Page 1

DRAWMER

Dual FET Compressor

& Pre-Amplifier

OPERATOR’S MANUAL

Warranty

Safety Consideration

Chapter 1 - Introduction

Introduction

Installation

Power Connection

Audio Connections

Chapter 2 - Control Description

Control Description

Hints and Tips

Chapter 3 - General Information

If a fault develops

Contacting Drawmer

Specification Data

Block Diagram

Recall Sheet

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

CONTENTS

Page 2

COPYRIGHT

This manual is copyrighted © 2019 by Drawmer Electronics Ltd. With all rights reserved. Under copyright

laws, no part of this publication may be reproduced, transmitted, stored in a retrieval system or translated

into any language in any form by any means, mechanical, optical, electronic, recording, or otherwise, without the written permission of Drawmer Electronics Ltd.

ONE YEAR LIMITED WARRANTY

Drawmer Electronics Ltd., warrants the Drawmer 1970 Dual

FET Compressor & Pre-Am plifier to conform substantially

to the specifications of this manual for a period of one year

from the original date of purchase when used in accordance

with the specifications detailed in this manual. In the case

of a valid warranty claim, your sole and exclusive remedy

and Drawmer’s entire liability under any theory of liability

will be to, at Drawmer’s discretion, repair or replace the

product without charge, or, if not possible, to refund the

purchase price to you. This warranty is not transferable. It

applies only to the original purchaser of the product.

SAFETY CONSIDERATIONS

DRAWMER

1970

Dual FET Compressor

& Pre-Amplifier

For warranty service please call your local Drawmer dealer.

Alternativ ely call Drawmer Electronics Ltd. at +44 (0)1709

527574. Then ship the defectiv e product, with transportation

and insurance charges prepaid, to Drawmer Electronics

Ltd., Coleman Street, Parkgate, Rotherham, S62 6EL UK.

Wri te the RA number in large letters in a prominent position

on the shipping box. Enclose your name, address,

telephone number, copy of the original sales invoice and a

detailed description of the problem. Drawmer will not accept

responsibility for loss or damage during transit.

This warranty is void if the product has been damaged by

misuse, modification or unauthorised repair.

THIS WARRANTY IS IN LIEU OF ALL WARRANTIES,

WHETHER ORAL OR WRITTEN, EXPRESSED, IMPLIED

OR STATUTORY. DRAWMER MAKES NO OTHER

WARRANTY EITHER EXPRESS OR IMPLIED,

INCLUDING, WITHOUT LIMITATION, ANY IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR

A PARTICULAR PURPOSE, OR NON-INFRINGEMENT.

PURCHASER’S SOLE AND EXCLUSIVE REMEDY

UNDER THIS WARRANTY SHALL BE REPAIR OR

REPLACEMENT AS SPECIFIED HEREIN.

IN NO EVENT W ILL DRAWMER ELECTRONICS LTD. BE

LIABLE FOR ANY DIRECT, INDIRECT, SPECIAL,

INCIDENTAL OR CONSEQUENTIAL DAMAGES

RESULTING FROM ANY DEFECT IN THE PRODUCT,

INCLUDING LOST PROFITS, DAMAGE TO PROPERTY,

AND, TO THE EXTENT PERMITTED BY LAW, DAMAGE

FOR PERSONAL INJURY, EVEN IF DRAWMER HAS

BEEN ADVISED OF THE POSSIBILITY OF SUCH

DAMAGES.

CAUTION - MAINS FUSE

TO REDUCE THE RISK OF FIRE

REPLACE THE MAINS FUSE ONLY WITH

A FUSE THAT CONFORMS TO IEC127-2.

250 VOLT WORKING, TIME DELAY TYPE

AND BODY SIZE OF 20mm x 5mm.

THE MAINS INPUT FUSE MUST BE

RATED AT 230V=T250mA and 115V=T500mA.

CAUTION - MAINS CABLE

DO NOT ATTEMPT TO CHANGE

OR TAMPER WITH THE

SUPPLIED MAINS CABLE.

CAUTION - SERVICING

DO NOT PERFORM ANY SERVICING.

REFER ALL SERVICING TO QUALIFIED

SERVICE PERSONNEL.

WARNING

TO REDUCE THE RISK OF FIRE OR

ELECTRIC SHOCK DO NOT EXPOSE

THIS EQUIPMENT TO RAIN OR MOISTURE.

Some states and specific countries do not allow the

exclusion of implied warranties or limitations on how long

an implied warranty may last, so the above limitations may

not apply to you. This warranty giv es you specific legal

rights. You may have additional rights that vary from state

to state, and country to country.

In the interests of product development, Drawmer reserve the right to modify or

improve specifications of this product at any time, without prior notice.

2

DRAWMER 1970 OPERATOR’S MANUAL

Page 3

DRAWMER

DUAL FET COMPRESSOR & PRE-AMPLIFIER

INTRODUCTION

CHAPTER 1

The 1970 Dual F.E.T. Compressor and Pre-Amplifier builds

on a heritage inspired by the first pro audio "tool box"

compressor, the illustrious Drawmer 1960, but with a

greatly expanded feature set, making it one of the most

adaptable mic preamplifier/compressors on the market

today. Bringing vintage audio characteristics at an

affordable price.

Whilst the feature set of the 1970 is similar to the Drawmer

1960, and the layout of the controls will add to the

compari sons, the 1970 has been greatly improved and

the DI EQ has been fine tuned to be more accurate than

its stable-mate, with various enhancements.

The 1970 use the latest THAT Corporation technology in

the 2 mic preamps to provide ultra clean, transparent and

precise recordings that can be processed at a later stage

using your favourite warming method, be it saturation, valve,

transformer or tape. In addition each channel is capable

of 66dB of gain, with switchable mic impedance for

accurate mic matching to bring out the best from any

microphone used. Phase reverse is also included.

From tracking instruments via the dedicated D.I. input, to

recording vocals via the ultra clean mic pre's, recording a

guitar cabinet with two microphones, or a singer playing

guitar, or even stereo buss compression using the

comprehensive linking and mix facilities, the 1970 is the

perfect versatile tool for any studio or live event.

Two THAT Corporation ultra clean mic pre's with 66dB

•

of gain with phantom power and switchable mic

impedance for accurate mic matching

Separate Line & Mic input XLR's

•

1 pro quality instrument DI input with low and high EQ.

•

Can be used as 2 mono tracking compressors or 1

•

stereo buss compressor (av oiding image shifting) via

the class leading comprehensive linking facilities.

FETs can be bypassed altogether to provide ultra clean

•

outputs.

Standard controls such as Threshold, Ratio, Attack &

•

Release, with 8 LED GR Metering on each band.

Rear panel Side-chain insert points provide even further

•

control.

‘Big’ and 'Air' Modes Help to preserve the very deep

•

lows and Enhance the sparkling highs.

Variable Wet/Dry Mix plus Output Gain knobs on both

•

channels give a 'Parallel Compression' function without

the need for external mixing devices, prov iding complete

and effortless control over the amount of compression

used and output levels.

Two backlit Analogue V.U. Meters with Switchable

•

+10dB Rescale Mode. Time delay relays on outputs

for clean power up/down.

Internal Low Hum Toroidal Linear Power Supply with

•

Voltage Selector Switch.

Classic Drawmer build quality with rugged steel

•

chassis and aluminium front panel.

Designed and Handmade by Drawmer in the UK.

•

DRAWMER 1970 OPERATOR’S MANUAL

3

Page 4

INSTALLATION

The 1970 is designed for standard 19" rack mounting and occupies 2U of rack space. Fibre or plastic

washers may be used to prevent the front panel becoming marked by the mounting bolts.

- Care should be taken in the choice of positioning. The unit should not be mounted where other

equipment obstructs the normal air flow. The unit should not be situated near any heat source, such

as a radiator, stove or a high power amplifier that would generate heat.

- The appliance should not be operated near any water or in a location where moisture might be

present.

- Always connect the mains earth to the unit.

If the 1970 is to be continuously moved from one location to another, we suggest using additional support in

the rack at the rear of the unit.

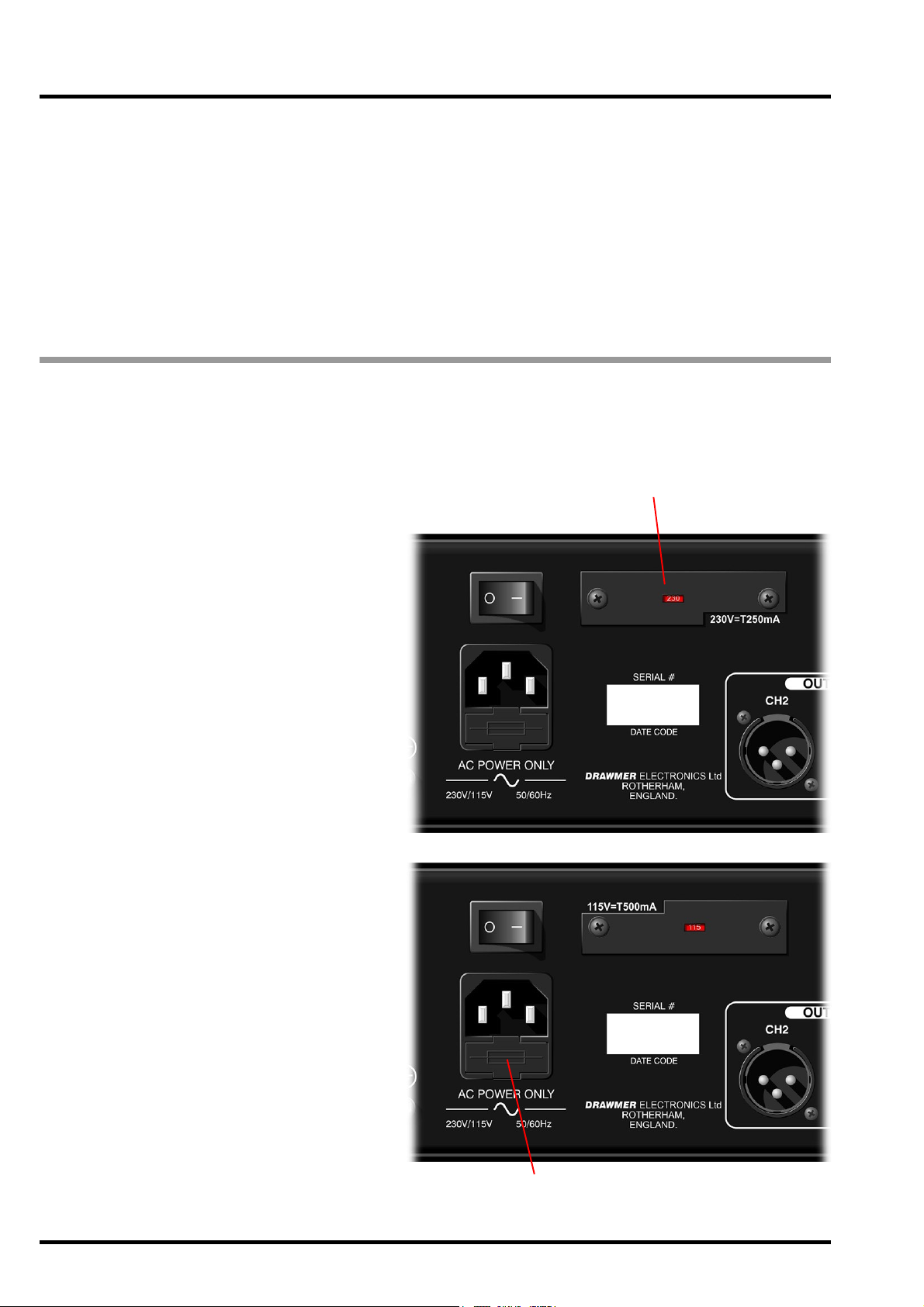

POWER CONNECTION

The unit will have been supplied with a power cable suitable

for domestic power outlets in your country. For your own safety

it is important that you use this cable. The unit should always

be connected to the mains supply earth using this cable, and

no other.

If for some reason the unit is to be used at a mains

input operating voltage which is different to that

as supplied, the following procedure must be

carried out.

COVER-PLATE

1: Disconnect the unit from the mains.

2: Remove the two screws holding the voltage

selection cover-plate.

3: Remove the cover plate and slide the switch

fully to its opposite end.

4: Rotate the cover plate one half turn (180

degrees) and refit the two screws.

5: Replace with a correctly rated fuse for the

selected operation voltage in the IEC socket:

230V-T250mA and 115V-T500mA

6: Re-connect to mains power source.

Never disconnect the earth

from the mains supply

IEC SOCKET FUSE DRAWER

4

DRAWMER 1970 OPERATOR’S MANUAL

Page 5

AUDIO CONNECTIONS

The inputs and outputs are electronically balanced on conventionally wired XLRs (pin 1 screen, pin 2 hot,

pin 3 cold and XLR shell is connected to chassis). The 1970 fully conforms to the EMC standards, if the unit

is used where it maybe exposed to high levels of disturbance such as found close to a TV or radio transmitter

we suggest that the screen of the signal cable is connected to the chassis connection on the XLR type

connector. The operating level is nominally +4dBu.

If ground loop problems are encountered, never disconnect the mains earth, but instead, try disconnecting

the signal screen on one end of each of the cables connecting the outputs of the 1970 to the patchbay. If

such measures are necessary, balanced operation is recommended.

The side-chain access points are unbalanced. The side chain feature on the 1970 is part of the compressor

feedback stage and would normally be connected to a normalised or semi-normalised pair of patchbay

contacts. This would allow the user to insert additional EQ for some de-essing, or frequency conscious

compression. The intended use of the audio insert jacks would be to patch in EQ (eg 1961, 1974), reverb

or similar processing. Connection is via stereo ¼" jacks, the wiring convention being: ring is signal send, tip

is signal return and sleeve ground.

DRAWMER 1970 OPERATOR’S MANUAL

5

Page 6

CHAPTER 2

CONTROL DESCRIPTION

The 1970 shares similar parameters to those found on the Drawmer 1960, and anyone familiar with that or the 1969 will

be immediately at home, the difference being that the 1970 has an expanded feature set and therefore more controls,

such as variable mic impedance, “Big” and “Air”. With the exception of the Instrument D.I. section, both channels of the

1970 are identical and may be used independently or linked for stereo operation.

INSTRUMENT

1

Instrument Input

A 1/4” jack provides a specialised instrument input stage with the addition of both gain and equalisation, suitable

for use with both active and passive guitar pickup systems as well as with electronic keyboards.

Gain 0 - 10

A variable control that prov ides up to 25dB of gain when the Boost Switch is off or 45dB with Boost.

Boost Switch Off - On

When on adds an additional 20dB of gain to the instrument signal.

Bass EQ 0 - 10

Passive equaliser control which provides cut and boost at approximately 50-100Hz, the EQ being approximately

flat at position 5.

Treble EQ 1 - 10

Passive equaliser control which provides cut and boost at approximately 5kHz, the EQ being approximately flat

at position 5.

Note that, as the Bass and Treble EQ are passive they interact with each other altering the amount of cut and

boost and also the centre point of the EQ’s as one control effects on the other.

E.Q Switch Off - On

Switches the two equaliser controls out of circuit when a flat response is required (off), or for an 'A/B' comparison

of EQ effectiv eness.

Bright Off - On

When on adds 12dB of gain at approximately 2kHz-8kHz with a roll off at either side to simulate the

voicing of a typical guitar amplifier.

2

MIC

Gain 0 - +66dB

A twelve position microphone preamplifier switch adds gain in 6dB steps from 0dB to +66dB, making it incredibly

easy to replicate previous settings and have total control over levels.

3

SOURCE

Select Mic +48V/Mic 200 Ohm/Mic 600 Ohm/Mic 2.4 kOhm/Line/Instrument

The source select is a six position rotary switch that, as well as setting the input source, also sets the load

impedance of the microphone.

In the +48V Phantom Power switch position the red LED will illuminate to indicate that 48V of dc voltage is being

sent down the XLR cable in order to power the electronics of a condenser microphone.

NOTE: DO NOT ACTIVATE THE +48V SETTING UNLESS THE MICROPHONE REQUIRES IT.

The switch can also provide three settings of load impedance in order to aid the matching for a dynamic microphone,

at settings of 200, 600 and 2.4k Ohms.

In addition the same switch sets the source to Instrument (via the front panel instrument DI section) and Line (via

the dedicated input on the rear panel).

6

DRAWMER 1970 OPERATOR’S MANUAL

Page 7

Phase Reverse Off - On

This switch reverses the signal polarity, and is often useful when recording an instrument with more than one

microphones. If, for example, you record a guitar cabinet with two mics, the two signals could be so similar that

they would cancel each other out partially, resulting in a very thin sound. Reversing the phase of one channel

would rectify this.

High Pass Filter Switch Off - On

The signal path incorporates a switchable high-pass filter (also known as Low Cut), set to 70Hz at a slope of 12dB

per Octave, and is used to attenuate low frequency signals that might otherwise prove troublesome, eg. traf fic

rumble or stage vibration, and let the higher frequencies pass.

4

COMPRESSOR

Link Switch Off - On

When linked the signals of both channels are combined and an average control voltage is created to supply the

levels for the compressor. The same degree of gain reduction is applied to both audio channels to prevent image

shifting which would otherwise occur whenever the left and right signal dynamics varied from each other by any

significant degree. When linked the controls of Channel 1 become the master and the controls of channel 2 are

unused.

Note, the link switch only links the compressor and as no effect on the output controls.

Threshold -40.0dB - +20dB

Determines the input level above which gain reduction will be applied. Soft knee compression takes place for

signals exceeding the threshold lev el by a few decibels, above which level conventional 'ratio' compression is

applied.

Big Switch Off - On

Big, when on, reduces the side-chain's sensitivity to low frequencies, with the result that less gain reduction is

applied at those frequencies, creating the eff ect that the bass is louder or 'bigger'. The 'BIG' mode enables

application in buss compression situations where you still want thick and warm tone yet complete dynamics

control.

Air Switch Off - On

Air is used to re-introduce high frequencies, which can sometimes be lost after heavy compression, so that it

sounds more intimate, detailed and transparent, but without making it sound harsh or introducing any noticeably

unnatural artifacts. Cymbals are more vibrant without becoming splashy, and vocals sound more open but without

becoming sibilant.

Ratio 1:1 - 10:1

Ratio determines the amount of compression (attenuation) to be used once the 'soft-knee' region is exceeded. If

the ratio is set to 5:1 a signal exceeding the threshold by 5dB will be attenuated down to 1dB above the threshold,

and likewise, a signal exceeding the threshold by 15dB will be attenuated down to 3dB above it. A ratio of 1:1

provides no compression, 4:1 is moderate, 8:1 strong, whilst 10:1 would be seen as approaching limiting.

Attack 0.2mS - 100mS

Sets the rate at which the compressor will respond to input signals that exceed the threshold level.

Release 0.05S - 3.5S

Sets the time taken for the signal to return to normal after the input level has fallen below threshold.

PGM Switch Off - On

When on causes the release times to vary in a manner which automatically adapts to the dynamics of the

incoming signal.

Gain Reduction Meter 1, 2, 3, 5, 7, 10, 15, 20 -dB

An eight segment LED bargraph meter continuously monitors the gain reduction applied by the compressor and

gives an indication of the amount of gain required to bring the signal back to its input level after it has been

compressed.

DRAWMER 1970 OPERATOR’S MANUAL

7

Page 8

5

OUTPUT

Mix Wet / Dry

A variable control that mixes a user

defined amount of 'uncompressed'

signal (dry) with the compressed

signal (wet) to create a 'parallel

compression effect' without the

need for external mixing devices. In this way the amount of ov erall compression on the signal is under complete

control.

Bypass Off - On

A fully balanced hard-wire

bypass connects the input

source directly to the output

without passing through the

compressor FET’s, the mix and

gain controls at all. Use this to provide an ultra clean microphone signal.

Note: this can be used to hear an A/B comparison of the compressor, should you wish.

Gain Off - On

During compression the signal is attenuated, gain may be required to produce the required output level. Adjust so

that the output signal approaches the desired lev el only on signal peaks.

Link Off - On

The Link switch only links the controls of the Output section and has no effect on the linking of the compressor these are linked by the Link switch in the Compressor section.

With the link switch off the Mix, Gain and Bypass controls of the two channels are independent of each other, this

allows for the 1970 to be used to track two independent signals, but also allows for unbalanced stereo signals to be

adjusted should image shifting occur during compression. When the link switch is active the left controls become

master and adjust both channels, acting as a stereo control.

VU Meter

Two backlit moving coil VU meters monitor the level of the output signal

+10dB Pad VU - +10dB

Adjusts the meters to show either normal output level, (and for those working at ‘hot’ output levels) VU +10dB i.e.

with the switch at VU +10dB, when the VU meter reads 0dB the actual level is +10dB.

REAR CONNECTIONS

6

In addition to the instrument j ack connector located in the instrument section on the front panel there are also:

Mic Input

Two dedicated microphone inputs via balanced XLR’s are located on the rear panel.

Line Input

Two dedicated line level inputs via balanced XLR’s.

Side Chain

The side chain connector is part of the compressor feedback stage and would norm ally be connected to a

normalised or semi-normalised pair of patchbay contacts. This would allow the user to insert additional EQ for

some de-essing, or frequency conscious compression. Connection is via unbalanced stereo ¼" jacks: ring is

signal send, tip is signal return and sleeve ground.

Output

Two dedicated outputs via balanced XLR’s.

POWER

7

I.E.C./Power Switch/Voltage Selector Switch

See the Power Connection section of the manual

8

DRAWMER 1970 OPERATOR’S MANUAL

Page 9

Hints and Tips

Mic Impedance

When it comes to mic impedance matching you may have encountered the general rule of thumb that the impedance of

the preamp input should be 10X that of the mic to get an input impedance that is appropriate for the mic and to avoid

loading the source, however, it is less known that mismatching can create some interesting tonal differences that can

be used more creatively. The result will depend on the microphone used, as the tonal changes will be obvious with some

mic’s but others will hardly alter, and on the material you're working with and also what you're trying to achieve. The

1970 has 3 settings per mic input: 200, 600 and 2400 Ohms, making it easy for you to explore the various tones.

Recording a Guitar using 2 Microphones

A common technique when recording guitar, to get the perfect tone that you’re trying to achieve is to record a single

cabinet with two mic’s, one for each channel, with one in the centre of the cone and another a few inches away, for

example. There are many online tutorials on how to create this technique.

Another widely used technique especially when recording bass guitar, is to record one channel via a mic’d cabinet, and

the other directly into the instrument input on the 1970, or v ia eff ects using the line input, and blend the two signals at

a later stage.

Note that in both cases phase problems can occur so some delay on one of the channels may need to be added.

In both techniques the 1970 is perfect for the job, enabling you to independently control the gain and compression of

each channel to the required amounts with ease to get the desired tone/character.

Parallel Compression Made Easy

The Mix control of each channel works in a similar way to that of the parallel compression technique but with the

advantage of being one simple knob. It works by adding variable amounts of the uncompressed signal (dry) to that of the

compressed signal (wet), effectively reducing the perceived amount of compression taking place. The most effective

way of using the control is to set it at the 3 or 4 position, so that a good amount of compression is heard but a little more

can still be added should it be required - then set up the compressor as you would normally. Finally introduce the dry

signal by rotating the knob clockwise until the perfect amount of compression is found.

Keep it Clean

The mic stage of the 1970 has been designed to prov ide as clean a recording as possible. The adage being that if you

introduce distortion/warmth at the recording stage it can't be removed, and the recording will be stuck with it, but by

contrast, if you obtain a clean recording you can add warmth and distortion at a later time, via tubes, saturation,

transformers etc, and in a way that gives you complete control over the effect.

The design of the 1970 takes this one step further - a fully balanced hard-wire bypass, located in the output section,

connects the input source (the mics and instrument) directly to the output XLR without passing through any of the

compressor FET circuitry, or the mix and gain controls at all, and so introducing as little distortion as is possible, and

providing an ultra clean microphone signal.

DRAWMER 1970 OPERATOR’S MANUAL

9

Page 10

GENERAL INFORMATION

CHAPTER 3

IF A FAULT DEVELOPS

For warranty service please call Drawmer Electronics Ltd. or

their nearest authorised service facility, giving full details of

the difficulty.

A list of all main dealers can be found on the Drawmer

webpag es.

On receipt of this information, service or shipping instructions

will be forwarded to you.

No equipment should be returned under the warranty without

prior consent from Drawmer or their authorised representative.

For service claims under the warranty agreement a service

Returns Authorisation (RA) number will be issued.

Write this RA number in large letters in a prominent position

on the shipping box. Enclose your name, address, telephone

number, copy of the original sales invoice and a detailed

description of the problem.

Authorised returns should be prepaid and must be insured.

All Drawmer products are packaged in specially designed

containers for protection. If the unit is to be returned, the original

container must be used. If this container is not available, then

the equipment should be packaged in substantial shockproof

material, capable of withstanding the handling for the transit.

CONTACTING DRAWMER

Drawmer Electronics Ltd., will be pleased to answer all

application questions to enhance your usage of this

equipment. Please address correspondence to:

Drawmer (Technical Help line)

Coleman Street

Parkgate

Rotherham

S62 6EL

UK

Alternatively contact us by E-mail on :

for sales enquiries: sales@drawmer.com

or for technical issues: tech@drawmer.com

Further information on all Drawmer dealers, Authorised service

departments and other contact information can be obtained

from our web pages on:

http://www.drawmer.com

1970 DUAL FET COMPRESSOR AND PRE-AMPLIER

DATA SPECIFICATION

INPUT

Input Impedance 20k Ohms or greater

Maximum Input Level +21dBu

OUTPUT

Output Impedance 100 Ohms

Maximum Output Level +21dBu into 10k Ohms Load

FREQUENCY RESPONSE

20Hz to 20kHz +/-0.5dB

CROSSTALK < -75dB @ 1kHz

NOISE AT UNITY GAIN

20Hz - 20kHz >93dB

% DISTORTION (THD & NOISE) @ 1kHz

0dB (ref +4) 0.01%

10dB (ref +4) 0.01%

MIC EIN -130dB

POWER REQUIREMENTS

230Volt or 115V at 50-60hZ, 630VA

FUSE RATING

T250mA for 230Volt,

T500mA for 115Volt

Conforming to IEC 127-2

FUSE TYPE

20mm x 5mm, Class 3 Timed-Blo, 250Volt working

CASE SIZE

482mm (W) x 88mm (H) x 270mm (D)

WEIGHT 4.2Kgs

10

DRAWMER 1970 OPERATOR’S MANUAL

Page 11

BLOCK DIAGRAM

DRAWMER 1970 OPERATOR’S MANUAL

1970 ver 01 A 08/01/20

11

Page 12

12

DRAWMER 1970 OPERATOR’S MANUAL

Loading...

Loading...