Page 1

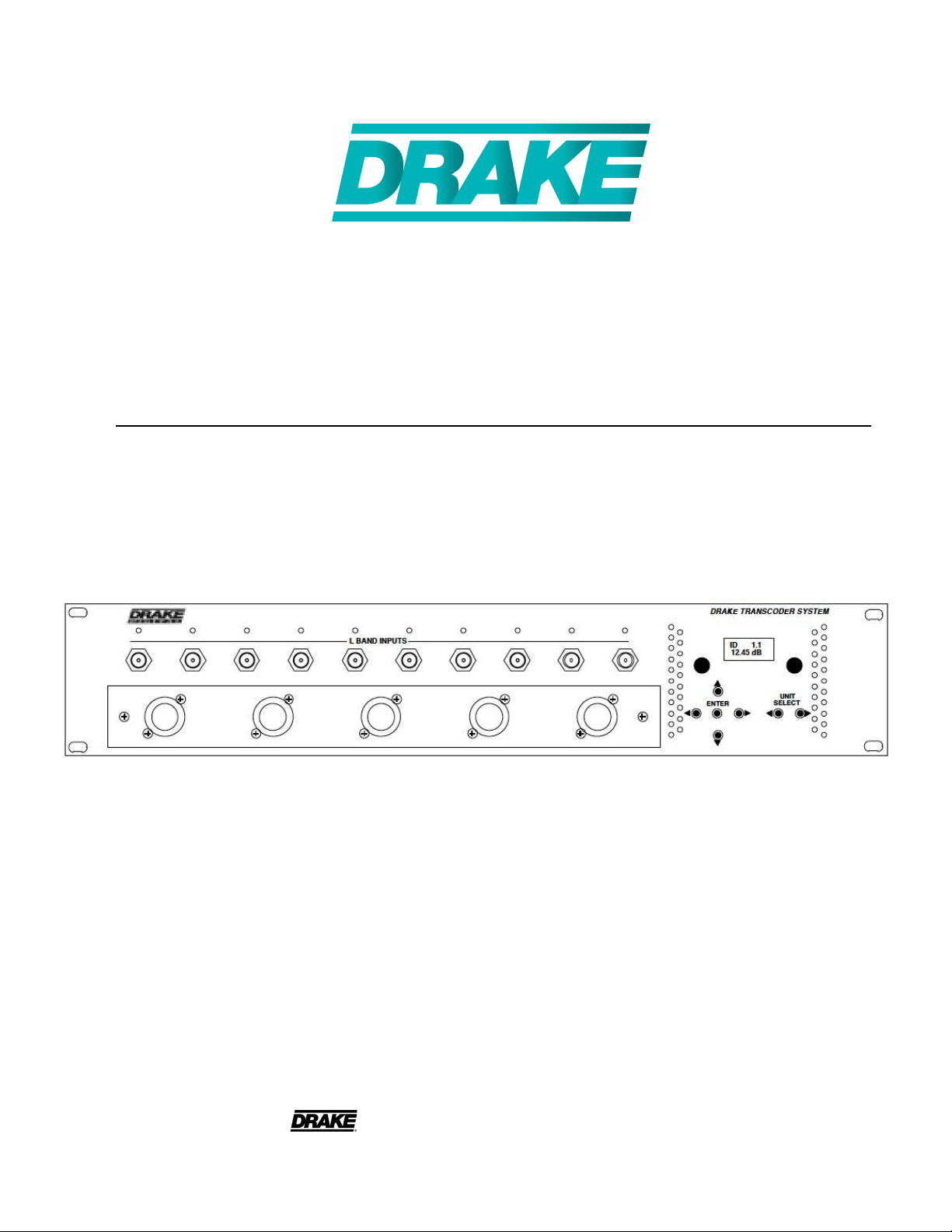

SCT4860 Transcoder System

Instruction Manual

is a registered trademark of the R.L. Drake Holdings, LLC

© Copyright 2012 R. L. Drake Holdings, LLC P/N: 651228900A Printed in China

Rev: 20121008

1002388

Page 2

2

Table of Contents, Caution, & Important Safety Instructions

CAUTION STATEMENTS .....................................................................................................................................2

IMPORTANT SAFETY INSTRUCTIONS ..............................................................................................................2

SPECIFICATIONS ................................................................................................................................................4

GENERAL DESCRIPTION ...................................................................................................................................5

INSTALLATION AND MOUNTING .........................................................................................................................6

CONTROLS AND CONNECTIONS ...................................................................................................................... 7

LNB INPUT / SETUP AND PROGRAMMING .......................................................................................................9

ADDITIONAL FEATURES ....................................................................................................................................12

CATV CHANNEL FREQUENCIES ......................................................................................................................15

BROADCAST TV CHANNEL FREQUENCIES ...................................................................................................16

SERVICE / IF YOU NEED TO CALL FOR HELP .................................................................................................17

WARRANTY .........................................................................................................................................................19

Caution Statements:

WARNING: TO PREVENT FIRE OR

ELECTRICAL SHOCK, DO NOT

EXPOSE TO RAIN OR MOISTURE

WARNING: TO REDUCE THE RISK OF FIRE OR ELECTRIC SHOCK, DO NOT EXPOSE THIS PRODUCT TO

RAIN OR MOISTURE.

DO NOT OPEN THE CABINET, REFER SERVICING TO QUALIFIED PERSONNEL ONLY.

CAUTION: TO PREVENT ELECTRIC SHOCK, DO NOT USE THIS (POLARIZED) PLUG WITH AN EXTENSION

CORD RECEPTACLE OR OTHER OUTLET UNLESS THE BLADES CAN BE FULLY INSERTED TO

PREVENT BLADE EXPOSURE.

A product and cart combination should be moved

with care. Quick stops, excessive force and uneven

surfaces may cause the product and cart combination

to overturn.

The lightning flash with arrow head symbol, within an

equilateral triangle, is intended to alert the user to the

presence of uninsulated "dangerous voltage" within

the product's enclosure that may be of sufficient

magnitude to constitute a risk of electric shock to

persons.

The exclamation point within an equilateral triangle is

intended to alert the user to the presence of important

operating and maintenance (servicing) instructions in

the literature accompanying the product.

ATTENTION: POUR PREVENIR LES CHOCS ELECTRIQUES, NE PAS UTILISER CETTE FICHE POLARISEE

AVEC UN PROLONGATEUR, UNE PRISE DE COURANT OU UNE AUTRE SORTIE DE COURANT,

SAUF SI LES LAMES PEUVENT ETRE INSEREES A FOND SANS EN LAISSER AUCUNE PARTIE A

DECOUVERT.

Important Safety Instructions:

1. Read Instructions: All the safety and operating instructions should be read before the product is operated.

2. Retain Instructions: The safety and operating instructions should be retained for future reference.

3. Heed Warnings: All warnings on the product and in the operating instructions should be adhered to.

4. Follow Instructions: All operating and use instructions should be followed.

5. Cleaning: Unplug this product from the wall outlet before cleaning. Do not use liquid cleaners or aerosol cleansers. Use a damp cloth for cleaning.

6. Attachments: Do not use attachments that are not recommended by the product manufacturer as they may cause hazards.

7. Water and Moisture: Do not use this product near water—for example, near a bathtub, wash bowl, kitchen sink or laundry tub; in a wet basement;

or near a swimming pool; and the like.

Page 3

3Important Safety Instructions (continued)

8. Accessories: Do not place this product on an unstable cart, stand, tripod, bracket, or table. The product may fall, causing serious injury to a child

or adult, and serious damage to the product. Use only with a cart, stand, tripod, bracket, or table recommended by the manufacturer, or sold with

the product. Any mounting of the product should follow the manufacturer's instructions, and should use a mounting accessory recommended by the

manufacturer.

9. A product and cart combination should be moved with care. Quick stops, excessive force, and uneven surfaces may cause the product and cart

combination to overturn.

10. Ventilation: Slots and openings in the cabinet are provided for ventilation and to ensure reliable operation of the product and to protect it from

overheating, and these openings must not be blocked or covered. The openings should never be blocked by placing the product on a bed, sofa, rug,

or similar surface. This product should not be placed in a built-in installation such as bookcase or rack unless proper ventilation is provided or the

manufacturer's instructions have been adhered to.

11. Power Sources: This product should be operated only from the type of power source indicated on the marking label. If you are not sure of the type

of power supplied to your home, consult your product dealer or local power company. For products intended to operate from battery power, or other

sources, refer to the operating instructions.

12. Grounding or Polarization: This product may be equipped with a polarized alternating-current line plug (a plug having one blade wider than the

other). This plug will fit into the power outlet only one way. This is a safety feature. If you are unable to insert the plug fully into the outlet, try reversing

the plug. If the plug should still fail to fit, contact your electrician to replace your obsolete outlet. Do not defeat the safety purpose of the polarized

plug. Alternate Warnings – If this product is equipped with a three-wire grounding- type plug, a plug having a third (grounding) pin, the plug will only fit

into a grounding-type power outlet. This is a safety feature. If you are unable to insert the plug into the outlet, contact your electrician to replace your

obsolete outlet. Do not defeat the safety purpose of the grounding-type plug.

13. Mise à la terre ou Polarisation: Cet appareil est équipé avec un cordon d'alimentation à trois fils. Il est a brancher sur une prise ayant un connecteur

a la terre. Assurez-vous que la connection a la terre ne manque pas.

14. Power-Cord Protection: Power-supply cords should be routed so that they are not likely to be walked on or pinched by items placed upon or against

them, paying particular attention to cords at plugs, convenience receptacles, and the point where they exit from the product.

15. Lightning: For added protection for this product during a lightning storm, or when it is left unattended and unused for long periods of time, unplug it

from the wall outlet and disconnect the antenna or cable system. This will prevent damage to the product due to lightning and power-line surges.

16. Power Lines: An outside antenna system should not be located in the vicinity of overhead power lines, other electric light or power circuits, where it

can fall into such power lines or circuits. When installing an outside antenna system, extreme care should be taken to keep from touching such power

lines or circuits as contact with them may be fatal.

17. Overloading: Do not overload wall outlets, extension cords, or integral convenience receptacles as this can result in a risk of fire or electric shock.

18. Object and Liquid Entry: Never push objects of any kind into this product through openings as they may touch dangerous voltage points or short-out

parts that could result in a fire or electric shock. Never spill liquid of any kind on the product.

19. Servicing: Do not attempt to service this product yourself as opening or removing covers may expose you to dangerous voltage or other hazards.

Refer all servicing to qualified service personnel.

20. Damage Requiring Service: Unplug this product from the wall outlet and refer servicing to qualified service personnel under the following conditions:

a) When the power-supply cord or plug is damaged,

b) If liquid has been spilled, or objects have fallen into the product,

c) If the product has been exposed to rain or water,

d) If the product does not operate normally by following the operating instructions.

Adjust only those controls that are covered by the operating instructions as an improper adjustment of other controls may result in damage and will

often require extensive work by a qualified technician to restore the product to its normal operation, e. If the product has been dropped or damaged

in any way, and f. When the product exhibits a distinct change in performance—this indicates a need for service.

21. Replacement Parts: When replacement parts are required, be sure the service technician has used replacement parts specified by the manufacturer

or have the same characteristics as the original part. Unauthorized substitutes may result in fire, electric shock or other hazards.

22. Safety Check: Upon completion of any service or repairs to this product, ask the service technician to perform safety checks to determine that the

product is in proper operating condition.

23. Wall or Ceiling Mounting: The product should be mounted to a wall or ceiling only as recommended by the manufacturer.

24. Heat: The product should be situated away from heat sources such as radiators, heat registers, stoves, or other products (including amplifiers) that

produce heat.

Page 4

4

Specications

SATELLITE INPUT

I/Q Amplitude Imbalance: <1dB

QAM OUTPUT

Level Adjustment Increment: 1 dB, nominal

Channel Amplitude Error: <1 dB

Frequency Range: 950 MHz to 2150 MHz

Tuning Increment: 500 kHz

Acquisition Range: ±5.0 MHz minimum

Input Level: -25 dBm to -70 dBm

Input Impedance: 75 Ohms, return loss of 10 dB minimum

I/Q Phase Imbalance: <1 Degree

Mode: QPSK, 8PSK

FEC: DCII, DVB, advanced Turbo modes

VITERBI Autoscan: 1/2, 2/3, 3/4, 5/6, 6/7, 7/8 - DVB

5/11, 1/2, 3/5, 2/3, 3/4, 4/5, 5/6, 7/8 - DCII

Turbo QPSK modes: 1/2, 3/4, 2/3, 5/6, 7/8

Turbo 8PSK modes: 2/3, 5/6, 8/9, 3/4, 4/5

Input Data Rate: 2 Mbaud to 30 Mbaud.

Output Impedance: 75 Ohms, return loss of 10 dB minimum

Output Level: + 25 to +40 dBmV, displayed

Display Error: ± 2 dB maximum

Frequency Range: 54 MHz to 864 MHz

Frequency Plan: Standard, IRC, or HRC CATV channels or off-air broadcast channels.

Broadband Spurious: -60 dB, 5 MHz to 900 MHz

Broadband Noise: -75 dBc, 6 MHz bandwidth

Phase Noise: -103 dBc/Hz @ 10 kHz offset

Frequency Stability: ± 5 kHz

QAM I/Q Phase Error: <1 degree

Carrier Suppression: 45 dB

MER: >40 dB, with blind equalizer.

Mode: 16, 32, 64, 128, 256, 512, 1024 QAM

Symbol Rate: 1 Mbaud to 7 Mbaud

FEC: ITU-T J.83 Annex A or Annex B

RS232 CONTROL

Data Link: 4800 baud interface to PS151 via power supply cable.

RS232 Input: DB-9 connector on PS151 for connection to modem or PC.

RS232 Output: DB-9 connector on PS151 for connection to additional transcoders.

GENERAL

Operating Temperature Range: 0o C to +50o C, ambient.

Size: 1.1" W x 3.4" H x 13.25" D.

Weight: 1 lb. 6 oz.

Power Requirement: All voltages are provided by the Drake model PS151 power supply. PS151 power requirement: 90

to 260 VAC / 150 W, maximum w. 10 transcoders powered.

TRANSPORT STREAM GROOMING

Auto clock mode: None

Fixed clock mode: Null packets are dropped or added as necessary to provide user selected fixed output baud rate.

PCR Restamping: When required.

Specifications subject to change without notice or obligation.

Page 5

5General Description

General Description

The R.L. Drake model SCT4860 is a professional quality, modular, digital headend component providing QPSK

or 8PSK input to QAM transmodulation and RF upconversion functions in a single module. Up to ten SCT4860

modules and a power supply module can be accommodated in the RMT150 rack mounting tray, occupying only

a 2 unit (3.5”) high rack space. The SCT4860 can transcode DigiCipher II or DVB digital satellite signals, included

those with advanced turbo satellite FEC modes, outputting QAM modulation.

The SCT4860 accepts L band RF inputs between 950 and 2150 MHz from the LNB at the satellite dish. The

transcoder demodulates the selected satellite QPSK or 8PSK signal. The forward error correction (FEC)

imbedded in the data stream is used to help retrieve an error free digital transport stream containing the desired

digital programming multiplex.

If a fixed output clock rate has been reached the null packets in the transport stream are processed to provide

the selected rate. When required, PCRs are recalculated.

The transcoder then applies cable environment FEC to this stream and remodulates using QAM modulation that

occupies a nominal 6 MHz wide cable channel slot. QAM modes up through 1024 QAM are supported.

The RF upconverter then upconverts the IF QAM signal to the selected output channel - any standard EIA, IRC, or

HRC CATV channel or a broadcast off-air channel frequency in the range of 54 to 860 MHz.

Bandpass flatness and phase noise are very closely controlled in the SCT4860 to insure a high MER and S/N ratio

of the output signal. This insures that the transcoder will not introduce a source of errors into the distribution process.

Because the MPEG2 transport stream information is not modified by the transcoder, all encryption, authorization,

and program guide information is passed on to the CATV set top box, unchanged.

Page 6

6

Installation and Mounting

Installation and Mounting

Install the SCT4860 transcoders in the RMT150 rack mounting frame. Slide each module into the tray so that the

"F" connector extends though the front panel hole, the LED is properly aligned behind its front panel hole, and the

hook shaped projection on the bottom of the module engages the rear of the mounting tray. Secure the module

with the supplied standard 1/2 inch "F" connector mounting nut and nylon washer.

Similarly, mount the PS151 power supply in the RMT150 tray, making sure that the LCD display and control

buttons line up with their corresponding holes in the front panel, and that the hook shaped projections on the rear

of the unit engage the rear of the mounting tray. Secure the unit in place, with the supplied Philips head black

screws, from the front panel. Connect each SCT4860 to the PS151 with the cable included with the SCT4860.

Each SCT4860 can connect to any one of the ten sockets on the power supply. However, to minimize confusion, it

is suggested that the left most unit (as viewed from the front panel) be connected to power supply socket number

1, the second from the left to number 2, etc.

Connect the LNB signal from the LNB splitter to each SCT4860 module at the front panel connector. Connect

each SCT4860 RF output "F" connector on the rear of the unit to the output combiner. The Drake model LBS2250

is a combination LNB L band multiswitch/amplified splitter in addition to a CATV output combiner. It provides

these functions in only 1 RU of rack space. Also, plug the cable from the front panel fan module into the FAN

POWER receptacle on the rear of the power supply. Plug the line cord from the PS151 into the AC power source.

SCT4860s can be mixed with SCT1860s, SCT2860s, or SCT3860s and one PS151.

When installing the RMT150 tray of transcoders, it is not necessary to leave a vertical airspace between the

transcoder tray and other equipment unless that other equipment specifies that a space should be left open. The

air flow through the transcoders and power supply has been designed to allow immediate adjacent mounting of

multiple RMT150 trays with SCT4860 transcoders and PS151 power supplies installed. Of course, air spaces

may be left in between RMT150s if desired.

Page 7

Controls and Connections

7

Front Panel Controls and Indicators

F1 - LCD Display - This displays the PS151 or selected transcoder parameter and its setting.

F2 -UNIT SELECT (Left) and (Right) Buttons - These select either the PS151 power supply or one of ten

SCT4860 transcoders. Information from the selected unit will be displayed on the LCD display for parameter

adjustment. When either button is pressed once, the LED of the selected transcoder will blink for about 3 seconds,

but the unit selected will not change. The second press within 3 seconds will increment ( ) or decrement ( ) to the

next higher or lower numbered unit. The PS151 power supply menu falls between transcoder numbers 10 and 1.

F3 - (Left) and (Right) Buttons - Use the left or right buttons to navigate from screen to screen to view a

parameter setting. This will not alter any settings. If in the adjust mode, stop at the parameter you wish to adjust

and use the (up) and (down) buttons to adjust.

F4 - (Up) and (Down) Buttons - Use the up and down arrows to adjust a parameter value when in the adjust

mode. When not in the adjust mode, pressing the (up) button will display the software version readout, and

pressing the (down) button will display the QAM modulation output baud rate readout.

F5 - ENTER - Use the ENTER button to enter the adjust mode or to save and load a new setting or settings. Hold

for 2 seconds until the display flashes to enter the adjust mode. After adjustment using the up or down arrow

buttons, press again to save and load the new settings. You may save one parameter at a time after it is adjusted

or wait until all adjustments are made and press to save and load all at once.

F6 - FAN - One of five front panel cooling fans. To ensure proper cooling, do not block these openings.

F7 - L BAND INPUTS - These are the L band inputs from the LNB. The level must be between -70 and -25 dBm

The L band frequency range will be in the 950 to 2150 MHz range.

F8 - LED - The LED on each SCT4860 will blink on and off for approximately 3 seconds when that unit is selected.

When in the adjust mode, it will blink continuously. When in the normal mode, it will be lit continuously whenever

power is applied.

Page 8

8

Controls and Connections (continued)

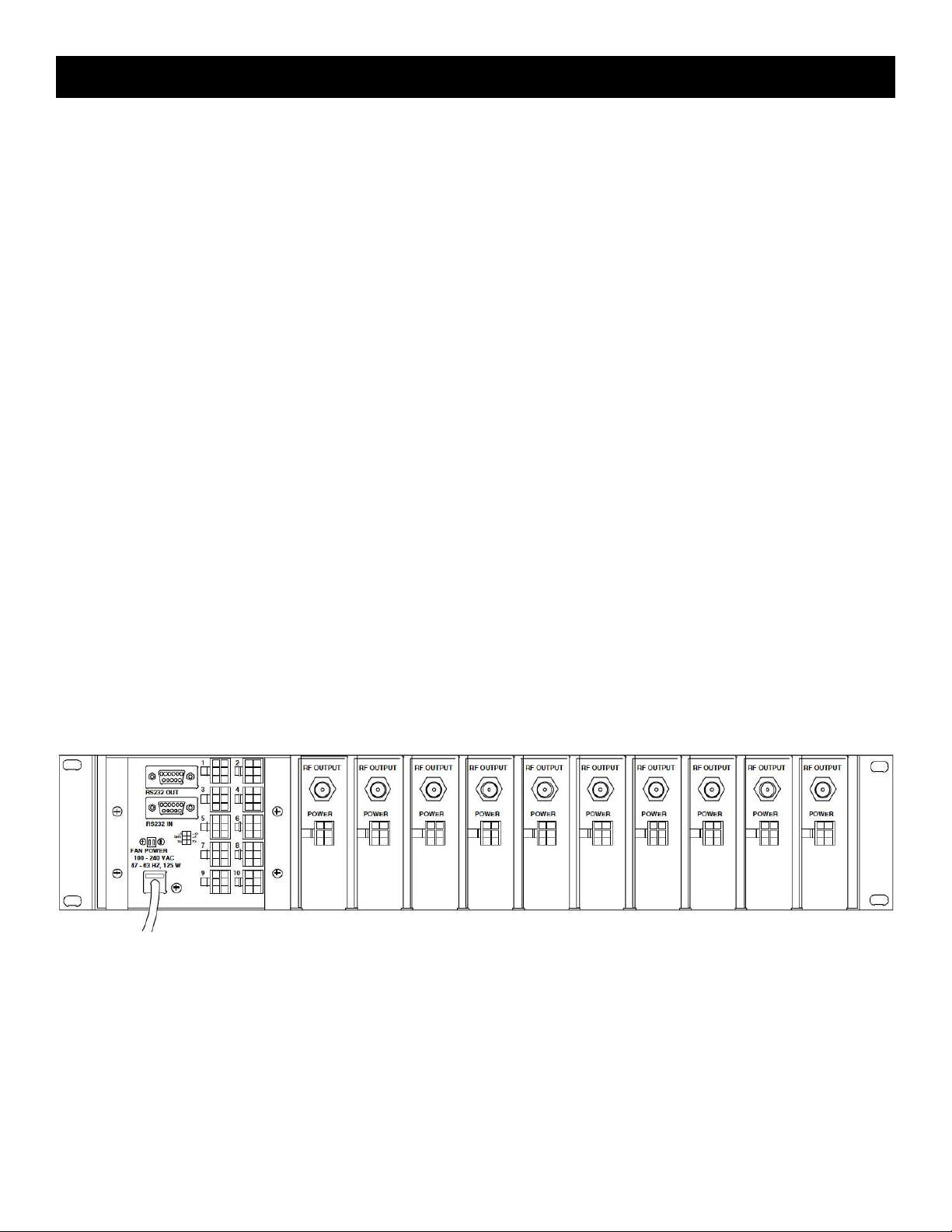

Rear Panel Connections

R1 - RS232 OUT - This RS232 serial connector can connect to the RS232 IN connector on another rack containing

a PS150, PS151, or PS100 power supply (included transcoders could be SCT860, SCT1860, SCT2860, or

SCT3860 transcoders), thus allowing computer control of multiple racks of these units with the same PC connection.

R2 - RS232 IN - Connecting this RS232 serial connector to the serial port of a personal computer equipped with

Drake RS232 remote control software, allows remote monitoring and programming of each transcoder. Alternatively

can be connected to the Drake SCTeci. No connection is required for front panel control.

R3 - Fan Power- Connect the two conductor cable from the front panel fans to this connector.

R4 - Power Out - These connectors are for connecting the power cables from each individual SCT4860 to the

PS151 power supply. The other end of each cable can be plugged into any one of the ten transcoders. However, to

minimize confusion, it is strongly suggested that the left most unit (as viewed from the front panel) be connected to

power supply socket number 1, the second from the left to number 2, etc. Do not attempt to use any power supply

other than this Drake supplied model.

R5 - Power In - This connector supplies power and program control to the SCT4860. Connect a cable from this

connector to the appropriate connector on the PS151 power supply (see R4 above).

R6 - RF Output - This is the QAM output channel RF output. The frequency range is between 54 and 864 MHz

depending upon the channel selected. The output level is +25 to +40 dBmV, nominal, adjustable in 1 dB steps.

NOTE: Although the above discussions refer to the SCT4860 transcoder modules, other Drake

transcoders may be mixed with SCT4860s in the same RMT150 rack mounting tray. These include

the SCT1860, SCT2860, and SCT3860. The PS151 power supply/control module will recognize

each type of transcoder. Also, SCT4860 transcoders, although controlled by a different power

supply model, the PS100, can have the RS232 control 'daisy chained' with the PS150 and PS151

controlled transcoders.

Page 9

LNB Input / Setup and Programming

9

LNB Input and LNB Powering

The SCT4860 receives its input signal from the IF output of the LNB located on the satellite dish. Because this LNB

output usually is split among multiple transcoders, the LNB power must be obtained from a separate power inserter

and supply that is connected ahead of an L band splitter. The SCT4860 does not have the capability to supply LNB

power.

SETUP AND PROGRAMMING

The programming of each SCT4860 in an RMT150 rack mounting tray is done from the PS151 power supply

mounted in that rack. The UNIT SELECT buttons on the PS151 are used to select the unit to be programmed,

including the PS151 itself. The actual programming is done via the five buttons on the left side of the PS151. If the

RS232 remote control is connected, all programming other than the setting of the PS151 RACK ID number and

password programming can be done remotely. The chart below shows each of the menus that are available for

parameter set up and/or viewing for both SCT4860s and the PS151 Power Supply. Pressing the left or right arrow

buttons will navigate through these menus. You may do this without danger of disturbing any of the current settings.

As you navigate through the menus, the parameter is listed on the top line of the display and the current setting

is shown on the bottom line. For set up purposes, it is best to progress clockwise in the chart below (use the right

arrow button), starting from the RS232 adjustment on the PS151 and the MODE menu for each of the SCT4860s.

The charts below show all of the settings that are available through these menus.

Page 10

10

To adjust /set a parameter(s), enter the adjust mode by pressing the center "ENTER" button for several seconds

until the display begins to flash. You are now in the adjust mode and the up and down buttons will take you

through the various parameters. Find the desired setting and then use the right arrow to progress to the next

menu. After setting all parameters in all menus, press the "ENTER" button once. This will load the settings and

save them in memory.

Pressing the left or right UNIT SELECT button will also load the settings and save them in memory , just as would

pressing the "ENTER" button, in addition to moving to an adjacent transcoder.

Note that many of the parameters will not be changed until the "ENTER" button is pressed. These include:

MODE related settings, LNB type, IF FREQ, BD RATE, ENCODER, MODULATE, and INTERLV. If you need

to see the result of a change right away for these parameters, press the "ENTER" button to load and store the

new parameter setting and then you can reenter the adjust mode by pressing the "ENTER" button again for

several seconds. The RACK ID, RS232, OUTPUT, RF OUT level, and CHANNEL (output) settings will all change

immediately as soon as they are adjusted.

PRESETS FOR HITS

The SCT4860 provides factory loaded presets for HITS. When a preset is selected and entered, all of the operating

parameters for the satellite tuner, demodulator and for the QAM modulator are set to the preset settings. You will

then need to set only the output channel and level and LNB related parameters. Note that selecting and entering

the HITS options in the mode menu, changes any other parameters that might have been adjusted previously

to the preset values. If you do not wish to use presets, be sure that you have chosen the DCII selection before

pressing the enter button to load and save the values.

Setup and Programming (continued)

SCT4860 QUICK START for HITS - Front Panel Control

1)Connect cables from LNB, to output combiner, and to PS151 power supply.

2)Plug PS151 AC line cord into power source.

3)Use the Unit Select (Left) and (Right) buttons to select the PS151 power supply.

4)Push ENTER button on PS151 for 2 seconds until display flashes to enter adjust mode.

5)Use the Unit Select (Left) or (Right) buttons to select RS232.

6) Use (Up) or (Down) buttons to set to 4800 unless another rate is indicated when setting up a modem interface.

Press ENTER to save this setting.

7)Use the Unit Select (Left) and (Right) buttons to select the desired SCT4860.

8)Push ENTER button on PS151 for 2 seconds until display flashes to enter adjust mode.

9) (Left) arrow - CHANNEL menu - Use the (Up) or (Down) arrow buttons to select the desired EIA CATV output

channel for this program multiplex.

10) (Right) arrow - MODE menu - Up or Down arrows to select HITS.

11) (Right) arrow - HITS menu. Up or Down arrows to select the desired multiplex corresponding to the EIA output

channel that you set in step 9. This correlation is determined by the channel map used for your installation.

12) (Right) arrow - LNB menu - Up or Down arrows - STACKED or DUAL POL - Set to the type you are using.

13) ENTER - Push once to store and load all of the above settings.

Page 11

Setup and Programming (continued)

By selecting the HITS mode in step 10, instead of the generic DCII setting, many of the other adjustable

parameters have been preset to the values required for these networks, determined by the preset programming

in the SCT4860. If you reenter the adjust mode later and make changes to the preset parameters or if you altered

any of the parameters that were preset during the steps above such that the values do not match the preset

values, the display in the mode menu will revert to DCII.

If the dish has been aimed, you should now see a SN readout on the display. If it is less than 7 dB, the transcoder

will not stay locked to the satellite signal. If the SN reading is showing only around 2 dB, you likely are not pointed

at the correct satellite or the dish is not peaked. For reliable operation, the SN level should be above 10 dB and

preferably even higher. The better the margin above the approximately 7 dB threshold, the less likely you will

encounter drop outs due to thunderstorms or snow storms.

NOTE: If you are using the RS232 remote control program, all of the above adjustments may be

made via the PC,except the RACK ID assignment for the PS151 module.

DISH NETWORK AUTO SET

When the using the SCT4860 for DISH Network, select DISHScan from the MODE menu. Next, in the IF FREQ

menu, select the IF frequency that corresponds to the DISH Network transponder that is desired. You will then

advance all the way to the OUTPUT menu as the SCT4860 will automatically search for and set the satellite symbol

rate and FEC. Based on what is found, the SCT4860 will then automatically select the proper QAM encoding, QAM

modulation level, Interleave, etc. Finally, set the desired output level and EIA channel in the appropriate menus.

11

If the modulation on a particular transponder is changed by DISH in the future, the SCT4860 will automatically

reacquire the new signal, assuming it's on the same frequency, and automatically set the various satellite

demodulator and QAM modulator parameters.

Using the presets will significantly shorten the set up time for a new headend. These preset settings can be altered

at any time if the required parameters change in the future. Whenever DISHScan is selected, the rain fade logic is

automatically enabled.

TURBO FEC

Some advanced satellite FEC modes may be selected under the TURBO menu.

Page 12

12

OUTPUT LEVEL

The SCT4860 provides a +40 dBmV QAM output level that is desirable when transcoders are combined with

analog modulators that have +45 dBmV output level. The SCT4860 output level can be turned down as much as

15 dB if a lower level is desired. Each SCT4860’s RF output level can be read out on the PS151 power supply

LCD when that unit is selected, or via the RS232 remote connection.

Because some operators may not have test equipment designed to measure QAM power levels, and analog

meters may be grossly inaccurate if a QAM signal is read, the SCT4860 has a CW output mode that can be

useful for measuring/adjusting the output level of the transcoder with any meter that measures CW carrier power.

A special QAM instrument is not required. No input signal is required for this measurement. The CW carrier power

is equal to the QAM power level that will result when the unit is returned to a normal QAM modulation mode.

IMPORTANT NOTE: When the SCT4860 is placed in the continuous wave (CW) mode, the output carrier

frequency will be at the center of the output channel. It will not be located at the NTSC video carrier frequency.

Adjust test equipment accordingly to obtain an accurate result.

The PC control software allows all transcoders to be easily switched to the CW mode at one time for set up

purposes. After any level tweaks are made, they can all be switched back to normal mode at one time. It is also

possible to individually select a single transcoder to be switched to the CW mode, if desired. In a typical leveling

process, the output of the headend is monitored after the final combiner and all analog channel levels are set

to the desired level. Then, with the SCT4860s all set for CW output, the SCT4860 CW carrier levels can be all

tweaked to a desired level (usually 6 to 10 dB) below the analog video carrier levels. When switched back to

normal mode, the SCT4860s will all be outputting QAM channel powers equal to the CW powers set up.

Additional Features

RAIN FADE LOGIC

When the rain fade feature is enabled, the transcoder will mute its RF output whenever the input S/N drops below

a usual level. This logic is always enabled in the DISHScan mode.

STANDBY MODE

The SCT4860 has a standby output mode which turns off the RF output. This can be used when it is desirable

to keep a backup unit on line. The standby mode can be selected via the OUTPUT menu.

POWER SUPPLY

The SCT4860 requires multiple power supply voltages that are all obtained from the Drake model PS151 power

supply module. The PS151 mounts in the RMT150 rack tray along with one to ten SCT4860 (or other similar

Drake models) transcoders. The PS151 buffers and distributes the RS232 remote control data from its DB9,

RS232 INPUT connector to up to ten transcoders and to the DB9, RS232 OUTPUT connector. Multiple PS151s

can be ‘daisy chained’ via the DB9 INPUT and OUTPUT connectors to allow control of up to 70 transcoder

modules with a single connection to a PC.

The PS151 operates over a wide range of AC input voltages from 90 VAC to 264 VAC. The USA version has

an attached 3 wire line cord. Power consumption from the AC line will be around 150 W maximum with ten

transcoders installed. In many cases, the power will below this level.

Page 13

Additional Features (continued)

RS232 REMOTE CONTROL AND MONITORING

The SCT4860 provides for remote control and/or monitoring of all transcoder parameter settings. It is possible

to view all of the current parameter settings including the output level setting for each transcoder. It is also

possible to remotely monitor the SNR level and the baud rate. The LBS2250 settings may monitored or changed.

The transcoder parameter settings may be uploaded to a PC file for saving on the PC or a new parameter

configuration from the PC file can be downloaded to the SCT4860. A single parameter may be adjusted if desired.

It is possible to put all transcoders in or out of CW mode with a single command. A unit may be placed in or taken

out of the standby mode. A password can be assigned to prevent unauthorized changes to parameter settings but

the present settings can be read out remotely without entering the password. Further details on the RS232 control

program are provided with the instructions included with the CDROM containing the control program (shipped

with your PS151 power supply).

The previously described remote interface is accomplished by connecting an RS232 interface cable between the

PS151 power supply DB9 INPUT connector and a PC serial port. The required program is supplied by Drake with

the PS151 power supply. This setup will allow RS232 interfacing to up to ten SCT4860 transcoders connected to

the PS151. When more than one tray of transcoders is used, the OUTPUT DB9 connector on the PS151 can be

used to link to a second PS151 as well as a PS150 (SCT1860s) or a PS100 (SCT860s) in the same headend.

Use a DB9 to DB9 RS232 jumper cable from the OUTPUT of the first supply to the INPUT of the second supply.

You can extend this to additional supplies as long as the total number of PS151s to control does not exceed 7

(70 SCT1860/2860/3860/4860s) and the number of SCT860s does not exceed 64.

13

In order for the PC software to identify the proper SCT4860 to which you wish to connect, each SCT4860 must be

assigned a unit ID number. The unit ID number consists of the rack number, a dash, and the number of the unit

in a given rack. For example, the third unit (plugged into power socket numbered 3) in rack number one would

have a unit ID number of "1-3", and the tenth unit in rack number three would have a unit number of "3-10". The

number of each unit in a given rack is determined by the connector number on the PS151 power supply to which

it is connected. Programming the rack number is easily accomplished by using the PS151 "RACK ID:" menu and

setting the ID number with the PS151 front panel set up buttons. If no RS232 control is desired, this RACK ID

number should be set to 0.

The PS151 will not respond to RS232 activity when its RACK ID is 0. Any number of PS151s can have a rack ID

of 0.

When using RS232, assign a unique ID, between 1-1 and 7-10, for each SCT4860 to be controlled. Do not duplicate

a number among any of the up to 70 transcoders that are to be connected through the same RS232 path to the PC.

This RS232 connection can be used by directly connecting to a PC serial port or remotely by interfacing through

modems. If an auto answer modem is used at the headend, one can interface via telephone connection. The RS232

connection can be used to download new operating firmware to the SCT4860, if needed for use with future options.

For remote control operation, PS150/SCT1860 systems and/or PS100/SCT860 systems can be “daisy chained”

with PS151/SCT2860s, SCT3860s, and SCT4860s, if desired, and can be controlled by the same PC using the

Drake supplied software. A maximum of 64 SCT860s can be connected in this fashion in addition to the maximum

of 70 SCT1860/2860/3860/4860s. Any combination of PS100s, PS150s, and PS151s can be connected in this

manner as long as the maximum numbers indicated above are not exceeded.

Page 14

14

Using the SCTs with the LBS2250 L Band Splitter: The LBS2250 unit should be mounted above the RMT150

with no extra space between the units. One or two LNB, L band inputs in the range of 950 to 2250 MHz may be

connected to the inputs of the LBS. On the front panel side of the rack, the LNB inputs of each SCT should be

connected with a short coaxial jumper cable to the output of the LBS that is directly above it. Then the power

supply cable of any one of the transcoders should be 'looped through' the LBS2250.

When a LBS2250 has been connected as described in the previous paragraph, a new menu will appear in the

SCT menu chain, between the MODE and CHANNEL menus (see chart). This is where the user may select the

setting of the LNB input switch for that transcoder - either LNB input A or LNB input B may be selected.

An eight character name such as 'DISH 110' can be programmed for the A setting and the B setting so that

the setting is more meaning if monitored remotely. This name may be programmed only via the RS232 remote

program using version 2.7 or above CDROM.

Additional Features (continued)

Page 15

CATV CHANNEL FREQUENCIES

Table 1: CATV

15

Page 16

16

BROADCAST TV CHANNEL FREQUENCIES

Table 2: BC TV

Page 17

Service / If You Need To Call For Help

SERVICE INFORMATION

You may contact the R.L. DRAKE Service Department for additional information or assistance by calling +1 (937)

746-6990, Monday through Friday, between 8:00 A.M. and 4:00 P.M. Eastern Time, except on holidays.

You may also contact the R.L. DRAKE Service Department by E-mail at the following address: TechSupport@

rldrake.com or by Telefax: +1 (937) 806-1510.

Should you want to return your unit for service, package the unit carefully using the original carton or other

suitable container.

Write your return address clearly on the shipping carton and on an enclosed cover letter describing the service

required, symptoms or problems. Also include your daytime telephone number and a copy of your proof of

purchase.

The unit will be serviced under the terms of the R.L. DRAKE HOLDINGS LLC Limited Warranty and returned to

you.

IF YOU NEED TO CALL FOR HELP

Call our Customer Service/Technical Support line at +1 (937) 746-6990 between 8:00 A.M. and 4:00 P.M. Eastern

Time, weekdays. Please have the unit’s serial number available. We will also need to know the specifics of any

other equipment connected to the unit. When calling, please have the unit up and running, near the phone if

possible.

17

Our technician(s) will likely ask certain questions to aid in diagnosis of the problem. Also, have a voltmeter handy,

if possible. R.L. DRAKE also provides technical assistance by e-mail: TechSupport@rldrake.com or by Telefax: +1

(937) 806-1510.

Many of the products that are sent to us for repair are in perfect working order when we receive them. For these

units, there is a standard checkout fee that you will be charged. Please perform whatever steps are applicable

from the installation sections of the Owner's Manual before calling or writing—this could save unnecessary phone

charges. Please do not return the unit without contacting R.L. DRAKE first: it is preferred to help troubleshoot the

problem over the phone (or by mail) first, saving you both time and money.

Inside the carton, enclose a note with your name, address, daytime phone number, and a description of the unit’s

problem.

The unit must be sent to the following address:

Service Department

R.L. DRAKE

710 Pleasant Valley Drive

Springboro, Ohio 45066. USA

Be sure to include your street address which will be needed for UPS return. UPS Surface (Brown Label) takes

7-10 days to reach us depending on your location, Blue takes 2-3 days.

Red is an overnight service. Send the unit in a way that it can be traced if we can’t verify receipt of shipment. We

suggest UPS or insured postal shipment.

If the unit is still under the original owner’s warranty, R.L. DRAKE will pay the cost of the return shipment to you.

Our return shipping policy is that we will return it UPS Brown if received Brown or by US Mail, it will be returned

Blue if received Blue or Red—or it will be returned however you prefer if you furnish the return cost for the

method you select.

Page 18

18

If the unit is out of warranty, use one of the following methods for return shipment:

When calling, the technician can estimate the repair charges for you over the phone. This is another good reason

to call before sending a unit in for repair.

Typically, equipment is repaired in five to ten working days after it arrives at R.L. DRAKE if we have all the

facts. If we must call you, it may take longer. R.L. DRAKE is not responsible for damage caused by lightning,

nonprofessional alterations, “acts of God”, shipping damage, poor storage/handling, etc. R.L. DRAKE will make

note of any shipping damage upon receipt.

You will need to send proof of purchase to receive warranty service. Typically, a copy of the invoice from an R.L.

DRAKE dealer will suffice. The warranty is for the original owner only and is not transferable.

If You Need To Call For Help (continued)

1) You designate billing to American Express, VISA, MasterCard or Discover card;

2) You prepay the service charges with a personal check, or

3) You specify some other method of return and payment.

Page 19

19Warranty

Three Year Limited Warranty

R.L. DRAKE HOLDINGS LLC warrants to the original purchaser this product shall be free from defects in material

or workmanship for three (3) years from the date of original purchase.

During the warranty period R.L. DRAKE HOLDINGS LLC or an authorized Drake service facility will provide,

free of charge, both parts and labor necessary to correct defects in material and workmanship. At its option, R.L.

DRAKE HOLDINGS LLC may replace a defective unit.

To obtain such a warranty service, the original purchaser must:

1. Retain invoice or original proof of purchase to establish the start of the warranty period.

Notify R.L. DRAKE HOLDINGS LLC or the nearest authorized service facility, as soon as possible after

2.

discovery of a possible defect, of:

a) the model and serial number,

b) the identity of the seller and the approximate date of purchase; and

A detailed description of the problem, including details on the electrical connection to associated

c)

equipment and the list of such equipment.

Deliver the product to R.L. DRAKE HOLDINGS LLC or the nearest authorized service facility, or ship

3.

the same in its original container or equivalent, fully insured and shipping charges prepaid.

Correct maintenance, repair, and use are important to obtain proper performance from this product. Therefore

carefully read the Instruction Manual. This warranty does not apply to any defect that R.L. DRAKE HOLDINGS

LLC determines is due to:

Improper maintenance or repair, including the installation of parts or accessories that do not conform

1.

to the quality and specifications of the original parts.

2. Misuse, abuse, neglect or improper installation.

3. Accidental or intentional damage.

All implied warranties, if any, including warranties of merchantability and fitness for a particular purpose, terminate

three (3) years from the date of the original purchase.

The foregoing constitutes R.L. DRAKE HOLDINGS LLC'S entire obligation with respect to this product, and the

original purchaser shall have no other remedy and no claim for incidental or consequential damages, losses or

expenses. Some states do not allow limitations on how long an implied warranty lasts or do not allow the exclusions

or limitation of incidental or consequential damages, so the above limitation and exclusion may not apply to you.

This warranty gives you specific legal rights and you may also have other rights which vary from state to state.

This warranty shall be construed under the laws of Ohio.

For Service, contact:

R.L. DRAKE HOLDINGS LLC

710 Pleasant Valley Drive

Springboro, Ohio 45066. USA

Customer Service and Parts Telephone: +1 (937) 746-6990

Telefax: +1 (937) 806-1510

Web Site: http://www.rldrake.com

Page 20

R.L. Drake Holdings LLC

710 Pleasant Valley Drive

Springboro, Ohio 45066. USA

Customer Service and Parts Telephone: +1 (937) 746-6990

Telefax: +1 (937) 806-1510

Web Site: http://www.rldrake.com

Loading...

Loading...