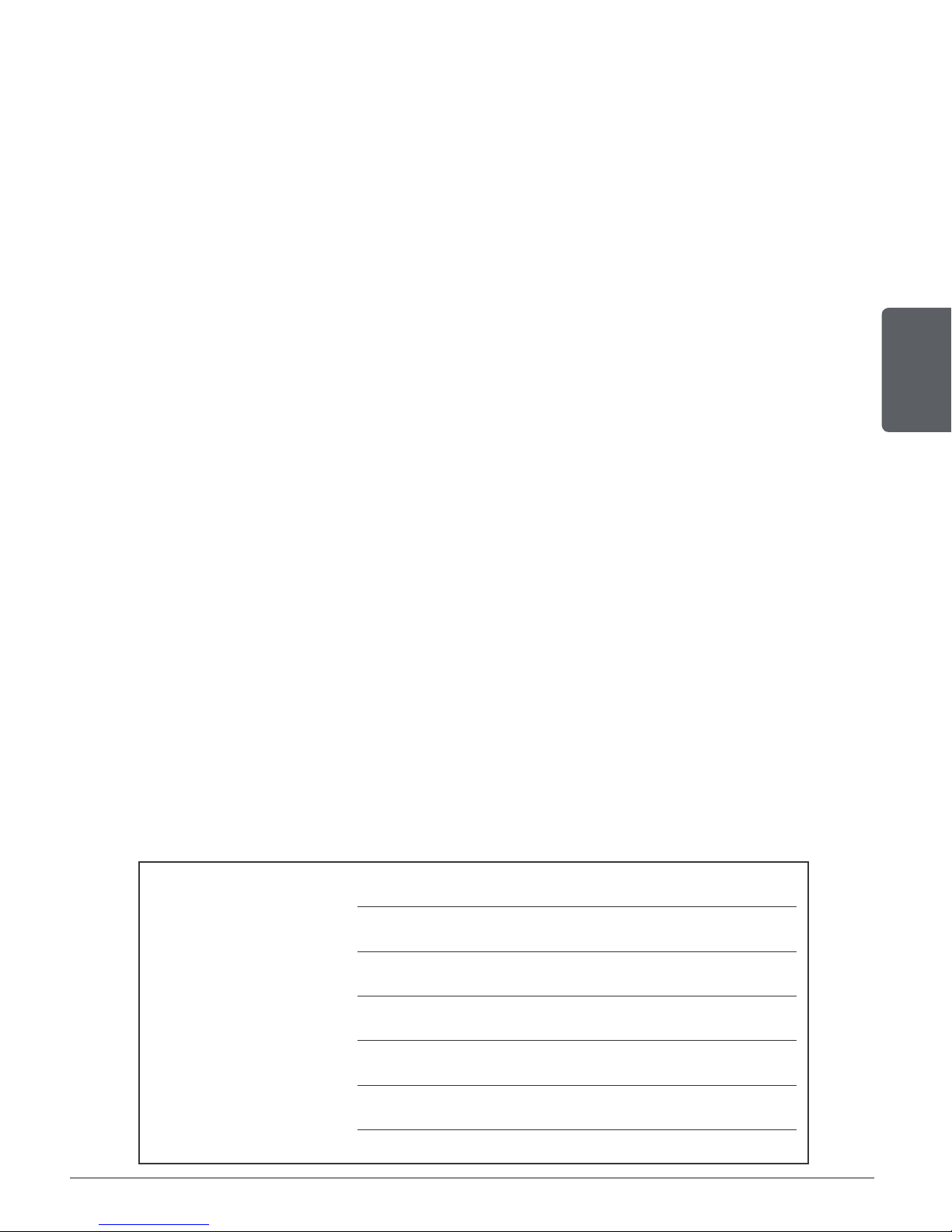

CERTIFICATION PLATE

ENGLISH

Page 6

Installation and operation manual - Atlas woodburning cookstove

Page 7

PART A - OPERATION AND MAINTENANCE

1. Safety Information

• Operate only with doors fully closed. If door is left partly open, gas and flame may be drawn out of

the opening, creating risks from both fire and smoke.

• The cookstove is not designed to be used when the door is open. Open the door only to startup

or to reload the stove.

• Don’t leave unattended when the door is slightly open for startups. Always close the door after

ignition.

• HOT WHILE IN OPERATION, KEEP CHILDREN, CLOTHING AND FURNITURE AWAY.

CONTACT MAY CAUSE SKIN BURNS. GLOVES MAY BE NEEDED FOR COOKSTOVE

OPERATION.

• Using the cookstove with cracked or broken components, such as glass, firebricks or baffle may

produce an unsafe condition and may damage the cookstove.

ENGLISH

• Open the air control fully before opening the combustion chamber door.

• Do not store fuel within cookstove minimum installation clearances.

• Do not wood in the accessory compartment, underneath the combustion chamber. .

• Burn only seasoned natural firewood.

• Do not elevate the fire by using a grate.

• A smoke detector, a carbon monoxide detector and a fire extinguisher should be installed in the

house. The location of the fire extinguisher should be known by all family members.

• DO NOT USE CHEMICALS OR FLUIDS TO START THE FIRE.

• DO NOT BURN GARBAGE OR FLAMMABLE LIQUIDS SUCH AS GASOLINE, NAPHTHA,

FUEL OIL, ENGINE OIL, KEROSENE, CHARCOAL LIGHTER FUEL, SIMILAR LIQUIDS, OR

AEROSOLS TO START, REVIVE OR NEAR THE FIRE. KEEP ALL SUCH LIQUIDS WELL AWAY

FROM THE HEATER WHILE IT IS IN USE.

• This appliance should always be maintained and operated in accordance with these instructions.

WARNING: This product can expose you to chemicals including carbon monoxide,

which is known to the State of California to cause cancer, birth defects or other

reproductive harm. For more information go to www.P65warnings.ca.gov

Installation and operation manual - Atlas woodburning cookstove

Page 7

Page 8

2. General information

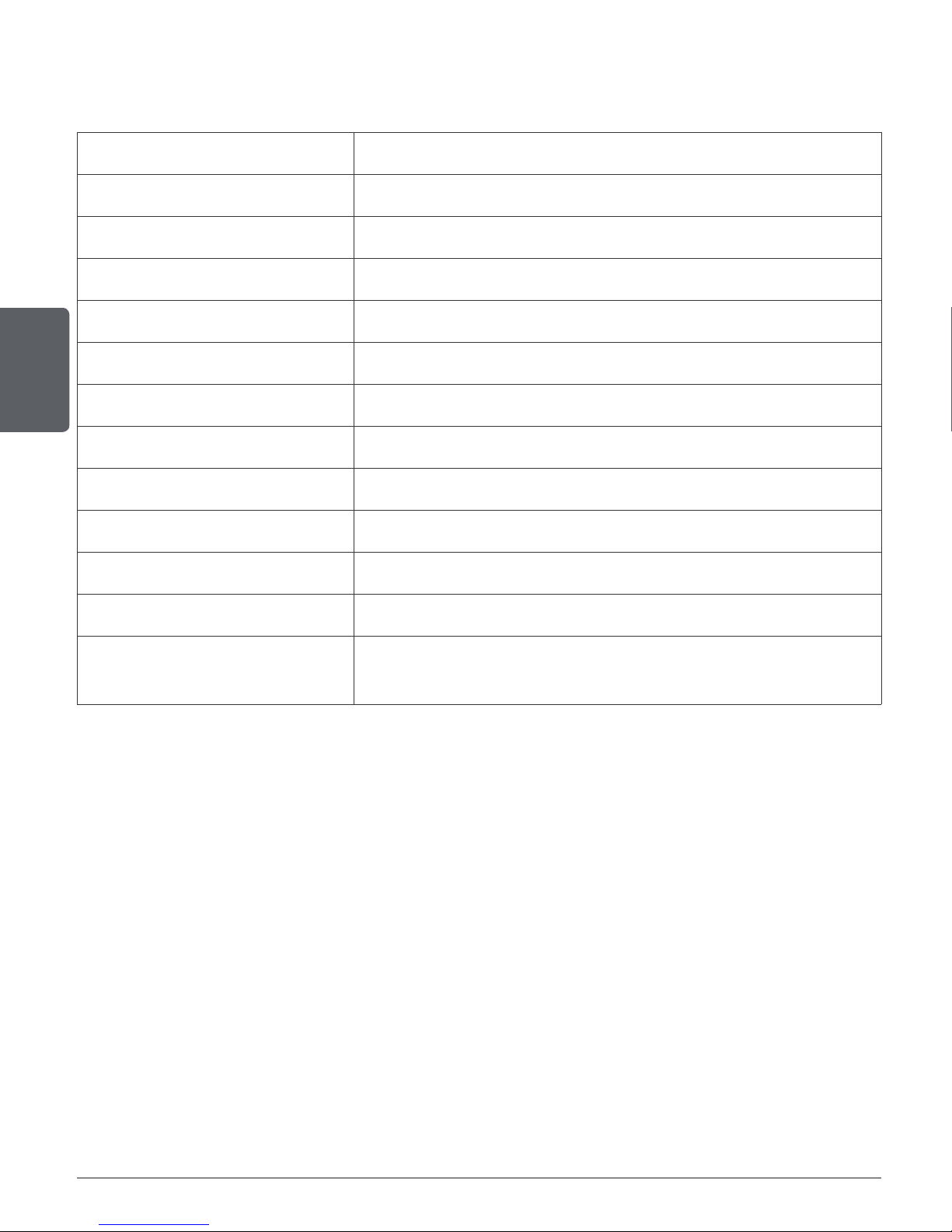

2.1 Specifications

Model Atlas woodburning cookstove (DB04810)

Fuel Type Dry Cordwood

Recommended log length 15 - 18 in (400 - 500 mm)

Flue outlet diameter 6 in (150 mm)

Chimney diameter 6 in (150 mm)

Type of chimney UL 103 HT, ULC S629

Necessary flue draft 0,05" H2O (12 Pa)

ENGLISH

Alcove installation Not approved

Mobile home installation

‡

Not approved

Shipping weight 330 lb (150 kg)

American standards (security) UL 1482

Canadian standards (security) ULC S627

Oven dimensions (W x D x H)

‡Mobile home (Canada) or prefabricated home (USA): The US department of Housing and urban development describes “prefabricated homes”

better known as “mobile homes” as follows; constructed buildings on xed wheels and those transported on temporary wheels/axles installed on a

permanent foundation. In Canada, a mobile home is a dwelling which the assembly of each component is done or mostly done before moving it to

a location where it will be placed on foundations and connected to service facilities that meet the standards CAN/CSA-Z240 MH.

21 ½" x 13" x 8 ¾"

(546 mm x 330 mm x 222 mm)

Page 8

Installation and operation manual - Atlas woodburning cookstove

Page 9

2.2 Cookstove Dimensions

Ø

150mm

5 3/8"

136mm

27"

684mm

6"

18"

459mm

11"

278mm

19"

484mm

Figure 1: Top view

19"

484mm

10"

252mm

49 3/8"

1254mm

47 3/8"

1202mm

ENGLISH

Figure 2: Front view Figure 3: Side view

Installation and operation manual - Atlas woodburning cookstove

Page 9

Page 10

3. Fuel

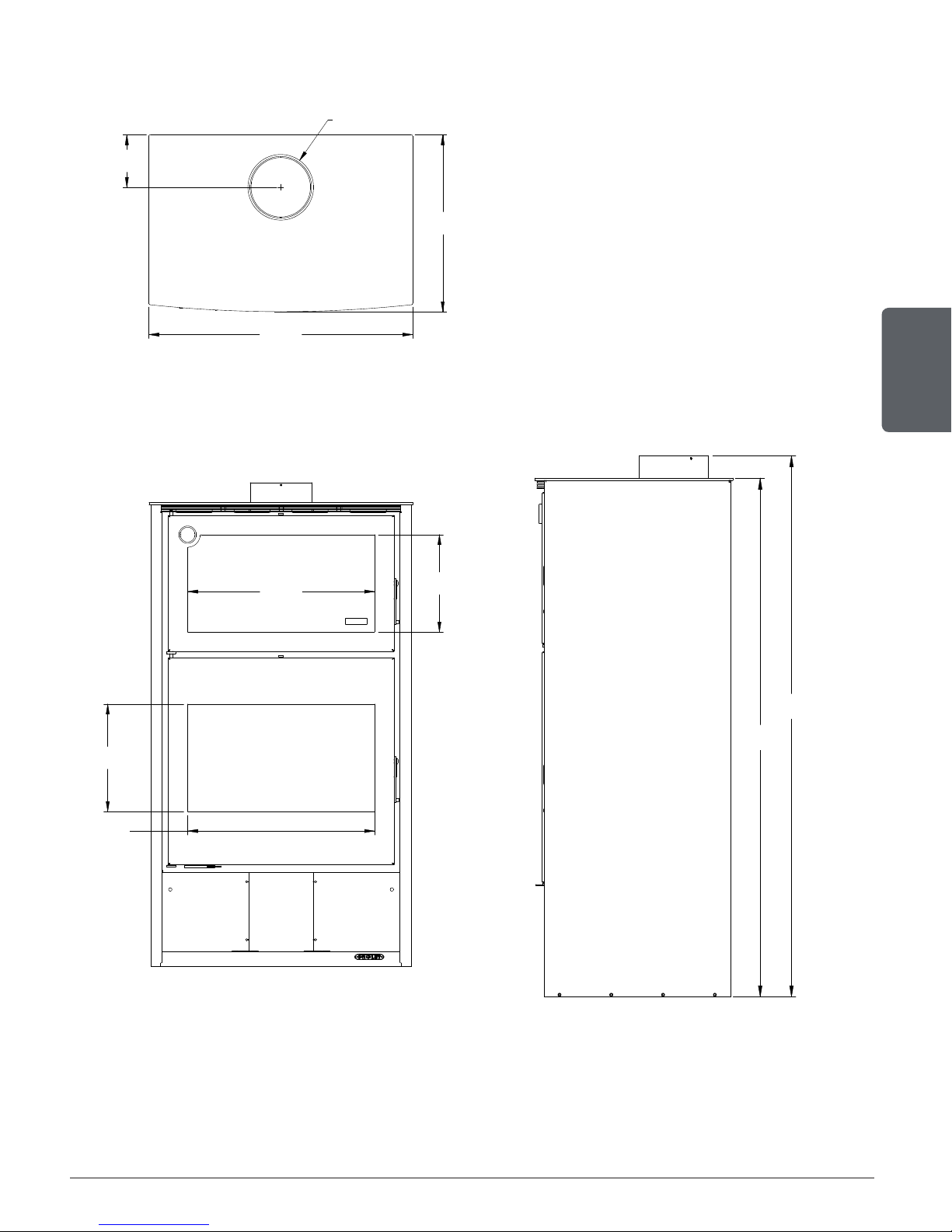

3.1 Recommended Fuel

Wood burner performance depends greatly on the fuel used. Good firewood has been cut to

the correct length for the appliance, split to a range of sizes and stacked in the open until its

moisture content is down to 15% to 20%. Proper fuel makes it easier to regulate heat and keep

the wood burner and flue in better condition.

Use split pieces of wood, they will burn better than logs. Make sure to have various size of

wood.Thin firewood should be used to get higher thermal power, use it after lighting the fire for

a faster response as more heat is needed. Use thick wood for a slower combustion when less

heat is needed or for overnight fire. If necessary, when starting the fire, burn a combination of

thin and thick firewood.

Store firewood in a dry, ventilated place protected from the rain for one to two years depending

on the storage and weather conditions.

ENGLISH

DO NOT BURN GARBAGE OF ANY KIND, COAL OR CHARCOAL, TREATED, PAINTED OR

COATED WOOD, PLYWOOD OR PARTICLE BOARD, FINE PAPER, COLORED PAPER OR

CARDBOARD, SALT WATER DRIFTWOOD, MANUFACTURED LOGS CONTAINING WAX OR

CHEMICAL ADDITIVES, RAILROAD TIES AND LIQUIDS SUCH AS KEROSENE OR DIESEL

FUEL TO START A FIRE.

Do not burn manufactured logs made of wax impregnated sawdust or

logs with any chemical additives. Manufactured logs made of 100%

compressed sawdust can be burned with caution in the number of these

logs burned at one time. Start with one manufactured log and see how

the cookstove reacts. Never use more than two manufactured logs.

4. Stove Operation

4.1 Components Location

A Oven thermometer

B Combustion chamber

C Air control

D Accessory compartment

E Cleaning access panel

F Oven

A

E

F

B

G

C

H

G Cooking grills

H Ash pan

Page 10

D

Figure 4: Component Location

Installation and operation manual - Atlas woodburning cookstove

Page 11

It is prohibited to put or store: alcohol, gasoline, liquid fuel, flammable materials,

ashes, paper and wood in the accessory compartment.

4.2 Cooking

Cooking can be done in the stainless steel oven, using the cooking grills and the trays provided

with the cookstove. It can also be done in the combustion chamber, using the cooking grils only.

Do not use the trays in the combustion chamber.

The panoramic windows allow you to see the cooking or baking without having to open the

door. The door’s integrated thermometer simplifies the reading of the oven temperature. The

temperature indicated by the thermometer is only used as a reference. During cooking, keep the

oven door closed to keep a constant temperature.

4.3 First Fires

Before ignition, make sure the chimney is clean and clear. The cookstove startup must be done

only when all the installation steps for the cookstove and the chimney have been completed.

During the first fires, the cookstove will give off an unpleasant smell along with a light smoke.

This has to do with the hardening of the paint process. The paint heats up, hardens, and

adheres to metal. The smell and the smoke will disappear when the cookstove has been heated

for several hours. Increase the fire intensity gradually. Open a window. Even though the smoke

and the smell are unpleasant, they are not toxic.

4.4 Lighting a Fire

Load a generous amount of firewood, placing a layer of wood chips or thin firewood and another

layer of thicker wood on top. You must leave the pieces crossed and with enough separation

between them to allow proper air flow.

Light the first layer of wood chips or thin wood using fire-starters or special lighting products,

if necessary.

Leave the door ajar, so that enough air can enter for the fire to light quickly.

Once the wood is well-lit, wait until the temperature is high before completely closing the door

(10 to 45 minutes, depending on factors like wood, air circulation, etc.) and adjust the air inlet.

If you find that the volume of flames decreases, or the fire tends to go out and the smoke inside

the fireplace increases, open the air intake more or repeat the previous step.

ENGLISH

When reloading, if there are not enough embers to light the new load of wood, open the door

and the air inlet.

DO NOT USE FLAMMABLE LIQUIDS SUCH AS GASOLINE, NAPHTHA, FUEL OIL, MOTOR

OIL, OR AEROSOLS TO START OR REKINDLE THE FIRE.

DO NOT LEAVE THE COOKSTOVE UNATTENDED WHEN THE DOOR IS SLIGHTLY OPENED.

ALWAYS CLOSE AND LATCH THE DOOR AFTER THE FIRE IGNITES.

Installation and operation manual - Atlas woodburning cookstove

Page 11

Page 12

4.5 Maintaining Wood Fires

4.5.1 General Advice

Wood burns best in cycles. A cycle starts when a new load of wood is ignited by hot coals and

ends when that load has been consumed down to a bed of charcoal about the same size as it

was when the wood was loaded. Trying to produce a steady fire by placing a single log at regular

intervals is not recommended. Always place at least three, and preferably more pieces on the

fire at a time so that the heat radiated from one piece helps to ignite the pieces next to it.

Prolonged and continuous use at a very low rate of combustion or with very wet

wood can cause highly flammable creosote to build up in the flue.

Burning in cycles means the stove door does not need to be opened while the wood is flaming.

This is an advantage since it is preventing smoke leaking from the stove when the door is opened

as a full fire is burning. This is especially true if the chimney is on the outside wall of the house.

ENGLISH

If the door must be open while the fire is flaming, fully open the air control for a few

minutes then open the door slowly.

4.5.2 Ash Removal

Ash should be removed from the firebox every two to three days. Ash should not accumulate

excessively in the firebox since it will affect the proper operation of the cookstove.

The best time to remove ash is when the stove is relatively cold, but there is still a little chimney

draft to draw the ash dust into the stove and prevent going out into the room.

Ashes should be placed in a tightly covered metal container. The container must be placed on a

non-combustible floor or on the ground well away from all combustible materials.

Ashes can contain hot embers that can stay hot for several days. If the ashes are disposed of

by burial in soil or otherwise locally dispersed, they should be kept in the closed metal container

until they are completly cooled. No other waste should be placed in this container.

NEVER STORE ASHES INDOORS OR IN A NON-METALIC CONTAINER OR ON A WOODEN

DECK.

4.5.3 Raking Charcoal

When it is time to reload the stove, start by removing the ashes first, then rake charcoal towards

the front of the firebox before reloading. Most of the remaining charcoal will be at the back of

the firebox, furthest from the door. Rake the coals towards the door before loading.

Page 12

Installation and operation manual - Atlas woodburning cookstove

Page 13

Raking the coals is useful for two reasons. First, it brings them near where most of the combustion

air enters the firebox. This will ignite the new load quickly. Secondly, the charcoal will not be

smothered by the new load of wood. When the embers are simply spread inside the combustion

chamber, the new load smoulders for a long time before igniting.

4.5.4 Firing Each New Load Hot

Place the new load of wood on and behind the charcoal, not too close to the glass. Close the

door and open the air control fully until the firebox is full of flames, the wood has charred to

black and its edges are glowing red. Firing each load of wood hot accomplishes the following

things:

− Removes surface moisture from the wood,

− Creates a layer of char on the wood, which slows down the smoke release,

− Heats the firebox components so they reflect heat back to the fire, and

− Heats the chimney so it can produce strong, steady draft for the rest of the cycle.

Although it is important to fire each new load hot, do not allow the fire to burn at full intensity

for more than a few minutes.

THE COOKSTOVE SHOULD NOT BE LEFT UNATTENDED WHILE A NEW LOAD IS BEING

FIRED HOT.

DO NOT OVERFIRE.

Overloading the appliance with firewood decreases performance, reduces energy

efficiency and accelerates the wear and tear of the appliance. Do not exceed

the maximum load of firewood of 7 kg. Overloading the appliance voids all the

manufacturer’s warranties.

4.6 Adjusting Primary and Secondary Air Inlet

The control of the primary and secondary air inlet is simultaneous and is done with a single

regulation control, located under the combustion chamber door.

The optimum regulation of the air inlet can vary according to various factors, such as the

chimney flue, the temperature of the cookstove and, the quality of the firewood (moisture, size

and shape).

ENGLISH

Do not alter the air regulation control to increase firing for any reason.

In order to avoid burns while regulating air flow and opening the doors, always use

the cold hand provided with the stove.

Installation and operation manual - Atlas woodburning cookstove

Page 13

Page 14

CLOSE

Figure 5: Cold hand Figure 6: Air inlet control

4.6.1 Regulating the air during lighting

ENGLISH

FERMÉ OPEN

OUVERT

Opening the air inlet completely is mandatory during the lighting, and it is recommended to leave

the door ajar during lighting as well, in order to avoid condensation of fumes on the glass. Wait

enough time (until the hearth has warmed up) before starting to regulate the air inlet.

4.6.2 Regulating the air during combustion

Once the device is hot enough, has a good reserve of embers and the flame is well-lit one can

regulate the air inlet to achieve good combustion and performance.. The air intake may be

regulated to an opening of 15% - 40%. During the operation of the heater you must not

completely close the air inlet.

Page 14

Installation and operation manual - Atlas woodburning cookstove

Page 15

5. Cookstove Maintenance

This cookstove will give many years of reliable service if used and maintained properly. Some of

the internal components of the firebox, such as vermiculite and baffle will wear over time under

intense heat. Defective parts should always be replaced with original parts. Firing each load

hot to begin a cycle will not cause premature deterioration of the cookstove. However, letting

the cookstove run with the air intake fully open for the entire burn cycles can cause damage

over time. The hotter the cookstove becomes throughout burn cycles, the more quickly its

components will deteriorate. For this reason, the cookstove should never be left unattended

while a new load is being fired hot.

5.1 Cleaning and Painting the Cookstove

Painted surfaces can be wiped down with a soft, dry cloth. If the paint is scratched or damaged,

it is possible to repaint it with a heat-resistant paint. Do not clean or paint the cookstove

when it is hot. Before painting, the surface should be sanded lightly with sandpaper and then

wiped off to remove dust. Apply two thin layers of paint. For best results, use the original paint,

available in aerosol cans.

It is very important not to wet the wood burner with window-cleaner, water or special cleaning

products. Heatproof paint is not waterproof.

ENGLISH

5.2 Vermiculite Slabs and Baffle

Before installing the slabs and the baffle, ensure that none are broken or damaged in any way,

and replace the damaged ones. Check for damage at least annually and replace any broken or

damaged ones with new ones.

5.3 Combustion Chamber

The cookstove cleaning frequency depends on the type and quality of combustible used. A high

humidity rate, ashes, soot, or chemical components in the wood could increase the number of

cleanings necessary. Therefore, it is important to pay attention to the combustible used.

To get the maximum performance from the cookstove, ashes should be removed regulary. The

use of a personal, central, or commercial vacuum cleaner to clean up the cookstove is not

recommended. Ash particles can damage the vacuum engine. Furthermore, hot ashes could

ignite the content of the vacuum. The use of a specialized ash vacuum is highly recommended.

The ashes must be stored in a metallic container with a waterproof lid. This closed container

should be put on a noncombustible surface, away from any flammable material. If the ashes are

meant to be buried or locally dispersed, they should be kept in a closed container until they are

completely cold.

5.4 Grills and Trays

Clean trays like regular dishes. Clean grills with a brush and soft soap.

5.5 Glass Maintenance

Do not clean the glass when the cookstove is hot. To clean the glass, first spray the cleaning

product on a cloth and then proceed to clean the glass only, without wetting the rest of the door.

Window-cleaners and special products often contain chemicals that attack the paint and the

ceramic fibre seals and cause oxidation of the metal parts.

Installation and operation manual - Atlas woodburning cookstove

Page 15

Page 16

Never use an abrasive cleaner on the window. Do not clean the window when it’s hot. Do not

force, hit, slam, or do anything that could weaken the glass door. Do not use the cookstove if

the window is missing, cracked, or broken.

5.5.1 Replacing the Glass Door and the Glass Gasket

The glass used in the this cookstove is 4 mm thick, and was tested to reach temperatures up to

1400º F. It has the following dimensions :

− Oven (W x H): 20" x 13 ⅛"

− Combustion chamber (W x H): 20" x 16"

If the glass breaks, it must be replaced with one having the same specification. Contact your

dealer to obtain a genuine replacement part.

Tempered glass or ordinary glass will not withstand the high temperatures of the

cookstove.

ENGLISH

To replace the glass, follow the steps below :

1. Remove the door from its hinges and lay it facing down on a soft

surface such as a cloth or a carpet.

2. Remove the screws that holds the brackets in place.

3. Remove the glass.

4. Install the gasket all aroung the new glass (see image).

5. Reinstall the new glass.

5.5.2 Replacing the Door Gasket

To maintain optimal performance, the door

should always be perfectly sealed with the

combustion chamber. The gasket must be

inspected periodically to get a tight seal.

With time, the door gasket will compress and

harden which will allow air to infiltrate. You can

test the condition of the gasket by closing and

locking the door on a piece of paper. Check

the periphery of the door. If the paper slides

easily at any place around the door, it is time

to change the gasket.

Figure 7: Verifying the door seal

The right diameter and density of the gasket are important to maintain a tight seal. Refer to a

dealer for a genuine replacement part. See section "13. Exploded View and Parts List" for more

details.

Put the door facing down on a soft surface such as a cloth or a carpet. Remove the gasket

and use a screwdriver to scrape away the old adhesive. Apply high temperature sealant in the

groove of the gasket. Push the gasket into the groove. Do not stretch the gasket while installing.

Keep approximately ½ inch longer when cutting and then push it into the groove. Push away the

exceeding fibres under the gasket. Close the door and do not use the cookstove for 24 hours.

Page 16

Installation and operation manual - Atlas woodburning cookstove

Page 17

6. Chimney Maintenance

6.1 Why Sweep the Chimney?

Wood smoke can condense inside the chimney and the chimney connector, forming a flammable

deposit called creosote. If the creosote builds up in the evacuation system, it can combust when

the fire is very hot. An extremely hot fire can progress to the extremity of the chimney. Severe

chimney fires can damage even the best chimneys.

Smouldering fires can quickly cause a thick layer of creosote. When those are avoided, the gases

coming out of the chimney are almost transparent. Creosote is therefore formed more slowly.

Your new cookstove has the necessary characteristics to help you make clean fires producing

little or no smoke. Therefore, less creosote will accumulate in the chimney.

6.2 Cleaning Frequency

It is not possible to predict how long or how much creosote will form in the chimney. It is

important, therefore, to check monthly for deposits in the chimney until the rate of creosote

formation is known.

The chimney must be inspected regularly during the heating season to determine if creosote

buildup has occurred. If a significant layer of creosote has accumulated (3 mm or more), remove

it to reduce the risk of a chimney fire.

ENGLISH

Weekly cleaning may be necessary in mild weather, while monthly cleaning may be sufficient in

the colder months. Even though creosote is slowly forming in the system, the chimney should

be inspected and cleaned at least once a year.

Contact the municipal or provincial fire department for information on how to handle a chimney

fire. Have a clearly understood plan for managing a chimney fire.

It is recommended to clean the chimney system at the end of each heating season. During

summer, the air is more humid and with minimum air circulation in the appliance, creosote or the

soot left in the pipes can produce an acid that will accelerate the corrosion process of steel and

may perforate it prematurely. Consequently, this will not be covered by the warranty. Have the

chimney system cleaned by a professional sweeper.

6.3 Chimney Sweeping

Chimney sweeping can be difficult and dangerous. If you don’t have any experience sweeping

chimneys, you may want to hire a professional sweeper to inspect and clean your system the

first time. After seeing how the sweeping is done, you will know if it is a job you can do yourself.

The most commonly used equipment includes fiberglass rods with threaded connections and

plastic brushes. The brush is forcibly moved from top to bottom of the chimney to remove the

creosote by rubbing.

The chimney connector and its components should always be cleaned at the same time as the

chimney.

When the chimney is clean, open the access panel in front of the cookstove and remove the

accumulation of creosote and soot. Also clean accumulation inside the combustion chamber,

over the baffle.

Installation and operation manual - Atlas woodburning cookstove

Page 17

Page 18

PART B - INSTALLATION

7. General Information

7.1 Security

• Read this manual completely before installing the cookstove. It is important to fully respect the

installation instructions. If the cookstove is not correctly installed, it could result in a fire, bodily

injuries or even death.

• The information given on the certification label affixed to the appliance always overrides the

information published, in any other media (owner’s manual, catalogues, flyers, magazines and web

sites).

• Mixing of appliance components from different sources or modifying components may result in

hazardous condtions. Where any such changes are planned, Stove Builder International Inc. Should

be contacted in advance. Any modification of the appliance that has not been approved in writing

by the testing authority violates CSA B365 (Canada), and ANSI NFPA 211 (USA).

ENGLISH

• DO NOT CONNECT TO OR USE IN CONJUNCTION WITH ANY AIR DISTRIBUTION

DUCTWORK UNLESS SPECIFICALLY APPROVED FOR SUCH INSTALLATION.

• DO NOT CONNECT THIS UNIT TO A CHIMNEY FLUE SERVING ANOTHER APPLIANCE.

• Connect this stove only to a listed factory-built chimney for use with solid fuel or to a lined masonry

chimney conforming to local and national building codes.

• If required, a supply of combustion air shall be provided to the room.

• Do not use makeshift materials or make any compromises when installing this cookstove.

• DO NOT INSTALL IN A MOBILE HOME.

7.2 Regulations Governing the Installation of the Cookstove

In Canada, the CSA B365 Installation Code for Solid Fuel Burning Appliances and Equipment

is to be followed in the absence of local code requirements. In the USA, the ANSI NFPA 211

Standard for Chimneys, Fireplaces, Vents and Solid Fuel-Burning Appliances is to be followed

in the absence of local code requirements.

This cookstove must be connected to a chimney complying with the requirements for Type HT

chimneys in the Standard for Factory-Built Chimneys for Residential Type and Building Heating

Appliances, UL 103 HT and ULC S627 or to a code-approved masonry chimney with a flue liner.

7.3 Cookstove Positioning

Choose a location to avoid the chimney conflicting with floor joists, roof trusses, wall studs,

water pipes, electric wires, and that allows the least possible deviations in the chimney. The

location of the cookstove must allow enough room for its maintenance and the exhaust system.

This cookstove weighs approximately 150 kg (330 lb). To validate the installation of additional

floor joist, consult the local building code.

Page 18

Installation and operation manual - Atlas woodburning cookstove

Page 19

7.4 Location of the Certification Label

Since the information given on the certification label affixed to the appliance always overrides

the information published, in any other media (owner’s manual, catalogues, flyers, magazines

and web sites) it is important to refer to it in order to have a safe and compliant installation. In

addition, important information about the stove can be found (model, serial number, etc.). The

certification label is located on the back of the stove.

It is recommended to note the stove serial number on page 5 of this manual since it will

be needed to precisely identify the version of the appliance in the event replacement parts or

technical assistance is required. It is also recommended to register the warranty online.

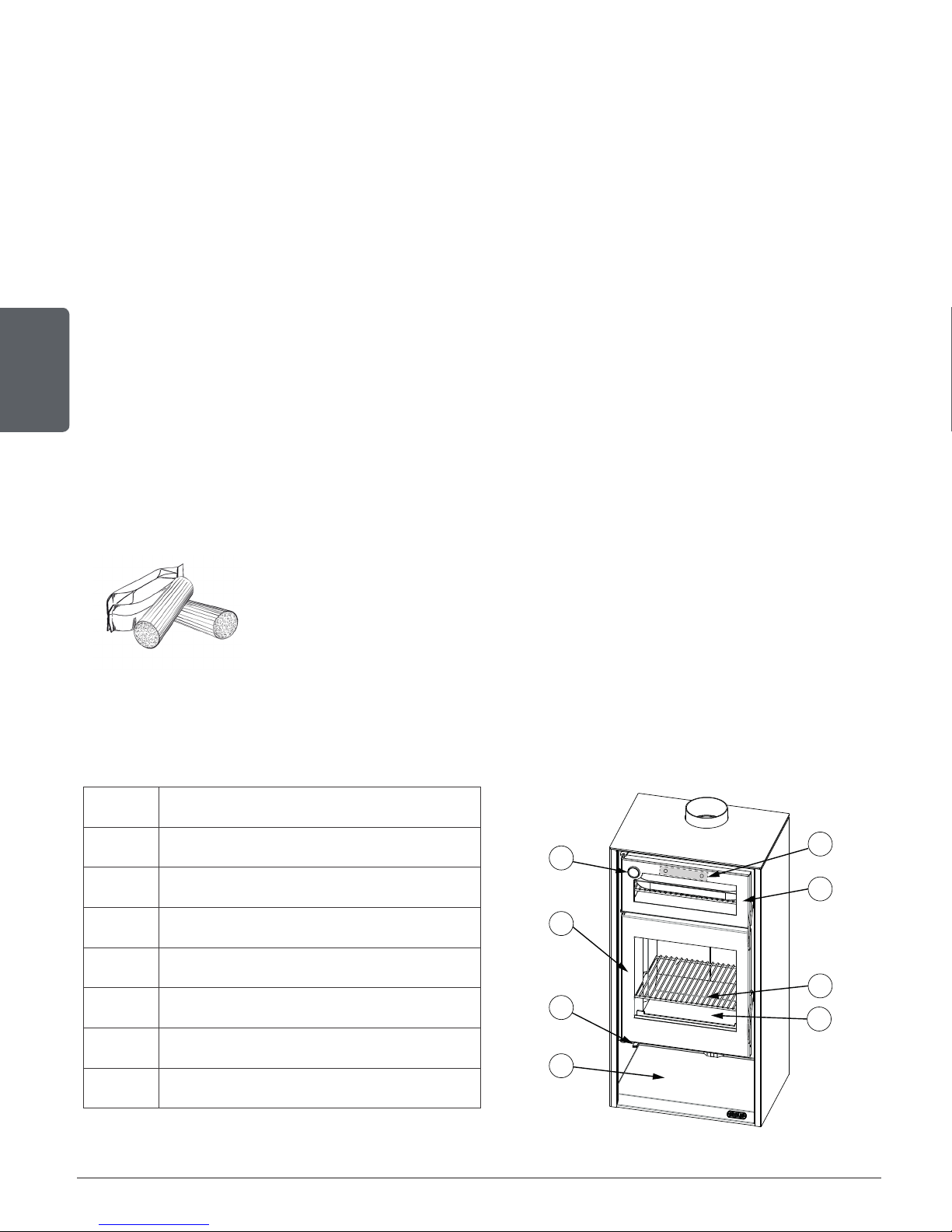

8. Clearances to Combustible Materials

The clearances given in this section have been established following test results in accordance

with the procedures described in the standards ULC S627 (Canada) and UL 1482 (USA). When

this cookstove is installed respecting the indicated minimum clearances or more, the flammable

surfaces won’t overheat during normal or even abnormal usage.

None of the cookstove parts or smoke pipe can be installed closer to the combustible

materials than the minimum clearances indicated.

ENGLISH

Fuel, solid or liquid, should not be located closer to combustibles than the minimum

clearances given.

The clearances to the combustible walls can differ slightly between Canada and the United

States and can also vary depending on the use of a single wall or double connector. Make sure

to use the proper clearances for the location and the type of pipe.

The clearances of the appliance and the flue pipes must be met individually, meaning the

appliance can not be installed closer to the combustible materials than the single or double wall

pipe allows. Refer to the following images and tables for minimum required clearances

Installation and operation manual - Atlas woodburning cookstove

Page 19

Page 20

ENGLISH

B

E

A

D

L

K

Figure 8: Clearances - Top Figure 9: Clearances - Side

C

F

F

Figure 10: Clearances - Corner

Page 20

Installation and operation manual - Atlas woodburning cookstove

Page 21

APPLIANCE CLEARANCES (INSTALLATION

WITH SINGLE OR DOUBLE WALL PIPE

CONNECTOR)

APPLIANCE CLEARANCES (INSTALLATION

WITH DOUBLE WALL PIPE CONNECTOR AND

HEAT SHIELD AC027101)

Canada USA Canada USA

A 15 ½" (394 mm) 15 ½" (394 mm) A 2 ½" (64 mm) 2 ½" (64 mm)

B 13" (330 mm) 13" (330 mm) B 2 ½" (64 mm) 2 ½" (64 mm)

C 12" (305 mm) 12" (305 mm) C 2 ½" (64 mm) 2 ½" (64 mm)

K 48" (122 cm) 48" (122 cm) K 48" (122 cm) 48" (122 cm)

L 84" (213 cm) 84" (213 cm) L 84" (213 cm) 84" (213 cm)

If the above clearances are met, then the distances measured from the flue outlet will be:

DISTANCES2 FROM PIPE CONNECTOR WITH

SINGLE WALL PIPE CONNECTOR

DISTANCES2 FROM PIPE CONNECTOR WITH

DOUBLE WALL PIPE CONNECTOR

Canada USA Canada USA

D 18" (457 mm) 18" (457 mm) D 5" (127 mm) 5" (127 mm)

E 23 ½" (597 mm) 23 ½" (597 mm) E 12 ½" (318 mm) 12 ½" (318 mm)

F 21 ½" (546 mm) 21 ½" (546 mm) F 12 ½" (318 mm) 12 ½" (318 mm)

8.4.1 Clearances with heat shield AC02784

1

Note that to reduce the clearances of an appliance using a single wall pipe connector, the use

of a heat shield certified with the single wall pipe connector to be used as close as 6" from

combustible materials must be used. Only in this case, the same clearances as a certified

double wall pipe connector can be used.

APPLIANCE CLEARANCES (INSTALLATION

WITH DOUBLE WALL PIPE CONNECTOR)

DISTANCES2 FROM DOUBLE WALL PIPE

CONNECTOR

ENGLISH

Canada USA Canada USA

A 6" (152 mm) 6" (152 mm) D 8 ½" (216 mm) 8 ½" (216 mm)

B 13" (330 mm) 13" (330 mm) E 23 ½" (597 mm) 23 ½" (597 mm)

C 12" (305 mm) 12" (305 mm) F 21 ½" (546 mm) 21 ½" (546 mm)

K 48" (122 cm) 48" (122 cm)

L 84" (213 cm) 84" (213 cm)

1

Sold separately. See installation manual for more details.

2

The pipe distances listed in this table refer to the distances obtained when the cookstove is installed in accordance with the appliance clearances

above mentioned.

Installation and operation manual - Atlas woodburning cookstove

Page 21

Page 22

Floor Protection

This cookstove is designed to prevent the floor from overheating. However, it must be placed on

a non-flammable surface to protect the floor from hot embers that may fall during loading. The

floor protection must be a continuous non-combustible surface such as steel with a minimum

thickness of 0.015" (0.38 mm), ceramic, concrete board, brick or other equivalent approved

material. Ceramic should be placed on a continuous non-combustible board to prevent contact

between the cinder and the floor through cracks or gaps in the ceramic grout. See the local code

for approved alternatives. No protection is required if the unit is installed on a non-combustible

surface (eg concrete floor) See table and figure below.

Table 1 : Floor Protection

G

FLOOR PROTECTION

ENGLISH

1

G

H 8" (203 mm) N/A

2

I

2

J

Canada USA

8" (203 mm) N/A

18" (457 mm) 16" (406 mm)

N/A 8" (203 mm)

H

J

I

Figure 11: Floor Protection

8.1 Clearances Reduction to the Walls and the Ceiling

It is often desired to use as little space as possible when installing cookstove. To do this, it

is possible to reduce the clearances safely and install the cookstove closer to the walls by

permanently installing a heat shield between the cookstove and the flammable material. Two

different heat shields , AC02710 and AC02784, are available to reduce clearances easily and

safely.

It is also possible to fabricate the heat shield but one must be careful since the rules for

heat shield construction are sometimes complicated. Read and apply the instructions carefully.

Some regions may have different regulations. Consult the local building code or contact the fire

department for restrictions, inspection and installation requirements in the area.

8.1.1 Heat Shield Construction Rules

• Adhesives used in the shield construction must not inflame or loose their adhesive properties at the

temperature that potentially will be reached.

• The assembly hardware must allow for complete vertical ventilation.

• The assembly hardware that penetrates in the combustible material from the screen surface can

only be used on the edges of the screen.

1

In Canada, the oor protection is limited to the back clearance (G) if it is less than 8" (203 mm). In the United States, it is only required under the

connected horizontal section and must exceed at least 2" (51 mm) on each side of the connection.

2

From door opening.

Page 22

Installation and operation manual - Atlas woodburning cookstove

Page 23

Table 2 : Clearances Reduction Percentages Table

CLEARANCES MAY BE REDUCED BY

THESE PERCENTAGES

TYPE OF SHIELD

Sheet metal, a minimum of 24 gauge (0.61 mm)

in thickness , spaced out at least 25 mm (1 in)*

by non-combustible spacers

Ceramic tiles, or equivalent non-combustible

material, on non-combustible board spaced

out at least 25 mm (1 in)* by non-combustible

spacers

SIDES AND REAR TOP (CEILING)

CAN /USA

(%)

USA

MIN.

CAN /USA

(%)

67 12 in 50 18 in

50 18 in 33 24 in

USA

MIN.

ENGLISH

Ceramic tiles, or equivalent non-combustible

material, on non-combustible board, with a

minimum of 24 gauge (0.61 mm) sheet metal

backing spaced out at least 25 mm (1 in)* by

non-combustible spacers

Brick, spaced out at least 25 mm (1 in)* by

non-combustible spacers

Brick, with a minimum of 24 gauge (0.61 mm)

sheet metal backing, spaced out at least 25

mm (1 in)* by non-combustible spacers

67 12 in 50 24 in

50 18 in N/A N/A

67 12 in N/A N/A

* In Canada this space can be 21 mm (7/8")

Installation and operation manual - Atlas woodburning cookstove

Page 23

Page 24

8.2 Clearances for Shield Installation

Minimum clearance

between the top of

1

the appliance and the

unprotected ceiling

Shield extension above

2

appliance

Minimum space behind the

3

shield

Clearance at the bottom of

4

the screen

Minimum clearance from

ENGLISH

5

the top of the screen to the

ceiling:

The assembly hardware must not be located

6

at less than 200 mm (8") from the combustion

chamber central axis.

Screen edges clearances

7

from the side and back

walls for ceiling screen

Screen overtaking beyond

8

the sides of the appliance

925 mm

(36 ½")

500 mm

(20")

USA 25 mm (1")

Can. 21 mm

(7/8")

USA 25 mm (1")

Can. min. 25 mm

(1") max 76 mm

(3")

76 mm (3")

75 mm (3")

450 mm (18")

8

6

8

7

3

1

1

2

3

4

5

5

1

2

6

3

4

Page 24

Installation and operation manual - Atlas woodburning cookstove

Page 25

9. The Exhaust System

9.1 General Information

The exhaust system, consisting of the chimney and the pipe that connects the cookstove to the

chimney, acts as the engine that drives the wood heating system. Even the best appliance will

not work as securely and adequately as expected if it is not connected to an adequate chimney.

The heat contained in the exhaust gas, which goes from the cookstove to the chimney connector,

then to the chimney, is not lost heat. The chimney uses that heat to create the draft that draws

the combustion air, keeps the smoke in the appliance and evacuates the gas securely toward

open air. You can consider the heat contained in the exhaust gas as the combustible that the

chimney uses to create the draft.

9.2 Suitable Chimneys

To be suitable, a prefabricated metal chimney must follow the standards UL 103 HT (USA) or

ULC S629 (Canada). Furthermore, this wood burning cookstove has a performance and optimal

efficiency when it is connected to a 6" chimney flue.

9.2.1 Prefabricated Metal Chimney

ENGLISH

These are sometimes referred to as "high temp"

chimneys because they have the specific characteristics

to withstand the temperatures that can be created by

wood burning stoves. Factory-built chimneys are tested

as a system with all the necessary components for

installation. The instructions provided with the chimney

by its manufacturer are the only reliable source of

installation guidelines. To be safe and effective, the

chimney must be installed exactly in accordance with

the manufacturer’s instructions. Only components

intended for the brand and model of chimney shoud

be used. Never fabricate or substitute parts from other

chimney brands. The chimney must be a type suitable

for solid fuel.

Installation and operation manual - Atlas woodburning cookstove

Page 25

Page 26

9.2.2 Masonry Chimney

The cookstove may also be connected to a masonry

chimney, provided the chimney complies with the

construction rules found in the building code enforced

locally. The chimney must have either a clay liner or

a suitably listed stainless steel liner. If the masonry

chimney has a square or rectangular liner that is

larger in cross sectional area than a round 6" flue, it

should be relined with a suitably listed 6" stainless

steel liner. Do not downsize the flue to less than 6"

unless the venting system is straight and exceeds 25

feet in height. When passing through a combustible

wall, the use of an insulated listed thimble is required.

ENGLISH

9.3 Chimney Height

The chimney top must be high enough to overcome air turbulence caused by the wind blowing

around the house and over the roof. The chimney must exceed by at least 1 meter (3 ft.) its

highest exit point from the roof and by at least 60 cm (2 ft.) for any part of the roof or any

obstacle located at a horizontal distance of at least 3 m (10 ft.).

Page 26

Installation and operation manual - Atlas woodburning cookstove

Page 27

10. Combustion Air Supply

For the cookstove draft to work correctly, the room must have an outside or fresh air inlet, with

a minimum of 4" diameter, from the house exterior to the room, that is at least sufficient to

replenish the volume of air that comes out of the chimney flue. In well insulated houses an air

inlet must be fitted through the outer wall that is not exposed to the prevailing winds, depending

on the surrounding conditions of the house. If a vent is installed, it must be fitted in such a way

that it cannot be blocked.

The outdoor air must be routed through a duct no more than 300 mm (12") away from the

appliance, in order not to interfere with its operation. A watertight mechanical valve will close

the air inlet when the cookstove is not used. Protection against rodents must be installed on

external edge.

When the cookstove and the chimney are completely cold, it may be necessary before starting

up to provide an external air supply by opening a door or a window for a short period. A

house constructed or renovated in a waterproof manner is prone to not having the air exchange

required for the proper functioning of a wood heating appliance.

In that case, avoid, during startups, to use appliances that evacuate air outside of the house,

such as:

ENGLISH

• Cookstove hood

• Bathroom vent

• Air exchange system

The supply of fresh combustion air can be done in several ways, provided they comply with CSA

B365 and NFPA211.

• Ventilated central vacuum cleaner

• Dryer

11. Chimney Connector Installation

The chimney connector is the single or double wall pipe, installed between the cookstove and

the chimney. The components of the single wall pipe are sold in most hardware or construction

supply stores. These sections usually do not comply with a precise standard and are not certified.

Consequently, several rules found in the heating appliance installation codes are applied to the

installation of the single wall pipe.

The double wall chimney connectors have gone through testing and are certified. The rules

for double wall pipes are found in the manufacturer’s installation guide. These rules are very

different from the single wall pipes.

11.1 Single Wall Chimney Connector Installation

The entire chimney connector has been called "the weak link" in the security of the wood heating

system because if the connector is not properly installed, it can provoke a fire.

The best smoke pipe installation goes straight from the cookstove to the base of the chimney

with no elbow. Straight installation will cause fewer problems such as smoke returns when the

door is open to reload the appliance. They are also more stable and easier to maintain than

installations with elbows. Avoid, as much as possible, horizontal smoke pipes sections because

they reduce the chimney draft and are more conducive to creosote accumulation.

Installation and operation manual - Atlas woodburning cookstove

Page 27

Page 28

ENGLISH

Vertical or horizontal

installation, prefabricated

exterior chimney

Vertical installation,

prefabricated interior

chimney

Vertical or horizontal

installation, masonry exterior

chimney

The rules below are based on the rules found in the installation code of a solid fuel burning

appliance. It is imperative to carefully follow these installation instructions or those of the local

code.

• An ideal pipe installation is the one that goes straight from the cookstove directly into the chimney,

without elbows. A straight installation requires either a telescopic section or a coupling pipe so it

can be mounted or dismounted without having to move the cookstove. A straight pipe installation

offers the minimum amount of restriction to the exhaust of the smoke and gives a better draft.

Straight installations also need less maintenance because there are no angles where creosote can

be deposited.

• The maximum length of the horizontal pipe is 3m (10 ft.) including the elbows.

• The minimum clearance in relation to combustible materials is : 450 mm (18"). The minimum

clearance can be reduced if an appropriate heat shield is installed. See the heat shield installation

instructions for more details.

• The pipe between the cookstove and the chimney must be as short and straight as possible. It is

often better to use two 45 elbows instead of one 90 elbow.

• The maximum number of 90 elbows is two.

• The maximum unsupported horizontal length is 1m (3 ft.)

• Galvanized smoke pipes must not be used because their coating vaporizes itself at high temperature

and produces dangerous gas. Use black smoke pipes.

• Flue pipes must have a thickness of at least 24 ga.

• Flue pipe connectors must overlap at least 30 mm (1 ¼")

• Each installation connector must be fixed with at least three screws.

Page 28

Installation and operation manual - Atlas woodburning cookstove

Page 29

• The installation must be able to expand: the installation of elbows allow expansion; straight

installations must have a coupling pipe with an extremity without attachment or with a telescopic

section.

• Minimum upward slope toward the chimney: 20 mm/m (¼" per foot)

• One of the installation extremities must be firmly fixed to the cookstove nozzle with three metal

screws and the other extremity firmly fixed to the chimney.

• It must be possible to clean the pipes either by a manhole or by removing the pipes. The removal

of the pipes must not require moving the cookstove.

• The male parts of the pipe sections must be toward the appliance so the ashes and the condensation

stay inside the pipe.

• A chimney connector shall not pass through an attic or roof space, closet or similar concealed

space, or a floor, or ceilling. Where passage through a waII, or partition of combustible construction

is desired, the installation shall conform to CAN/CSA-B365, Installation Code for Solid-Fuel-Burning

Appliances and Equipment

• The chimney connector must be in good condition and kept clean.

ENGLISH

Installation and operation manual - Atlas woodburning cookstove

Page 29

Page 30

12. Troubleshooting

PROBLEM POSSIBLE CAUSES SOLUTION

• Draft too low

Oven window

or combustion

chamber’s window

blackening.

ENGLISH

Irregular draw.

Black smoke

leaking out of the

cookstove.

• Bad air intake adjustment

• Too much combustible in the

cookstove.

• Wood with a high rate of

relative humidity > 20-25%

• Unregulated combustion.

• Inadequate or dirty chimney.

• Dirt in the combustion

chamber or in the cookstove.

• Strong winds

• Ignition with green wood.

• Smoke pipe obstructed.

• Check that all the pipes are clean.

• Modify the chimney: increase the height

or check surrondings.

• Reduce the quantity of combustible in

the combustion chamber.

• Dry the wood longer.

• Sweep the chimney or have it clean by a

professional.

• Clean the cookstove.

• Relocate chimney or fresh air intake.

• Ignite the cookstove with suitable

combustible.

• Ask for professional qualified assistance.

Smoke coming out

of the cookstove.

• Combustion chamber’s door

open while the cookstove is

heating.

• Insufficient draw

• Bad adjustments of the air

inlets during startup.

• The cookstove must be

cleaned.

• Check the door closing and the tightness

of the gaskets.

• Check the chimney system.

• Eliminate or reduce to minimum the

deviations and horizontal lengths in the

chimney.

• Check all the chimney sections as well as

its height on the outside.

• Ask for a chimney inspection by a certified

technician.

• Regularly clean the cookstove as

indicated.

Page 30

Installation and operation manual - Atlas woodburning cookstove

Page 31

13. Exploded View and Parts List

2x

17

4x

16

9

8

2x

15

ENGLISH

12

11

14

18

2x

2x

3

13

2x

10

2x

3

2

1

Installation and operation manual - Atlas woodburning cookstove

2

5

6

7

2x

3

2x

4

Page 31

Page 32

IMPORTANT: THIS IS DATED INFORMATION. When requesting service or replacement parts

for your unit, please provide the model number and the serial number. We reserve the right to

change parts due to technology upgrade or availability. Contact an authorized dealer to obtain

any of these parts. Never use substitute materials. Use of non-approved parts can result in poor

performance and safety hazards.

# Item Description Qty

1

31040 Thermometer 1

2

AC06400 3/4" (Flat) x 6' black self-adhesive glass gasket 2

3

31041 Glass support 6

4

23082 Over glass 1

5

AC06705 Glue and 1/4" x 7' white door gasket kit 1

6

23083 Combustion chamber glass 1

7

31042 Small glass support 2

ENGLISH

8

31039 Front baffle support 1

9

31034 Stainless steel baffle 1

10

31036 Cold hand 1

11

31033 Fire grate 1

12

31035 Stainless steel left combustion chamber panel 1

13

21531 Vermiculite back board 2

14

31038 Stainless steel right combustion chamber panel ( 1

15

21532 Vermiculite baffle 2

16

21533 Refractory brick 4

17

31043 Cleaning access panel blind screw 2

18

31037 Cooking grill 2

Page 32

Installation and operation manual - Atlas woodburning cookstove

Page 33

ATLAS COOKING STOVE LIMITED LIFETIME WARRANTY

DROLET COOKING STOVE LIMITED LIFETIME WARRANTY

The warranty of the manufacturer extends only to the original retail purchaser and is not transferable. This warranty covers brand new

products only, which have not been altered, modified nor repaired since shipment from factory. Proof of purchase (dated bill of sale),

model name and serial number must be supplied when making any warranty claim to your DROLET dealer.

This warranty applies to normal residential use only. Damages caused by misuse, abuse, improper installation, lack of

maintenance, over firing, negligence or accident during transportation, power failures, downdrafts, venting problems or underestimated heating area are not covered by this warranty. The recommended heated area for a given appliance is defined by the

manufacturer as its capacity to maintain a mi nimum acceptable temperature in the designated area in case of a power failure.

This warranty does not cover any scratch, corrosion, distortion, or discoloration. Any defect or damage caused by the use of unauthorized

or other than original parts voids this warranty. An authorized qualified technician must perform the installation in accordance with the

instructions supplied with this product and all local and national building codes. Any service call related to an improper installation is not

covered by this warranty.

The manufacturer may require that defective products be returned or that digital pictures be provided to support the claim. Returned

products are to be shipped prepaid to the manufacturer for investigation. Transportation fees to ship the product back to the purchaser

will be paid by the manufacturer. All parts covered by this warranty are limited according to the table below.

The manufacturer, at its discretion, may decide to repair or replace any part or unit after inspection and investigation of the defect. The

manufacturer may, at its discretion, fully discharge all obligations with respect to this warranty by refunding the wholesale price of any

warranted but defective parts. The manufacturer shall, in no event, be responsible for any uncommon, indirect, consequential damages of

any nature, which are in excess of the original purchase price of the product. A one-time replacement limit applies to all parts benefiting

from lifetime coverage. This warranty applies to products purchased after March 1

st

, 2015.

ENGLISH

WARRANTY APPLICATION*

DESCRIPTION

PARTS LABOUR

Combustion chamber (welds only) and cast iron door frame. Lifetime N/A

Surrounds, ash drawer, trims (extrusions), and convector air-mate. 5 years N/A

Removable stainless steel combustion chamber components, deflectors, and

supports.

5 years N/A

Glass retainers, handle assembly, and air control mechanism. 3 years N/A

Carbon steel combustion chamber components. 2 years N/A

Paint (peeling**), plating (defective manufacture**), ceramic glass (thermal

breakage only**), gaskets, insulation, and oven thermometer.

Firebricks, vermiculite combustion chamber components, oven mitt, and

cooking accessories.

All parts replaced under the warranty.

*Subject to limitations above. **Picture required.

Shall your unit or a components be defective, contact immediately your DROLET dealer. To accelerate processing of your warranty

claim, make sure to have on hand the following information when calling:

Your name, address and telephone number;

Bill of sale and dealer’s name;

Installation configuration;

Serial number and model name as indicated on the

nameplate fixed to the back of your unit;

Nature of the defect and any relevant information.

1 year

N/A N/A

90 days

N/A

N/A

Before shipping your unit or defective component to our plant, you must obtain an Authorization Number from your DROLET

dealer. Any merchandise shipped to our plant without authorization will be refused automatically and returned to sender.

Installation and operation manual - Atlas woodburning cookstove

Page 33

Page 34

NOTES

Page 35

Page 36

This document is available for free download on the

manufacturer’s website. It is a copyrighted document.

Resale is strictly prohibited. The manufacturer may update

this document from time to time and cannot be responsible

for problems, injuries, or damages arising out of the use

of information contained in any document obtained from

unauthorized sources.

Stove Builder International inc.

250, rue de Copenhague,

St-Augustin-de-Desmaures (Québec) Canada

G3A 2H3

418-908-8002

www.drolet.ca/en/

tech@sbi-international.com

Loading...

Loading...